EP2829503B2 - Élément de commande d'un chariot de manutention - Google Patents

Élément de commande d'un chariot de manutention Download PDFInfo

- Publication number

- EP2829503B2 EP2829503B2 EP14177269.9A EP14177269A EP2829503B2 EP 2829503 B2 EP2829503 B2 EP 2829503B2 EP 14177269 A EP14177269 A EP 14177269A EP 2829503 B2 EP2829503 B2 EP 2829503B2

- Authority

- EP

- European Patent Office

- Prior art keywords

- control

- levers

- switch

- control levers

- hand

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- G—PHYSICS

- G05—CONTROLLING; REGULATING

- G05G—CONTROL DEVICES OR SYSTEMS INSOFAR AS CHARACTERISED BY MECHANICAL FEATURES ONLY

- G05G11/00—Manually-actuated control mechanisms provided with two or more controlling members co-operating with one single controlled member

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B66—HOISTING; LIFTING; HAULING

- B66F—HOISTING, LIFTING, HAULING OR PUSHING, NOT OTHERWISE PROVIDED FOR, e.g. DEVICES WHICH APPLY A LIFTING OR PUSHING FORCE DIRECTLY TO THE SURFACE OF A LOAD

- B66F9/00—Devices for lifting or lowering bulky or heavy goods for loading or unloading purposes

- B66F9/06—Devices for lifting or lowering bulky or heavy goods for loading or unloading purposes movable, with their loads, on wheels or the like, e.g. fork-lift trucks

- B66F9/075—Constructional features or details

- B66F9/20—Means for actuating or controlling masts, platforms, or forks

-

- G—PHYSICS

- G05—CONTROLLING; REGULATING

- G05G—CONTROL DEVICES OR SYSTEMS INSOFAR AS CHARACTERISED BY MECHANICAL FEATURES ONLY

- G05G1/00—Controlling members, e.g. knobs or handles; Assemblies or arrangements thereof; Indicating position of controlling members

- G05G1/04—Controlling members for hand actuation by pivoting movement, e.g. levers

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T74/00—Machine element or mechanism

- Y10T74/20—Control lever and linkage systems

- Y10T74/20207—Multiple controlling elements for single controlled element

- Y10T74/20372—Manual controlling elements

- Y10T74/20384—Levers

- Y10T74/2039—Pair of levers

Definitions

- the present invention relates to an operating element for an industrial truck.

- a control element for an industrial truck has become known in which an armrest extends in the longitudinal direction of the vehicle and a plurality of control elements are arranged at a front end of the armrest.

- the control elements at least two control elements have an actuating section, wherein the actuating sections are arranged to be operated by a hand resting on the armrest.

- the actuating sections are arranged along a curved line that corresponds to an actuating circle for the fingers of the hand resting on the armrest.

- a control element for a work vehicle in which the hand of an operator rests on a hood-shaped gear lever that can be pivoted about an axis. Buttons are arranged along the circumference, which can be operated with the thumb and index and middle fingers when the hand is resting on the gear lever.

- a control element for a forklift truck is known in which a steering wheel and switching means are arranged on a common control arm, whereby the position of the control arm in the driver's cab is adjustable.

- a hand-operated control element with three control levers is known for controlling a reach truck.

- the three control levers can be pivoted around a common axis, with an outer control lever being provided with additional buttons.

- a hand-operated operating device for an operator station of an industrial truck has become known, with a stationary, raised palm rest located to the side next to and in front of the standing or sitting operator, with an upper support surface onto which the palm of the operator's hand can be placed from above, a front surface facing away from the operator and a surface facing the operator and at least one operating element for a function of the industrial truck at the end of the palm rest facing away from the support surface, which is arranged in such a way that it can be operated with at least one finger, wherein the front and rear surfaces are dimensioned in such a way that the palm rest can be grasped between the fingers and a proximal section of the palm facing the wrist, and a section lying on the front surface and lowered relative to the support surface is arranged in such a way that the fingers of the hand lying on the support surface can be bent and the operating element is arranged on the side of the lowered section opposite the front surface.

