EP2296520B2 - Dosiersystem für eine geschirrspülmaschine - Google Patents

Dosiersystem für eine geschirrspülmaschine Download PDFInfo

- Publication number

- EP2296520B2 EP2296520B2 EP09777177.8A EP09777177A EP2296520B2 EP 2296520 B2 EP2296520 B2 EP 2296520B2 EP 09777177 A EP09777177 A EP 09777177A EP 2296520 B2 EP2296520 B2 EP 2296520B2

- Authority

- EP

- European Patent Office

- Prior art keywords

- cartridge

- dosing

- dosing device

- chamber

- dishwasher

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47L—DOMESTIC WASHING OR CLEANING; SUCTION CLEANERS IN GENERAL

- A47L15/00—Washing or rinsing machines for crockery or tableware

- A47L15/42—Details

- A47L15/44—Devices for adding cleaning agents; Devices for dispensing cleaning agents, rinsing aids or deodorants

- A47L15/4463—Multi-dose dispensing arrangements

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47L—DOMESTIC WASHING OR CLEANING; SUCTION CLEANERS IN GENERAL

- A47L15/00—Washing or rinsing machines for crockery or tableware

- A47L15/42—Details

- A47L15/44—Devices for adding cleaning agents; Devices for dispensing cleaning agents, rinsing aids or deodorants

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47L—DOMESTIC WASHING OR CLEANING; SUCTION CLEANERS IN GENERAL

- A47L15/00—Washing or rinsing machines for crockery or tableware

- A47L15/0018—Controlling processes, i.e. processes to control the operation of the machine characterised by the purpose or target of the control

- A47L15/006—Controlling processes, i.e. processes to control the operation of the machine characterised by the purpose or target of the control using wireless communication between internal components of the machine

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47L—DOMESTIC WASHING OR CLEANING; SUCTION CLEANERS IN GENERAL

- A47L15/00—Washing or rinsing machines for crockery or tableware

- A47L15/42—Details

- A47L15/44—Devices for adding cleaning agents; Devices for dispensing cleaning agents, rinsing aids or deodorants

- A47L15/4445—Detachable devices

- A47L15/4454—Detachable devices with automatic identification means, e.g. barcodes, RFID tags or magnetic strips

Definitions

- the invention relates to a dosing system, a combination dosing device for dispensing a plurality of preparations for use in dishwashers, and a dishwasher.

- Dishwashing detergents are available to the consumer in a large number of supply forms.

- automatic dishwashing detergents in particular are of great importance with the spread of household dishwashers.

- These machine dishwashing detergents are typically offered to the consumer in solid form, for example as a powder or as tablets, but increasingly also in liquid form.

- the main focus has been on the convenient dosing of cleaning agents and the simplification of the work steps required to carry out a cleaning process.

- one of the main goals of the manufacturers of mechanical cleaning agents is to improve the cleaning performance of these agents, with increased attention being paid recently to the cleaning performance in low-temperature cleaning cycles or in cleaning cycles with reduced water consumption.

- new ingredients such as more effective surfactants, polymers, enzymes or bleaches, were preferably added to the cleaning agents.

- new ingredients are only available to a limited extent and the amount of ingredients used per cleaning cycle cannot be increased to any desired extent for ecological and economic reasons, there are natural limits to this approach.

- WO 02/29150 A1 discloses a self-sufficient dosing device for a dishwasher that can be coupled to a cartridge.

- the metering device includes a sensor unit and a control unit.

- DE 10 2006 043916 A1 describes an actuator, a closure element, and a dosing chamber with an inlet opening and an outlet opening for a water-bearing household appliance.

- the object of the invention is to provide an improved dosing system according to claim 1, 2 or 3, a combination dosing device according to claim 4, and a dishwasher according to claim 5.

- the dosing system consists of the basic components of a cartridge and a dosing device that can be coupled to the cartridge, which in turn is formed from other assemblies such as component carriers, actuators, closure elements, sensors, energy sources and/or control units.

- the dosing system according to the invention is movable. Movable within the meaning of this application means that the dosing system is not permanently connected to a dishwasher, but can be removed from a dishwasher by the user or positioned in a dishwasher, ie can be handled independently

- the dosing device is not detachably connected to a dishwasher for the user and only the cartridge is movable.

- the dosing system can be formed from materials that are dimensionally stable up to a temperature of 120°C.

- the preparations to be dosed can have a pH of between 2 and 12, depending on the intended use, all components of the dosing system that come into contact with the preparations should have an appropriate acid and/or alkali resistance. Furthermore, these components should be largely chemically inert, for example to nonionic surfactants, enzymes and/or fragrances, by selecting a suitable material.

- a cartridge in the context of this application is understood to mean a packaging means which is suitable for enclosing or holding together at least one free-flowing, pourable or spreadable preparation and which can be coupled to a dosing device for dispensing at least one preparation.

- the cartridge has a preferably dimensionally stable chamber for storing a preparation.

- a cartridge can also comprise a plurality of chambers which can be filled with compositions that differ from one another.

- the cartridge prefferably has at least one outlet opening which is arranged in such a way that the preparation can be released from the cartridge by gravity when the dosing device is in the position of use.

- no further means of conveyance are required for releasing preparation from the cartridge, as a result of which the structure of the dosing device can be kept simple and the production costs can be kept low.

- the use of funding, such as pumps, can be omitted, which can increase the service life of a battery or accumulators of the dosing device.

- At least one second chamber is provided for receiving at least one second free-flowing or spreadable preparation, the second chamber having at least one outlet opening which is arranged in such a way that the product is released from the second chamber by gravity when the dosing device is in the position of use can be effected.

- the arrangement of a second chamber is particularly advantageous when preparations are stored in the mutually separate chambers of the cartridge which are usually not storable together, such as bleaches and enzymes.

- one of the chambers can be designed to release volatile preparations, such as a fragrance, to the environment.

- the cartridge is designed in one piece.

- the cartridges can be formed cost-effectively in one production step, in particular by means of suitable blow molding processes.

- the chambers of a cartridge can be separated from one another, for example, by webs or material bridges that are formed during or after the blow molding process.

- the cartridge can also be formed in several pieces by components that are produced by injection molding and then joined together.

- the cartridge is formed in several pieces in such a way that at least one chamber, preferably all chambers, can be individually removed from the dosing device or inserted into the dosing device.

- at least one chamber preferably all chambers

- the cartridge is formed in several pieces in such a way that at least one chamber, preferably all chambers, can be individually removed from the dosing device or inserted into the dosing device.

- the individual chambers in such a way that the chambers can only be coupled to one another or to the dosing device in a specific location or position, thereby preventing a user from using a chamber in a position that is not intended for this purpose connects to the dosing device.

- the chamber walls can in particular be shaped in such a way that they can be connected to one another in a form-fitting manner. It is particularly advantageous, in the case of a cartridge formed from at least three chambers, to shape the cartridges in such a way that the chambers can only be positively connected to one another in a certain defined position.

- the chambers of a cartridge can be fixed to one another by suitable connection methods, so that a container unit is formed.

- the chambers can be fixed to one another in a detachable or non-detachable manner by means of a suitable positive, non-positive or material connection.

- the fixation can be done by one or more of the connection types from the group of snap-in connections, Velcro connections, press connections, fusion connections, adhesive connections, welded connections, soldered connections, screw connections, wedge connections, clamp connections or snap connections.

