EP1153552A2 - Schieber für ein Verschlussband, vorzugsweise aus Kunststoff - Google Patents

Schieber für ein Verschlussband, vorzugsweise aus Kunststoff Download PDFInfo

- Publication number

- EP1153552A2 EP1153552A2 EP01108160A EP01108160A EP1153552A2 EP 1153552 A2 EP1153552 A2 EP 1153552A2 EP 01108160 A EP01108160 A EP 01108160A EP 01108160 A EP01108160 A EP 01108160A EP 1153552 A2 EP1153552 A2 EP 1153552A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- slide

- slider

- fastener tape

- centerpiece

- flanks

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 229920003023 plastic Polymers 0.000 title claims description 10

- 239000004033 plastic Substances 0.000 title claims description 10

- 229920001903 high density polyethylene Polymers 0.000 claims description 8

- 239000004700 high-density polyethylene Substances 0.000 claims description 8

- 239000000463 material Substances 0.000 description 6

- -1 polyethylene Polymers 0.000 description 6

- 238000004519 manufacturing process Methods 0.000 description 5

- 239000004698 Polyethylene Substances 0.000 description 4

- 238000000034 method Methods 0.000 description 4

- 229920000573 polyethylene Polymers 0.000 description 4

- 239000004743 Polypropylene Substances 0.000 description 2

- 238000005452 bending Methods 0.000 description 2

- 238000011161 development Methods 0.000 description 2

- 230000018109 developmental process Effects 0.000 description 2

- 229920001684 low density polyethylene Polymers 0.000 description 2

- 239000004702 low-density polyethylene Substances 0.000 description 2

- 229920001155 polypropylene Polymers 0.000 description 2

- 238000003892 spreading Methods 0.000 description 2

- 241000269350 Anura Species 0.000 description 1

- 230000000295 complement effect Effects 0.000 description 1

- 230000007423 decrease Effects 0.000 description 1

- 230000003247 decreasing effect Effects 0.000 description 1

- 238000002347 injection Methods 0.000 description 1

- 239000007924 injection Substances 0.000 description 1

- 230000003993 interaction Effects 0.000 description 1

- 230000007257 malfunction Effects 0.000 description 1

- 239000000155 melt Substances 0.000 description 1

- 238000003825 pressing Methods 0.000 description 1

- 238000007789 sealing Methods 0.000 description 1

- 238000000926 separation method Methods 0.000 description 1

- 238000009864 tensile test Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D33/00—Details of, or accessories for, sacks or bags

- B65D33/16—End- or aperture-closing arrangements or devices

- B65D33/25—Riveting; Dovetailing; Screwing; using press buttons or slide fasteners

- B65D33/2508—Riveting; Dovetailing; Screwing; using press buttons or slide fasteners using slide fasteners with interlocking members having a substantially uniform section throughout the length of the fastener; Sliders therefor

- B65D33/2584—Riveting; Dovetailing; Screwing; using press buttons or slide fasteners using slide fasteners with interlocking members having a substantially uniform section throughout the length of the fastener; Sliders therefor characterized by the slider

- B65D33/2588—Riveting; Dovetailing; Screwing; using press buttons or slide fasteners using slide fasteners with interlocking members having a substantially uniform section throughout the length of the fastener; Sliders therefor characterized by the slider being provided with flexing or moving parts

-

- A—HUMAN NECESSITIES

- A44—HABERDASHERY; JEWELLERY

- A44B—BUTTONS, PINS, BUCKLES, SLIDE FASTENERS, OR THE LIKE

- A44B19/00—Slide fasteners

- A44B19/24—Details

- A44B19/26—Sliders

- A44B19/267—Sliders for slide fasteners with edges of stringers having uniform section throughout the length thereof

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T24/00—Buckles, buttons, clasps, etc.

- Y10T24/25—Zipper or required component thereof

- Y10T24/2511—Zipper or required component thereof with distinct, stationary means for anchoring slider

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T24/00—Buckles, buttons, clasps, etc.

- Y10T24/25—Zipper or required component thereof

- Y10T24/2532—Zipper or required component thereof having interlocking surface with continuous cross section

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T24/00—Buckles, buttons, clasps, etc.

