EP2524970A1 - Extremely stable steel flat product and method for its production - Google Patents

Extremely stable steel flat product and method for its production Download PDFInfo

- Publication number

- EP2524970A1 EP2524970A1 EP11166622A EP11166622A EP2524970A1 EP 2524970 A1 EP2524970 A1 EP 2524970A1 EP 11166622 A EP11166622 A EP 11166622A EP 11166622 A EP11166622 A EP 11166622A EP 2524970 A1 EP2524970 A1 EP 2524970A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- steel

- temperature

- content

- flat

- heating

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

- 229910000831 Steel Inorganic materials 0.000 title claims abstract description 200

- 239000010959 steel Substances 0.000 title claims abstract description 200

- 238000000034 method Methods 0.000 title claims description 38

- 238000004519 manufacturing process Methods 0.000 title claims description 10

- 238000010438 heat treatment Methods 0.000 claims abstract description 72

- 238000001816 cooling Methods 0.000 claims abstract description 66

- 238000000638 solvent extraction Methods 0.000 claims abstract description 64

- 229910000734 martensite Inorganic materials 0.000 claims abstract description 58

- 229910052799 carbon Inorganic materials 0.000 claims abstract description 36

- 229910052719 titanium Inorganic materials 0.000 claims abstract description 35

- 229910052720 vanadium Inorganic materials 0.000 claims abstract description 35

- 229910052758 niobium Inorganic materials 0.000 claims abstract description 34

- 229910052710 silicon Inorganic materials 0.000 claims abstract description 26

- 229910052748 manganese Inorganic materials 0.000 claims abstract description 25

- 229910052750 molybdenum Inorganic materials 0.000 claims abstract description 24

- 229910001566 austenite Inorganic materials 0.000 claims abstract description 22

- XEEYBQQBJWHFJM-UHFFFAOYSA-N Iron Chemical compound [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 claims abstract description 20

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 claims abstract description 15

- 229910052782 aluminium Inorganic materials 0.000 claims abstract description 15

- 229910052804 chromium Inorganic materials 0.000 claims abstract description 15

- 229910052796 boron Inorganic materials 0.000 claims abstract description 13

- 229910052791 calcium Inorganic materials 0.000 claims abstract description 13

- 229910052742 iron Inorganic materials 0.000 claims abstract description 12

- 229910052717 sulfur Inorganic materials 0.000 claims abstract description 9

- 229910000859 α-Fe Inorganic materials 0.000 claims abstract description 9

- 239000012535 impurity Substances 0.000 claims abstract description 8

- 229910052757 nitrogen Inorganic materials 0.000 claims abstract description 8

- 229910052698 phosphorus Inorganic materials 0.000 claims abstract description 8

- 229910001563 bainite Inorganic materials 0.000 claims abstract description 5

- 238000009792 diffusion process Methods 0.000 claims description 27

- 238000003618 dip coating Methods 0.000 claims description 14

- 230000000717 retained effect Effects 0.000 claims description 12

- 229910052759 nickel Inorganic materials 0.000 claims description 9

- 239000000155 melt Substances 0.000 claims description 7

- 239000011253 protective coating Substances 0.000 claims description 7

- 229910052802 copper Inorganic materials 0.000 claims description 6

- 238000004364 calculation method Methods 0.000 claims description 4

- -1 iron carbides Chemical class 0.000 claims description 3

- 239000011572 manganese Substances 0.000 abstract description 24

- 239000011651 chromium Substances 0.000 abstract description 17

- 239000011575 calcium Substances 0.000 abstract description 9

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 abstract description 8

- 230000009466 transformation Effects 0.000 abstract description 7

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 abstract description 5

- 229910001567 cementite Inorganic materials 0.000 abstract description 5

- PWHULOQIROXLJO-UHFFFAOYSA-N Manganese Chemical compound [Mn] PWHULOQIROXLJO-UHFFFAOYSA-N 0.000 abstract description 4

- ZOKXTWBITQBERF-UHFFFAOYSA-N Molybdenum Chemical compound [Mo] ZOKXTWBITQBERF-UHFFFAOYSA-N 0.000 abstract description 4

- NINIDFKCEFEMDL-UHFFFAOYSA-N Sulfur Chemical compound [S] NINIDFKCEFEMDL-UHFFFAOYSA-N 0.000 abstract description 4

- 239000011733 molybdenum Substances 0.000 abstract description 4

- 239000010703 silicon Substances 0.000 abstract description 4

- 239000011593 sulfur Substances 0.000 abstract description 4

- OYPRJOBELJOOCE-UHFFFAOYSA-N Calcium Chemical compound [Ca] OYPRJOBELJOOCE-UHFFFAOYSA-N 0.000 abstract description 3

- VYZAMTAEIAYCRO-UHFFFAOYSA-N Chromium Chemical compound [Cr] VYZAMTAEIAYCRO-UHFFFAOYSA-N 0.000 abstract description 3

- OAICVXFJPJFONN-UHFFFAOYSA-N Phosphorus Chemical compound [P] OAICVXFJPJFONN-UHFFFAOYSA-N 0.000 abstract description 3

- 239000011574 phosphorus Substances 0.000 abstract description 3

- 239000010955 niobium Substances 0.000 abstract 5

- 239000010936 titanium Substances 0.000 abstract 5

- RTAQQCXQSZGOHL-UHFFFAOYSA-N Titanium Chemical compound [Ti] RTAQQCXQSZGOHL-UHFFFAOYSA-N 0.000 abstract 4

- GUCVJGMIXFAOAE-UHFFFAOYSA-N niobium atom Chemical compound [Nb] GUCVJGMIXFAOAE-UHFFFAOYSA-N 0.000 abstract 4

- XUIMIQQOPSSXEZ-UHFFFAOYSA-N Silicon Chemical compound [Si] XUIMIQQOPSSXEZ-UHFFFAOYSA-N 0.000 abstract 3

- 230000001747 exhibiting effect Effects 0.000 abstract 3

- LEONUFNNVUYDNQ-UHFFFAOYSA-N vanadium atom Chemical compound [V] LEONUFNNVUYDNQ-UHFFFAOYSA-N 0.000 abstract 3

- ZOXJGFHDIHLPTG-UHFFFAOYSA-N Boron Chemical compound [B] ZOXJGFHDIHLPTG-UHFFFAOYSA-N 0.000 abstract 2

- WPBNNNQJVZRUHP-UHFFFAOYSA-L manganese(2+);methyl n-[[2-(methoxycarbonylcarbamothioylamino)phenyl]carbamothioyl]carbamate;n-[2-(sulfidocarbothioylamino)ethyl]carbamodithioate Chemical compound [Mn+2].[S-]C(=S)NCCNC([S-])=S.COC(=O)NC(=S)NC1=CC=CC=C1NC(=S)NC(=O)OC WPBNNNQJVZRUHP-UHFFFAOYSA-L 0.000 abstract 1

- 239000000047 product Substances 0.000 description 84

- 238000005452 bending Methods 0.000 description 16

- 238000000576 coating method Methods 0.000 description 12

- 230000000694 effects Effects 0.000 description 12

- 230000008569 process Effects 0.000 description 12

- 239000011248 coating agent Substances 0.000 description 11

- 230000015572 biosynthetic process Effects 0.000 description 8

- 238000002474 experimental method Methods 0.000 description 8

- 239000011241 protective layer Substances 0.000 description 6

- 238000005275 alloying Methods 0.000 description 5

- 150000001247 metal acetylides Chemical class 0.000 description 5

- 238000010791 quenching Methods 0.000 description 5

- 230000000171 quenching effect Effects 0.000 description 5

- HCHKCACWOHOZIP-UHFFFAOYSA-N Zinc Chemical compound [Zn] HCHKCACWOHOZIP-UHFFFAOYSA-N 0.000 description 4

- 238000000265 homogenisation Methods 0.000 description 4

- 229910052725 zinc Inorganic materials 0.000 description 4

- 239000011701 zinc Substances 0.000 description 4

- 230000001419 dependent effect Effects 0.000 description 3

- 230000002349 favourable effect Effects 0.000 description 3

- KSOKAHYVTMZFBJ-UHFFFAOYSA-N iron;methane Chemical compound C.[Fe].[Fe].[Fe] KSOKAHYVTMZFBJ-UHFFFAOYSA-N 0.000 description 3

