EP2028126A1 - Support avec poignée - Google Patents

Support avec poignée Download PDFInfo

- Publication number

- EP2028126A1 EP2028126A1 EP08013311A EP08013311A EP2028126A1 EP 2028126 A1 EP2028126 A1 EP 2028126A1 EP 08013311 A EP08013311 A EP 08013311A EP 08013311 A EP08013311 A EP 08013311A EP 2028126 A1 EP2028126 A1 EP 2028126A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- carrying handle

- handle

- identification

- containers

- receiving

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 238000004806 packaging method and process Methods 0.000 claims description 35

- 239000000463 material Substances 0.000 claims description 14

- 239000004033 plastic Substances 0.000 claims description 11

- 229920003023 plastic Polymers 0.000 claims description 11

- 238000002347 injection Methods 0.000 claims description 3

- 239000007924 injection Substances 0.000 claims description 3

- 239000011049 pearl Substances 0.000 claims description 2

- 238000003780 insertion Methods 0.000 abstract description 2

- 230000037431 insertion Effects 0.000 abstract description 2

- 230000002787 reinforcement Effects 0.000 abstract 1

- 210000003739 neck Anatomy 0.000 description 24

- 230000003014 reinforcing effect Effects 0.000 description 10

- 235000013361 beverage Nutrition 0.000 description 7

- 210000003811 finger Anatomy 0.000 description 7

- 238000005452 bending Methods 0.000 description 4

- 210000003813 thumb Anatomy 0.000 description 4

- 229920001903 high density polyethylene Polymers 0.000 description 3

- 239000004700 high-density polyethylene Substances 0.000 description 3

- 239000002184 metal Substances 0.000 description 3

- 230000006978 adaptation Effects 0.000 description 2

- 239000000969 carrier Substances 0.000 description 2

- 238000001514 detection method Methods 0.000 description 2

- 239000011888 foil Substances 0.000 description 2

- 238000002372 labelling Methods 0.000 description 2

- 230000002093 peripheral effect Effects 0.000 description 2

- WYTGDNHDOZPMIW-RCBQFDQVSA-N alstonine Natural products C1=CC2=C3C=CC=CC3=NC2=C2N1C[C@H]1[C@H](C)OC=C(C(=O)OC)[C@H]1C2 WYTGDNHDOZPMIW-RCBQFDQVSA-N 0.000 description 1

- 238000013459 approach Methods 0.000 description 1

- 239000011324 bead Substances 0.000 description 1

- 235000013405 beer Nutrition 0.000 description 1

- 230000009286 beneficial effect Effects 0.000 description 1

- 230000008901 benefit Effects 0.000 description 1

- 210000000078 claw Anatomy 0.000 description 1

- 230000006835 compression Effects 0.000 description 1

- 238000007906 compression Methods 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 238000011161 development Methods 0.000 description 1

- 230000018109 developmental process Effects 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 239000013013 elastic material Substances 0.000 description 1

- 238000000605 extraction Methods 0.000 description 1

- 210000005224 forefinger Anatomy 0.000 description 1

- 230000001771 impaired effect Effects 0.000 description 1

- 230000013011 mating Effects 0.000 description 1

- 230000007246 mechanism Effects 0.000 description 1

- 238000000034 method Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 238000000465 moulding Methods 0.000 description 1

- 239000002985 plastic film Substances 0.000 description 1

- 230000009467 reduction Effects 0.000 description 1

- 239000012858 resilient material Substances 0.000 description 1

- 238000000926 separation method Methods 0.000 description 1

- 229920006300 shrink film Polymers 0.000 description 1

- 230000007480 spreading Effects 0.000 description 1

- 239000003381 stabilizer Substances 0.000 description 1

- 230000000087 stabilizing effect Effects 0.000 description 1

- 239000000725 suspension Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D71/00—Bundles of articles held together by packaging elements for convenience of storage or transport, e.g. portable segregating carrier for plural receptacles such as beer cans or pop bottles; Bales of material

- B65D71/50—Bundles of articles held together by packaging elements for convenience of storage or transport, e.g. portable segregating carrier for plural receptacles such as beer cans or pop bottles; Bales of material comprising a plurality of articles held together only partially by packaging elements formed otherwise than by folding a blank

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2203/00—Decoration means, markings, information elements, contents indicators

- B65D2203/06—Arrangements on packages concerning bar-codes

Definitions

- the invention relates to a carrying handle for one or more containers with at least one gripping element and at least one receiving element for receiving the at least one container, a packaging unit and a device for applying corresponding handles to containers.

- Such carrying handles are well known in the art.

- a carrying and holding device for containers of cylindrical cross-section, in particular cans, out consisting of an upright inner part, which is arranged between the adjacent containers, from at right angles thereto extending retaining tabs, overlap the bottom and lid of the stacked containers, and from a suspension.

- Inner part, retaining tabs and support means are integrally stamped from a thin metal sheet, wherein the retaining tabs have inwardly extending projections which engage with the bottom and top edge and the bottom and top surface of each container in engagement.

- a container package for holding and carrying a plurality of containers, bottles, and the like, and a method for assembling the same, and a package for a group of containers each having a neck portion.

- the juxtaposed containers each have a body portion and a neck portion projecting upwardly and inwardly therefrom, which is smaller than the body portion, the containers being arranged side by side in parallel with each other in a grape-shaped group.

- An elastic support is slipped onto the neck portions of the containers with a plurality of constricting recesses for receiving the neck portion of a respective container whose mutual center distances are smaller than the center distances between corresponding abutting containers, thereby receding the foot portions of the containers with respect to the group of containers are applied externally.

- an elastic endless belt is guided around, through which the foot portion of the Container resiliently acted upon in a laterally abutting position.

- the carrier and the endless belt are under a sufficiently high tension to hold the containers in the package.

- a bottle carrier for collectively detecting at least two bottles, which are in particular beverage bottles known.

- the bottleneck are provided below its bead partially embracing approaches.

- the bottle carrier is made of a resilient material, such as plastic.

- the DE 25 31 325 A1 discloses a container package having a plurality of containers disposed substantially adjacent to one another and divided into a plurality of groups, each comprising at least two containers.

- An upper support member includes and secures first end portions of each container, whereas a second sheet or foil support portion has interconnected portions.

