EP2402256A1 - Bouchon couronne de bouton-poussoir avec récipient secondaire attaché - Google Patents

Bouchon couronne de bouton-poussoir avec récipient secondaire attaché Download PDFInfo

- Publication number

- EP2402256A1 EP2402256A1 EP11182661A EP11182661A EP2402256A1 EP 2402256 A1 EP2402256 A1 EP 2402256A1 EP 11182661 A EP11182661 A EP 11182661A EP 11182661 A EP11182661 A EP 11182661A EP 2402256 A1 EP2402256 A1 EP 2402256A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- container

- cover member

- base member

- push button

- catch

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D49/00—Arrangements or devices for preventing refilling of containers

- B65D49/02—One-way valves

- B65D49/08—Spring-loaded valves

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D47/00—Closures with filling and discharging, or with discharging, devices

- B65D47/04—Closures with discharging devices other than pumps

- B65D47/06—Closures with discharging devices other than pumps with pouring spouts or tubes; with discharge nozzles or passages

- B65D47/08—Closures with discharging devices other than pumps with pouring spouts or tubes; with discharge nozzles or passages having articulated or hinged closures

- B65D47/0804—Closures with discharging devices other than pumps with pouring spouts or tubes; with discharge nozzles or passages having articulated or hinged closures integrally formed with the base element provided with the spout or discharge passage

- B65D47/0828—Closures with discharging devices other than pumps with pouring spouts or tubes; with discharge nozzles or passages having articulated or hinged closures integrally formed with the base element provided with the spout or discharge passage and elastically biased towards the open position only

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D15/00—Containers having bodies formed by interconnecting or uniting two or more rigid, or substantially rigid, sections made of different materials

- B65D15/02—Containers having bodies formed by interconnecting or uniting two or more rigid, or substantially rigid, sections made of different materials of curved, or partially curved, cross-section, e.g. cans, drums

- B65D15/04—Containers having bodies formed by interconnecting or uniting two or more rigid, or substantially rigid, sections made of different materials of curved, or partially curved, cross-section, e.g. cans, drums with curved, or partially curved, walls made by winding or bending paper

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D43/00—Lids or covers for rigid or semi-rigid containers

- B65D43/14—Non-removable lids or covers

- B65D43/16—Non-removable lids or covers hinged for upward or downward movement

- B65D43/163—Non-removable lids or covers hinged for upward or downward movement the container and the lid being made separately

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D49/00—Arrangements or devices for preventing refilling of containers

- B65D49/02—One-way valves

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D51/00—Closures not otherwise provided for

- B65D51/16—Closures not otherwise provided for with means for venting air or gas

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D51/00—Closures not otherwise provided for

- B65D51/18—Arrangements of closures with protective outer cap-like covers or of two or more co-operating closures

- B65D51/20—Caps, lids, or covers co-operating with an inner closure arranged to be opened by piercing, cutting, or tearing

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D51/00—Closures not otherwise provided for

- B65D51/24—Closures not otherwise provided for combined or co-operating with auxiliary devices for non-closing purposes

- B65D51/28—Closures not otherwise provided for combined or co-operating with auxiliary devices for non-closing purposes with auxiliary containers for additional articles or materials

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2251/00—Details relating to container closures

- B65D2251/0003—Two or more closures

- B65D2251/0006—Upper closure

- B65D2251/0018—Upper closure of the 43-type

- B65D2251/0021—Upper closure of the 43-type of the B65D43/16-type

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2251/00—Details relating to container closures

- B65D2251/0003—Two or more closures

- B65D2251/0006—Upper closure

- B65D2251/0025—Upper closure of the 47-type

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2251/00—Details relating to container closures

- B65D2251/0003—Two or more closures

- B65D2251/0068—Lower closure

- B65D2251/0093—Membrane

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2543/00—Lids or covers essentially for box-like containers

- B65D2543/00009—Details of lids or covers for rigid or semi-rigid containers

- B65D2543/00018—Overall construction of the lid

- B65D2543/00259—Materials used

- B65D2543/00296—Plastic

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2543/00—Lids or covers essentially for box-like containers

- B65D2543/00009—Details of lids or covers for rigid or semi-rigid containers

- B65D2543/00435—Lids secured to an intermediate ring or like annular member fixed to the container mouth

Definitions

- Containers with a flip top to dispense or access a product therein are well known. Also known is the provision of a container with an additional item to be used with the product, where the additional item Is provided beneath a flip top and separated from the opening. However, some such flip tops do not secure the item in place and are generally limited by the size of the neck of the container. Other flip tops have been provided with an item attached to an inside of the top, so that the item extends down into the opening and body of the container. However, room must be left in the container for the Item, as a result of which the item is subject to being knocked loose or opened by the product in the container.

- a container which includes a main container body having a rigid rim and a flip top for the main body.

- This flip top includes a base member which is attached to the rigid rim of the main body and a cover member which is hingedly connected to the base member and which has a first catch member.

- the base member also includes a push button which is formed therewith such that the push button is resiliently mounted.

- This push button includes a second catch member such that the second catch member interacts with the first catch member when the cover member is in a closed position relative to the base member to hold the cover member to the base member, and such that the first and second catch members are separable from one another when the push button is pushed.

- the cover member includes a skirt portion and a cutout in the skirt portion, where the first catch member extends from the cutout.

- the push button of the base member also extends upwards from an adjacent portion of the base member.

- the flip top is an integral injection molded plastic.

- first catch members are located to either side of the cutout

- second catch members of the push button are located on lateral wings on either side of the push button which extend behind the cutout on opposite sides thereof.

- a lower edge of each wing is located adjacent an upper edge of the base member.

- a resilient link is used to interconnect the base member and the push button in order to mount the push button upstanding from and resiliently to the base member. The resilient link being located such that the resilient movement of the push button as the push button is pushed causes at least one of the lower edges of the wings to contact and move past the upper edge of the base member, producing a perceivable sensation indicative of the separation of the first and second catch members.

- the base member includes an upstanding leg.

- the skirt portion covers the base member, and extends about the upstanding leg when the cover member is in the closed position.

- the main body includes a non-metal surrounding wall, and the rigid rim is a composite formed of a metal rolled with a top portion of the non-metal surrounding wall.

