EP2333219B2 - Vorgefertigte Tür- oder Fensterrahmen-Einheit mit isolierender Randeinfassung - Google Patents

Vorgefertigte Tür- oder Fensterrahmen-Einheit mit isolierender Randeinfassung Download PDFInfo

- Publication number

- EP2333219B2 EP2333219B2 EP10196965.7A EP10196965A EP2333219B2 EP 2333219 B2 EP2333219 B2 EP 2333219B2 EP 10196965 A EP10196965 A EP 10196965A EP 2333219 B2 EP2333219 B2 EP 2333219B2

- Authority

- EP

- European Patent Office

- Prior art keywords

- frame

- counter

- structure according

- surround

- insulating surround

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E06—DOORS, WINDOWS, SHUTTERS, OR ROLLER BLINDS IN GENERAL; LADDERS

- E06B—FIXED OR MOVABLE CLOSURES FOR OPENINGS IN BUILDINGS, VEHICLES, FENCES OR LIKE ENCLOSURES IN GENERAL, e.g. DOORS, WINDOWS, BLINDS, GATES

- E06B1/00—Border constructions of openings in walls, floors, or ceilings; Frames to be rigidly mounted in such openings

- E06B1/02—Base frames, i.e. template frames for openings in walls or the like, provided with means for securing a further rigidly-mounted frame; Special adaptations of frames to be fixed therein

Definitions

- This invention regards a counter-frame structure for a window, a French window or a skylight to be inserted in an opening in a wall or roof, separating the interior and exterior of a building.

- the frames are made with special attention to the selection of materials, inserting suitable insulation materials into the sections comprising the frames, for example a polystyrene or a polyurethane foam, and/or envisaging appropriate gaskets between the mobile and fixed parts of the frames. In this way it is sought to increase the frame's thermal cut-off and thus increase its insulation coefficient.

- suitable insulation materials for example a polystyrene or a polyurethane foam

- FR-A-2 539 801 discloses a prefabricated element suitable to be fitted into an opening of a wall for forming a decorative covering for the opening and making it possible to receive the framework of the corresponding doors or windows.

- the prefabricated element may be filled with a thermal insulating material.

- EP-A-1 455 027 discloses a heat insulation kit applied externally to a cellar ventilation window to prevent the formation of a heat bridge between the cellar wall and the light shaft.

- U1 discloses a framework assembly including a door frame, window sash and a damming system, resting against the frame work assembly, formed according to building material class A1 or A2.

- EP-A-1 172 495 discloses a thermal insulation of the surround frame of a building opening, comprising at least two first heat insulating elements for arranging above and below the building opening, and at least two second heat insulating elements for arranging next to the first elements and lateral to the building opening.

- Document DE 199 51 901 A1 describes a structure comprising features as mentioned in the preamble of the present claim 1.

- the purpose of this invention is to propose a counter-frame structure that gives the entire frame system greater thermal efficiency while at the same time obviating the installation drawbacks mentioned above.

- the other functional elements of the frame structure can be assembled at the time of installation since the structure is adaptable to any type of frame and blind or - most favourably - can be supplied to the building contractor already mounted on the structure.

- the structure is conceived for mounting prior to application of the insulating skin, taking into account the thickness thereof in such a way that subsequently any discontinuity between frame and wall can be eliminated. Insulation of inclined external surfaces or reveals can be carried out at various angulations.

- the structure in accordance with the invention reduces, if it does not eliminate, the thermal bridges still found in state of the art frames, in particular between wall and counter-frame, between wall and reveals insulation and between wall and skin, all of this without burdensome building work. In other words, once installed the frame is already completely insulated.

- the structure is conceived in such a way that various types and sizes of insulation may be used, e.g. up to 400 mm thickness.

- a further advantage is that the customer can deal with one single supplier for counter-frame, frame insulation, blinds and internal/external sills.

- the counter-frame structure is applicable to frames in any material whatsoever, e.g. wood, aluminium, PVC or combinations thereof, and can be used in various types of buildings such as prefabs, traditional buildings in masonry and concrete and also in renovations.

- the counter-frame structure of the present invention comprises a counter-frame 10 for door and window frames and an insulating surround 12, in heat insulation material, which surrounds counter-frame 10 at least on the sides facing wall 5 in which it is to be placed and facing the exterior of the said wall.

- Counter-frame 10 and insulating surround 12 are connected in such a way as to form a single block 1; 2 to be inserted in an opening in wall 5.

- thermoplastic polymeric material in particular a polystyrene.

- the insulating surround 12 is of such thickness as to extend between internal side 5' and external side 5" of wall 5 in which the structure is inserted.

