EP2524970A1 - Hochfestes Stahlflachprodukt und Verfahren zu dessen Herstellung - Google Patents

Hochfestes Stahlflachprodukt und Verfahren zu dessen Herstellung Download PDFInfo

- Publication number

- EP2524970A1 EP2524970A1 EP11166622A EP11166622A EP2524970A1 EP 2524970 A1 EP2524970 A1 EP 2524970A1 EP 11166622 A EP11166622 A EP 11166622A EP 11166622 A EP11166622 A EP 11166622A EP 2524970 A1 EP2524970 A1 EP 2524970A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- steel

- temperature

- content

- flat

- heating

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D1/00—General methods or devices for heat treatment, e.g. annealing, hardening, quenching or tempering

- C21D1/18—Hardening; Quenching with or without subsequent tempering

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D1/00—General methods or devices for heat treatment, e.g. annealing, hardening, quenching or tempering

- C21D1/18—Hardening; Quenching with or without subsequent tempering

- C21D1/19—Hardening; Quenching with or without subsequent tempering by interrupted quenching

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D1/00—General methods or devices for heat treatment, e.g. annealing, hardening, quenching or tempering

- C21D1/78—Combined heat-treatments not provided for above

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D6/00—Heat treatment of ferrous alloys

- C21D6/002—Heat treatment of ferrous alloys containing Cr

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D8/00—Modifying the physical properties by deformation combined with, or followed by, heat treatment

- C21D8/02—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of plates or strips

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D8/00—Modifying the physical properties by deformation combined with, or followed by, heat treatment

- C21D8/02—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of plates or strips

- C21D8/0247—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of plates or strips characterised by the heat treatment

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D8/00—Modifying the physical properties by deformation combined with, or followed by, heat treatment

- C21D8/02—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of plates or strips

- C21D8/04—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of plates or strips to produce plates or strips for deep-drawing

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D8/00—Modifying the physical properties by deformation combined with, or followed by, heat treatment

- C21D8/02—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of plates or strips

- C21D8/04—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of plates or strips to produce plates or strips for deep-drawing

- C21D8/0447—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of plates or strips to produce plates or strips for deep-drawing characterised by the heat treatment

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/001—Ferrous alloys, e.g. steel alloys containing N

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/02—Ferrous alloys, e.g. steel alloys containing silicon

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/04—Ferrous alloys, e.g. steel alloys containing manganese

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/06—Ferrous alloys, e.g. steel alloys containing aluminium

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/12—Ferrous alloys, e.g. steel alloys containing tungsten, tantalum, molybdenum, vanadium, or niobium

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/14—Ferrous alloys, e.g. steel alloys containing titanium or zirconium

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/18—Ferrous alloys, e.g. steel alloys containing chromium

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/18—Ferrous alloys, e.g. steel alloys containing chromium

- C22C38/28—Ferrous alloys, e.g. steel alloys containing chromium with titanium or zirconium

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/18—Ferrous alloys, e.g. steel alloys containing chromium

- C22C38/32—Ferrous alloys, e.g. steel alloys containing chromium with boron

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/18—Ferrous alloys, e.g. steel alloys containing chromium

- C22C38/34—Ferrous alloys, e.g. steel alloys containing chromium with more than 1.5% by weight of silicon

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/18—Ferrous alloys, e.g. steel alloys containing chromium

- C22C38/38—Ferrous alloys, e.g. steel alloys containing chromium with more than 1.5% by weight of manganese

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C2/00—Hot-dipping or immersion processes for applying the coating material in the molten state without affecting the shape; Apparatus therefor

- C23C2/02—Pretreatment of the material to be coated, e.g. for coating on selected surface areas

- C23C2/022—Pretreatment of the material to be coated, e.g. for coating on selected surface areas by heating

- C23C2/0224—Two or more thermal pretreatments

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D2211/00—Microstructure comprising significant phases

- C21D2211/008—Martensite

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/12—All metal or with adjacent metals

- Y10T428/12493—Composite; i.e., plural, adjacent, spatially distinct metal components [e.g., layers, joint, etc.]

- Y10T428/12771—Transition metal-base component

- Y10T428/12785—Group IIB metal-base component

- Y10T428/12792—Zn-base component

- Y10T428/12799—Next to Fe-base component [e.g., galvanized]

Definitions

- the invention relates to a high-strength flat steel product and to a method for producing such a flat steel product.

- the invention relates to a high-strength flat steel product provided with a metallic protective layer and to a method for producing such a product.

- cooling rates are given a negative value because they lead to a decrease in temperature. Accordingly, cooling rates have a lower value for a rapid cooling than for a slower cooling. The leading to an increase in temperature heating rates, however, are given a positive.

- High strength steels regularly tend to corrode because of their alloying constituents and are therefore typically coated with a metallic protective layer which protects the respective steel substrate from contact with the ambient oxygen.

- a metallic protective layer which protects the respective steel substrate from contact with the ambient oxygen.

- Various methods for applying such a metallic protective layer are known. These include hot-dip coating, also known in technical language as "fire-coating", and electrolytic coating.

- the coating metal is deposited electrochemically on the flat steel product to be coated, which is at most slightly heated in the process, during hot dip coating the products to be coated are subjected to a heat treatment before immersion in the respective melt bath.

- the respective flat steel product is heated to high temperatures under a certain atmosphere in order to set the desired structure and to produce an optimum for the adhesion of the metallic coating surface state of the respective flat steel product.

- the flat steel product passes through the melt bath, which also has an elevated temperature, to keep the coating material molten.

- the steel strip is dip-coated.

- the metallic coating applied in this case should preferably be a zinc coating.

- a cold strip is to be obtained in this way, the optimized mechanical properties, such as a tensile strength of at least 1200 MPa, an elongation of at least 13% and a hole widening of at least 50%, has.

- the cold rolled strip processed in the manner described above is said to be made of a steel containing, in addition to iron and unavoidable impurities (in% by weight) 0.05-0.5% C, 0.01-2.5% Si, 0.5 - 3.5% Mn, 0.003 - 0.100% P, up to 0.02% S and 0.010 - 0.5 Al.

- the steel should have a microstructure comprising (in area%) up to 10% ferrite, up to 10% martensite and 60-95 tempered martensite, and further 5 - 20% retained austenite, as determined by X-ray diffraction.

- the steel (in weight%) can be 0.005 - 2.00% Cr, 0.005 - 2.00 Mo, 0.005 - 2.00% V, 0.005 - 2.00% Ni and 0.005 - 2.00% Cu and 0.01-0.20% Ti, 0.01-0.20 Nb, 0.0002-0.005% B, 0.001-0.005% Ca and 0.001-0.005% of rare earths.

- the object of the invention was to provide a low-cost producible high-strength flat steel product which has further optimized mechanical properties, which are expressed in particular in a very good bending behavior.

- a method for producing such a flat steel product should be specified.

- this method should be incorporated into a process for hot dip coating of flat steel products.

- the solution according to the invention of the abovementioned object consists in that during the production of a flat steel product according to the invention at least the steps mentioned in claim 6 are completed.

- the operations specified in claim 7 can optionally also be carried out.

- a steel flat product according to the invention consists of a steel which, in addition to iron and unavoidable impurities (in% by weight) C: 0.10-0.50%, Si: 0.1-2.5%, Mn: 1.0. 3.5%, Al: up to 2.5%, P: up to 0.020%, S: up to 0.003%, N: up to 0.02%, and optionally one or more of the elements "Cr, Mo, V, Ti, Nb, B and Ca" in the following contents: Cr: 0.1-0.5%, Mo: 0.1-0.3%, V : 0.01 - 0.1%, Ti: 0.001 - 0.15%, Nb: 0.02 - 0.05%, wherein for the sum ⁇ (V, Ti, Nb) of the contents of V, Ti and Nb ⁇ (V, Ti, Nb) is at most equal to 0.2%, B: 0.0005 - 0.005%, Ca: up to 0.01%.

- Essential for the superior mechanical properties of the flat steel product according to the invention is that it has a structure with (in area%) less than 5% ferrite, less than 10% bainite, 5-70% unanbergem martensite, 5-30% retained austenite and 25 80% tempered martensite. At least 99% of the number of iron carbides contained in tempered martensite has a size of less than 500 nm.

- Over-tempered martensite is characterized in that more than 1% number of carbide grains (iron carbides) are more than 500 nm in size.

- over-cut martensite can be detected by scanning electron microscopy at 20,000 magnifications on steel samples etched with 3% nitric acid.

- the C content of the steel of a flat steel product according to the invention is limited to values between 0.10 and 0.50 wt.%. Carbon influences a flat steel product according to the invention in many respects.

- C plays a major role in the formation of austenite and lowering the Ac3 temperature.

- a sufficient concentration of C allows complete austenitization at temperatures ⁇ 960 ° C, even if at the same time elements, such as Al, are present, which increase the Ac3 temperature.

- the retained austenite is also stabilized by the presence of C. This effect continues during the partitioning step.

- a stable residual austenite leads to a maximum strain range, in which the effect of the TRIP effect (TRANSformation Induced Plasticity) becomes noticeable.