- the fixation can also be formed by a shrink tube (so-called sleeve), which is pulled over the whole or sections of the cartridge in a heated state and firmly encloses the chambers or the cartridge in the cooled state.

- the bottom of the chambers can be inclined in a funnel shape towards the discharge opening.

- the inner wall of a chamber can be designed by selecting a suitable material and/or surface design in such a way that a low level of material adhesion of the preparation to the inner chamber wall is achieved. This measure also allows the remaining emptying of a chamber to be further optimized.

- the cartridge can also be designed asymmetrically. It is particularly preferred to shape the asymmetry of the cartridge in such a way that the cartridge can only be coupled to the dosing device in a predefined position, which prevents incorrect operation by the user that would otherwise be possible.

- a dosing chamber can be in or on one chamber, in the flow direction of the preparation caused by gravity the outlet opening of a chamber.

- the amount of preparation that is to be released into the environment when the preparation is released from the chamber is determined by the dosing chamber. This is particularly advantageous when the closure element of the dosing device, which causes the preparation to be released from a chamber to the environment, can only be put into a release and a closed state without measuring or checking the amount released.

- the dosing chamber then ensures that a predefined amount of preparation is released without immediate feedback of the currently dispensed, outflowing amount of preparation.

- the dosing chambers can be formed in one piece or in several pieces. Furthermore, it is possible to design the dosing chambers to be permanently connected to the cartridge or to be detachable. With a dosing chamber that is detachably connected to the cartridge, it is possible in a simple manner to connect dosing chambers with dosing volumes that differ from one another to a cartridge or to exchange them, which means that the dosing volumes can be easily adapted to the preparation stored in a chamber and thus simple packaging of the cartridge for different preparations and their dosage is possible.

- one or more chambers have a liquid-tight sealable, preferably head-side, second chamber opening in addition to a preferably bottom-side outlet opening.

- This chamber opening makes it possible, for example, to refill the preparation stored in this chamber.

- ventilation options can be provided in particular in the head area of the cartridge in order to ensure pressure equalization between the inside of the cartridge chambers and the environment when the filling level of the chambers falls.

- These ventilation options can be designed, for example, as a valve, in particular a silicone valve, micro-openings in a chamber or cartridge wall, or the like.

- the cartridge chambers are not ventilated directly, but rather via the dosing device or no ventilation, e.g. when using flexible containers such as bags, this has the advantage that at elevated temperatures during a washing cycle of a dishwasher by heating the contents of the chamber, a pressure is built up, which presses the preparations to be dosed in the direction of the outlet openings, so that the cartridge can be easily emptied of residues. Furthermore, with such air-free packaging there is no risk of substances in the preparation oxidizing, which makes pouch packaging or bag-in-bottle packaging appear expedient, particularly for preparations which are sensitive to oxidation.

- the volume ratio formed from the construction volume of the dosing device and the filling volume of the cartridge is preferably ⁇ 1, particularly preferably ⁇ 0.1, particularly preferably ⁇ 0.05. In this way it is achieved that with a given overall construction volume of dosing device and cartridge, the majority of the construction volume is occupied by the cartridge and the preparation contained therein.

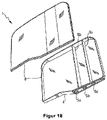

- the cartridge can assume any shape. It can, for example, be cube-like, spherical or plate-like.

- the cartridge and the dosing device can in particular be designed with regard to their three-dimensional shape in such a way that they ensure the lowest possible loss of useful volume, in particular in a dishwasher.

- the dosing device In order to use the dosing device in dishwashers, it is particularly advantageous to shape the device based on dishes to be cleaned in dishwashers. For example, this can be plate-shaped, approximately the dimensions of a plate. This allows the dosing device to be positioned in a space-saving manner, e.g. in the lower basket of the dishwasher. Furthermore, the correct positioning of the dosing unit is immediately intuitive to the user due to the plate-like shape.

- the dosing device and the cartridge When coupled to one another, the dosing device and the cartridge preferably have a height:width:depth ratio of between 5:5:1 and 50:50:1, particularly preferably approximately 10:10:1.

- the "slim" design of the dosing device and the cartridge makes it possible in particular to position the device in the lower cutlery basket of a dishwasher in the receptacles provided for plates. This has the advantage that the preparations dispensed from the dosing device get directly into the wash liquor and cannot adhere to other items to be washed.

- the dosing system is dimensioned such that the dosing system can only be positioned in the receptacles provided for this purpose of the lower basket is allowed.

- the width and the height of the dosing system can be selected in particular between 150 mm and 300 mm, particularly preferably between 175 mm and 250 mm.

- the dosing unit in the form of a cup or pot with a substantially circular or square base.

- the outlet openings of a cartridge are preferably arranged in a line, as a result of which a slim, plate-shaped design of the dosing device is made possible.

- the cartridge In order to provide an immediate visual fill level check, it is advantageous to form the cartridge, at least in sections, from a transparent material.

- a further possibility for reducing the influence of heat on a preparation in a chamber of the cartridge is to isolate the chamber by suitable measures, e.g. by using thermal insulation materials such as Styrofoam, which completely or partially enclose the chamber or the cartridge in a suitable manner.

- a further measure for protecting heat-sensitive substances in a cartridge is, in the case of a plurality of chambers, their mutual arrangement.

- the chamber containing a heat-sensitive product is partially or completely enclosed by at least one other chamber filled with a product, with this product and this chamber acting as thermal insulation for the enclosed chamber in this configuration.

- a first chamber, which contains a heat-sensitive product is partially or completely surrounded by at least one other chamber filled with a product, so that the heat-sensitive product in the first chamber has a slower temperature rise when the environment heats up than the products in the surrounding chambers.

- the chambers can be arranged one around the other according to the Matryoshka principle, so that a multi-layer insulation layer is formed.

- At least one preparation which is stored in an enclosing chamber, has a thermal conductivity of between 0.01 and 5 W/m*K, preferably between 0.02 and 2 W/m*k, particularly preferably between 0.024 and 1 W/m*K.

- the cartridge is in particular designed to be dimensionally stable.

- the cartridge is also conceivable to design the cartridge as a flexible packaging material such as a tube.

- flexible containers such as bags, in particular if they are used in accordance with the "bag-in-bottle" principle in a substantially dimensionally stable receiving container.

- the use of flexible packaging eliminates the need to provide a ventilation system for pressure equalization--unlike in the case of the dimensionally stable cartridge configurations described at the outset.

- the cartridge has an RFID label that contains at least information about the content of the cartridge and that can be read by a sensor unit that can be provided in particular in the dosing device or dishwasher.

- This information can be used, for example, to select a dosing program stored in the control unit of the dosing device. This can ensure that a dosing program that is optimal for a specific preparation is always used. It can also be provided that in the absence of an RFID label or in the case of an RFID label with an incorrect or faulty identifier, no dosing takes place through the dosing device and instead an optical or acoustic signal is generated that alerts the user to the present error indicates.

- the cartridges can also have structural elements which interact with corresponding elements of the dispensing device according to the lock and key principle, so that, for example, only cartridges of a specific type can be coupled to the dispensing device. Furthermore, this configuration makes it possible for information about the cartridge coupled to the dosing device to be transmitted to the control unit of the dosing device, as a result of which the dosing device can be controlled in a way that is tailored to the content of the corresponding container.

- the cartridge is designed in particular to hold free-flowing cleaning agents.

- a cartridge particularly preferably has a plurality of chambers for the spatially separated reception of different preparations of a cleaning agent.