- the container package includes and holds each container group.

- the interconnected parts of the second sheet or foil support member include band portions comprising two containers without extending between the two containers.

- the upper support member has two openings for engagement with the thumb and a finger to allow the container packaging to be carried.

- the DE 89 15 740 U1 discloses a container comprising containers and support frames, the support frame having a dimensionally stable plate with a plurality of recesses for holding the containers, and wherein the containers have means for holding them in the recesses at a distance from the container bottom. This prevents slippage of the container placed in the recesses from above. Furthermore, the container has a connected to the plate upwardly projecting central handle. The plate has a recess corresponding to the contour of the carrying handle, and the carrying handle itself is essentially U-shaped or V-shaped in the side view in order to achieve better stackability.

- the carrier itself comprises a structural frame carrying a plurality of collars, each of which can receive the neck of a container and engage with the projection located on the periphery of the container. Further, each collar has a resilient edge depending therefrom which cooperates with a portion of the outer surface of the respective container to prevent relative movement between the container and the carrier.

- the collars have a plurality of spaced apart resilient tabs or tabs which engage the projections of the containers. For wear, the wearer has two openings in which can be grasped with thumb and a finger to carry the container packaging or the carrier.

- the DE 699 05 308 T2 discloses a device for transporting bottles or similar containers, in which a plate-like element is provided with at least one slot, in which slot an outward-facing part of a portion of the bottles or containers of reduced diameter is received. Furthermore, a gripping element protrudes from the plate-like element, which is rigidly formed on the transport device. The gripping member projects upward from a central portion of the plate-like member.

- an elongated support body which has a support bracket above the support body and on its underside at least two hanging rail-like receptacles for receiving a plurality of bottles in a row.

- individual receptacles arranged at a distance in the longitudinal direction can also be provided for accommodating only one bottle at a time.

- the recordings are closed at one end or provided with a stop stop and at the other end for the bottle supply educated.

- a holding member for securing the respective bottle necks is also provided in the receptacle.

- a support device for at least one container in particular a bottle, known which comprises a base body made of a first plastic having an at least partially bounded by an edge opening, wherein in the worn state a collar of a container is supported on the edge.

- An edge region of the edge is formed from at least one further plastic which has a higher elasticity than the first plastic of the base body.

- the support device further comprises a handle, in particular the first plastic, wherein the base body and the handle are disclosed as being integrally formed.

- the handle is rigidly integrally formed on the base body.

- a container carrier which has a flexible platform.

- This includes a container engaging portion having an opening through the platform for receiving the neck of a container, a handle portion having a base extending transversely to a longitudinal axis of the platform, a pair of handle legs, the proximal ends of the handle legs integrally formed with the ends of the base member are.

- the distal ends of the handle leg are integral with the container engaging portion at opposite points on the container engaging portion and having a flange integral with the base member and extending inwardly from the base member over substantially the length of the base member.

- the inner periphery of the The container engaging portion and the handle portion provide an opening to allow the fingers of a user to engage.

- the flange has transverse fold lines formed in the surface of the platform. In this way, a bending of the handle portion to its gripping is possible.

- the DE 20 2005 005 970 U1 discloses a bottle feeder for PET returnable bottles, which consists of the same material as the returnable bottles themselves and has six punched holes for receiving the bottle necks or bottle heads.

- Thestationnbündler is U-shaped from a strong plastic sheet.

- the DE 20 2005 014 112 U1 discloses a carrying handle having a substantially plate-shaped support member, at the lateral peripheral edge of which a plurality of snap-in devices for snapping and holding objects are provided spaced therefrom. These snap-in devices are designed like a claw. Furthermore, the carrying handle has a rigid, upwardly projecting handle, which is formed integrally with the carrier element. As a common stabilizing agent, a band is provided in the lower region of the recorded objects.

- a similar carrier for bottles and the same container in which also a mounting bracket and a support body is provided with edge-shaped clip-like receptacles for the bottles.

- the mounting bracket is relatively wide and integrally connected by articulated joints with the support body and connected foldable.

- the US 2004/0256250 A1 further discloses a bottle carrier in which annular receiving elements are provided for receiving bottle necks. The bottle necks are held therein over resilient tab-like elements. A U-shaped handle is also attached at two locations on webs between the individual receiving elements for the bottle necks via a hinged hinge.

- a similar structure only for receiving a container discloses the US 6,394,517 B1 , This is the handle, however attached laterally to the receiving element for receiving the Falschenhalses and spent by bending in a vertical carrying position.

- the EP 1 710 171 A1 discloses a corresponding carrier for a plurality of bottles, in which, in contrast to the two abovementioned but still protruding tabs are arranged end to the carrier, which are to serve for facilitating the application and removal of rings on and from bottle necks.

- protruding elements are also in the US 5,306,060 disclosed, wherein in these straps another handle is provided for engaging. For carrying is attacked only at a bridge between two receiving elements for receiving bottlenecks.

- a modification to the structure mentioned in this document is in the US 5,735,562 disclosed. Here, three or four receiving elements are connected by webs crosswise.

- US 6,715,810 B2 is disclosed a corresponding structure with again outer side tabs according to the above prior art.

- a carrier for carrying two tube-like containers is in the US 2006/0254934 A1 disclosed.

- retaining lugs are externally formed on receiving rings, which hold on the lid of the container.

- the US 6,129,397 discloses a six-fold carrier having six receiving elements with inwardly projecting retaining tabs for receiving the bottle necks and between the individual receiving elements connecting webs. For carrying is attacked at the connecting webs or in particular at the central connecting web by engaging in two correspondingly provided openings.

- An alternative variant to this is in the US 2007/0039836 A1 disclosed.

- two handle tabs are arranged in the inner openings of the carrier, which can be grasped by the thumb and a finger of one hand. The two grip tabs are bent out of the plane of the carrier when grasped.

- the present invention is therefore based on the object to further develop a carrying handle according to the preamble of claim 1 that a very good stackability of several handles above each other is possible and at the same time a comfortable grip on the handle for carrying a plurality of containers, especially bottles, being straight at Carrying several bottles a compact well-to-carry packaging unit should be created.

- the object is achieved by a carrying handle according to the preamble of claim 1, characterized in that the handle element is arranged out of the plane of the handle out telescopically over at least two torsion points on the handle.

