EP0943777B1 - Vormontiertes und voreingestelltes Sektionaltor, und seine Konditionierung - Google Patents

Vormontiertes und voreingestelltes Sektionaltor, und seine Konditionierung Download PDFInfo

- Publication number

- EP0943777B1 EP0943777B1 EP99400680A EP99400680A EP0943777B1 EP 0943777 B1 EP0943777 B1 EP 0943777B1 EP 99400680 A EP99400680 A EP 99400680A EP 99400680 A EP99400680 A EP 99400680A EP 0943777 B1 EP0943777 B1 EP 0943777B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- door

- leaf

- rails

- panel

- lateral

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E06—DOORS, WINDOWS, SHUTTERS, OR ROLLER BLINDS IN GENERAL; LADDERS

- E06B—FIXED OR MOVABLE CLOSURES FOR OPENINGS IN BUILDINGS, VEHICLES, FENCES OR LIKE ENCLOSURES IN GENERAL, e.g. DOORS, WINDOWS, BLINDS, GATES

- E06B3/00—Window sashes, door leaves, or like elements for closing wall or like openings; Layout of fixed or moving closures, e.g. windows in wall or like openings; Features of rigidly-mounted outer frames relating to the mounting of wing frames

- E06B3/32—Arrangements of wings characterised by the manner of movement; Arrangements of movable wings in openings; Features of wings or frames relating solely to the manner of movement of the wing

- E06B3/48—Wings connected at their edges, e.g. foldable wings

- E06B3/485—Sectional doors

Definitions

- the invention relates to sectional doors with ceiling erasure and vertical travel such as garage doors.

- It relates more particularly to a door once manufactured, pre-assembled and pre-adjusted on the one hand, once set up in the building to which it is on the other hand; packaging incorporating several pre-assembled doors; and finally a method of mounting a such door.

- EP-A-304 642, EP-A-370 324 and EP-A-370 376 are interested in the structure of the longitudinal edges of two adjacent panels.

- the garage doors considered are intended to be implemented in a construction comprising a opening that the door is intended to obscure.

- the overall dimensions of the door (horizontal width and vertical height) are larger than the dimensions of the opening in question.

- Construction usually includes a ceiling and two partitions on either side of the opening defining a fall of the lintel and the right and left corner pieces respectively of appreciable dimensions.

- the lintel fallout is necessary due to the presence, at this point, of rails, of a tree supporting cable winding drums, of one or more leaf return members.

- the corner pieces they are necessary for the housing of roller bearing pins, rollers and side rails.

- the object of the invention is in particular to limit the height of the lintel fallout and the width of the corner pieces, as well that the assembly and adjustment times on the site of the construction.

- the object of the invention is also a door which does not have not the disadvantages of those currently known, which be simple while being solid and easy to set up artwork.

- each thin and light panel of the leaf is around 9 to 10 Kg / m2, in particular around 9.5 Kg / m2.

- the total thickness of each thin and light panel of the leaf is less than 3 cm.

- the second set includes a crosspiece for connecting the guide rails higher when the door is mounted in situation.

- the second set is placed flat against the leaf of the first set, the two sets forming a package.

- the invention relates to a packaging incorporating several sectional erasing doors ceiling and vertical travel as described previously, comprising a pallet support and rack and receiving a plurality of doors placed side by side, and further comprising a plurality of first pre-set pre-set, each first assembly further supporting the two guide rails upper housed upside down inside the first together.

- This package can contain up to nine doors.

- the invention relates to a method of implementation, in a construction provided with a opening, an erasing door on the ceiling and vertical travel, said door having been manufactured, pre-assembled and pre-adjusted, if necessary conditioned as previously indicated, in which the door is brought manufactured, pre-assembled and pre-set on the site of the construction and we set up and fix it to said construction of the first and second sets.

- a construction includes an opening in which is mounted a door as just described.

- the construction is such that the fallout of the lintel and the corner pieces are reduced in size which can be less than 10 cm, in particular of the order of 8 cm and around 9 cm.

- the guide rails the hinges are located on the side inside and the longitudinal ribs on the outside.

- the opening 1 is typically that allowing passage of a motor vehicle, door 2 therefore being a door garage.

- the lintel fallout 4 and the corner pieces 5 are large reduced compared to those in the state of technical.

- the sizes are less than 10 cm and in particular of the order of 8 cm for the lintel fallout and about 9 cm for each corner.

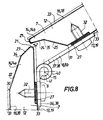

- Door 2 includes a leaf 6, movable between a position closure ( Figure 1) and an open position.

- the leaf 6 In the closed position, the leaf 6 is disposed vertically or substantially vertically in opening 1.

- the leaf 6 In the open position, the leaf 6 is disposed horizontally or substantially horizontally towards the ceiling adjacent to the lintel drop 4.

- the door 2 considered is therefore of the erasure type at ceiling and vertical travel.

- She is also sectional type, leaf 6 comprising a succession panels 7 similar or identical to each other. Of them adjacent panels are arranged and mounted one on top of the other in a way to be associated with each other by means pivot 8.