- the strength of the martensite is most strongly influenced by the respective C content. Too high a content of C leads to such a strong shift of the martensite start temperature to ever lower temperatures that the production of the flat steel product according to the invention becomes excessively difficult. In addition, too high C contents can adversely affect weldability.

- the Si content in the steel of the flat steel product according to the invention should be less than 2.5% by weight. Silicon is important for suppressing cementite formation. The formation of cementite would break the C as a carbide and would then no longer stand for the stabilization of the retained austenite to disposal. In addition, the stretch would be worsened.

- the effect achieved by the addition of Si can in part also be achieved by alloying aluminum. However, a minimum of 0.1% by weight of Si should always be present in the flat steel product according to the invention in order to utilize its positive effect.

- Manganese contents of 1.0-3.5% by weight, in particular up to 3.0% by weight, are important for the hardenability of the flat steel product according to the invention and the prevention of perlite formation during cooling. These properties make it possible to form a starting structure consisting of martensite and retained austenite, and as such is suitable for the partitioning step carried out according to the invention.

- manganese proves advantageous with regard to the setting of comparatively low cooling rates of, for example, faster than -100 K / s.

- an excessively high Mn concentration has a negative influence on the elongation properties and the weldability of a flat steel product according to the invention.

- Aluminum is present in the steel of a flat steel product of the present invention at levels of up to 2.5% for deoxidation and for the setting of any nitrogen present.

- Al can also be used for the suppression of cementite and does not have such a negative effect on the surface properties as high contents of Si.

- Al is not as effective as Si and also increases the austenitizing temperature. Therefore, the Al content is of a flat steel product according to the invention is limited to a maximum of 2.5% by weight and preferably to values of between 0.01 and 1.5% by weight.

- Phosphorus is unfavorable to weldability and should therefore be present in the steel of a flat steel product of the present invention at levels less than 0.02% by weight.

- the S content in the steel of a flat steel product according to the invention should be below 0.003 wt .-%.

- nitrogen in the steel of a flat steel product according to the invention has a detrimental effect on the formability.

- the N content of a flat steel product according to the invention should therefore be less than 0.02% by weight.

- V, Ti and Nb are added to the steel of a flat steel product according to the invention.

- These elements contribute to higher strength through the formation of very finely divided carbides or carbonitrides.

- a minimum Ti content of 0.001% by weight leads to a freezing of the grain and phase boundaries during the Partitioning step.

- too high a concentration of V, Ti and Nb can be detrimental to the stabilization of retained austenite. Therefore, the sum of the contents of V, Ti and Nb in a flat steel product according to the invention is limited to 0.2% by weight.

- Chromium is an effective inhibitor of perlite, contributes to the strength and therefore may be added up to 0.5% by weight to the steel of a flat steel product according to the invention. Above 0.5% by weight, there is a risk of pronounced grain boundary oxidation. In order to be able to safely use the positive influence of Cr, the Cr content can be set to 0.1-0.5% by weight.

- molybdenum is also a very effective element for suppressing perlite formation.

- the steel of a flat steel product according to the invention can be alloyed with 0.1-0.3% by weight.

- Calcium in contents of up to 0.01% by weight is used in the steel of a steel flat product according to the invention for setting sulfur and for inclusion modification.

- the method according to the invention for producing a high-strength steel flat product, optionally provided with a metallic protective coating provided by hot-dip coating comprises the following working steps:

- the steel constituting the flat steel product contains C: 0.10-0.50%, Si: 0.1-2.5%, Mn: 1.0 - 3.5%, Al: up to 2.5%, P: up to 0.020%, S: up to 0.003%, N: up to 0.02%, and optionally one or more of the elements "Cr, Mo, V, Ti, Nb, B and Ca "in the following contents: Cr: 0.1 - 0.5%, Mo: 0.1 - 0.3%, V: 0.01 - 0.1%, Ti: 0.001 - 0.15%, Nb: 0.02 - 0.05%, where for the sum ⁇ (V, Ti, Nb) the contents of V, Ti and Nb holds ⁇ (V, Ti, Nb) ⁇ 0.2 %, B: 0.0005

- the thus provided flat steel product is then heated to a above the Ac3 temperature of the steel of the steel flat product and at most 960 ° C amount austenitizing temperature T HZ at a heating rate ⁇ H1 , ⁇ H2 of at least 3 ° C / s. Fast heating reduces the process time and improves the overall cost-effectiveness of the process.

- the heating to the Austenitmaschinestemperatur T HZ can in two uninterrupted successive stages be performed with different heating rates ⁇ H1 , ⁇ H2 .

- the heating at lower temperatures can be done very quickly to increase the efficiency of the process.

- the dissolution of carbides begins.

- lower heating rates ⁇ H2 are advantageous in order to ensure a uniform distribution of the carbon and other possible alloying elements, such. Mo or Cr.

- the carbides are deliberately annealed already below the A c1 temperature to exploit the faster diffusion in the ferrite over the slower diffusion in austenite.

- the dissolved atoms can be distributed more uniformly in the material as a result of a lower heating rate ⁇ H2 .

- a limited heating rate ⁇ H2 is also favorable during the austenite transformation, ie between A c1 and A c3 . This contributes to a homogeneous starting structure before quenching and thus a uniformly distributed martensite and a fine retained austenite after quenching and ultimately improved mechanical properties of the flat steel product.

- the heating rate ⁇ H1 of the first stage may be 5-25 ° C / s and the heating rate ⁇ H2 of the second stage 3-10 ° C, especially 3-5 ° C / s amount.

- the flat steel product with the first heating rate ⁇ H1 can be heated to an intermediate temperature T w of 200-500 ° C, in particular 250-500 ° C, and the heating can then be continued at the second heating rate ⁇ H2 up to the austenitizing temperature T HZ .

- the flat steel product is kept at the austenitizing temperature T Hz for an austenitizing time t HZ of 20-180 s.

- the annealing temperature in the holding zone should be above the A c3 temperature in order to achieve complete austenitization.

- the steel sheet After annealing at temperatures above A c3 , the steel sheet is cooled to a cooling stop temperature T Q greater than the martensite stop temperature T Mf and less than the martensite start temperature T Ms (T Mf ⁇ T Q ⁇ T Ms ) at a cooling rate ⁇ Q ,

- the cooling rate ⁇ Q is in the range of -20 ° C / s to -120 ° C / s.

- the condition ⁇ Q ⁇ ⁇ Q (min) can be surely satisfied in practice even for steels having a low C or Mn content.

- Parallel to the yield strength increase can be achieved by the inventively carried out cooling to the cooling stop temperature and the subsequent holding of the flat steel product at this temperature over the times prescribed by the invention, an improvement of the forming properties. If tensile strength and tensile elongation are to be maximized, the holding time t Q should rather be kept in the lower range, ie between 10 and 30 s. Longer holding times t Q of 30 - 60 s tend to have a positive effect on the forming properties. This concerns in particular the bending angle.

- the cooling stop temperature T Q is at least 200 ° C.

- the steel flat product After cooling and holding the steel flat product at the cooling stop temperature T Q , the steel flat product is heated to a 400-500 ° from the cooling stop temperature T Q with a heating rate ⁇ P1 of 2 - 80 ° C / s, especially 2 - 40 ° C / s C, in particular 450 - 490 ° C, amounting temperature T P heated.

- the heating to the temperature T P is preferably carried out within a heating time t A of 1 - 150 s, in order to achieve optimum efficiency. At the same time, the heating can make a contribution x Dr to a diffusion length x D explained below.

- the purpose of the heating and a subsequent optional additional holding of the flat steel product at the temperature T P over a holding period t Pi of up to 500 s is the enrichment of the retained austenite with carbon from the supersaturated martensite.

- the holding period t Pi is in particular up to 200 s, wherein holding periods t Pi of less than 10 s are particularly practical.

- the partitioning can already during the heating as a so-called “Ramped Partitioning” done by the held after the heating hold at the partitioning temperature T P (so-called “isothermal” partitioning) or by a combination of isothermal and ramped partitioning.

- the high temperatures necessary for the subsequent hot-dip coating can be achieved without causing special tempering effects, ie over-tempering of the martensite.

- the slower heating rate ⁇ P1 envisaged for ramped partitioning in comparison to isothermal partitioning permits a particularly precise control of the respectively prescribed partitioning temperature T P with reduced energy input, since higher temperature gradients require a higher energy expenditure in the system.

- the inventively predetermined partitioning temperature T P ensures sufficient homogenization of the carbon in the austenite, this homogenization being able to be influenced by the heating speed ⁇ P1 , the partitioning temperature T P and the optional holding at the partitioning temperature T P over a suitable holding time t Pi .

- the proportions x Dr or x Di can also be "0" depending on the respective process control, the total diffusion length x D being always> 0 as a result of the method according to the invention.

- the method according to the invention provides optimum work results if the sum of the respective diffusion lengths x Di , x Dr to be considered is at least 1.0 ⁇ m, in particular at least 1.5 ⁇ m.

- the operating parameters in the heat treatment so that the diffusion length increases, the bending angle of the respective flat steel product can be improved, while the hole expansion is only slightly affected.

- the hole widening can be improved, but this can be accompanied by a deterioration of the bending properties.

- Even larger diffusion lengths eventually cause the deterioration of both bending properties and hole widening.

