EP1186355B1 - Flaschenreinigungsmaschine - Google Patents

Flaschenreinigungsmaschine Download PDFInfo

- Publication number

- EP1186355B1 EP1186355B1 EP01120680A EP01120680A EP1186355B1 EP 1186355 B1 EP1186355 B1 EP 1186355B1 EP 01120680 A EP01120680 A EP 01120680A EP 01120680 A EP01120680 A EP 01120680A EP 1186355 B1 EP1186355 B1 EP 1186355B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- cleaning machine

- bottle cleaning

- machine according

- eddy

- intake opening

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000004140 cleaning Methods 0.000 title claims abstract description 24

- 239000003517 fume Substances 0.000 claims 1

- 239000000126 substance Substances 0.000 claims 1

- HEMHJVSKTPXQMS-UHFFFAOYSA-M Sodium hydroxide Chemical compound [OH-].[Na+] HEMHJVSKTPXQMS-UHFFFAOYSA-M 0.000 description 9

- 239000007789 gas Substances 0.000 description 5

- 238000005406 washing Methods 0.000 description 5

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 4

- 229910052782 aluminium Inorganic materials 0.000 description 4

- UFHFLCQGNIYNRP-UHFFFAOYSA-N Hydrogen Chemical compound [H][H] UFHFLCQGNIYNRP-UHFFFAOYSA-N 0.000 description 3

- 238000000605 extraction Methods 0.000 description 2

- 208000035415 Reinfection Diseases 0.000 description 1

- AZDRQVAHHNSJOQ-UHFFFAOYSA-N alumane Chemical group [AlH3] AZDRQVAHHNSJOQ-UHFFFAOYSA-N 0.000 description 1

- 239000007864 aqueous solution Substances 0.000 description 1

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 1

- 235000013405 beer Nutrition 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 239000002775 capsule Substances 0.000 description 1

- 239000007799 cork Substances 0.000 description 1

- 238000009795 derivation Methods 0.000 description 1

- 238000007599 discharging Methods 0.000 description 1

- 230000008030 elimination Effects 0.000 description 1

- 238000003379 elimination reaction Methods 0.000 description 1

- 238000004880 explosion Methods 0.000 description 1

- 238000003197 gene knockdown Methods 0.000 description 1

- 230000035784 germination Effects 0.000 description 1

- 239000001257 hydrogen Substances 0.000 description 1

- 229910052739 hydrogen Inorganic materials 0.000 description 1

- 239000000203 mixture Substances 0.000 description 1

- 239000001301 oxygen Substances 0.000 description 1

- 229910052760 oxygen Inorganic materials 0.000 description 1

- 238000005192 partition Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B08—CLEANING

- B08B—CLEANING IN GENERAL; PREVENTION OF FOULING IN GENERAL

- B08B15/00—Preventing escape of dirt or fumes from the area where they are produced; Collecting or removing dirt or fumes from that area

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B08—CLEANING

- B08B—CLEANING IN GENERAL; PREVENTION OF FOULING IN GENERAL

- B08B9/00—Cleaning hollow articles by methods or apparatus specially adapted thereto

- B08B9/08—Cleaning containers, e.g. tanks

- B08B9/20—Cleaning containers, e.g. tanks by using apparatus into or on to which containers, e.g. bottles, jars, cans are brought

Definitions

- the invention relates to a bottle cleaning machine with an up and Dispensing station and several arranged in the direction of flow of the bottles treatment stations and a suction channel for steam or other air masses.

- Container washing machines in particular high-performance washing machines for the cellar industry

- Laugenstation a so-called Laugenstation on, immersed in the container to be cleaned in a tub which is filled with cleaning liquor.

- an aqueous Solution of NaOH used as lye.

- the tub is heated to the lye temperature to, for example, 80 ° C hold.

- To be cleaned containers often have aluminum equipment.

- one-liter liter crown cork beer bottles are usually in the head area with one so-called aluminum capsule provided, the largest part of the cleaning yet is available.

- Even labels may consist entirely or partially of aluminum.

- the object of the invention is to provide a device with which in a cleaning machine accumulated and to be eliminated air masses more targeted and broader sucked and can be derived.

- suction channel runs transversely to the direction of movement of the bottles and as a vortex hood is formed with a Vorbelsenkenabsaugung.

- the formation of the invention is a particularly advantageous derivation of gases to be removed from the housing of a bottle washing machine, Swaths, air masses and the like. guaranteed.

- the air masses can be fast and targeted on the entire width of the longitudinal or transversely installed suction ducts are detected and derived by this.

- the Throughput of the suction duct is the machine performance appropriate automatically adaptable.

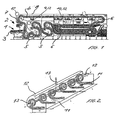

- a bottle washer with the feeding station 1 and the dispensing station 2 shown.