- 239000000463 material Substances 0.000 description 3

- 235000019362 perlite Nutrition 0.000 description 3

- 239000010451 perlite Substances 0.000 description 3

- 230000008092 positive effect Effects 0.000 description 3

- 238000005496 tempering Methods 0.000 description 3

- 238000000137 annealing Methods 0.000 description 2

- 230000008859 change Effects 0.000 description 2

- 239000000470 constituent Substances 0.000 description 2

- 230000006866 deterioration Effects 0.000 description 2

- 230000001627 detrimental effect Effects 0.000 description 2

- 229910052751 metal Inorganic materials 0.000 description 2

- 239000002184 metal Substances 0.000 description 2

- 230000004048 modification Effects 0.000 description 2

- 238000012986 modification Methods 0.000 description 2

- 230000001681 protective effect Effects 0.000 description 2

- 230000006641 stabilisation Effects 0.000 description 2

- 238000011105 stabilization Methods 0.000 description 2

- 238000003466 welding Methods 0.000 description 2

- 229910019582 Cr V Inorganic materials 0.000 description 1

- GRYLNZFGIOXLOG-UHFFFAOYSA-N Nitric acid Chemical compound O[N+]([O-])=O GRYLNZFGIOXLOG-UHFFFAOYSA-N 0.000 description 1

- 238000002441 X-ray diffraction Methods 0.000 description 1

- 230000002411 adverse Effects 0.000 description 1

- 229910045601 alloy Inorganic materials 0.000 description 1

- 239000000956 alloy Substances 0.000 description 1

- 238000004458 analytical method Methods 0.000 description 1

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 1

- 239000000919 ceramic Substances 0.000 description 1

- 239000010960 cold rolled steel Substances 0.000 description 1

- 238000005097 cold rolling Methods 0.000 description 1

- 238000000354 decomposition reaction Methods 0.000 description 1

- 238000004090 dissolution Methods 0.000 description 1

- 238000007710 freezing Methods 0.000 description 1

- 230000008014 freezing Effects 0.000 description 1

- 238000005246 galvanizing Methods 0.000 description 1

- 239000007789 gas Substances 0.000 description 1

- 238000005098 hot rolling Methods 0.000 description 1

- 238000007654 immersion Methods 0.000 description 1

- 230000006872 improvement Effects 0.000 description 1

- 239000003112 inhibitor Substances 0.000 description 1

- 230000010354 integration Effects 0.000 description 1

- 230000003993 interaction Effects 0.000 description 1

- 239000000203 mixture Substances 0.000 description 1

- 229910017604 nitric acid Inorganic materials 0.000 description 1

- 150000004767 nitrides Chemical class 0.000 description 1

- 230000003647 oxidation Effects 0.000 description 1

- 238000007254 oxidation reaction Methods 0.000 description 1

- 229910052760 oxygen Inorganic materials 0.000 description 1

- 239000001301 oxygen Substances 0.000 description 1

- 238000005554 pickling Methods 0.000 description 1

- 239000002244 precipitate Substances 0.000 description 1

- 230000002265 prevention Effects 0.000 description 1

- 238000004886 process control Methods 0.000 description 1

- 238000004626 scanning electron microscopy Methods 0.000 description 1

- 238000007711 solidification Methods 0.000 description 1

- 230000008023 solidification Effects 0.000 description 1

- 239000000758 substrate Substances 0.000 description 1

- 230000001629 suppression Effects 0.000 description 1

- 238000009827 uniform distribution Methods 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D1/00—General methods or devices for heat treatment, e.g. annealing, hardening, quenching or tempering

- C21D1/18—Hardening; Quenching with or without subsequent tempering

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D1/00—General methods or devices for heat treatment, e.g. annealing, hardening, quenching or tempering

- C21D1/18—Hardening; Quenching with or without subsequent tempering

- C21D1/19—Hardening; Quenching with or without subsequent tempering by interrupted quenching

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D1/00—General methods or devices for heat treatment, e.g. annealing, hardening, quenching or tempering

- C21D1/78—Combined heat-treatments not provided for above

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D6/00—Heat treatment of ferrous alloys

- C21D6/002—Heat treatment of ferrous alloys containing Cr

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D8/00—Modifying the physical properties by deformation combined with, or followed by, heat treatment

- C21D8/02—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of plates or strips

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D8/00—Modifying the physical properties by deformation combined with, or followed by, heat treatment

- C21D8/02—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of plates or strips

- C21D8/0247—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of plates or strips characterised by the heat treatment

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D8/00—Modifying the physical properties by deformation combined with, or followed by, heat treatment

- C21D8/02—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of plates or strips

- C21D8/04—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of plates or strips to produce plates or strips for deep-drawing

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D8/00—Modifying the physical properties by deformation combined with, or followed by, heat treatment

- C21D8/02—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of plates or strips

- C21D8/04—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of plates or strips to produce plates or strips for deep-drawing

- C21D8/0447—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of plates or strips to produce plates or strips for deep-drawing characterised by the heat treatment

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/001—Ferrous alloys, e.g. steel alloys containing N

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/02—Ferrous alloys, e.g. steel alloys containing silicon

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/04—Ferrous alloys, e.g. steel alloys containing manganese

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/06—Ferrous alloys, e.g. steel alloys containing aluminium

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/12—Ferrous alloys, e.g. steel alloys containing tungsten, tantalum, molybdenum, vanadium, or niobium

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/14—Ferrous alloys, e.g. steel alloys containing titanium or zirconium

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/18—Ferrous alloys, e.g. steel alloys containing chromium

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/18—Ferrous alloys, e.g. steel alloys containing chromium

- C22C38/28—Ferrous alloys, e.g. steel alloys containing chromium with titanium or zirconium

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/18—Ferrous alloys, e.g. steel alloys containing chromium

- C22C38/32—Ferrous alloys, e.g. steel alloys containing chromium with boron

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/18—Ferrous alloys, e.g. steel alloys containing chromium

- C22C38/34—Ferrous alloys, e.g. steel alloys containing chromium with more than 1.5% by weight of silicon

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/18—Ferrous alloys, e.g. steel alloys containing chromium

- C22C38/38—Ferrous alloys, e.g. steel alloys containing chromium with more than 1.5% by weight of manganese

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C2/00—Hot-dipping or immersion processes for applying the coating material in the molten state without affecting the shape; Apparatus therefor

- C23C2/02—Pretreatment of the material to be coated, e.g. for coating on selected surface areas

- C23C2/022—Pretreatment of the material to be coated, e.g. for coating on selected surface areas by heating

- C23C2/0224—Two or more thermal pretreatments

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D2211/00—Microstructure comprising significant phases

- C21D2211/008—Martensite

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/12—All metal or with adjacent metals

- Y10T428/12493—Composite; i.e., plural, adjacent, spatially distinct metal components [e.g., layers, joint, etc.]

- Y10T428/12771—Transition metal-base component

- Y10T428/12785—Group IIB metal-base component

- Y10T428/12792—Zn-base component

- Y10T428/12799—Next to Fe-base component [e.g., galvanized]

Definitions

- the invention relates to a high-strength flat steel product and to a method for producing such a flat steel product.

- the invention relates to a high-strength flat steel product provided with a metallic protective layer and to a method for producing such a product.

- cooling rates are given a negative value because they lead to a decrease in temperature. Accordingly, cooling rates have a lower value for a rapid cooling than for a slower cooling. The leading to an increase in temperature heating rates, however, are given a positive.

- High strength steels regularly tend to corrode because of their alloying constituents and are therefore typically coated with a metallic protective layer which protects the respective steel substrate from contact with the ambient oxygen.

- a metallic protective layer which protects the respective steel substrate from contact with the ambient oxygen.

- Various methods for applying such a metallic protective layer are known. These include hot-dip coating, also known in technical language as "fire-coating", and electrolytic coating.

- the coating metal is deposited electrochemically on the flat steel product to be coated, which is at most slightly heated in the process, during hot dip coating the products to be coated are subjected to a heat treatment before immersion in the respective melt bath.

- the respective flat steel product is heated to high temperatures under a certain atmosphere in order to set the desired structure and to produce an optimum for the adhesion of the metallic coating surface state of the respective flat steel product.

- the flat steel product passes through the melt bath, which also has an elevated temperature, to keep the coating material molten.

- the steel strip is dip-coated.

- the metallic coating applied in this case should preferably be a zinc coating.

- a cold strip is to be obtained in this way, the optimized mechanical properties, such as a tensile strength of at least 1200 MPa, an elongation of at least 13% and a hole widening of at least 50%, has.

- the cold rolled strip processed in the manner described above is said to be made of a steel containing, in addition to iron and unavoidable impurities (in% by weight) 0.05-0.5% C, 0.01-2.5% Si, 0.5 - 3.5% Mn, 0.003 - 0.100% P, up to 0.02% S and 0.010 - 0.5 Al.

- the steel should have a microstructure comprising (in area%) up to 10% ferrite, up to 10% martensite and 60-95 tempered martensite, and further 5 - 20% retained austenite, as determined by X-ray diffraction.

- the steel (in weight%) can be 0.005 - 2.00% Cr, 0.005 - 2.00 Mo, 0.005 - 2.00% V, 0.005 - 2.00% Ni and 0.005 - 2.00% Cu and 0.01-0.20% Ti, 0.01-0.20 Nb, 0.0002-0.005% B, 0.001-0.005% Ca and 0.001-0.005% of rare earths.