- Optimal work results arise when the operating parameters are set in the method according to the invention so that diffusion lengths of 1.5 to 5.7 microns, in particular from 2.0 to 4.5 microns are achieved.

- the interaction with the cooling and holding step preceding the partitioning can also be achieved by the Yield ratio can be influenced. If, for example, a high martensite content of 40% or more is generated by selecting a low cooling stop temperature T Q and / or a longer hold time t Q in the cooling step, by selecting a high partitioning temperature T P and time t Pt a larger diffusion length x D and thus ultimately a high yield ratio can be achieved. If less than about 40% martensite is produced, then the influence of the diffusion length x D on the yield ratio is rather small.

- the yield ratio is a measure of the solidification potential of the steel.

- a relatively low yield ratio of about 0.50 has a positive effect on the tensile elongation, but is unfavorable for the hole widening and the bending angle.

- a higher yield ratio of about 0.90 can improve hole widening and bending properties, but leads to losses in tensile elongation.

- the steel flat product is cooled starting from the partitioning temperature T P with a cooling rate ⁇ P2 which amounts to -3 ° C / s to -25 ° C / s, in particular -5 ° C / s to -15 ° C / s.

- the flat steel product according to the invention is to be additionally provided with a hot-dip coating in the course of the method according to the invention, it is initially cooled to a melt-bath inlet temperature T B of 400-500 ° C., starting from the partitioning temperature T P at the cooling rate ⁇ P2 .

- the steel flat product for hot dip coating passes through a melt bath, at the leaving of which the thickness of the protective coating produced on the flat steel product is adjusted in a conventional manner, for example by wiping nozzles.

- the protective coated steel flat product exiting the melt bath is finally cooled to room temperature at the cooling rate ⁇ P2 to again produce martensite.

- the process according to the invention is particularly suitable for the production of flat steel products which are provided with a zinc coating.

- other metallic coatings which can be applied by hot-dip coating to the respective flat steel product, such as ZnAl, ZnMg or comparable protective coatings, are also possible.

- the product produced according to the invention has a microstructure containing 25 to 80% tempered martensite (martensite from the first cooling step), 5 to 70% unannealed, new martensite (martensite from the second cooling step), 5 to 30% retained austenite, less than 10% Bainite (0% included) and less than 5% ferrite (0% included).

- the inventive method thus enables the production of a refined flat steel product having a tensile strength of 1200 to 1900 MPa, a yield strength of 600 to 1400 MPa, a yield ratio of 0.40 to 0.95, an elongation (A 50 ) of 10 to 30% and a very good formability.

- the product R m * A 50 is 15,000-35,000 MPa%.

- high strength and good forming properties are paired with each other.

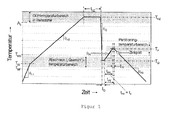

- FIG. 1 a variant of the method according to the invention is shown in which the heating time t A required for heating the steel flat product from the cooling stop temperature T Q to the partitioning temperature T P is equal to the duration t Pr of the ramped partitioning and the flat steel product in the course of this process a hot dip coating in a Zinc bath ("zinc pot”) is subjected.

- the heating time t A required for heating the steel flat product from the cooling stop temperature T Q to the partitioning temperature T P is equal to the duration t Pr of the ramped partitioning and the flat steel product in the course of this process a hot dip coating in a Zinc bath ("zinc pot”) is subjected.

- the variant comprising a hot-dip coating of the method according to the invention can be carried out in a conventional fire-coating system if certain modifications are made to it.

- ceramic radiant tubes may be needed.

- the high cooling rates ⁇ Q of up to -120 K / s can be achieved with modern gas jet cooling.

- the heating to the partitioning temperature T P after holding at the cooling stop temperature T Q can be achieved through use a booster can be achieved. After the partitioning step, the belt passes through the melt bath and is cooled in a controlled manner to regenerate martensite.

- the samples have the inventively given, in FIG. 1 through process steps shown with the process parameters given in Table 2.

- the process parameters between parameters according to the invention and parameters not according to the invention have been varied in order to demonstrate the effects of a procedure which is outside the scope of the invention.

- the calculation of the diffusion length was based on time steps of 1 s each.

- microstructural constituents of the cold strip samples obtained are given in Table 4.

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Materials Engineering (AREA)

- Mechanical Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Physics & Mathematics (AREA)

- Thermal Sciences (AREA)

- Crystallography & Structural Chemistry (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Heat Treatment Of Sheet Steel (AREA)

- Coating With Molten Metal (AREA)

- Heat Treatment Of Steel (AREA)

Priority Applications (9)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP11166622A EP2524970A1 (de) | 2011-05-18 | 2011-05-18 | Hochfestes Stahlflachprodukt und Verfahren zu dessen Herstellung |

| ES12721842.8T ES2628409T3 (es) | 2011-05-18 | 2012-05-16 | Producto plano de acero, de alta resistencia, y procedimiento para su fabricación |

| CN201280024105.XA CN103597100B (zh) | 2011-05-18 | 2012-05-16 | 高强度的扁钢产品及其制造方法 |

| PCT/EP2012/059076 WO2012156428A1 (de) | 2011-05-18 | 2012-05-16 | Hochfestes stahlflachprodukt und verfahren zu dessen herstellung |

| KR1020137030555A KR102001648B1 (ko) | 2011-05-18 | 2012-05-16 | 고강도 판상 강 제품 및 그 제조 방법 |

| PL12721842T PL2710158T3 (pl) | 2011-05-18 | 2012-05-16 | Wysoko wytrzymały płaski produkt stalowy i sposób jego wytwarzania |

| JP2014510785A JP6193219B2 (ja) | 2011-05-18 | 2012-05-16 | 高強度鋼板製品及びその製造方法 |

| US14/117,711 US9650708B2 (en) | 2011-05-18 | 2012-05-16 | High-strength flat steel product and method for producing same |

| EP12721842.8A EP2710158B1 (de) | 2011-05-18 | 2012-05-16 | Hochfestes stahlflachprodukt und verfahren zu dessen herstellung |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP11166622A EP2524970A1 (de) | 2011-05-18 | 2011-05-18 | Hochfestes Stahlflachprodukt und Verfahren zu dessen Herstellung |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| EP2524970A1 true EP2524970A1 (de) | 2012-11-21 |

Family

ID=46124355

Family Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP11166622A Withdrawn EP2524970A1 (de) | 2011-05-18 | 2011-05-18 | Hochfestes Stahlflachprodukt und Verfahren zu dessen Herstellung |

| EP12721842.8A Revoked EP2710158B1 (de) | 2011-05-18 | 2012-05-16 | Hochfestes stahlflachprodukt und verfahren zu dessen herstellung |

Family Applications After (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP12721842.8A Revoked EP2710158B1 (de) | 2011-05-18 | 2012-05-16 | Hochfestes stahlflachprodukt und verfahren zu dessen herstellung |

Country Status (8)

| Country | Link |

|---|---|

| US (1) | US9650708B2 (enExample) |

| EP (2) | EP2524970A1 (enExample) |

| JP (1) | JP6193219B2 (enExample) |

| KR (1) | KR102001648B1 (enExample) |

| CN (1) | CN103597100B (enExample) |

| ES (1) | ES2628409T3 (enExample) |

| PL (1) | PL2710158T3 (enExample) |

| WO (1) | WO2012156428A1 (enExample) |

Cited By (41)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN103160680A (zh) * | 2013-04-03 | 2013-06-19 | 北京科技大学 | 一种制备30GPa%级复相钢的Q&PB热处理工艺 |

| WO2014114159A1 (zh) * | 2013-01-22 | 2014-07-31 | 宝山钢铁股份有限公司 | 一种具有低屈服比的超高强韧钢板及其制造方法 |

| WO2014186722A3 (en) * | 2013-05-17 | 2015-01-08 | Ak Steel Properties, Inc. | High strength steel exhibiting good ductility and method of production via quenching and partitioning treatment by zinc bath |

| EP2905348A1 (de) * | 2014-02-07 | 2015-08-12 | ThyssenKrupp Steel Europe AG | Hochfestes Stahlflachprodukt mit bainitisch-martensitischem Gefüge und Verfahren zur Herstellung eines solchen Stahlflachprodukts |

| CN104928590A (zh) * | 2015-06-11 | 2015-09-23 | 北京交通大学 | 一种Mn-Si-Cr低碳贝氏体钢、钎杆及其制备方法 |

| WO2015177615A1 (fr) * | 2014-05-20 | 2015-11-26 | Arcelormittal | Tôle d'acier doublement recuite a hautes caracteristiques mecaniques de resistance et de ductilite, procede de fabrication et utilisation de telles tôles |

| WO2016001700A1 (en) * | 2014-07-03 | 2016-01-07 | Arcelormittal | Method for producing a high strength steel sheet having improved strength, ductility and formability |

| WO2016001706A1 (en) * | 2014-07-03 | 2016-01-07 | Arcelormittal | Method for producing a high strength steel sheet having improved strength and formability and obtained sheet |

| WO2016001708A1 (en) * | 2014-07-03 | 2016-01-07 | Arcelormittal | Method for producing a high strength coated steel sheet having improved strength, formability and obtained sheet |