- Y10T24/25—Zipper or required component thereof

- Y10T24/2532—Zipper or required component thereof having interlocking surface with continuous cross section

- Y10T24/2534—Opposed interlocking surface having dissimilar cross section

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T24/00—Buckles, buttons, clasps, etc.

- Y10T24/25—Zipper or required component thereof

- Y10T24/2561—Slider having specific configuration, construction, adaptation, or material

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T24/00—Buckles, buttons, clasps, etc.

- Y10T24/26—Slit closing means including guides on opposite edges of slit and slidable bridging component

Definitions

- the invention relates to a slide for a fastener tape. It also affects one Closure tape with such a slider and a bag, preferably made of Plastic, with such a fastener tape.

- Such sliders and fastener tapes which also as profile strip closures or Sliding closure strips or tapes can already be called known.

- Most of the known slides are injection molded individually manufactured and then automatically individually using complicated devices the slide fastener tapes applied.

- Most of these sliders do necessary that they are aligned in the direction of assembly using so-called vibrating pots - Be supplied to a device that spreads the slide and then it astride the previously opened fastener tape.

- Such a device is known for example from DE-PS 31 36 075.

- the slides are fed one after the other to a rotor, which is the upper part of the slide is detected while the side parts (wings) of the slide in one Stator spread slowly and then through the rotor onto the slide fastener tape be postponed.

- DE-OS 21 01 875 describes a device for applying slides on complementary locking elements that are intermittent on the device slide past, each consisting of an endless chain of elastic sliders a slider from the chain is pressed onto the belt.

- the slide side parts (Wings) are flexurally elastic, so that they can be easily spread and pressed open spring back and hold the fastener tape properly. With this Method is a trouble-free production at a relatively high speed possible.

- a major disadvantage is that the slide due to their small size can only be accepted to a limited extent by consumers. she are not very handy and can be removed from the fastener tape with rough handling to be torn down.

- Another disadvantage is that these sliders only in the front part a very short arrow-like centerpiece with inwards reaching Have flanks.

- the object of the invention is to provide an improved slide for a fastener tape to propose.

- the slider that preferably consists of plastic, comprises a centerpiece, two towards each other running inner surfaces and two supporting flanks.

- the slider can be essentially one Have a U-shaped shape. In this case it consists of a base part and two adjoining side parts or wings.

- the fastener tape the preferably consists of plastic, generally comprises two parts or sub-bands with profiles that can interlock.

- the slider is used for sliding or pushing assembly and separation of the fastener tape or the interlocking profiles or parts.

- the slide Centerpiece there is another in the area of the inner surfaces of the slide Centerpiece provided.

- This is preferably a proportionate one small centerpiece or a centerpiece that is smaller than the actual centerpiece.

- the other centerpiece is located between the inner surfaces of the slide. It is also located between the actual heart and the supporting flanks.

- the other centerpiece holds the two profile parts with its side flanks of the slide fastener tape safely up to the middle part of the slide firmly and prevents the slide end from tipping upwards.

- the slide closure band halves are firmly guided up to the middle of the slide and held; they are then taken over by the narrower end of the slide.

- the slide is then on the now closed fastener tape still held by the smaller supporting flanks. If the side parts of the slider bent slightly apart due to the use of force, such as tugging should be, the slider tilts up at its end prevents since the further centerpiece in the middle of the slider the fastener tape holds on.

- the invention includes one Improvement of a method for applying an endless chain of slides on a slide fastener tape.

- the further centerpiece is preferably connected to the other centerpiece.

- the connection is preferably made by a web. It is advantageous to have one to provide a thin web.

- the slider has a U-shaped shape, locate it the attachments preferably on the base part, namely on the side walls or wings opposite side of the base part.

- the essays serve for Spread or spread the slide open when the slide is attached a fastener tape.

- the slide is preferably made of HDPE, i.e. low-pressure polyethylene (high density polyethylene).

- HDPE can be made with high pressure polyethylene (low density polyethylene, NDPE) from which most bags or pouches are made are well recyclable, but also with polypropylene, from which more and more Bags and fastener tapes are made.

- the invention further relates to a fastener tape, preferably made of plastic, the has a slide according to the invention, and a bag, preferably made of Plastic, which is characterized by a fastener tape according to the invention.

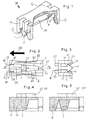

- Fig. 1 shows a slide of the known type in a perspective view.