- a thickness of insulating surround 12 permits, in the upper part, incorporation of a recess or other containing and guiding devices for the blind elements 42, 48 of the frame and, in the lower part, the creation of a support base for the internal 22 and external window sills 23.

- the counter-frame structure 1, 2 is suitable for insertion in a wall 5 consisting of a part in masonry 6 and an external protective facing known as "skin" 7.

- the insulating surround 12 extends frontally to the level of skin 7 in such a way as to create a continuous insulation between the heat insulation material of the surround 12 and that of skin 7.

- surround 12 comprises a frontal portion 7a with the same thickness and in the same material as skin 7, and a rear portion 6a, also in insulating material, corresponding to the thickness of the masonry part 6.

- the counter-frame structure can be adapted to the size of the space and therefore inserted in the wall 5 with extreme precision, connecting it up with insulating materials to the elements comprising the wall 5 itself.

- the internal and external surfaces of insulating surround 12, meaning those facing the interior 5' and exterior 5" of the building, are covered with a layer of rendering 14 which extends to conceal counter-frame 10.

- the rendering operation usually carried out with the counter-frame 10 installed, takes place at building phase, thus avoiding soiling or damaging the counter-frame 10 at the door/window installation phase.

- a pre-rendering operation is carried out in such a way that, having mounted the counter-frame 10, the builders then carry out a final rendering that connects the external surface of the counter-frame structure with the wall 5 of the building.

- the coat of rendering 14 or pre-rendering is laid on scrim or template 16 which covers the internal and external surfaces of insulating surround 12.

- insulating surround 12 is profiled in such a way as to define at least one housing 18 for a blind element 42,48 (as will be better specified below in the description of examples of implementation).

- the insulating surround 12 integrates, or is equipped to integrate, at least certain functional elements of the door/window-frame 32 such as guides for sliding parts 44,49 and sealing elements against water or dust.

- the guides 44, 49 for rolling or sliding elements are created in insulating surround 12 at a distance from the elements of counter-frame 10 in such a way as to interpose layer 12" of heat insulation material. This results in avoiding or reducing the effect of any thermal bridge that would be created by contact between the said guides and counter-frame 10.

- the insulating surround 12 includes a base element 20 which can be covered by at least one plate in such a way as to create internal sill 22 and/or external sill 23 of the window-frame 32.

- the insulating surround 12 extends in such a way as to at least partially overlap frame 30 which is fixed, or will be fixed upon installation, to counter-frame 10. At least partial overlapping is understood as being at least from the part facing the exterior 5". In fact in this way the external side of frame 30 is covered by insulating surround 12 and therefore benefits from greater thermal protection. Having thus limited cooling of the exposed surface of frame 30, heat dispersion from interior 5' to exterior 5" by way of the frame 30 is therefore avoided right from the start.

- the insulating surround 12 actually extends also to overlap the opening window-frame 32 in such a way that only the glazed part is visible from outside. In this case, over and above the aesthetic result, external surface cooling of both frame 30 and window-frame 32 is avoided, thus reducing overall heat dispersion.

- the use of a surround 12 in heat-insulation material that extends to the external surface 5" of the wall 5, with the possibility of easily forming the surround elements according to taste means that the frame structure can be connected to the said external surface 5" with special lines, for example with inclined surfaces 36 that open towards the exterior. This among other things means maximising the entry of light through the door/window-frame, especially when the surround 12 overlaps the frame. It should be noted that to date the same result has been sought by breaking the wall 5 or the external protective skin 7, with considerable negative consequences in terms of time and costs.

- insulating surround 12 is formed by a plurality of elements 12', for example in the form of square bars or blocks, closely coupled in such a way as to leave no interstices through which heat could be propagated.

- These elements 12' of surround 12 are coupled by means of flat and extended contact surfaces or, even more favourably, are linked with a geometrical or jointed coupling.

- the elements 12' of surround 12 are fixed to counter-frame 10 of the door/window-frame.

- said elements 12' of surround 12 are fixed to the counter-frame 10 by gluing and/or by screwing and/or by means of clamps or profiled sheet metal.

- the upper and lower horizontal sides 10' and vertical sides or uprights 10" that define the sides of counter-frame 10, and the adjacent elements of surround 12, are profiled to be coupled geometrically or by a joint.

- the said sides 10' , 10" of counter-frame 10 have a longitudinal channel 11 in which a corresponding longitudinal projection 13 of the surround elements is inserted.

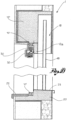

- Figures 1 and 2 illustrate two counter-frame structures of a window and a French window respectively, in accordance with the invention, seen from the interior.

- the said figures show the counter-frame 10 (including upper and lower horizontal sides 10' and vertical sides or uprights 10") with the insulating surround 12, formed by elements 12', 20.

