EP0963469B1 - Machine a tisser a rapieres - Google Patents

Machine a tisser a rapieres Download PDFInfo

- Publication number

- EP0963469B1 EP0963469B1 EP98910712A EP98910712A EP0963469B1 EP 0963469 B1 EP0963469 B1 EP 0963469B1 EP 98910712 A EP98910712 A EP 98910712A EP 98910712 A EP98910712 A EP 98910712A EP 0963469 B1 EP0963469 B1 EP 0963469B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- guide

- gripper

- rapier

- guide elements

- weaving machine

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 235000014676 Phragmites communis Nutrition 0.000 claims description 24

- 238000009941 weaving Methods 0.000 claims description 19

- 239000004744 fabric Substances 0.000 claims description 2

- 230000000149 penetrating effect Effects 0.000 claims 1

- 206010000496 acne Diseases 0.000 description 2

- 238000003780 insertion Methods 0.000 description 2

- 230000037431 insertion Effects 0.000 description 2

- 238000012986 modification Methods 0.000 description 2

- 230000004048 modification Effects 0.000 description 2

- 230000015572 biosynthetic process Effects 0.000 description 1

- 238000010304 firing Methods 0.000 description 1

- 230000032258 transport Effects 0.000 description 1

Images

Classifications

-

- D—TEXTILES; PAPER

- D03—WEAVING

- D03D—WOVEN FABRICS; METHODS OF WEAVING; LOOMS

- D03D47/00—Looms in which bulk supply of weft does not pass through shed, e.g. shuttleless looms, gripper shuttle looms, dummy shuttle looms

- D03D47/27—Drive or guide mechanisms for weft inserting

- D03D47/277—Guide mechanisms

-

- D—TEXTILES; PAPER

- D03—WEAVING

- D03D—WOVEN FABRICS; METHODS OF WEAVING; LOOMS

- D03D47/00—Looms in which bulk supply of weft does not pass through shed, e.g. shuttleless looms, gripper shuttle looms, dummy shuttle looms

- D03D47/27—Drive or guide mechanisms for weft inserting

- D03D47/271—Rapiers

- D03D47/272—Rapier bands

Definitions

- the invention relates to a rapier weaving machine with a a shed can be brought in and pulled out of the shed Gripper attached to a gripper belt the guide elements are assigned by a warp thread family movable into and out of the shed and guide means for guiding a gripper belt.

- a rapier weaving machine of the type mentioned is out U.S. Patent 5,183,084.

- To guide the gripper belt guide elements are provided, which are arranged in two rows are.

- the guide elements of the reed facing Row are a guide surface of the bottom of the Gripper band assigned.

- the guide elements of the reed facing row are hook-shaped and encompass a side edge of the gripper belt. Such hook-shaped Guide elements increase the risk that they will Break and / or damage to the warp threads if through the warp thread coulter and into the shed move out again.

- the invention has for its object a rapier weaving machine and in particular to design their management elements in such a way that the risk is significantly reduced that Guide elements that damage the warp threads.

- the guide elements which are arranged in two rows, two guide surfaces of the Underside of the gripper belt are assigned, and that at least the section of the At least guide elements on the side facing the reed near the gripper belt with the bottom of the Gripper band forms obtuse angles.

- the inventive design leads to the warp threads be less damaged if the guide elements through the warp thread sheet into and out of the shed be moved out. This is particularly advantageous for warp threads, the pimples or knots or other irregularities have, since they slide along the guide elements, without the risk of being detached from the guide elements be recorded.

- the guide elements in particular with the shed open to the maximum on the reed side facing an obtuse angle with that of them form a penetrated warp thread family. So that is the danger further reduced that the guide elements in particular moving out of the already closing shed Catch knots or pimples or irregularities and such lead to damage to the warp threads.

- the upper edges of all guide elements are preferably located in all positions of the guide elements below the Area of the underside of the gripper belt.

- the Upper edges of all guide elements the underside of the gripper belt to lead.

