EP2275372B1 - Leichtlaufwalze - Google Patents

Leichtlaufwalze Download PDFInfo

- Publication number

- EP2275372B1 EP2275372B1 EP09165302A EP09165302A EP2275372B1 EP 2275372 B1 EP2275372 B1 EP 2275372B1 EP 09165302 A EP09165302 A EP 09165302A EP 09165302 A EP09165302 A EP 09165302A EP 2275372 B1 EP2275372 B1 EP 2275372B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- roll

- roller

- arrangement

- range

- bearings

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 239000000835 fiber Substances 0.000 claims description 33

- 230000002787 reinforcement Effects 0.000 claims description 29

- 239000002131 composite material Substances 0.000 claims description 23

- 238000005452 bending Methods 0.000 claims description 7

- 239000011159 matrix material Substances 0.000 description 7

- 230000000694 effects Effects 0.000 description 3

- 239000003822 epoxy resin Substances 0.000 description 3

- 229920000647 polyepoxide Polymers 0.000 description 3

- 229920000049 Carbon (fiber) Polymers 0.000 description 2

- 230000000712 assembly Effects 0.000 description 2

- 238000000429 assembly Methods 0.000 description 2

- 239000004917 carbon fiber Substances 0.000 description 2

- 238000005087 graphitization Methods 0.000 description 2

- 230000007257 malfunction Effects 0.000 description 2

- 239000000463 material Substances 0.000 description 2

- 229920002239 polyacrylonitrile Polymers 0.000 description 2

- 238000000197 pyrolysis Methods 0.000 description 2

- 229920005989 resin Polymers 0.000 description 2

- 239000011347 resin Substances 0.000 description 2

- 238000010276 construction Methods 0.000 description 1

- 230000001404 mediated effect Effects 0.000 description 1

- 238000000034 method Methods 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H27/00—Special constructions, e.g. surface features, of feed or guide rollers for webs

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41F—PRINTING MACHINES OR PRESSES

- B41F13/00—Common details of rotary presses or machines

- B41F13/02—Conveying or guiding webs through presses or machines

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H2401/00—Materials used for the handling apparatus or parts thereof; Properties thereof

- B65H2401/10—Materials

- B65H2401/11—Polymer compositions

- B65H2401/112—Fibre reinforced

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H2601/00—Problem to be solved or advantage achieved

- B65H2601/20—Avoiding or preventing undesirable effects

- B65H2601/24—Deformation of part of handling machine

Definitions

- the present invention relates to a roller assembly used in printing machines, especially in rotary printing machines.

- Rotary printing presses use a large number of deflection rollers that can neither be actively driven nor actively decelerated. In the event of a malfunction (for example, in the case of a paper tear), the rotary printing press must be stopped. Since a rotary printing press is often operated at relatively high paper speeds (e.g., 1000 m / min and 18 m / sec, respectively), the deceleration process takes a relatively long time and the broke is considerable (sometimes over 100 meters of paper tape).

- a roller assembly has a roller and two rotary bearings.

- the roller has a reinforcement with a fiber composite material which is arranged inside the roller, wherein the ratio of the distance of the radial line of action of the rotary bearing to the roller end relative to the total length of the roller is in the range of 0.015 to 0.05.

- the reinforcement is preferably arranged between the rotary bearings and designed such that the roller is reinforced in relation to a bending load.

- the reinforcement with a fiber composite material may have various configurations.

- the reinforcement can be a tube made of a fiber composite material have, which rests from the inside of the roller.

- the reinforcement may comprise strips of a fiber composite material, which run parallel to the roll axis and are arranged radially within the roll. If strips are used, a support tube can additionally be provided in order to support the strips of a fiber composite material from the inside.

- the reinforcement with a fiber composite material high rigidity of the roller assembly is achieved, wherein the roller with the reinforcement at the same time has a relatively low moment of inertia.

- the rotary bearings of the roller assembly can be arranged on a (fixed) axis, which extends over the entire length of the roller.

- the rotary bearings are preferably arranged at an end region of the roller.