- Some possible combinations of filling the chambers with different preparations are listed below as an example - but not exhaustively: chamber 1 chamber 2 chamber 3 chamber 4 A Alkaline cleaning preparation Enzymatic cleaning preparation - - B Alkaline cleaning preparation Enzymatic cleaning preparation rinse aid - C Alkaline cleaning preparation Enzymatic cleaning preparation rinse aid perfume D Alkaline cleaning preparation Enzymatic cleaning preparation rinse aid disinfectant preparation E Alkaline cleaning preparation Enzymatic cleaning preparation rinse aid pre-treatment preparation

- all preparations are flowable, as this ensures that the preparations dissolve quickly in the washing liquor of the dishwasher, giving these preparations a rapid to immediate cleaning or rinsing effect, especially on the walls of the washing cabinet and / or a achieve light guide of the cartridge and/or the dosing device.

- the cartridge usually has a total filling volume of ⁇ 5000 ml, in particular ⁇ 1000 ml, preferably ⁇ 500 ml, particularly preferably ⁇ 250 ml, very particularly preferably ⁇ 50 ml.

- the chambers of a cartridge can have the same or different filling volumes.

- the ratio of the chamber volumes is preferably 5:1, in a configuration with three chambers it is preferably 4:1:1, these configurations being particularly suitable for use in dishwashers.

- the cartridge preferably has three chambers.

- one chamber contains an alkaline cleaning preparation

- another chamber contains an enzymatic preparation

- a third chamber contains a rinse aid, with the volume ratio of the chambers being approximately 4:1:1.

- the chamber containing the alkaline cleaning preparation preferably has the largest filling volume of the existing chambers.

- the chambers that store an enzymatic preparation or a rinse aid preferably have approximately the same filling volumes.

- the cartridge With a two- and/or three-chamber design of the cartridge, it is possible in particular to store a fragrance, disinfection and/or pretreatment preparation in a further chamber that is detachably arranged on the cartridge or on the dosing device.

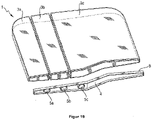

- the cartridge comprises a cartridge base which, in the position of use, is directed downwards in the direction of gravity and on which at least one outlet opening arranged on the base in the direction of gravity is preferably provided for each chamber.

- the outlet openings arranged on the bottom are designed in particular in such a way that at least one, preferably all outlet openings can be connected in a communicating manner with the inlet openings of the dosing device, i.e. preparation can flow from the cartridge into the dosing device via the outlet openings, preferably under the effect of gravity.

- one or more chambers have an outlet opening that is not arranged on the bottom side in the direction of gravity. This is particularly advantageous if, for example, a fragrance is to be released into the surroundings of the cartridge.

- the cartridge is preferably formed from at least two elements which are materially connected to one another, with the connecting edge of the elements running on the cartridge base outside the outlet openings, ie the connecting edge does not intersect the outlet openings. This is particularly advantageous since this avoids problems with sealing when coupling to the dosing device in the area of the outlet openings, which occur in particular with the high thermal cycling stresses that usually occur in a dishwasher.

- the material connection can be produced, for example, by gluing, welding, soldering, pressing or vulcanizing.

- a metallic heating mirror which contains the contour of the interfaces to be connected, heats the interfaces and briefly puts them in the plastic state, so that after removing the heating mirror and assembling the parts, these plastic areas solidify again as a melt and form a solid one connect.

- individually injection-moulded parts for example, be connected to each other by means of laser welding.

- laser welding one of the two materials that is to be melted at the interface must carry an absorbent in order to absorb the energy content of the laser beam and convert it into heat, which then causes the corresponding material area to melt. This is typically achieved with color pigments that thermally interact with the laser beam directed into the material.

- boundary surfaces to be joined can also be covered if the material in front of them in the direction of incidence of the laser beam is transparent to the laser beam and has no absorption properties.

- the joining edge runs along the top, bottom and side faces of the cartridge.

- two cartridge elements can be produced, in particular by injection molding, with either both elements being trough-shaped or one element being trough-shaped and the second element being cover-like.

- At least one of the two cartridge elements can comprise at least one separating web which separates two adjacent chambers of the cartridge from one another when the elements are in the assembled state.

- one cartridge element is a cup-like container with at least one chamber and the second element is the cartridge base or head, which is connected to the cup-like container in a liquid-tight manner along the connecting edge.

- such a further chamber for receiving a preparation can be arranged on the cartridge and configured in such a way that volatile substances such as fragrances are released from the preparation into the environment of the chamber.

- the outlet openings of the cartridge are closed by closure means at least when the cartridge is in the filled, unopened state.

- the closure means can be designed in such a way that they allow the outlet opening to be opened once by destroying the closure means.

- closure means are, for example, sealing foils or closure caps.

- the outlet openings are each provided with a closure which allows preparation to flow out of the respective chambers when coupled to a dosing device and essentially prevents preparation from flowing out when the cartridge is uncoupled.

- a closure is designed as a slotted silicone valve.

- the ventilation openings of the cartridge are closed with a closure element before a first coupling with the dosing device.

- the closure element can in particular be a stopper or a cap which is opened, for example pierced, by the coupling process when it is first coupled to the dosing device.

- the cartridge elements forming the cartridge are preferably made of a plastic and can be molded in a common injection molding process, it being advantageous to mold a connecting web acting as a hinge between the two elements, so that after molding the two elements rest against one another by folding over and are connected in a materially bonded manner along the connecting edge.

- an energy source in particular a battery or accumulator, is arranged on or in the cartridge, preferably on or in the bottom of the cartridge. Furthermore, means for electrically coupling the energy source to the dosing device can be provided on the cartridge.

- the cartridge has at least one chamber for storing at least one free-flowing or pourable cleaning agent preparation for coupling to a dosing device that can be positioned inside a household appliance for dispensing at least one cleaning agent preparation, the cartridge being coupled to the dosing device state is protected against the entry of rinsing water into the chamber(s) and the cartridge comprises at least one discharge opening on the bottom in the direction of gravity for - in particular under the effect of gravity - dispensing of preparation from at least one chamber and at least one ventilation opening on the bottom in the direction of gravity for ventilation of at least one chamber, wherein the Ventilation opening is separated from the discharge opening and the ventilation opening communicating with at least one chamber of cartridge is connected.

- the cartridge comprises at least two chambers, very particularly preferably at least three chambers. It is advantageous here that a ventilation opening and a discharge opening are provided for each chamber.

- the bottom ventilation opening communicates with a ventilation channel whose end facing away from the ventilation opening opens out above the maximum fill level of the cartridge in the dispensing position of the cartridge coupled to the dosing device.

- the ventilation channel it is advantageous for the ventilation channel to be formed entirely or partially in or on the walls and/or webs of the cartridge.

- the ventilation channel can be formed integrally in or on the walls and/or webs of the cartridge.

- the ventilation duct can advantageously be formed by joining at least two elements forming the cartridge.

- a ventilation channel can be formed by joining a separating web of the cartridge, formed in the shell-shaped element, to two webs enclosing the separating web and arranged on the cartridge element.

- the ventilation duct is formed by cohesive joining, in particular by welding, of a separating web of the cartridge formed in the shell-shaped element with two webs enclosing the separating web and arranged on the cartridge element.

- the ventilation channel can also be used as a so-called Be trained dip tube.