- Another possibility is, at least in the area of the end of the gripper belt in which the gripper is located to provide a guide web on the underside of the gripper belt, which is guided by means of the guide elements.

- the underside of the gripper belt at least in the area of the end of the gripper belt, where the gripper is on a guide bar which is from the guide elements is guided.

- This guide part can Have guide web, which is guided by means of the guide elements is.

- In extension of the guide bar of the guide part can be a guide bar attached to the gripper belt and / or a guide web of the gripper belt can be provided. This makes it possible for the gripper and / or the section of the gripper belt in the area of the gripper in the transverse direction to guide the direction of movement of the gripper belt.

- Guide means according to the invention for guiding a gripper belt each have at least two guide elements, the Upper edges lie in one plane and the two parallel to each other Guide surfaces assigned to the underside of the gripper belt are.

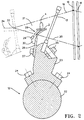

- the rapier weaving machine shown in FIGS. 1 to 6 contains two gripper belts 1, 2. At the end of the gripper belt 1 a donor gripper 3 and at the end of the gripper belt 2 Slave gripper 4 arranged. These are in the weft direction A inserted into the shed and pulled out again.

- the means Drive means 5 driven gripper belt 1 brings the Encoder gripper 3 with the weft thread to be entered from the entry side to the middle of the shed. There the takes over Slave gripper 4, which in a corresponding manner with the help of by means of drive means 6 driven gripper belt 2 moves the weft and transports it to the opposite Side of the shed.

- the drive means 5 and 6, each in the area of a side frame 7 and 8 of the Rapier weaving machines are arranged, each comprise a means Drive elements driven gear 9 and 10, the works with the respective gripper belt 1 or 2.

- the Gripper belts 1, 2 are in contact by means of guide blocks 11 held with the gears 9, 10.

- the rapier weaving machine also contains a sley 12 which a reed 13 is attached and in the side frame 7 and 8 is stored.

- the sley 12 is by means of drive means 14, 15 driven to reciprocating movement.

- the drive means 14, 15 and the drive means 5, 6 can be operated synchronously.

- the gripper belts 1, 2 are arranged in the region of the side frames 7, 8 by means of stationary Guided tours 16 and 17.

- the rapier weaving machine contains furthermore schematically represented subject education means 18, by means of not shown specialist drive means can be raised and lowered in sync with the Shutter drive means 14, 15 can be operated.

- 2 are also two warps 19, 20 shown, between which a shed 21 is formed, in the a weft thread is inserted.

- These warp threads 19, 20 are formed by means of the subject formation means 18, of which only two are shown and which are based on a predefined one Patterns raised and lowered before each shot entry become.

- the sley 12 has a shutter shaft 22 on which a shutter profile 23 is fastened by means of screws 24.

- a shutter profile 23 is fastened by means of screws 24.

- the reed 13 is fastened on the store profile 23 by means of fastening means 25 attached.

- a is on the store profile 23 Intermediate profile 26 fastened by means of screws 27, to which attached a plurality of guide means 28 according to the invention is.

- the individual guide means 28 are attached with With the help of a screw 29, which has a retaining projection 30 of the guide means 28 penetrates and into an in the intermediate profile 26 provided thread 31 is screwed.

- the thread 31 runs at an angle to the perpendicular to the intermediate profile 26.

- the holding projection 30 has an inclined surface 32 on, which runs perpendicular to the thread 31 and on which the Head of the screw 29 is supported.

- the plurality of guide means 28 is by means of the back and forth pivoting movement of the sley 12 through the lower Warp thread sheet 20 moved back and forth into the shed 21. These guide means move in one plane through the lower warp thread sheet 20, which is perpendicular to Shot direction A runs.

- Fig. 2 the position is shown, in which due the pivoting of the sley 12, the guide means 28 on have penetrated as far as possible into the shed 21, which in this Position is also most open.

- the guide means 28 form the guide for the underside the gripper belts 1, 2.

