EP0971091B1 - Ensemble d'articulation pour l'actionnement d'un volet ou similaire - Google Patents

Ensemble d'articulation pour l'actionnement d'un volet ou similaire Download PDFInfo

- Publication number

- EP0971091B1 EP0971091B1 EP99113108A EP99113108A EP0971091B1 EP 0971091 B1 EP0971091 B1 EP 0971091B1 EP 99113108 A EP99113108 A EP 99113108A EP 99113108 A EP99113108 A EP 99113108A EP 0971091 B1 EP0971091 B1 EP 0971091B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- drive element

- linear drive

- flap

- axis

- lever

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 239000000779 smoke Substances 0.000 claims description 5

- 238000006073 displacement reaction Methods 0.000 claims 9

- 241000446313 Lamella Species 0.000 description 1

- 238000005452 bending Methods 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 238000003780 insertion Methods 0.000 description 1

- 230000037431 insertion Effects 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

Images

Classifications

-

- A—HUMAN NECESSITIES

- A62—LIFE-SAVING; FIRE-FIGHTING

- A62C—FIRE-FIGHTING

- A62C2/00—Fire prevention or containment

- A62C2/06—Physical fire-barriers

- A62C2/24—Operating or controlling mechanisms

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05F—DEVICES FOR MOVING WINGS INTO OPEN OR CLOSED POSITION; CHECKS FOR WINGS; WING FITTINGS NOT OTHERWISE PROVIDED FOR, CONCERNED WITH THE FUNCTIONING OF THE WING

- E05F15/00—Power-operated mechanisms for wings

- E05F15/50—Power-operated mechanisms for wings using fluid-pressure actuators

- E05F15/53—Power-operated mechanisms for wings using fluid-pressure actuators for swinging wings

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24F—AIR-CONDITIONING; AIR-HUMIDIFICATION; VENTILATION; USE OF AIR CURRENTS FOR SCREENING

- F24F13/00—Details common to, or for air-conditioning, air-humidification, ventilation or use of air currents for screening

- F24F13/08—Air-flow control members, e.g. louvres, grilles, flaps or guide plates

- F24F13/10—Air-flow control members, e.g. louvres, grilles, flaps or guide plates movable, e.g. dampers

- F24F13/14—Air-flow control members, e.g. louvres, grilles, flaps or guide plates movable, e.g. dampers built up of tilting members, e.g. louvre

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05Y—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES E05D AND E05F, RELATING TO CONSTRUCTION ELEMENTS, ELECTRIC CONTROL, POWER SUPPLY, POWER SIGNAL OR TRANSMISSION, USER INTERFACES, MOUNTING OR COUPLING, DETAILS, ACCESSORIES, AUXILIARY OPERATIONS NOT OTHERWISE PROVIDED FOR, APPLICATION THEREOF

- E05Y2900/00—Application of doors, windows, wings or fittings thereof

- E05Y2900/10—Application of doors, windows, wings or fittings thereof for buildings or parts thereof

- E05Y2900/13—Type of wing

- E05Y2900/148—Windows

- E05Y2900/152—Roof windows

- E05Y2900/154—Skylights

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24F—AIR-CONDITIONING; AIR-HUMIDIFICATION; VENTILATION; USE OF AIR CURRENTS FOR SCREENING

- F24F11/00—Control or safety arrangements

- F24F11/30—Control or safety arrangements for purposes related to the operation of the system, e.g. for safety or monitoring

- F24F11/32—Responding to malfunctions or emergencies

- F24F11/33—Responding to malfunctions or emergencies to fire, excessive heat or smoke

- F24F11/34—Responding to malfunctions or emergencies to fire, excessive heat or smoke by opening air passages

Definitions

- the invention relates to a hinge assembly for actuation a flap or the like according to the preamble of the claim 1.

- the Joint arrangement can be single or double flaps made of sheet metal be actuated or slats of a lamellar fan.

- a rotatable or tiltable Element such as B. actuates a flap or a blade.