- the object of the invention was to provide a low-cost producible high-strength flat steel product which has further optimized mechanical properties, which are expressed in particular in a very good bending behavior.

- a method for producing such a flat steel product should be specified.

- this method should be incorporated into a process for hot dip coating of flat steel products.

- the solution according to the invention of the abovementioned object consists in that during the production of a flat steel product according to the invention at least the steps mentioned in claim 6 are completed.

- the operations specified in claim 7 can optionally also be carried out.

- a steel flat product according to the invention consists of a steel which, in addition to iron and unavoidable impurities (in% by weight) C: 0.10-0.50%, Si: 0.1-2.5%, Mn: 1.0. 3.5%, Al: up to 2.5%, P: up to 0.020%, S: up to 0.003%, N: up to 0.02%, and optionally one or more of the elements "Cr, Mo, V, Ti, Nb, B and Ca" in the following contents: Cr: 0.1-0.5%, Mo: 0.1-0.3%, V : 0.01 - 0.1%, Ti: 0.001 - 0.15%, Nb: 0.02 - 0.05%, wherein for the sum ⁇ (V, Ti, Nb) of the contents of V, Ti and Nb ⁇ (V, Ti, Nb) is at most equal to 0.2%, B: 0.0005 - 0.005%, Ca: up to 0.01%.

- Essential for the superior mechanical properties of the flat steel product according to the invention is that it has a structure with (in area%) less than 5% ferrite, less than 10% bainite, 5-70% unanbergem martensite, 5-30% retained austenite and 25 80% tempered martensite. At least 99% of the number of iron carbides contained in tempered martensite has a size of less than 500 nm.

- Over-tempered martensite is characterized in that more than 1% number of carbide grains (iron carbides) are more than 500 nm in size.

- over-cut martensite can be detected by scanning electron microscopy at 20,000 magnifications on steel samples etched with 3% nitric acid.

- the C content of the steel of a flat steel product according to the invention is limited to values between 0.10 and 0.50 wt.%. Carbon influences a flat steel product according to the invention in many respects.

- C plays a major role in the formation of austenite and lowering the Ac3 temperature.

- a sufficient concentration of C allows complete austenitization at temperatures ⁇ 960 ° C, even if at the same time elements, such as Al, are present, which increase the Ac3 temperature.

- the retained austenite is also stabilized by the presence of C. This effect continues during the partitioning step.

- a stable residual austenite leads to a maximum strain range, in which the effect of the TRIP effect (TRANSformation Induced Plasticity) becomes noticeable.

- the strength of the martensite is most strongly influenced by the respective C content. Too high a content of C leads to such a strong shift of the martensite start temperature to ever lower temperatures that the production of the flat steel product according to the invention becomes excessively difficult. In addition, too high C contents can adversely affect weldability.

- the Si content in the steel of the flat steel product according to the invention should be less than 2.5% by weight. Silicon is important for suppressing cementite formation. The formation of cementite would break the C as a carbide and would then no longer stand for the stabilization of the retained austenite to disposal. In addition, the stretch would be worsened.

- the effect achieved by the addition of Si can in part also be achieved by alloying aluminum. However, a minimum of 0.1% by weight of Si should always be present in the flat steel product according to the invention in order to utilize its positive effect.

- Manganese contents of 1.0-3.5% by weight, in particular up to 3.0% by weight, are important for the hardenability of the flat steel product according to the invention and the prevention of perlite formation during cooling. These properties make it possible to form a starting structure consisting of martensite and retained austenite, and as such is suitable for the partitioning step carried out according to the invention.

- manganese proves advantageous with regard to the setting of comparatively low cooling rates of, for example, faster than -100 K / s.

- an excessively high Mn concentration has a negative influence on the elongation properties and the weldability of a flat steel product according to the invention.

- Aluminum is present in the steel of a flat steel product of the present invention at levels of up to 2.5% for deoxidation and for the setting of any nitrogen present.

- Al can also be used for the suppression of cementite and does not have such a negative effect on the surface properties as high contents of Si.

- Al is not as effective as Si and also increases the austenitizing temperature. Therefore, the Al content is of a flat steel product according to the invention is limited to a maximum of 2.5% by weight and preferably to values of between 0.01 and 1.5% by weight.

- Phosphorus is unfavorable to weldability and should therefore be present in the steel of a flat steel product of the present invention at levels less than 0.02% by weight.

- the S content in the steel of a flat steel product according to the invention should be below 0.003 wt .-%.

- nitrogen in the steel of a flat steel product according to the invention has a detrimental effect on the formability.

- the N content of a flat steel product according to the invention should therefore be less than 0.02% by weight.

- V, Ti and Nb are added to the steel of a flat steel product according to the invention.

- These elements contribute to higher strength through the formation of very finely divided carbides or carbonitrides.

- a minimum Ti content of 0.001% by weight leads to a freezing of the grain and phase boundaries during the Partitioning step.

- too high a concentration of V, Ti and Nb can be detrimental to the stabilization of retained austenite. Therefore, the sum of the contents of V, Ti and Nb in a flat steel product according to the invention is limited to 0.2% by weight.

- Chromium is an effective inhibitor of perlite, contributes to the strength and therefore may be added up to 0.5% by weight to the steel of a flat steel product according to the invention. Above 0.5% by weight, there is a risk of pronounced grain boundary oxidation. In order to be able to safely use the positive influence of Cr, the Cr content can be set to 0.1-0.5% by weight.

- molybdenum is also a very effective element for suppressing perlite formation.

- the steel of a flat steel product according to the invention can be alloyed with 0.1-0.3% by weight.

- Calcium in contents of up to 0.01% by weight is used in the steel of a steel flat product according to the invention for setting sulfur and for inclusion modification.

- the method according to the invention for producing a high-strength steel flat product, optionally provided with a metallic protective coating provided by hot-dip coating comprises the following working steps:

- the steel constituting the flat steel product contains C: 0.10-0.50%, Si: 0.1-2.5%, Mn: 1.0 - 3.5%, Al: up to 2.5%, P: up to 0.020%, S: up to 0.003%, N: up to 0.02%, and optionally one or more of the elements "Cr, Mo, V, Ti, Nb, B and Ca "in the following contents: Cr: 0.1 - 0.5%, Mo: 0.1 - 0.3%, V: 0.01 - 0.1%, Ti: 0.001 - 0.15%, Nb: 0.02 - 0.05%, where for the sum ⁇ (V, Ti, Nb) the contents of V, Ti and Nb holds ⁇ (V, Ti, Nb) ⁇ 0.2 %, B: 0.0005

- the thus provided flat steel product is then heated to a above the Ac3 temperature of the steel of the steel flat product and at most 960 ° C amount austenitizing temperature T HZ at a heating rate ⁇ H1 , ⁇ H2 of at least 3 ° C / s. Fast heating reduces the process time and improves the overall cost-effectiveness of the process.

- the heating to the Austenitmaschinestemperatur T HZ can in two uninterrupted successive stages be performed with different heating rates ⁇ H1 , ⁇ H2 .

- the heating at lower temperatures can be done very quickly to increase the efficiency of the process.

- the dissolution of carbides begins.

- lower heating rates ⁇ H2 are advantageous in order to ensure a uniform distribution of the carbon and other possible alloying elements, such. Mo or Cr.

- the carbides are deliberately annealed already below the A c1 temperature to exploit the faster diffusion in the ferrite over the slower diffusion in austenite.

- the dissolved atoms can be distributed more uniformly in the material as a result of a lower heating rate ⁇ H2 .

- a limited heating rate ⁇ H2 is also favorable during the austenite transformation, ie between A c1 and A c3 . This contributes to a homogeneous starting structure before quenching and thus a uniformly distributed martensite and a fine retained austenite after quenching and ultimately improved mechanical properties of the flat steel product.

- the heating rate ⁇ H1 of the first stage may be 5-25 ° C / s and the heating rate ⁇ H2 of the second stage 3-10 ° C, especially 3-5 ° C / s amount.

- the flat steel product with the first heating rate ⁇ H1 can be heated to an intermediate temperature T w of 200-500 ° C, in particular 250-500 ° C, and the heating can then be continued at the second heating rate ⁇ H2 up to the austenitizing temperature T HZ .

- the flat steel product is kept at the austenitizing temperature T Hz for an austenitizing time t HZ of 20-180 s.

- the annealing temperature in the holding zone should be above the A c3 temperature in order to achieve complete austenitization.

- the steel sheet After annealing at temperatures above A c3 , the steel sheet is cooled to a cooling stop temperature T Q greater than the martensite stop temperature T Mf and less than the martensite start temperature T Ms (T Mf ⁇ T Q ⁇ T Ms ) at a cooling rate ⁇ Q ,

- the cooling rate ⁇ Q is in the range of -20 ° C / s to -120 ° C / s.

- the condition ⁇ Q ⁇ ⁇ Q (min) can be surely satisfied in practice even for steels having a low C or Mn content.