- the support surface and the lowered section as well as the front and rear surfaces are formed on a shell body, wherein at least one operating element is embedded laterally in the shell body in such a way that it can be actuated with the thumb of a hand resting on the support surface.

- An operating device for an industrial truck with at least one operating element arranged on an operating console, in particular an armrest, has become known, which is arranged on a surface which is inclined in a cylindrical or shell-shaped manner, wherein the operating elements are laterally spaced from one another by the curvature in such a way that an operator has to reach between them.

- a multifunction lever and an operating unit for an industrial truck have become known in which the lateral arrangement of an operating lever for a multifunction lever is ergonomically designed so that a quick switch between the two is possible.

- US8104566B2 shows a control element for a construction vehicle with control levers and switches arranged between the control levers, whereby these are arranged slightly in front of or behind two control levers within an area and the area is laterally limited by two imaginary parallel lines determined by the position of the control levers.

- the control levers are each designed for a two-axis movement and are spatially spaced from one another. A hand positioned between the levers can operate the control levers and the switch with the fingers without changing the grip, whereby both control levers can only be moved using the fingers without changing the position of the hand.

- the invention is based on the object of creating an operating element for an industrial truck which allows ergonomically favorable operation for as many functions as possible even with different hand sizes and avoids accidental incorrect operation even when wearing work gloves.

- the control element according to the invention is provided and intended for an industrial truck.

- the control element has two control levers and at least one switch arranged between the control levers.

- the control levers are each designed for a two-axis movement, so that each control lever can be freely tilted in any direction.

- the control levers are spatially spaced from one another in such a way that a hand positioned between the control levers allows both control levers and the at least one switch to be operated with the fingers.

- Both control levers can be operated with the balls and/or fingers of one hand without having to grasp the control levers, so that both control levers can be operated simultaneously with one hand without great effort or an unnatural hand position.

- Both control levers can be moved using just the fingers without changing the position of the hand.

- the distance between the control levers is also large enough so that incorrect operation of the control levers or the at least one switch is ruled out.

- the operating lever has a spherically widening lever end, which forms a support surface for the palm of the hand, especially for the ball of the hand.

- the switch or switches between the control levers are designed as buttons.

- the buttons can be assigned different functions for operating the industrial truck.

- one of the buttons can be assigned as a signal generator.

- the other button can be provided as a confirmation button, for example.

- the operating element is provided with a shell-like housing cover from which the operating levers protrude and in which at least one button is arranged slightly recessed.

- the housing cover serves as a rest for the hand or the ball of the hand of an operator.

- the operating levers can be operated from this position.

- the slightly recessed button prevents the button from being accidentally operated.

- At least one of the operating levers is assigned a changeover switch that is assigned one or more hydraulic functions.

- the changeover switch is preferably designed as a toggle switch that has two defined switching positions.

- a rocker switch can also be provided.

- a slide switch is provided in the middle of the operating levers, which has a slider extending parallel to an imaginary connecting line between the operating levers. According to the invention, the slide switch is moved transversely to the connecting line for switching.

- control element A preferred embodiment of the control element is explained in more detail below.

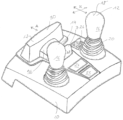

- the only figure shows a shell-like housing part 10, which is preferably made of plastic and is integrated into the interior paneling at an operator station for an industrial truck.

- Two operating levers 12 and 14 protrude from the housing part 10.

- Each of the operating levers 12, 14 has a lever head 16 which widens towards the top and forms a support surface 18 for the palm of the hand at its upper end.

- Each of the operating levers 12, 14 can be moved like a joystick along the double arrows K shown. The movement in the two arrow directions can be superimposed so that each operating lever can be swiveled in any direction. Alternatively, a lane guidance via a corresponding switching gate is also possible.

