EP2881663B2 - Müllaufgabevorrichtung - Google Patents

Müllaufgabevorrichtung Download PDFInfo

- Publication number

- EP2881663B2 EP2881663B2 EP13005687.2A EP13005687A EP2881663B2 EP 2881663 B2 EP2881663 B2 EP 2881663B2 EP 13005687 A EP13005687 A EP 13005687A EP 2881663 B2 EP2881663 B2 EP 2881663B2

- Authority

- EP

- European Patent Office

- Prior art keywords

- waste feed

- wall

- panel

- panels

- feed device

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 239000002699 waste material Substances 0.000 title claims description 37

- 239000002826 coolant Substances 0.000 claims description 34

- 238000002485 combustion reaction Methods 0.000 claims description 6

- 238000004056 waste incineration Methods 0.000 claims description 3

- 238000001816 cooling Methods 0.000 description 13

- 238000010276 construction Methods 0.000 description 4

- 239000000498 cooling water Substances 0.000 description 4

- 239000002131 composite material Substances 0.000 description 3

- 238000003466 welding Methods 0.000 description 3

- 229910000831 Steel Inorganic materials 0.000 description 2

- 238000007599 discharging Methods 0.000 description 2

- 239000010959 steel Substances 0.000 description 2

- 230000008646 thermal stress Effects 0.000 description 2

- 230000006735 deficit Effects 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 238000009434 installation Methods 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 238000007747 plating Methods 0.000 description 1

- 230000003014 reinforcing effect Effects 0.000 description 1

- 230000003068 static effect Effects 0.000 description 1

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23G—CREMATION FURNACES; CONSUMING WASTE PRODUCTS BY COMBUSTION

- F23G5/00—Incineration of waste; Incinerator constructions; Details, accessories or control therefor

- F23G5/44—Details; Accessories

- F23G5/442—Waste feed arrangements

- F23G5/444—Waste feed arrangements for solid waste

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23K—FEEDING FUEL TO COMBUSTION APPARATUS

- F23K3/00—Feeding or distributing of lump or pulverulent fuel to combustion apparatus

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23G—CREMATION FURNACES; CONSUMING WASTE PRODUCTS BY COMBUSTION

- F23G2205/00—Waste feed arrangements

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23G—CREMATION FURNACES; CONSUMING WASTE PRODUCTS BY COMBUSTION

- F23G2205/00—Waste feed arrangements

- F23G2205/14—Waste feed arrangements using hopper or bin

Definitions

- the invention relates to a refuse-dispensing device for discharging refuse into a combustion chamber of a waste incineration plant and to a panel for such a refuse-disposal device.

- Generic garbage loaders are well known in the art and generally include a hopper into which garbage from a garbage bunker is filled by crane and a garbage chute downstream of which the garbage is fed to a hopper by which it is preferably fed is introduced in a controlled manner in the combustion chamber using task tappets.

- the refuse collection shaft is enclosed by a refuse hull wall supported by a support frame.

- a support frame In the interest of the most space-saving design of the support frame is formed in known refuse collection shaft devices as an integral part of the refuse collection shaft wall. Specifically, the Müllaufgabeschachtwand, which in turn is formed from each other welded plates, placed on the support frame. In operation of the waste incineration plant, the support frame is in the thermal zone of influence of the combustion chamber.

- both the refuse collection well wall and the support frame is often cooled by means of a cooling medium.

- a water-cooled refuse-dispensing apparatus comprising a refuse-disposal shaft wall enclosing a refuse-disposal shaft is disclosed, for example, in US Pat KR 101 246 174 described.

- wear plates are generally also welded onto the side thereof facing the refuse collection shaft or the refuse.

- weld seams are often formed on the side of the refuse collection well wall facing the refuse collection shaft. In the case of a burn-back, these welds can fail, which can lead to leakage of the cooling medium in the refuse chute and ultimately to a total failure of the cooling.

- repair is often limited or possible with great effort, which is inter alia related to the fact that the individual parts are very large and heavy and also often consist of a variety of welded individual components. For a repair of said parts thus costly construction work are required, which usually also involve time-consuming welding.

- the object of the present invention is to provide a waste disposal device available, which ensures high reliability and can be maintained with relatively little effort.

- the invention relates to a refuse-dispensing apparatus for discharging refuse into a combustion chamber of a refuse incineration plant comprising a waste refuse shaft wall enclosing a refuse-disposal shaft.