- Parallel to the yield strength increase can be achieved by the inventively carried out cooling to the cooling stop temperature and the subsequent holding of the flat steel product at this temperature over the times prescribed by the invention, an improvement of the forming properties. If tensile strength and tensile elongation are to be maximized, the holding time t Q should rather be kept in the lower range, ie between 10 and 30 s. Longer holding times t Q of 30 - 60 s tend to have a positive effect on the forming properties. This concerns in particular the bending angle.

- the cooling stop temperature T Q is at least 200 ° C.

- the steel flat product After cooling and holding the steel flat product at the cooling stop temperature T Q , the steel flat product is heated to a 400-500 ° from the cooling stop temperature T Q with a heating rate ⁇ P1 of 2 - 80 ° C / s, especially 2 - 40 ° C / s C, in particular 450 - 490 ° C, amounting temperature T P heated.

- the heating to the temperature T P is preferably carried out within a heating time t A of 1 - 150 s, in order to achieve optimum efficiency. At the same time, the heating can make a contribution x Dr to a diffusion length x D explained below.

- the purpose of the heating and a subsequent optional additional holding of the flat steel product at the temperature T P over a holding period t Pi of up to 500 s is the enrichment of the retained austenite with carbon from the supersaturated martensite.

- the holding period t Pi is in particular up to 200 s, wherein holding periods t Pi of less than 10 s are particularly practical.

- the partitioning can already during the heating as a so-called “Ramped Partitioning” done by the held after the heating hold at the partitioning temperature T P (so-called “isothermal” partitioning) or by a combination of isothermal and ramped partitioning.

- the high temperatures necessary for the subsequent hot-dip coating can be achieved without causing special tempering effects, ie over-tempering of the martensite.

- the slower heating rate ⁇ P1 envisaged for ramped partitioning in comparison to isothermal partitioning permits a particularly precise control of the respectively prescribed partitioning temperature T P with reduced energy input, since higher temperature gradients require a higher energy expenditure in the system.

- the inventively predetermined partitioning temperature T P ensures sufficient homogenization of the carbon in the austenite, this homogenization being able to be influenced by the heating speed ⁇ P1 , the partitioning temperature T P and the optional holding at the partitioning temperature T P over a suitable holding time t Pi .

- the proportions x Dr or x Di can also be "0" depending on the respective process control, the total diffusion length x D being always> 0 as a result of the method according to the invention.

- the method according to the invention provides optimum work results if the sum of the respective diffusion lengths x Di , x Dr to be considered is at least 1.0 ⁇ m, in particular at least 1.5 ⁇ m.

- the operating parameters in the heat treatment so that the diffusion length increases, the bending angle of the respective flat steel product can be improved, while the hole expansion is only slightly affected.

- the hole widening can be improved, but this can be accompanied by a deterioration of the bending properties.

- Even larger diffusion lengths eventually cause the deterioration of both bending properties and hole widening.

- Optimal work results arise when the operating parameters are set in the method according to the invention so that diffusion lengths of 1.5 to 5.7 microns, in particular from 2.0 to 4.5 microns are achieved.

- the interaction with the cooling and holding step preceding the partitioning can also be achieved by the Yield ratio can be influenced. If, for example, a high martensite content of 40% or more is generated by selecting a low cooling stop temperature T Q and / or a longer hold time t Q in the cooling step, by selecting a high partitioning temperature T P and time t Pt a larger diffusion length x D and thus ultimately a high yield ratio can be achieved. If less than about 40% martensite is produced, then the influence of the diffusion length x D on the yield ratio is rather small.

- the yield ratio is a measure of the solidification potential of the steel.

- a relatively low yield ratio of about 0.50 has a positive effect on the tensile elongation, but is unfavorable for the hole widening and the bending angle.

- a higher yield ratio of about 0.90 can improve hole widening and bending properties, but leads to losses in tensile elongation.

- the steel flat product is cooled starting from the partitioning temperature T P with a cooling rate ⁇ P2 which amounts to -3 ° C / s to -25 ° C / s, in particular -5 ° C / s to -15 ° C / s.

- the flat steel product according to the invention is to be additionally provided with a hot-dip coating in the course of the method according to the invention, it is initially cooled to a melt-bath inlet temperature T B of 400-500 ° C., starting from the partitioning temperature T P at the cooling rate ⁇ P2 .

- the steel flat product for hot dip coating passes through a melt bath, at the leaving of which the thickness of the protective coating produced on the flat steel product is adjusted in a conventional manner, for example by wiping nozzles.

- the protective coated steel flat product exiting the melt bath is finally cooled to room temperature at the cooling rate ⁇ P2 to again produce martensite.

- the process according to the invention is particularly suitable for the production of flat steel products which are provided with a zinc coating.

- other metallic coatings which can be applied by hot-dip coating to the respective flat steel product, such as ZnAl, ZnMg or comparable protective coatings, are also possible.

- the product produced according to the invention has a microstructure containing 25 to 80% tempered martensite (martensite from the first cooling step), 5 to 70% unannealed, new martensite (martensite from the second cooling step), 5 to 30% retained austenite, less than 10% Bainite (0% included) and less than 5% ferrite (0% included).

- the inventive method thus enables the production of a refined flat steel product having a tensile strength of 1200 to 1900 MPa, a yield strength of 600 to 1400 MPa, a yield ratio of 0.40 to 0.95, an elongation (A 50 ) of 10 to 30% and a very good formability.

- the product R m * A 50 is 15,000-35,000 MPa%.

- high strength and good forming properties are paired with each other.

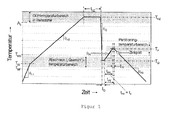

- FIG. 1 a variant of the method according to the invention is shown in which the heating time t A required for heating the steel flat product from the cooling stop temperature T Q to the partitioning temperature T P is equal to the duration t Pr of the ramped partitioning and the flat steel product in the course of this process a hot dip coating in a Zinc bath ("zinc pot”) is subjected.

- the heating time t A required for heating the steel flat product from the cooling stop temperature T Q to the partitioning temperature T P is equal to the duration t Pr of the ramped partitioning and the flat steel product in the course of this process a hot dip coating in a Zinc bath ("zinc pot”) is subjected.

- the variant comprising a hot-dip coating of the method according to the invention can be carried out in a conventional fire-coating system if certain modifications are made to it.

- ceramic radiant tubes may be needed.

- the high cooling rates ⁇ Q of up to -120 K / s can be achieved with modern gas jet cooling.

- the heating to the partitioning temperature T P after holding at the cooling stop temperature T Q can be achieved through use a booster can be achieved. After the partitioning step, the belt passes through the melt bath and is cooled in a controlled manner to regenerate martensite.

- the samples have the inventively given, in FIG. 1 through process steps shown with the process parameters given in Table 2.

- the process parameters between parameters according to the invention and parameters not according to the invention have been varied in order to demonstrate the effects of a procedure which is outside the scope of the invention.

- the calculation of the diffusion length was based on time steps of 1 s each.

- microstructural constituents of the cold strip samples obtained are given in Table 4.

Abstract

Description

Die Erfindung betrifft ein hochfestes Stahlflachprodukt und ein Verfahren zur Herstellung eines solchen Stahlflachprodukts.The invention relates to a high-strength flat steel product and to a method for producing such a flat steel product.

Insbesondere betrifft die Erfindung ein mit einer metallischen Schutzschicht versehenes hochfestes Stahlflachprodukt und ein Verfahren zur Herstellung eines solchen Produkts.In particular, the invention relates to a high-strength flat steel product provided with a metallic protective layer and to a method for producing such a product.

Wenn hier von Stahlflachprodukten die Rede ist, sind damit Stahlbänder, -bleche oder daraus gewonnene Blechzuschnitte, wie Platinen gemeint.When it comes to flat steel products, this refers to steel strips, sheets or sheet metal blanks derived therefrom, such as sinkers.

Wenn nachfolgend Abkühl- oder Erwärmungsgeschwindigkeiten oder -raten genannt sind, dann sind Abkühlgeschwindigkeiten negativ angegeben, weil sie zu einer Temperaturabnahme führen. Dementsprechend weisen Abkühlraten bei einer schnellen Abkühlung einen niedrigeren Wert auf als bei einer langsameren Abkühlung. Die zu einer Temperaturzunahme führenden Erwärmungsgeschwindigkeiten sind dagegen positiv angegeben.If cooling or heating rates or rates are mentioned below, then cooling rates are given a negative value because they lead to a decrease in temperature. Accordingly, cooling rates have a lower value for a rapid cooling than for a slower cooling. The leading to an increase in temperature heating rates, however, are given a positive.