- the operating levers 12 and 14 each have a sleeve 20 which comprises a flat material folded in an accordion shape in order to shield a lever mechanism of the operating levers from environmental influences such as dust, dirt and the like.

- buttons 22, 24 are arranged between the operating levers 12, 14.

- Button 22 is equipped as a signal generator for an acoustic warning signal.

- Button 24 is intended, for example, as a confirmation button.

- buttons 22 and 24 are integrated into the housing 10 and slightly recessed.

- a switch 26 is designed as a toggle switch and protrudes from the housing 10.

- the toggle switch 26 is provided for switching between different hydraulic functions.

- the toggle switch 26 can be designed such that its toggle lever 28 is always in the neutral position shown and is switched forwards or backwards.

- the toggle switch 26 can also be designed such that the toggle lever 28 has a defined front position and a defined rear position between which switching takes place.

- the operating element also has a sliding lever 30 which can be moved along the double arrow A.

- the sliding lever 30 has a front sliding body 32 and a rear sliding body 34.

- the sliding bodies 32 and 34 are connected to one another by a web 36.

- the rear sliding body 34 is arranged in such a way that a hand resting on the operating lever 12 or 14 can press with the index finger and middle finger against the rear wall 38 of the rear sliding body 34 in order to push the slider away from the operating lever in the direction of the double arrow A.

- the rear sliding body 34 can be partially gripped behind with the index finger so that the slider as a whole is pulled towards the operating levers 12 and 14.

Landscapes

- Engineering & Computer Science (AREA)

- Transportation (AREA)

- Structural Engineering (AREA)

- Automation & Control Theory (AREA)

- Physics & Mathematics (AREA)

- General Physics & Mathematics (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Civil Engineering (AREA)

- Life Sciences & Earth Sciences (AREA)

- Geology (AREA)

- Mechanical Engineering (AREA)

- Mechanical Control Devices (AREA)

- Forklifts And Lifting Vehicles (AREA)

- Arrangement Or Mounting Of Control Devices For Change-Speed Gearing (AREA)

Claims (7)

- Organe de commande pour un chariot de manutention, avec deux leviers de commande (12, 14) et au moins un interrupteur (22, 24) arrangé entre les leviers de commande, dans lequel les leviers de commande (12, 14) sont chacun configuré pour un mouvement biaxial (K), caractérisé en ce que les leviers de commande sont spatialement espacés l'un de l'autre de sorte qu'avec une main positionnée entre les leviers, les leviers de commande et l'au moins un interrupteur (22, 24) entre les leviers de commande peuvent être actionnés par les doigts sans imposer une saisie de ceux-ci, les deux leviers de commande pouvant être mobiles seulement via les doigts sans aucun change de la position de la main et qu'un interrupteur à coulisse (30) est pourvu dans la moitié entre les leviers de commande, qui a au moins un corps coulissant (32, 34) s'étendant en parallèle à une ligne de connexion imaginaire entre les leviers de commande (12, 14), l'interrupteur à coulisse (30) étant déplacé en travers à sa ligne de connexion afin de commuter..

- Organe de commande selon la revendication 1, caractérisé en ce que chacun des leviers de commande (12, 14) a un bout de levier (16) qui s'élargit de manière convexe.

- Organe de commande selon la revendication 1 or 2, caractérisé en ce que l'un ou les plusieurs interrupteur(s) (22, 24) est/sont réalisé(s) comme bouton(s) poussoir(s).

- Organe de commande selon l'une quelconque des revendications 1 à 3, caractérisé en ce que deux boutons poussoirs (22, 24) sont pourvus entre les leviers de commande (12, 14).

- Organe de commande selon l'une quelconque des revendications 1 à 4, caractérisé en ce que un couvercle de boîtier (10) est pourvu, à partir duquel les leviers de commande (12, 14) font saillie et dans lequel l'au moins un interrupteur (22, 24) est arrangé de manière escamotée dans un évidement.