- Door 2 also includes lateral guide rails 9 and upper guide rails 10. These rails are arranged respectively vertically or substantially vertically, horizontally or substantially horizontally. They are placed inside the construction, respectively on either side and above of opening 1. They are located near this opening 1.

- the rails 9 and 10 form two sets on either side of opening 1. Each of these two sets have one or two side rails 9 and one or two upper rails 10, the last adjacent to upper extremities of the side rails 9. Both sets of rails 9 and 10 are located in two planes vertical parallel to each other, perpendicular to the plane of the opening 1.

- the rails 9 are fixed, directly or not to the wall of the building in which is housed the opening 1.

- the rails 10 are fixed in particular to the ceiling.

- D a horizontal direction located in the plane of opening 1, perpendicular to the plane of the two rail sets 9 and 10.

- Rollers 11 of axis D cooperating with the rails 9 and 10 are carried by the panels 7 projecting from their edges vertical lateral 12.

- the rollers 11 can slide in the rails 9 and 10 to allow movement of the leaf 6 between its open and closed positions.

- Door 2 also includes in the production considered a mechanism 13 comprising a shaft 13a of axis D arranged towards the junction of rails 9 and 10 - and therefore towards the upper end of the rails 9-, two drums 13b cable winding mounted on the parts lateral ends of the shaft 13a towards the outside of the leaf 6 and between the latter and the side rails 9; of them cables linked on the one hand to the lower end panel of the leaf 6, on the other hand wound on the drums 13b; a or more elastic return members 13c mounted on the shaft 13a, such as a helical spring; ways to operation 13d, in this case manuals such as a handle controlling a latch cooperating with a window for hanging in the door frame 2.

- a mechanism 13 comprising a shaft 13a of axis D arranged towards the junction of rails 9 and 10 - and therefore towards the upper end of the rails 9-, two drums 13b cable winding mounted on the parts lateral ends of the shaft 13a towards the outside of the leaf 6 and between the latter and the side rail

- Cables are arranged vertically or substantially vertically between the side edges of leaf 6 and the rails 9. They are located in the immediate vicinity of the plane of opening 1. They pass between this plane and the supports of pebbles 11. They are therefore not accessible in a non desired.

- the panels 7 include an end panel lower 7a, an upper end panel 7b and a or several intermediate panels 7c.

- the leaf 6 comprises in all four identical panels 7.

- the panels 7 have a general outline in front elevation rectangular, the long side being horizontal and direction D and the small vertical side (when door 2 is installed and closed).

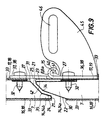

- a panel 7 is limited by the two side edges 12 and two longitudinal edges 14.

- the longitudinal edges 14 have, in cross section transverse, a generally pseudo-triangular profile.

- Two adjacent panels 7 are associated with pivoting relative to each other around an axis 15 parallel to direction D. They present two songs longitudinal substantially complementary to each other namely respectively a song called salient 14a (or male) and a song said to come in 14b (or female).

- the protruding edges 14a are, when door 2 is mounted and closed, directed towards up and in the up position. And, conversely, the songs returning 14b are directed downwards and in the low position.

- a panel 7 therefore comprises, at the top, a projecting edge 14a and, at the bottom, an inside song 14b.

- the protruding edge 14a has a general shape to concavity turned towards the inside of the panel 7.

- the edge reentrant 14b has a general shape with convexity facing the inside of the panel 7.

- a panel 7 includes first and second facings respectively 16 and 17, defining its large faces visible exterior 18 and 19, which are parallel.

- the facings 16 and 17 are made from sheets thin metal, rigidly secured one to the other.

- facings 16 and 17 are made from steel sheets with a thickness of about 0.4 mm.

- the two facings 16 and 17 are, in this embodiment, made from the same type of thin sheet.

- the two facings 16 and 17 are made from different types of leaves.

- the sheets of facings 16 and 17 can be made in other materials than steel, since this material is suitable for the use and performance required.

- the first facing 16 is that located on the outside of construction, that is to say towards the "noble" visible face 18 of door 2.

- the second facing 17 clearly visible on the Figure 1, is located on the inside of the building (face 19).

- At least one of the facings - in this case the first facing 16- has at least one rib of stiffening 20 recessed, longitudinal, extending between the two songs 12.

- the other facing, 17, is in this realization without such groove and is substantially plan.

- the longitudinal rib 20 extends entirely over the distance between the two edges 12. According to another embodiment, the rib 20 extends over only a part of this distance.

- the longitudinal rib 20 a in cross section transverse, a substantially triangular profile or round.

- the facing 16 comprises, in the embodiment shown corresponding to a panel 7 of appreciable width, several longitudinal ribs 20. These are of identical or close profile.

- the ribs 20 are located essentially in the middle area of panel 7, at the distance between the edges 14. They are spread so that less substantially equidistant from each other. In the considered realization where door 2 includes four panels 7, each of which includes five ribs longitudinal 20.

- the internal space 56 of the panel 7, closed at the periphery by the two facings 16, 17, is filled -at least partially- of a synthetic material which expands manufacturing.

- the panel 7 is devoid of reinforcement or interior insert of substantial stiffening.