Hochfeste Stähle neigen aufgrund ihrer Legierungsbestandteile regelmäßig zu Korrosion und werden daher typischerweise mit einer metallischen Schutzschicht belegt, die das jeweilige Stahlsubstrat gegen einen Kontakt mit dem Umgebungssauerstoff schützt. Es sind verschiedene Verfahren zum Auftrag einer solchen metallischen Schutzschicht bekannt. Dazu zählen das Schmelztauchbeschichten, in der Fachsprache auch "Feuerbeschichten" genannt, sowie das elektrolytische Beschichten.High strength steels regularly tend to corrode because of their alloying constituents and are therefore typically coated with a metallic protective layer which protects the respective steel substrate from contact with the ambient oxygen. Various methods for applying such a metallic protective layer are known. These include hot-dip coating, also known in technical language as "fire-coating", and electrolytic coating.

Während beim elektrolytischen Beschichten das Beschichtungsmetall elektro-chemisch auf dem zu beschichtenden, im Prozess allenfalls geringfügig erwärmten Stahlflachprodukt abgeschieden wird, werden beim Schmelztauchbeschichten die zu beschichtenden Produkte vor dem Eintauchen in das jeweilige Schmelzenbad einer Wärmebehandlung unterzogen. Dabei wird das jeweilige Stahlflachprodukt unter einer bestimmten Atmosphäre auf hohe Temperaturen erwärmt, um das gewünschte Gefüge einzustellen und einen für die Haftung des metallischen Überzugs optimalen Oberflächenzustand des jeweiligen Stahlflachprodukts herzustellen. Anschließend durchläuft das Stahlflachprodukt das Schmelzenbad, das ebenfalls eine erhöhte Temperatur aufweist, um den Beschichtungswerkstoff schmelzflüssig zu halten.Whereas in electrolytic coating, the coating metal is deposited electrochemically on the flat steel product to be coated, which is at most slightly heated in the process, during hot dip coating the products to be coated are subjected to a heat treatment before immersion in the respective melt bath. In this case, the respective flat steel product is heated to high temperatures under a certain atmosphere in order to set the desired structure and to produce an optimum for the adhesion of the metallic coating surface state of the respective flat steel product. Subsequently, the flat steel product passes through the melt bath, which also has an elevated temperature, to keep the coating material molten.

Die notwendigerweise hohen Temperaturen bedingen bei durch Schmelztauchbeschichten mit einer metallischen Schutzschicht versehenen Stahlflachprodukten eine Obergrenze der Festigkeit von 1000 MPa. Stahlflachprodukte mit einer noch höheren Festigkeit lassen sich in der Regel nicht feuerbeschichten, da sie in Folge der damit einhergehenden Erwärmung in Folge von Anlasseffekten erhebliche Festigkeitsverluste erleiden. Hochfeste Stahlflachprodukte werden daher derzeit regelmäßig elektrolytisch mit einer metallischen Schutzschicht versehen. Dieser Arbeitsschritt setzt eine einwandfrei saubere Oberfläche voraus, die in der Praxis nur durch ein vor dem elektrolytischen Beschichten durchzuführendes Beizen gewährleistet werden kann.The necessarily high temperatures require an upper limit of the strength of 1000 MPa for flat-rolled steel products provided by hot-dip coating with a metallic protective layer. Steel flat products with an even higher strength can not usually be fire-rated because they suffer considerable strength losses as a result of the associated heating due to tempering effects. High-strength flat steel products are therefore currently regularly electrolytically provided with a metallic protective layer. This step requires a perfectly clean surface, which can be guaranteed in practice only by a to be carried out before the electrolytic coating pickling.

Aus der

- Warmwalzen eines Warmbands aus einer Bramme,

- Kaltwalzen des Warmbands zu einem Kaltband,

- Wärmebehandeln des Kaltbands, wobei im Zuge dieser Wärmebehandlung

- das Kaltband mit einer mittleren Erwärmungsgeschwindigkeit von maximal 2 °C/s von einer Temperatur, die um 50 °C niedriger ist als die Ac3-Temperatur des Stahls, aus dem das Kaltband besteht, auf die jeweilige Ac3-Temperatur erwärmt wird,

- das Kaltband anschließend für mindestens 10 s auf einer Temperatur gehalten wird, die mindestens der jeweiligen Ac3-Temperatur entspricht,

- daraufhin das Kaltband mit einer mittleren Abkühlgeschwindigkeit von mindestens 20 °C/s auf eine Temperatur abgekühlt wird, die 100 - 200 °C unterhalb der Martensitstarttemperatur des jeweils verarbeiteten Stahls liegt, und

- schließlich das Kaltband für 1 bis 600 s auf eine 300 - 600 °C betragende Temperatur erwärmt wird.

- Hot rolling a hot strip from a slab,

- Cold rolling the hot strip to a cold strip,

- Heat treating the cold strip, being in the course of this heat treatment

- the cold-rolled strip is heated at a mean heating rate not exceeding 2 ° C / s from a temperature 50 ° C lower than the Ac3 temperature of the steel constituting the cold strip to the respective Ac3 temperature,

- The cold strip is then held for at least 10 s at a temperature which corresponds at least to the respective Ac3 temperature.

- then the cold strip is cooled at a mean cooling rate of at least 20 ° C / s to a temperature which is 100 - 200 ° C below the martensite start temperature of each processed steel, and

- Finally, the cold strip for 1 to 600 s is heated to a 300-600 ° C temperature.

Abschließend wird das Stahlband schmelztauchbeschichtet. Bei der dabei aufgetragenen metallischen Beschichtung soll es sich vorzugsweise um eine Zink-Beschichtung handeln. Im Ergebnis soll auf diesem Wege ein Kaltband erhalten werden, das optimierte mechanische Eigenschaften, wie eine Zugfestigkeit von mindestens 1200 MPa, eine Dehnung von mindestens 13 % und eine Lochaufweitung von mindestens 50 %, besitzt.Finally, the steel strip is dip-coated. The metallic coating applied in this case should preferably be a zinc coating. As a result, a cold strip is to be obtained in this way, the optimized mechanical properties, such as a tensile strength of at least 1200 MPa, an elongation of at least 13% and a hole widening of at least 50%, has.

Das in der voranstehend beschriebenen Weise verarbeitete Kaltband soll aus einem Stahl bestehen, der neben Eisen und unvermeidbaren Verunreinigungen (in Gew.- %) 0,05 - 0,5 % C, 0,01 - 2,5 % Si, 0,5 - 3,5 % Mn, 0,003 - 0,100 % P, bis zu 0,02 % S und 0,010 - 0,5 Al enthält. Gleichzeitig soll der Stahl eine Mikrostruktur aufweisen, welche (in Flächen- %) bis zu 10 % aus Ferrit, bis zu 10 % aus Martensit und 60 - 95 angelassenen Martensit und darüber hinaus 5 - 20 Restaustenit aufweist, der durch Röntgenstrahlbeugung ermittelt wird.The cold rolled strip processed in the manner described above is said to be made of a steel containing, in addition to iron and unavoidable impurities (in% by weight) 0.05-0.5% C, 0.01-2.5% Si, 0.5 - 3.5% Mn, 0.003 - 0.100% P, up to 0.02% S and 0.010 - 0.5 Al. At the same time, the steel should have a microstructure comprising (in area%) up to 10% ferrite, up to 10% martensite and 60-95 tempered martensite, and further 5 - 20% retained austenite, as determined by X-ray diffraction.

Darüber hinaus kann der Stahl (in Gew.- %) 0,005 - 2,00 % Cr, 0,005 - 2,00 Mo, 0,005 - 2,00 % V, 0,005 - 2,00 % Ni und 0,005 - 2,00 % Cu sowie 0,01 - 0,20 % Ti, 0,01 - 0,20 Nb, 0,0002 - 0,005 % B, 0,001 - 0,005 % Ca und 0,001 - 0,005 % an Seltenen Erden enthalten.In addition, the steel (in weight%) can be 0.005 - 2.00% Cr, 0.005 - 2.00 Mo, 0.005 - 2.00% V, 0.005 - 2.00% Ni and 0.005 - 2.00% Cu and 0.01-0.20% Ti, 0.01-0.20 Nb, 0.0002-0.005% B, 0.001-0.005% Ca and 0.001-0.005% of rare earths.

Vor dem Hintergrund des voranstehend erläuterten Standes der Technik bestand die Aufgabe der Erfindung darin, ein kostengünstig herstellbares hochfestes Stahlflachprodukt anzugeben, das weiter optimierte mechanische Eigenschaften besitzt, die sich insbesondere in einem sehr guten Biegeverhalten ausdrücken.Against the background of the prior art explained above, the object of the invention was to provide a low-cost producible high-strength flat steel product which has further optimized mechanical properties, which are expressed in particular in a very good bending behavior.

Darüber hinaus sollte ein Verfahren zur Herstellung eines solchen Stahlflachprodukts angegeben werden. Insbesondere sollte sich dieses Verfahren in einen Prozess zur Schmelztauchbeschichtung von Stahlflachprodukten einbinden lassen.In addition, a method for producing such a flat steel product should be specified. In particular, this method should be incorporated into a process for hot dip coating of flat steel products.