- the object is achieved in that the container surrounded by a ring element are.

- a carrying handle for one or more containers is provided with at least one gripping element and at least one receiving element for receiving the at least one container, wherein the gripping element is in the unused state of the carrying handle in the plane thereof and only for the use of the carrying handle, so the Attaching to the container, the handle element is pulled out of the plane of the carrying handle, wherein it is in contrast to the prior art

- the handle element thereby does not form U-shaped over the plane of the handle, but by telescoping or "Entwringen” a central portion of the handle element remains substantially straight and thus can be better attacked by the person wearing a U-shaped handle forming element which usually cuts into the forefinger and small finger of the hand of the wearer and thereby leads to a poor wearing comfort.

- the gripping element can be telescoped out of the plane of the carrying handle so far that the distance between the gripping element and the uppermost extent of at least one container received in the carrying handle permits the insertion of a hand of a carrying person.

- the carrying person can conveniently reach over the uppermost extent of the container received in the carrying handle under the gripping element and carry the packaging unit.

- the lying in the plane of the handle for the handle element proves to be very beneficial, especially with respect to the handles of the prior art, in which the gripping elements project rigidly over the plane of the carrying handle.

- the space required for such a grip element of the prior art is therefore much larger than in the invention, which does not lead to a larger footprint for the carrying handle. This proves to be extremely advantageous not only in pick and place machines, but of course also in warehousing.

- the grip element advantageously has at least one slightly curved section for centering when stacking a plurality of carrying handles on each other.

- Another stacking aid for facilitating centering of the carrying handles on each other can be provided that the receiving elements for receiving the container, that is, of the head portions, not completely flat, but have a slight inclination.

- the at least one receiving element for receiving the at least one container is advantageously formed like a collar with inwardly projecting retaining tabs or retaining lugs.

- both the inwardly projecting retaining tabs or retaining lugs may have a slight inclination and the circumferential collar of the receiving elements, whereby a self-centering can be achieved in this area of stacked carrying handles.

- multipacks can be produced, for example, four or six grouped containers, especially bottles or cans.

- a barrel can be provided with such a carrying handle, whereby this, for example, a 5 liter party beer keg, is recorded with its upper edge in a receiving element.

- the gripping element is formed on both sides, ie at opposite points on the receiving element via torsion or torsion, so that when attacking the handle element this "twisted" into its position, that is twisted at the torsion and thus does not buckle, but his desired maintains a manageable shape without forming an O-shape.

- two telescopically arranged on the carrying handle gripping elements may be provided, which can either be guided and locked to each other or latched or so out of the plane of the handle are

- the two handle elements are advantageous about the two torsion out of the plane of the carrying handle Tartched and each other so that they come together in the middle about the carrying handle for the cans, especially six cans, and centrally by a hand of wearing person and the packaging unit can be worn over example, six cans over it.

- the respective torsion points on the handle elements serve as Aufricht Anlagen.

- another device or another mechanism can be provided in order to achieve the same goal, namely a telescoping of the handle member in the region of its central handle bar approximately parallel to the plane of the handle, to a buckling of the handle member and thus an uncomfortable attitude when carrying the handle for the wearer to avoid.

- At least one ring element for surrounding on the outside is detachably fastened to the carrying handle.

- This ring element surrounds the receiving elements and arranged between them stiffening or connecting webs, that is arranged on the outside of this.

- the ring element is provided, so to speak, as an outer boundary of the carrying handle and can be separated from this.

- it is advantageously releasably connected by web elements with the at least one receiving element and / or the stiffening webs.

- a predetermined breaking point between the ring element and web elements is provided or between the web elements and the at least one receiving element and / or the stiffening webs.

- the ring member such a material that a stretching or spreading of the ring member when pushed down along the container walls after reaching the end position for the ring element, ie immediately eliminates the expansion force when the elastic force disappears, the ring element sets directly to the outer surfaces of this surrounded container.

- at least one closure device for fastening to the containers is advantageously provided on the ring element.

- the closure device can be detected by a device for closing the device for applying the carrying handles and can be closed after the ring element has been pushed down along the containers. This closing may be accomplished by a juxtaposed movement of parts of the means for closing the closure means.

- the means for closing the closure means may comprise sliding elements which engage two ends of the closure means and close them by movement towards each other. Instead of sliding elements, other means can be provided which allow a closure of the respective closure device.

- the closure device may comprise at least one barbed element and at least one mating element cooperating therewith.

- the barbed element is pressed against the counter-element cooperating therewith, so that both elements interlock with one another and lead to closure of the closure device and thus closure of the ring element.

- the closure device may advantageously comprise a latching device, in particular a housing part provided with shoulders and a closure part which can be inserted therein and is provided with at least one outside projection.

- the closure part provided with the at least one outer-side projection is used to close the ring element in the Housing part inserted and locked behind the heels of the housing part.

- Another way of closing the ring element around the containers is to provide the ring element with a section of barbs hooked into one another.

- the ring element is in this case formed closed and has the portion as an example V-shaped bent portion. The barbs can be hooked into each other upon further compression of the V-shaped portion, so that thereby a reduction in the length of the ring member and, correspondingly, a desired firm embrace of the container is made possible by the ring member.

- Another possibility, which can also be combined with the other variants, is to provide a closure device in the manner of a string of pearls with elements lined up in a row, in particular conical elements.

- conical elements for example, attack each other so that they hooked like barbs together and thereby allow a closure.

- the ring element for generating a support surface for engaging when pushed down along the container walls on an upper support surface is V-shaped.

- a support surface on the ring member in the region in which the means for pushing down attacks, for this a better application of force to the ring member for separating the remaining handle is possible.

- the ring element can for example also be formed in cross-section T-shaped, in turn, an upper Support surface can be created with as little additional material consumption.

- the outside stiffening webs may be formed in particular as secants between the individual receiving elements. As a result, further material savings is possible. Further, for the device acting on the ring element of the device for applying the carrying handles to the container, it becomes more easily possible to grip between the ring element and corresponding openings in the carrying handle in the region of the stiffening webs, when these are arranged approximately parallel to one another.