- a box 40 for a roller blind 42 ( figures 3 and 4 ), also inserted in surround 12 and, in figure 1 , an internal sill 22.

- no base element 20 is provided as support for sills 22, 23, but the surround 12 terminates in any case with a lower horizontal bar 20' suitable for setting into the floor to prevent the passage of heat from the lower part of the frame.

- lateral elements 12' of insulating surround 12 extend in the lower part to the level of the lower extremity of bar 20'.

- Figures 3 and 4 illustrate a vertical section of counter-frame structure 1 for a window, before and after fixing of the actual door/window-frame 30, 32 to counter-frame 10.

- the internal and external sills 22 and 23 can be seen resting on base element 20.

- the upper horizontal element 12' of surround 12 has, frontally, towards the exterior of the door/window-frame, a box structure suitable for delimiting housing 18 for a box 40 containing a roller blind element 42.

- insulating surround 12 comprises, as well as the upper element mentioned above that rests on the upper horizontal side of the counter-frame 10, a further profiled section indicated as 12a which covers the frontal side of counter-frame 10 and also extends to overlap frame 30.

- profile 12a of surround 12 and the upper horizontal side 10' of the counter-frame 10 are coupled geometrically with a male (longitudinal projection 13)-female (longitudinal channel 11) type joint.

- An analogous arrangement of the elements of the counter-frame 10 and the insulating surround 12 are found in the lower part of the counter-frame structure.

- Figures 3 and 4 moreover show guide 44 for movement of roller blind element 42.

- Figure 5 moreover shows a horizontal element 10a for fixing surround 12 to counter-frame 10.

- This horizontal element 10a for example a wooden bar, is sunk into upper transversal element 12' of surround 12 to connect the latter, e.g. by means of screws, to the lower horizontal side 10' of counter-frame 10.

- Figures 8 and 9 illustrate a simpler counter-frame structure for a window, e.g. for a window with shutters, therefore without an integrated blind element.

- the upper part of surround 12 is limited to profile 12a which is joint-coupled frontally with upper horizontal side 10' of counter-frame 10.

- Note in figure 9 the presence of a pair of vertical bars 46 set in insulating profiles, e.g. in the same material as counter-frame 10, which serve as supports for the shutter hinges.

- horizontal element 12a of surround 12 partially covers window frame 30 while vertical elements of surround 12, which are joint-coupled with uprights 10" of the counter-frame 10, completely cover frame 30.

- Figure 10 is a vertical section view of a counter-frame structure for a window with an adjustable slats blind device 48. Apart from the different blind element the structure of the counter-frame block-insulating surround is substantially the same as that of figures 3 and 4 .

- Figure 11 illustrates a counter-frame structure analogous to the previous one but for a French window.

- the lower part of the structure features a lower bar 20' of the surround 12, set in the floor and in any case fixed to counter-frame 10.

- guide 49 for the adjustable slats is obtained in the centre of side profiles of surround 12, well spaced from counter-frame 10. Also note in this case the presence of insulating perimeter elements 6a and 7a of the wall connection which is fixed, e.g. by gluing, to counter-frame 10 and vertical uprights of surround 12. Said vertical uprights of surround 12 completely cover window frame 30 and are joint-coupled to vertical uprights 10" of counter-frame 10.

- Figure 13 is a vertical section view of counter-frame structure for a sliding French window without blind.

- insulating surround 12 includes the wall connection elements and a frontal crosspiece that partially covers the sliding frame, joint-coupled to upper horizontal side 10' of counter-frame 10.

- Figure 13a again referring to a counter-frame structure for sliding doors, differs from the previous one inasmuch as we have housing 18 for a blind element. Note how housing 18 is obtained from the bringing together of frontal profile 12a, which in this case extends below to a greater extent, completely protecting the window frame, with upper horizontal profile and thus creating the necessary thickness to obtain housing 18.

- the horizontal section of figure 14 shows two side insulation profiles which also integrate guide 49 for the blind element and further vertical insulation profiles 12b that fill the empty space between frame and sliding door.

- FIGS 15 and 16 concern a further example of application of the invention. More precisely a counter-frame structure for a window with fixed glazing 50, which can be shaded with adjustable slats element 48, of which it can be noted the housing 18, provided in the upper part of insulating surround 12, and sliding guides 49 integrated in vertical insulation profiles. Most favourably, the glazing 50 is directly fixed to counter-frame 10, completely enclosed by insulating surround 12. Also at the level of the vertical uprights of the structure, surround 12 extends both forward and rearward with regard to counter-frame 10.