- Their leading edges lie in one in Fig. 2 drawn in dashed lines essentially horizontal Level which is below a stop edge 33 of a Fabric 34 is on which the wefts after insertion be posted by means of the reed 13, as in Fig. 2 is shown in dashed lines on the left.

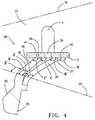

- the guide means 28 two different guide elements 35 and 36, which are arranged on the holding projection 30 are.

- the plurality of guide members 35 and the plurality of the guide elements 36 are each arranged in a row, which in the longitudinal direction of the sley 12 and thus in Direction of movement of the gripper belts 1, 2 extends.

- the series the guide elements 35 guides the underside of the gripper belt 1 or 2 on a guide surface 37 which the reed 13th is facing.

- the row of guide elements 36 leads the Underside of the gripper belts 1, 2 on a guide surface 38, which faces away from the reed 13.

- the series of guide elements 35 is thus between the row of guide elements 36 and the reed 13.

- Fig. 6 is a guide element 35 and a guide element 36 offset in the weft direction A to each other on a holding approach 30 provided.

- Fig. 4 which is an enlarged section the position of the guide means 28 with the guide elements 35 and 36 in the position described in FIG. 2 shows, the rod-shaped or rod-shaped guide elements 35 and 36 to the underside of the gripper belts 1, 2 directed that they each on the reed facing Side obtuse angles B, B 'and C, C' on the order of form about 120 ° to about 150 °.

- the essentially straight forward Portions of the guide members 35, 36 through the The warp thread sheet 20 penetrate into the shed 21 and in the weft direction A have less strength than crosswise at least in the vicinity of the gripper belts 1, 2 these angles B, B 'and C, C' each with their reed 13 facing Side edges, each in a direction perpendicular to the weft direction A.

- the angles B and B 'and the angles C and C' each approximately the same.

- the guide elements 35, 36 one in essential rectilinear section in the part of its length, which penetrates into the shed 21.

- the guide elements 35, 36 aligned so that they with the warp threads of Warp thread sheet 20 on the side facing away from the reed 13 obtuse angles D, D 'and E, E' between their side flanks and form the warp thread sheet 20.

- form the side flanks of the guide elements 35, 36 the side facing away from the reed 13 with the warp thread family 20 also obtuse angles F, F 'and G, G', while the guide elements 35, 36 into the opening shed 21 or move out of the closing shed 21. 4 and 5, the angles D, D ', angles E, E ', angles F, F' and angles G, G ', respectively essentially the same size.

- the gripper belts 1, 2 are provided with openings 39 (FIG. 4 and FIG. 10) provided, which cooperate with the teeth of the gears 9, 10. As can be seen from Fig. 3, these are openings 39 essentially in the middle of the gripper belts 1, 2 intended.

- the guide elements 35 and 36 are arranged that the gripper belts 1, 2 are not in the area of this Open openings 39 so that none in the area of these openings Wear is generated by the guide elements 35, 36.

- the upper edges of the guide elements 35, 36 provided with curves, so that the risk of damage the gripper belts 1, 2 and the warp threads of the warp thread family 20 is reduced.

- Guide elements 35 and a guide element 36 are provided.

- the guide element 36 is between the two guide elements 35 arranged.

- the guide elements 35 and 36 in a common, perpendicular to Shot direction A extending plane arranged so that the Guide elements 35 and 36 between the same warp threads Warp thread sheet 20 can be introduced into the shed 21.

- the guide elements 35 and 36 are so long that the Holding approach 30 and the place where the two guide elements 35 and 36 are merged below the lower one Warp thread sheet 20 remain, so that a warp thread between the two guide elements 35, 36 should be detected, always reach the warp thread sheet 20 during shedding can.

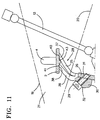

- Figs. 9 and 10 is in the area of the ends the gripper belts 1, 2, in which the grippers 3, 4 are located, in each case on the undersides of the gripper belts 1, 2

- Guide web 42 attached between the guide elements 35 and 36 is performed. This prevents that the gripper belts 1, 2 can move in the transverse direction M, so that they are not towards the reed 13 or from the reed 13 can dodge away.