- the slider 30 is essentially U-shaped. It has a base part 6 on and two protruding side parts 4 and 5, also called wings can be.

- the inner surfaces 31, 32 of the side parts 4, 5 converge. Their distance from each other decreases in a direction that the direction of the Arrow 33 is opposite.

- a frog 1 is arranged at one end of the inner surfaces 31, 32. It is at the end of the slide at which the distance between the inner surfaces 31, 32 is the largest.

- the heart shaped arrow-shaped towards the bottom 1 has side flanks 2, 3, which together with smaller flanks of the side walls 4, 5 and the side walls 4, 5 and corresponding side walls of the The centerpiece 1 form separate inlet channels for the closure profile parts.

- the slider 30 is pressed down onto a fastener tape. Give here the side walls 4, 5 to the outside until the fastener tape in the Slide is located. In this position, a closure profile runs through one the two inlet channels on both sides of the centerpiece 1. At the other end of the slider run the locked or assembled fastener tapes through the outlet channel.

- the rear part of the slider 30 facing away from the centerpiece 1 is on the fastener tape only by short flanks or support flanks z, which are from the side parts 4 and 5 protrude inwards, held. This allows the slider 30 on this Place by stretching the side parts 4, 5 slip over the closure profile and tilt upwards, which leads to malfunction.

- Figures 2 to 6 show a slide according to the invention.

- Fig. 2 there is another (second), smaller centerpiece 7, which is between the front (first, actual), larger heart 8 and the rear End of the slide.

- the further centerpiece 7 is also located between the inner surfaces 31, 32. It has outward-facing support flanks 12, 13. Furthermore, the second frog 7 with the frog 8 through a thin one Web 24 connected.

- the outer ends of the support flanks 16, 17 of the core 8 are from the inner Ends of the support flanks 18, 19 projecting inwards from the side walls 20, 21 spaced. As a result, slots 9, 10 for the halves of the fastener tape educated.

- Support flanks 14, 15 are provided which protrude inwards from the inner surfaces 31, 32. The inner ends of the support flanks 14, 15 are spaced apart from one another, whereby an opening 11 is formed.

- the two halves of the slide fastener tape run separated by the two slots 9, 10 when the slide in the direction of Arrow 33 is moved.

- the fastener halves are in the thinner rear part the slide is closed. They come out of the opening as a closed closure 11 out.

- the further, second, smaller centerpiece 7 holds the side flanks 12, 13 of the two profile parts of the slide fastener tape safely up to the middle part of the slide and prevents the opposite of the frog 8 from tipping over Slider end up.

- the slide fastener halves are according to the invention firmly guided and held to the middle of the slide; you will be then taken from the narrower end of the slider.

- On the now closed The slider is then closed by the smaller support flanks 14, 15 held. Should one then pull the side parts 20, 21 of the Bend the slide slightly apart and threatens the slide on its the centerpiece Tilting 8 opposite end upward holds the other, smaller one Centerpiece 7 in the middle of the slide this slide on the fastener tape firmly.

- FIG. 3 shows the slide according to FIG. 2 from the front (from the slots 9, 10) off, i.e. at the inlet of the two halves of the fastener tape.

- the support flanks 16, 17 the centerpiece 8 hold the fastener halves from the inside, while the support flanks 18, 19 of the side walls 20, 21 firmly from the outside on the slide hold.

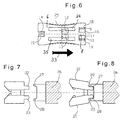

- attachments 22, 23 are on the upper part of the slide, that is, on the Base part 6, attachments 22, 23 are provided which are substantially rectangular Have cross-section, which is however somewhat rounded at the corners. This Attachments 22, 23 are used to spread the slide by means of a pusher, such as shown in Figures 7 and 8.

- FIG. 4 shows a section along the line A-A in FIG. 2.

- the heart pieces 8 and 7 are connected to each other by a thin web 24.

- the frogs 8, 7 not connected by a web, but separated from each other.

- This embodiment has the advantage that material is saved and that the side parts spread more easily when shooting open the slider.

- Fig. 6 shows the slide in a top view from above.

- On the (middle, smaller) further centerpiece 7 are the supporting flanks 12, 13 to see.

- the base part 6 has openings 34, 35.

- the small support flanks 14, 15 are located on the side parts 20, 21.