- the pivot bearings can be advantageously supported, wherein the end point of the axis, which serve to fasten the roller assembly, do not have to absorb bending moments.

- pivot bearings can be arranged on axle sections which are separated from one another.

- the assembly may be more expensive, and that the shaft sections must also absorb bending moments.

- this has the advantage that the bars of reinforcement, which rotate together with the roller in operation, can extend beyond the center, since no continuous solid axis in the way.

- the entire roller arrangement has been optimized in order to achieve the least possible deflection.

- the length of the roller, the position of the rotary bearings, the wall thicknesses of the roller and the reinforcement with fiber composite were taken into account. It has been found that the ratio of the distance between the radial line of action of the rotary bearing to the end of the roller relative to the total length of the roller is advantageously in the range of 0.015 to 0.05, in particular from 0.03 to 0.04, in particular about or exactly 0.035.

- the ratio of outer diameter of the roller to the total length of the roller is preferably in the range of 0.03 to 0.1, in particular 0.04 to 0.7, in particular about 0.05 to 0.06, preferably about or exactly 0.54.

- the ratio of the wall thickness of the roller in the area between the rotary bearings relative to the outer diameter of the roller is in the range of 0.01 to 0.08, in particular 0.02 to 0.06, in particular about 0.015 to 0.04, preferably about or exactly 0, 03.

- the ratio of the wall thickness of the fiber composite tube to the wall thickness of the roller in the region between the pivot bearings is in the range of 0.2 to 1.0, in particular 0.5 to 0.9, in particular about 0.6 to 0.8, preferably about or exactly 0.71.

- roller cover At the ends of the axes preferably roller cover are arranged, wherein between the roller covers and the roller, an air gap is present.

- the air gap extends in the circumferential direction and is in the range of 0.3 to 2 mm, in particular in the range of 0.5 to 1.8 mm, in particular in the range of 0.9 to 1.4 mm, preferably about or exactly 1.25 mm.

- multifilament carbon fibers or polyacrylonitrile-based fibers which are preferably carbonized by pyrolysis or refined by graphitization to Ultra High Modulus (UHM) fibers.

- UHM Ultra High Modulus

- the fibers can be embedded in a matrix, in particular in a duroplastic matrix or a resin matrix (typically epoxy resin).

- the course of the fiber directions is preferably in the region of the total reinforcement in the longitudinal direction (with respect to the roller axis).

- the fibers run alternatively or additionally in the angular range of 30-60 ° to the longitudinal direction, and if necessary, are arranged crossed.

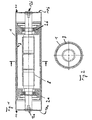

- Fig. 1 and Fig. 2 show a longitudinal or cross section through a roller assembly according to a first embodiment of the present invention.

- the illustrated roller assembly comprises a roller 1 and two rotary bearings 2a, 2b .

- the roller 1 has a reinforcement with a fiber composite material, which is arranged inside the roller 1 .

- the reinforcement is preferably arranged between the rotary bearings 2a, 2b and designed such that the roller 1 is reinforced with respect to a bending load.

- the reinforcement consists in the in Fig. 1 illustrated embodiment of a tube 3 made of a fiber composite material, which rests from the inside to the roller 1 .

- the reinforcement achieves a high rigidity of the roller arrangement, with the roller simultaneously having a relatively low moment of inertia with the reinforcement.

- the roller arrangement or the rotary printing press can be brought to a standstill faster in the event of a malfunction with one or more roller arrangements according to the invention than is the case with roller arrangements according to the prior art, wherein the braking effect is mediated via the paper web.

- the reinforcement minimizes the deflection of the roll, which is generated due to the force of the paper web, so that the paper web is not partially stretched by the deflection. Because at a point with a high deflection, the path that the paper web has to travel is less than at a point with a small deflection.

- the rotary bearings 2a, 2b of the roller assembly are in the embodiment according to Fig. 1 arranged on a fixed axis 8 , which extends over the entire length of the roller.

- the rotary bearings 2a, 2b are arranged at an end region of the roller, ie right and left. With a fixed Axis, the pivot bearings can be supported advantageously, the end point of the axis, which serve to fasten the roller assembly, do not have to absorb bending moments.

