EP1186355B1 - Machine de nettoyage de bouteilles - Google Patents

Machine de nettoyage de bouteilles Download PDFInfo

- Publication number

- EP1186355B1 EP1186355B1 EP01120680A EP01120680A EP1186355B1 EP 1186355 B1 EP1186355 B1 EP 1186355B1 EP 01120680 A EP01120680 A EP 01120680A EP 01120680 A EP01120680 A EP 01120680A EP 1186355 B1 EP1186355 B1 EP 1186355B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- cleaning machine

- bottle cleaning

- machine according

- eddy

- intake opening

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000004140 cleaning Methods 0.000 title claims abstract description 24

- 239000003517 fume Substances 0.000 claims 1

- 239000000126 substance Substances 0.000 claims 1

- HEMHJVSKTPXQMS-UHFFFAOYSA-M Sodium hydroxide Chemical compound [OH-].[Na+] HEMHJVSKTPXQMS-UHFFFAOYSA-M 0.000 description 9

- 239000007789 gas Substances 0.000 description 5

- 238000005406 washing Methods 0.000 description 5

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 4

- 229910052782 aluminium Inorganic materials 0.000 description 4

- UFHFLCQGNIYNRP-UHFFFAOYSA-N Hydrogen Chemical compound [H][H] UFHFLCQGNIYNRP-UHFFFAOYSA-N 0.000 description 3

- 238000000605 extraction Methods 0.000 description 2

- 208000035415 Reinfection Diseases 0.000 description 1

- AZDRQVAHHNSJOQ-UHFFFAOYSA-N alumane Chemical group [AlH3] AZDRQVAHHNSJOQ-UHFFFAOYSA-N 0.000 description 1

- 239000007864 aqueous solution Substances 0.000 description 1

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 1

- 235000013405 beer Nutrition 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 239000002775 capsule Substances 0.000 description 1

- 239000007799 cork Substances 0.000 description 1

- 238000009795 derivation Methods 0.000 description 1

- 238000007599 discharging Methods 0.000 description 1

- 230000008030 elimination Effects 0.000 description 1

- 238000003379 elimination reaction Methods 0.000 description 1

- 238000004880 explosion Methods 0.000 description 1

- 238000003197 gene knockdown Methods 0.000 description 1

- 230000035784 germination Effects 0.000 description 1

- 239000001257 hydrogen Substances 0.000 description 1

- 229910052739 hydrogen Inorganic materials 0.000 description 1

- 239000000203 mixture Substances 0.000 description 1

- 239000001301 oxygen Substances 0.000 description 1

- 229910052760 oxygen Inorganic materials 0.000 description 1

- 238000005192 partition Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B08—CLEANING

- B08B—CLEANING IN GENERAL; PREVENTION OF FOULING IN GENERAL

- B08B15/00—Preventing escape of dirt or fumes from the area where they are produced; Collecting or removing dirt or fumes from that area

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B08—CLEANING

- B08B—CLEANING IN GENERAL; PREVENTION OF FOULING IN GENERAL

- B08B9/00—Cleaning hollow articles by methods or apparatus specially adapted thereto

- B08B9/08—Cleaning containers, e.g. tanks

- B08B9/20—Cleaning containers, e.g. tanks by using apparatus into or on to which containers, e.g. bottles, jars, cans are brought

Definitions

- the invention relates to a bottle cleaning machine with an up and Dispensing station and several arranged in the direction of flow of the bottles treatment stations and a suction channel for steam or other air masses.

- Container washing machines in particular high-performance washing machines for the cellar industry

- Laugenstation a so-called Laugenstation on, immersed in the container to be cleaned in a tub which is filled with cleaning liquor.

- an aqueous Solution of NaOH used as lye.

- the tub is heated to the lye temperature to, for example, 80 ° C hold.

- To be cleaned containers often have aluminum equipment.

- one-liter liter crown cork beer bottles are usually in the head area with one so-called aluminum capsule provided, the largest part of the cleaning yet is available.

- Even labels may consist entirely or partially of aluminum.

- the object of the invention is to provide a device with which in a cleaning machine accumulated and to be eliminated air masses more targeted and broader sucked and can be derived.

- suction channel runs transversely to the direction of movement of the bottles and as a vortex hood is formed with a Vorbelsenkenabsaugung.

- the formation of the invention is a particularly advantageous derivation of gases to be removed from the housing of a bottle washing machine, Swaths, air masses and the like. guaranteed.

- the air masses can be fast and targeted on the entire width of the longitudinal or transversely installed suction ducts are detected and derived by this.

- the Throughput of the suction duct is the machine performance appropriate automatically adaptable.