- a ring member is not required in all types of containers, but especially in larger-sized containers, which otherwise tend to move away from each other in the portion not received in the carrying handle. This is particularly the case with larger bottles of beverage, which is why it is particularly suitable here to use a carrying handle with such a ring element, wherein the ring element prevents the larger-sized beverage bottles sliding apart.

- a stacking of such packaging units, for example, six bottles of beverage is easily possible because the ring element is arranged so that no additional space is required, but rather in the usual way, a populating a pallet is possible.

- identification element in particular identification flag or identification band

- identification element is used to identify the packaging unit of carrying handle and one or more containers, so that, for example, detection in a retail security system or even at a scanner cash register is possible in a simple manner.

- the identification element may be formed, for example, in the form of a flag or as a band or band, which extends in particular over the entire length of the ring member.

- identification element is understood to mean the most varied forms of such an identification element for identifying the packaging unit.

- the identification element in particular identification flag or identification band, can be advantageously labeled, in particular can be printed. It can be provided in particular with an EAN code. This code contains all the data that is important for capturing the contents of the packaging unit and, in particular, the price that can be recorded by a scanner cash register. An additional labeling of the packaging unit is therefore no longer necessary when attaching such an identification element.

- RFID transponder instead of printing or inscribing the identification element, in particular identification flag or identification bands, this can be provided with an RFID transponder.

- RFID transponders With such RFID transponders, a contactless reading of a variety of information stored in the transponders is possible. Herein can not only the container contents and the number of containers of the packaging unit are stored, but of course their price and other possibly interesting information. Since such RFID transponders can be used in a carry handle or a packaging unit, especially in the cash register personschen shops, the provision of such RFID transponder proves just in such packaging units with multiple and possibly from packaging unit to packaging unit different numbers of containers which are offered in grocery stores, etc., as particularly advantageous.

- An identification element, in particular identification flag or identification band, with an RFID transponder advantageously has an RFID tag inserted between two or more layers of a plastic material.

- the layers or layers of plastic may consist of a sprayed plastic or the entire unit of the identification element, in particular Ken Vietnamesesfähnchens or identification bands, be prepared as an injection molded part.

- Can be advantageous Packaging units, in particular for the beverage industry, are provided with such identification elements, wherein an identification element, in particular identification flag or identification band, in particular in the range of or in a carrying handle of the packaging unit can be arranged.

- the identification element in particular identification flag or identification band, is advantageously fastened to the ring element.

- the identification element in particular identification flag or identification band, arranged for pivoting when attached to the containers via two torsion points on or surrounding the container ring element.

- the identification element in particular flag identification or identification band, positioned at an angle of about 65 ° to the horizontal, so that a good reading or scanning of the identification element is possible.

- it is irrelevant in principle in which angle the identification element is arranged, as long as a good readability is given in this case.

- the readability of the RFID transponder may be impaired, so that when using the identification element with RFID transponder it is advantageously ensured that the identification element does not come into contact with a metal container.

- the identification element in particular identification flag or identification band

- the identification element can advantageously be arranged within a receiving element for a can. It is fastened here in particular via connecting webs, which allow telescoping because of their shape. When inserting the can into this receiving element, the latter pushes the identification element out of the receiving element, so that the identification element is subsequently arranged above the can. An identification of the handle with the corresponding doses is therefore also possible.

- an identification element in particular identification flag

- the identification element in particular identification flag

- the identification element in particular the identification flag

- the identification element centrally between the receiving elements. If no further movement of the identification element, in particular identification flag or identification band, required at its mounting location, simple connecting webs may be sufficient for attaching the identification element, instead of twistable or telescopic connecting webs.

- the identification element in particular identification flags or identification bands, can either be provided with the appropriate information prior to the attachment of the carrying handle or after the application of the carrying handle on the containers, wherein, for example, printing can take place via an inkjet printer or another labeling of the identification element.

- the carrying handle is advantageously designed as an injection molded part.

- it consists of a recyclable plastic, including HDPE, ie a high density polyethylene produced under low pressure.

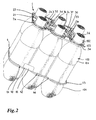

- FIG. 1 shows a plan view of a first embodiment of a handle 1 for six bottles 100, which in FIG. 2 are shown.

- the carrying handle 1 has six receiving elements 2a to 2f for receiving the bottle heads 102. Furthermore, the carrying handle has a gripping element 3, which extends between the receiving elements 2a to 2f. On the outside, the receiving elements are surrounded by a ring element 4. Between the individual receiving elements 2a to 2f 4 stiffening webs 5, 6, 7, 8, 9, 10 are provided with an edge approximately parallel to the ring member.

- the stiffening webs 5 to 9 have an approximately parallel to the ring member extending edge and extending with flat curved portions 50, 51, 60, 61, 70, 71, 80, 81, 90, 91 between the respective adjacent receiving elements.

- the stiffening web 10 is formed bent between the two receiving elements 2a and 2f.

- an identification flag 11 as an embodiment of an identification element for characterizing the later packaging unit of carrying handle and bottles is disposed on the ring member 4 and also extends into the space between the two receiving members 2a and 2f.

- an identification band or another form of identification element can be provided which is or is connected in a suitable manner to the carrying handle, in particular ring element.

- the identification flag 11 is arranged on a portion 40 of the ring element, which is connected via two torsion points 41, 42 to the rest of the ring element 4. About the two torsion points, it is possible to bend out the portion 40 with the identification flag 11 from the plane of the handle. As a result, a slight hiring of Ken Vietnamesesfähnchens in the later position of the ring member is possible, which is separated from the rest of the handle and along the bottles with respect to this pushed down to keep the bottles together also in the lower area. The final position of the flag 11 may be better FIG. 2 be removed.

- the identification flag 11 is here at an angle of about 65 ° relative to the horizontal. In such a position, an easy detection of the contents of the identification flag, eg the data of the packaging unit, including price data, eg by a scanner cash register, is possible.

- the grip element 3 surrounding, further connecting webs 12, 13, 14, 15, 16, 17 are provided. All connecting webs have a curved shape, wherein the connecting webs 12 to 16 are supported by further planar stiffening sections 120, 121, 130, 131, 140, 141, 150, 151, 160, 161 relative to the receiving elements 2a to 2f. Only the connecting web 17, which is arranged in the region of the identification flag 11, has no further stiffening sections. In principle, however, this could also have further stiffening sections, which are omitted for reasons of space here.