- the bottles 3 are in bottle cells 4 by the individual cleaning departments 5,6 out and in the area of the dispensing station 2, for example, by rotating discharge surfaces underpinned and down to discontinued or pushed onto a drain conveyor.

- a steam extraction duct 7 arranged, the inside wall is practically used as a partition for Machine housing 8 may be formed.

- suction channels 9,10 in the individual treatment zones and divisions 5,6 of such a cleaning machine be provided.

- suction 7.7 'with a slit-shaped suction port 11 which according to the embodiment runs transversely to the bottle conveying direction. But this can also be longitudinal to the bottle conveying direction run.

- the suction port 11 is part of a swirling flow generating vortex hood 12, which at least laterally on one side a support tube 13 for discharging the sucked air masses.

- a swirling flow generating vortex hood 12 which at least laterally on one side a support tube 13 for discharging the sucked air masses.

- very wide cleaning machines or long vortex hoods 12 can laterally provided on both sides and also in the middle of the vortex hood 12 more support tubes 13 be.

- the gap width of the intake passage 7 may be adjustable and depending on the machine throughput can be changed.

- At least a portion of the vortex hood 12 can directly shape the housing or part of the housing. Incidentally, any cross-sectional shapes can be provided be.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Cleaning In General (AREA)

- Centrifugal Separators (AREA)

Description

Claims (6)

- Flaschenreinigungsmaschine mit einer Auf- und Abgabestation und mehreren in Durchlaufrichtung der Flaschen angeordneten Behandlungsstationen sowie mindestens einem Absaugkanal für Schwaden und/oder andere Luftmassen, dadurch gekennzeichnet, daß der Absaugkanal mindestens teilweise mit einer schlitzförmigen Ansaugöffnung (7,7') ausgebildet ist, die quer und/oder längs im Reinigungsmaschinengehäuse (8) verläuft und als Teil einer eine Drallströmung erzeugenden Wirbelhaube (12) ausgebildet ist.

- Flaschenreinigungsmaschine gemäß Oberbegriff des Anspruchs 1, dadurch gekennzeichnet, daß der Absaugkanal (7,7') quer zur Bewegungsrichtung der Flaschen verläuft und als Wirbelhaube (12) mit einer Wirbelsenkenabsaugung ausgebildet ist.

- Flaschenreinigungsmaschine nach den vorhergehenden Ansprüchen, dadurch gekennzeichnet, daß die Spaltweite der schlitzförmigen Ansaugöffnung (7,7') veränderbar ist.

- Flaschenreinigungsmaschine nach den vorhergehenden Ansprüchen, dadurch gekennzeichnet, daß die Spaltweite der schlitzförmigen Ansaugöffnung (7,7') manuell und/oder motorisch in Abhängigkeit von der Maschinendurchsatzleistung veränderbar ist.

- Flaschenreinigungsmaschine nach den vorhergehenden Ansprüchen, dadurch gekennzeichnet, daß mindestens seitlich einseitig und/oder mittig ein Stützrohr (13) zur Abführung der angesaugten Luft vorgesehen ist.

- Flaschenreinigungsmaschine nach den vorhergehenden Ansprüchen, dadurch gekennzeichnet, daß mindestens ein Teil der Wirbelhaube (12) aus Gehäuseteilen (8) der Reinigungsmaschine gebildet ist.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE10045083A DE10045083A1 (de) | 2000-09-12 | 2000-09-12 | Flaschenreinigungsmaschine |

| DE10045083 | 2000-09-12 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP1186355A2 EP1186355A2 (de) | 2002-03-13 |

| EP1186355A3 EP1186355A3 (de) | 2003-08-20 |

| EP1186355B1 true EP1186355B1 (de) | 2004-07-21 |

Family

ID=7655933

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP01120680A Expired - Lifetime EP1186355B1 (de) | 2000-09-12 | 2001-09-03 | Flaschenreinigungsmaschine |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP1186355B1 (de) |

| AT (1) | ATE271427T1 (de) |

| DE (2) | DE10045083A1 (de) |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB514293A (en) * | 1937-05-06 | 1939-11-03 | Cherry Burrell Corp | Improvements in or relating to machines for washing bottles or similar containers |

| US4208761A (en) * | 1978-01-24 | 1980-06-24 | New England Machinery, Inc. | Bottle conveying and cleaning apparatus |

| DE3914412A1 (de) * | 1989-04-29 | 1990-10-31 | Seitz Enzinger Noll Masch | System zur nutzung der abwaerme einer flaschenreinigungsmaschine |

| DE4232986C2 (de) * | 1992-10-01 | 1996-10-31 | Khs Masch & Anlagenbau Ag | Flaschenreinigungsmaschine mit einer Auf- und Abgabestation |