- Organe de commande selon la revendication 5, caractérisé en ce que la main positionnée entre les leviers repose sur le couvercle de boîtier avec son poignet.

- Organe de commande selon l'une quelconque des revendications 1 à 6, caractérisé en ce qu'un inverseur (26) pour une ou plusieurs fonctions hydrauliques sur le chariot de manutention est associé à au moins un levier de commande (12).

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102013012176.0A DE102013012176A1 (de) | 2013-07-22 | 2013-07-22 | Bedienelement für ein Flurförderzeug |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP2829503A1 EP2829503A1 (fr) | 2015-01-28 |

| EP2829503B1 EP2829503B1 (fr) | 2016-01-20 |

| EP2829503B2 true EP2829503B2 (fr) | 2024-08-28 |

Family

ID=51212693

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP14177269.9A Active EP2829503B2 (fr) | 2013-07-22 | 2014-07-16 | Élément de commande d'un chariot de manutention |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US20150033899A1 (fr) |

| EP (1) | EP2829503B2 (fr) |

| CN (1) | CN104391539B (fr) |

| DE (1) | DE102013012176A1 (fr) |

| ES (1) | ES2567423T5 (fr) |

Families Citing this family (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP6247174B2 (ja) * | 2014-08-01 | 2017-12-13 | 株式会社クボタ | 運転支援システム |

| USD789264S1 (en) * | 2016-01-21 | 2017-06-13 | Pilot, Inc. | Shift knob cover |

| USD789263S1 (en) * | 2016-01-21 | 2017-06-13 | Pilot, Inc. | Shift knob cover |

| AU2017213884B2 (en) | 2016-02-05 | 2022-09-15 | Crown Equipment Corporation | Control elements for materials handling vehicles |

| DE102016118457A1 (de) | 2016-09-29 | 2018-03-29 | Jungheinrich Aktiengesellschaft | Verfahren zur Bedienung eines Flurförderzeugs mit einem Bedienelement sowie ein Flurförderzeug |

| DE102016118458A1 (de) | 2016-09-29 | 2018-03-29 | Jungheinrich Aktiengesellschaft | Verfahren zur Bedienung eines Flurförderzeugs mit einem Bedienelement |

| DE102016118459A1 (de) | 2016-09-29 | 2018-03-29 | Jungheinrich Aktiengesellschaft | Flurförderzeug mit einem einen Bedienhebel aufweisenden Bedienmittel sowie Verfahren zur Bedienung eines solchen Flurförderzeugs |

| WO2020206239A1 (fr) * | 2019-04-04 | 2020-10-08 | Jlg Industries, Inc. | Station de commande pour véhicules compacts |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB2325211A (en) † | 1997-05-16 | 1998-11-18 | Lansing Linde Ltd | An operating arrangement for a load supporting device on a lift truck |

| EP1350669A2 (fr) † | 2002-04-03 | 2003-10-08 | Kabushiki Kaisha Toyota Jidoshokki | Organe de manoeuvre et accoudoir pour véhicule industriel |

| US8104566B2 (en) † | 2008-03-07 | 2012-01-31 | Deere & Company | Arrangement of steering wheel and operator seat assembly |

Family Cites Families (28)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| IT1145601B (it) * | 1981-12-21 | 1986-11-05 | Lear Snc Di Foggini E C | Leva di comando particolarmente per carri di velocita di autoveicoli e sua procedimento di fabbricazione |

| IT8553363U1 (it) * | 1985-05-10 | 1986-11-10 | Foggini Progetti | Rivestimento integrale preformato per leve di comando del cambio di velocita' di autoveicoli |

| SE507063C2 (sv) | 1993-11-29 | 1998-03-23 | Bt Ind Ab | Bärarm med manöverorgan till lyfttruckar |