- the hinge assembly is intended to meet the requirement for SHE system, i. Smoke and heat exhaust systems meet, where a smoke vent in alarm position a large opening angle of should reach about 165 °.

- a known joint arrangement of the type mentioned is completely independent in and out of such an alert operable, with the opening and closing of a Flap over a whole large swivel range to about 165 ° may be, for which only a drive element is needed.

- a known hinge assembly is an end of a linear drive element at one of a stationary first Rotary axis of a flap or dome remote location of the flap pivotally mounted on a truss part of the flap.

- the linear drive element is a first Swivel axis pivotally mounted on a support lever, the in turn around a fixed second pivot axis nearby the axis of rotation of the flap is pivotable. This is the first Swivel axis approximately in the middle of the longitudinal extent of the support lever.

- An additional bellcrank is with a first end at an end remote from the second pivot axis of the Support lever arranged pivotally.

- a second end of the reversing lever engages pivotally on the truss part of the flap at a distance to its axis of rotation and to the mounting location of the first end of the drive element (EP 0 443 050 B1).

- These Joint arrangement is distinguished from other joint arrangements by a relatively space-saving position of the linear Drive elements, in particular a lifting cylinder, off.

- a less space-saving variant of the joint arrangement with only one linear drive element is at the first Pivot axis of the additional lever with a first end pivotally arranged, the second end of the truss part the flap at a distance to its axis of rotation and to the mounting location the first end of the drive element attacks.

- the invention is therefore based on the object, a joint assembly of the type mentioned above in such a way that this on the flap, lamella or the like, at the linear drive element attacks, no additional lateral forces initiates, so that the traverse or a truss bottom is not required.

- the hinge assembly with these features can be designed be that they are also used to operate smoke flaps in SHE systems have a large opening angle with completely independent Opening and closing allows, without being on the smoke damper flap to apply additional lateral forces, the otherwise intercept by a truss part. It will only Forces in the flap or the actuatable element the axis of rotation or hinge as well as on the swivel executed Location of the linear drive element on the Flap, the latter location substantially parallel to the axis of rotation is opposite, initiated. Reaction forces of the linear Drive elements are via the lever and the support lever only in a fixed pivot point of the reversing lever or a stationary second pivot axis of the support lever initiated.

- the hinge assembly according to the invention may be in their dimensions adapted flexibly to given operational requirements as long as the characteristics of the characterizing part of the Claim 1 are satisfied.

- the second end of the reversing lever at a fixed pivot point and the third pivot axis about which the bellcrank the linear drive element is pivotable must be observed be that the first pivot axis of the linear drive element on the support lever and the third pivot axis to which of the lever on the linear drive element is pivotable when operating the linear drive element describe circular trajectories that intersect and cause a resultant rotation of the linear drive element.

- the drive element can be linear move, in the case of a flap, to which the linear drive element, in particular a piston rod a compressed air cylinder in the closed state from below engages, during the rotation of the linear drive element this simultaneously moved up.

- a simple basic form of the joint arrangement is apparent according to claim 3, characterized in that the second end of the reversing lever at the fixed pivot closer to the stationary first axis of rotation of the flap as the stationary second pivot axis the support lever and preferably under the fixed second pivot axis of the support lever is mounted.

- This embodiment is especially recommended for a fixed Console in a curb.

- this console is fixed according to claim 4 Fulcrum of the second end of the bell crank on the fixed console, which is near the axis of rotation of the flap from this in its closed position preferably in Substantially perpendicular to this protrudes, in essence arranged below the axis of rotation of the flap.

- the stationary second pivot axis of the support lever on the console is in substantially below the fixed pivot point of the second End of the reversing lever attached to the console.

- the third pivot axis about which the linear drive element is pivotable at one end of the support lever.

- Compressed air are supplied, as well as the first Pivot axis of the linear drive element on the support lever.

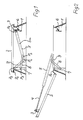

- Fig. 1 denotes a curb, on which a flap by means of a hinge about a stationary first axis of rotation P 0 is pivotable.