- the guide web 42 has this embodiment has a triangular cross section.

- the guide bridge 43 is in this embodiment in one piece with the Gripper belts 1, 2. This guide web 43 projects, for example with a part 43A beyond the gripper belts 1, 2.

- the guide web 43 has one in this embodiment trapezoidal cross-section.

- the guide web 43 is located below the bottom the gripper belts 1, 2 and thus also below that of the Upper edges 40, 41 of the guide elements 35, 36 plane formed. Since it is in this embodiment with the front Part 43A extends beyond the end of the gripper belts 1, 2, he can use warp threads on one of the top edges 41 or 42 of the guide elements 35 or 36 get stuck, from push these top edges 40, 41 before these top edges 40, 41 can be reached from the underside of the gripper belts 1, 2. It can be clearly seen from FIG. 11 that the guide web 43 not even with the upper edges 40, 41 of the guide elements 35, 36 comes into contact.

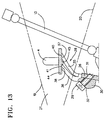

- 13 and 14 is in extension the gripper belts 1, 2 in the area of the grippers 3, 4 Guide part 44 attached, the bottom with the bottom the gripper belts 1, 2 are aligned so that its underside is guided by the guide elements 35, 36.

- This guide part 44 has a downwardly projecting guide bar 45, which is guided between the guide elements 35, 36.

- the guide web 45 is in one piece with the guide part 44. In this exemplary embodiment, the guide web 45 is in a distance from the front end of the guide part 44, so that the grippers 3, 4 are similar to the US patent 5 183 084 are already introduced into the shed 21 can before the guide means 28 in their end position 13 are located.

- the guide web 45 has one rectangular cross section.

- a guide part 44 is provided, which has a guide web 48.

- this guide web 48 In extension of this guide web 48 are on the gripper belts 1, 2 each a guide web 49 is provided.

- the boardwalks 49 close directly to the guide bar 48 of the guide parts 44 at.

- the guide web 48 protrudes over the front edge of the guide parts 44 with part 48A out. This results in the same advantages that already with the guide web 43 the front part 43A with reference to FIGS. 11 and 12 were.

- the guide webs 42, 43, 45, 47, 48, 49 can have a triangular, have a rectangular or trapezoidal cross-section or another cross section. These are guideways shaped so that they between the guide members 35 and 36th can be performed so that they prevent the Gripper belts 1, 2 towards the reed 13 or away from it Move reed 13.

- any known gripper can be used as the gripper 3, 4 are used, for example those from US Pat. 4 708 174 or 4 860 800 known grippers.

- the invention is not based on the illustrated and described Embodiments limited.

- Changes within the skill of a person skilled in the art and / or combinations of the exemplary embodiments without departing from the scope of the invention by the appended claims are defined.

- the invention can also be used in rapier weaving machines, the only one gripper driven by a gripper belt have, which is then between the weft insertion side and the opposite side of the loom moves.

Landscapes

- Engineering & Computer Science (AREA)

- Textile Engineering (AREA)

- Looms (AREA)

- Woven Fabrics (AREA)

Claims (10)

- Métier à tisser à pinces avec au moins une pince (3, 4) pouvant être insérée dans une foule (21) et pouvant être retirée de nouveau de la foule, qui est montée sur une bande à pinces (1, 2) à laquelle sont associés des éléments de guidage (35, 36) qui, à travers une nappe de fils de chaine (20), peuvent être introduits dans la foule (21) et sortis de celle-ci, caractérisée en ce que les éléments de guidage (35, 36), qui sont disposés en deux rangées, sont associés avec leurs arêtes supérieures (40, 41) à deux faces de guidage (37, 38) du côté inférieur de la bande à pinces (1, 2), et en ce que les éléments de guidage (35, 36) sont inclinés vers le peigne (13), de telle sorte qu'au moins le tronçon des éléments de guidage (35, 36) traversant la nappe de fils de chaíne (20), au côté orienté vers le peigne, forme au moins au voisinage de la bande à pinces (1, 2) avec le côté inférieur de la bande à pinces (1, 2) des angles obtus (B, B', C, C').