Diese Aufgabe ist in Bezug auf das Stahlflachprodukt erfindungsgemäß dadurch gelöst worden, dass ein solches Produkt die in Anspruch 1 angegebenen Merkmale aufweist.This object has been achieved in relation to the flat steel product according to the invention in that such a product has the features specified in claim 1.

In Bezug auf das Verfahren besteht die erfindungsgemäße Lösung der oben genannten Aufgabe darin, dass bei der Herstellung eines erfindungsgemäßen Stahlflachprodukts mindestens die in Anspruch 6 genannten Arbeitsschritte absolviert werden. Um eine Einbindung des erfindungsgemäßen Verfahrens in einen Prozess zur Schmelztauchbeschichtung zu ermöglichen, können dabei optional zusätzlich die in Anspruch 7 angegebenen Arbeitsschritte durchgeführt werden.With regard to the method, the solution according to the invention of the abovementioned object consists in that during the production of a flat steel product according to the invention at least the steps mentioned in claim 6 are completed. In order to enable integration of the method according to the invention into a process for hot-dip coating, the operations specified in claim 7 can optionally also be carried out.

Vorteilhafte Ausgestaltungen der Erfindung sind in den abhängigen Ansprüchen angegeben und werden nachfolgend wie der allgemeine Erfindungsgedanke im Einzelnen erläutert.Advantageous embodiments of the invention are specified in the dependent claims and are explained below as the general inventive concept in detail.

Ein erfindungsgemäßes Stahlflachprodukt, das optional mit einer durch Feuerverzinken aufgebrachten metallischen Schutzschicht versehen ist, besitzt eine Zugfestigkeit Rm von mindestens 1200 MPa. Darüber hinaus zeichnet sich ein erfindungsgemäßes Stahlflachprodukt regelmäßig durch

- eine Dehngrenze Rp0,2 von 600 - 1400 MPa,

- ein Streckgrenzenverhältnis Rp/Rm von 0,40 - 0,95,

- eine Dehnung A50 von 10 - 30 %,

- ein Produkt Rm*A50 aus Zugfestigkeit Rm und Dehnung A50 von 15.000 - 35.000 MPa*%,

- eine Lochaufweitung von λ: 50 - 120 %

(λ=(df-d0)/d0 in [%] mit df = Lochdurchmesser nach der Aufweitung und d0 = Lochdurchmesser vor der Aufweitung) und - einen Bereich für den zulässigen Biegewinkel α (nach Rückfederung bei einem Biegedornradius = 2 x Blechdicke) von 100° - 180° (ermittelbar gemäß DIN EN 7438)

- a yield strength R p0.2 of 600-1400 MPa,

- a yield ratio R p / R m of 0.40-0.95,

- an elongation A 50 of 10 - 30%,

- a product R m * A 50 of tensile strength R m and elongation A 50 of 15,000-35,000 MPa *%,

- a hole widening of λ: 50 - 120%

(λ = (df-d0) / d0 in [%] with df = hole diameter after widening and d0 = hole diameter before widening) and - a range for the permissible bending angle α (after springback at a bending mandrel radius = 2 x sheet thickness) of 100 ° - 180 ° (determinable in accordance with DIN EN 7438)

Hierzu besteht ein erfindungsgemäßes Stahlflachprodukt aus einem Stahl, der neben Eisen und unvermeidbaren Verunreinigungen (in Gew.-%) C: 0,10 - 0,50 %, Si: 0,1 - 2,5 %, Mn: 1,0 - 3,5 %, Al: bis zu 2,5 %, P: bis zu 0,020 %, S: bis zu 0,003 %, N: bis zu 0,02 %, und optional eines oder mehrere der Elemente "Cr, Mo, V, Ti, Nb, B und Ca" in folgenden Gehalten enthält: Cr: 0,1 - 0,5 %, Mo: 0,1 - 0,3 %, V: 0,01 - 0,1 %, Ti: 0,001 - 0,15 %, Nb: 0,02 - 0,05 %, wobei für die Summe Σ(V,Ti,Nb) der Gehalte an V, Ti und Nb gilt Σ(V,Ti,Nb) höchstens gleich 0,2 %, B: 0,0005 - 0,005 %, Ca: bis zu 0,01 %.For this purpose, a steel flat product according to the invention consists of a steel which, in addition to iron and unavoidable impurities (in% by weight) C: 0.10-0.50%, Si: 0.1-2.5%, Mn: 1.0. 3.5%, Al: up to 2.5%, P: up to 0.020%, S: up to 0.003%, N: up to 0.02%, and optionally one or more of the elements "Cr, Mo, V, Ti, Nb, B and Ca" in the following contents: Cr: 0.1-0.5%, Mo: 0.1-0.3%, V : 0.01 - 0.1%, Ti: 0.001 - 0.15%, Nb: 0.02 - 0.05%, wherein for the sum Σ (V, Ti, Nb) of the contents of V, Ti and Nb Σ (V, Ti, Nb) is at most equal to 0.2%, B: 0.0005 - 0.005%, Ca: up to 0.01%.

Wesentlich für die überlegenen mechanischen Eigenschaften des erfindungsgemäßen Stahlflachproduktes ist dabei, dass es ein Gefüge mit (in Flächen-%) weniger als 5 % Ferrit, weniger als 10 % Bainit, 5 - 70 % unangelassenem Martensit, 5 - 30 % Restaustenit und 25 - 80 % angelassenem Martensit aufweist. Dabei haben mindestens 99 % der Anzahl der im angelassenen Martensit enthaltenen Eisenkarbide eine Größe von weniger als 500 nm.Essential for the superior mechanical properties of the flat steel product according to the invention is that it has a structure with (in area%) less than 5% ferrite, less than 10% bainite, 5-70% unangelassenem martensite, 5-30% retained austenite and 25 80% tempered martensite. At least 99% of the number of iron carbides contained in tempered martensite has a size of less than 500 nm.

Demzufolge ist in einem erfindungsgemäßen Stahlflachprodukt der Gehalt an so genanntem "überangelassenem Martensit" auf ein Minimum reduziert. Überangelassener Martensit ist dadurch gekennzeichnet, dass mehr als 1 % Anzahl der Karbidkörner (Eisenkarbide) mehr als 500 nm groß sind. Überangelassener Martensit kann beispielsweise im Rasterelektronenmikroskop festgestellt werden, bei 20.000-facher Vergrößerung, an Stahlproben, die mit 3 %-iger Salpetersäure geätzt wurden. Durch die Vermeidung von überangelassenem Martensit erhält ein erfindungsgemäßes Stahlflachprodukt optimale mechanische Eigenschaften, die sich insbesondere im Hinblick auf seine Biegeeigenschaften, die durch den hohen Biegewinkel α von 100° bis 180° gekennzeichnet sind, günstig auswirken.Consequently, in a steel flat product according to the invention, the content of so-called "over-tempered martensite" is reduced to a minimum. Over-tempered martensite is characterized in that more than 1% number of carbide grains (iron carbides) are more than 500 nm in size. For example, over-cut martensite can be detected by scanning electron microscopy at 20,000 magnifications on steel samples etched with 3% nitric acid. By avoiding over-tempered martensite, a flat steel product according to the invention obtains optimum mechanical properties, which have a favorable effect in particular with regard to its bending properties, which are characterized by the high bending angle α of 100 ° to 180 °.

Der C-Gehalt des Stahls eines erfindungsgemäßen Stahlflachprodukts ist auf Werte zwischen 0,10 und 0,50 Gew.-% begrenzt. Kohlenstoff beeinflusst ein erfindungsgemäßes Stahlflachprodukt in vielerlei Hinsicht. Zuerst spielt C eine große Rolle bei der Bildung des Austenits und der Absenkung der Ac3-Temperatur. So ermöglicht eine ausreichende Konzentration an C eine vollständige Austenitisierung bei Temperaturen ≤ 960 °C auch dann noch, wenn gleichzeitig Elemente, wie Al, vorhanden sind, die die Ac3-Temperatur erhöhen. Beim Abschrecken wird zudem der Restaustenit durch die Anwesenheit von C stabilisiert. Dieser Effekt setzt sich während des Partitioning-Schritts fort. Ein stabiler Restaustenit führt zu einem maximalen Dehnungsbereich, in welchem sich die Wirkung des TRIP-Effekts (TRansformation Induced Plasticity) bemerkbar macht. Des Weiteren wird die Festigkeit des Martensits am stärksten vom jeweiligen C-Gehalt beeinflusst. Zu hohe Gehalte an C führen zu einer so starken Verschiebung der Martensitstarttemperatur zu immer tieferen Temperaturen, dass die Erzeugung des erfindungsgemäßen Stahlflachprodukts übermäßig erschwert wird. Darüber hinaus kann durch zu hohe C-Gehalte die Schweißbarkeit negativ beeinflusst werden.The C content of the steel of a flat steel product according to the invention is limited to values between 0.10 and 0.50 wt.%. Carbon influences a flat steel product according to the invention in many respects. First, C plays a major role in the formation of austenite and lowering the Ac3 temperature. Thus, a sufficient concentration of C allows complete austenitization at temperatures ≤ 960 ° C, even if at the same time elements, such as Al, are present, which increase the Ac3 temperature. During quenching, the retained austenite is also stabilized by the presence of C. This effect continues during the partitioning step. A stable residual austenite leads to a maximum strain range, in which the effect of the TRIP effect (TRANSformation Induced Plasticity) becomes noticeable. Furthermore, the strength of the martensite is most strongly influenced by the respective C content. Too high a content of C leads to such a strong shift of the martensite start temperature to ever lower temperatures that the production of the flat steel product according to the invention becomes excessively difficult. In addition, too high C contents can adversely affect weldability.