- Figures 7 and 8 show the interaction of the slide with a plunger 26 for spreading the slide.

- the plunger 26 has projections 27, 28, which are spaced apart.

- the mutually facing surfaces of the projections 27, 28 are inclined to each other, in such a way that the distance between these surfaces with increasing distance from the plunger 26 enlarged. In this way, the mutually facing inner surfaces of the Projections 27, 28 formed a conical recess.

- Slider is its flexural elasticity. On the one hand, the slide must be after the Spread back to its original position, on the other hand this may Spreading is not too difficult. Furthermore, the slide body may Spread out and don't become brittle for a long time afterwards. He is also not allowed to Get cracks. Finally, the slider should move together with the sealing bag and have the sliding closure tape reused (recycled).

- the material must be made of the same or similar basic material consist of like the pockets or the pouches from which the slide closure pouch is made is made.

- a particularly suitable plastic material is low pressure polyethylene (high density polyethylene HDPE), which is made with high pressure polyethylene (low density polyethylene, NDPE) from which most bags or bags are made, can be recycled well.

- the bags and more and more the fastener tape is also made of polypropylene. Even with this material together, the sliders made of HDPE can be recycled, i.e. ground and reuse.

- a material is, for example, an HDPE from Borealis A / S with a melt flow rate of 12g / 10 min and a Shore hardness of 62.

- the bending elasticity of the slide has been investigated by numerous tests and can e.g. can be defined as follows: attempts at the end of the slide, starting measured from an end opening on the molded 20-piece strand from 0.45 to 0.60 mm on the free passage including the outer small support flanks 14, 15.

- a slider is molded on its two connecting sides of the chain attached to a spring balance by means of two clamps and the end opening in a tensile test the slider so far loaded that it is on the profile-encompassing outer Support flanks 14, 15 to the thickness of the fastener tape, about 1.8 mm, opens. This requires a tensile load between 700 and 1300 grams. After completion the tensile load on the slide is reset by the end opening Elasticity to 0.9 to 1.0 mm.

- the slide is now permanently functional, i.e. it opens and closes it Closure tape securely without becoming brittle or tearing. It then has an end opening of approx. 1.8 mm, minus outer support flanks encompassing the profile of approx. 0.4 mm, i.e. about 1.0 mm, and the closing pressure is permanent.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Slide Fasteners (AREA)

- Bag Frames (AREA)

- Sliding-Contact Bearings (AREA)

- Package Frames And Binding Bands (AREA)

- Clamps And Clips (AREA)

Abstract

Description

- Fig. 1

- einen Schieber nach der DE-OS 16 32 574 in einer perspektivischen Darstellung,

- Fig. 2

- einen erfindungsgemäßen Schieber in einer Draufsicht von unten,

- Fig. 3

- den Schieber gemäß Fig. 2 in einer Ansicht von vorne (auf die in Fig. 2 links gezeigte Seite des Schiebers),

- Fig. 4

- einen Schnitt längs der Linie A-A in Fig. 2,

- Fig. 5

- eine abgewandelte Ausführungsform, bei der das weitere kleinere Herzstück nicht durch einen Steg mit dem ersten größeren Herzstück verbunden ist,

- Fig. 6

- den Schieber gemäß Fig. 2 bis 5 in einer Draufsicht von oben,

- Fig. 7

- den Schieber und einen Stößel, wobei sich der Stössel in zurückgezogener Stellung befindet und

- Fig. 8

- den Stössel beim Aufdrücken des Schiebers auf das Verschlußband.

Claims (6)

- Schieber für ein Verschlußband mit einem Herzstück (8), zwei aufeinander zu laufenden Innenflächen (31, 32) und zwei Stützflanken (14, 15),

dadurch gekennzeichnet, daß im Bereich der Innenflächen (31, 32) ein weiteres Herzstück (7) vorgesehen ist. - Schieber nach Anspruch 1, dadurch gekennzeichnet, daß das weitere Herzstück (7) mit dem Herzstück (8) verbunden ist, vorzugsweise durch einen Steg (24).

- Schieber nach Anspruch 1 oder 2, dadurch gekennzeichnet, daß an der Oberseite des Schiebers Aufsätze (22, 23) vorgesehen sind.