- At least part of the refuse collection well wall is formed from a plurality of separate, detachably connected panels which on their side facing the refuse feed shaft comprise a panel inner wall and, on its side facing away from the refuse feed shaft, a panel outer wall spaced from the panel inner wall and having a panel cavity with the panel inner wall encloses.

- the panels are usually independently solvable.

- the panel cavity is preferably intended to receive a cooling medium during operation, and in particular to be flowed through by a cooling medium.

- a cooling surface is formed by the panel cavity, which effectively dampens the thermal load on the panel in the event of burn-back. Since each panel defines a panel cavity that can be shut off separately from the coolant supply, the present invention allows even the damaged panel, but not the entire refuse well wall, to be affected by the cooling failure even in the event of leakage, as discussed below.

- water is usually used as a coolant.

- the refuse deposit chute wall inner surface i. the surface which comes into direct contact with the refuse during operation of the refuse-dispensing apparatus is formed directly by the panel inner wall.

- the refuse-dispensing device comprises a support frame for supporting the panels of the refuse-input shaft wall, the support frame being arranged on the outside of the refuse-receiving shaft wall facing away from the refuse-receiving shaft and releasably connected to the panels of the refuse-receiving shaft wall. Since in operation between the support frame and the refuse chute is always formed by the panel cavity with the cooling medium contained cooling surface, the support frame is effectively protected in the event of burnback before a high thermal load, resulting in a high durability of the refuse collection device and thus also to contributes to high operational safety. Due to the fact that the support frame is outside the thermal influence zone, can be dispensed with a cooling of the support frame, moreover, whereby the construction is greatly simplified.

- the Müllaufgabeschachtwand forming panels of the support frame according to the invention is arranged spaced from the refuse collection shaft wall. It is conceivable, for example, that the Müllaufgabeschachtwand on the carrier element spaced therefrom by means of vertical support elements, such. B. consoles, is supported.

- the support frame may optionally be provided for static reasons, at least one also on the side facing away from the refuse chute outside the Müllaufgabeschachtwand and releasably connected to the refuse chute wall bandage. Also this is like the support frame outside the thermal influence zone, which can be dispensed with even for the bandage on a cooling.

- the panels according to the invention are releasably connected to each other.

- the connecting line between two adjacent panels parallel to the axial direction of the refuse bins ie usually vertical, runs.

- the affected panel is detached from the adjacent panels and from the support frame (and optionally from one or more horizontal bandages), usually in the form of a horizontal steel profile, and then lifted upwards in a vertical direction.

- connection of two side by side panels can be effected by means of a screw connection, wherein the respectively arranged on the longitudinal sides U-profiles of both panels are screwed together.

- the U-profiles have corresponding screw holes for this purpose.

- the panel inner wall is at least in its extension in the axial direction of the refuse hopper, i. in the vertical direction, formed continuously. She is usually trained throughout the entire height of the garbage shaft.

- the panel inner wall is formed from a single continuous plate. It is conceivable, for example, that the plate is formed from a sheet known to those skilled in the art with weld plating or S235 sheet metal.

- the panel inner wall is in other words free of Welded seams, in particular horizontal welding seams. Since the weld seams in prior art devices are particularly susceptible to failure under thermal stress and just in case they run horizontally, may result in failure to the garbage disturbing paragraphs or bridges, this embodiment, the reliability of the refuse dispenser over these prior art devices increase.

- the panel cavity is preferably cooled by means of a cooling medium and particularly preferably flows through the cooling medium.

- deflecting ribs extending parallel to one another between the inner wall of the panel and the outer wall of the panel are preferably arranged for deflecting the cooling medium.

- the Umlenkrippen thereby perpendicular to the axial direction of the refuse hopper, i. horizontal.

- deflecting ribs are offset relative to one another is to be interpreted broadly in the context of the present invention and includes any embodiment which results in a staggered arrangement of two longitudinally successive flow passages.

- At least one part of the panels is assigned in each case one cooling medium supply line which opens into the panel cavity. This ensures that in the event of leakage, this is limited only locally to the affected panel, while the other panels or the cooling of these panels are not affected.

- the cooling medium supply is interrupted only to the affected by the leakage panel.

- the cooling medium supply line is assigned means for interrupting the cooling medium supply to the respective panel cavity.