- a longitudinal edge 14 has a thickness ranging from decreasing, continuously, from the large faces 18, 19 to its longitudinal free edge 21.

- Edge 14 is essentially defined by several faces substantially successive planes of one of the facings, in the occurrence the outer facing 16 having the longitudinal ribs 20.

- edge 14 is defined by at most four faces (two faces in the embodiment shown), and a rounding forming the longitudinal free edge 21.

- these two faces are, from of the first large outer face 18 and as regards the facing 16, a face 22 of greater width followed a face 23 of smaller width, the latter being itself followed and terminated by the rounding of edge 21 of connection with the second large inner face 19.

- these two faces are, from of the first large outer face 18 and as regards the facing 16, by means of the rounded edge 21, a face 24 of smaller width and one side 25 of greater width of connection with the second large inner face 19.

- the facing 16 is folded and rolled in order to achieve the faces 22, 23, 24, 25 and the rounded edges 21.

- At least one face 26 of the rib 20 a relative to the first large outer face 18 of the facing 16, in the considered embodiment, an analogous or similar inclination from that of the face 22 of the protruding longitudinal edge 14a.

- the profile of the rib 20 is similar to or close to the profile formed by the two adjacent longitudinal edges of the two panels 7 associated and coplanar adjacent. This last profile is in the occurrence formed by a part of the face 22 of one of the panels 7 and the rounding 21 opposite the other panel 7.

- a panel 7 has a total thickness of less than 3 cm.

- the total mass of a panel 7 according to the structure described can be of the order of 9 to 10 kg / m 2 , in particular close to 9.5 kg / m 2 .

- the facing 16 is provided with longitudinal ribs 20 and also provided with at least one - and if necessary several - transverse ribs in hollow, similar in profile or close to that of a rib longitudinal 20, the panel being of the so-called cassette type.

- cassettes are typically stamped patterns on the exterior facing, forming shape reliefs rectangular or asymmetrical, with a slight hollow on the inner surface and surrounded by a border peripheral.

- the depth of a rib longitudinal 20 is of the order of magnitude of a third of the total thickness of the panel 7.

- the two sheets forming the facings 16 and 17 are rigidly secured to each other towards each of the edges 14 by folding with nesting 27.

- This folding 27 is flat and substantially coplanar with a large faces of the panel 7 in this case the second large inner face 19, on the side of the facing 17. In this embodiment, the folding 27 is therefore located on the side opposite to (i.e. opposite) the first large face 18 where the longitudinal rib (s) 20 is located.

- Folding 27 is obtained by means of a fold 28 in one direction of facing 16 and of a fold 29 in the other direction of facing 17, the two folds 28, 29 being nested one inside the other in the manner of a hook ( Figures 5a, 5b, 6a, 6b).

- the folding 27 is located with regard to the projecting edge 14a substantially opposite the edge 30 formed by the first inclined face 22 of the edge on the first large face opposite 18. With regard to the inside edge 14b, the folding 27 is located near the edge 31 formed by the first inclined face 25 of the edge on the same second large face 19.

- a folding 27 also forms a functional means of fixing of a hinge element of the pivoting means 8. Indeed, a folding 27 allows effective clamping of a (or more) screws 32 for hinge fixing.

- the facing 16 has a general U-shaped bowl, while the facing 17 is substantially flat.

- the panel 7 also comprises, fixed to each of its edges 12, an added U-shaped profile 33.

- a song 14 includes a face 22, 24 inclined between 15 ° and 25 °, in particular about 20 ° with respect to the large faces 18, 19. It also has a face 23, 25 inclined between 40 ° and 50 ° in particular about 45 ° on these same large faces 18, 19.

- Two adjacent faces of a song 14, namely 22, 23 of a part 24, 25 on the other hand form an edge between them and a salient or re-entrant angle respectively 34, 35, between 150 ° and 160 °, in particular about 155 °.

- the rounding 21 has a radius of curvature of the order or less than a tenth of the total thickness of the panel 7.

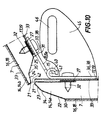

- the pivot means 8 comprise at least two hinges end 8a towards the side edges 12 and, if applicable if necessary, one or more intermediate hinges 8b.

- the two elements 36, 37 of each hinge 8 are fixed to the panels 7 at least on folds with nesting 27. These elements include platinum-shaped parts 38 provided with holes 39 for the screws 32 of the shoulder head type and curved parts 40 for passage and fixing a pin 41 forming the axis 15.

- the pivot axis 15 of the hinges 8, therefore of the panels 7, is situated outside the space taken up by the panels, near the second large face 19 and the facing 17 where the folding 27 is located, substantially at the right of the middle part of the protruding edge 14a of the first panel 7 and substantially to the right of the free edge 21 of the inside edge 14b of the second panel when it extends the first in a coplanar fashion.

- the panel 7 described as "first” is in the lower position and the one described as "second" is in the upper position.

- pivot axis 15 is spaced from the second large face 19 and the facing 17 of the first panel 7 worth about a third of the magnitude, half, or even less, of the total thickness of the panel 7.