- the filling level (F) of the cartridge in the unopened, filled state of the cartridge is at an inclination of up to 45 ° not present at the ventilation duct mouth (83).

- the ventilation channel mouth approximately in the middle on or in the chamber wall of the cartridge head.

- the viscosity of a free-flowing preparation and the ventilation channel are configured in such a way that the preparation is not drawn into the ventilation channel by capillary forces when the preparation is on the Ventilation duct mouth pending.

- the coupling of the cartridge to the dosing device should advantageously be designed in such a way that a mandrel is arranged on the dosing device, which is connected to the inlet opening of the dosing device and communicates with the connectable cartridge or cartridge chamber in such a way that when the ventilation opening of the cartridge or In the cartridge chamber with the dosing device, the mandrel displaces a volume ⁇ v in the ventilation duct, as a result of which a pressure ⁇ p is generated in the ventilation duct which is suitable for conveying the flowable preparation located in the ventilation duct into the chamber connected to the ventilation duct and storing the preparation.

- the ventilation opening of a chamber is connected in communication with the dosing device-side mandrel before the closed outlet opening of the corresponding chamber is opened, for example by communicating with the inlet opening of the dosing device.

- a ventilation chamber is arranged between the ventilation opening and the ventilation channel.

- the cartridge can be designed in such a way that it can be arranged detachably or permanently in or on the dosing device and/or a dishwasher.

- the dosing device for dispensing at least one free-flowing cleaning agent preparation into the interior of a household appliance comprises a cartridge that can be coupled to the dosing device, the cartridge storing at least one free-flowing cleaning agent preparation and the cartridge having at least one outlet opening on the bottom in the direction of gravity, which coupled to the dosing device, is connected in a communicating manner to an inlet opening of the dosing device, with the dosing device and the cartridge having means which interact in such a way that a releasable latching between the dosing device and the cartridge can be produced, with the dosing device and the cartridge being rotated relative to one another in the latched state pivot at a pivot point (SP), and that the outlet port of the cartridge and the inlet port of the dosing console are configured such that, after the cartridge and D dispensing device are connected in a communicating manner by pivoting the cartridge into the coupling state between dispensing console and cartridge.

- SP pivot point

- outlet openings of the chambers and the inlet openings of the dosing device are arranged and configured in such a way that they are sequentially connected to one another by pivoting in the latched state into the coupling state of dosing device and cartridge.

- the dosing device and/or the cartridge can have means which cause the cartridge to be detachably fixed to the dosing device when the dosing device and cartridge are coupled.

- This can be realized, for example, by a collar running on the bottom side of the cartridge, which is set back slightly compared to a corresponding collar on the dosing device side, so that it is guided on the cartridge-side collar inside the collar on the dosing device side.

- the outlet openings of the chambers are arranged one behind the other in the pivoting direction. It is particularly preferred that the outlet openings of the chambers are arranged on a line (L) in the pivoting direction.

- outlet openings of the chambers have approximately the same distance from one another.

- the greatest distance between an outlet opening of a chamber and the pivot point (SP) of the cartridge corresponds to approximately 0.5 times the distance of the cartridge width (B).

- At least two chambers of the cartridge can have different volumes from one another.

- the chamber of the cartridge with the greatest volume is at the greatest distance from the pivot point (SP) of the cartridge 1.

- the ventilation opening of a chamber lies in front of an outlet opening of the chamber in the pivoting direction when the cartridge is coupled to the dosing device.

- the ratio of the depth (T) of the cartridge to the width (B) of the cartridge is preferably approximately 1:20.

- the ratio of the height (H) of the cartridge to the width (B) of the cartridge is preferably approximately 1:1.2.

- the ventilation opening of a chamber lies in front of an outlet opening of the chamber in the pivoting direction when the cartridge is coupled to the dosing device. This ensures that the ventilation opening of the cartridge is opened first before the outlet opening of the cartridge is opened when the cartridge is coupled to the dosing device.

- the cartridge for coupling to a dosing device for dispensing at least one cleaning agent preparation from the cartridge into the interior of a household appliance comprises a light guide arranged in or on the cartridge, into which a light signal from outside the cartridge can be coupled. It is particularly preferred to couple a light signal, which is emitted from the dosing device, into the cartridge.

- the light guide can be formed entirely or partially in or on the walls and/or webs of the cartridge.

- the light guide integrally in or on the walls and/or webs of the cartridge.

- the light guide preferably consists of a transparent plastic material. However, it is also possible to form the entire cartridge from a transparent material.

- the light guide is capable of guiding light in the visible range (380-780 nm). It is particularly preferable that the light guide is capable of conducting light in the near infrared range (780nm-3000nm). In particular, it is preferred that the light guide is capable of conducting light in the mid-infrared range (3.0 ⁇ m-50 ⁇ m).

- the light guide consists of a transparent plastic material with a high refractive index.

- the light guide is advantageously completely or partially enclosed, at least in sections, by a material with a lower optical refractive index.

- the material with the lower optical refractive index can be a preparation stored in a chamber of the cartridge.

- the refractive index of the light guide can be determined according to DIN EN ISO 489, for example.

- the refractive index of the preparation can be determined using an Abbe refractometer according to DIN 53491.

- the preparation that completely or partially encloses the light guide has a transmittance of 45%-95%, particularly preferably 60%-90%, very particularly preferably 75%-85%.

- the light guide preferably has a transmittance of >75%, very particularly preferably >85%.

- the transmittance can be determined according to DIN5036.

- the wavelength of the light that is sent through the light guide corresponds approximately to the wavelength of at least one preparation that encloses the light guide at least in sections, which is not absorbed by the preparation from the visible spectrum.

- the wavelength of the light that is transmitted through the light guide and the wavelength that is not absorbed by the preparation is between 600-800 nm.

- the light signal that can be coupled into the light guide is, in particular, a carrier of information, in particular, for example, with regard to the operating state of the dosing device and/or the filling level of the cartridge.

- the light guide is designed in such a way that the light signal that can be coupled into the light guide can also be coupled out of the light guide again.

- the light guide can be designed in such a way that the light signal can be coupled out at a point on the cartridge which is different from the point at which the light signal can be coupled into the cartridge.

- the coupling and decoupling of the light signal can be realized in particular on a prismatic edge of the cartridge.

- the distance between the light source arranged in the dosing device, in particular an LED, and the point at which the light is coupled into the cartridge when the cartridge and dosing device are coupled should be kept as small as possible.

- the light signal and the light guide are configured in such a way that a light signal visible to a user can be generated on and/or in the cartridge.

- the light guide can be severed at at least one point in the cartridge in such a way that the preparation can fill the point of separation.

- a fill level and/or inclination sensor can be implemented in a simple manner, with a light signal that passes through the separation point without preparation being different from the light signal that passes through the separation point that is completely or partially filled with preparation.

- control unit required for operation and at least one actuator are integrated in the dosing device.

- a sensor unit and/or an energy source is also preferably arranged on or in the dosing device.

- the dosing device consists of a splash-proof housing that prevents the ingress of splashing water, such as can occur when used in a dishwasher, into the interior of the dosing device, in which at least the control unit, sensor unit and/or actuator are arranged.

- the dosing device is essentially watertight, ie the dosing device is functional even when it is completely surrounded by liquid.

- multi-component epoxy and acrylate casting compounds such as methacrylate esters, urethane-metha and cyanoacrylates or two-component materials with polyurethanes, silicones, epoxy resins can be used as casting materials.