- a piston rod 4 of a Doppelhubzylinders 5 At the opposite end to the first axis of rotation P 0 engages the flap 2 via a locking element 3, a piston rod 4 of a Doppelhubzylinders 5 as a linear drive element.

- the pivotable connection of the piston rod to the locking element 3 and the flap 2 is designated P 1 .

- the locking element cooperates with a locking bracket 6 which is fixedly mounted inside the curb, such that upon actuation of the piston rod 4, see Fig. 2, an unlocking takes place.

- a bracket 7 is fixed to the inside of the curb, which protrudes approximately at right angles and perpendicularly downward with respect to the closed flap 2.

- the bracket 7 serves to support a support lever 8 and a reversing lever 9, whose one end with a fixed pivot point P 2 closer to the stationary first axis of rotation of the flap is arranged as a fixed pivot axis P 3 of the support lever 8, wherein the fixed pivot point P 2 and the fixed pivot axis P 3 are arranged here along a vertical line.

- the support lever 8 is arranged with an opposite to the stationary pivot axis P 3 end to the Doppelhubzylinder 5 and that in the central axis 5a of this Doppelhubzylinders 5.

- P 5 forms the first pivot axis of the Doppelhubzylinders 5 on the support lever 8, in the region of one end the double-stroke cylinder is arranged opposite to the pivotable connection point P 1 on the locking element 3 or the flap 2.

- the pivot axis P 4 of the reversing lever 9 is arranged.

- the pivot axis P 4 is referred to as the third pivot axis, because at least one second pivot axis is present at the pivotable connection point P 1 .

- the locking element 3 Upon actuation of the Doppelhubzylinders in the alarm position (see Figure 2), the locking element 3 is unlocked by the piston rod 4 of the locking console 6 and the flap 2 is raised and pivoted, with only forces on the first axis of rotation P 0 on the hinge of the flap and on the pivotable connection point P 1 are introduced into the flap, which is thus little burden.

- the kinematics of the arrangement of the flap 2 of the Doppelhubzylinders 5 of the support lever 8 and the reversing lever 9 is formed so that during the pivotal movement of the flap 2, the first pivot axis P 5 of Doppelhubzylinders 5 about the stationary second pivot axis P 3 of the support lever 8 describes a circular path, which intersects with a circular path which describes the point P 4 as the third pivot axis of the Doppelhubzylinders at one end of the reversing lever 9 about its stationary pivot axis P 2 on the console 7. Segments of this circular path are shown in Fig. 3 with dotted lines.

- a first variant which allows the joint arrangement according to the invention, it is assumed from Fig. 3 of a top frame with a bracket 11 which is located on the same side inside of the top frame on which above the first axis of rotation P 0 of the flap 2 is arranged so do not continuously extend from the area of this first axis of rotation P 0 down as the console 7 in Figs. 1 and 2.

- a locking bracket is in the top frame 10 of FIG. 3 on the opposite side inside 12 extends downward.

- FIG. 3 In the first variant of FIG. 3 is a support lever 13, whose central axis is shown with a dash-dot line, pivotally between a first pivot axis P 5 in the central axis of the Doppelhubzylinders 5 as a linear drive element on the one hand and the stationary second pivot axis P 3 , in the Console 11 is mounted below at a vertical distance from the first axis of rotation P 0 , arranged.

- a likewise indicated only by its center line dash-dotted lever 14 is pivotable on the one hand about a third pivot axis P 4 on the Doppelhubzylinder 5 and on the other hand about a fixed pivot point P 2 below in the locking console 12th

- the double-stroke cylinder 5 When the double-stroke cylinder 5 is actuated, it in turn releases with its piston rod 4 a locking element 3 from the locking console 12 and pushes or pivots the flap 2 from the closed horizontal position into the wide-open alarm position of the flap 2 '.

- the kinematics in turn, as in the basic form so that the point P, a circle segment around the point P 2 describes until the bellcrank is in the alarm position 14 '.

- the point P 5 which represents the first pivot axis, describes a circular segment about the fixed second pivot axis P 3 of the support lever 13, which is designated in the alarm position by 13 '. Both circle segments intersect.