- Machine à tisser à pinces selon la revendication 1, caractérisée en ce que les éléments de guidage (35, 36), au côté éloigné du peigne (13), forment un angle obtus (E, E', D, D') avec la nappe de fils de chaine (20) traversée par eux.

- Machine à tisser à pinces selon la revendication 1 ou 2, caractérisée en ce que le côté inférieur de la bande à pinces (1, 2) est guidé au moyen des arêtes supérieures (40, 41) des éléments de guidage (35, 36) dans un plan sensiblement horizontal qui se situe en dessous d'un bord de butée (33) d'un tissu (34).

- Machine à tisser à pinces selon l'une des revendications 1 à 3, caractérisée en ce que la bande à pinces (1, 2) présente, au moins approximativement au milieu de celle-ci, des ouvertures (39), et en ce que les faces de guidage (37, 38) sont prévues de part et d'autre des ouvertures.

- Machine à tisser à pinces selon l'une des revendications 1 à 4, caractérisée en ce qu'il est prévu dans le prolongement de l'extrémité de la bande à pinces (1, 2), au voisinage des griffes (3, 4), une partie de guidage (44) qui est guidée au moyen des éléments de guidage (35, 36).

- Machine à tisser à pinces selon la revendication 5, caractérisée en ce que la partie de guidage (44) présente une nervure de guidage (45, 48) qui est guidée au moyen des éléments de guidage (35, 36) transversalement à la direction de déplacement de la bande à pinces (1, 2).

- Machine à tisser à pinces selon l'une des revendications 1 à 6, caractérisée en ce que la bande à pinces (1, 2) est pourvue au moins au voisinage de son extrémité, dans laquelle est disposée la pince (3, 4), d'une nervure de guidage (42, 43, 47, 49) qui est guidée au moyen des éléments de guidage (35, 36) transversalement à la direction de déplacement de la bande à pinces (1, 2).

- Machine à tisser à pinces selon l'une des revendications 1 à 7, caractérisée en ce que la nervure de guidage (42, 43, 47, 49) de la bande à pinces (1, 2) et/ou la nervure de guidage (45, 48) de la partie de guidage (44) sont guidées entre les arêtes supérieures (40, 41) des éléments de guidage (35, 36) orientées vers le côté inférieur de la bande à pinces (1, 2), aux arêtes latérales de ces éléments de guidage.

- Machine à tisser à pinces selon l'une des revendications 6 à 8, caractérisée en ce que la nervure de guidage (43) de la bande à pinces (1, 2) ou la nervure de guidage (48) de la partie de guidage (44) font saillie sur l'extrémité de la bande à pinces (1, 2) ou sur l'extrémité de la partie de guidage (44).

- Moyens de guidage pour le guidage d'une bande à pinces dans une machine à tisser à pinces, caractérisés en ce que les moyens de guidage (28) présentent chacun au moins deux éléments de guidage (35, 36), qui sont inclinés vers le peigne et dont les arêtes supérieures (40, 41) se situent dans un plan commun, et qui sont associés, avec leurs arêtes supérieures, à deux faces de guidage (37, 38) s'étendant parallèlement l'une à l'autre, du côté inférieur de la bande à pinces (1, 2).