- Schieber nach einem der vorhergehenden Ansprüche, dadurch gekennzeichnet, daß der Schieber aus HDPE hergestellt ist.

- Verschlußband, vorzugsweise aus Kunststoff gekennzeichnet durch einen Schieber nach einem der Ansprüche 1 bis 4.

- Tasche oder Beutel, vorzugsweist aus Kunststoff, gekennzeichnet durch ein Verschlußband nach Anspruch 5.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE10023059A DE10023059B4 (de) | 2000-05-11 | 2000-05-11 | Schieber für ein Verschlußband, Verschlußband und Tasche oder Beutel, vorzugsweise aus Kunststoff |

| DE10023059 | 2000-05-11 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP1153552A2 true EP1153552A2 (de) | 2001-11-14 |

| EP1153552A3 EP1153552A3 (de) | 2004-02-18 |

| EP1153552B1 EP1153552B1 (de) | 2006-06-21 |

Family

ID=7641636

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP01108160A Expired - Lifetime EP1153552B1 (de) | 2000-05-11 | 2001-03-30 | Schieber für ein Verschlussband, vorzugsweise aus Kunststoff |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US6490769B2 (de) |

| EP (1) | EP1153552B1 (de) |

| AT (1) | ATE330501T1 (de) |

| DE (2) | DE10023059B4 (de) |

| DK (1) | DK1153552T3 (de) |

| ES (1) | ES2266043T3 (de) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2903087A1 (fr) * | 2006-06-29 | 2008-01-04 | S2F Flexico Sarl | Dispositif de fermeture a curseur pour sachet, comprenant des moyens anti-arrachement |

Families Citing this family (21)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6584666B1 (en) * | 1999-06-10 | 2003-07-01 | The Glad Products Company | Method and apparatus for assembling slider members onto interlocking fastening strips using a rail |

| US6691375B1 (en) * | 1999-06-10 | 2004-02-17 | The Glad Products Company | Closure device and method of assembly |

| US7454823B2 (en) * | 1999-06-10 | 2008-11-25 | The Glad Products Company | Method and apparatus for assembling slider members onto interlocking fastening strips |

| PL371935A1 (en) * | 2001-10-17 | 2005-07-11 | Illinois Tool Works Inc. | Sliders for reclosable containers |

| US6983573B2 (en) * | 2002-06-07 | 2006-01-10 | Reynolds Consumer Products, Inc. | Method of applying a slider device to an open closure mechanism on a resealable bag |

| US6951421B2 (en) * | 2003-02-14 | 2005-10-04 | Illinois Tool Works Inc. | Reclosable packaging having slider-operated string zipper |

| US6811528B1 (en) * | 2004-02-09 | 2004-11-02 | Chun-Shan Chen | Machine for installing a zipper slider to a zipper bag |

| US7574781B2 (en) | 2004-04-09 | 2009-08-18 | S.C. Johnson Home Storage, Inc. | Closure assembly with slider |

| EP1802213B1 (de) * | 2004-10-11 | 2015-08-26 | Ashok Chaturvedi | Auslaufsicherer, wiederverschliessbarer flexibler beutel |

| US20060171610A1 (en) * | 2005-01-31 | 2006-08-03 | Buchman James E | Internal gripping slider and method |

| US7188394B2 (en) * | 2005-01-31 | 2007-03-13 | S.C. Johnson Home Storage, Inc. | Hollow ribbed slider for a reclosable pouch |

| DE602005025537D1 (de) * | 2005-02-03 | 2011-02-03 | Ashok Chaturvedi | Kindersicherer wiederverschliessbarer beutel |

| US20060269171A1 (en) * | 2005-05-26 | 2006-11-30 | Turvey Robert R | Slider with laterally displaceable engagement members |

| US7461434B2 (en) * | 2005-05-26 | 2008-12-09 | S.C. Johnson Home Storage, Inc. | Slider for closure assembly |

| US7574782B2 (en) * | 2005-05-26 | 2009-08-18 | S.C. Johnson Home Storage, Inc. | Apparatus and method of operatively retaining an actuating member on an elongate closure mechanism |

| US7797802B2 (en) | 2007-11-29 | 2010-09-21 | S.C. Johnson & Son, Inc. | Actuating member for a closure assembly and method |

| US8245364B2 (en) * | 2008-04-23 | 2012-08-21 | S.C. Johnson & Son, Inc. | Closure mechanism having internal projections to decrease slider pull-off |