- the two longitudinal edges 14a, 14b opposite the two panels 7 are spaced from each other by a free space 42, reduced.

- This space 42 thus configured and proportioned forms an external finger clip.

- the faces 24, 25 of the re-entrant edge 14b are substantially tangents to an arc having the axis of pivot 15.

- the end hinges 8a are fixed to the profiles reported 33 forming the side edges 12.

- door 2 also includes an anti inner finger clip 43 in the form of plates or added profiles, fixed flat on the second panel 7, on the second large face 19 where the folding 27 is located (facing 17).

- an anti inner finger clip 43 in the form of plates or added profiles, fixed flat on the second panel 7, on the second large face 19 where the folding 27 is located (facing 17).

- Such a plate or section 43 extends until it is slightly below the pivot axis 15, when the two panels in question are in extension relative to each other in a coplanar fashion.

- the plate or profile 43 is folded at 44 to come against the facing 16 of the first panel when the two panels are in overtime and co-planar.

- the internal anti-finger clip 43 is not an insert fixed flat on the large side 19 of the second panel 7, but is integrated into side 19 of the facing 17.

- the large face 19 then extends to be slightly offset from the middle of the edge protruding 14a from the first panel 7, when the two panels in question are an extension of one to the other in a coplanar fashion (Figure 7a).

- the large face 19 is folded at 44 to come against the facing 16 of the first panel 7 when the two panels are in extension and coplanar, and to form the folding 27 for the second panel 7.

- One of the two elements of an end hinge 8a namely element 36 for example, has a square shape having on the one hand the plate 38 and on the other hand a tab 45 provided with an oblong lumen 46, extending substantially perpendicular to the plate 38 in question, in which is rigidly fixed but adjustable in position a pin 47 supporting the roller 11.

- the said pin 47 has in cross section a profile 48 non-circular, in particular polygonal, for clamping fixation.

- the panels 7 thus formed have the advantage of being of a reduced weight. So it is the same for the whole leaf 6.

- This structure results in the drum cable winding can be reduced in diameter, such as between 65 and 75 mm.

- the lintel fallout and the corner pieces can also be reduced in size, as it has been indicated previously.

- the door further comprises a lock, for example a reminder automatic, two control rods with end caps ends which come to lock in strikes fixed.

- a lock for example a reminder automatic, two control rods with end caps ends which come to lock in strikes fixed.

- the lock is operated by a handle locked by a key cylinder.

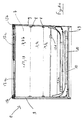

- a pre-assembly allows two sets to be made.

- a first set includes the lateral guide rails 9, the leaf 6 placed between them, the rollers 11 cooperating with the rails 9 and, finally, the mechanism 13.

- a second set includes upper guide rails 10, optionally a cross member 49 intended to connect them.

- the first set 6, 7, 9, 11, 13 is compact and fits in a generally shaped envelope flattened parallelepiped. Indeed, as has been previously mentioned, this set is limited laterally by the rails 9, the drums 13b not projecting not of this set since placed between leaf 6 and the rails 9. As for the cables, they are incorporated in the door 2 hardware, i.e. they are not projecting.

- the first set of door 2 which has just been described is such that it can also be preset during the manufacturing. This pre-setting concerns the length, arrangement and tension of cables as well as springs 13c.

- This constructive arrangement is advantageous because it leads to a quality pre-setting during manufacturing and avoids tedious, long or delicate operations at the final installation site of the door.

- the second set 10, 49 can be placed flat against the leaf 6 of the first assembly on the side of the second large face 19.

- the two sets which have just been described do they form a package that can fit into a thickness overall less than 125 mm, while in the condition of the technical thickness is close to and even exceeds 155 mm.

- Doors 2 as just described are conditioned by a package 50.

- the packaging 50 comprises a support 51 forming a pallet for its part 52 and a rack for its part 53.

- the rack 53 is suitable for receiving a plurality of doors as just described, placed side by side side.

- the support 51 includes, for the rack portion 53 two lateral flanks 54. Furthermore, the packaging 50 also comprises, in the embodiment considered, two side flat irons 55.

- Such packaging can receive up to nine doors each in the form of a package previously described. These doors are placed two by two symmetrical way that the first two large faces 18 or both second large faces 19 of the two doors are facing each other from each other, or placed in the same direction.

- the doors being thus arranged, they can be fixed removably by their side rails 9 to the sides 54 by means of screws.

- the support 51 is placed in the lower part, forming a pallet.

- the flat irons 55 are placed in the upper part.

- the overall size of such packaging comprising nine doors and part of a parallelepiped is for example 1.15 mx 3.20 m by 2.60 m in height, or less.

- the doors once manufactured are conditioned as well that it has just been described. This conditioning is easily transportable given the limited weight of panels 7.

- Packaging 50 allows storage convenient waiting of doors before they are put in place in a construction.

- the door having been pre-assembled in manufacturing and pre-adjusted, mounting can be quick.