- the entire roller arrangement has been optimized in order to achieve the least possible deflection.

- the length of the roller, the position of the rotary bearings, the wall thicknesses of the roller and the reinforcement with fiber composite were taken into account. It was found that the ratio of the distance between the radial line of action of the pivot bearing to the end of the roll over the total length of the roll is advantageously about 0.035.

- the ratio of outer diameter of the roll to the total length of the roll is preferably about 0.54.

- the ratio of the wall thickness of the roller in the area between the pivot bearings relative to the outer diameter of the roller is about 0.03.

- the ratio of the wall thickness of the fiber composite pipe to the wall thickness of the roll in the area between the rotary bearings is about 0.71.

- Roller covers 10a, 10b are preferably respectively arranged at the ends of the axles, an air gap 11 being present between the roller covers 10a, 10b and the roller.

- the air gap runs in the circumferential direction and is in the range of 1.25 mm. The action of the fixed roller cover and the rotating roller prevents dirt from entering the interior of the roller assembly.

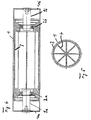

- Fig. 3 shows a longitudinal section through a roller assembly according to a second embodiment of the present invention.

- This embodiment corresponds to the first embodiment except that there is no continuous axis. Instead, the pivot bearings 2a, 2b are arranged on axle sections 9a, 9b , which are separated from one another.

- FIG. 4 and FIG. 5 show a longitudinal or cross section through a roller assembly according to a third embodiment of the present invention.

- This embodiment corresponds to the second embodiment, wherein the reinforcement additionally comprises strips 4 made of a fiber composite material which extend parallel to the roll axis and are arranged radially inside the roll 1.

- the strips extend over the roller center.

- Fig. 6 and Fig. 7 show a longitudinal or cross section through a roller assembly according to a fourth embodiment of the present invention.

- strips 6 are also provided, but do not extend beyond the roller center.

- a further support tube 5 is provided here radially inwardly with respect to the strips 6 in order to support the strips 6 of a fiber composite material from the inside.

- the support tube may also consist of the fiber composite material.

- a tube 3 may be provided in addition, as is the case in the first embodiment.

- FIGS. 8 and 9 show a longitudinal or cross section through a roller assembly according to a fifth embodiment of the present invention.

- This embodiment has as a reinforcement exclusively strips 7 made of fiber composite material, but no tube made of a fiber composite material.

- multifilament carbon fibers or polyacrylonitrile-based fibers can be used, which are preferably carbonized by pyrolysis or refined by graphitization to UltraHochmodul fibers (UHM).

- UHM UltraHochmodul fibers

- the fibers can be embedded in a matrix, in particular in a duroplastic matrix or a resin matrix (typically epoxy resin).

- the course of the fiber directions is preferably in the region of the total reinforcement in the longitudinal direction (with respect to the roller axis).

- the fibers run alternatively or additionally in the angular range of 30-60 ° to the longitudinal direction, and if necessary, are arranged crossed.

- the reinforcement can be introduced in all embodiments in a state when the matrix or the epoxy resin is not yet cured. In this way, a firm bond between the reinforcement and the roller is achieved.

- the reinforcement can also be formed beforehand, and then inserted and glued into the roll.

- the roll assembly is balanced, wherein - if necessary - balancing weights are arranged or glued in the interior of the roll at appropriate locations.

- pivot bearings are shown in the embodiments as a ball bearing. However, plain bearings or air bearings can be used instead.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Rolls And Other Rotary Bodies (AREA)

- Rotary Presses (AREA)

- Registering, Tensioning, Guiding Webs, And Rollers Therefor (AREA)