- the surrounding wall is made of a foil paperboard and is generally circular in cross section, and the cover member is dome shaped.

- the rigid rim includes a flange extending inwardly.

- the cover member then includes an inner sealing member which engages the flange, either vertically or radially, when the cover member is in the closed position.

- the base member includes a leg which extends below an outside portion of the rim, and the leg includes a shoulder which is trapped below the outside portion of the rim to securely attached the base member to the rim.

- the main container body houses a powdered beverage mix, preferably a dry coffee related product.

- the cover member then includes a secondary container in which a secondary powdered additive used in conjunction with the beverage mix is contained.

- a mounting means is provided for removably mounting the secondary container to an inside surface of the cover member.

- the rim includes an internal flange, and a removable membrane is attached to the flange below the secondary container.

- the mounting means includes opposed resilient arms extending from the inside surface between which the secondary container is trapped and held in place.

- a spring member is provided which biases the cover member away from the closed position.

- a container unit which includes a main container in which a dry beverage mix is contained and a secondary container containing a dry additive for a beverage made with the dry beverage mix.

- the unit also includes a top which closes the main container and which is openable relative to the main container, the top removably mounting the secondary container to an inside surface thereof.

- the top includes opposed resilient arms extending from an inside surface thereof between which the secondary container is trapped and held in place.

- the top includes a base member which is attached to a rigid rim of the main container, and a cover member which is hingedly connected to the base member.

- This cover member includes a first catch member.

- the base member then includes a push button which is resiliently mounted and which includes a second catch member. The second catch member interacts with the first catch member when the cover member is in a closed position relative to the base member to hold the cover member to the base member, and the first and second catch members are separable from one another when the push button is pushed.

- the cover member includes a skirt portion and a cutout in the skirt portion where the first catch member extends from the cutout.

- the push button of the base member extends upwards from an adjacent portion of the base member.

- the flip top is an integral injection molded plastic.

- first catch members are located to either side of the cutout

- second catch members of the push button are located on lateral wings on either side of the push button which extend behind the cutout on opposite sides thereof.

- a lower edge of each wing is located adjacent an upper edge of the base member.

- a resilient link is used to interconnect the base member and the push button in order to mount the push button upstanding from and resiliently to the base member. The resilient link being located such that the resilient movement of the push button as the push button is pushed causes at least one of the lower edges of the wings to contact and move past the upper edge of the base member, producing a perceivable sensation indicative of the separation of the first and second catch members.

- the base member includes an upstanding leg.

- the skirt portion covers the base member and extends about the upstanding leg when the cover member is in the closed position.

- the main body includes a non-metal surrounding wall.

- the rigid rim is a composite formed of a metal rolled with a top portion of the non-metal surrounding wall.

- the surrounding wall is made of a foil paperboard, the surrounding wall is generally circular in cross section, and the cover member is dome shaped.

- the rigid rim includes a flange extending inwardly.

- the cover member includes an inner sealing member which engages, either vertically or radially, the flange when the cover member is in the closed position.

- the base member includes a leg which extends below an outside portion of the rim, and the leg includes a shoulder which is trapped below the outside portion of the rim to securely attached the base member to the rim.

- the rim includes an internal flange and a removable membrane attached to the flange below the secondary container, and a spring member which biases the cover member to an open position.

- a second container of sufficient size can be provided with a first container.

- a flip top is provided with a push button which is attractive and easily operated to release a cover member thereof.

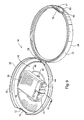

- Figure 1A is a cross sectional elevation view of a portion of a cylindrical container unit having a main container and a flip top according to the present invention.

- Figure 1 B is an enlarged cross sectional view of a portion of the cylindrical container unit shown by broken line 1B in figure 1A .

- Figure 2 is a cross sectional view of the flip top depicted in an open position (and taken along section line 2-2 in figure 3 ).

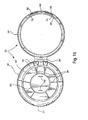

- Figure 3 is a top plan view of the flip top of the container unit depicted in figure 2 .

- Figure 4 is a bottom plan view of the flip top of the container unit depicted in figure 2 .

- Figure 5 is a elevation view of the base member of the flip top taken from the direction of arrow 5 in figure 2 .

- Figure 6 is a cross sectional view of the base member of the flip top taken along section line 6-6 in figure 4 .

- Figure 7A is a cross sectional view of the cover member of the flip top taken along section line 7A-7A in figure 4 with part of the sealing ring cut away for clarity.

- Figure 7B is a cross sectional view of the cover member of the flip top taken along section line 7B-7B in figure 3 .

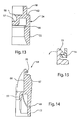

- Figure 7C is a cross sectional view of an enlarged portion of the latch shown by broken line 7C in figure 2 .

- Figure 8A is an enlarged cross sectional view of the hinge shown by broken line 8A in figure 2 .

- Figure 8B is a cross sectional view of the hinge taken along section line 8B-8B in figure 3 .

- Figure 9 is a perspective view of the flip top depicted in figure 1 showing the mounting of a second container to the cover member.

- Figure 10 is a cross sectional view of a portion of the cover member taken along section line 10-10 in figure 9 .

- Figure 11 is a perspective view of a flip top similar to that of figure 9 but having an alternative mounting for an alternative second container.

- Figure 12 is a cross sectional view of a portion of the cover member taken along section line 12-12 in figure 11 .

- Figure 13 is a cross sectional view of an enlarged portion of the cover member shown by broken line 13 in figure 6 .

- Figure 14 is a cross sectional view of an enlarged portion of the cover member shown by broken line 14 in figure 2 .

- Figure 15 is a cross sectional view of the first catch member of the push button shown in figure 14 showing the relationship to the second catch member.

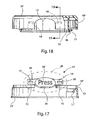

- Figure 16 is a perspective view of an alternative embodiment of a flip top similar to that of figures 1-5 but having an alternative push button with a perceivable sensation feature.

- Figure 17 is a front elevational view in partial cross section of the base member of the flip top depicted in figure 16 .

- Figure 18 is a front elevational view in partial cross section of the cover member of the flip top depicted in figure 16 .

- Figure 19 is an elevational cross sectional view of the cover member depicted in figure 18 taken along section line 19-19.

- Figure 20 is an enlarged perspective view of the portion of figure 17 identified with broken line 20.

- Container unit 10 includes a main body or first container 12 and a flip top 14.