| WO2016001891A1 (en) * | 2014-07-03 | 2016-01-07 | Arcelormittal | Method for producing a high strength coated steel sheet having improved strength and ductility and obtained sheet |

| WO2016001702A1 (en) * | 2014-07-03 | 2016-01-07 | Arcelormittal | Method for producing a high strength coated steel sheet having improved strength, ductility and formability |

| WO2016005615A1 (es) * | 2014-07-08 | 2016-01-14 | Gerdau Investigacion Y Desarrollo Europa, S.A. | Acero microaleado para conformado en caliente de piezas de alta resistencia y alto limite elastico y procedimiento para obtener componentes de dicho acero |

| WO2016016683A1 (en) * | 2014-07-30 | 2016-02-04 | Arcelormittal | A method for producing a high strength steel piece |

| EP1997923B1 (en) * | 2006-03-20 | 2016-03-09 | National Institute for Materials Science | Method for producing an ni-base superalloy |

| DE102014017275A1 (de) * | 2014-11-18 | 2016-05-19 | Salzgitter Flachstahl Gmbh | Hochfester lufthärtender Mehrphasenstahl mit hervorragenden Verarbeitungseigenschaften und Verfahren zur Herstellung eines Bandes aus diesem Stahl |

| DE102014017273A1 (de) * | 2014-11-18 | 2016-05-19 | Salzgitter Flachstahl Gmbh | Hochfester lufthärtender Mehrphasenstahl mit hervorragenden Verarbeitungseigenschaften und Verfahren zur Herstellung eines Bandes aus diesem Stahl |

| DE102014017274A1 (de) * | 2014-11-18 | 2016-05-19 | Salzgitter Flachstahl Gmbh | Höchstfester lufthärtender Mehrphasenstahl mit hervorragenden Verarbeitungseigenschaften und Verfahren zur Herstellung eines Bandes aus diesem Stahl |

| WO2016177763A1 (de) | 2015-05-06 | 2016-11-10 | Thyssenkrupp Steel Europe Ag | Stahlflachprodukt und verfahren zu seiner herstellung |

| EP2710158B1 (de) | 2011-05-18 | 2017-03-15 | ThyssenKrupp Steel Europe AG | Hochfestes stahlflachprodukt und verfahren zu dessen herstellung |

| EP3128027A4 (en) * | 2014-03-31 | 2017-04-19 | JFE Steel Corporation | High-strength cold rolled steel sheet having high yield ratio, and production method therefor |

| DE102015119417B4 (de) * | 2014-11-26 | 2017-10-19 | GM Global Technology Operations LLC (n. d. Ges. d. Staates Delaware) | Verfahren zum presshärten einer galvanisierten stahllegierung |

| CN107429363A (zh) * | 2015-04-08 | 2017-12-01 | 新日铁住金株式会社 | 热处理钢板构件以及其的制造方法 |

| CN107922986A (zh) * | 2015-07-24 | 2018-04-17 | 蒂森克虏伯钢铁欧洲股份公司 | 具有高最小屈服极限的高强度钢和这种钢的生产方法 |

| DE102017130237A1 (de) * | 2017-12-15 | 2019-06-19 | Salzgitter Flachstahl Gmbh | Hochfestes, warmgewalztes Stahlflachprodukt mit hohem Kantenrisswiderstand und gleichzeitig hohem Bake-Hardening Potential, ein Verfahren zur Herstellung eines solchen Stahlflachprodukts |

| EP3511430A1 (de) * | 2018-01-12 | 2019-07-17 | SMS Group GmbH | Verfahren für eine kontinuierliche wärmebehandlung eines stahlbands, und anlage zum schmelztauchbeschichten eines stahlbands |

| US10385415B2 (en) | 2016-04-28 | 2019-08-20 | GM Global Technology Operations LLC | Zinc-coated hot formed high strength steel part with through-thickness gradient microstructure |

| WO2020064096A1 (de) * | 2018-09-26 | 2020-04-02 | Thyssenkrupp Steel Europe Ag | Verfahren zur herstellung eines beschichteten stahlflachprodukts und beschichtetes stahlflachprodukt |

| US10619223B2 (en) | 2016-04-28 | 2020-04-14 | GM Global Technology Operations LLC | Zinc-coated hot formed steel component with tailored property |

| EP3390040B1 (en) | 2015-12-15 | 2020-08-26 | Tata Steel IJmuiden B.V. | High strength hot dip galvanised steel strip |

| WO2020169342A1 (de) | 2019-02-21 | 2020-08-27 | Thyssenkrupp Steel Europe Ag | Verfahren zum herstellen eines bauteils mittels innenhochdruckumformen |

| US10822680B2 (en) | 2015-04-08 | 2020-11-03 | Nippon Steel Corporation | Steel sheet for heat treatment |

| US10954580B2 (en) | 2015-12-21 | 2021-03-23 | Arcelormittal | Method for producing a high strength steel sheet having improved strength and formability, and obtained high strength steel sheet |

| CN114250415A (zh) * | 2021-12-10 | 2022-03-29 | 江苏沙钢集团有限公司 | 一种大壁厚塑料模具钢板的制造方法 |

| EP3988679A4 (en) * | 2019-08-20 | 2022-11-02 | JFE Steel Corporation | HIGH STRENGTH COLD ROLLED STEEL PLATE AND METHOD OF PRODUCTION THEREOF |

| CN115341142A (zh) * | 2022-08-04 | 2022-11-15 | 钢铁研究总院有限公司 | 一种温成型用钢及其制备方法 |

| US11530469B2 (en) | 2019-07-02 | 2022-12-20 | GM Global Technology Operations LLC | Press hardened steel with surface layered homogenous oxide after hot forming |

| US11613789B2 (en) | 2018-05-24 | 2023-03-28 | GM Global Technology Operations LLC | Method for improving both strength and ductility of a press-hardening steel |

| US11612926B2 (en) | 2018-06-19 | 2023-03-28 | GM Global Technology Operations LLC | Low density press-hardening steel having enhanced mechanical properties |

| WO2023233036A1 (en) * | 2022-06-03 | 2023-12-07 | Thyssenkrupp Steel Europe Ag | High strength, cold rolled steel with reduced sensitivity to hydrogen embrittlement and method for the manufacture thereof |

| RU2812417C1 (ru) * | 2023-07-18 | 2024-01-30 | Федеральное государственное бюджетное образовательное учреждение высшего образования "Российский государственный аграрный университет - МСХА имени К.А. Тимирязева" (ФГБОУ ВО РГАУ - МСХА имени К.А. Тимирязева) | Способ получения высокопрочного стального листа |

| DE102022125128A1 (de) * | 2022-09-29 | 2024-04-04 | Salzgitter Flachstahl Gmbh | Verfahren zur Herstellung eines Stahlbandes aus einem hochfesten Mehrphasenstahl und entsprechendes Stahlband |

Families Citing this family (58)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FI20115702A7 (fi) | 2011-07-01 | 2013-01-02 | Rautaruukki Oyj | Menetelmä suurlujuus- rakenneteräksen valmistamiseksi ja suurlujuusrakenneterästuote |

| JP6017341B2 (ja) * | 2013-02-19 | 2016-10-26 | 株式会社神戸製鋼所 | 曲げ性に優れた高強度冷延鋼板 |

| US9869009B2 (en) * | 2013-11-15 | 2018-01-16 | Gregory Vartanov | High strength low alloy steel and method of manufacturing |

| EP3097214B1 (en) * | 2014-01-24 | 2021-02-24 | Rautaruukki Oyj | Hot-rolled ultrahigh strength steel strip product |

| CN105132814B (zh) * | 2014-06-09 | 2018-02-27 | 鞍钢股份有限公司 | 一种耙片用带钢及生产方法与耙片热处理方法 |

| WO2016001704A1 (en) | 2014-07-03 | 2016-01-07 | Arcelormittal | Method for manufacturing a high strength steel sheet and sheet obtained |

| JP6343688B2 (ja) | 2014-07-03 | 2018-06-13 | アルセロールミタル | 超高強度被覆または非被覆鋼板を製造する方法および得られる鋼板 |

| DE102014114365A1 (de) * | 2014-10-02 | 2016-04-07 | Thyssenkrupp Steel Europe Ag | Mehrschichtiges Stahlflachprodukt und daraus hergestelltes Bauteil |

| WO2016079565A1 (en) * | 2014-11-18 | 2016-05-26 | Arcelormittal | Method for manufacturing a high strength steel product and steel product thereby obtained |

| EP3187613B1 (en) | 2014-12-12 | 2019-09-04 | JFE Steel Corporation | High-strength cold-rolled steel sheet and method for producing same |

| JP2016153524A (ja) * | 2015-02-13 | 2016-08-25 | 株式会社神戸製鋼所 | 切断端部での耐遅れ破壊特性に優れた超高強度鋼板 |

| CN104831180B (zh) * | 2015-05-15 | 2016-09-28 | 东北大学 | 一种深海用海洋软管铠装层用钢及其制备方法 |

| DE102015111177A1 (de) * | 2015-07-10 | 2017-01-12 | Salzgitter Flachstahl Gmbh | Höchstfester Mehrphasenstahl und Verfahren zur Herstellung eines kaltgewalzten Stahlbandes hieraus |