Landscapes

- Engineering & Computer Science (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Securing Of Glass Panes Or The Like (AREA)

- Refrigerator Housings (AREA)

- Passenger Equipment (AREA)

- Wing Frames And Configurations (AREA)

- Body Structure For Vehicles (AREA)

- Elevator Door Apparatuses (AREA)

- Lock And Its Accessories (AREA)

- Automobile Manufacture Line, Endless Track Vehicle, Trailer (AREA)

- Window Of Vehicle (AREA)

Claims (13)

- Sektionstür (2) mit Einschlag unter der Decke und vertikalem Ausschlag wie typischerweise eine Garagentür, mit:dadurch gekennzeichnet, dass die Tür für ihre Installation vormontiert ist, in diesem Zustand gelagert und an den Installationsort geliefert und transportiert werden kann, wobei die besagte vormontierte Tür folgende Baugruppen aufweist:seitlichen Führungsschienen (9), die vertikal angeordnet sind, wenn die Tür montiert ist, und die vertikale Seitenschienen genannt werden;oberen Führungsschienen (10), den sogenannten horizontalen Seitenschienen, die die vertikalen Seitenschienen verlängern, wenn die Tür montiert ist;einem Türflügel (6) bestehend aus einer Folge von Platten (7) und Rollen (11) tragend, wobei jede Platte schwenkend an mindestens einer anderen ähnlichen Platte (7) montiert werden kann, um eine zu einer normalerweise horizontalen Längsrichtung (D) parallel verlaufende Achse, wenn die Tür montiert ist, wobei jede dünne und leichte Platte eine erste und eine zweite Verkleidung (16, 17) aus dünnen Metallblättern oder einem ähnlichen Material aufweist, wobei der von den beiden Verkleidungen am Umfang geschlossene Raum zumindest teilweise mit einem bei der Herstellung expandiertem Kunststoff gefüllt ist; wobei die Rollen (11) mit den vertikalen (9) und horizontalen (10) Seitenschienen zusammenwirken sollen, um den Türflügel in geeigneter Weise zu führen;einer in Längsrichtung zu einem Ende der vertikalen Seitenschienen (9) hin verlaufenden Welle (13a);einer oder zwei Kabeltrommeln (13b), die an den äußeren Enden der Welle (13a), aus dem Türflügel heraus gerichtet und zwischen dem Türflügel und den Seitenschienen (9) befestigt sind;einem oder zwei Kabeln, die einerseits mit dem Türflügel (6) an der unteren Endplatte verbunden und andererseits auf der oder den Kabeltrommeln (13b) aufgerollt sind, wobei diese Kabel dadurch nicht ungewünscht zugänglich sind;einem oder mehreren federnden Rückstellorganen (13c), die vorgespannt auf der Welle (13a) montiert sind, wie beispielsweise eine Schraubenfeder;manuellen und/oder motorisierten Betätigungsmitteln (13d) des Türflügels;eine erste Baugruppe (6, 7, 9, 11, 13), die vor der Installation am Standort vormontiert und voreingestellt ist, bestehend aus: den vertikalen Seitenschienen (9), dem Türflügel (6), der Welle, der/den Kabeltrommel(n) (13b), dem oder den Kabeln, dem oder den federnden Rückstellorganen (13c), den manuellen und/oder motorisierten Betätigungsmitteln (13d) des Türflügels;eine zweite Baugruppe (10, 49) bestehend aus den oberen horizontalen Führungsschienen (10).

- Tür nach Anspruch 1, dadurch gekennzeichnet, dass die Masse einer jeden dünnen und leichten Platte des Türflügels etwa 9 bis 10 kg/m2 beträgt, insbesondere etwa 9,5 kg/m2.

- Tür nach Anspruch 1 oder 2, dadurch gekennzeichnet, dass die Gesamtdicke einer jeden dünnen und leichten Platte des Türflügels weniger als 3 cm beträgt.

- Tür nach einem der Ansprüche 1 bis 3, dadurch gekennzeichnet, dass die zweite Baugruppe einen Querbalken (49) für den Anschluss der oberen Führungsschienen umfasst, wenn die Tür montiert ist.

- Tür nach einem der Ansprüche 1 bis 4, dadurch gekennzeichnet, dass die zweite Baugruppe (10, 49) flach gegen den Türflügel der ersten Baugruppe angeordnet ist, wobei die beiden Baugruppen ein Paket bilden.

- Tür nach einem der Ansprüche 1 bis 5, dadurch gekennzeichnet, dass die Voreinstellung der ersten Baugruppe die Länge, die Anordnung und die Spannung der Kabel sowie die Feder(n) 13c betrifft.

- Verpackung (50), die mehrere Sektionstüren mit Einschlag unter der Decke und vertikalem Aufschlag gemäss den Ansprüchen 1 bis 6 enthält, mit einem Träger (51), der eine Palette und ein Gestell (53) bildet und eine Vielzahl von nebeneinander angeordneten Türen aufnimmt, und des weiteren eine Vielzahl von ersten vormontierten, voreingestellten Baugruppen enthält, wobei jede erste Baugruppe außerdem die beiden Kopf bei Fuß innerhalb der ersten Baugruppe platzierten oberen Führungsschienen trägt.