- the grip element 3 has a straight in the plan view middle holding portion 30 which is secured via four torsion bars 31, 32, 33, 34 to the connecting webs 13, 14, 16, 17.

- the attachment takes place via respective torsion points 35, 36, 37, 38.

- the middle holding portion 30 of the handle member 3 has a slightly curved shape in the side view, which better the FIG. 2 can be removed. By this slightly curved shape of the middle holding portion centering when stacking several carrying handles on each other for storage in a simple manner possible.

- the individual receiving elements can be designed accordingly to facilitate stacking.

- the receiving elements 2a to 2f each have retaining tabs 20 which engage on the underside of a protruding portion on the bottle head, which in FIG. 2 you can see.

- the retaining tabs 20 protrude inward from a circumferential retaining ring 21 and are, as well FIG. 2 can be better taken out of the plane of the handle out slightly inclined.

- retaining tabs 20 also other holding devices may be provided, such as retaining lugs or webs.

- retaining lugs or webs instead of the respective nine retaining tabs, a different number of retaining tabs can be provided, in particular when providing a different shape for this.

- the shape can also be chosen here arbitrarily, in particular, an adaptation to the respective bottle neck shape or bottle head shape is possible here.

- the surrounding the carrying handle ring member 4 is what the top view in FIG. 1 can not be removed, formed in cross-section approximately V-shaped to have a sufficient support surface 43 when pushing down the ring member along the bottles.

- the ring element is not rectangular in cross-section or square, so that can be saved by the V-shape over such a square or rectangular cross-sectional shape material.

- the ring member 4 is further secured via web members 44, 45, 46 to the remainder of the carrying handle, namely the stiffening webs 6, 7, 9.

- a respective predetermined breaking point 47, 48, 49 is provided between the web elements 44 to 46 and the stiffening webs 6, 7, 9.

- the ring element can be made of such an elastic material that after pushing down, thus stretching of the ring element in the area of the bulges 101 of the bottles 100, it springs back again into its original unstretched form. If the ring element does not have such an elasticity, a closure device 110 is provided for closing, that is, lashing the ring element around the bottles.

- a closure device 110 is in one embodiment in FIG. 1 also shown. This has a paragraph 111 provided with housing 111. Further, it has a closure part 113 which is formed arrow-shaped, wherein it has a tapered projection 114 at its front end. Furthermore, it has a further projection 115 along its longitudinal extension, which can engage in the housing 112 in a corresponding recess 116.

- the closure member 113 is inserted into the housing 112 and locked in the desired paragraph 111 with its front projection 114. Due to the latching an unintentional release is no longer possible here, so that the closure device ensures that the container or bottles 100 of the ring element 4 tightly enclosed.

- This may also be the perspective view in FIG. 3 be removed. Here, the latched position of the closure device is shown. According to the embodiment in FIG. 3 can the case on its top open, so that the proper locking within the housing is visible from the outside. Likewise, the housing 112 may be formed closed.

- corresponding devices may be provided in automatic placement machines or the device for applying the carrying handles to the containers, via slide elements or corresponding other devices in the region of the housing 112 and in the region of the closure part 113 attacks and move them against each other until a close concern of the ring member 4 is done around the bottles around.

- FIG. 4 shows an alternative embodiment of a carrying handle 200 which is adapted to receive six cans.

- six receiving elements 2a to 2f are formed, but provide shorter retaining tabs 245, since usually the upper edge is less pronounced in doses as a circumferential projection in beverage bottles.

- each stiffening webs 205 to 210 are also provided.

- these are all formed uniformly, since a flag ID 211 is disposed within the receiving element 2d.

- the stiffening webs 205 to 210 are each formed as narrow, slightly curved webs between the individual receiving elements 2a to 2f.

- the individual receiving elements also arranged in the inner region of the handle connecting webs 212 to 217 are provided.

- each further connecting webs 218, 219, 220, 221 are provided between the respective stiffening webs and connecting webs on the outside and inside of the carrying handle. They are wider than the stiffening and connecting webs, so that over this a stiffening of the entire handle is possible.

- the two receiving elements 2c and 2f are also connected via a further connecting web 222 connected together to stiffen the middle portion of the handle.

- the carrying handle has two handle members 230, 231. Both are arranged within a respective receiving element, namely within the receiving elements 2c and 2f. Both gripping elements are mirror-symmetrical to each other and each have a central web 232, 233 and from this v-shaped mutually extending torsion bars 234, 235, 236, 237 on. These are fastened via respective torsion points 238 to the receiving elements 2c and 2f.

- the gripping elements 230, 231 Due to the V-shape of the torsion bars and the further bending relative to the respective central webs of the gripping elements 230, 231, these can in turn be telescoped out of the plane of the carrying handle when pulled out of the plane of the carrying handle, and in turn via the torsion points the torsion bars and thereby results in an approximately parallel extraction of the central webs 232, 233 from the plane of the carrying handle.

- the two gripping elements 230, 231 are brought together in the direction of the connecting web 222 between the two receiving elements 2c and 2f and can then be grasped by a hand of a carrying person and the packaging unit of carrying handle and six cans can be comfortably carried.

- the identification flag 211 or in the carrying handle according to Figure 1 to 3 the identification flag 11 is provided. On this a corresponding code can be printed or otherwise applied. Alternatively, it is also possible to introduce here an RFID transponder in the identification flag, which contains the desired data.

- the identification flag 211 is arranged via telescopic webs 240 to 243 within the receiving element 2d.

- the telescopic webs 240 are serpentine curved back and forth, so that pushing out of the identification flag 11 from the plane of Carrying handle is easily possible. This is done automatically when a can head is inserted into the receiving element 2d.

- it also proves to be advantageous to connect the four telescopic webs 240 to 243 via corresponding torsion points 244 on the receiving element 2d or its retaining tabs 245.

- FIG. 5 Another embodiment of a carrying handle 300 is shown in FIG. 5 for wearing a 5 liter drum, for example.

- a receiving element 302 is provided.

- This also has retaining tabs 320.

- an unillustrated receiving ring may be provided, from which protrude the retaining tabs in the interior of the receiving element.