| WO2017085135A1 (de) | 2015-11-16 | 2017-05-26 | Benteler Steel/Tube Gmbh | Stahllegierung mit hohem energieaufnahmevermögen und stahlrohrprodukt |

| DE102015119839A1 (de) * | 2015-11-17 | 2017-05-18 | Benteler Steel/Tube Gmbh | Stahllegierung mit hohem Energieaufnahmevermögen und Stahlrohrprodukt |

| WO2017109542A1 (en) * | 2015-12-21 | 2017-06-29 | Arcelormittal | Method for producing a high strength steel sheet having improved ductility and formability, and obtained steel sheet |

| SE539519C2 (en) | 2015-12-21 | 2017-10-03 | High strength galvannealed steel sheet and method of producing such steel sheet | |

| KR101714930B1 (ko) * | 2015-12-23 | 2017-03-10 | 주식회사 포스코 | 구멍확장성이 우수한 초고강도 강판 및 그 제조방법 |

| WO2017115107A1 (en) | 2015-12-29 | 2017-07-06 | Arcelormittal | Method for producing a ultra high strength galvannealed steel sheet and obtained galvannealed steel sheet |

| US11473180B2 (en) * | 2016-01-27 | 2022-10-18 | Jfe Steel Corporation | High-yield-ratio high-strength galvanized steel sheet and method for manufacturing the same |

| CN106244918B (zh) * | 2016-07-27 | 2018-04-27 | 宝山钢铁股份有限公司 | 一种1500MPa级高强塑积汽车用钢及其制造方法 |

| KR102177591B1 (ko) * | 2016-08-10 | 2020-11-11 | 제이에프이 스틸 가부시키가이샤 | 고강도 강판 및 그 제조 방법 |

| KR101830538B1 (ko) * | 2016-11-07 | 2018-02-21 | 주식회사 포스코 | 항복비가 우수한 초고강도 강판 및 그 제조방법 |

| JP2020501017A (ja) | 2016-11-29 | 2020-01-16 | タタ、スティール、アイモイデン、ベスローテン、フェンノートシャップTata Steel Ijmuiden Bv | 熱間成形された物品の製造方法及び得られた物品 |

| CN110088326B (zh) * | 2016-12-14 | 2022-06-24 | 蒂森克虏伯钢铁欧洲股份公司 | 热轧扁钢产品及其生产方法 |

| KR101917472B1 (ko) * | 2016-12-23 | 2018-11-09 | 주식회사 포스코 | 항복비가 낮고 균일연신율이 우수한 템퍼드 마르텐사이트 강 및 그 제조방법 |

| US10260121B2 (en) | 2017-02-07 | 2019-04-16 | GM Global Technology Operations LLC | Increasing steel impact toughness |

| CN109280861A (zh) * | 2017-07-21 | 2019-01-29 | 蒂森克虏伯钢铁欧洲股份公司 | 具有良好耐老化性的扁钢产品及其生产方法 |

| EP3658307B9 (de) * | 2017-07-25 | 2022-01-12 | ThyssenKrupp Steel Europe AG | Blechbauteil, hergestellt durch warmumformen eines stahlflachprodukts und verfahren zu dessen herstellung |

| CN110997961B (zh) * | 2017-08-22 | 2022-02-25 | 蒂森克虏伯钢铁欧洲股份公司 | Q&p钢用于生产磨损应用的成型组件的用途 |

| EP4043603A1 (de) * | 2017-09-28 | 2022-08-17 | ThyssenKrupp Steel Europe AG | Stahlflachprodukt und verfahren zu seiner herstellung |

| CN107904488B (zh) * | 2017-11-06 | 2020-02-07 | 江阴兴澄特种钢铁有限公司 | 一种特厚高强高韧抗层状撕裂q550钢板及其制造方法 |

| WO2019111029A1 (en) | 2017-12-05 | 2019-06-13 | Arcelormittal | Cold rolled and annealed steel sheet and method of manufacturing the same |

| JP6711464B2 (ja) | 2018-03-30 | 2020-06-17 | Jfeスチール株式会社 | 高強度亜鉛めっき鋼板の製造方法および高強度部材の製造方法 |

| DE102018207888A1 (de) * | 2018-05-18 | 2019-11-21 | Volkswagen Aktiengesellschaft | Stahlmaterial und Verfahren zur Herstellung eines Stahlmaterials |

| US20210189517A1 (en) * | 2018-05-22 | 2021-06-24 | Thyssenkrupp Steel Europe Ag | Sheet Metal Part Formed from a Steel Having a High Tensile Strength and Method for Manufacturing Said Sheet Metal Part |

| US11597986B2 (en) | 2018-06-12 | 2023-03-07 | Thyssenkrupp Steel Europe Ag | Flat steel product and method for producing same |

| WO2020128574A1 (en) * | 2018-12-18 | 2020-06-25 | Arcelormittal | Cold rolled and heat-treated steel sheet and method of manufacturing the same |

| CN109868412A (zh) * | 2019-02-18 | 2019-06-11 | 山东钢铁股份有限公司 | 一种焊前免预热大厚度低碳当量500MPa级高强钢及其制造方法 |

| WO2020221889A1 (en) * | 2019-04-30 | 2020-11-05 | Tata Steel Nederland Technology B.V. | A high strength steel product and a process to produce a high strength steel product |

| KR102819975B1 (ko) | 2019-06-03 | 2025-06-16 | 티센크루프 스틸 유럽 악티엔게젤샤프트 | 부식방지 코팅이 구비된 강판 제품으로부터 판금 부품을 제조하는 방법 |

| PT3754034T (pt) | 2019-06-17 | 2022-04-20 | Tata Steel Ijmuiden Bv | Tratamento térmico de tira de aço laminada a frio |

| EP3754037B2 (en) | 2019-06-17 | 2025-04-16 | Tata Steel IJmuiden B.V. | Method of heat treating a high strength cold rolled steel strip |

| PT3754035T (pt) | 2019-06-17 | 2022-04-21 | Tata Steel Ijmuiden Bv | Método de tratamento térmico de uma tira de aço laminada a frio |

| CA3149331A1 (en) * | 2019-08-07 | 2021-02-11 | United States Steel Corporation | High ductility zinc-coated steel sheet products |

| CA3163376C (en) * | 2019-12-13 | 2024-02-27 | Arcelormittal | Heat treated cold rolled steel sheet and a method of manufacturing thereof |

| EP4139492A1 (de) * | 2020-04-22 | 2023-03-01 | ThyssenKrupp Steel Europe AG | Warmgewalztes stahlflachprodukt und verfahren zu seiner herstellung |

| CN112795852A (zh) * | 2020-11-23 | 2021-05-14 | 唐山钢铁集团有限责任公司 | 1200MPa级高扩孔性能冷轧镀锌带钢及其生产方法 |

| JP7276618B2 (ja) * | 2021-04-09 | 2023-05-18 | Jfeスチール株式会社 | 高強度冷延鋼板およびその製造方法 |

| CN113215493B (zh) * | 2021-05-11 | 2022-01-07 | 北京理工大学 | 一种高强度榴弹弹钢及其制备方法 |

| CN113862566A (zh) * | 2021-09-18 | 2021-12-31 | 张家港广大特材股份有限公司 | 一种飞轮转子及其制备方法 |

| CN116732445A (zh) * | 2022-03-01 | 2023-09-12 | 宝山钢铁股份有限公司 | 一种用于镀锌钢板的冷轧基板、镀锌钢板及其制造方法 |

| CN117305724A (zh) * | 2022-06-22 | 2023-12-29 | 宝山钢铁股份有限公司 | 一种高延伸、高扩孔性能的1300MPa以上级冷轧钢板及其制造方法 |

| CN117305683A (zh) * | 2022-06-22 | 2023-12-29 | 宝山钢铁股份有限公司 | 一种1300MPa以上级冷轧钢板及其制造方法 |

| EP4524278A4 (en) * | 2022-06-22 | 2025-07-30 | Baoshan Iron & Steel | STEEL WITH HIGH FRICTION CAPACITY AND MANUFACTURING PROCESS THEREFOR |

| EP4667606A1 (en) * | 2023-03-30 | 2025-12-24 | Kabushiki Kaisha Kobe Seiko Sho (Kobe Steel, Ltd.) | Plated steel sheet and method for manufacturing same |

| EP4592407A1 (de) | 2024-01-26 | 2025-07-30 | ThyssenKrupp Steel Europe AG | Höchstfester stahl mit guten umform- und oberflächeneigenschaften |

| CN120700411A (zh) * | 2024-03-25 | 2025-09-26 | 宝山钢铁股份有限公司 | 一种汽车大梁用钢及其制造方法 |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH0693340A (ja) * | 1992-09-14 | 1994-04-05 | Kobe Steel Ltd | 伸びフランジ性の優れた高強度合金化溶融亜鉛めっき鋼板の製造方法及び製造設備 |

| WO2004022794A1 (en) * | 2002-09-04 | 2004-03-18 | Colorado School Of Mines | Method for producing steel with retained austenite |

| CA2734976A1 (en) * | 2008-09-10 | 2010-03-18 | Jfe Steel Corporation | High strength steel sheet and method for manufacturing the same |

| EP2267176A1 (en) | 2008-02-08 | 2010-12-29 | JFE Steel Corporation | High-strength hot-dip galvanized steel sheet with excellent processability and process for producing the same |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6395108B2 (en) | 1998-07-08 | 2002-05-28 | Recherche Et Developpement Du Groupe Cockerill Sambre | Flat product, such as sheet, made of steel having a high yield strength and exhibiting good ductility and process for manufacturing this product |

| JP5365216B2 (ja) * | 2008-01-31 | 2013-12-11 | Jfeスチール株式会社 | 高強度鋼板とその製造方法 |

| JP4324225B1 (ja) | 2008-03-07 | 2009-09-02 | 株式会社神戸製鋼所 | 伸びフランジ性に優れた高強度冷延鋼板 |

| JP5400484B2 (ja) * | 2009-06-09 | 2014-01-29 | 株式会社神戸製鋼所 | 伸び、伸びフランジ性および溶接性を兼備した高強度冷延鋼板 |

| JP5333298B2 (ja) | 2010-03-09 | 2013-11-06 | Jfeスチール株式会社 | 高強度鋼板の製造方法 |

| EP2524970A1 (de) | 2011-05-18 | 2012-11-21 | ThyssenKrupp Steel Europe AG | Hochfestes Stahlflachprodukt und Verfahren zu dessen Herstellung |