- first container 12 is used for containing a first dry product 16 used to make a flavored beverage therefrom, preferably such as a flavored creamer to be added to coffee to make cappuccino or the like, or such as a dry powder used to make cappuccino, coffee, tea or hot chocolate or the like from hot water, or as otherwise desired.

- First container 12 preferably has a composite composition when containing a powdered product or the like.

- first container 12 is formed with a surrounding side wall 18 of plastic or lined (foil) paperboard.

- side wall 18 is generally cylindrical in cross section, though typically not a straight cylinder but with curves, protrusions or indentations along the height thereof as well appreciated by those of ordinary skill to aid in gripping and/or for aesthetic reasons.

- first container 12 could be of other shapes as desired, including rectangular, oval, etc. as well known in the art; and from other materials as desired, such as plastic.

- First container 12 also includes a bottom or bottom closure (not shown) and a sealed top 20.

- sealed top 20 meets the formed top part of surrounding side wall 18, a metallic rim 22 is provided which makes this area relatively rigid (though other materials such as plastic could be used so long as the rim does not easily deform from its circular shape and is thus suitable to retain flip top 14 thereon as discussed below).

- sealed top 20 includes a removable membrane such as a foil seal 21 which is provided to seal product 16 in container 10 after manufacture and during shipping and transport to the consumer.

- Foil seal 21 is attached at its periphery to an inwardly directed flange 23 of rim 22, and it will be appreciated that flange 23 thus serves to reinforce the rigidity of rim 22.

- Flange 23 extends completely about first container 12 as shown schematically by the broken line in figure 4 (which otherwise does not depict first container 12).

- Foil seal 21 is suitably removable by the consumer at the first use of first product 16 by tearing or breaking thereof, or preferably by pulling against a weak adhesive attaching the outer periphery of foil seal 21 to flange 23 as known in the art. Where foil seal 21 is attached adhesively, foil seal 21 is removable via a tab (not shown) or the like. When the removable foil seal 21 is removed, first product 16 is then easily removed from main body 12, as with a spoon or the like or carefully poured therefrom.

- Foil seal 21 also preferably includes a one-way valve 25 (shown only schematically in figure 4 ) or the like by which any pressure which might build up in first container 12 is released, as also well known in the art.

- Flip top 14 is preferably formed of an injection-moulded plastic or the like and broadly includes two parts, a base member 24 and a cover member 26.

- Base member 24 and cover member 26 are integrally connected together by a butterfly hinge 28 along adjacent peripheral portions thereof, though a straight hinge could be used if desired.

- Flip top 14 is shown as an integral piece in figures 2-4 , while base member 24, cover member 26 and hinge 28 are shown separately in respective figures 5-6 , 7A-7C and 8 .

- Hinge 28 has a weakened portion 27 which permits cover member 26 to easily pivot between a closed position as shown in figure 1A and preferably a full open position as shown in figures 2-4 .

- hinge 28 is designed (e.g., inherently biased) to resiliently move cover member 26 away from the closed position toward the full open position.

- the degree and strength required for the opening of cover member 26 can be as small or great as desired, and will be determined by the size and design of hinge 28, This degree and strength should at least be sufficient to make it easy for the user to move cover member 26 to an opened position where product 16 in first container 12 is easily accessed, which need not be a full open position but could be an intermediate position such as upstanding vertically from base member 24. If desired or needed, an extra spring component or the like can be added to make sure that cover member 26 moves to a sufficiently opened position.

- spring member 29 is shown in figure 2 upstanding from base member 24 which could be used for this purpose though it is expected that spring member 29 will not be needed in this embodiment.

- spring member 29 is resiliently bent (doubled) over, so that as spring member 29 seeks to return to its unbent position, spring member thus serves to resiliently urge cover member 26 back to the open position.

- Cover member 26 is optionally used to hold and protect an item or second container 30 during shipping and storage by the consumer.

- second container 30 contains a second dry product or additive 32 which is designed to be used in conjunction with or complementary to first dry beverage product 16 in first container 12, though second product 32 could be otherwise used as desired or needed.

- second product 32 could be for example chocolate or cinnamon sprinkles or powder or the like, or some other flavoring or complement as desired.

- cover member 26 primarily serves as an easily pivoted cover and seal for first product 16 in first container 12 after foil seal 21 is removed by the user (as discussed subsequently) for easy access to first product 16.

- second container 30 is provided and is rectangular as shown

- cover member 26 mounts rectangular second container 30 securely to an inside surface 34 thereof.

- This mounting is accomplished by use of a mounting means including outstanding arms 36 extending inwardly from inside surface 34 and preferably formed integrally therewith. Arms 36 are provided with an enlarged head 38 as shown in figures 1A and 9-10 .

- the spacing and longitudinal extent of arms 36 are designed to resiliently capture and hold second container 30 securely against inside surface 34.

- a small raised ledge 40 (as shown in figure 9 ) is provided on inside surface 34 against which second container 30 is pressed by heads 38.

- Small projections 42 are also upstanding from inside surface 34 on either side of second container 30, to prevent second container 30 from shifting too far to one side or the other during shipping and storage by the user.

- second container 30 includes a pivoted cap 44 or the like which is suitably pivoted out of a closed position to allow a small portion of second product 32 to be dispensed as by shaking of second container 30 above the coffee or like beverage after first product 16 has been added thereto.

- pivoted cap 44 is preferably designed to be held closed by one arm 36 when trapped between arms 36 to prevent second product 32 from accidentally being added to first product 16 while second container 30 is mounted to inside surface 34 of cover member 26. Between uses, second container 30 is designed to be easily returned to the mounted position between arms 36 for a convenient user storage until a subsequent use with another coffee is desired.

- second container 30' is broadly cylindrically shaped and includes a circular projecting flange 46. Flange 46 is retained underneath of enlarged heads 38' of arcuate arms 36' as shown (which arms 36' are thus shorter than arms 36). It will be appreciated that second container 30' includes a pivoted cap 44' having protruding-pegs fitting into and closing dispensing apertures 48, and that cap 44' is held closed by being pressed against inside surface 34'. Like second container 30, second container 30' is also designed to be returned to the mounted position onto inside surface 34' after use and thus for storage until second container 30' is needed again.