- FIG. 4 In the second variant of FIG. 4 is located within a top frame 15 on the opposite to the stationary first axis of rotation of the flap 2 side inside a console 16 which extends from an upper part designed for locking downwards, where in turn a fixed pivot point P. 2 a reversing lever 17 is pivotally mounted. At its opposite end, the reversing lever 17 is in turn arranged on the third pivot axis P 4 of the Doppelhubzylinders as a linear drive element, and indeed at its end, which is opposite to the locking element 3.

- a support lever 18 is further arranged from the end of the Doppelhubzylinders 5 about the first pivot axis of the Doppelhubzylinders P 5 to a support lever 18 which is in the drawn basic position, the closed position of the flap 2, parallel to the Doppelhubzylinder.

- To the first pivot axis P 5 opposite end of the support lever is mounted in a stationary second pivot axis P 3 , which is here perpendicular to the fixed pivot point P 2 of the reversing lever in the console 16.

- This embodiment is thus characterized by the fact that the console 16 opposite the inside of the attachment frame 15 no console or the like may be arranged must, to the reversing lever 17 or the support lever 18 at each store one end stationary. Nevertheless, the principle is Same kinematics with respect to the movement of the flap 2 in achieves the unillustrated wide open alarm position, as shown in Fig. 3.

Landscapes

- Engineering & Computer Science (AREA)

- General Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Emergency Management (AREA)

- Chemical & Material Sciences (AREA)

- Public Health (AREA)

- Combustion & Propulsion (AREA)

- Business, Economics & Management (AREA)

- Health & Medical Sciences (AREA)

- Transmission Devices (AREA)

- Power-Operated Mechanisms For Wings (AREA)

- Holders For Apparel And Elements Relating To Apparel (AREA)

- Catching Or Destruction (AREA)

- Air-Flow Control Members (AREA)

- Harvester Elements (AREA)

- Mechanically-Actuated Valves (AREA)

Claims (9)

- Agencement d'articulation pour l'actionnement d'un volet, clapet ou élément similaire, notamment un volet ou une coupole d'évacuation de fumées, qui peut basculer autour d'un premier axe de rotation (P0) en position fixe, d'une position fermée dans une position d'alarme ainsi qu'inversement, comprenant un élément d'entraínement linéaire (5) dont une extrémité est reliée de manière pivotante au volet, en un point du volet éloigné de l'axe de rotation, et qui, d'autre part, est monté pivotant autour d'un premier axe de pivotement (P5) sur un levier de support (8) qui, pour sa part, peut pivoter autour d'un second axe de pivotement (P3) en position fixe, situé à distance, notamment en-dessous, du premier axe de rotation en position fixe, du volet, un levier de renvoi (9, 14, 17) supplémentaire étant monté avec une première extrémité sur l'élément d'entraínement (5) de manière à pouvoir y pivoter autour d'un troisième axe de pivotement (P4),

caractérisé en ce qu'une seconde extrémité du levier de renvoi (9, 14, 17) est montée en un point de rotation fixe (P2) de façon telle que le premier axe de pivotement (P5) de l'élément d'entraínement linéaire (5) sur le levier de support (8, 13, 18), ainsi que le troisième axe de pivotement (P4), autour duquel peut pivoter le levier de renvoi (9, 14, 17) sur l'élément d'entraínement linéaire (5), décrivent, lors de l'actionnement de l'élément d'entraínement linéaire (5), des trajectoires de mouvement de forme circulaire, qui se croisent et produisent une rotation résultante de l'élément d'entraínement linéaire (5). - Agencement d'articulation selon la revendication 1, caractérisé en ce que le troisième axe de pivotement (P4), autour duquel peut pivoter l'élément d'entraínement linéaire sur le levier de renvoi (9, 14, 17), est disposé plus près d'une extrémité de l'élément d'entraínement linéaire, qui est éloignée du volet, que le premier axe de pivotement (P5) autour duquel peut pivoter le levier de support (8, 13, 18) sur l'élément d'entraínement linéaire.