Landscapes

- Engineering & Computer Science (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Wing Frames And Configurations (AREA)

- Door And Window Frames Mounted To Openings (AREA)

- Residential Or Office Buildings (AREA)

- Securing Of Glass Panes Or The Like (AREA)

Claims (18)

- Rahmen-Gegenstruktur für Tür/Fensterrahmen (30), die zum Einsetzen in eine Öffnung in einer Außenwand oder ein Dach eines Gebäudes geeignet ist, wobei die Rahmen-Gegenstruktur als einzelner Block (1; 2) ausgebildet ist, der in die Öffnung eingesetzt werden soll und eine isolierende Randeinfassung (12) in einem wärmeisolierenden Material aufweist, wobei die isolierende Randeinfassung derart profiliert ist, dass in einem oberen Teil der isolierenden Randeinfassung (12) zumindest ein Gehäuse (18) für einen Kasten oder eine Führung einer Jalousie gefertigt ist, dadurch gekennzeichnet, dassdie Rahmen-Gegenstruktur ferner einen Gegenrahmen (10) für einen Tür/Fensterrahmen (30) aufweist, wobei der Gegenrahmen und die isolierende Randeinfassung derart miteinander verbunden sind, dass sie den einzelnen Block bilden,wobei die isolierende Randeinfassung (12) den Gegenrahmen (10) zumindest an den Seiten, die der Wand (5) und dem Äußeren des Gebäudes zugewandt sind, umschließt,und wobei die isolierende Randeinfassung (12) eine solche Dicke hat, dass sie sich von der inneren Seite zur äußeren Seite der Wand erstreckt, in die die Struktur eingesetzt werden soll.

- Struktur nach Anspruch 1, wobei die innere und äußere Oberfläche der isolierenden Randeinfassung (12) von einer Schicht aus Putz (14) oder Vorputz bedeckt sind, die sich erstreckt, um den Gegenrahmen (10) zu verkleiden.

- Struktur nach Anspruch 2, wobei die innere (5') und äußere (5") Oberfläche der isolierenden Randeinfassung (12) von einer Schicht aus Putz (14) oder Vorputz bedeckt sind, die sich erstreckt, um den Gegenrahmen (10) zu verkleiden.

- Struktur nach einem der vorstehenden Ansprüche, wobei die isolierende Randeinfassung (12) ein Gehäuse für einen Rollladen (42) oder eine verstellbare Lamellenjalousie (48) umfasst.

- Struktur nach einem der vorstehenden Ansprüche, wobei die isolierende Randeinfassung (12) aufnimmt oder geeignet ist zum Aufnehmen von zumindest einigen Funktionselementen des Rahmens (30), wie Führungen (44; 49) für gleitende Teile und für wasserdichte/staubdichte Dichtteile.

- Struktur nach Anspruch 5, wobei die Führungen (44; 49) für gleitende Teile in die isolierende Randeinfassung (12) mit einem Abstand von den Elementen (10', 10") des Gegenrahmens (10) so eingearbeitet sind, dass ein Zwischenraum für eine Schicht (12") aus wärmeisolierendem Material verbleibt.

- Struktur nach einem der vorstehenden Ansprüche, wobei die isolierende Randeinfassung (12) ein Basiselement (20) umfasst, auf das zumindest eine Platte so aufgesetzt ist, dass sie die innere Fensterbank (23) und/oder die äußere Fensterbank (22) des Rahmens (30) erzeugt.

- Struktur nach einem der vorstehenden Ansprüche, wobei die isolierende Randeinfassung (12) Teile von aufrechten (10") und Teile von oberen/unteren horizontalen Seiten (10`) umfasst, die von einem jeweiligen Profil (34) aus Metall oder Kunststoffmaterial bedeckt sind, das dazu geeignet ist, sichtbar zu bleiben.

- Struktur nach einem der vorstehenden Ansprüche, wobei die isolierende Randeinfassung (12) zum zumindest teilweisen Überlappen des nach außen weisenden Rahmen(30)-Teils geeignet ist.

- Struktur nach Anspruch 9, wobei die isolierende Randeinfassung (12) auch zum Überlappen des Türrahmens (32) derart geeignet ist, dass von außen nur die Verglasung (50) des Rahmens (32) sichtbar ist.

- Struktur nach einem der vorstehenden Ansprüche, wobei die isolierende Randeinfassung (12) mit der äußeren Seite (5") der Wand (5) über schräge Flächen (36) so verbunden ist, dass der Eintritt von Licht durch den Rahmen (30) maximiert wird.

- Struktur nach einem der vorstehenden Ansprüche, wobei die isolierende Randeinfassung (12) eine Vielzahl von eng gekoppelten Elementen (12', 12a, 12b) umfasst, wovon zumindest einige der Elemente an dem Gegenrahmen (10) befestigt sind.