| US9126724B2 (en) * | 2013-03-15 | 2015-09-08 | Exopack Llc | Child-resistant zipper assemblies and packages utilizing the same |

| US9456663B1 (en) * | 2014-03-18 | 2016-10-04 | Rodawg Holdings Llc | Child-proof locking system |

| US10869526B2 (en) | 2019-01-04 | 2020-12-22 | Target Brands, Inc. | Slide closure with stabilizing fins and associated garment |

| US11077989B2 (en) * | 2019-06-21 | 2021-08-03 | Reynolds Presto Products Inc. | Slider device, zipper closure system, and methods of use |

Family Cites Families (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR1529652A (fr) * | 1967-03-07 | 1968-06-21 | Curseur pour fermeture de sachets constitués par des bandes profilées complémentaires | |

| FR2076728A5 (de) * | 1970-01-26 | 1971-10-15 | Minigrip Europ As | |

| FR2491742A1 (fr) * | 1980-10-14 | 1982-04-16 | Flexico France Sarl | Machine pour la pose automatique de curseurs sur des bandes de fermeture a profiles d'accouplement |

| DE3208245A1 (de) * | 1982-03-08 | 1983-09-15 | ASF Gleitverschluß GmbH, 8500 Nürnberg | Verfahren zum aufbringen eines schiebers auf verschlussleisten eines profilleistenverschlusses und schieber und einrichtung zum durchfuehren des verfahrens |

| US5010627A (en) * | 1990-03-07 | 1991-04-30 | Mobil Oil Corporation | Foldable plastic slider and method of assembly with a plastic reclosable fastener |

| US5007142A (en) * | 1990-03-07 | 1991-04-16 | Mobil Oil Corp. | Method of assembling a snapped-together multipart plastic slider with a plastic reclosable fastener |

| FR2667225B1 (fr) * | 1990-10-01 | 1992-12-31 | Flexico France Sarl | Curseur pour sachets ou sacs munis d'une fermeture plastique a deux profils emboitables. |

| WO1992019450A1 (en) * | 1991-04-26 | 1992-11-12 | Mobil Oil Corporation | Method for assembling a multipart plastic slider with a plastic reclosable fastener by ultrasonic welding |

| AU645414B2 (en) * | 1991-04-27 | 1994-01-13 | Ykk Corporation | Slider with yoke for slide fastener and its joining method |

| US5283932A (en) * | 1993-06-10 | 1994-02-08 | Mobil Oil Corporation | Flexible plastic zipper slider with rigidizing structure for assembly with profiled plastic zipper |

| FR2721381B1 (fr) * | 1994-06-20 | 1996-08-02 | Seb Sa | Dispositif de production d'eau chaude ou de vapeur. |

| US5871281A (en) * | 1996-11-25 | 1999-02-16 | Kcl Corporation | Zipper slider pivoting wedge |

| US6059456A (en) * | 1997-04-23 | 2000-05-09 | Reynolds Consumer Products, Inc. | Reclosable profile arrangement using slidable closure strip |

-

2000

- 2000-05-11 DE DE10023059A patent/DE10023059B4/de not_active Expired - Fee Related

-

2001

- 2001-03-30 ES ES01108160T patent/ES2266043T3/es not_active Expired - Lifetime

- 2001-03-30 DK DK01108160T patent/DK1153552T3/da active

- 2001-03-30 EP EP01108160A patent/EP1153552B1/de not_active Expired - Lifetime

- 2001-03-30 AT AT01108160T patent/ATE330501T1/de not_active IP Right Cessation

- 2001-03-30 DE DE50110208T patent/DE50110208D1/de not_active Expired - Lifetime

- 2001-05-11 US US09/852,791 patent/US6490769B2/en not_active Expired - Fee Related

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2903087A1 (fr) * | 2006-06-29 | 2008-01-04 | S2F Flexico Sarl | Dispositif de fermeture a curseur pour sachet, comprenant des moyens anti-arrachement |

| EP1873072A3 (de) * | 2006-06-29 | 2008-03-05 | S2F Flexico | Schließvorrichtung mit Läufer für Beutel, die Abreissschutzmittel umfasst |

| US7976219B2 (en) | 2006-06-29 | 2011-07-12 | S2F Flexico | Closing device with slider for sachet, comprising anti-engagement means |