- Agencement d'articulation selon la revendication 1 ou 2, caractérisé en ce que la seconde extrémité du levier de renvoi (9) au niveau du point de rotation (P2) en position fixe, est située plus près du premier axe de rotation (P0) en position fixe du volet (2), que le second axe de pivotement (P3) en position fixe du levier de support (8), et de préférence en-dessous de celui-ci.

- Agencement d'articulation selon la revendication 3, caractérisé en ce que le point de rotation (P2) en position fixe de la seconde extrémité du levier de renvoi (9) est disposé, sensiblement en-dessous de l'axe de rotation (P0) du volet (2), sur une console fixe (7) qui, à proximité de l'axe de rotation (P0) du volet (2), s'écarte, de préférence environ perpendiculairement, dudit volet (2) dans sa position fermée, et en ce que le second axe de pivotement (P3) en position fixe du levier de support (8), est placé sur la console (7), sensiblement en-dessous du point de rotation (P2) en position fixe de la seconde extrémité du levier de renvoi (9) sur la console (7).

- Agencement d'articulation selon l'une des revendications précédentes, caractérisé en ce que le troisième axe de pivotement (P4) de la première extrémité du levier de renvoi (9, 14, 17) et le premier axe de pivotement de l'élément d'entraínement linéaire sur le levier de support (8, 13, 18) se situent sur l'axe médian (5a) de l'élément d'entraínement linéaire.

- Agencement d'articulation selon l'une des revendications précédentes, caractérisé par un élément d'entraínement linéaire qui est approprié pour absorber des forces latérales.

- Agencement d'articulation selon l'une des revendications précédentes, caractérisé en ce que le volet (2), à son extrémité éloignée de celle où se trouve le point de rotation (P0) en position fixe, est relié de manière pivotante à l'élément d'entraínement linéaire directement, c'est-à-dire sans interposition d'une pièce de traverse.

- Agencement d'articulation selon l'une des revendications précédentes, caractérisé en ce qu'en guise d'élément d'entraínement linéaire, il est prévu un vérin à double effet.

- Agencement d'articulation selon la revendication 3 ou 4, caractérisé en ce que le troisième axe de pivotement (P4), autour duquel l'élément d'entraínement linéaire peut pivoter autour du levier de renvoi (9, 14, 17), se situe à l'extrémité de l'élément d'entraínement linéaire.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19830678A DE19830678C2 (de) | 1998-07-09 | 1998-07-09 | Gelenkanordnung zur Betätigung einer Klappe oder dergleichen |

| DE19830678 | 1998-07-09 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0971091A2 EP0971091A2 (fr) | 2000-01-12 |

| EP0971091A3 EP0971091A3 (fr) | 2003-06-11 |

| EP0971091B1 true EP0971091B1 (fr) | 2004-05-19 |

Family

ID=7873452

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP99113108A Expired - Lifetime EP0971091B1 (fr) | 1998-07-09 | 1999-07-07 | Ensemble d'articulation pour l'actionnement d'un volet ou similaire |

Country Status (5)

| Country | Link |

|---|---|

| EP (1) | EP0971091B1 (fr) |

| AT (1) | ATE267327T1 (fr) |

| DE (2) | DE19830678C2 (fr) |

| ES (1) | ES2217650T3 (fr) |

| PL (1) | PL193843B1 (fr) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102006018485A1 (de) * | 2006-04-19 | 2007-10-25 | Andreas Grasl | Gelenkanordnung zum Betätigen einer Klappe, insbesondere Rauchabzugsklappe |