- the material from which the dosing device is formed prevents or at least reduces the growth of a biofilm.

- additives such as biocides, for example, can be used for this purpose.

- areas of the dosing device that are at risk of microbial growth, in particular areas where rinsing water can accumulate to be partially equipped with a material that prevents or at least reduces the growth of a biofilm.

- correspondingly acting foils can also be used.

- the dosing device comprises at least one first interface, which interacts in or on a household appliance, in particular a corresponding interface configured in a dishwasher, in such a way that electrical energy and/or signals are transmitted from the household appliance to the dosing device and/or from the Dosing device is realized for household appliance.

- the interfaces are formed by plug connectors.

- the interfaces can be designed in such a way that wireless transmission of electrical energy and/or electrical and/or optical signals is effected.

- the interfaces provided for the transmission of electrical energy are inductive transmitters or receivers of electromagnetic waves.

- the interface of a dishwasher can be designed as a transmitter coil with an iron core operated with alternating current, and the interface of the dosing device can be designed as a receiver coil with an iron core.

- the transmission of electrical energy can also be provided by means of an interface which comprises an electrically operated light source on the household appliance side and a light sensor, for example a photodiode or a solar cell, on the dosing device side.

- a light sensor for example a photodiode or a solar cell

- the light emitted by the light source is converted by the light sensor into electrical energy, which in turn feeds, for example, an accumulator on the dosing device.

- an interface on the dosing device and the water-carrying device, such as a dishwasher for the transmission (i.e. sending and receiving) of electromagnetic and/or optical signals, which in particular contain operating status, measurement and/or control information of the dosing device and/or represent the water-carrying device such as a dishwasher.

- such an interface can be designed in such a way that wireless transmission of electrical energy and/or electromagnetic and/or optical signals is effected.

- At least one interface is configured to transmit and/or receive optical signals in the wavelength range between 600-800 nm. Since darkness usually prevails inside the washing compartment when a dishwasher is in operation, signals in the visible, optical range, for example in the form of signal pulses or flashes of light, can be emitted and/or detected by the dosing device. It has proven particularly advantageous to use wavelengths between 600-800 nm in the visible spectrum.

- the interface includes at least one LED.

- the interface particularly preferably comprises at least two LEDs. It is also possible according to a further preferred embodiment of the invention to provide at least two LEDs which emit light at different wavelengths. This makes it possible, for example, to define different signal bands on which information can be sent or received.

- At least one LED is an RGB LED whose wavelength can be adjusted.

- one LED can be used to define different signal bands that emit signals on different wavelengths. It is also conceivable, for example, for light to be emitted at a different wavelength during the drying process, during which there is high humidity (mist) in the washing area, than during a washing step, for example.

- the interface of the dosing device can be configured so that the LED is provided both for emitting signals inside the dishwasher, especially when the dishwasher door is closed, and for optically displaying an operating state of the dosing device, especially when the dishwasher door is open.

- the interface of the dosing device is configured such that it emits an optical signal when the dishwasher is closed and unloaded, that an average illuminance E between 0.01 and 100 lux, preferably between 0.1 and 50 lux measured at the walls delimiting the washing chamber.

- This illuminance is then sufficient to bring about multiple reflections with or on the other washing chamber walls and thus to reduce or prevent possible signal shadows in the washing chamber, in particular when the dishwasher is loaded.

- the signal transmitted and/or received by the interface is in particular a carrier of information, in particular a control signal or a signal that represents an operating state of the dosing device and/or the dishwasher.

- the dosing device for dispensing at least one detergent and/or cleaning agent preparation from a cartridge into the interior of a household appliance has a light source, by means of which a light signal can be coupled into a light guide of the cartridge.

- the light source can be an LED.

- the dosing device can be optically hidden between other items to be washed in the position of use in the plate holder of a dish drawer in a dishwasher.

- the corresponding light signals can also be guided into the head area of the cartridge, for example, so that the light signals can be seen by the user even if the dosing device is positioned in the plate holder between other items to be washed, since when the dish drawer is properly loaded, the area at the top of the items to be washed and the cartridge usually remains uncovered.

- the light signal coupled into the light guide of the cartridge and passing through the light guide is also possible for the light signal coupled into the light guide of the cartridge and passing through the light guide to be detectable by a sensor located on the dosing device. This is explained in more detail in a subsequent section.

- the dosing device for dispensing at least one detergent and/or cleaning agent preparation into the interior of a household appliance comprises at least one optical transmitter unit, the optical transmitter unit being configured in such a way that signals from the transmitter unit are converted into a system that can be coupled to the dosing device Cartridge can be coupled and signals from the transmitter unit can be radiated into the environment of the dosing device.

- both a signal transmission between the dosing device and, for example, a household appliance such as a dishwasher and the signal entry into a cartridge can be realized by means of an optical transmission unit.

- the optical transmission unit can be an LED, which preferably emits light in the visible and/or IR range. It is also conceivable to use another suitable optical transmission unit, such as a laser diode. An optical transmission unit is to be used that emits light in the wavelength range between 600-800nm.

- the dosing device can include at least one optical receiving unit.

- This makes it possible, for example, for the dosing device to be able to receive signals from an optical transmission unit arranged in the household appliance.

- This can be implemented by any suitable optical receiving unit, such as photocells, photomultipliers, semiconductor detectors, photodiodes, photoresistors, solar cells, phototransistors, CCD and/or CMOS image sensors.

- the optical receiving unit is suitable for receiving light in the wavelength range of 600-800nm.

- the optical receiving unit on the dosing device can also be designed such that the signals that can be coupled from the transmitting unit into a cartridge coupled to the dosing device can be decoupled from the cartridge and can be detected by the optical receiving unit of the dosing device.

- the signals transmitted by the transmitter unit into the surroundings of the dosing device can preferably represent information regarding operating states or control commands.

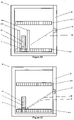

- the dosing device for dispensing at least one free-flowing detergent and/or cleaning agent preparation into the interior of a household appliance can, in particular, have a dosing chamber, the cartridge that can be coupled to the dosing device is connected in a communicating manner to a dosing chamber inlet located in the dosing device, so that when the dosing device is in the position of use, the preparation is released by the force of gravity of the cartridge flows into the dosing chamber, with a dosing chamber outlet following the dosing chamber inlet in the direction of gravity being arranged, which can be closed by a valve, with a floating body being arranged in the dosing chamber, the density of which is lower than the density of the preparation, the floating body being designed in this way that preparation can flow around and/or through the floating body and the floating body and the metering chamber inlet are configured in such a way that the metering chamber inlet can be closed by the floating body.

- the floating body can close the dosing chamber inlet in a sealing or non-sealing manner.

- the floating body rests against the dosing chamber inlet, but does not seal it against the inflow of preparation from the cartridge, so that an exchange of preparation between the cartridge and the dosing chamber is possible.

- the float body acts as a targeted throttle, which minimizes the slippage between the dosing chamber inlet and dosing chamber outlet when the valve opens and thus also determines the dosing accuracy.

- the floating body and the dosing chamber can be designed as a self-closing valve, on the one hand in order to achieve the lowest possible energy consumption in an energy self-sufficient dosing device; on the other hand, a defined amount of preparation, which roughly corresponds to the filling volume of the dosing chamber, is released.