- Struktur nach Anspruch 12, wobei diese Elemente (12`, 12a, 12b) der isolierenden Randeinfassung (12) miteinander mit einer geometrischen Kopplung oder Gelenkkopplung verbunden sind.

- Struktur nach Anspruch 13, wobei die Elemente (12', 12a, 12b) der isolierenden Randeinfassung (12) an dem Gegenrahmen (10) mit einer Gelenkkopplung und/oder durch Kleben und/oder durch Schrauben und/oder durch Klemmen oder profiliertes Metallblech befestigt sind.

- Struktur nach einem der vorstehenden Ansprüche, wobei der Rahmen (30) ein Bodenfenster ist, und wobei die isolierende Randeinfassung (12) eine untere Schiene (20`) umfasst, die zum Einsetzen in ein Gehäuse in dem Boden geeignet ist.

- Struktur nach einem der vorstehenden Ansprüche, wobei die isolierende Randeinfassung (12) einen vorderen Teil (7a) der gleichen Dicke und aus dem gleichen Material wie die Schutzhaut (7) der Wand (5) und einen hinteren Teil (6a) entsprechend der Dicke des Teils der Wand (5) im Mauerwerk aufweist.

- Struktur nach einem der vorstehenden Ansprüche, umfassend einen Tür-/Fensterrahmen (30), der an dem Gegenrahmen (10) befestigt ist.

- Struktur nach Anspruch 17, umfassend einen kompletten Rahmen (30, 32), der an dem Gegenrahmen (10) befestigt ist.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP10196965.7A EP2333219B2 (de) | 2008-09-05 | 2008-09-05 | Vorgefertigte Tür- oder Fensterrahmen-Einheit mit isolierender Randeinfassung |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP10196965.7A EP2333219B2 (de) | 2008-09-05 | 2008-09-05 | Vorgefertigte Tür- oder Fensterrahmen-Einheit mit isolierender Randeinfassung |

| EP08425591.8A EP2161402B2 (de) | 2008-09-05 | 2008-09-05 | Vorgefertigte Tür- oder Fensterrahmen-Einheit mit isolierender Randeinfassung |

Related Parent Applications (3)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP08425591.8 Division | 2008-09-05 | ||

| EP08425591.8A Division EP2161402B2 (de) | 2008-09-05 | 2008-09-05 | Vorgefertigte Tür- oder Fensterrahmen-Einheit mit isolierender Randeinfassung |

| EP08425591.8A Division-Into EP2161402B2 (de) | 2008-09-05 | 2008-09-05 | Vorgefertigte Tür- oder Fensterrahmen-Einheit mit isolierender Randeinfassung |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP2333219A1 EP2333219A1 (de) | 2011-06-15 |

| EP2333219B1 EP2333219B1 (de) | 2018-12-19 |

| EP2333219B2 true EP2333219B2 (de) | 2024-12-11 |

Family

ID=40329428

Family Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP10196965.7A Active EP2333219B2 (de) | 2008-09-05 | 2008-09-05 | Vorgefertigte Tür- oder Fensterrahmen-Einheit mit isolierender Randeinfassung |

| EP08425591.8A Active EP2161402B2 (de) | 2008-09-05 | 2008-09-05 | Vorgefertigte Tür- oder Fensterrahmen-Einheit mit isolierender Randeinfassung |

Family Applications After (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP08425591.8A Active EP2161402B2 (de) | 2008-09-05 | 2008-09-05 | Vorgefertigte Tür- oder Fensterrahmen-Einheit mit isolierender Randeinfassung |

Country Status (8)

| Country | Link |

|---|---|

| EP (2) | EP2333219B2 (de) |

| AT (1) | ATE495336T2 (de) |

| DE (1) | DE602008004523D1 (de) |

| DK (1) | DK2161402T3 (de) |

| ES (1) | ES2359661T3 (de) |

| HR (1) | HRP20110118T1 (de) |

| PL (1) | PL2161402T3 (de) |

| SI (1) | SI2161402T1 (de) |

Families Citing this family (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| ITRM20100542A1 (it) * | 2010-10-13 | 2012-04-14 | Paolo Gusmeroli | "falso telaio prefabbricato con struttura a sandwich per vani porta e finestra" |

| EP2479369B1 (de) | 2011-01-20 | 2016-07-13 | Südtirol Fenster S.r.l. | Vorgefertigte Fensterrahmeneinheit mit isolierender Randeinfassung und integriertem Sims |

| CN103867072B (zh) * | 2012-12-12 | 2016-07-06 | 贵阳铝镁设计研究院有限公司 | 一种保温节能的外墙窗的制作方法及结构 |