Priority Applications (6)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| ES09165302T ES2386932T3 (es) | 2009-07-13 | 2009-07-13 | Rodillo de marcha fácil |

| EP09165302A EP2275372B1 (de) | 2009-07-13 | 2009-07-13 | Leichtlaufwalze |

| JP2010146202A JP5656473B2 (ja) | 2009-07-13 | 2010-06-28 | 印刷機用ロールアセンブリ |

| US12/824,276 US20110005414A1 (en) | 2009-07-13 | 2010-06-28 | Low Friction Roll |

| CA2709113A CA2709113C (en) | 2009-07-13 | 2010-07-07 | Fiber composite reinforced printing roll |

| CN201010231325.2A CN101954778B (zh) | 2009-07-13 | 2010-07-13 | 低摩擦辊及具有该辊的印刷机 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP09165302A EP2275372B1 (de) | 2009-07-13 | 2009-07-13 | Leichtlaufwalze |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2275372A1 EP2275372A1 (de) | 2011-01-19 |

| EP2275372B1 true EP2275372B1 (de) | 2012-05-30 |

Family

ID=40902883

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP09165302A Active EP2275372B1 (de) | 2009-07-13 | 2009-07-13 | Leichtlaufwalze |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US20110005414A1 (ko) |

| EP (1) | EP2275372B1 (ko) |

| JP (1) | JP5656473B2 (ko) |

| CN (1) | CN101954778B (ko) |

| CA (1) | CA2709113C (ko) |

| ES (1) | ES2386932T3 (ko) |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102010015108A1 (de) * | 2010-04-16 | 2011-10-20 | Goebel Gmbh | Rotationszylinder für eine Verarbeitungsmaschine |

| DE202011003940U1 (de) * | 2011-03-14 | 2012-06-15 | Texmag Gmbh Vertriebsgesellschaft | Walze |

| EP2524805A1 (en) * | 2011-05-20 | 2012-11-21 | KBA-NotaSys SA | Ink wiping system for an intaglio printing press |

| US10450480B2 (en) * | 2013-03-13 | 2019-10-22 | Hentzen Coatings, Inc. | Water-reducible single-component moisture-curing polyurethane coatings |

Family Cites Families (32)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3808657A (en) * | 1972-01-26 | 1974-05-07 | Marathon Rollers Inc | Hickey roll and method of making same |

| CH643796A5 (de) * | 1980-04-11 | 1984-06-29 | Sig Schweiz Industrieges | Umlenkrolle fuer bahnfoermiges, blattartiges material. |

| US4339858A (en) * | 1980-11-03 | 1982-07-20 | Minnesota Mining And Manufacturing Company | Dampener roll cover |

| JPH0342254Y2 (ko) * | 1986-10-27 | 1991-09-04 | ||

| FR2635718A1 (fr) * | 1988-08-23 | 1990-03-02 | Francille Jean | Cylindre notamment d'imprimerie |

| IT1248446B (it) * | 1990-12-19 | 1995-01-19 | Componenti Grafici Srl | Rullo pressore per macchina da stampa, con sistema di condizionamento e di lubrificazione ad olio |

| DE4109438C2 (de) * | 1991-03-22 | 2001-12-20 | Koenig & Bauer Ag | Farbheber für Druckmaschinen |

| DE4125620C2 (de) * | 1991-08-02 | 1995-04-20 | Roland Man Druckmasch | Montagevorrichtung für eine Walze, insbesondere Papierleitwalze |

| JP3190463B2 (ja) * | 1992-12-28 | 2001-07-23 | 中部ベアリング株式会社 | ローラコンベア用ベアリング |

| JPH0676247U (ja) * | 1993-04-06 | 1994-10-28 | 西研グラフィックス株式会社 | 印刷機用ガイドローラ |

| DE29518150U1 (de) * | 1995-07-10 | 1996-01-11 | Polywest Kunststofftechnik Saueressig & Partner GmbH & Co. KG, 48683 Ahaus | Nahtlose Druckhülse, insbesondere für einen Flexodruckzylinder |

| DE29609007U1 (de) * | 1996-05-20 | 1996-07-04 | MAN Roland Druckmaschinen AG, 63075 Offenbach | Walze für eine Druckmaschine |

| US5857950A (en) * | 1996-11-06 | 1999-01-12 | Pamarco Incorporated | Fluid metering roll |

| DE29701547U1 (de) * | 1997-01-30 | 1997-03-20 | Voith Sulzer Papiermaschinen GmbH, 89522 Heidenheim | Walze für Auftragseinrichtung |