- the means may be present, for example, in the form of shut-off valves known to the person skilled in the art.

- the cooling medium supply line supplying the cooling medium opens into a lower region of the panel cavity, which is flowed through from a lower end region to an upper end region. From the upper end region, the cooling medium passes, for example, into an overflow channel, where it is collected and available for further use, for example for a further section of the refuse-dispensing device to be cooled, or is supplied to the re-cooling.

- the refuse-disposal shaft has a rectangular shape in cross-section.

- the refuse collection well wall is formed of four partial walls, two longitudinal side walls and two wide side walls.

- the total number of panels forming the refuse hull wall is in the range from 6 to 30.

- a number from 2 to 14 for the longitudinal side wall and a number at least 1 for the wide side wall is conceivable.

- the panels is formed in the form of a rectangle with a length A and a width B.

- the length A corresponds substantially to the height of the respective section of the refuse-input shaft wall.

- the length A is thus in the range of about 3 to 6 m, in particular about 5 m.

- the width B is preferably in a range of about 1 m.

- the panels both in terms of volume and weight, have dimensions which enable a relatively simple handling during the assembly or disassembly of the refuse collection shaft wall.

- the assembly or disassembly by means of the garbage crane or by means of an auxiliary crane takes place, which have a sufficient capacity for the corresponding panels.

- simple assembly aids such as tie rods or brackets are also used.

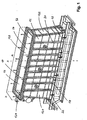

- FIG. 1 As in Fig. 1 is shown, the previously known refuse chute device on a enclosed by a refuse chute wall 12 refuse chute 14.

- the refuse collection shaft 14 has a parallel to the refuse flow direction extending axis X and in cross section a rectangular shape with a length a and a width b and takes in the in Fig. 1 concretely shown embodiment in cross section in Müllrelraum continuously.

- the refuse collection well wall 12 is formed of four side walls 121, 122, 123, 124, specifically two rectangular or slightly trapezoidal wide side walls 122, 124 and two trapezoidal longitudinal side walls 121, 123.

- the longitudinal side walls 121, 123 are each other welded plates 16 are formed, of which in Fig. 1 for the partial wall 123, five plates are shown.

- Welded seams 17 are thus present between the plates 16 on the waste input shaft wall inner surface 32 formed by the refuse collection shaft wall 12.

- the previously shown known refuse-dispensing device also has welded wear plates welded onto the refuse-input shaft wall inner surface 32.

- the garbage collecting shaft wall 12 formed from the side walls 121, 122, 123, 124 is welded in the lower region with a horizontally encircling steel profile 18 which rests on the truss-like support frame 22 and forms an integral part of the garbage collecting device with this in the previously known device.

- the entire garbage shaft is cooled; the forwarding of the coolant between the individual wall surface elements via curved cooling medium channels 19th

- waste disposal chute wall 12 of sixteen separate panels 24a-p is formed, wherein the two longitudinal side walls 121, 123 of seven panels 24a-g and 24i-o and the two wide side walls 122, 124 from a single panel 24h or 24p is formed.

- the panels 24a-p extend in their longitudinal direction over the entire height H of the refuse feed duct 14.

- the length of the panels corresponds to z. B. 5 m.

- the width B of the five panels 24b-f and 24j-n, respectively not arranged at the edge is identical and constant in the longitudinal direction, while for the two arranged on the edge panels 24a, 24g and 24i, 24o continuously increases in the direction of refuse flow.

- the five panels 24b-f and 24j-n arranged on the longitudinal side are not rectangular, wherein the width B of the rectangle in the embodiment shown is approximately 1 m.

- the width B of the rectangle in the embodiment shown is approximately 1 m.

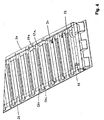

- the panels 24a-p include a panel inner wall 26 and a panel outer wall 28 spaced therefrom which encloses a panel cavity 30 with the panel inner wall 26.

- the panel inner wall 26 forms due to the in Fig. 2 the fact that each panel 24a-24p extends in its longitudinal direction over the entire height H of the garbage chute and is preferably formed from a single plate, a continuous surface.

- the panel inner walls 26 of all panels 24a-p thereby forms the Müllaufgabeschachtwandinnen Chemistry 32, which thus has no horizontal paragraphs.

- Fig. 2 in combination with Fig. 3 is shown, two adjacent panels of a longitudinal side wall 121, 123 by means of U-profiles 34 are releasably screwed together.