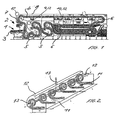

- a bottle washer with the feeding station 1 and the dispensing station 2 shown.

- the bottles 3 are in bottle cells 4 by the individual cleaning departments 5,6 out and in the area of the dispensing station 2, for example, by rotating discharge surfaces underpinned and down to discontinued or pushed onto a drain conveyor.

- a steam extraction duct 7 arranged, the inside wall is practically used as a partition for Machine housing 8 may be formed.

- suction channels 9,10 in the individual treatment zones and divisions 5,6 of such a cleaning machine be provided.

- suction 7.7 'with a slit-shaped suction port 11 which according to the embodiment runs transversely to the bottle conveying direction. But this can also be longitudinal to the bottle conveying direction run.

- the suction port 11 is part of a swirling flow generating vortex hood 12, which at least laterally on one side a support tube 13 for discharging the sucked air masses.

- a swirling flow generating vortex hood 12 which at least laterally on one side a support tube 13 for discharging the sucked air masses.

- very wide cleaning machines or long vortex hoods 12 can laterally provided on both sides and also in the middle of the vortex hood 12 more support tubes 13 be.

- the gap width of the intake passage 7 may be adjustable and depending on the machine throughput can be changed.

- At least a portion of the vortex hood 12 can directly shape the housing or part of the housing. Incidentally, any cross-sectional shapes can be provided be.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Cleaning In General (AREA)

- Centrifugal Separators (AREA)

Claims (6)

- Laveuse de bouteilles comprenant un poste de chargement et de dégagement et plusieurs postes de traitement, disposés suivant la direction de passage des bouteilles, ainsi qu'au moins un canal d'évacuation des vapeurs et/ou des autres masses d'air, caractérisée en ce que le canal d'évacuation présente, au moins partiellement, une ouverture d'aspiration (7, 7') en forme de fente, qui s'étend transversalement et/ou longitudinalement dans le carter (8) de la laveuse et fait partie d'un capot à tourbillon (12) provoquant un écoulement giratoire.

- Laveuse de bouteilles selon le préambule de la revendication 1, caractérisée en ce que le canal d'évacuation (7, 7') est perpendiculaire à la direction de déplacement des bouteilles et est conformé en capot à tourbillon (12) avec une aspiration qui abaisse le tourbillon.

- Laveuse de bouteilles selon les revendications précédentes, caractérisée en ce que la largeur de l'ouverture d'aspiration (7, 7') en forme de fente est susceptible d'être modifiée.

- Laveuse de bouteilles selon les revendications précédentes, caractérisée en ce que la largeur de l'ouverture d'aspiration (7, 7') en forme de fente est susceptible d'être modifiée manuellement et/ou de façon motorisée, en fonction du débit de la machine.

- Laveuse de bouteilles selon les revendications précédentes, caractérisée en ce qu"est prévu, latéralement, sur un côté et/ou au milieu, au moins un tube support (13) servant à évacuer l'air aspiré.

- Laveuse de bouteilles selon les revendications précédentes, caractérisée en ce qu "au moins une partie du capot à tourbillon (12) est constituée par des composants (8) de la laveuse.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE10045083A DE10045083A1 (de) | 2000-09-12 | 2000-09-12 | Flaschenreinigungsmaschine |

| DE10045083 | 2000-09-12 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP1186355A2 EP1186355A2 (fr) | 2002-03-13 |

| EP1186355A3 EP1186355A3 (fr) | 2003-08-20 |

| EP1186355B1 true EP1186355B1 (fr) | 2004-07-21 |

Family

ID=7655933

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP01120680A Expired - Lifetime EP1186355B1 (fr) | 2000-09-12 | 2001-09-03 | Machine de nettoyage de bouteilles |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP1186355B1 (fr) |

| AT (1) | ATE271427T1 (fr) |

| DE (2) | DE10045083A1 (fr) |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB514293A (en) * | 1937-05-06 | 1939-11-03 | Cherry Burrell Corp | Improvements in or relating to machines for washing bottles or similar containers |

| US4208761A (en) * | 1978-01-24 | 1980-06-24 | New England Machinery, Inc. | Bottle conveying and cleaning apparatus |

| DE3914412A1 (de) * | 1989-04-29 | 1990-10-31 | Seitz Enzinger Noll Masch | System zur nutzung der abwaerme einer flaschenreinigungsmaschine |

| DE4232986C2 (de) * | 1992-10-01 | 1996-10-31 | Khs Masch & Anlagenbau Ag | Flaschenreinigungsmaschine mit einer Auf- und Abgabestation |