- base member 24 In order to securely attach flip top 14 to rim 22 of first container 12, the periphery of base member 24 is particularly shaped as shown best in figures 1A, 1 B and 13 .

- base member 24 includes a short depending leg 50 which is positioned on the inside surface of rim 22 above flange 23, and a long depending leg 52 which is positioned along and which extends below a bottom outside surface or the like of rim 22.

- rim 22 In order to securely hold base member 24 to rim 22 which as noted above is rigid, rim 22 has a lower outside end 54 and long leg 52 includes a complementary located shoulder 56 which fits just below outside end 54.

- shoulder 56 is trapped below outside end 54 to securely hold base member 24 in place on first container 12.

- the construction of base member 24 serves to make it relatively rigid as well, so that it stays securely on rigid rim 22 once mounted thereon.

- base member 24 also includes an upstanding leg 58.

- a peripheral skirt portion 60 of cover member 26 is positioned just outside of upstanding leg 58 and engages a landing 62 of base member 24 provided outside of upstanding leg 58 to present a smooth and pleasing appearance.

- a sealing ring 55 depends from inside surface 34 such that sealing ring 55 engages flange 23 of rigid rim 22 when cover member 26 is in the closed position (see figure 1A ). Sealing ring 55 thus serves to assure that none of product 16 located in first container 12 will leak past sealing ring 55 after foil seal 21 is removed, especially when container unit 10 is shaken or dropped.

- Sealing ring 55 also serves to add strength to cover member 26 during production (including mounting of a second container, and subsequent filling of first container 12 where that comes last - see below) and as it sits atop first container 12 with base member 24 during shipping and handling.

- cover member 26 acts as a protective sealing cover for first product 16 in first container 12 as well as a holder for second container 30 if one is provided.

- Holding means 64 includes a push button 66 which is located between a circumferential gap in upstanding leg 58 as shown in figure 5 , and which extends upwards past the top of upstanding leg 58.

- Push button 66 has a finger press portion 67 which is pushed by the user to resiliently move push button 66 radially inward a slight amount as shown by the arrow in figure 15 . This radial movement is allowed by the use of a groove 68 in the material of base member 24 around push button 66 where push button 68 is integrally formed with base member 24.

- first catch member 70 Located at a top end of push button 66 is a first catch member 70; which location of first catch member 70 above the remainder of base member 24 provides catch member 70 at a distant position from groove 68 so that a sufficient movement thereof is achieved when push button 66 is pushed.

- second catch member 74 is Located to and located above a cutout 72 in cover member 26 . Both catch members 70 and 74 are longitudinally curved as shown, following the complementary contours respectively of push button 66 and cutout 72.

- first catch member 70 catches and holds second catch member 74 underneath thereof to hold cover member 26 in the closed position against the opening bias of and about hinge 28 (and/or spring 29).

- second catch member 74 is no longer held underneath first catch member 70, so cover member 26 in then free to move upwards due to the opening bias of hinge 28.

- Cover member 26 thus pivots upward and is opened (or can be further opened as far as needed) to provide access first product 16 in first container 12 and to provide access to remove second container 30 (if provided) from inside surface 34 of cover member 26.

- flip top 80 is preferably formed of an injection-moulded plastic or the like and broadly includes two parts, a base member 24' and a cover member 26'. Base member 24' and cover member 26' are integrally connected together by a simple connecting hinge 28' which has a weakened line therealong so as to be sufficiently resilient to allow the two members 24' and 26' to pivot relative to one another as desired.

- hinge 28' is designed (e.g., inherently biased) to resiliently move cover member 26' away from the closed position with base member 24', but in this embodiment just sufficiently biased only to raise cover member 26' slightly away from base member 24'. If desired or needed, an extra spring component or the like can be added in the manner as noted above with hinge 28.

- Cover member 26' of this alternative embodiment is optionally used to hold and protect a small item or second container during shipping and storage by the consumer, and thus any such item would be secured inside of integral central reinforcing cylindrical band 82 by any suitable mechanism such as arms 36' - though if it is not desired to hold a second container, arms 36' could be eliminated.

- integral radiating reinforcing struts 84 as shown are integrally formed with reinforcing cylindrical band 82.

- the periphery of base member 24' is particularly shaped and acts much like the periphery of base member 24 as shown in figures 1A, 1B and 13 and hence will not be discussed in detail further.

- flange 27' of base member 24' of flip top 80 is similar to flange 57 found on base member 24, and corresponding flange 23' (shown partially in figure 18 ) of this container similar to flange 23 of container 12.

- cover member 26' does have a sealing ring 55' similar to sealing ring 55, but it will be noted that sealing ring 55' bows outward slightly at the distal end 86 thereof.

- Base member 24' like base member 24 also includes an upstanding leg 58' such that when cover member 26' is in the closed position, a peripheral skirt portion 60' of cover member 26' is positioned just outside of upstanding leg 58' and engages a landing 62' of base member 24' provided outside of upstanding leg 58'.

- Holding means 64' broadly similar to holding means 64 is provided as shown best in figures 16-20 .

- Holding means 64' includes a push button 66' which is likewise located in a circumferential gap or downwardly scalloped portion in upstanding leg 58' as shown in figure 17 , and which extends upwards past the top of upstanding leg 58'.

- Push button 66' is pushed by the user to resiliently move push button 66' radially inward a slight amount This radial movement is allowed by the use of a resilient link 88 at the bottom of push button 66' to the material of base member 24', so that push button 66' is integrally formed with base member 24'. It will be appreciated that this movement of push button 66' relative to the remainder of base member 24' is necessary as the rigid rim of the container otherwise prevents base member 24' from deflecting inwards as push button 66' is pushed.

- each wing 90 includes thereon an embossed or outwardly extending catch member 70'. As shown in figure 19 , the upper surface of each catch member 70' is slanted while the lower surface is perpendicular.

- second catch members 74' are associated second catch members 74', each formed as a mating inwardly extending depression on the inside surface of skirt portion 60' as shown in figures 18-19 .

- embossed/depressed catch members 70' and 74' assure a positive locking of the two together, while the slanted portions provide for an easy sliding movement of catch member 70' past the edge of upstanding leg 58' and into catch member 74'. It will be appreciated that the embossed/depressed configurations of catch members 70' and 74' could be reversed, in which case, the slanted portions and flat portions of the embossed catch member on skirt portion 60 and the associated depressions in wings 90 would be reversed in orientation.