| DE29714284U1 (de) | 1997-08-09 | 1997-10-16 | Jungheinrich Ag, 22047 Hamburg | Handbetätigte Stellvorrichtung für den Bedienungsstand bzw. -sitz eines Schubmaststaplers |

| SE520647C2 (sv) | 1999-04-23 | 2003-08-05 | Atlet Ab | Handmanövreringsanordning för arbetsfordon |

| US6634453B2 (en) * | 2001-08-29 | 2003-10-21 | Deere & Company | Ergonomic tractor seat armrest and hand control |

| EP1433123A1 (fr) * | 2001-09-04 | 2004-06-30 | Ziad Badarneh | Dispositif de commande permettant de commander des fonctions dans un equipement electronique |

| JP4291544B2 (ja) | 2002-04-03 | 2009-07-08 | 株式会社豊田自動織機 | 産業車両 |

| DE10344029A1 (de) * | 2003-09-23 | 2005-04-14 | Still Gmbh | Multifunktionshebel und Bedieneinheit für ein Flurförderzeug |

| US7218313B2 (en) * | 2003-10-31 | 2007-05-15 | Zeetoo, Inc. | Human interface system |

| US7178623B2 (en) * | 2003-12-19 | 2007-02-20 | Caterpillar Inc | Operator control assembly |

| US7063321B2 (en) * | 2004-06-10 | 2006-06-20 | Intec, Inc. | Gel grip controller |

| US7290635B2 (en) * | 2004-07-02 | 2007-11-06 | Caterpillar Inc. | Work machine operator control station with moveably attached controller |

| US7635045B2 (en) * | 2004-07-30 | 2009-12-22 | Caterpillar Inc. | Machine tool control console |

| DE102005007789A1 (de) | 2005-02-19 | 2006-08-24 | Jungheinrich Aktiengesellschaft | Handbetätigte Bedienvorrichtung für einen Bedienplatz eines Flurförderzeugs |

| JP4852912B2 (ja) * | 2005-07-15 | 2012-01-11 | 株式会社豊田自動織機 | 産業車両 |

| US8333250B2 (en) * | 2008-03-07 | 2012-12-18 | Deere & Company | Mounting console with visibility improvements |

| JP4596020B2 (ja) * | 2008-03-07 | 2010-12-08 | 株式会社デンソー | 車両用操作装置 |

| US7806470B2 (en) * | 2008-11-20 | 2010-10-05 | Deere & Company | Vehicle command armrest assembly |

| EP2391777B1 (fr) * | 2009-01-20 | 2016-10-26 | Husqvarna AB | Système de commande pour engin de travaux télécommandé |

| DE102009032493A1 (de) * | 2009-07-09 | 2011-01-13 | Linde Material Handling Gmbh | Bedienvorrichtung und Bedienvorrichtungssystem für Flurförderzeug |

| US20120235947A1 (en) * | 2010-01-29 | 2012-09-20 | Saeko Yano | Map information processing device |

| US9567065B2 (en) * | 2010-10-07 | 2017-02-14 | Bae Systems Plc | Vehicle armrest |

| GB201020499D0 (en) * | 2010-12-03 | 2011-01-19 | Valtra Oy Ab | Driver interface module |

| JP5165160B2 (ja) * | 2011-01-27 | 2013-03-21 | パナソニック株式会社 | ロボットアームの制御装置及び制御方法、ロボット、ロボットアーム制御プログラム、並びに、集積電子回路 |

| AU2012258458B9 (en) * | 2011-12-01 | 2014-11-06 | Joy Global Surface Mining Inc | Cab module for a mining machine |

| JP6317202B2 (ja) * | 2014-07-08 | 2018-04-25 | 株式会社クボタ | 多機能操作具及びアームレスト操作装置 |

| US10036139B2 (en) * | 2014-11-24 | 2018-07-31 | Caterpillar Inc. | Machine input device having multi-axis tool control |