- the floating body has a rate of rise of 1.5 mm/sec to 25 mm/sec, preferably 2 mm/sec to 20 mm/sec. sec, particularly preferably 2.5 mm/sec to 17.5 mm/sec in the detergent and/or cleaning agent preparation. This ensures that the dosing chamber inlet is closed sufficiently quickly by the rising floating body and thus that the interval between two doses of preparation is sufficiently short.

- the rising speed of the floating body can advantageously also be stored in the control unit of the dosing device that actuates the valve. This makes it possible to also switch the valve in such a way that a delivery of preparation greater than the volume of the dosing chamber is realized.

- the valve is then opened again before the float reaches its upper closed position at the metering chamber inlet and closes the metering chamber inlet.

- the float and the dosing chamber are configured in such a way that, in the delivery position of the valve assigned to the dosing chamber outlet, the rising speed of the float in the washing and/or cleaning agent preparation is smaller than the flow rate of the preparation surrounding the floating body from the dosing chamber.

- the floating body prefferably be essentially spherical.

- the floating body can also be essentially cylindrical.

- the metering chamber is substantially cylindrical. Furthermore, it is advantageous that the diameter of the dosing chamber is slightly larger than the diameter of the cylindrical or spherical floating body, so that there is a slippage between the dosing chamber and the floating body with regard to the preparation.

- the floating body is made of a foamed, polymeric material, in particular foamed PP.

- the dosing chamber is L-shaped.

- an orifice can be arranged in the dosing chamber between the dosing chamber inlet and dosing chamber outlet, with the orifice opening being designed in such a way that it can be closed by the floating body in a sealing or non-sealing manner, with the floating body preferably being arranged between the orifice and the dosing chamber inlet.

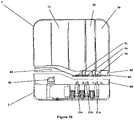

- the dosing device comprises a component carrier on which at least the actuator and the closure element as well as the energy source and/or the control unit and/or the sensor unit and/or the dosing chamber are arranged.

- the component carrier has receptacles for the components mentioned and/or the components are formed in one piece with the component carrier.

- the receptacles for the components in the component carrier can be provided for a non-positive, positive and/or material connection between a corresponding component and the corresponding receptacle.

- the dosing chamber, the actuator, the closure element, the energy source, the control unit and/or the sensor unit are each detachably arranged on the component carrier.

- the energy source, the control unit and the sensor unit are combined in one assembly and arranged on or in the component carrier.

- the energy source, the control unit and the sensor unit are combined in one assembly. This can be implemented, for example, by arranging the energy source, the control unit and the sensor unit on a common electrical printed circuit board.

- the component carrier is designed like a trough and is manufactured as an injection molded part. It is particularly preferred that the dosing chamber is formed in one piece with the component carrier.

- the component carrier Due to the component carrier, a largely simple automatic assembly with the necessary components of the dosing device is possible.

- the component carrier can thus preferably be automatically prefabricated as a whole and assembled to form a dosing device.

- the trough-like component carrier can be sealed in a liquid-tight manner by a cover-like closure element, for example, after assembly.

- the closure element can be designed, for example, as a film that is connected to the component carrier in a liquid-tight, materially bonded manner and forms one or more liquid-tight chambers with the trough-like component carrier.

- the closure element can also be a console into which the component carrier can be inserted, the console and the component carrier forming the dosing device when assembled.

- the component carrier and the console work together in such a way that a liquid-tight connection is formed between the component carrier and the console, so that no flushing water can get into the interior of the dispensing device or the component carrier.

- the receptacle for the actuator on the component carrier is arranged above the dispensing chamber in the direction of gravity, as a result of which a compact design of the dispensing device can be implemented.

- the compact design can be further optimized by arranging the dosing chamber inlet on the component carrier above the receptacle of the actuator when the dosing device is in the position of use is. It is also preferable for the components to be arranged on the component carrier essentially in a row with one another, in particular along the longitudinal axis of the component carrier.

- the receptacle for the actuator has an opening which is in line with the dosing chamber outlet, so that a closure element can be moved back and forth by the actuator through the opening and the dosing chamber outlet.

- the component carrier is formed from a transparent material.

- the component carrier comprises at least one optical fiber, via which light from the vicinity of the dispensing device can be guided to an optical transmitter and/or receiver unit into and/or out of the interior(s) of the dispensing device or the component carrier, with the optical fiber in particular is formed in one piece with the transparent component carrier.

- At least one opening is provided in the dosing device, through which light from the surroundings of the dosing device can be coupled into and/or out of the light guide.

- an actuator is a device that converts an input variable into a different type of output variable and with which an object is moved or its movement is generated, the actuator being coupled to at least one closure element in such a way that the preparation is released directly or indirectly at least one cartridge chamber can be effected.

- the actuator can be driven by means of drives selected from the group of gravity drives, ion drives, electric drives, motor drives, hydraulic drives, pneumatic drives, gear drives, threaded spindle drives, ball screws, linear drives, roller screws, toothed worm drives, piezoelectric drives, chain drives, and/or recoil drives.

- drives selected from the group of gravity drives, ion drives, electric drives, motor drives, hydraulic drives, pneumatic drives, gear drives, threaded spindle drives, ball screws, linear drives, roller screws, toothed worm drives, piezoelectric drives, chain drives, and/or recoil drives.

- the actuator can be formed from an electric motor that is coupled to a gear that converts the rotary movement of the motor into a linear movement of a carriage that is coupled to the gear. This is particularly advantageous in the case of a slim, plate-shaped design of the dosing unit.

- At least one magnetic element can be arranged on the actuator, which causes product to be dispensed from the container with a magnetic element of the same polarity on a dispenser as soon as the two magnetic elements are positioned against one another in such a way that magnetic repulsion of the magnetic elements of the same polarity is achieved and a non-contact release mechanism is implemented.

- the actuator is a bistable solenoid which, together with a closure element which engages in the bistable solenoid and is designed as a plunger, forms a pulse-controlled, bistable valve.

- Bistable lifting magnets are electromechanical magnets with a linear direction of movement, whereby the plunger locks in any end position without current.

- Bistable solenoids or valves are known in the prior art.

- a bistable valve requires an impulse to change the valve position (open/closed) and then remains in this position until a counter impulse is sent to the valve. Therefore one also speaks of a pulse-controlled valve.

- a major advantage of such impulse-controlled valves is that they do not consume any energy to remain in the valve end positions, the closed position and release position, but only require an energy impulse to change the valve positions, so the valve end positions can be considered stable.

- a bistable valve remains in the switching position which last received a control signal.

- the closure element (plunger core) is moved to an end position by a current pulse.

- the current is switched off, the locking element holds the position.

- the locking element is moved to the other end position by a current pulse.

- the current is switched off, the locking element holds the position.

- a bistable property of lifting magnets can be realized in different ways.

- a division of the coil is known. The coil is divided more or less in the middle so that a gap is created. A permanent magnet is inserted into this gap. The plunger itself is turned both at the front and at the back so that in the respective end position it has a flat surface to the frame of the magnet. The magnetic field of the permanent magnet flows over this surface. The diving core sticks here.

- the use of two separate coils is also possible.

- the principle is similar to that of the split-coil bistable solenoid. The difference is that they are actually electrically two different coils. These are controlled separately, depending on the direction in which the plunger is to be moved.

- the closure element is coupled to the actuator in such a way that the closure element can be moved by the actuator into a closed position and into an open position (dispensing position), the closure element being designed as an open/close valve element, that the actuator is designed in such a way that it assumes one of two end positions, controlled by a suitable pulse, and stably maintains the end position reached without control, and that the combination thus forms a pulse-controlled, bistable open/close valve.