Um eine gute Oberflächenqualität eines erfindungsgemäßen Stahlflachprodukts zu gewährleisten, soll der Si-Gehalt im Stahl des erfindungsgemäßen Stahlflachprodukts weniger als 2,5 Gew.-% betragen. Silizium ist aber wichtig für die Unterdrückung der Zementitbildung. Durch Bildung von Zementit würde der C als Carbid abgebunden und stünde dann nicht mehr für die Stabilisierung des Restaustenits zur Verfügung. Darüber hinaus würde die Dehnung verschlechtert. Die durch die Zugabe von Si erzielte Wirkung kann teilweise auch durch Zulegieren von Aluminium erreicht werden. Jedoch sollte stets ein Minimum von 0,1 Gew.-% Si im erfindungsgemäßen Stahlflachprodukt vorhanden sein, um dessen positive Wirkung zu nutzen.In order to ensure a good surface quality of a flat steel product according to the invention, the Si content in the steel of the flat steel product according to the invention should be less than 2.5% by weight. Silicon is important for suppressing cementite formation. The formation of cementite would break the C as a carbide and would then no longer stand for the stabilization of the retained austenite to disposal. In addition, the stretch would be worsened. The effect achieved by the addition of Si can in part also be achieved by alloying aluminum. However, a minimum of 0.1% by weight of Si should always be present in the flat steel product according to the invention in order to utilize its positive effect.

Mangan-Gehalte von 1,0 - 3,5 Gew.-%, insbesondere bis zu 3,0 Gew.-%, sind wichtig für die Härtbarkeit des erfindungsgemäßen Stahlflachprodukts und die Vermeidung der Perlit-Bildung während der Abkühlung. Diese Eigenschaften ermöglichen die Bildung eines Ausgangsgefüges, das aus Martensit und Restaustenit besteht und als solches für den erfindungsgemäß durchgeführten Partitioning-Schritt geeignet ist. Darüber hinaus erweist sich Mangan vorteilhaft im Hinblick auf die Einstellung vergleichbar niedriger Abkühlraten von beispielsweise schneller als -100 K/s. Eine zu hohe Mn-Konzentration hat dagegen einen negativen Einfluss auf die Dehnungseigenschaften und die Schweißbarkeit eines erfindungsgemäßen Stahlflachprodukts.Manganese contents of 1.0-3.5% by weight, in particular up to 3.0% by weight, are important for the hardenability of the flat steel product according to the invention and the prevention of perlite formation during cooling. These properties make it possible to form a starting structure consisting of martensite and retained austenite, and as such is suitable for the partitioning step carried out according to the invention. In addition, manganese proves advantageous with regard to the setting of comparatively low cooling rates of, for example, faster than -100 K / s. On the other hand, an excessively high Mn concentration has a negative influence on the elongation properties and the weldability of a flat steel product according to the invention.

Aluminium ist im Stahl eines erfindungsgemäßen Stahlflachprodukts in Gehalten von bis zu 2,5 % zur Desoxidation und zum Abbinden von gegebenenfalls vorhandenem Stickstoff vorhanden. Wie erwähnt, kann Al aber auch für die Unterdrückung von Zementit verwendet werden und wirkt sich dabei nicht so negativ auf die Oberflächenbeschaffenheit aus wie hohe Gehalte an Si. Al ist jedoch nicht so wirksam wie Si und erhöht zudem die Austenitisierungstemperatur. Daher ist der Al-Gehalt eines erfindungsgemäßen Stahlflachprodukts auf maximal 2,5 Gew.-% und bevorzugt auf Werte zwischen 0,01 und 1,5 Gew.-% begrenzt.Aluminum is present in the steel of a flat steel product of the present invention at levels of up to 2.5% for deoxidation and for the setting of any nitrogen present. As mentioned above, however, Al can also be used for the suppression of cementite and does not have such a negative effect on the surface properties as high contents of Si. However, Al is not as effective as Si and also increases the austenitizing temperature. Therefore, the Al content is of a flat steel product according to the invention is limited to a maximum of 2.5% by weight and preferably to values of between 0.01 and 1.5% by weight.

Phosphor ist ungünstig für die Schweißbarkeit und soll daher im Stahl eines erfindungsgemäßen Stahlflachprodukts in Gehalten von weniger als 0,02 Gew.-% vorhanden sein.Phosphorus is unfavorable to weldability and should therefore be present in the steel of a flat steel product of the present invention at levels less than 0.02% by weight.

Schwefel führt in ausreichender Konzentration zur Bildung von MnS bzw. (Mn,Fe)S, welches sich negativ auf die Dehnung auswirkt. Daher soll der S-Gehalt im Stahl eines erfindungsgemäßen Stahlflachprodukts unterhalb von 0,003 Gew.-% liegen.Sulfur leads in sufficient concentration to the formation of MnS or (Mn, Fe) S, which has a negative effect on the elongation. Therefore, the S content in the steel of a flat steel product according to the invention should be below 0.003 wt .-%.

Als Nitrid abgebunden wirkt sich Stickstoff im Stahl eines erfindungsgemäßen Stahlflachprodukts schädlich auf die Umformbarkeit aus. Der N-Gehalt eines erfindungsgemäßen Stahlflachprodukts soll daher weniger als 0,02 Gew.-% betragen.Bonded as nitride, nitrogen in the steel of a flat steel product according to the invention has a detrimental effect on the formability. The N content of a flat steel product according to the invention should therefore be less than 0.02% by weight.

Zur Verbesserung bestimmter Eigenschaften können im Stahl eines erfindungsgemäßen Stahlflachprodukts "Cr, Mo, V, Ti, Nb, B und Ca" vorhanden sein.To improve certain properties, "Cr, Mo, V, Ti, Nb, B and Ca" may be present in the steel of a flat steel product according to the invention.

So kann es im Hinblick auf eine Optimierung der Festigkeit zweckmäßig sein, dem Stahl eines erfindungsgemäßen Stahlflachprodukts eines oder mehrere der Mikrolegierungselemente V, Ti und Nb zuzugeben. Diese Elemente tragen durch die Bildung sehr fein verteilter Karbide oder Carbonitride zu einer höheren Festigkeit bei. Ein minimaler Ti-Gehalt von 0,001 Gew.-% führt zu einer Einfrierung der Korn- und Phasengrenzen während des Partitioning-Schritts. Eine zu hohe Konzentration an V, Ti und Nb kann sich aber schädlich auf die Stabilisierung des Restaustenits auswirken. Daher ist die Summe der Gehalte an V, Ti und Nb in einem erfindungsgemäßen Stahlflachprodukt auf 0,2 Gew.-% begrenzt.Thus, with a view to optimizing the strength, it may be expedient to add one or more of the micro-alloying elements V, Ti and Nb to the steel of a flat steel product according to the invention. These elements contribute to higher strength through the formation of very finely divided carbides or carbonitrides. A minimum Ti content of 0.001% by weight leads to a freezing of the grain and phase boundaries during the Partitioning step. However, too high a concentration of V, Ti and Nb can be detrimental to the stabilization of retained austenite. Therefore, the sum of the contents of V, Ti and Nb in a flat steel product according to the invention is limited to 0.2% by weight.

Chrom ist ein effektiver Inhibitor des Perlits, trägt zur Festigkeit bei und darf daher bis zu 0,5 Gew.-% dem Stahl eines erfindungsgemäßen Stahlflachprodukts zulegiert werden. Oberhalb von 0,5 Gew.-% besteht die Gefahr ausgeprägter Korngrenzenoxidation. Um den positiven Einfluss von Cr sicher nutzen zu können, kann der Cr-Gehalt auf 0,1 - 0,5 Gew.-% festgesetzt werden.Chromium is an effective inhibitor of perlite, contributes to the strength and therefore may be added up to 0.5% by weight to the steel of a flat steel product according to the invention. Above 0.5% by weight, there is a risk of pronounced grain boundary oxidation. In order to be able to safely use the positive influence of Cr, the Cr content can be set to 0.1-0.5% by weight.