- the refuse collection chute inner surface 32 has no weld seam between the panels, as is the case in the prior art embodiment with plates welded together.

- Each panel has two, the panel on the long sides enclosing U-profiles 34 assigned.

- the U-profile comprises two legs 36a, 36b and a web 38 arranged therebetween.

- a first leg 36a of the U-profile 34 is welded to the panel inner wall 26 on its inside facing away from the refuse chute 14, so that part of the web 38 of the U-profile 34 Profile 34 terminates the panel cavity 30 on its longitudinal side.

- screw holes 40 are provided for the screw.

- the support frame 22 for supporting the panels 24a-p of the refuse collection well wall 12 is as in FIG Fig. 2 shown on the outside of the refuse chute 14 facing away from the outside of the Müllaufgabeschachtwand 12 (or the panel outer wall 28) and spaced therefrom arranged.

- the support of the refuse collection shaft wall 12 on the support frame 22 by means of the U-profile screwed 34 supporting elements 42 takes place.

- the support members 42 are bolted to the second leg 36b of the U-profile 34 in its protruding from the panel 24 section.

- the garbage collection shaft wall 12 is supported by means of a screwed in the upper third of the section shown with the U-profile 34, the refuse chute 14 horizontally encircling bandage 44.

- each of the panels 24a-p is assigned a cooling medium supply line 48 branching off from a cooling medium ring line 46. This opens into a lower end region 52 of the panel cavity 30 and has means 50 for interrupting the cooling medium supply to the respective panel cavity 30.

- cooling water is supplied in operation to each panel, which subsequently flows through the panel cavity 30 from the lower end portion 52 to an upper end portion 54.

- two deflecting ribs 58a, 58b successive in the axial direction of the refuse feed duct are offset relative to one another, ie, a flow passage 57a or 57b is alternately viewed in the longitudinal direction of the panel on one longitudinal side or on the longitudinal side opposite the longitudinal side panel.

- the cooling water passes through ademediumauslass 55 in an in Fig. 2 shown overflow trough 56, where the cooling water is collected and in the sequence z. B. the recooling is supplied.

- the cooling water supply to the panel affected by the damage can be interrupted and the module can be loosened by loosening the screw connection to the respectively adjacent panels, to the supporting elements and to the bandage from the composite and lifted out by means of a crane.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Environmental & Geological Engineering (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

Priority Applications (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| PL13005687T PL2881663T5 (pl) | 2013-12-06 | 2013-12-06 | Urządzenie do podawania śmieci |

| EP13005687.2A EP2881663B2 (de) | 2013-12-06 | 2013-12-06 | Müllaufgabevorrichtung |

| ES13005687T ES2611178T5 (es) | 2013-12-06 | 2013-12-06 | Dispositivo de alimentación de basura |

| US14/559,539 US9816702B2 (en) | 2013-12-06 | 2014-12-03 | Waste feed device |

| JP2014248125A JP6444154B2 (ja) | 2013-12-06 | 2014-12-08 | 廃棄物送込装置 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP13005687.2A EP2881663B2 (de) | 2013-12-06 | 2013-12-06 | Müllaufgabevorrichtung |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP2881663A1 EP2881663A1 (de) | 2015-06-10 |

| EP2881663B1 EP2881663B1 (de) | 2016-10-19 |

| EP2881663B2 true EP2881663B2 (de) | 2019-11-13 |

Family

ID=49726438

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP13005687.2A Active EP2881663B2 (de) | 2013-12-06 | 2013-12-06 | Müllaufgabevorrichtung |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US9816702B2 (es) |

| EP (1) | EP2881663B2 (es) |

| JP (1) | JP6444154B2 (es) |

| ES (1) | ES2611178T5 (es) |

| PL (1) | PL2881663T5 (es) |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP2381174A1 (de) † | 2010-04-21 | 2011-10-26 | Marco Bachmann | Verkleidungselement für Vorrichtungsteile von Verbrennungsöfen |