-

2013

- 2013-07-22 DE DE102013012176.0A patent/DE102013012176A1/de not_active Ceased

-

2014

- 2014-07-16 ES ES14177269T patent/ES2567423T5/es active Active

- 2014-07-16 EP EP14177269.9A patent/EP2829503B2/fr active Active

- 2014-07-21 US US14/336,673 patent/US20150033899A1/en not_active Abandoned

- 2014-07-22 CN CN201410539360.9A patent/CN104391539B/zh active Active

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB2325211A (en) † | 1997-05-16 | 1998-11-18 | Lansing Linde Ltd | An operating arrangement for a load supporting device on a lift truck |

| EP1350669A2 (fr) † | 2002-04-03 | 2003-10-08 | Kabushiki Kaisha Toyota Jidoshokki | Organe de manoeuvre et accoudoir pour véhicule industriel |

| US8104566B2 (en) † | 2008-03-07 | 2012-01-31 | Deere & Company | Arrangement of steering wheel and operator seat assembly |

Also Published As

| Publication number | Publication date |

|---|---|

| EP2829503A1 (fr) | 2015-01-28 |

| CN104391539B (zh) | 2018-05-18 |

| US20150033899A1 (en) | 2015-02-05 |

| CN104391539A (zh) | 2015-03-04 |

| ES2567423T3 (es) | 2016-04-22 |

| ES2567423T5 (es) | 2025-03-04 |

| EP2829503B1 (fr) | 2016-01-20 |

| DE102013012176A1 (de) | 2015-01-22 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2829503B2 (fr) | Élément de commande d'un chariot de manutention | |

| EP1288763B1 (fr) | Dispositif de commande d'un véhicule agricole | |

| DE19624463A1 (de) | Steuereinrichtung für Nutzfahrzeuge, insbesondere für landwirtschaftliche nutzbare Schlepper | |

| EP1632426B1 (fr) | Timon pour un chariot élévateur | |

| DE3925872C2 (fr) | ||

| DE19951379C2 (de) | Handbetätigtes Lenkorgan für ein Flurförderzeug | |

| EP1693334B1 (fr) | Dispositif de commande à main pour poste de conduite d'un chariot industriel | |

| EP1727728A1 (fr) | Element de commande | |

| DE102020001889A1 (de) | Bedienelementanordnung für ein mobiles Arbeitsgerät sowie Verfahren zur Durchführung eines Lenkvorgangs bei einem derartigen Arbeitsgerät | |

| EP2880503B1 (fr) | Élément de commande manuell speciallement pour engin | |

| DE102005018220B4 (de) | Bedieneinrichtung für ein Fahrzeug | |

| DE19956870B4 (de) | Handbetätigtes Lenkorgan für Fahrzeuge | |

| DE60011786T2 (de) | Betätigungsvorrichtung für Arbeitsfahrzeuge | |

| EP1747964B1 (fr) | Élément de commande avec mini-levier | |

| EP1775254B1 (fr) | Panneau de commande pour un chariot de manutention avec une commande pour le pouce du type joystick | |

| EP3054367B1 (fr) | Vehicule, en particulier vehicule a chenille destine a l'entretien et au damage de pistes de ski | |

| EP3009325B1 (fr) | Volant pour chariot de manutention dote d'un poste de travail du conducteur | |

| EP1748026B1 (fr) | Dispositif de commande pour chariot de manutention | |

| EP2075216B1 (fr) | Tête de timon pour un chariot de manutention | |

| DE102023001993B3 (de) | Steer-by-Wire-Lenkrad für einen Kraftwagen sowie Verfahren | |

| DE102008045731B4 (de) | Deichselkopf für ein Flurförderzeug | |

| DE102014112896B4 (de) | Flurförderzeug mit einer Anzeige- und Bedienvorrichtung | |

| DE10235159A1 (de) | Verstellbares Lenkrad für Kraftfahrzeuge | |

| DE10205876A1 (de) | Flurförderzeug mit einer Bedienanordnung |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 17P | Request for examination filed |