Molybdän ist wie Cr ebenfalls ein sehr wirksames Element zur Unterdrückung der Perlitbildung. Um diesen günstigen Einfluss effektiv zu nutzen, kann dem Stahl eines erfindungsgemäßen Stahlflachprodukts 0,1 - 0,3 Gew.-% zulegiert werden.Like Cr, molybdenum is also a very effective element for suppressing perlite formation. In order to effectively use this favorable influence, the steel of a flat steel product according to the invention can be alloyed with 0.1-0.3% by weight.

Bor seigert auf den Korngrenzen und bremst deren Bewegung. Dies führt bei Gehalten ab 0,0005 Gew.-% zu einem feinkörnigen Gefüge, was sich vorteilhaft auf die mechanischen Eigenschaften auswirkt. Beim Zulegieren von B muss allerdings genügend Ti für die Abbindung des N vorhanden sein. Bei einem Gehalt von rund 0,005 Gew.-% tritt eine Sättigung des positiven Einflusses von B ein. Daher wird der B-Gehalt auf 0,0005 - 0,005 Gew.-% festgelegt.Bor sighs on the grain boundaries and slows their movement. At levels of 0.0005% by weight, this leads to a fine-grained microstructure, which has an advantageous effect on the mechanical properties. When alloying B, however, sufficient Ti must be present for the setting of the N. At a level of about 0.005 wt%, saturation of the positive influence of B occurs. Therefore, the B content is set to 0.0005 - 0.005 wt%.

Kalzium in Gehalten von bis zu 0,01 Gew.-% wird im Stahl eines erfindungsgemäßen Stahlflachprodukts zum Abbinden von Schwefel und zur Einschlussmodifikation eingesetzt.Calcium in contents of up to 0.01% by weight is used in the steel of a steel flat product according to the invention for setting sulfur and for inclusion modification.

Das Kohlenstoff-Äquivalent CE ist ein wichtiger Parameter für die Beschreibung der Schweißbarkeit. Es sollte beim Stahl eines erfindungsgemäßen Stahlflachprodukts im Bereich von 0,35 - 1,2 liegen, insbesondere 0,5 - 1,0 betragen. Zur Berechnung des Kohlenstoff-Äquivalents CE wird hier eine von der American Welding Society (AWS) entwickelte und in der Veröffentlichung D1.1/D1.1M:2006, Structural Welding Code - Steel. Section 3.5.2. (Table 3.2). pp. 58 and 66, veröffentlichte Formel verwendet:

mit

- %C: C-Gehalt des Stahls,

- %Mn: Mn-Gehalt des Stahls,

- %Si: Si-Gehalt des Stahls,

- %Cr: Cr-Gehalt des Stahls,

- %Mo: Mo-Gehalt des Stahls,

- %V: V-Gehalt des Stahls,

- %Ni: Ni-Gehalt des Stahls,

- %Cu: Cu-Gehalt des Stahls.

With

- % C: C content of the steel,

- % Mn: Mn content of the steel,

- % Si: Si content of the steel,

- % Cr: Cr content of the steel,

- % Mo: Mo content of the steel,

- % V: V content of the steel,

- % Ni: Ni content of the steel,

- % Cu: Cu content of the steel.

Das erfindungsgemäße Verfahren zum Herstellen eines hochfesten, optional mit einem durch Schmelztauchbeschichten metallischen Schutzüberzug versehenen Stahlflachprodukts, umfasst folgende Arbeitsschritte:The method according to the invention for producing a high-strength steel flat product, optionally provided with a metallic protective coating provided by hot-dip coating, comprises the following working steps:

Es wird ein unbeschichtetes, also noch nicht mit dem jeweiligen Schutzüberzug versehenes Stahlflachprodukt zur Verfügung gestellt, das aus demselben Stahl erzeugt ist, wie das bereits voranstehend erläuterte erfindungsgemäße Stahlflachprodukt. Der Stahl, aus dem das Stahlflachprodukt besteht, enthält dementsprechend neben Eisen und unvermeidbaren Verunreinigungen (in Gew.-%) C: 0,10 - 0,50 %, Si: 0,1 - 2,5 %, Mn: 1,0 - 3,5 %, Al: bis zu 2,5 %, P: bis zu 0,020 %, S: bis zu 0,003 %, N: bis zu 0,02 %, sowie optional eines oder mehrere der Elemente "Cr, Mo, V, Ti, Nb, B und Ca" in folgenden Gehalten: Cr: 0,1 - 0,5 %, Mo: 0,1 - 0,3 %, V: 0,01 - 0,1 %, Ti: 0,001 - 0,15 %, Nb: 0,02 - 0,05 %, wobei für die Summe Σ(V,Ti,Nb) der Gehalte an V, Ti und Nb gilt Σ(V,Ti,Nb) ≤ 0,2 %, B: 0,0005 - 0,005 %, Ca: bis zu 0,01 %. Bei dem bereitgestellten Stahlflachprodukt kann es sich insbesondere um ein kaltgewalztes Stahlflachprodukt handeln. Jedoch ist es auch denkbar, ein warmgewalztes Stahlflachprodukt in erfindungsgemäßer Weise zu verarbeiten.It is an uncoated, so not yet provided with the respective protective cover flat steel product made available, which is made of the same steel, as the already explained above flat steel product according to the invention. Accordingly, in addition to iron and unavoidable impurities (in% by weight), the steel constituting the flat steel product contains C: 0.10-0.50%, Si: 0.1-2.5%, Mn: 1.0 - 3.5%, Al: up to 2.5%, P: up to 0.020%, S: up to 0.003%, N: up to 0.02%, and optionally one or more of the elements "Cr, Mo, V, Ti, Nb, B and Ca "in the following contents: Cr: 0.1 - 0.5%, Mo: 0.1 - 0.3%, V: 0.01 - 0.1%, Ti: 0.001 - 0.15%, Nb: 0.02 - 0.05%, where for the sum Σ (V, Ti, Nb) the contents of V, Ti and Nb holds Σ (V, Ti, Nb) ≤ 0.2 %, B: 0.0005 - 0.005%, Ca: up to 0.01%. The provided flat steel product may in particular be a cold-rolled flat steel product. However, it is also conceivable to process a hot-rolled flat steel product in accordance with the invention.

Das derart bereitgestellte Stahlflachprodukt wird dann auf eine oberhalb der Ac3-Temperatur des Stahls des Stahlflachprodukts liegende und höchstens 960 °C betragende Austenitisierungstemperatur THZ mit einer Erwärmungsgeschwindigkeit θH1,θH2 von mindestens 3 °C/s erwärmt. Durch die schnelle Erwärmung wird die Prozesszeit verkürzt und die Wirtschaftlichkeit des Verfahrens insgesamt verbessert.The thus provided flat steel product is then heated to a above the Ac3 temperature of the steel of the steel flat product and at most 960 ° C amount austenitizing temperature T HZ at a heating rate θ H1 , θ H2 of at least 3 ° C / s. Fast heating reduces the process time and improves the overall cost-effectiveness of the process.

Die Erwärmung auf die Austenitisierungstemperatur THZ kann in zwei unterbrechungsfrei aufeinander folgenden Stufen mit unterschiedlichen Erwärmungsgeschwindigkeiten θH1,θH2 durchgeführt werden.The heating to the Austenitisierungstemperatur T HZ can in two uninterrupted successive stages be performed with different heating rates θ H1 , θ H2 .

Das Aufheizen bei niedrigeren Temperaturen, d. h. unterhalb von Tw, kann dabei sehr schnell erfolgen, um die Wirtschaftlichkeit des Prozesses zu steigern. Bei höheren Temperaturen beginnt die Auflösung von Karbiden. Hierfür sind niedrigere Aufheizgeschwindigkeiten θH2 vorteilhaft, um eine gleichmäßige Verteilung des Kohlenstoffs und weiterer, möglicher Legierungselemente, wie z. B. Mo oder Cr, zu erreichen. Die Karbide werden gezielt bereits unterhalb der Ac1-Temperatur angelöst, um die schnellere Diffusion im Ferrit gegenüber der langsameren Diffusion im Austenit auszunutzen. Somit können sich die gelösten Atome in Folge einer niedrigeren Aufheizgeschwindigkeit θH2 gleichmäßiger im Werkstoff verteilen.The heating at lower temperatures, ie below T w , can be done very quickly to increase the efficiency of the process. At higher temperatures, the dissolution of carbides begins. For this purpose, lower heating rates θ H2 are advantageous in order to ensure a uniform distribution of the carbon and other possible alloying elements, such. Mo or Cr. The carbides are deliberately annealed already below the A c1 temperature to exploit the faster diffusion in the ferrite over the slower diffusion in austenite. Thus, the dissolved atoms can be distributed more uniformly in the material as a result of a lower heating rate θ H2 .