- container 12 will be provided with a (metal, rolled rim) bottom last In the manufacturing process, so that flip top 14 (including second container 30 as desired) will be attached to first container 12 before first product 16 is added through the still opened bottom of the inverted container unit 10.

- a filter paper 75 covers one-way release valve 25 to prevent one-way valve 25 from becoming clogged with the powdered first product 16 during the filling operation thereof. As both the release valve 25 and filter paper 75 are attached to foil seal 21, both come off when foil seal 21 is initially removed by the user.

- flip top 14 also includes a top exterior rim 76 on cover member 26.

- Rim 76 is designed to receive a bottom of another container unit 10 therein, so that rim 76 promotes a steady stacking of container units 10 as known in the art.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Closures For Containers (AREA)

- Details Of Rigid Or Semi-Rigid Containers (AREA)

- Package Specialized In Special Use (AREA)

- Packging For Living Organisms, Food Or Medicinal Products That Are Sensitive To Environmental Conditiond (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US11/840,651 US20080083758A1 (en) | 2006-06-12 | 2007-08-17 | Push button flip top with attached second container |

| EP08162482.7A EP2025606B1 (fr) | 2007-08-17 | 2008-08-15 | Récipient avec un couvercle articulé muni d'un bouton poussoir |

Related Parent Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP08162482.7 Division | 2008-08-15 | ||

| EP08162482.7A Division-Into EP2025606B1 (fr) | 2007-08-17 | 2008-08-15 | Récipient avec un couvercle articulé muni d'un bouton poussoir |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| EP2402256A1 true EP2402256A1 (fr) | 2012-01-04 |

Family

ID=39892868

Family Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP08162482.7A Not-in-force EP2025606B1 (fr) | 2007-08-17 | 2008-08-15 | Récipient avec un couvercle articulé muni d'un bouton poussoir |

| EP11182661A Withdrawn EP2402256A1 (fr) | 2007-08-17 | 2008-08-15 | Bouchon couronne de bouton-poussoir avec récipient secondaire attaché |

Family Applications Before (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP08162482.7A Not-in-force EP2025606B1 (fr) | 2007-08-17 | 2008-08-15 | Récipient avec un couvercle articulé muni d'un bouton poussoir |

Country Status (14)

| Country | Link |

|---|---|

| US (1) | US20080083758A1 (fr) |

| EP (2) | EP2025606B1 (fr) |

| JP (2) | JP5537785B2 (fr) |

| KR (2) | KR101560826B1 (fr) |

| CN (1) | CN101481030B (fr) |

| BR (1) | BRPI0803407A2 (fr) |

| CA (2) | CA2638632A1 (fr) |

| ES (1) | ES2557877T3 (fr) |

| HK (1) | HK1135948A1 (fr) |

| IL (2) | IL215295A0 (fr) |

| PL (1) | PL2025606T3 (fr) |

| RU (2) | RU2483011C2 (fr) |

| TW (1) | TWI534050B (fr) |

| UA (1) | UA98759C2 (fr) |

Families Citing this family (22)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2916741B1 (fr) * | 2007-05-29 | 2009-08-28 | Airsec Soc Par Actions Simplif | Dispositif de fermeture a securite enfant,a vis et a bague temoin de premiere ouverture |

| US20090114650A1 (en) * | 2007-11-01 | 2009-05-07 | Houston Jr Michael Roderick | Compartment container |

| US20090166361A1 (en) * | 2007-12-29 | 2009-07-02 | Airsec | Two-part, flip top, snap cap for vials |

| US20090232947A1 (en) * | 2008-03-14 | 2009-09-17 | Gerard Laurent Buisson | Packaging system to provide fresh packed coffee |

| EE00991U1 (et) * | 2009-11-26 | 2011-01-17 | As Enko | Ballooni tarvikute hoidik |

| CN103299025A (zh) * | 2011-01-11 | 2013-09-11 | 帕克汉尼芬公司 | 带有通电弹簧唇部的流线分流器密封装置 |

| GB201205264D0 (en) * | 2012-03-26 | 2012-05-09 | Bapco Closures Res Ltd | Container closure with tamper evidence |

| WO2014084721A1 (fr) * | 2012-11-27 | 2014-06-05 | N.V. Nutricia | Construction de récipient pour un matériau en poudre |

| HUE037292T2 (hu) * | 2013-02-08 | 2018-08-28 | Obrist Closures Switzerland | Továbbfejlesztések egy záróelemben vagy záróelemhez |

| ES2429942B1 (es) * | 2013-07-05 | 2014-09-10 | José Francisco González Sánchez | Precinto higiénico para envases |

| US9233465B2 (en) * | 2014-05-06 | 2016-01-12 | Chia Wei Lai | Tool box |

| WO2015187003A1 (fr) * | 2014-06-05 | 2015-12-10 | N.V. Nutricia | Structure de couvercle pour un récipient |

| CN104839124B (zh) * | 2015-06-04 | 2017-02-22 | 张国山 | 一种适用于捕虫机的捕虫纸易安装装置 |

| CN207041183U (zh) * | 2015-11-04 | 2018-02-27 | 蒲木科技韩国株式会社 | 其上一体形成有按钮的粉盒容器 |

| USD804300S1 (en) | 2015-11-12 | 2017-12-05 | The J. M. Smucker Company | Container |

| JP6625888B2 (ja) * | 2016-01-28 | 2019-12-25 | 東洋製罐グループホールディングス株式会社 | 食品用容器の蓋体、食品用容器 |

| RU2653119C1 (ru) * | 2017-03-20 | 2018-05-07 | Общество с ограниченной ответственноостью "Аквафор" (ООО "Аквафор") | Устройство очистки жидкости |

| CN108861027A (zh) * | 2017-05-08 | 2018-11-23 | 内蒙古伊利实业集团股份有限公司 | 包装盖、包装盖的开启方法及包括该包装盖的包装容器 |

| EP3424841B1 (fr) * | 2017-07-05 | 2024-04-03 | Reemtsma Cigarettenfabriken GmbH | Systèmes d'emballage comprenant un emballage et un humidificateur |

| EP3483087B1 (fr) * | 2017-11-08 | 2020-12-30 | The Procter & Gamble Company | Produit de consommation |

| CN109850993B (zh) * | 2017-11-30 | 2023-01-03 | 杜也兵 | 带u型双仓叠加结构的净水机及其自闭仓制造方法 |

| WO2020237734A1 (fr) * | 2019-05-28 | 2020-12-03 | 山西晋德一品商贸有限公司 | Bouchon de bouteille d'alcool fort stable au stockage |

Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR1421595A (fr) * | 1964-11-06 | 1965-12-17 | Produits De Cementation Soc D | Godet perfectionné pour nuancier |

| FR1591349A (fr) * | 1968-11-07 | 1970-04-27 | ||

| WO1998021113A1 (fr) * | 1996-11-12 | 1998-05-22 | Bouchons Mac Inc. | Capuchon de fermeture |

| WO2000073147A1 (fr) * | 1999-05-28 | 2000-12-07 | Castillo James A | Dispositif pour maintenir des ingredients separes dans des produits alimentaires liquides |

| WO2005075314A2 (fr) * | 2004-02-05 | 2005-08-18 | N.V. Nutricia | Emballage pour matiere pulverulente |

| EP1600396A1 (fr) * | 2004-05-24 | 2005-11-30 | Dolci Preziosi S.R.L. | Fermeture pour récipient |

| WO2007009076A2 (fr) * | 2005-07-12 | 2007-01-18 | Nottingham Spirk Design Associates, Inc. | Contenant polymere pour cereales ainsi que systeme et procede d'utilisation de celui-ci |

Family Cites Families (71)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1514379A (en) * | 1924-11-04 | Food container | ||

| US2766796A (en) * | 1953-01-12 | 1956-10-16 | Earl S Tupper | Vacuum and seal type of receptacle |

| US3077409A (en) * | 1958-07-02 | 1963-02-12 | American Can Co | Coffee package |

| ES167545Y (es) * | 1971-04-01 | 1972-02-16 | Alvarez Gil Lloret | Recipientes para bebidas compuestas. |

| US3746158A (en) * | 1971-05-07 | 1973-07-17 | Swift & Co | Container attachment |

| US3768688A (en) * | 1971-09-08 | 1973-10-30 | Gillette Co | Cap |

| US3796813A (en) * | 1972-01-05 | 1974-03-12 | R Kurland | Closure cap for a container |

| JPS58161863U (ja) * | 1982-04-23 | 1983-10-28 | 森永乳業株式会社 | 摺り切り部を一体に保持した合成樹脂製蓋 |

| JPS59115756U (ja) * | 1983-01-25 | 1984-08-04 | 株式会社資生堂 | 容器 |

| US4596713A (en) * | 1983-04-14 | 1986-06-24 | Burdette Darrell C | Microwave food packets capable of dispersing a food additive during heating |

| US4522298A (en) * | 1984-07-02 | 1985-06-11 | North American Systems, Inc. | Coffee filter package arrangement |

| GB8427925D0 (en) * | 1984-11-05 | 1984-12-12 | Johnsen Jorgensen Plastics Ltd | Child-resistant closure |

| JPS61244759A (ja) * | 1985-04-15 | 1986-10-31 | 大和製罐株式会社 | 缶詰用オ−バ−キヤツプ |

| US4742928A (en) * | 1987-06-11 | 1988-05-10 | W. Braun Company | Dispensing closure with articulated flip-top cap |

| JPH0644836Y2 (ja) * | 1988-03-03 | 1994-11-16 | 日本クラウンコルク株式会社 | 振出容器蓋 |

| JPH0447088Y2 (fr) * | 1989-10-26 | 1992-11-06 | ||

| US5031784A (en) * | 1990-03-30 | 1991-07-16 | Wright Frank S | One-piece child-resistant closure |

| FR2662059B1 (fr) * | 1990-05-15 | 1993-06-11 | Lir France Sa | Appareil distributeur de produits de beaute. |

| DE4023602A1 (de) * | 1990-07-25 | 1992-01-30 | Majer Christian Gmbh Co Kg | Verbunddose, insbesondere zur verpackung von nahrungsmitteln |

| JPH0450622U (fr) * | 1990-09-03 | 1992-04-28 | ||

| JPH0644754U (ja) * | 1992-11-24 | 1994-06-14 | スミ株式会社 | 食品包装容器 |

| CH687019A5 (de) * | 1993-03-09 | 1996-08-30 | Alfatechnic Patent Ag | Einteiliger Kunststoffschnappscharnierverschluss. |

| US5632420A (en) * | 1993-11-03 | 1997-05-27 | Zeller Plastik, Inc. | Dispensing package |

| DE69605877T2 (de) * | 1995-04-10 | 2000-07-06 | Eisai Co., Ltd. | Behälter mit schraubkappe |

| JP3276532B2 (ja) * | 1995-05-16 | 2002-04-22 | 株式会社ニフコ | 容器用キャップ |

| JP3669758B2 (ja) * | 1995-06-15 | 2005-07-13 | ユニ・チャーム株式会社 | 蓋装置 |

| US5628533A (en) * | 1995-10-23 | 1997-05-13 | Yazaki Corporation | Torsional snap-fit latch |

| US5709232A (en) * | 1995-11-15 | 1998-01-20 | Charles Chang | Cosmetic jar and storage device |

| US5979681A (en) * | 1995-12-21 | 1999-11-09 | The Procter & Gamble Company | Child resistant attachment for containers |

| US5752614A (en) * | 1996-11-19 | 1998-05-19 | Sonoco Products Company | Easy-opening closure for hermetic sealing a retortable container |

| JP3746901B2 (ja) * | 1997-10-15 | 2006-02-22 | ユニ・チャーム株式会社 | 開閉自在容器 |

| US6021903A (en) * | 1998-02-20 | 2000-02-08 | Tenneco Packaging Inc. | Plastic container with sauce cup holder |

| KR200247896Y1 (ko) * | 1998-12-11 | 2002-11-22 | 김준현 | 보조용기가구비된용기뚜껑 |

| US6372270B1 (en) * | 1999-05-26 | 2002-04-16 | Sean P. Denny | Drink mix apparatus for making personal quantities of beverage |