- the retaining tabs are here, as well as in the embodiment of the handle for cans according to FIG. 4 , formed relatively short towards the interior of the receiving element, since the edge of a 5 liter drum is formed relatively narrow, so that these short retaining tabs for reaching under the edge of this sufficient.

- the carrying handle according FIG. 5 is also provided with a handle member 330. This is attached at two mutually approximately opposite points on the outside of the receiving element 302 via torsion points 331, 332. In the rest position, the gripping element 330 lies in the plane of the receiving element 302.

- the gripping element 330 has a slightly wider central holding section 333 and two webs 334, 335 extending therefrom to the two torsion points 331, 332.

- the middle holding web 333 can be held in a parallel plane above the plane of the receiving element 302.

- there is advantageously no deformation of the middle holding web 333 so that a comfortable carrying position can be achieved.

- Carrying handles serve for receiving six containers in the form of bottles or cans or other containers which fit into the receiving elements.

- embodiments may also be provided in which less or more containers than packaging unit to be packed.

- the provision of carrying handles for four cans or four bottles is possible.

- the identification flag 211 may be placed in a central inner opening of the carrying handle, so it need not be placed within a receiving element.

- the handle member may be disposed in the region of the central inner opening within the carrying handle, instead of the arrangement in two adjacent receiving elements, as in FIG. 4 shown. It can also be provided here only a handle element, since this is sufficient for a handle for four doses.

- All handles can be made of HDPE or of any other suitable material, in particular plastic material.

- each of the handle element is telescoped out of the plane of the handle, at least two torsion points on the handle or at least one ring element for surrounding the outside of the container , which are detachably attached to the carrying handle, or in which at least one identification element, such as a identification flag, identification band, etc., is arranged on the carrying handle or a packaging unit of a plurality of containers.

- at least one identification element such as a identification flag, identification band, etc.

- corresponding carrying handles for other packaging unit sizes can be formed, in which in each case likewise a ring element or identification element or a corresponding grip element fastened to the carrying handle via torsion points are provided. All mentioned in the foregoing and shown in the figures features can be combined with each other.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Details Of Rigid Or Semi-Rigid Containers (AREA)

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE200710034870 DE102007034870A1 (de) | 2007-07-24 | 2007-07-24 | Tragegriff |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2028126A1 true EP2028126A1 (fr) | 2009-02-25 |

| EP2028126B1 EP2028126B1 (fr) | 2013-05-01 |

Family

ID=39760929

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP20080013311 Not-in-force EP2028126B1 (fr) | 2007-07-24 | 2008-07-24 | Support avec poignée |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP2028126B1 (fr) |

| DE (1) | DE102007034870A1 (fr) |

Cited By (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2012159694A1 (fr) * | 2011-05-20 | 2012-11-29 | Khs Gmbh | Ensembles d'articles, procédé de production de ces ensembles et dispositif de manipulation, transport, emballage et/ou palettisation d'articles |

| WO2013004339A1 (fr) * | 2011-07-05 | 2013-01-10 | Khs Gmbh | Emballage multiple et procédé de réalisation d'un tel emballage multiple |

| GB2519659A (en) * | 2013-10-03 | 2015-04-29 | P4Ck Ltd | Drinks carrier |

| US9815605B2 (en) | 2009-11-23 | 2017-11-14 | British Polythene Limited | Container carrier |

| CN109328171A (zh) * | 2016-05-02 | 2019-02-12 | 维实洛克包装系统有限公司 | 用于形成物品载体的坯件 |

| EP3455145A4 (fr) * | 2017-07-14 | 2019-12-11 | Oregon Precision Industries, Inc. Dba Paktech | Support de récipient à poignée surélevée souple |

| EP2948387B1 (fr) | 2013-01-22 | 2021-06-02 | Loadhog Limited | Agencement de coiffage de charge |

Citations (30)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE1138194B (de) | 1960-10-19 | 1962-10-18 | Snap Pac Corp | Trage- und Haltevorrichtung fuer Behaelter |

| US3084792A (en) * | 1960-09-23 | 1963-04-09 | Illinois Tool Works | Container carrier |

| DE2120303A1 (de) | 1970-04-30 | 1971-11-18 | Owens-Illinois, Inc., Toledo, Ohio (V.StA.) | Behälterverpackung |

| DE2144334A1 (de) | 1971-09-03 | 1973-03-08 | Walter Heubl | Flaschentraeger |

| US3727754A (en) * | 1971-06-16 | 1973-04-17 | Illinois Tool Works | Container carrier |

| DE2531325A1 (de) | 1974-07-16 | 1976-01-29 | Illinois Tool Works | Behaelterverpackung |

| US4545480A (en) * | 1983-10-17 | 1985-10-08 | Illinois Tool Works Inc. | Bottle multi-package and multi-packaging device |

| DE8915740U1 (de) | 1989-06-02 | 1991-04-04 | Grafenwald Kunststoff GmbH & Co Verarbeitungs und Vertriebs KG, 5508 Hermeskeil | Gebinde bestehend aus Behältern und Tragrahmen |

| US5306060A (en) | 1992-07-06 | 1994-04-26 | Oregon Precision Industries, Inc. | Carrier strap for bottles or jugs |

| DE4411188A1 (de) | 1993-04-08 | 1994-10-13 | Int Omni Pak Corp | Träger für Flaschen und ähnliche Behälter |

| US5735562A (en) | 1997-02-18 | 1998-04-07 | Oregon Precision Industries, Inc. | Multi-container carrier |

| US6129397A (en) | 1998-07-15 | 2000-10-10 | Oregon Precision Industries | Six pack carrier |

| EP1077183A1 (fr) * | 1999-08-17 | 2001-02-21 | Illinois Tool Works Inc. | Porte-récipients |

| WO2002040357A2 (fr) * | 2000-11-14 | 2002-05-23 | Dow Global Technologies Inc. | Ensemble a poignee pour recipients contenant un fluide volumineux |

| US6394517B1 (en) | 2001-04-11 | 2002-05-28 | Oregon Precision Industries | Single bottle carrier |

| DE20311628U1 (de) | 2003-07-29 | 2003-09-25 | Guzik, Werner, 92224 Amberg | Halter für Flaschen |

| DE69905308T2 (de) | 1998-04-10 | 2003-12-11 | Guglielmo Ferrari | Vorrichtung zum Transportieren von Flaschen |