Family Cites Families (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1561733A (en) * | 1924-08-01 | 1925-11-17 | Gus F Lenk | Charging hopper and cover for incinerators |

| US3031982A (en) * | 1959-08-27 | 1962-05-01 | Combustion Eng | Mixed refuse incinerator using traveling grate stoker and water cooled feed chute |

| DE1934916C3 (de) * | 1969-07-10 | 1973-01-04 | L. & C. Steinmueller Gmbh, 5270 Gummersbach | Beschickungseinrichtung für Drehrohröfen |

| US4806056A (en) * | 1986-07-07 | 1989-02-21 | Waste Recovery, Inc. | Modular fuel metering apparatus and method for use thereof |

| JP3001018U (ja) * | 1994-02-14 | 1994-08-16 | 中園化学株式会社 | 焼却炉 |

| JP2984191B2 (ja) * | 1994-12-27 | 1999-11-29 | 株式会社クボタ | ホッパ部の構造 |

| FR2788121B1 (fr) * | 1998-12-30 | 2001-03-23 | Electricite De France | Four de fusion de dechets solides avec boites a eau |

| JP3580768B2 (ja) * | 2000-10-10 | 2004-10-27 | 株式会社タクマ | 電気式溶融炉の炉壁構造及び炉壁冷却方法 |

| DE202010011448U1 (de) * | 2009-08-17 | 2011-05-19 | Wagner, Ernst, 28203 | Automatische Höhenverstellung für Müllaufgabetrichter für Müllheizkraftwerke |

| KR101218923B1 (ko) * | 2010-09-15 | 2013-01-04 | 한국수력원자력 주식회사 | 유도코일과 용융로 일체형 유도가열식 저온용융로 |

| KR101246174B1 (ko) * | 2012-11-22 | 2013-03-22 | (주)태종 | 소각로용 수냉식 투입슈트 |

-

2013

- 2013-12-06 PL PL13005687T patent/PL2881663T5/pl unknown

- 2013-12-06 EP EP13005687.2A patent/EP2881663B2/de active Active

- 2013-12-06 ES ES13005687T patent/ES2611178T5/es active Active

-

2014

- 2014-12-03 US US14/559,539 patent/US9816702B2/en active Active

- 2014-12-08 JP JP2014248125A patent/JP6444154B2/ja active Active

Patent Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP2381174A1 (de) † | 2010-04-21 | 2011-10-26 | Marco Bachmann | Verkleidungselement für Vorrichtungsteile von Verbrennungsöfen |

Also Published As

| Publication number | Publication date |

|---|---|

| ES2611178T3 (es) | 2017-05-05 |

| JP2015114099A (ja) | 2015-06-22 |

| ES2611178T5 (es) | 2020-08-07 |

| PL2881663T5 (pl) | 2020-06-29 |

| EP2881663B1 (de) | 2016-10-19 |

| PL2881663T3 (pl) | 2017-05-31 |

| JP6444154B2 (ja) | 2018-12-26 |

| EP2881663A1 (de) | 2015-06-10 |

| US20150159864A1 (en) | 2015-06-11 |

| US9816702B2 (en) | 2017-11-14 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE3313615C2 (de) | Rostblock eines Rostbelages zu einem Verbrennungsrost zur Müllverbrennung | |

| EP0811818B2 (de) | Rostplatte sowie Verfahren zur Herstellung einer Rostplatte | |

| EP1992897B1 (de) | Verfahren und Einrichtung zum Kühlen einer auf einem Förderrost liegenden Schüttgutschicht | |

| EP0499912B1 (de) | Roststab und Rost für Verbrennungsanlagen | |

| WO2007039102A1 (de) | Verfahren und vorrichtung zum reinigen von brammen, dünnbrammen, profilen oder dergleichen | |

| EP2978545B1 (de) | Kühlstrecke mit unterem spritzbalken | |

| EP2044378B1 (de) | Vorrichtung zum kühlen von schüttgut | |

| DE102008052085B4 (de) | Anlage mit einer Fördereinrichtung für Verbrennungskessel | |

| EP1612483B1 (de) | Rostplatte, zugehöriger Verbrennungsrost und korrespondierende Reststoffverbrennungsanlage | |

| EP2881663B2 (de) | Müllaufgabevorrichtung | |

| CH693802A5 (de) | Verfahren zur Kuehlung von Roststaeben fuer Verbren nungsrost und Roststab respektive Rost hierfuer. | |

| DE102009042722A1 (de) | Roststab | |

| DE102015101356A1 (de) | Roststab mit Kühlmittel-Kanal | |

| EP3243027B1 (de) | Feuerfeste wand, insbesondere für einen verbrennungsofen | |