| CN103590735A (zh) * | 2013-12-02 | 2014-02-19 | 哈尔滨森鹰窗业股份有限公司 | 带有电动百叶的四玻铝包木窗 |

| CN104153677B (zh) * | 2014-07-18 | 2016-03-02 | 天津金木共生科技有限公司 | 一种铝木复合门窗 |

| PL414259A1 (pl) * | 2015-10-04 | 2017-04-10 | Marbet Spółka Z Ograniczoną Odpowiedzialnością | Sposób montażu stolarki otworowej i zestaw elementów montażowych stolarki otworowej |

| FR3083258B1 (fr) | 2018-06-29 | 2020-12-25 | Afl Foessel | Ensemble pour l'installation et/ou la renovation d'une fenetre |

| FR3083257B1 (fr) | 2018-06-29 | 2020-12-25 | Afl Foessel | Ensemble comprenant un pre-cadre et un dormant de fenetre monte dans le pre-cadre |

| CN111005646A (zh) * | 2019-12-11 | 2020-04-14 | 华东建筑设计研究院有限公司 | 一种超低能耗建筑外窗结构及其施工方法 |

| EP3854975B1 (de) | 2020-01-23 | 2022-12-21 | Daw Se | Vorgefertigte umfassungszarge für eine gebäudeöffnung, wärmedämmverbundsystem, gebäudefassade und gebäude, enthaltend die umfassungszarge, und verwendung der umfassungszarge |

| WO2024130370A1 (pt) * | 2022-12-21 | 2024-06-27 | Soares Clayvert De Faria | Porta antiesmagamento, borda flexível, componente rígido, folha de porta e sistema de porta antiesmagamento |

Citations (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3119692A1 (de) † | 1981-05-18 | 1982-12-02 | Heinz Ing.(grad.) 8644 Pressig Carl | Vorfertigbares bauelement |

| EP0132779A2 (de) † | 1983-07-23 | 1985-02-13 | Hans Schlitzberger | Fensterzarge |

| DE29519675U1 (de) † | 1995-12-12 | 1996-02-01 | Endter, Walter Josef, 98529 Suhl | Bauelement |

| AT401280B (de) † | 1992-11-12 | 1996-07-25 | Kraler Franz | Verlorene schalung mit einem ersten schalungsabschnitt |

| DE29900597U1 (de) † | 1999-01-15 | 2000-06-29 | D & M Rolladentechnik GmbH, 56204 Hillscheid | Rolladenvorrichtung |

| DE19905622A1 (de) † | 1999-02-11 | 2000-08-17 | Gerd Heinrichs | Elemente zum Dämmen von Außenöffnungen, wie Fenster und Türen, die gleichzeitig auch rationelle Einbauhilfe für die Einbauteile dieser Öffnungen sind |

| DE19951901A1 (de) † | 1999-10-28 | 2001-05-03 | Bernd Beck | Bauelement |

| DE10040497C1 (de) † | 2000-08-18 | 2001-10-11 | Gutmann Hermann Werke Gmbh | Zarge für ein Fenster oder eine Tür in wärmegedämmter Ausführung |

| AT412109B (de) † | 2002-12-27 | 2004-09-27 | Kraler Franz | Verlorene schalung |

| DE202006004425U1 (de) † | 2006-03-17 | 2006-06-01 | Rehau Ag + Co. | Rahmenbaugruppe |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE2557878C3 (de) * | 1975-12-22 | 1980-02-21 | Heinrich 5400 Koblenz Schultes | Schallschutzfenster |

| FR2539801B1 (fr) * | 1983-01-20 | 1985-08-23 | Rogez Patrice | Procede de finition en particulier au niveau des ouvertures formees dans le gros oeuvre de batiments et elements prefabriques pour la mise en oeuvre de ce procede |

| DE29808250U1 (de) | 1998-05-07 | 1998-08-27 | Koch Marmorit Gmbh, 79283 Bollschweil | Vorgefertigtes Bauelement |

| EP1172495B1 (de) | 2000-07-12 | 2005-09-28 | Knauf Marmorit GmbH | Wärmedämmung für die Leibung einer Gebäudeöffnung |

| FR2822495A1 (fr) † | 2001-03-21 | 2002-09-27 | Christian Triomphe | Bloc baie integre manuportable conforme a la nouvelle reglementation thermique 2001 pret a la pose dans les elements de gros oeuvre monte a la colle |

| AT412190B (de) † | 2002-10-25 | 2004-11-25 | Fries Planung & Marketing | Stapelbarer geschirrkorb für geschirrspülmaschinen |

| DE20303405U1 (de) | 2003-03-03 | 2003-07-17 | Josef Hain GmbH & Co. KG, 83561 Ramerberg | Wärmedämmelement |