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| BE9700165A BE1010943A3 (nl) | 1997-02-24 | 1997-02-24 | Grijperweefmachine met een aantal geleidingsmiddelen. |

| BE9700165 | 1997-02-24 | ||

| PCT/EP1998/000988 WO1998038366A1 (fr) | 1997-02-24 | 1998-02-20 | Machine a tisser a rapieres |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0963469A1 EP0963469A1 (fr) | 1999-12-15 |

| EP0963469B1 true EP0963469B1 (fr) | 2002-12-11 |

Family

ID=3890364

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP98910712A Expired - Lifetime EP0963469B1 (fr) | 1997-02-24 | 1998-02-20 | Machine a tisser a rapieres |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US6276403B1 (fr) |

| EP (1) | EP0963469B1 (fr) |

| BE (1) | BE1010943A3 (fr) |

| DE (1) | DE59806626D1 (fr) |

| ES (1) | ES2186138T3 (fr) |

| WO (1) | WO1998038366A1 (fr) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| BE1014950A3 (nl) * | 2001-08-29 | 2004-07-06 | Wiele Michel Van De Nv | Inrichting voor het aandrijven en geleiden van een grijper van een weefmachine. |

| CN102995241B (zh) * | 2012-12-10 | 2013-11-20 | 浙江万利纺织机械有限公司 | 一种剑杆织机防止纬线纱端缠绕经线的装置 |

| BE1028436B1 (nl) * | 2020-06-25 | 2022-01-31 | Vandewiele Nv | Geleidingsinrichting in een grijperweefmachine, grijperweefmachine en werkwijze voor het omvormen van een grijperweefmachine |

Family Cites Families (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| NL128152C (fr) * | 1900-01-01 | |||

| BE658330A (fr) * | 1964-01-17 | 1900-01-01 | ||

| BE902141A (nl) * | 1985-04-09 | 1985-10-09 | Picanol Nv | Verbeterde grijpers voor weefmachines. |

| BE902913A (nl) * | 1985-07-17 | 1986-01-17 | Picanol Nv | Lansgeleiding voor grijperweefmachines |

| ES2012386B3 (es) * | 1986-06-03 | 1990-03-16 | Picanol Nv | Pinza de alimentacion para telares. |

| IT1227335B (it) * | 1988-09-08 | 1991-04-08 | Vamatex Spa | Mezzi per guidare il moto di pinze di alimentazione della trama all'interno del passo di telai di tessitura senza navette |

| BE1004305A3 (nl) * | 1989-07-06 | 1992-10-27 | Picanol Nv | Grijperweefmachine met lansgeleiding. |

| US5176185A (en) * | 1990-07-24 | 1993-01-05 | Sulzer Brothers Limited | Guide teeth for a rapier picking tape |

| IT1271130B (it) * | 1994-11-30 | 1997-05-26 | Vamatex Nuova Spa | Mezzi per guidare il moto di una coppia di pinze all'interno del passo di telai di tessitura |

-

1997

- 1997-02-24 BE BE9700165A patent/BE1010943A3/nl not_active IP Right Cessation

-

1998

- 1998-02-20 US US09/355,976 patent/US6276403B1/en not_active Expired - Fee Related

- 1998-02-20 WO PCT/EP1998/000988 patent/WO1998038366A1/fr active IP Right Grant

- 1998-02-20 EP EP98910712A patent/EP0963469B1/fr not_active Expired - Lifetime

- 1998-02-20 ES ES98910712T patent/ES2186138T3/es not_active Expired - Lifetime

- 1998-02-20 DE DE59806626T patent/DE59806626D1/de not_active Expired - Lifetime

Also Published As

| Publication number | Publication date |

|---|---|

| DE59806626D1 (de) | 2003-01-23 |

| US6276403B1 (en) | 2001-08-21 |

| EP0963469A1 (fr) | 1999-12-15 |

| BE1010943A3 (nl) | 1999-03-02 |

| ES2186138T3 (es) | 2003-05-01 |

| WO1998038366A1 (fr) | 1998-09-03 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DD269408A5 (de) | Fuehrungsmittel zur bewegung eines mit greifern versehenen schusspaares innerhalb des webfaches eines webstuhles | |

| DE68916602T2 (de) | Vorrichtung zur Steuerung der Bewegung der Schusseintragsgreifer im Fach von schützenlosen Webmaschinen. | |