| US6250346B1 (en) * | 1999-05-28 | 2001-06-26 | James Anzai Castillo | Device for maintaining separate ingredients in liquid food products |

| JP3068535U (ja) * | 1999-10-27 | 2000-05-12 | 名古屋製酪株式会社 | 蓋付き容器 |

| US6325252B1 (en) * | 2000-04-19 | 2001-12-04 | Owens-Illinois Closure Inc. | Closure dispensing engine with attached outer decoative shell |

| ATE294747T1 (de) * | 2000-07-13 | 2005-05-15 | Alpla Werke | Verschluss für ein behältnis |

| JP4159235B2 (ja) * | 2000-09-04 | 2008-10-01 | エム・エフ・ヴィ株式会社 | ヒンジキャップ |

| KR200228292Y1 (ko) * | 2001-01-09 | 2001-06-15 | 장태순 | 용기 내용물 이외에 별도의 복용제제를 포장할 수 있는포장병용 뚜껑 |

| US6631833B2 (en) * | 2001-02-16 | 2003-10-14 | Ccl Container Corporation | Oval-shaped tube closure |

| US6481589B2 (en) * | 2001-02-22 | 2002-11-19 | Seaquist Closures Foreign, Inc. | Non-dispensing closure |

| US20020157970A1 (en) * | 2001-04-26 | 2002-10-31 | Carlson Stephen G. | Beverage flavor dispensing cap |

| US7004349B2 (en) * | 2003-08-01 | 2006-02-28 | Dart Industries Inc. | Container with elastomeric lid spring |

| US6729498B2 (en) * | 2001-06-29 | 2004-05-04 | The Procter & Gamble Company | Dispenser for wipes |

| AUPR848001A0 (en) * | 2001-10-29 | 2001-11-15 | Dixon, Brodie | Container/bottle cap with a storage compartment |

| US6814990B2 (en) * | 2002-02-22 | 2004-11-09 | Kraft Foods Holdings, Inc. | Beverage system |

| US6976578B1 (en) * | 2002-05-07 | 2005-12-20 | Antony Austin Kenihan | Dispensing lid closure for beverage container and method of making and using the closure |

| US6932231B2 (en) * | 2002-09-27 | 2005-08-23 | Kevin Haynes | Beverage cup lid with a condiment addition well |

| US7055713B2 (en) * | 2002-11-12 | 2006-06-06 | Sonoco Development, Inc. | Easy-opening closure for retortable container |

| US7074443B2 (en) * | 2002-11-19 | 2006-07-11 | Kraft Foods Holdings, Inc. | Vented can overcap |

| US6708735B1 (en) * | 2002-12-11 | 2004-03-23 | Antony Austin Kenihan | Dispensing lid closure for confections and methods of making and using the closure |

| FR2849429B1 (fr) * | 2002-12-31 | 2005-05-27 | Plastohm Sa | Bouchon de fermeture d'un flacon, a ouverture controlee |

| JP4837881B2 (ja) * | 2003-01-14 | 2011-12-14 | ユニ・チャーム株式会社 | 蓋付き容器 |

| US20040238553A1 (en) * | 2003-05-30 | 2004-12-02 | Lane Gordon S. | Container with hinged cover |

| US7404495B2 (en) * | 2003-07-28 | 2008-07-29 | Rexam Closure Systems Inc. | Child-resistant flip-top dispensing closure and package |

| USD504318S1 (en) * | 2003-10-23 | 2005-04-26 | Societe Des Produits Nestle S.A. | Container |

| US6986807B2 (en) * | 2004-02-06 | 2006-01-17 | Brunk S Fred | Desiccant bottle cap |

| US20050178677A1 (en) * | 2004-02-16 | 2005-08-18 | Sonoco Development, Inc. | Container assembly having an overcap with a storage compartment |

| JP4658507B2 (ja) * | 2004-03-31 | 2011-03-23 | 竹本容器株式会社 | 自開式キャップ機構 |

| JP2005306452A (ja) * | 2004-04-23 | 2005-11-04 | Meiji Seika Kaisha Ltd | 食品用容器 |

| US7451896B2 (en) * | 2004-10-27 | 2008-11-18 | Owens-Illinois Closure, Inc. | Child-resistant dispensing closure, package and method of manufacture |

| US7735665B2 (en) * | 2005-02-18 | 2010-06-15 | Rexam Closure Systems Inc. | Child-resistant flip-top dispensing closure, package and method of manufacture |

| US20060219652A1 (en) * | 2005-03-30 | 2006-10-05 | Owens-Illinois Closure Inc. | Plastic closure for containers |

| US7537112B2 (en) * | 2005-08-04 | 2009-05-26 | Ronald Frank Balazik | Drink mix system |

| US7703621B2 (en) * | 2005-08-25 | 2010-04-27 | Union Street Brand Packaging Llc | Moisture retention seal |

| US8308004B2 (en) * | 2005-11-22 | 2012-11-13 | Rexam Healthcare Packaging Inc. | Dispensing package having non-removable and non-rotatable dispensing closure |

| US7721907B2 (en) * | 2005-11-22 | 2010-05-25 | Rexam Closure Systems Inc. | Child-resistant flip-top dispensing closure and package |

| US7731042B2 (en) * | 2005-12-21 | 2010-06-08 | Seaquist Closures Foreign, Inc. | Closure with hinged lid and stress relief recesses |

| US7614519B2 (en) * | 2006-11-30 | 2009-11-10 | Rockline Industries, Inc. | Push button dispensing lid |

| US7861873B1 (en) * | 2007-05-29 | 2011-01-04 | Rexam Closures And Containers Inc. | Flip-top dispensing system with a child resistant latch mechanism |

-

2007

- 2007-08-17 US US11/840,651 patent/US20080083758A1/en not_active Abandoned

-

2008

- 2008-08-11 TW TW097130486A patent/TWI534050B/zh not_active IP Right Cessation

- 2008-08-12 CA CA002638632A patent/CA2638632A1/fr not_active Abandoned

- 2008-08-12 CA CA2872988A patent/CA2872988A1/fr not_active Abandoned

- 2008-08-13 IL IL215295A patent/IL215295A0/en unknown

- 2008-08-13 IL IL193424A patent/IL193424A/en not_active IP Right Cessation

- 2008-08-14 KR KR1020080080033A patent/KR101560826B1/ko active IP Right Grant

- 2008-08-14 UA UAA200810400A patent/UA98759C2/uk unknown

- 2008-08-15 ES ES08162482.7T patent/ES2557877T3/es active Active

- 2008-08-15 JP JP2008209232A patent/JP5537785B2/ja not_active Expired - Fee Related