| US6715810B2 (en) | 2002-09-09 | 2004-04-06 | Oregon Precision Industries, Inc. | Three bottle carrier |

| WO2004076310A2 (fr) | 2003-02-26 | 2004-09-10 | Schoeller Wavin Systems Services Gmbh | Support pour recipients, en particulier des bouteilles |

| US6789828B1 (en) | 2003-08-04 | 2004-09-14 | Oregon Precision Industries, Inc. | Stabilizing two-bottle carrier |

| US20040256250A1 (en) | 2003-06-23 | 2004-12-23 | Borg Zakary J. | Balanced multiple container carrier |

| DE202005005970U1 (de) | 2005-04-14 | 2005-07-21 | Seifert, Gregor | Flaschenbündler für PET-Pfandflaschen |

| DE102004019437A1 (de) | 2004-04-19 | 2005-11-03 | Markus E.Kfm. Wulf | Tragvorrichtung für wenigstens ein Behältnis, insbesondere eine Flasche |

| DE202005016091U1 (de) | 2005-10-13 | 2005-12-08 | Schoeller Arca Systems Services Gmbh | Träger für Flaschen u.dgl. Behälter |

| DE202005014112U1 (de) | 2005-08-01 | 2005-12-29 | Terramark Markencreation Gmbh | Tragegriff |

| EP1710171A1 (fr) | 2005-04-08 | 2006-10-11 | Oregon Precision Industries, Inc. | Porte-conténeurs équilibré |

| US20060254934A1 (en) | 2005-05-16 | 2006-11-16 | Oregon Precision Industries, Inc. | Tandem harness for tub-like containers |

| EP1752386A1 (fr) | 2005-08-09 | 2007-02-14 | Oregon Precision Industries, Inc. | Moyens pour lier ensemble et porter plusieures bouteilles |

| US20070039836A1 (en) | 2005-08-19 | 2007-02-22 | Oregon Precision Industries, Inc. | Multiple container carrier |

| DE112004002843T5 (de) | 2004-05-13 | 2007-05-10 | Roberts Polypro Inc. | Behälterträger |

-

2007

- 2007-07-24 DE DE200710034870 patent/DE102007034870A1/de not_active Withdrawn

-

2008

- 2008-07-24 EP EP20080013311 patent/EP2028126B1/fr not_active Not-in-force

Patent Citations (30)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3084792A (en) * | 1960-09-23 | 1963-04-09 | Illinois Tool Works | Container carrier |

| DE1138194B (de) | 1960-10-19 | 1962-10-18 | Snap Pac Corp | Trage- und Haltevorrichtung fuer Behaelter |

| DE2120303A1 (de) | 1970-04-30 | 1971-11-18 | Owens-Illinois, Inc., Toledo, Ohio (V.StA.) | Behälterverpackung |

| US3727754A (en) * | 1971-06-16 | 1973-04-17 | Illinois Tool Works | Container carrier |

| DE2144334A1 (de) | 1971-09-03 | 1973-03-08 | Walter Heubl | Flaschentraeger |

| DE2531325A1 (de) | 1974-07-16 | 1976-01-29 | Illinois Tool Works | Behaelterverpackung |

| US4545480A (en) * | 1983-10-17 | 1985-10-08 | Illinois Tool Works Inc. | Bottle multi-package and multi-packaging device |

| DE8915740U1 (de) | 1989-06-02 | 1991-04-04 | Grafenwald Kunststoff GmbH & Co Verarbeitungs und Vertriebs KG, 5508 Hermeskeil | Gebinde bestehend aus Behältern und Tragrahmen |

| US5306060A (en) | 1992-07-06 | 1994-04-26 | Oregon Precision Industries, Inc. | Carrier strap for bottles or jugs |

| DE4411188A1 (de) | 1993-04-08 | 1994-10-13 | Int Omni Pak Corp | Träger für Flaschen und ähnliche Behälter |

| US5735562A (en) | 1997-02-18 | 1998-04-07 | Oregon Precision Industries, Inc. | Multi-container carrier |

| DE69905308T2 (de) | 1998-04-10 | 2003-12-11 | Guglielmo Ferrari | Vorrichtung zum Transportieren von Flaschen |

| US6129397A (en) | 1998-07-15 | 2000-10-10 | Oregon Precision Industries | Six pack carrier |

| EP1077183A1 (fr) * | 1999-08-17 | 2001-02-21 | Illinois Tool Works Inc. | Porte-récipients |

| WO2002040357A2 (fr) * | 2000-11-14 | 2002-05-23 | Dow Global Technologies Inc. | Ensemble a poignee pour recipients contenant un fluide volumineux |

| US6394517B1 (en) | 2001-04-11 | 2002-05-28 | Oregon Precision Industries | Single bottle carrier |

| US6715810B2 (en) | 2002-09-09 | 2004-04-06 | Oregon Precision Industries, Inc. | Three bottle carrier |

| WO2004076310A2 (fr) | 2003-02-26 | 2004-09-10 | Schoeller Wavin Systems Services Gmbh | Support pour recipients, en particulier des bouteilles |

| US20040256250A1 (en) | 2003-06-23 | 2004-12-23 | Borg Zakary J. | Balanced multiple container carrier |

| DE20311628U1 (de) | 2003-07-29 | 2003-09-25 | Guzik, Werner, 92224 Amberg | Halter für Flaschen |

| US6789828B1 (en) | 2003-08-04 | 2004-09-14 | Oregon Precision Industries, Inc. | Stabilizing two-bottle carrier |

| DE102004019437A1 (de) | 2004-04-19 | 2005-11-03 | Markus E.Kfm. Wulf | Tragvorrichtung für wenigstens ein Behältnis, insbesondere eine Flasche |

| DE112004002843T5 (de) | 2004-05-13 | 2007-05-10 | Roberts Polypro Inc. | Behälterträger |

| EP1710171A1 (fr) | 2005-04-08 | 2006-10-11 | Oregon Precision Industries, Inc. | Porte-conténeurs équilibré |

| DE202005005970U1 (de) | 2005-04-14 | 2005-07-21 | Seifert, Gregor | Flaschenbündler für PET-Pfandflaschen |

| US20060254934A1 (en) | 2005-05-16 | 2006-11-16 | Oregon Precision Industries, Inc. | Tandem harness for tub-like containers |

| DE202005014112U1 (de) | 2005-08-01 | 2005-12-29 | Terramark Markencreation Gmbh | Tragegriff |

| EP1752386A1 (fr) | 2005-08-09 | 2007-02-14 | Oregon Precision Industries, Inc. | Moyens pour lier ensemble et porter plusieures bouteilles |

| US20070039836A1 (en) | 2005-08-19 | 2007-02-22 | Oregon Precision Industries, Inc. | Multiple container carrier |

| DE202005016091U1 (de) | 2005-10-13 | 2005-12-08 | Schoeller Arca Systems Services Gmbh | Träger für Flaschen u.dgl. Behälter |