Also Published As

| Publication number | Publication date |

|---|---|

| ES2266043T3 (es) | 2007-03-01 |

| EP1153552A3 (de) | 2004-02-18 |

| US20010039698A1 (en) | 2001-11-15 |

| DE10023059B4 (de) | 2013-04-11 |

| DE50110208D1 (de) | 2006-08-03 |

| DE10023059A1 (de) | 2001-11-15 |

| US6490769B2 (en) | 2002-12-10 |

| EP1153552B1 (de) | 2006-06-21 |

| DK1153552T3 (da) | 2006-07-31 |

| ATE330501T1 (de) | 2006-07-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE10023059B4 (de) | Schieber für ein Verschlußband, Verschlußband und Tasche oder Beutel, vorzugsweise aus Kunststoff | |

| DE3345661C2 (de) | Schnürung | |

| DE19924539C2 (de) | Fluiddichter Reißverschluß | |

| DE69925347T2 (de) | Trennbarer unterer Endanschlag für Reissverschlüsse | |

| DE2505206C3 (de) | Reißverschlußschieber | |

| DE2063493C3 (de) | Verfahren und Vorrichtung zum Aufsetzen von Schiebern auf eine Reißverschlußgliederreihe | |

| DE2815638C2 (de) | Reißverschlußschieber | |

| DE68909560T2 (de) | Trennbarer Reissverschluss. | |

| DE2915635C2 (de) | Teilbarer Reißverschluß | |

| EP0847246A1 (de) | Reissverschluss | |

| DE3419238A1 (de) | Loesbares schloss | |

| AT389805B (de) | Reissverschluss | |

| DE2537059C2 (de) | Reißverschlußkette und Vorrichtung zu deren Herstellung | |

| DE2940496C2 (de) | Reißverschluß | |

| DE4230730B4 (de) | Umreifungsmaschine mit einem Bandführungsrahmen | |

| DE2733532C2 (de) | Verfahren zum Anbringen eines aus einem Einsteckteil und aus einem mit einem Stift versehenen Kastenteil bestehenden Teilbarkeitselementes an zwei Reißverschlußbändern | |

| DE2610071A1 (de) | Verfahren zum herstellen endseitig versiegelter reissverschlusshaelften | |

| DE2336162A1 (de) | Oberer endanschlag fuer reissverschluesse | |

| DE2461510A1 (de) | Oberer endanschlag fuer reissverschluesse | |

| DE2930918C2 (de) | Reißverschluß mit dreiteiliger Endverbindung | |

| DE2941137C2 (de) | Teilbare Reißverschlußkette | |

| DE7007100U (de) | Reissverschluss. | |

| DE1278775B (de) | Trennbares, aus spritzbarem Kunststoff bestehendes Endglied fuer einen Reissverschluss | |

| DE3011029A1 (de) | Gegossenes kupplungsteil fuer einen reissverschluss | |

| DE4133095A1 (de) | Packbeutel |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK RO SI |

|

| 17P | Request for examination filed |

Effective date: 20040609 |

|

| AKX | Designation fees paid |

Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| 17Q | First examination report despatched |

Effective date: 20050630 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20060621 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060621 Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060621 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: T3 |

|

| REF | Corresponds to: |

Ref document number: 50110208 Country of ref document: DE Date of ref document: 20060803 Kind code of ref document: P |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060921 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20060924 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061121 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| ET | Fr: translation filed | ||

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2266043 Country of ref document: ES Kind code of ref document: T3 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20070322 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| BERE | Be: lapsed |

Owner name: ASF VERWALTUNGS G.M.B.H. Effective date: 20070331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070331 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060922 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070330 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060621 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070330 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060621 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20120321 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20130326 Year of fee payment: 13 Ref country code: DK Payment date: 20130321 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20130321 Year of fee payment: 13 |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: EBP Effective date: 20140331 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: V1 Effective date: 20141001 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20141001 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140330 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20150427 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140331 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 16 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20160321 Year of fee payment: 16 Ref country code: FR Payment date: 20160328 Year of fee payment: 16 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20160330 Year of fee payment: 16 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 50110208 Country of ref document: DE |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20170330 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20171130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20171003 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170330 |