- Verpackung nach Anspruch 7, dadurch gekennzeichnet, dass der Träger (51) zwei seitliche Flanken (54) aufweist, an denen die seitlichen Führungsschienen (9) abnehmbar befestigt sind, und gegebenenfalls:zwei Flacheisen (55), an denen die seitlichen Führungsschienen (9) gegenüber den Flanken (54) abnehmbar befestigt sindund/oder ein Metallprofil, das abnehmbar unter den seitlichen Führungsschienen (9) befestigt ist und ermöglicht, jede Tür während des Transports zu schützen und den Abstand zwischen den beiden seitlichen Flanken (54) zu halten.

- Verpackung nach Anspruch 8, dadurch gekennzeichnet, dass sie bis zu neun Türen enthalten kann.

- Einbauverfahren in einem mit einer Öffnung versehenen Bauwerk einer Tür mit Einschlag unter der Decke und seitlichem Ausschlag, wie sie in den Ansprüchen 1 und 6 beschrieben wird, gegebenenfalls verpackt nach einem der Ansprüche 7 bis 9, dadurch gekennzeichnet, dass man die hergestellte, vormontierte und voreingestellte Tür auf den Bauplatz bringt und die erste und die zweite Baugruppe an dem besagten Bauwerk befestigt.

- Sektionstür mit Einschlag unter der Decke und vertikalem Ausschlag wie typischerweise eine Garagentür, die in die Öffnung eines Bauwerks montiert werden soll, mit:dadurch gekennzeichnet, dass sie aus folgenden Elementen besteht:seitlichen Führungsschienen (9) und oberen Führungsschienen (10;einem Türflügel (6) bestehend aus einer Folge von Platten (7) und Rollen (11) tragend, wobei jede Platte schwenkend an mindestens einer anderen ähnlichen Platte (7) montiert werden kann, um eine zu einer normalerweise horizontalen Längsrichtung (D) parallel verlaufende Achse, wenn die Tür montiert ist, wobei jede dünne und leichte Platte eine erste und eine zweite Verkleidung (16, 17) aus dünnen Metallblättern oder einem ähnlichen Material aufweist, wobei der von den beiden Verkleidungen am Umfang geschlossene Raum zumindest teilweise mit einem bei der Herstellung expandiertem Kunststoff gefüllt ist; wobei die Rollen (11) mit den seitlichen (9) und oberen (10) Schienen zusammenwirken sollen, um den Türflügel in geeigneter Weise zu führen;einer in Längsrichtung zu der Verbindung der seitlichen und oberen Schienen hin verlaufenden Welle (13a);einer oder zwei Kabeltrommeln (13b), die an den äußeren Enden der Welle, aus dem Türflügel heraus gerichtet und zwischen dem Türflügel und den Seitenschienen befestigt sind;einem oder zwei Kabeln, die einerseits mit dem Türflügel an der unteren Endplatte verbunden und andererseits auf der oder den Kabeltrommeln aufgerollt sind;einem oder mehreren federnden Rückstellorganen (13c), die auf der Welle montiert sind, wie beispielsweise eine Schraubenfeder;und manuellen und/oder motorisierten Betätigungsmitteln;einer ersten Baugruppe entsprechend Anspruch 1, die mit Befestigungsmitteln am Bauwerk befestigt ist;einer zweiten Baugruppe mit oberen Führungsschienen entsprechend Anspruch 1.

- Tür nach Anspruch 11, dadurch gekennzeichnet, dass die Masse einer jeden dünnen und leichten Platte des Türflügels etwa 9 bis 10 kg/m2 beträgt, insbesondere etwa 9,5 kg/m2, und dass die Gesamtdicke einer jeden dünnen und leichten Platte des Türflügels weniger als 3 cm beträgt.

- Tür nach einem der Ansprüche 11 oder 12, gekennzeichnet durch eine oder mehrere Kabeltrommeln zum Aufrollen des oder der Kabel mit kleinem Durchmesser beispielsweise zwischen 65 und 75 mm.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR9803486 | 1998-03-20 | ||

| FR9803486A FR2776334B1 (fr) | 1998-03-20 | 1998-03-20 | Panneau destine a une porte sectionnelle, porte sectionnelle et conditionnement |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0943777A1 EP0943777A1 (de) | 1999-09-22 |

| EP0943777B1 true EP0943777B1 (de) | 2001-11-07 |

| EP0943777B2 EP0943777B2 (de) | 2009-02-18 |

Family

ID=9524321

Family Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP99400680A Expired - Lifetime EP0943777B2 (de) | 1998-03-20 | 1999-03-19 | Vormontiertes und voreingestelltes Sektionaltor, und seine Konditionierung |

| EP99400679A Withdrawn EP0943776A1 (de) | 1998-03-20 | 1999-03-19 | Für ein Sektionaltor bestimmtes Paneel, Sektionaltor und seine Konditionierung |

Family Applications After (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP99400679A Withdrawn EP0943776A1 (de) | 1998-03-20 | 1999-03-19 | Für ein Sektionaltor bestimmtes Paneel, Sektionaltor und seine Konditionierung |