Cited By (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US9815605B2 (en) | 2009-11-23 | 2017-11-14 | British Polythene Limited | Container carrier |

| WO2012159694A1 (fr) * | 2011-05-20 | 2012-11-29 | Khs Gmbh | Ensembles d'articles, procédé de production de ces ensembles et dispositif de manipulation, transport, emballage et/ou palettisation d'articles |

| WO2013004339A1 (fr) * | 2011-07-05 | 2013-01-10 | Khs Gmbh | Emballage multiple et procédé de réalisation d'un tel emballage multiple |

| EP2948387B1 (fr) | 2013-01-22 | 2021-06-02 | Loadhog Limited | Agencement de coiffage de charge |

| GB2519659A (en) * | 2013-10-03 | 2015-04-29 | P4Ck Ltd | Drinks carrier |

| GB2519659B (en) * | 2013-10-03 | 2018-08-15 | P4Ck Ltd | Drinks Carrier With Deformable Support Holes |

| CN109328171A (zh) * | 2016-05-02 | 2019-02-12 | 维实洛克包装系统有限公司 | 用于形成物品载体的坯件 |

| EP3452387B1 (fr) * | 2016-05-02 | 2024-07-03 | WestRock Packaging Systems, LLC | Ébauche pour former un dispositif porteur d'articles |

| EP3455145A4 (fr) * | 2017-07-14 | 2019-12-11 | Oregon Precision Industries, Inc. Dba Paktech | Support de récipient à poignée surélevée souple |

| US11001428B2 (en) | 2017-07-14 | 2021-05-11 | Oregon Precision Industries, Inc. | Container carrier with flexible raised handle |

Also Published As

| Publication number | Publication date |

|---|---|

| DE102007034870A1 (de) | 2009-01-29 |

| EP2028126B1 (fr) | 2013-05-01 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2028126B1 (fr) | Support avec poignée | |

| DE60208304T2 (de) | Behälterträger und Verpackung | |

| DE2635523A1 (de) | Packung und tragevorrichtung fuer mehrere flaschen oder dergleichen behaelter | |

| DE69311338T2 (de) | Mehrfachpackung für behälter | |

| EP2055648B1 (fr) | Section destinée à la fabrication d'un emballage circonférentiel pour bouteilles et unité d'emballage en étant pourvue | |

| DE1457489A1 (de) | Tragpaket | |

| EP2334567B1 (fr) | Poignée de manutention pour conteneur | |

| DE202008005594U1 (de) | Gebinde von Flüssigkeitsbehältern | |

| DE69529983T2 (de) | Flaschenträger mit verbesserter greifvorrichtung | |

| DE102019007143A1 (de) | Verschluss für einen Behälter, Behälter, Spritzgusswerkzeugsatz und Verfahren | |

| WO2014029491A1 (fr) | Pack et procédé de formation | |

| DE202012103324U1 (de) | Gebindeschablone zum Zusammenfügen von Verpackungseinheiten | |

| DE202009002012U1 (de) | Gebinde aus Flüssigkeitsbehältern | |

| DE202004017954U1 (de) | Trage für Bügelverschluss-Flaschen | |

| EP2383189B1 (fr) | Unité de transport/présentation avec support de transport/présentation pour récipients, de préférence récipients à boissons | |

| EP2711308B1 (fr) | Emballage d'entourage pour conteneurs | |

| DE3241474C2 (fr) | ||

| DE202004011166U1 (de) | Tragriemen für ein Flaschenpaket, ein Gebinde o.dgl. | |

| DE202019106962U1 (de) | Zuschnitt für eine Aufnahmevorrichtung für Getränkeverpackungen | |

| WO2008006555A1 (fr) | Dispositif porteur pour bouteilles (en matière plastique) | |

| DE102019123824A1 (de) | Verbindungsmittel | |

| EP1674401B1 (fr) | Procédé pour monter une bande publicitaire à un porte-articles et porte-articles correspondant | |

| EP0400400A2 (fr) | Ensemble d'emballage constitué par des réceptacles et un châssis de support | |

| DE112004002843T5 (de) | Behälterträger | |

| EP4334222A1 (fr) | Moyen d'emballage, unité d'emballage et procédé de formation d'unités d'emballage |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MT NL NO PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA MK RS |

|

| AKX | Designation fees paid |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MT NL NO PL PT RO SE SI SK TR |

|

| 17P | Request for examination filed |

Effective date: 20090825 |

|

| 17Q | First examination report despatched |

Effective date: 20091105 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MT NL NO PL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP Ref country code: AT Ref legal event code: REF Ref document number: 609797 Country of ref document: AT Kind code of ref document: T Effective date: 20130515 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502008009821 Country of ref document: DE Effective date: 20130704 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: VDEP Effective date: 20130501 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130501 Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130501 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130801 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130802 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130501 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130902 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130812 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130501 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130901 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130801 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130501 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130501 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130501 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130501 |

|

| BERE | Be: lapsed |

Owner name: RICHARDSON, MIRCO I. Effective date: 20130731 Owner name: WAFFENSCHMIDT, DIRK Effective date: 20130731 Owner name: ROTTGER, KLAUS Effective date: 20130731 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130501 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130501 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130501 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130501 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130501 Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130501 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130501 Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130501 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20140204 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20130801 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 502008009821 Country of ref document: DE Effective date: 20140201 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20140331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130731 Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140201 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130731 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130731 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130731 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130801 Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130724 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 609797 Country of ref document: AT Kind code of ref document: T Effective date: 20130724 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130724 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130501 Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130501 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130724 Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20080724 |