-

2008

- 2008-09-05 PL PL08425591T patent/PL2161402T3/pl unknown

- 2008-09-05 EP EP10196965.7A patent/EP2333219B2/de active Active

- 2008-09-05 DK DK08425591.8T patent/DK2161402T3/da active

- 2008-09-05 ES ES08425591T patent/ES2359661T3/es active Active

- 2008-09-05 DE DE602008004523T patent/DE602008004523D1/de active Active

- 2008-09-05 EP EP08425591.8A patent/EP2161402B2/de active Active

- 2008-09-05 SI SI200830219T patent/SI2161402T1/sl unknown

- 2008-09-05 AT AT08425591T patent/ATE495336T2/de active

-

2011

- 2011-02-17 HR HR20110118T patent/HRP20110118T1/hr unknown

Patent Citations (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3119692A1 (de) † | 1981-05-18 | 1982-12-02 | Heinz Ing.(grad.) 8644 Pressig Carl | Vorfertigbares bauelement |

| EP0132779A2 (de) † | 1983-07-23 | 1985-02-13 | Hans Schlitzberger | Fensterzarge |

| AT401280B (de) † | 1992-11-12 | 1996-07-25 | Kraler Franz | Verlorene schalung mit einem ersten schalungsabschnitt |

| DE29519675U1 (de) † | 1995-12-12 | 1996-02-01 | Endter, Walter Josef, 98529 Suhl | Bauelement |

| DE29900597U1 (de) † | 1999-01-15 | 2000-06-29 | D & M Rolladentechnik GmbH, 56204 Hillscheid | Rolladenvorrichtung |

| DE19905622A1 (de) † | 1999-02-11 | 2000-08-17 | Gerd Heinrichs | Elemente zum Dämmen von Außenöffnungen, wie Fenster und Türen, die gleichzeitig auch rationelle Einbauhilfe für die Einbauteile dieser Öffnungen sind |

| DE19951901A1 (de) † | 1999-10-28 | 2001-05-03 | Bernd Beck | Bauelement |

| DE10040497C1 (de) † | 2000-08-18 | 2001-10-11 | Gutmann Hermann Werke Gmbh | Zarge für ein Fenster oder eine Tür in wärmegedämmter Ausführung |

| AT412109B (de) † | 2002-12-27 | 2004-09-27 | Kraler Franz | Verlorene schalung |

| DE202006004425U1 (de) † | 2006-03-17 | 2006-06-01 | Rehau Ag + Co. | Rahmenbaugruppe |

Also Published As

| Publication number | Publication date |

|---|---|

| DE602008004523D1 (de) | 2011-02-24 |

| PL2161402T3 (pl) | 2011-06-30 |

| EP2333219B1 (de) | 2018-12-19 |

| EP2333219A1 (de) | 2011-06-15 |

| SI2161402T1 (sl) | 2011-05-31 |

| ATE495336T2 (de) | 2011-01-15 |

| DK2161402T3 (da) | 2011-03-14 |

| EP2161402B1 (de) | 2011-01-12 |

| EP2161402A1 (de) | 2010-03-10 |

| EP2161402B2 (de) | 2016-10-26 |

| ES2359661T3 (es) | 2011-05-25 |

| HRP20110118T1 (hr) | 2011-03-31 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2333219B2 (de) | Vorgefertigte Tür- oder Fensterrahmen-Einheit mit isolierender Randeinfassung | |

| CA2531937A1 (en) | Universal fenestration cap system and method | |

| EP2479369A1 (de) | Vorgefertigte Fensterrahmeneinheit mit isolierender Randeinfassung und integriertem Sims | |

| US20090277093A1 (en) | Component | |

| GB2228033A (en) | Method of, and strip means for, installing a window or door frame in a building | |

| JP4928371B2 (ja) | 建具周囲の排水構造 | |

| AU2007302888A1 (en) | Improved sill flashing | |

| DE29811818U1 (de) | Mehrschichtiger Wandaufbau mit Kasten für Jalousien oder Rolladen | |

| WO1989008767A1 (en) | Improvements in the installation of roller shutters | |

| CZ296197B6 (cs) | Záruben pro okno | |

| JP2001317271A (ja) | 建物外壁の開口部周辺構造 | |

| AU686700B2 (en) | Door frame and components therefor | |

| GB2363418A (en) | Profile portion including a cavity closer and a cill carrier | |

| US20070245649A1 (en) | Exterior casing trim | |

| EP1482100A3 (de) | Gebäudewandkonstruktion mit Rolladenkasten mit Wärmedämmplatten | |