-

2011

- 2011-05-18 EP EP11166622A patent/EP2524970A1/de not_active Withdrawn

-

2012

- 2012-05-16 CN CN201280024105.XA patent/CN103597100B/zh active Active

- 2012-05-16 KR KR1020137030555A patent/KR102001648B1/ko active Active

- 2012-05-16 PL PL12721842T patent/PL2710158T3/pl unknown

- 2012-05-16 US US14/117,711 patent/US9650708B2/en active Active

- 2012-05-16 ES ES12721842.8T patent/ES2628409T3/es active Active

- 2012-05-16 WO PCT/EP2012/059076 patent/WO2012156428A1/de not_active Ceased

- 2012-05-16 JP JP2014510785A patent/JP6193219B2/ja active Active

- 2012-05-16 EP EP12721842.8A patent/EP2710158B1/de not_active Revoked

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH0693340A (ja) * | 1992-09-14 | 1994-04-05 | Kobe Steel Ltd | 伸びフランジ性の優れた高強度合金化溶融亜鉛めっき鋼板の製造方法及び製造設備 |

| WO2004022794A1 (en) * | 2002-09-04 | 2004-03-18 | Colorado School Of Mines | Method for producing steel with retained austenite |

| EP2267176A1 (en) | 2008-02-08 | 2010-12-29 | JFE Steel Corporation | High-strength hot-dip galvanized steel sheet with excellent processability and process for producing the same |

| CA2734976A1 (en) * | 2008-09-10 | 2010-03-18 | Jfe Steel Corporation | High strength steel sheet and method for manufacturing the same |

Cited By (100)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1997923B1 (en) * | 2006-03-20 | 2016-03-09 | National Institute for Materials Science | Method for producing an ni-base superalloy |

| EP2710158B1 (de) | 2011-05-18 | 2017-03-15 | ThyssenKrupp Steel Europe AG | Hochfestes stahlflachprodukt und verfahren zu dessen herstellung |

| US10801090B2 (en) | 2013-01-22 | 2020-10-13 | Baoshan Iron & Steel Co., Ltd. | Ultra high obdurability steel plate having low yield ratio and process of manufacturing same |

| WO2014114159A1 (zh) * | 2013-01-22 | 2014-07-31 | 宝山钢铁股份有限公司 | 一种具有低屈服比的超高强韧钢板及其制造方法 |

| CN103160680A (zh) * | 2013-04-03 | 2013-06-19 | 北京科技大学 | 一种制备30GPa%级复相钢的Q&PB热处理工艺 |

| JP2018178262A (ja) * | 2013-05-17 | 2018-11-15 | エイケイ・スティール・プロパティーズ・インコーポレイテッドAk Steel Properties, Inc. | 鋼板の処理方法 |

| WO2014186689A3 (en) * | 2013-05-17 | 2015-01-22 | Ak Steel Properties, Inc. | High strength steel exhibiting good ductility and method of production via in-line heat treatment downstream of molten zinc bath |

| JP2016524038A (ja) * | 2013-05-17 | 2016-08-12 | エイケイ・スティール・プロパティーズ・インコーポレイテッドAk Steel Properties, Inc. | 良好な耐久性を示す高強度鋼、および焼入れと亜鉛浴による分配処理とによる製造方法 |

| CN113151735A (zh) * | 2013-05-17 | 2021-07-23 | 克利夫兰-克利夫斯钢铁资产公司 | 表现出良好延展性的高强度钢以及通过镀锌槽进行淬火和分配处理的制备方法 |

| EP2997172B1 (en) * | 2013-05-17 | 2020-08-26 | Ak Steel Properties, Inc. | Method of producton of a high strength steel exhibiting good ductility via quenching and partitioning treatment by zinc bath |

| WO2014186722A3 (en) * | 2013-05-17 | 2015-01-08 | Ak Steel Properties, Inc. | High strength steel exhibiting good ductility and method of production via quenching and partitioning treatment by zinc bath |

| CN105392906A (zh) * | 2013-05-17 | 2016-03-09 | Ak钢铁资产公司 | 表现出良好延展性的高强度钢及通过在熔融镀锌槽下游在线热处理的生产方法 |

| CN105247090A (zh) * | 2013-05-17 | 2016-01-13 | Ak钢铁资产公司 | 表现出良好延展性的高强度钢以及通过镀锌槽进行淬火和分配处理的制备方法 |

| RU2632042C2 (ru) * | 2013-05-17 | 2017-10-02 | Ак Стил Пропертиз, Инк. | Высокопрочная сталь, обладающая хорошей пластичностью, и способ получения посредством обработки методом закалки с распределением с помощью ванны для цинкования |

| US10724113B2 (en) | 2014-02-07 | 2020-07-28 | Thyssenkrupp Steel Europe Ag | High-strength flat steel product having a bainitic-martensitic microstructure and method for producing such a flat steel product |

| WO2015117934A1 (de) * | 2014-02-07 | 2015-08-13 | Thyssenkrupp Steel Europe Ag Ag | Hochfestes stahlflachprodukt mit bainitisch-martensitischem gefüge und verfahren zur herstellung eines solchen stahlflachprodukts |

| EP2905348A1 (de) * | 2014-02-07 | 2015-08-12 | ThyssenKrupp Steel Europe AG | Hochfestes Stahlflachprodukt mit bainitisch-martensitischem Gefüge und Verfahren zur Herstellung eines solchen Stahlflachprodukts |

| US10435762B2 (en) | 2014-03-31 | 2019-10-08 | Jfe Steel Corporation | High-yield-ratio high-strength cold-rolled steel sheet and method of producing the same |

| EP3128027A4 (en) * | 2014-03-31 | 2017-04-19 | JFE Steel Corporation | High-strength cold rolled steel sheet having high yield ratio, and production method therefor |

| CN106604999A (zh) * | 2014-05-20 | 2017-04-26 | 安赛乐米塔尔公司 | 具有高机械强度和延展特性的经双重退火的钢板、该板的制造方法和用途 |

| US10995386B2 (en) | 2014-05-20 | 2021-05-04 | Arcelormittal | Double annealed steel sheet having high mechanical strength and ductility characteristics, method of manufacture and use of such sheets |

| CN106604999B (zh) * | 2014-05-20 | 2018-04-10 | 安赛乐米塔尔公司 | 具有高机械强度和延展特性的经双重退火的钢板、该板的制造方法和用途 |

| WO2015177582A1 (fr) * | 2014-05-20 | 2015-11-26 | Arcelormittal Investigación Y Desarrollo Sl | Tôle d'acier doublement recuite à hautes caractéristiques mécaniques de résistance et ductilité, procédé de fabrication et utilisation de telles tôles |

| WO2015177615A1 (fr) * | 2014-05-20 | 2015-11-26 | Arcelormittal | Tôle d'acier doublement recuite a hautes caracteristiques mecaniques de resistance et de ductilite, procede de fabrication et utilisation de telles tôles |

| WO2016001710A1 (en) * | 2014-07-03 | 2016-01-07 | Arcelormittal | Method for producing a high strength coated steel having improved strength and ductility and obtained sheet |

| CN106661701B (zh) * | 2014-07-03 | 2018-09-04 | 安赛乐米塔尔公司 | 用于生产具有改进的强度和可成形性的高强度钢板的方法及获得的板 |

| US11618931B2 (en) | 2014-07-03 | 2023-04-04 | Arcelormittal | Method for producing a high strength steel sheet having improved strength, ductility and formability |

| US11555226B2 (en) | 2014-07-03 | 2023-01-17 | Arcelormittal | Method for producing a high strength steel sheet having improved strength and formability and obtained sheet |

| WO2016001898A3 (en) * | 2014-07-03 | 2016-03-17 | Arcelormittal | Method for producing a high strength steel sheet having improved strength, ductility and formability |

| US11492676B2 (en) | 2014-07-03 | 2022-11-08 | Arcelormittal | Method for producing a high strength coated steel sheet having improved strength, ductility and formability |