Families Citing this family (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DK176087B1 (da) | 2000-09-29 | 2006-05-22 | Vkr Holding As | Vindue med en manövreindretning til åbning og lukning heraf samt manövreindretning til et sådant vindue |

| DE10240039A1 (de) * | 2002-08-27 | 2004-03-04 | Suspa Holding Gmbh | Öffenbare Klappe, insbesondere Rauchgas-Abzugsklappe und Öffnungs-Mechanismus hierfür |

| PL210644B1 (pl) * | 2006-01-23 | 2012-02-29 | Rewa Społka Z Ograniczoną Odpowiedzialnością | Mechanizm otwierająco-zamykający klapy oddymiającej |

| DE102007041383B4 (de) | 2007-08-31 | 2009-10-22 | K + G Pneumatik Gmbh | Rauch- und Wärmeabzugs- und Lüftungseinrichtung umfassend Rauch- und Wärmeabzugs- und Lüftungsgeräte mit jeweils einem motorischen Antrieb |

| FR2946079B1 (fr) * | 2009-05-27 | 2015-10-09 | Souchier | Dispositif apte a l'ouverture d'un vantail. |

| CN108301724B (zh) * | 2018-01-18 | 2019-05-07 | 北京北方车辆集团有限公司 | 一种下翻式尾大门执行机构设计方法 |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3143318A1 (de) * | 1981-10-31 | 1983-05-19 | Josef 4815 Schloss Holte Fortmeier | "rauch- und waermeabzugsvorrichtung" |

| DE3338092C3 (de) * | 1983-10-20 | 1994-08-04 | Eberspaecher J | Vorrichtung zum rauch- und waermeabzug sowie zum be- und entlueften von geschlossenen raeumen |

| DE8912132U1 (fr) * | 1989-10-12 | 1990-04-19 | Fa. Otto Grasl, 3452 Heiligeneich, At | |

| DE19601318C2 (de) * | 1996-01-16 | 1999-01-21 | Grescha Ges Mbh & Co Grefe & S | Öffnungsmechanismus zum Öffnen und Schließen von Rauch- und Wärmeabzugsklappen |

-

1998

- 1998-07-09 DE DE19830678A patent/DE19830678C2/de not_active Expired - Lifetime

-

1999

- 1999-07-07 AT AT99113108T patent/ATE267327T1/de active

- 1999-07-07 EP EP99113108A patent/EP0971091B1/fr not_active Expired - Lifetime

- 1999-07-07 ES ES99113108T patent/ES2217650T3/es not_active Expired - Lifetime

- 1999-07-07 DE DE59909506T patent/DE59909506D1/de not_active Expired - Lifetime

- 1999-07-08 PL PL334269A patent/PL193843B1/pl unknown

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102006018485A1 (de) * | 2006-04-19 | 2007-10-25 | Andreas Grasl | Gelenkanordnung zum Betätigen einer Klappe, insbesondere Rauchabzugsklappe |

| DE102006018485B4 (de) * | 2006-04-19 | 2008-03-13 | Andreas Grasl | Gelenkanordnung zum Betätigen einer Klappe, insbesondere Rauchabzugsklappe |

Also Published As

| Publication number | Publication date |

|---|---|

| DE19830678A1 (de) | 2000-01-13 |

| DE19830678C2 (de) | 2000-11-30 |

| PL193843B1 (pl) | 2007-03-30 |

| ES2217650T3 (es) | 2004-11-01 |

| EP0971091A3 (fr) | 2003-06-11 |

| EP0971091A2 (fr) | 2000-01-12 |

| ATE267327T1 (de) | 2004-06-15 |

| DE59909506D1 (de) | 2004-06-24 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1312742B1 (fr) | Bras de compas pour panneau basculant, en particulier pour panneau oscillo-battant d'une fenêtre, porte ou similaire, fenêtre associée et procédé associé de basculement motorisé et manuel | |

| EP0520343A1 (fr) | Dispositif pour ouvrir et fermer un capot d'un véhicule | |

| EP0555757A1 (fr) | Charnière pour capot de véhicule | |

| EP1688289B1 (fr) | Dispositif pour le pivotement d'une partie d'un toit de véhicule | |

| EP0222160B1 (fr) | Mécanisme d'actionnement pour une porte de chargement de fret | |

| EP0933242B1 (fr) | Dispositif d'entraínement d'une capote de véhicule | |

| EP0971091B1 (fr) | Ensemble d'articulation pour l'actionnement d'un volet ou similaire | |