Country Status (7)

| Country | Link |

|---|---|

| EP (2) | EP0943777B2 (de) |

| AT (1) | ATE208456T1 (de) |

| AU (2) | AU2844099A (de) |

| CA (2) | CA2290449A1 (de) |

| DE (3) | DE943777T1 (de) |

| FR (1) | FR2776334B1 (de) |

| WO (2) | WO1999049169A1 (de) |

Families Citing this family (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| PT1213429E (pt) | 2001-04-03 | 2008-12-22 | Metecno Ind S P A | Porta seccionada com batente de alinhamento de painel |

| AU2003266978A1 (en) | 2002-08-13 | 2004-03-03 | Lothar Weil | Guide rail for the rollers of a leaf of a door, especially a sectional door |

| US7128123B2 (en) | 2004-02-26 | 2006-10-31 | Wayne-Dalton Corp. | Door mounting and track system for a sectional door |

| EP1722065A1 (de) * | 2005-05-09 | 2006-11-15 | Novoferm France | Platte mit Hohlprofilträgern zum aussteifen |

| FR3008447B1 (fr) | 2013-07-10 | 2016-03-11 | Novoferm France | Porte sectionnelle a effacement vers le haut et panneau pour la constitution du vantail d'une telle porte. |

| KR102112968B1 (ko) | 2016-06-24 | 2020-05-19 | 롤플렉스 엑스플로이타티에 비.브이. | 부분 접이식 오버헤드 도어 어셈블리 |

Family Cites Families (22)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2083467A (en) | 1930-04-29 | 1937-06-08 | Overhead Door Corp | Door construction |

| US3160200A (en) | 1961-09-28 | 1964-12-08 | Mckee Door Company | Drive mechanism for overhead doors |

| DE1509336A1 (de) * | 1964-07-27 | 1969-07-10 | Jakob Faulstroh Press U Stanzw | Plattenjalousietor,insbesondere fuer Garagen |

| US3311159A (en) | 1964-12-07 | 1967-03-28 | Taylor Garage Doors | Garage door hardware |

| GB1431473A (en) | 1973-09-13 | 1976-04-07 | Hillaldam Coburn Ltd | Counter-balance means for sectional overhead doors |

| FR2304756A1 (fr) | 1975-03-20 | 1976-10-15 | Henderson P C Ltd | Dispositif de controle de course pour panneaux de portes et installations analogues |

| US4379480A (en) * | 1980-07-14 | 1983-04-12 | Garland Manufacturing Company | Energy efficient garage door construction and the like |

| US4472910A (en) | 1982-09-29 | 1984-09-25 | Chamnberlain Manufacturing Corporation | Integral device for garage door opener |

| EP0230499B1 (de) | 1984-08-28 | 1991-07-03 | Nippon Mining Company Limited | Verfahren zur Herstellung von makrozyklischen Ketonen |

| FR2595746B2 (fr) * | 1985-03-15 | 1988-12-23 | Fermoba | Porte basculante, notamment porte de garage |

| DE3602520A1 (de) * | 1986-01-28 | 1987-07-30 | Hoermann Kg | Deckengliedertor und fuehrungszwischenstueck fuer die laufrollen des obersten torblattgliedes |

| DE3726699C5 (de) | 1987-08-11 | 2009-05-28 | Hörmann KG Brockhagen | Sektionaltorblatt |

| DE8908513U1 (de) * | 1988-11-25 | 1990-03-29 | Hörmann KG Brockhagen, 4803 Steinhagen | Torblatt-Scharnier |

| ES2050760T3 (es) | 1988-11-25 | 1994-06-01 | Hoermann Kg | Hoja de puerta. |

| DE3938021C3 (de) | 1988-11-25 | 2003-03-27 | Hoermann Kg | Torblatt |

| SE464822B (sv) * | 1989-05-25 | 1991-06-17 | Crawford Door Ab | Anordning vid portarrangemang |

| DE8910518U1 (de) * | 1989-09-04 | 1990-10-18 | Fa. Walter Teckentrup, 4837 Verl | Paneele für ein Sektionaltor |

| DE4116261A1 (de) * | 1991-05-17 | 1992-11-19 | Hoermann Kg | Vormontiertes torblatt |

| US5239777A (en) † | 1992-03-24 | 1993-08-31 | Atlas Roll-Lite Door Corporation | Overhead door pre-loaded and pre-assembled torsion spring counterbalance assembly |

| DK43693A (da) * | 1993-04-19 | 1994-10-20 | Nassau Door As | Hængselarrangement til et hejseportblad |

| IT233551Y1 (it) | 1994-02-04 | 2000-02-01 | Bremet Brevetti Metecno Spa | Pannello composito per realizzare portoni sezionali |

| WO1996036784A1 (en) | 1995-05-19 | 1996-11-21 | Wayne-Dalton Corp. | Rear mount counterbalance system for sectional doors |

-

1998

- 1998-03-20 FR FR9803486A patent/FR2776334B1/fr not_active Expired - Lifetime

-

1999

- 1999-03-19 CA CA002290449A patent/CA2290449A1/en not_active Abandoned

- 1999-03-19 EP EP99400680A patent/EP0943777B2/de not_active Expired - Lifetime

- 1999-03-19 WO PCT/FR1999/000652 patent/WO1999049169A1/fr active Application Filing