| EP0620303A1 (fr) | Métier à tisser à griffes | |

| DE2634966C2 (de) | Fachbildevorrichtung einer triaxialen Webmaschine | |

| EP0576854B1 (fr) | Métier à tisser à griffes | |

| EP0963469B1 (fr) | Machine a tisser a rapieres | |

| EP0972099B1 (fr) | Metier a tisser a rapieres | |

| EP0446424B1 (fr) | Métier à tisser à griffes pour tissus lourds | |

| DE1710332A1 (de) | Vorrichtung zur Ausbildung von Webkanten | |

| CH649325A5 (de) | Schussfadenueberwachungseinrichtung an einer duesenwebmaschine. | |

| EP0898000B1 (fr) | Métier à tisser à griffes avec des moyens de guidage pour guider un ruban à griffes et/ou une griffe | |

| DE2427883C3 (de) | Fachbildevorrichtung einer Webmaschine mit über Schaftzugorgane gesteuerten Schäften | |

| DE8033879U1 (de) | Greiferwebstuhl | |

| DE3642712C2 (fr) | ||

| EP1799894B1 (fr) | Elements de guidage destines a un element de transport a prehenseur d'une machine a filer | |

| EP0980448B1 (fr) | Machine a tisser a lances | |

| EP2372001A1 (fr) | Elément de guidage pour un élément de transport de poignée d'une machine à tisser | |

| EP1108080B1 (fr) | Metier a tisser a lance comprenant au moins une bande a lance ainsi que des moyens de guidage | |

| DE3042054A1 (de) | Greiferstange fuer schuetzenlose webmaschinen | |

| EP0776390B1 (fr) | Metier a tisser a pince | |

| DE3248557C2 (fr) | ||

| DE1226499B (de) | Bandwebstuhl | |

| DE2204956C3 (de) | Nadelwebmaschine | |

| DE2404980A1 (de) | Rietzahnanordnung fuer eine wellenwebmaschine | |

| DE2449974A1 (de) | Webeblatt oder riet |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 19990702 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): CH DE ES FR GB IT LI |

|

| 17Q | First examination report despatched |

Effective date: 20010813 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): CH DE ES FR GB IT LI |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20021211 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: PATENTANWALTSBUERO G. PETSCHNER |

|

| REF | Corresponds to: |

Ref document number: 59806626 Country of ref document: DE Date of ref document: 20030123 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2186138 Country of ref document: ES Kind code of ref document: T3 |

|

| ET | Fr: translation filed | ||

| GBV | Gb: ep patent (uk) treated as always having been void in accordance with gb section 77(7)/1977 [no translation filed] |

Effective date: 20021211 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20030912 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: ZIMMERLI, WAGNER & PARTNER AG |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PFA Owner name: PICANOL N.V. Free format text: PICANOL N.V.#POLENLAAN 3-7#8900 IEPER (BE) -TRANSFER TO- PICANOL N.V.#POLENLAAN 3-7#8900 IEPER (BE) |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20100219 Year of fee payment: 13 Ref country code: CH Payment date: 20100222 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20100227 Year of fee payment: 13 Ref country code: FR Payment date: 20100315 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20100225 Year of fee payment: 13 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110228 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110228 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20111102 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110220 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 59806626 Country of ref document: DE Effective date: 20110901 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110228 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20120411 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110221 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 59806626 Country of ref document: DE Representative=s name: PATENTANWAELTE RUFF, WILHELM, BEIER, DAUSTER &, DE |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 59806626 Country of ref document: DE Representative=s name: PATENTANWAELTE RUFF, WILHELM, BEIER, DAUSTER &, DE Effective date: 20120814 Ref country code: DE Ref legal event code: R081 Ref document number: 59806626 Country of ref document: DE Owner name: PICANOL, BE Free format text: FORMER OWNER: PICANOL N.V., IEPER, BE Effective date: 20120814 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110901 |