Effective date: 20140716 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| R17P | Request for examination filed (corrected) |

Effective date: 20150715 |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: G05G 11/00 20060101ALI20150814BHEP Ipc: B66F 9/20 20060101AFI20150814BHEP Ipc: G05G 1/04 20060101ALI20150814BHEP |

|

| INTG | Intention to grant announced |

Effective date: 20150903 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 771638 Country of ref document: AT Kind code of ref document: T Effective date: 20160215 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502014000317 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2567423 Country of ref document: ES Kind code of ref document: T3 Effective date: 20160422 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D Ref country code: NL Ref legal event code: MP Effective date: 20160120 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160120 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 3 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160120 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160120 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160421 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160420 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160520 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160520 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160120 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160120 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160120 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160120 Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160120 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R026 Ref document number: 502014000317 Country of ref document: DE |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160120 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160120 |

|

| 26 | Opposition filed |

Opponent name: LINDE MATERIAL HANDLING GMBH Effective date: 20161012 |

|

| PLAX | Notice of opposition and request to file observation + time limit sent |

Free format text: ORIGINAL CODE: EPIDOSNOBS2 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160120 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160120 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160120 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160120 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160731 |

|

| PLAB | Opposition data, opponent's data or that of the opponent's representative modified |

Free format text: ORIGINAL CODE: 0009299OPPO |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160420 Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160120 |

|

| R26 | Opposition filed (corrected) |

Opponent name: LINDE MATERIAL HANDLING GMBH Effective date: 20161012 |

|

| PLAB | Opposition data, opponent's data or that of the opponent's representative modified |

Free format text: ORIGINAL CODE: 0009299OPPO |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160120 |

|

| PLBB | Reply of patent proprietor to notice(s) of opposition received |

Free format text: ORIGINAL CODE: EPIDOSNOBS3 |

|

| R26 | Opposition filed (corrected) |

Opponent name: LINDE MATERIAL HANDLING GMBH Effective date: 20161012 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 4 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160716 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160716 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170731 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170731 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20140716 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160120 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160120 Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160120 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 5 |

|

| PLCK | Communication despatched that opposition was rejected |

Free format text: ORIGINAL CODE: EPIDOSNREJ1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN GRANTED |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160120 Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160120 |

|

| APBM | Appeal reference recorded |

Free format text: ORIGINAL CODE: EPIDOSNREFNO |

|

| APBP | Date of receipt of notice of appeal recorded |

Free format text: ORIGINAL CODE: EPIDOSNNOA2O |

|

| APAH | Appeal reference modified |

Free format text: ORIGINAL CODE: EPIDOSCREFNO |

|

| APBQ | Date of receipt of statement of grounds of appeal recorded |

Free format text: ORIGINAL CODE: EPIDOSNNOA3O |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 771638 Country of ref document: AT Kind code of ref document: T Effective date: 20190716 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190716 |

|

| APBU | Appeal procedure closed |

Free format text: ORIGINAL CODE: EPIDOSNNOA9O |

|

| PLAY | Examination report in opposition despatched + time limit |

Free format text: ORIGINAL CODE: EPIDOSNORE2 |

|

| PLBC | Reply to examination report in opposition received |

Free format text: ORIGINAL CODE: EPIDOSNORE3 |

|

| PUAH | Patent maintained in amended form |

Free format text: ORIGINAL CODE: 0009272 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: PATENT MAINTAINED AS AMENDED |

|

| 27A | Patent maintained in amended form |

Effective date: 20240828 |

|

| AK | Designated contracting states |

Kind code of ref document: B2 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R102 Ref document number: 502014000317 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: DC2A Ref document number: 2567423 Country of ref document: ES Kind code of ref document: T5 Effective date: 20250304 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20250819 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20250722 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20250731 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20250724 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20250723 Year of fee payment: 12 |