| EP3443288B1 (de) | Vertikaler wärmetauscher | |

| EP3250855B1 (de) | Lufteinspeisevorrichtung für einen verbrennungsofen | |

| WO2015169752A1 (de) | Filtereinrichtung zur anordnung an und/oder in einer flüssigkeitsfördereinrichtung | |

| DE9304122U1 (de) | Anordnung zum Brechen und Kühlen des aus einem Brennofen austretenden Guts | |

| EP3630347B1 (de) | Wirbelboden sowie apparat enthaltend einen solchen wirbelboden | |

| EP3395463B2 (de) | Kühlung eines walzguts | |

| EP3384221B1 (de) | Rostplatte für einen rostkühler | |

| EP0606551B1 (de) | Walzenrost zum Betrieb eines Verbrennungskessels | |

| WO2021083797A1 (de) | Roststab für stufenrost | |

| DE1918429A1 (de) | Bunkeraustragvorrichtung | |

| DE29818612U1 (de) | Brennelement mit einem pyramidenförmigen Schmutzabscheider |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20131206 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| R17P | Request for examination filed (corrected) |

Effective date: 20150925 |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| INTG | Intention to grant announced |

Effective date: 20160513 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 838692 Country of ref document: AT Kind code of ref document: T Effective date: 20161115 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: PATENTANWAELTE SCHAAD, BALASS, MENZL AND PARTN, CH |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502013005014 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 4 |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: TRGR |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: FP |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161019 |

|

| REG | Reference to a national code |

Ref country code: NO Ref legal event code: T2 Effective date: 20161019 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170120 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161019 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2611178 Country of ref document: ES Kind code of ref document: T3 Effective date: 20170505 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170220 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161019 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170219 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20161231 Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161019 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R026 Ref document number: 502013005014 Country of ref document: DE |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161019 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161019 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161019 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161019 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161019 |

|

| 26 | Opposition filed |

Opponent name: DOOSAN LENTJES GMBH Effective date: 20170717 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161019 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170119 |

|

| PLAX | Notice of opposition and request to file observation + time limit sent |

Free format text: ORIGINAL CODE: EPIDOSNOBS2 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161019 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20161206 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161019 Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20161206 |

|

| PLBB | Reply of patent proprietor to notice(s) of opposition received |

Free format text: ORIGINAL CODE: EPIDOSNOBS3 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 5 |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20161231 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20131206 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161019 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161019 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161019 |

|

| APBM | Appeal reference recorded |

Free format text: ORIGINAL CODE: EPIDOSNREFNO |

|

| APBP | Date of receipt of notice of appeal recorded |

Free format text: ORIGINAL CODE: EPIDOSNNOA2O |

|

| APAH | Appeal reference modified |

Free format text: ORIGINAL CODE: EPIDOSCREFNO |

|

| APBU | Appeal procedure closed |

Free format text: ORIGINAL CODE: EPIDOSNNOA9O |

|

| PUAH | Patent maintained in amended form |

Free format text: ORIGINAL CODE: 0009272 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: PATENT MAINTAINED AS AMENDED |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: AELC |

|

| 27A | Patent maintained in amended form |

Effective date: 20191113 |

|

| AK | Designated contracting states |

Kind code of ref document: B2 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R102 Ref document number: 502013005014 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: NO Ref legal event code: TB2 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 838692 Country of ref document: AT Kind code of ref document: T Effective date: 20181206 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: FP |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: RPEO |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20181206 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161019 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: DC2A Ref document number: 2611178 Country of ref document: ES Kind code of ref document: T5 Effective date: 20200807 |

|

| P01 | Opt-out of the competence of the unified patent court (upc) registered |

Effective date: 20230506 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20231220 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: TR Payment date: 20231204 Year of fee payment: 11 Ref country code: SE Payment date: 20231220 Year of fee payment: 11 Ref country code: NO Payment date: 20231222 Year of fee payment: 11 Ref country code: NL Payment date: 20231220 Year of fee payment: 11 Ref country code: IT Payment date: 20231228 Year of fee payment: 11 Ref country code: FR Payment date: 20231221 Year of fee payment: 11 Ref country code: FI Payment date: 20231220 Year of fee payment: 11 Ref country code: DE Payment date: 20231214 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: PL Payment date: 20231123 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20240129 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20240101 Year of fee payment: 11 |