- the actuator can be designed for this purpose as a bistable solenoid with a space accommodating an armature and an outer receiving space surrounding it.

- the armature of the bistable solenoid may be configured to form or be coupled to the closure member.

- the space of the actuator accommodating the armature can be separated in a liquid-tight and preferably also gas-tight manner from the outer receiving space of the actuator.

- At least the outer surface of the anchor from a material that cannot be attacked by the washing or cleaning agent to be dosed, in particular from a plastic material.

- the armature preferably comprises a core made of a magnetizable, in particular a ferromagnetic material and a permanent magnet positioned in the outer receiving space, with a coil being arranged at each of its two axial ends.

- permanent magnets are arranged axially antipole in the armature at its axial ends and that yoke rings made of a ferromagnetic material, in particular iron, and between these a coil winding are arranged in the outer receiving space at both axial ends.

- the axial spacing of the yoke rings is greater than the axial spacing of the permanent magnets.

- yoke rings can be arranged in the armature at its axial ends, with permanent magnets being arranged axially anti-pole in the outer receiving space at both axial ends and a coil winding being arranged between them.

- the axial spacing of the permanent magnets is preferably greater than the axial spacing of the yoke rings.

- the one actuator/closure element combination is provided in a dosing device of a dosing system with a cartridge for free-flowing detergents or cleaning agents with a plurality of chambers for spatially separated accommodation of different preparations of a detergent or cleaning agent and with a cartridge that can be coupled

- the dosing device has: an energy source, a control unit, a sensor unit, an actuator which is connected to the energy source and the control unit in such a way that a control signal from the control unit causes the actuator to be actuated, a closure element which is connected to the actuator in the Art is coupled in that it can be moved by the actuator into a closed position and into an open position (dispensing position), at least one dosing chamber which is connected in a communicating manner to at least one of the cartridge chambers of the cartridge when the dosing device is assembled with a cartridge, wherein the dosing chamber has an inlet for washing or cleaning agent to flow in from a cartridge chamber and an outlet for washing or cleaning agent to flow out of

- the actuator is arranged in a component carrier in such a way that, when the dispensing device is in the operating position, a receptacle for the actuator is arranged on the component carrier in the direction of gravity above the dispensing chamber. It is particularly advantageous here that, when the dosing device is in the position of use, the inlet of the dosing chamber is arranged on the component carrier above the receptacle of the actuator.

- the dosing device has a component carrier in which, in the operating position of the dosing device, a receptacle for the actuator is arranged on the component carrier laterally next to the dosing chamber.

- the receptacle for the actuator preferably has an opening which is in line with the outlet of the metering chamber, the closure element being movable back and forth by the actuator through the opening to the outlet.

- a closure element within the meaning of this application is a component on which the actuator acts and which, as a result of this action, causes the opening or closing of an outlet opening.

- the closure element can be, for example, valves that can be brought into a product delivery position or closed position by the actuator.

- the embodiment of the closure element and the actuator in the form of a magnetic valve is particularly preferred, in which the dispenser is configured by the valve and the actuator by the electromagnetic or piezoelectric drive of the magnetic valve.

- the use of solenoid valves allows the quantity and timing of the dosing to be regulated very precisely.

- a sensor within the meaning of this application is a measured variable recorder or sensor that can qualitatively or quantitatively record specific physical or chemical properties and/or the material composition of its environment as a measured variable.

- the dosing unit preferably has at least one sensor that is suitable for detecting a temperature.

- the temperature sensor is designed in particular to detect a water temperature.

- the dosing unit includes a sensor for detecting the conductivity, whereby in particular the presence of water or the spraying of water, in particular in a dishwasher, is detected.

- the dosing unit has a sensor which can determine physical, chemical and/or mechanical parameters from the surroundings of the dosing unit.

- the sensor unit can include one or more active and/or passive sensors for the qualitative and/or quantitative detection of mechanical, electrical, physical and/or chemical variables, which are sent to the control unit as control signals.

- the sensors of the sensor unit from the group of timers, temperature sensors, infrared sensors, brightness sensors, temperature sensors, movement sensors, strain sensors, speed sensors, proximity sensors, flow sensors, color sensors, gas sensors, vibration sensors, pressure sensors, conductivity sensors, turbidity sensors, sound pressure sensors, "Lab-on-a -Chip” sensors, force sensors, acceleration sensors, inclination sensors, pH sensors, humidity sensors, magnetic field sensors, RFID sensors, magnetic field sensors, Hall sensors, biochips, odor sensors, hydrogen sulfide sensors and/or MEMS sensors.

- Suitable flow sensors can be selected from the group of orifice flow sensors, magnetic-inductive flow meters, mass flow measurement using the Coriolis method, vortex meter flow measurement methods, ultrasonic flow measurement methods, variable area flow measurement, annular piston flow measurement, thermal mass flow measurement or differential pressure flow measurement.

- At least two sensor units are provided for measuring mutually different parameters, one sensor unit being a conductivity sensor and another sensor unit being a temperature sensor. Furthermore, it is preferred that at least one sensor unit is a brightness sensor.

- the sensors are designed to detect the start, course and end of a washing program.

- the sensor combinations listed in the following table can be used - by way of example and not exhaustively sensor 1 sensor 2 sensor 3 sensor 4 conductivity sensor temperature sensor conductivity sensor temperature sensor brightness sensor conductivity sensor temperature sensor brightness sensor turbidity sensor sound sensor temperature sensor

- the conductivity sensor can be used, for example, to detect whether the conductivity sensor is wet with water, so that it can be used to determine, for example, whether there is water in the dishwasher.

- Washing programs usually have a characteristic temperature curve, which is determined, among other things, by the heating of the washing water and the drying of the washware, which can be detected by a temperature sensor.

- a brightness sensor can be used, for example, to detect the incidence of light inside a dishwasher when the dishwasher door is opened, which can be used to indicate the end of the washing program, for example.

- a turbidity sensor can also be provided. From this, for example, a dosing program in the dosing device that applies to the determined contamination situation can also be selected.

- a temperature-dependent viscosity curve of at least one preparation is stored in the control unit, with the dosage being adjusted by the control unit according to the temperature and thus the viscosity of the preparation.

- a device for directly determining the viscosity of the preparation is provided.

- the data line between the sensor and the control unit can be realized via an electrically conductive cable or wirelessly.

- at least one sensor is or can be positioned outside of the dosing device inside a dishwasher and a data line—in particular wirelessly—is designed to transmit the measurement data from the sensor to the dosing device.

- a wireless data line is formed in particular by the transmission of electromagnetic waves or light. It is preferred to design a wireless data line according to standardized standards such as Bluetooth, IrDA, IEEE 802, GSM, UMTS, etc.

- At least one sensor unit is arranged on or in the control unit.

- the sensor unit is arranged on the bottom of the dosing device, with the bottom of the dosing device being directed downwards in the direction of gravity in the position of use. It is particularly preferred that the sensor unit includes a temperature and/or a conductivity sensor. Such a configuration ensures that the dishwasher's spray arms will bring water onto the underside of the dispenser and thus into contact with the sensor. Due to the fact that the distance between the spray arms and the sensor is as small as possible due to the bottom arrangement of the sensor, the water experiences only a slight cooling between the outlet at the spray arms and the contact with the sensor, so that the most accurate possible temperature measurement can be carried out .