- 2008-08-15 EP EP08162482.7A patent/EP2025606B1/fr not_active Not-in-force

- 2008-08-15 RU RU2008133647/12A patent/RU2483011C2/ru not_active IP Right Cessation

- 2008-08-15 EP EP11182661A patent/EP2402256A1/fr not_active Withdrawn

- 2008-08-15 BR BRPI0803407-9A patent/BRPI0803407A2/pt not_active IP Right Cessation

- 2008-08-15 PL PL08162482T patent/PL2025606T3/pl unknown

- 2008-08-18 CN CN2008101449934A patent/CN101481030B/zh not_active Expired - Fee Related

-

2010

- 2010-01-06 HK HK10100073.8A patent/HK1135948A1/xx not_active IP Right Cessation

-

2012

- 2012-12-24 RU RU2012156135/12A patent/RU2012156135A/ru not_active Application Discontinuation

-

2013

- 2013-12-16 JP JP2013259537A patent/JP5926235B2/ja not_active Expired - Fee Related

-

2014

- 2014-10-06 KR KR1020140134572A patent/KR101560987B1/ko active IP Right Grant

Patent Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR1421595A (fr) * | 1964-11-06 | 1965-12-17 | Produits De Cementation Soc D | Godet perfectionné pour nuancier |

| FR1591349A (fr) * | 1968-11-07 | 1970-04-27 | ||

| WO1998021113A1 (fr) * | 1996-11-12 | 1998-05-22 | Bouchons Mac Inc. | Capuchon de fermeture |

| WO2000073147A1 (fr) * | 1999-05-28 | 2000-12-07 | Castillo James A | Dispositif pour maintenir des ingredients separes dans des produits alimentaires liquides |

| WO2005075314A2 (fr) * | 2004-02-05 | 2005-08-18 | N.V. Nutricia | Emballage pour matiere pulverulente |

| EP1600396A1 (fr) * | 2004-05-24 | 2005-11-30 | Dolci Preziosi S.R.L. | Fermeture pour récipient |

| WO2007009076A2 (fr) * | 2005-07-12 | 2007-01-18 | Nottingham Spirk Design Associates, Inc. | Contenant polymere pour cereales ainsi que systeme et procede d'utilisation de celui-ci |

Also Published As

| Publication number | Publication date |

|---|---|

| HK1135948A1 (en) | 2010-06-18 |

| CN101481030A (zh) | 2009-07-15 |

| KR20090018588A (ko) | 2009-02-20 |

| CA2638632A1 (fr) | 2009-02-17 |

| RU2012156135A (ru) | 2014-06-27 |

| KR20140135924A (ko) | 2014-11-27 |

| EP2025606A3 (fr) | 2009-03-25 |

| JP5537785B2 (ja) | 2014-07-02 |

| JP5926235B2 (ja) | 2016-05-25 |

| TW200914330A (en) | 2009-04-01 |

| KR101560987B1 (ko) | 2015-10-15 |

| KR101560826B1 (ko) | 2015-10-15 |

| CN101481030B (zh) | 2013-01-02 |

| JP2009078864A (ja) | 2009-04-16 |

| IL193424A (en) | 2014-07-31 |

| JP2014094783A (ja) | 2014-05-22 |

| UA98759C2 (uk) | 2012-06-25 |

| US20080083758A1 (en) | 2008-04-10 |

| PL2025606T3 (pl) | 2016-03-31 |

| EP2025606B1 (fr) | 2015-10-07 |

| TWI534050B (zh) | 2016-05-21 |

| CA2872988A1 (fr) | 2009-02-17 |

| EP2025606A2 (fr) | 2009-02-18 |

| ES2557877T3 (es) | 2016-01-29 |

| BRPI0803407A2 (pt) | 2009-12-08 |

| RU2008133647A (ru) | 2010-02-20 |

| IL215295A0 (en) | 2011-11-30 |

| RU2483011C2 (ru) | 2013-05-27 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2402256A1 (fr) | Bouchon couronne de bouton-poussoir avec récipient secondaire attaché | |

| US7484638B2 (en) | Plastic drink-through cup lid with fold-back tab | |

| US20190389636A1 (en) | Closure for a container and utensil therefor | |

| US20070039960A1 (en) | Spill-Resistant Reclosable Closure Assembly for a Lid | |

| US20070029320A1 (en) | Cup and lid combination | |

| US20110139783A1 (en) | Tamper-evident closure | |

| JP2010517884A (ja) | 流通性もしくは流動性を有する物質の収容容器 | |

| US7398893B2 (en) | Cup and lid combination | |

| US7398892B2 (en) | Cup and lid combination | |

| US20120160881A1 (en) | Dispensable product container | |

| JP4303510B2 (ja) | 容器の蓋 | |

| JP3741389B2 (ja) | 容器の蓋 | |

| KR102705708B1 (ko) | 캔뚜껑의 오픈기능을 갖는 위생커버 | |

| JPS6018363Y2 (ja) | ジュ−ス等のコツプ兼用充填容器 | |

| JP3791749B2 (ja) | チューブ容器 | |

| JP2577558Y2 (ja) | 紙容器用注出口成形体 | |

| TWM587639U (zh) | 杯蓋 | |

| JPS607326Y2 (ja) | カバ−付容易開封蓋体 | |

| JPH0333628Y2 (fr) | ||

| JPWO2005087599A1 (ja) | 飲料缶用キャップおよびこれを備えた飲料容器 | |

| JP2003070649A (ja) | ポット | |

| MX2008007304A (en) | Cup and lid combination |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| AC | Divisional application: reference to earlier application |

Ref document number: 2025606 Country of ref document: EP Kind code of ref document: P |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MT NL NO PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA MK RS |

|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20120626 |

|

| 17Q | First examination report despatched |

Effective date: 20130425 |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: INTERCONTINENTAL GREAT BRANDS LLC |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: KONINKLIJKE DOUWE EGBERTS B.V. |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 20170706 |