| US5894796A (en) * | 1997-08-01 | 1999-04-20 | Heidelberger Druckmaschinen Ag | Printing unit for a web-fed rotary printing press |

| DE29801421U1 (de) * | 1998-01-29 | 1999-05-27 | L. Blömker GmbH, 49536 Lienen | Rohrförmiger Walzenkörper |

| US6311615B1 (en) * | 1998-07-14 | 2001-11-06 | Heidelberger Druckmaschinen Ag | Composite nip roll and nip ring |

| ES2166201T3 (es) * | 1999-02-01 | 2002-04-01 | Fischer & Krecke Gmbh & Co | Cilindro portaplaca. |

| DE19955099B4 (de) * | 1999-11-16 | 2010-02-11 | Maschinenfabrik Wifag | Rotationskörpergebilde für eine Bahnbreitenkorrektur |

| DE19956949C2 (de) * | 1999-11-26 | 2003-05-28 | Koenig & Bauer Ag | Lagerung eines Formzylinders einer Rotationsdruckmaschine |

| JP2002012313A (ja) * | 2000-06-30 | 2002-01-15 | Sanwa Koki Kk | ベルトコンベア用ローラ,ベルトコンベア用ローラの製造方法及びベルトコンベア用ローラの製造用カシメ装置 |

| JP4073402B2 (ja) * | 2002-02-01 | 2008-04-09 | ケーニツヒ ウント バウエル アクチエンゲゼルシヤフト | 回転する構成部分における振動を減少させるための方法および装置 |

| US6799510B2 (en) * | 2002-05-02 | 2004-10-05 | New Hudson Corporation | Thin-walled bridge mandrel |

| DE20321351U1 (de) * | 2003-09-26 | 2006-10-26 | Koenig & Bauer Aktiengesellschaft | Walze eines Farb- oder Feuchtwerks einer Druckmaschine |

| US20050217519A1 (en) * | 2004-04-06 | 2005-10-06 | Taku Naitou | Stencil printing machine |

| JP2006023701A (ja) * | 2004-06-09 | 2006-01-26 | Bridgestone Corp | 現像ローラおよびそれを用いた画像形成装置 |

| EP1808293A1 (de) * | 2006-01-13 | 2007-07-18 | Fischer & Krecke GmbH & Co. KG | Druckzylinder für Flexodruck |

| KR101287529B1 (ko) * | 2006-10-27 | 2013-07-19 | 삼성전자주식회사 | 화상형성장치와 그 제조방법 |

| JP2008138735A (ja) * | 2006-11-30 | 2008-06-19 | Bridgestone Corp | 導電性ローラ |

| US8413580B2 (en) * | 2007-12-21 | 2013-04-09 | Day International, Inc. | Compressible printing sleeve carrier and method of making |

| US20090165662A1 (en) * | 2007-12-31 | 2009-07-02 | Nim-Cor, Inc. | Bridge mandrels for anilox and print roller applications and techniques for making them |

| US20090193991A1 (en) * | 2008-02-04 | 2009-08-06 | Felice Rossini | Blanket sleeve and cylinder and method of making same |

-

2009

- 2009-07-13 ES ES09165302T patent/ES2386932T3/es active Active

- 2009-07-13 EP EP09165302A patent/EP2275372B1/de active Active

-

2010

- 2010-06-28 JP JP2010146202A patent/JP5656473B2/ja active Active

- 2010-06-28 US US12/824,276 patent/US20110005414A1/en not_active Abandoned

- 2010-07-07 CA CA2709113A patent/CA2709113C/en not_active Expired - Fee Related

- 2010-07-13 CN CN201010231325.2A patent/CN101954778B/zh active Active

Also Published As

| Publication number | Publication date |

|---|---|

| EP2275372A1 (de) | 2011-01-19 |

| CN101954778A (zh) | 2011-01-26 |

| CA2709113C (en) | 2014-06-17 |

| JP5656473B2 (ja) | 2015-01-21 |

| ES2386932T3 (es) | 2012-09-06 |

| CN101954778B (zh) | 2013-03-06 |

| JP2011021746A (ja) | 2011-02-03 |

| US20110005414A1 (en) | 2011-01-13 |

| CA2709113A1 (en) | 2011-01-13 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1025996B1 (de) | Druckplattenzylinder | |