| EP0443050B1 (fr) | Clapet avec système de commande | |

| DE102011085177B4 (de) | Antriebssystem für ein KFZ-Dachsystem | |

| EP1847672B1 (fr) | Dispositif d'articulation destiné à l'actionnement d'un clapet, en particulier d'un clapet d'aspiration de la fumée | |

| EP0021080B1 (fr) | Fenêtre ou porte levante, coulissante ou basculante | |

| DE19912893A1 (de) | Cabrio-Fahrzeug mit einem Verdeck | |

| DE102007024742A1 (de) | Fenster, Tür oder dergleichen mit einer Entlastungseinrichtung | |

| DE202011004196U1 (de) | Verschlussvorrichtung | |

| WO2007076786A1 (fr) | Dispositif de recouvrement pour systemes de toit de vehicule comprenant un couvercle ouvrant | |

| EP0782509A1 (fr) | Commutateur sur colonne de direction pourvu de micro-commutateurs et ayant deux positions de fonctionnement et une position neutre | |

| EP0620350B1 (fr) | Ferrure pour une fenêtre ou une porte | |

| EP1170445A2 (fr) | Dispositif déflecteur pour panneau basculant ou oscillo-battant monté pivotant sur un cadre | |

| DE102011015093A1 (de) | Verdeckkastendeckel-Hinterkantenscharnier | |

| EP2025844B1 (fr) | Dispositif orientable | |

| EP1176276A1 (fr) | Structure de verrouillage autoverrouillable avec possibilité de réglage | |

| DE10254537A1 (de) | Fenster oder Tür | |

| DE3111579A1 (de) | Drehkippfenster | |

| EP1231345B1 (fr) | Dispositif de verrouillage et renvoi d'angle contrôlés | |

| EP0226698A2 (fr) | Verrouillage de fausse manoeuvre pour tiges de commande |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK RO SI |

|

| 17P | Request for examination filed |

Effective date: 20030828 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| RTI1 | Title (correction) |

Free format text: ARTICULATED ARRANGEMENT FOR ACTUATING A FLAP OR THE LIKE |

|

| AKX | Designation fees paid |

Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040519 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040519 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040519 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: A. BRAUN, BRAUN, HERITIER, ESCHMANN AG PATENTANWAE Ref country code: CH Ref legal event code: EP |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20040519 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: GERMAN |

|

| REF | Corresponds to: |

Ref document number: 59909506 Country of ref document: DE Date of ref document: 20040624 Kind code of ref document: P |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040707 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040731 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040819 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040819 |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: TRGR |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2217650 Country of ref document: ES Kind code of ref document: T3 |

|

| ET | Fr: translation filed | ||

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20050222 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20041019 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PFA Owner name: GRASL, ANDREAS Free format text: GRASL, ANDREAS#WIENER STRASSE 23#3452 HEILIGENEICH (AT) -TRANSFER TO- GRASL, ANDREAS#WIENER STRASSE 23#3452 HEILIGENEICH (AT) |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 20130725 Year of fee payment: 15 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PCAR Free format text: NEW ADDRESS: HOLBEINSTRASSE 36-38, 4051 BASEL (CH) |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: EUG |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140708 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 18 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 19 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 59909506 Country of ref document: DE Representative=s name: KEIL & SCHAAFHAUSEN PATENT- UND RECHTSANWAELTE, DE |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20170725 Year of fee payment: 19 Ref country code: ES Payment date: 20170814 Year of fee payment: 19 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20180726 Year of fee payment: 20 Ref country code: FR Payment date: 20180723 Year of fee payment: 20 Ref country code: IT Payment date: 20180720 Year of fee payment: 20 Ref country code: NL Payment date: 20180723 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20180719 Year of fee payment: 20 Ref country code: CH Payment date: 20180725 Year of fee payment: 20 Ref country code: BE Payment date: 20180723 Year of fee payment: 20 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20180707 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180707 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R071 Ref document number: 59909506 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MK Effective date: 20190706 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MK07 Ref document number: 267327 Country of ref document: AT Kind code of ref document: T Effective date: 20190707 |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MK Effective date: 20190707 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20190917 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180708 |