- the energy consumers of the dosing device in particular the control unit, can be connected to the energy source, including an on/off switch, and the energy source can only be switched on after the The on-state of the on/off switch is charged, with a sensor unit forming the on/off switch or being connected to it and switching it on.

- the sensor unit has two contacts in contact with the environment at the bottom on the bottom of the dosing device, in particular designed as contact pins protruding downwards from the bottom, that one contact as an anode contact and the other contact as a cathode contact the energy source is switched on and that without an electrically conductive connection between the contacts, the on/off switch in the off state remains in the off state and when an electrically conductive connection is created between the contacts, the on/off switch in the off state remains switch turns to the on state.

- the on/off switch is provided or combined with a self-locking circuit which ensures or ensures that the power supply to the energy consumers is self-retaining after the on/off switch has reached the on state until a switch-off signal from the control unit is received .

- the on/off switch can be designed in particular as a transistor circuit. It is preferable for the transistor of the on/off switch to be designed as a pnp transistor and to be connected to the supply voltage with the emitter, if necessary via a control circuit, to the supply voltage with the collector, if necessary via a control circuit, to ground and to the cathode contact and is connected to the base on the one hand, possibly via a control circuit, to the supply voltage, on the other hand, possibly via a control circuit, to the anode contact.

- the control circuit preferably has at least one control resistor, which is designed in particular as a resistance-voltage divider.

- a sensor unit designed as a conductivity sensor which has two contacts in contact with the environment at the bottom of the dosing device and that the anode contact of the on/off -Sensor unit is also the anode contact of the sensor unit forming the conductivity sensor.

- the sensor unit forming the temperature sensor can be integrated into a contact, in particular the cathode contact, of the sensor unit forming the conductivity sensor.

- the contact receiving the temperature sensor of the sensor unit forming the conductivity sensor preferably be designed as a hollow contact pin, in which the temperature sensor of the sensor unit forming the temperature sensor is arranged.

- the energy source, the control unit and the sensor unit are combined in one assembly and arranged on or in the component carrier.

- the contacts of a conductivity sensor arranged on the bottom are surrounded by an electrically conductive silicone.

- the conductivity sensor can be designed in particular in the form of a resistance measurement between two spaced-apart contacts which are in contact with the surroundings of the dosing device.

- the silicone is embedded flush in the bottom of the dosing device.

- the silicone has an approximately circular base. The silicone shows good wettability with water and thus delivers good measurement results with regard to the detection of water in the dishwasher.

- a control unit within the meaning of this application is a device that is suitable for influencing the transport of material, energy and/or information. To this end, the control unit influences actuators with the aid of information, in particular measurement signals from the sensor unit, which it processes in accordance with the control objective.

- control unit can be a programmable microprocessor.

- a plurality of dosing programs are stored on the microprocessor, which in a particularly preferred embodiment can be selected and executed according to the container coupled to the dosing device.

- control unit has no connection to the possibly existing control of the household appliance. Accordingly, no information, in particular electrical, optical or electromagnetic signals, is exchanged directly between the control unit and the control of the household appliance.

- control unit is coupled to the existing control of the household appliance.

- This coupling is preferably implemented wirelessly.

- a transmitter on or in a dishwasher preferably on or in the dosing chamber let into the door of the dishwasher, which wirelessly transmits a signal to the dosing unit when the control of the household appliance removes the dosing, for example of a cleaning agent from the Dosing chamber or caused by rinse aid.

- control unit Several programs for releasing different preparations or for releasing products in different applications can be stored in the control unit.

- the corresponding program can be called up by corresponding RFID labels or geometric information carriers formed on the container.

- the same control unit for a number of applications, for example for dosing detergents in dishwashers, for dispensing perfumes in room scenting, for applying cleaning substances to a toilet bowl, etc.

- control unit can be configured in such a way that on the one hand the dosing takes place in a sufficiently short time to ensure a good cleaning result and on the other hand the preparation is not dosed so quickly that gelling of the preparation surge occurs.

- This can be realized, for example, by an interval-like release, with the individual dosing intervals being set in such a way that the correspondingly dosed amount dissolves completely during a cleaning cycle.

- the dosing intervals for dispensing a preparation are between 30-90 seconds, particularly preferably 45-75 seconds.

- Preparations can be dispensed from the dosing device sequentially or simultaneously.

- the dishwasher and the dosing device work together in such a way that 1 mg to 1 g of surfactant are released in the final rinse program of the dishwasher per m 2 of washing compartment wall surface. This ensures that the walls of the wash chamber retain their gloss level even after a large number of wash cycles and that the dosing system retains its optical transmission capability.

- the dishwasher and the dosing device interact in such a way that at least one enzyme-containing preparation and/or alkaline preparation is released in the prewash and/or main wash program of the dishwasher, with the release of the enzyme-containing preparation preferably occurring before the release the alkaline preparation takes place.

- the dishwasher and the dosing device work together in such a way that 0.1 mg - 250 mg of enzyme protein are released in the pre-wash and/or main wash program of the dishwasher per m 2 of the wall surface of the wash compartment, which further improves or reduces the gloss level of the wash compartment walls .is retained even after a large number of rinsing cycles.

- data such as control and/or dosing programs of the control unit or operating parameters or protocols stored by the control unit can be read from the control unit or loaded into the control unit.

- This can be implemented, for example, by means of the optical interface, with the optical interface being correspondingly connected to the control unit.

- the data to be transmitted is then encoded and sent or received as light signals in the wavelength range between 600-800 nm.

- a sensor present in the dosing device to transmit data from and/or to the control unit.

- the contacts of a conductivity sensor which are connected to the control unit and which provides a conductivity determination by means of a resistance measurement at the contacts of the conductivity sensor, can be used for data transmission.

- control unit can be used to implement a method for operating a dosing device that is not permanently connected to a household appliance for dispensing at least one detergent and/or cleaning agent preparation into the interior of the household appliance, with at least one dosing program being stored in the control unit, and the control unit having at least an actuator located in the dosing device interacts in such a way that washing and/or cleaning agent preparation can be released from the dosing device into the interior of the household appliance

- the dosing device comprises at least one receiving unit for signals which are transmitted by at least one transmitting unit arranged in the household appliance and at least one part the signals in the dosing device-side control unit are converted into control commands for the actuators of the dosing device, with the receipt of the signals being monitored by the dosing device side by means of the control unit and when the signals are not received at the dosing device t a dosing program from the control unit of the dosing device is activated.

- the signal on the household appliance side is transmitted into the interior of the household appliance at predefined, periodic time intervals by the transmitter unit on the household appliance side.

- the transmitter unit is deposited in the control unit of the dosing device and in the household appliance. If the contact between the transmitter unit of the household appliance breaks after a signal has been received at the dosing device, this break can be detected by comparing the time that has elapsed since the last signal received and the time in which the receipt of a subsequent signal is expected after the defined, periodic time interval , can be determined on the dosing device side.

- the periodic signal intervals are selected to be between 1 second and 10 minutes, preferably between 5 seconds and 7 minutes, particularly preferably between 10 seconds and 5 minutes. It is particularly preferred that the periodic signal intervals are chosen to be between 3 minutes and 5 minutes.

- control unit of the dosing device activates a dosing program from the control unit of the dosing device after a predefined time interval t 1-2 beginning with t 1 in which no further domestic appliance-side signal has been received from the dosing device.