| GB2191529A (en) | Window frame | |

| GB2311127A (en) | Ventilation adjacent to window or door assemblies | |

| JP3233577B2 (ja) | サッシ窓 | |

| EP1529917A2 (de) | Fenster oder Türkonstruktion und sein Einbauverfahren in einem Gebäude | |

| CH671995A5 (en) | Prefab. metal frame for window opening - has faces for connection to window frame and shutter guide, and has sloping sill and top member | |

| AU2006100147A4 (en) | Seal for through-wall opening | |

| JP2025159986A (ja) | 建具 | |

| EP2048300B1 (de) | Vorgefertigte Wand mit Fenster oder Tür | |

| GB2351313A (en) | A bay window sub-frame including a cavity closer | |

| JPH0712523Y2 (ja) | 庇 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AC | Divisional application: reference to earlier application |

Ref document number: 2161402 Country of ref document: EP Kind code of ref document: P |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MT NL NO PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA MK RS |

|

| 17P | Request for examination filed |

Effective date: 20110907 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: EXAMINATION IS IN PROGRESS |

|

| 17Q | First examination report despatched |

Effective date: 20170616 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R079 Ref document number: 602008058419 Country of ref document: DE Free format text: PREVIOUS MAIN CLASS: E06B0001320000 Ipc: E06B0001020000 |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: E06B 1/60 20060101ALI20180515BHEP Ipc: E06B 1/32 20060101ALI20180515BHEP Ipc: E06B 1/56 20060101ALI20180515BHEP Ipc: E06B 1/02 20060101AFI20180515BHEP |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| INTG | Intention to grant announced |

Effective date: 20180712 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN GRANTED |

|

| AC | Divisional application: reference to earlier application |

Ref document number: 2161402 Country of ref document: EP Kind code of ref document: P |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MT NL NO PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA MK RS |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 602008058419 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 1078905 Country of ref document: AT Kind code of ref document: T Effective date: 20190115 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: KELLER AND PARTNER PATENTANWAELTE AG, CH |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20181219 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181219 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181219 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190319 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181219 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181219 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190319 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190320 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181219 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181219 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181219 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181219 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190419 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181219 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181219 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181219 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190419 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181219 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R026 Ref document number: 602008058419 Country of ref document: DE |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| PLAX | Notice of opposition and request to file observation + time limit sent |

Free format text: ORIGINAL CODE: EPIDOSNOBS2 |

|

| 26 | Opposition filed |

Opponent name: HELLA SONNEN- UND WETTERSCHUTZTECHNIK GMBH Effective date: 20190912 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181219 |

|

| PLBB | Reply of patent proprietor to notice(s) of opposition received |

Free format text: ORIGINAL CODE: EPIDOSNOBS3 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181219 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181219 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181219 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190905 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190905 |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20190930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190930 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20190905 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PFA Owner name: SUEDTIROL FENSTER S.R.L., IT Free format text: FORMER OWNER: SUEDTIROL FENSTER S.R.L., IT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190905 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181219 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20080905 Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181219 |

|

| PLAB | Opposition data, opponent's data or that of the opponent's representative modified |

Free format text: ORIGINAL CODE: 0009299OPPO |

|

| APBM | Appeal reference recorded |

Free format text: ORIGINAL CODE: EPIDOSNREFNO |

|

| APBP | Date of receipt of notice of appeal recorded |

Free format text: ORIGINAL CODE: EPIDOSNNOA2O |

|

| APAH | Appeal reference modified |

Free format text: ORIGINAL CODE: EPIDOSCREFNO |

|

| R26 | Opposition filed (corrected) |

Opponent name: HELLA SONNEN- UND WETTERSCHUTZTECHNIK GMBH Effective date: 20190912 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: UEP Ref document number: 1078905 Country of ref document: AT Kind code of ref document: T Effective date: 20181219 |

|

| APBQ | Date of receipt of statement of grounds of appeal recorded |

Free format text: ORIGINAL CODE: EPIDOSNNOA3O |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20220928 Year of fee payment: 15 |

|

| APAH | Appeal reference modified |

Free format text: ORIGINAL CODE: EPIDOSCREFNO |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20230930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20230930 |

|

| APBU | Appeal procedure closed |

Free format text: ORIGINAL CODE: EPIDOSNNOA9O |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20240911 Year of fee payment: 17 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20240917 Year of fee payment: 17 |

|

| PUAH | Patent maintained in amended form |

Free format text: ORIGINAL CODE: 0009272 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: PATENT MAINTAINED AS AMENDED |

|

| 27A | Patent maintained in amended form |

Effective date: 20241211 |

|

| AK | Designated contracting states |

Kind code of ref document: B2 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MT NL NO PL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R102 Ref document number: 602008058419 Country of ref document: DE |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20250704 Year of fee payment: 18 |