| WO2016001893A3 (en) * | 2014-07-03 | 2016-03-17 | Arcelormittal | Method for producing a high strength steel sheet having improved strength and formability and obtained sheet |

| WO2016001895A3 (en) * | 2014-07-03 | 2016-03-17 | Arcelormittal | Method for producing a high strength coated steel sheet having improved strength, ductility and formability |

| CN106536782A (zh) * | 2014-07-03 | 2017-03-22 | 安赛乐米塔尔公司 | 用于制造具有改进的强度和延展性的高强度经涂覆的钢板的方法以及获得的板 |

| EP3663416A1 (en) * | 2014-07-03 | 2020-06-10 | ArcelorMittal | Method for producing a high strength steel sheet having improved strength and formability and obtained sheet |

| WO2016001897A3 (en) * | 2014-07-03 | 2016-03-10 | Arcelormittal | Method for producing a high strength coated steel sheet having improved strength, formability and obtained sheet |

| CN106536782B (zh) * | 2014-07-03 | 2020-04-03 | 安赛乐米塔尔公司 | 用于制造具有改进的强度和延展性的高强度经涂覆的钢板的方法以及获得的板 |

| CN106661701A (zh) * | 2014-07-03 | 2017-05-10 | 安赛乐米塔尔公司 | 用于生产具有改进的强度和可成形性的高强度钢板的方法及获得的板 |

| US11718888B2 (en) | 2014-07-03 | 2023-08-08 | Arcelormittal | Method for producing a high strength coated steel sheet having improved strength, formability and obtained sheet |

| EP3831965A1 (en) * | 2014-07-03 | 2021-06-09 | ArcelorMittal | Method for producing a high strength coated steel sheet having improved strength, ductility and formability |

| EP3663415A1 (en) * | 2014-07-03 | 2020-06-10 | ArcelorMittal | Method for producing a high strength steel sheet having improved strength, ductility and formability |

| WO2016001702A1 (en) * | 2014-07-03 | 2016-01-07 | Arcelormittal | Method for producing a high strength coated steel sheet having improved strength, ductility and formability |

| US10995383B2 (en) | 2014-07-03 | 2021-05-04 | Arcelormittal | Method for producing a high strength coated steel sheet having improved strength and ductility and obtained sheet |

| WO2016001700A1 (en) * | 2014-07-03 | 2016-01-07 | Arcelormittal | Method for producing a high strength steel sheet having improved strength, ductility and formability |

| EP3164520B1 (en) | 2014-07-03 | 2020-03-11 | Arcelormittal | Method for producing a high strength steel sheet having improved strength, ductility and formability |

| WO2016001891A1 (en) * | 2014-07-03 | 2016-01-07 | Arcelormittal | Method for producing a high strength coated steel sheet having improved strength and ductility and obtained sheet |

| RU2680042C2 (ru) * | 2014-07-03 | 2019-02-14 | Арселормиттал | Способ производства высокопрочного стального листа, обладающего улучшенной прочностью, пластичностью и формуемостью |

| RU2686324C2 (ru) * | 2014-07-03 | 2019-04-25 | Арселормиттал | Способ изготовления высокопрочного стального листа с покрытием, обладающего улучшенными прочностью, формуемостью, и полученный лист |

| RU2686729C2 (ru) * | 2014-07-03 | 2019-04-30 | Арселормиттал | Способ производства высокопрочного стального листа с покрытием, обладающего высокой прочностью, пластичностью и формуемостью |

| RU2687284C2 (ru) * | 2014-07-03 | 2019-05-13 | Арселормиттал | Способ получения высокопрочного стального листа с покрытием, имеющего улучшенную прочность и пластичность, и полученный лист |

| WO2016001706A1 (en) * | 2014-07-03 | 2016-01-07 | Arcelormittal | Method for producing a high strength steel sheet having improved strength and formability and obtained sheet |

| EP3164522B1 (en) | 2014-07-03 | 2021-03-03 | Arcelormittal | Method for producing a high strength coated steel sheet having improved strength, ductility and formability |

| US10907232B2 (en) | 2014-07-03 | 2021-02-02 | Arcelormittal | Method for producing a high strength coated steel sheet having improved strength, formability and obtained sheet |

| EP3722445A1 (en) * | 2014-07-03 | 2020-10-14 | ArcelorMittal | High strength coated steel sheet having improved strength and formability |

| WO2016001708A1 (en) * | 2014-07-03 | 2016-01-07 | Arcelormittal | Method for producing a high strength coated steel sheet having improved strength, formability and obtained sheet |

| WO2016005615A1 (es) * | 2014-07-08 | 2016-01-14 | Gerdau Investigacion Y Desarrollo Europa, S.A. | Acero microaleado para conformado en caliente de piezas de alta resistencia y alto limite elastico y procedimiento para obtener componentes de dicho acero |

| US10415112B2 (en) | 2014-07-30 | 2019-09-17 | Arcelormittal | Method for producing a high strength steel piece |

| RU2690851C2 (ru) * | 2014-07-30 | 2019-06-06 | Арселормиттал | Способ изготовления высокопрочной стальной детали |

| CN108283003B (zh) * | 2014-07-30 | 2019-11-01 | 安赛乐米塔尔公司 | 用于制造高强度钢件的方法 |

| WO2016016779A3 (en) * | 2014-07-30 | 2016-03-31 | Arcelormittal | A method for producing a high strength steel piece |

| CN108283003A (zh) * | 2014-07-30 | 2018-07-13 | 安赛乐米塔尔公司 | 用于制造高强度钢件的方法 |

| WO2016016683A1 (en) * | 2014-07-30 | 2016-02-04 | Arcelormittal | A method for producing a high strength steel piece |

| KR20170041704A (ko) * | 2014-07-30 | 2017-04-17 | 아르셀러미탈 | 고강도 강 피스를 제조하기 위한 방법 |

| DE102014017275A1 (de) * | 2014-11-18 | 2016-05-19 | Salzgitter Flachstahl Gmbh | Hochfester lufthärtender Mehrphasenstahl mit hervorragenden Verarbeitungseigenschaften und Verfahren zur Herstellung eines Bandes aus diesem Stahl |

| DE102014017273A1 (de) * | 2014-11-18 | 2016-05-19 | Salzgitter Flachstahl Gmbh | Hochfester lufthärtender Mehrphasenstahl mit hervorragenden Verarbeitungseigenschaften und Verfahren zur Herstellung eines Bandes aus diesem Stahl |

| DE102014017274A1 (de) * | 2014-11-18 | 2016-05-19 | Salzgitter Flachstahl Gmbh | Höchstfester lufthärtender Mehrphasenstahl mit hervorragenden Verarbeitungseigenschaften und Verfahren zur Herstellung eines Bandes aus diesem Stahl |

| DE102015119417B4 (de) * | 2014-11-26 | 2017-10-19 | GM Global Technology Operations LLC (n. d. Ges. d. Staates Delaware) | Verfahren zum presshärten einer galvanisierten stahllegierung |

| US11041225B2 (en) | 2015-04-08 | 2021-06-22 | Nippon Steel Corporation | Heat-treated steel sheet member and method for producing the same |

| US10822680B2 (en) | 2015-04-08 | 2020-11-03 | Nippon Steel Corporation | Steel sheet for heat treatment |

| CN107429363B (zh) * | 2015-04-08 | 2019-08-23 | 日本制铁株式会社 | 热处理钢板构件以及其的制造方法 |

| CN107429363A (zh) * | 2015-04-08 | 2017-12-01 | 新日铁住金株式会社 | 热处理钢板构件以及其的制造方法 |

| WO2016177420A1 (de) | 2015-05-06 | 2016-11-10 | Thyssenkrupp Steel Europe Ag | Stahlflachprodukt und verfahren zu seiner herstellung |

| WO2016177763A1 (de) | 2015-05-06 | 2016-11-10 | Thyssenkrupp Steel Europe Ag | Stahlflachprodukt und verfahren zu seiner herstellung |

| CN104928590A (zh) * | 2015-06-11 | 2015-09-23 | 北京交通大学 | 一种Mn-Si-Cr低碳贝氏体钢、钎杆及其制备方法 |

| CN107922986A (zh) * | 2015-07-24 | 2018-04-17 | 蒂森克虏伯钢铁欧洲股份公司 | 具有高最小屈服极限的高强度钢和这种钢的生产方法 |

| US10597746B2 (en) | 2015-07-24 | 2020-03-24 | Thyssenkrupp Steel Europe Ag | High-strength steel having a high minimum yield limit and method for producing a steel of this type |

| EP3390040B1 (en) | 2015-12-15 | 2020-08-26 | Tata Steel IJmuiden B.V. | High strength hot dip galvanised steel strip |

| EP3390040B2 (en) † | 2015-12-15 | 2023-08-30 | Tata Steel IJmuiden B.V. | High strength hot dip galvanised steel strip |

| US10954580B2 (en) | 2015-12-21 | 2021-03-23 | Arcelormittal | Method for producing a high strength steel sheet having improved strength and formability, and obtained high strength steel sheet |

| US10385415B2 (en) | 2016-04-28 | 2019-08-20 | GM Global Technology Operations LLC | Zinc-coated hot formed high strength steel part with through-thickness gradient microstructure |