-

2000

- 2000-09-12 DE DE10045083A patent/DE10045083A1/de not_active Withdrawn

-

2001

- 2001-09-03 DE DE50102907T patent/DE50102907D1/de not_active Expired - Lifetime

- 2001-09-03 AT AT01120680T patent/ATE271427T1/de not_active IP Right Cessation

- 2001-09-03 EP EP01120680A patent/EP1186355B1/fr not_active Expired - Lifetime

Also Published As

| Publication number | Publication date |

|---|---|

| DE50102907D1 (de) | 2004-08-26 |

| EP1186355A3 (fr) | 2003-08-20 |

| EP1186355A2 (fr) | 2002-03-13 |

| DE10045083A1 (de) | 2002-03-28 |

| ATE271427T1 (de) | 2004-08-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE102011119171B3 (de) | Vorrichtung zur Behandlung von Behältern mit einer Absaugvorrichtung | |

| DE2612958A1 (de) | Vorrichtung zum entfernen von sauerstoff aus verpackungsbehaeltern | |

| DE8807146U1 (de) | Vorrichtung zum Transportieren von Flaschen | |

| DE10207499A1 (de) | Verfahren zum Reinigen von Fluidabgabeeinrichtungen und Reinigungsvorrichtung | |

| EP2331410A1 (fr) | Procédé et dispositif de remplissage | |

| EP3067126B1 (fr) | Dispositif de rinçage d'un récipient avec un fluide de rinçage | |

| EP1186355B1 (fr) | Machine de nettoyage de bouteilles | |

| DE10358265A1 (de) | Behälterbehandlungsvorrichtung mit Gasvorhang | |

| EP2688689B1 (fr) | Dispositif de soufflage de fonds de bouteilles | |

| DE102020129774A1 (de) | Vorrichtung zur Förderung und Reinigung von Kleinteilen mit einem offenen Hohlraum | |

| DE2645464C2 (de) | Einrichtung zum unmittelbaren Fördern von leichten Gegenständen in einer Rinne | |

| EP1513761B1 (fr) | Dispositif pour expulser l'air exterieur d'un espace a atmosphere purifiee | |

| DE102008049296A1 (de) | Vorrichtung zum Abblasen oder Trocknen von Kästen oder dergleichen Behältern | |

| AT396737B (de) | Vorrichtung zum abscheiden von dunst-, fett- und staubpartikeln aus einem luftstrom | |

| EP0387526B1 (fr) | Dispositif pour le traitement électrolytique d'objets dans une suite de bains | |

| DE19916233C1 (de) | Walzgerüst | |

| DE2623033A1 (de) | Verfahren und vorrichtung zur reinigung von gasen | |

| DE3145168A1 (de) | Vorrichtung zum automatischen abbuersten von flaschenkapseln | |

| EP1226087B1 (fr) | Dispositif de moussage pour r cipients de boisson | |

| DE19733582B4 (de) | Verfahren und Vorrichtung zum Behandeln von Flaschen oder dergleichen in einem Flüssigkeitsbad | |

| DE4035786A1 (de) | Blaskopf einer vorrichtung zum waschen von halbleitermaterialien | |

| DE1801797A1 (de) | Flaschenreinigungsmaschine | |

| WO2023089004A1 (fr) | Dispositif de lames d'air | |

| DE3939601A1 (de) | Vorrichtung zum trocknen von kleinteilen | |

| DE9310736U1 (de) | Verschließmaschine für Gefäße |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20010926 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK RO SI |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| AKX | Designation fees paid |

Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040721 Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040721 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040721 Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040721 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20040721 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: GERMAN |

|

| REF | Corresponds to: |

Ref document number: 50102907 Country of ref document: DE Date of ref document: 20040826 Kind code of ref document: P |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040903 Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040903 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20041021 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20041021 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20041021 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20041101 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| ET | Fr: translation filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20050422 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20050930 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20050930 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20070531 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: RN |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: FC |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20041221 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20061002 |

|

| PGRI | Patent reinstated in contracting state [announced from national office to epo] |

Ref country code: FR Effective date: 20071017 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: TD Effective date: 20111114 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: CD Owner name: KHS GMBH Effective date: 20111121 Ref country code: FR Ref legal event code: CD Owner name: KHS GMBH Effective date: 20111122 |

|

| BECN | Be: change of holder's name |

Owner name: KHS G.M.B.H. Effective date: 20120314 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 16 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 17 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20170921 Year of fee payment: 17 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20170921 Year of fee payment: 17 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 18 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MM Effective date: 20181001 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20180903 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20181001 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180903 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20200914 Year of fee payment: 20 Ref country code: DE Payment date: 20200925 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 20200925 Year of fee payment: 20 Ref country code: IT Payment date: 20200922 Year of fee payment: 20 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R071 Ref document number: 50102907 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MK Effective date: 20210903 |