| EP2385171B1 (de) | Yankeezylinder zum Trocknen einer Faserstoffbahn | |

| EP2275372B1 (de) | Leichtlaufwalze | |

| EP2743058B1 (de) | Strukturintegrierte Verstärkung in gewickelten Bauteilen aus Verbundwerkstoffen | |

| EP0543959B1 (de) | Verfahren zur herstellung eines mehrlagigen kartons | |

| DE102013222896A1 (de) | Vorrichtung zum Wickeln einer Materialbahn zu einer mehrlagigen Rolle | |

| EP1586703B1 (de) | Walze zur Behandlung flacher Materialien und Verfahren zur Herstellung dieser Walze | |

| DE19940424A1 (de) | Walze | |

| EP3670718B1 (de) | Ringspinnmaschine mit streckwerken | |

| WO2005067364A2 (de) | Druckformzylinder mit einer kohlefasern enthaltenden kunststoffhülse | |

| EP2743063B1 (de) | Strukturintegrierte Verstärkung in gewickelten Bauteilen aus Verbundwerkstoffen | |

| DE202009012298U1 (de) | Leitwalze | |

| WO2016198549A1 (de) | Wickelwelle zur aufnahme von wenigstens einer wickelhülse | |

| DE102007059073A1 (de) | Rollenpresse mit symmetrischer Walzenzentrierung | |

| DE19952320A1 (de) | Elastische Walze sowie Verfahren zur Herstellung einer solchen Walze | |

| DE10300404A1 (de) | Aufspulvorrichtung | |

| WO2017215853A1 (de) | Walzenvorrichtung | |

| DE202004004037U1 (de) | Vorrichtung zur Herstellung von Span- un Faserplatten | |

| DE102012203101A1 (de) | Walze | |

| EP4296414A1 (de) | Vorrichtung zur kalandrierung einer wattebahn | |

| WO2023217309A1 (de) | Antriebsvorrichtung für eine exzenterlagerung sowie ein entsprechender kalander | |

| EP0366690A1 (de) | Verfahren zum aufbringen eines nichtmetallischen walzenbezuges | |

| DE102008002112A1 (de) | Biegeeinstellwalze | |

| EP1970488A1 (de) | Pressenanordnung | |

| WO2004000706A1 (de) | Vorrichtung zum hin- und hergehenden abtafeln von bahnmaterial |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO SE SI SK SM TR |

|

| 17P | Request for examination filed |

Effective date: 20110203 |

|

| 17Q | First examination report despatched |

Effective date: 20110221 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 559984 Country of ref document: AT Kind code of ref document: T Effective date: 20120615 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502009003663 Country of ref document: DE Effective date: 20120726 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2386932 Country of ref document: ES Kind code of ref document: T3 Effective date: 20120906 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: VDEP Effective date: 20120530 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D Effective date: 20120530 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120530 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120530 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120830 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120530 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120930 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120530 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120530 Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120530 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120831 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120530 |

|

| BERE | Be: lapsed |

Owner name: TEXMAG GMBH VERTRIEBSGESELLSCHAFT Effective date: 20120731 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120530 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120530 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120530 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120530 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120530 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120530 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120731 Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120530 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120530 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20121001 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20130301 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120731 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502009003663 Country of ref document: DE Effective date: 20130301 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120530 Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120713 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120830 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130731 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130731 Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120530 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120713 Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120530 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090713 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 502009003663 Country of ref document: DE Representative=s name: PETERREINS SCHLEY PATENT- UND RECHTSANWAELTE, DE |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 7 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 559984 Country of ref document: AT Kind code of ref document: T Effective date: 20140713 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140713 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 8 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20180426 Year of fee payment: 19 Ref country code: ES Payment date: 20170801 Year of fee payment: 9 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 10 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20180713 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180713 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20190917 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180714 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20240611 Year of fee payment: 16 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20240612 Year of fee payment: 16 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20240604 Year of fee payment: 16 |