-

2000

- 2000-09-12 DE DE10045083A patent/DE10045083A1/de not_active Withdrawn

-

2001

- 2001-09-03 DE DE50102907T patent/DE50102907D1/de not_active Expired - Lifetime

- 2001-09-03 AT AT01120680T patent/ATE271427T1/de not_active IP Right Cessation

- 2001-09-03 EP EP01120680A patent/EP1186355B1/de not_active Expired - Lifetime

Also Published As

| Publication number | Publication date |

|---|---|

| DE50102907D1 (de) | 2004-08-26 |

| EP1186355A3 (de) | 2003-08-20 |

| EP1186355A2 (de) | 2002-03-13 |

| DE10045083A1 (de) | 2002-03-28 |

| ATE271427T1 (de) | 2004-08-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE102011119171B3 (de) | Vorrichtung zur Behandlung von Behältern mit einer Absaugvorrichtung | |

| DE2612958A1 (de) | Vorrichtung zum entfernen von sauerstoff aus verpackungsbehaeltern | |

| DE8807146U1 (de) | Vorrichtung zum Transportieren von Flaschen | |

| DE10207499A1 (de) | Verfahren zum Reinigen von Fluidabgabeeinrichtungen und Reinigungsvorrichtung | |

| EP2331410A1 (de) | Verfahren und vorrichtung zum füllen | |

| EP3067126B1 (de) | Vorrichtung zum spülen eines behälters mit einem spülmedium | |

| EP1186355B1 (de) | Flaschenreinigungsmaschine | |

| DE10358265A1 (de) | Behälterbehandlungsvorrichtung mit Gasvorhang | |

| EP2688689B1 (de) | Vorrichtung zum abblasen von flaschenböden | |

| DE102020129774A1 (de) | Vorrichtung zur Förderung und Reinigung von Kleinteilen mit einem offenen Hohlraum | |

| DE2645464C2 (de) | Einrichtung zum unmittelbaren Fördern von leichten Gegenständen in einer Rinne | |

| EP1513761B1 (de) | Vorrichtung zum beseitigen von fremdluft aus einem reinraum | |

| DE102008049296A1 (de) | Vorrichtung zum Abblasen oder Trocknen von Kästen oder dergleichen Behältern | |

| AT396737B (de) | Vorrichtung zum abscheiden von dunst-, fett- und staubpartikeln aus einem luftstrom | |

| EP0387526B1 (de) | Vorrichtung zum Galvanisieren von Behandlungsgut in einer Reihe von hintereinander angeordneten Bädern | |

| DE19916233C1 (de) | Walzgerüst | |

| DE2623033A1 (de) | Verfahren und vorrichtung zur reinigung von gasen | |

| DE3145168A1 (de) | Vorrichtung zum automatischen abbuersten von flaschenkapseln | |

| EP1226087B1 (de) | Aufschäumvorrichtung für getränkebehälter | |

| DE19733582B4 (de) | Verfahren und Vorrichtung zum Behandeln von Flaschen oder dergleichen in einem Flüssigkeitsbad | |

| DE4035786A1 (de) | Blaskopf einer vorrichtung zum waschen von halbleitermaterialien | |

| DE1801797A1 (de) | Flaschenreinigungsmaschine | |

| WO2023089004A1 (de) | Luftklingenvorrichtung | |

| DE3939601A1 (de) | Vorrichtung zum trocknen von kleinteilen | |

| DE9310736U1 (de) | Verschließmaschine für Gefäße |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20010926 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK RO SI |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| AKX | Designation fees paid |

Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040721 Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040721 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040721 Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040721 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20040721 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: GERMAN |

|

| REF | Corresponds to: |

Ref document number: 50102907 Country of ref document: DE Date of ref document: 20040826 Kind code of ref document: P |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040903 Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040903 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20041021 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20041021 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20041021 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20041101 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| ET | Fr: translation filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20050422 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20050930 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20050930 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20070531 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: RN |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: FC |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20041221 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20061002 |

|

| PGRI | Patent reinstated in contracting state [announced from national office to epo] |

Ref country code: FR Effective date: 20071017 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: TD Effective date: 20111114 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: CD Owner name: KHS GMBH Effective date: 20111121 Ref country code: FR Ref legal event code: CD Owner name: KHS GMBH Effective date: 20111122 |

|

| BECN | Be: change of holder's name |

Owner name: KHS G.M.B.H. Effective date: 20120314 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 16 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 17 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20170921 Year of fee payment: 17 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20170921 Year of fee payment: 17 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 18 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MM Effective date: 20181001 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20180903 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20181001 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180903 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20200914 Year of fee payment: 20 Ref country code: DE Payment date: 20200925 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 20200925 Year of fee payment: 20 Ref country code: IT Payment date: 20200922 Year of fee payment: 20 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R071 Ref document number: 50102907 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MK Effective date: 20210903 |