| US10619223B2 (en) | 2016-04-28 | 2020-04-14 | GM Global Technology Operations LLC | Zinc-coated hot formed steel component with tailored property |

| DE102017130237A1 (de) * | 2017-12-15 | 2019-06-19 | Salzgitter Flachstahl Gmbh | Hochfestes, warmgewalztes Stahlflachprodukt mit hohem Kantenrisswiderstand und gleichzeitig hohem Bake-Hardening Potential, ein Verfahren zur Herstellung eines solchen Stahlflachprodukts |

| US11584971B2 (en) | 2017-12-15 | 2023-02-21 | Salzgitter Flachstahl Gmbh | High-strength, hot-rolled flat steel product with high edge cracking resistance and, at the same time, high bake-hardening potential, and method for producing such a flat steel product |

| EP3511430A1 (de) * | 2018-01-12 | 2019-07-17 | SMS Group GmbH | Verfahren für eine kontinuierliche wärmebehandlung eines stahlbands, und anlage zum schmelztauchbeschichten eines stahlbands |

| US11613789B2 (en) | 2018-05-24 | 2023-03-28 | GM Global Technology Operations LLC | Method for improving both strength and ductility of a press-hardening steel |

| US11951522B2 (en) | 2018-06-19 | 2024-04-09 | GM Global Technology Operations LLC | Low density press-hardening steel having enhanced mechanical properties |

| US11612926B2 (en) | 2018-06-19 | 2023-03-28 | GM Global Technology Operations LLC | Low density press-hardening steel having enhanced mechanical properties |

| EP4083236A1 (de) * | 2018-09-26 | 2022-11-02 | ThyssenKrupp Steel Europe AG | Verfahren zur herstellung eines beschichteten stahlflachprodukts und beschichtetes stahlflachprodukt |

| JP7029574B2 (ja) | 2018-09-26 | 2022-03-03 | ティッセンクルップ スチール ヨーロッパ アクチェンゲゼルシャフト | コーティングされた平鋼生産物を製造する方法及びコーティングされた平鋼生産物 |

| JP2021530624A (ja) * | 2018-09-26 | 2021-11-11 | ティッセンクルップ スチール ヨーロッパ アクチェンゲゼルシャフトThyssenKrupp Steel Europe AG | コーティングされた平鋼生産物を製造する方法及びコーティングされた平鋼生産物 |

| CN112789358A (zh) * | 2018-09-26 | 2021-05-11 | 蒂森克虏伯钢铁欧洲股份公司 | 制造经涂覆的扁钢产品的方法和经涂覆的扁钢产品 |

| WO2020064096A1 (de) * | 2018-09-26 | 2020-04-02 | Thyssenkrupp Steel Europe Ag | Verfahren zur herstellung eines beschichteten stahlflachprodukts und beschichtetes stahlflachprodukt |

| WO2020169342A1 (de) | 2019-02-21 | 2020-08-27 | Thyssenkrupp Steel Europe Ag | Verfahren zum herstellen eines bauteils mittels innenhochdruckumformen |

| US11530469B2 (en) | 2019-07-02 | 2022-12-20 | GM Global Technology Operations LLC | Press hardened steel with surface layered homogenous oxide after hot forming |

| US11926881B2 (en) | 2019-08-20 | 2024-03-12 | Jfe Steel Corporation | High-strength cold-rolled steel sheet and method for manufacturing the same |

| EP3988679A4 (en) * | 2019-08-20 | 2022-11-02 | JFE Steel Corporation | HIGH STRENGTH COLD ROLLED STEEL PLATE AND METHOD OF PRODUCTION THEREOF |

| CN114250415A (zh) * | 2021-12-10 | 2022-03-29 | 江苏沙钢集团有限公司 | 一种大壁厚塑料模具钢板的制造方法 |

| WO2023233036A1 (en) * | 2022-06-03 | 2023-12-07 | Thyssenkrupp Steel Europe Ag | High strength, cold rolled steel with reduced sensitivity to hydrogen embrittlement and method for the manufacture thereof |

| CN115341142A (zh) * | 2022-08-04 | 2022-11-15 | 钢铁研究总院有限公司 | 一种温成型用钢及其制备方法 |

| DE102022125128A1 (de) * | 2022-09-29 | 2024-04-04 | Salzgitter Flachstahl Gmbh | Verfahren zur Herstellung eines Stahlbandes aus einem hochfesten Mehrphasenstahl und entsprechendes Stahlband |

| RU2812417C1 (ru) * | 2023-07-18 | 2024-01-30 | Федеральное государственное бюджетное образовательное учреждение высшего образования "Российский государственный аграрный университет - МСХА имени К.А. Тимирязева" (ФГБОУ ВО РГАУ - МСХА имени К.А. Тимирязева) | Способ получения высокопрочного стального листа |

Also Published As

| Publication number | Publication date |

|---|---|

| US9650708B2 (en) | 2017-05-16 |

| WO2012156428A1 (de) | 2012-11-22 |

| US20140322559A1 (en) | 2014-10-30 |

| EP2710158B1 (de) | 2017-03-15 |

| JP6193219B2 (ja) | 2017-09-06 |

| JP2014518945A (ja) | 2014-08-07 |

| PL2710158T3 (pl) | 2017-09-29 |

| ES2628409T3 (es) | 2017-08-02 |

| CN103597100A (zh) | 2014-02-19 |

| KR102001648B1 (ko) | 2019-10-01 |

| KR20140024903A (ko) | 2014-03-03 |

| CN103597100B (zh) | 2016-01-27 |

| EP2710158A1 (de) | 2014-03-26 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2710158B1 (de) | Hochfestes stahlflachprodukt und verfahren zu dessen herstellung | |

| EP3555337B1 (de) | Warmgewalztes stahlflachprodukt und verfahren zu seiner herstellung | |

| EP2028282B1 (de) | Dualphasenstahl, Flachprodukt aus einem solchen Dualphasenstahl und Verfahren zur Herstellung eines Flachprodukts | |

| EP2031081B1 (de) | Dualphasenstahl, Flachprodukt aus einem solchen Dualphasenstahl und Verfahren zur Herstellung eines Flachprodukts | |

| EP2690183B1 (de) | Warmgewalztes Stahlflachprodukt und Verfahren zu seiner Herstellung | |

| EP2809819B1 (de) | Höchstfester mehrphasenstahl mit verbesserten eigenschaften bei herstellung und verarbeitung | |

| EP3688203B1 (de) | Stahlflachprodukt und verfahren zu seiner herstellung | |

| EP3655560B1 (de) | Stahlflachprodukt mit guter alterungsbeständigkeit und verfahren zu seiner herstellung | |

| EP2924141B1 (de) | Kaltgewalztes Stahlflachprodukt und Verfahren zu seiner Herstellung | |

| EP2905348B1 (de) | Hochfestes Stahlflachprodukt mit bainitisch-martensitischem Gefüge und Verfahren zur Herstellung eines solchen Stahlflachprodukts | |

| EP2489748B1 (de) | Aus einem Komplexphasenstahl hergestelltes warmgewalztes Stahlflachprodukt und Verfahren zu dessen Herstellung | |

| EP3807429B1 (de) | Stahlflachprodukt und verfahren zu seiner herstellung | |

| EP3221484B1 (de) | Verfahren zur herstellung eines hochfesten lufthärtenden mehrphasenstahls mit hervorragenden verarbeitungseigenschaften | |

| DE102015111177A1 (de) | Höchstfester Mehrphasenstahl und Verfahren zur Herstellung eines kaltgewalzten Stahlbandes hieraus | |

| EP3692178B1 (de) | Verfahren zur herstellung eines stahlbandes aus höchstfestem mehrphasenstahl | |

| EP3724359B1 (de) | Hochfestes, warmgewalztes stahlflachprodukt mit hohem kantenrisswiderstand und gleichzeitig hohem bake-hardening potential und verfahren zur herstellung eines solchen stahlflachprodukts | |

| WO2015024903A1 (de) | Verfahren zum herstellen eines stahlbauteils | |

| EP3872206B1 (de) | Verfahren zur herstellung eines nachbehandelten, kaltgewalzten stahlflachprodukts und nachbehandeltes, kaltgewalztes stahlflachprodukt | |

| EP4460586B1 (de) | Hochfester stahl mit verbesserter resistenz gegen wasserstoffversprödung | |

| EP3964591A1 (de) | Warmgewalztes stahlflachprodukt und verfahren zur herstellung eines warmgewalzten stahlflachprodukts | |

| WO2020038883A1 (de) | Warmgewalztes unvergütetes und warmgewalztes vergütetes stahlflachprodukt sowie verfahren zu deren herstellung | |

| WO2023025635A1 (de) | Kaltgewalztes stahlflachprodukt und verfahren zu seiner herstellung | |

| EP4139492A1 (de) | Warmgewalztes stahlflachprodukt und verfahren zu seiner herstellung | |

| EP4592409A1 (de) | Feuerbeschichteter höchstfester stahl mit guten oberflächen- und umformeigenschaften mit zinkeisenbasiertem überzug | |

| EP4592407A1 (de) | Höchstfester stahl mit guten umform- und oberflächeneigenschaften |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 20130522 |