- 1999-03-19 CA CA002290432A patent/CA2290432A1/en not_active Abandoned

- 1999-03-19 DE DE0943777T patent/DE943777T1/de active Pending

- 1999-03-19 DE DE69900423T patent/DE69900423T3/de not_active Expired - Fee Related

- 1999-03-19 DE DE0943776T patent/DE943776T1/de active Pending

- 1999-03-19 EP EP99400679A patent/EP0943776A1/de not_active Withdrawn

- 1999-03-19 WO PCT/FR1999/000651 patent/WO1999049168A1/fr active Application Filing

- 1999-03-19 AU AU28440/99A patent/AU2844099A/en not_active Abandoned

- 1999-03-19 AU AU28441/99A patent/AU2844199A/en not_active Abandoned

- 1999-03-19 AT AT99400680T patent/ATE208456T1/de not_active IP Right Cessation

Also Published As

| Publication number | Publication date |

|---|---|

| EP0943777A1 (de) | 1999-09-22 |

| WO1999049169A1 (fr) | 1999-09-30 |

| WO1999049168A1 (fr) | 1999-09-30 |

| DE69900423D1 (de) | 2001-12-13 |

| EP0943777B2 (de) | 2009-02-18 |

| AU2844099A (en) | 1999-10-18 |

| CA2290432A1 (en) | 1999-09-30 |

| AU2844199A (en) | 1999-10-18 |

| DE69900423T3 (de) | 2009-09-17 |

| EP0943776A1 (de) | 1999-09-22 |

| DE69900423T2 (de) | 2002-07-11 |

| ATE208456T1 (de) | 2001-11-15 |

| FR2776334A1 (fr) | 1999-09-24 |

| CA2290449A1 (en) | 1999-09-30 |

| DE943776T1 (de) | 2000-03-02 |

| FR2776334B1 (fr) | 2000-06-16 |

| DE943777T1 (de) | 2000-03-02 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0468888A1 (de) | Industrietor mit starren Paneelen | |

| EP0943777B1 (de) | Vormontiertes und voreingestelltes Sektionaltor, und seine Konditionierung | |

| FR2774661A1 (fr) | Conteneur repliable pour le stockage d'objets tels que des panneaux d'habillage de portieres d'automobiles | |

| EP1418293B1 (de) | System zum Herstellen einer flüssigkeitszurückhaltenden Wand, z.B. Swimmbeckenwand, mit vorgefertigten Panelen | |

| FR2800437A1 (fr) | Ensemble constitue d'un support rigide et d'un habillage du support, profile d'habillage et son utilisation pour un tel ensemble | |

| EP1749951B1 (de) | Verlorenes Schalungselement und Module zur Herstellung eines solchen Elements | |

| EP0008970A1 (de) | Metallschrank | |

| EP0684672A1 (de) | Gehäuse, insbesondere für Niederspannungsgeräte | |

| EP2158375B1 (de) | Hochschiebesicherung für Rollläden | |

| EP1722065A1 (de) | Platte mit Hohlprofilträgern zum aussteifen | |

| EP3938611B1 (de) | Metallblende, insbesondere zum schutz gegen zyklone | |

| EP0770832A1 (de) | Modulares Gitter | |

| FR2867220A1 (fr) | Vantail et porte basculante comprenant un tel vantail | |

| FR2765616A1 (fr) | Perfectionnements a des volets roulants | |

| EP1396603B1 (de) | Sektionaltorblatt und damit versehenes Tor | |

| EP0320423B1 (de) | Rolladenkasten | |

| EP1369549B1 (de) | Selbsttragendes Türblatt für ein Kipptor | |

| WO1999067498A1 (fr) | Porte de manutention | |

| EP4438832A1 (de) | Geländerkit und geländer | |

| EP1760247B1 (de) | Schrank mit Rollladentür | |

| EP0097104B1 (de) | Selbsttragendes metallisches, wellenförmiges Bauelement für ein Gebäudedach | |

| EP3095929B1 (de) | Struktur für schwimmbecken | |

| FR2725741A1 (fr) | Structure de capotage pour la protection de materiels ou dispositifs divers, en particulier de vehicules automobiles | |

| FR2788552A1 (fr) | Dispositif d'entrainement et d'equilibrage motorise d'un ouvrant | |

| FR3084686A1 (fr) | Dispositif de bridage d'une huisserie, notamment d'une huisserie metallique |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| 17P | Request for examination filed |

Effective date: 19991102 |

|

| TCNL | Nl: translation of patent claims filed | ||

| DET | De: translation of patent claims | ||

| AKX | Designation fees paid |

Free format text: AT BE CH DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| 17Q | First examination report despatched |

Effective date: 20000726 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20011107 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20011107 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20011107 Ref country code: AT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20011107 |

|

| REF | Corresponds to: |

Ref document number: 208456 Country of ref document: AT Date of ref document: 20011115 Kind code of ref document: T |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: FRENCH |

|

| REF | Corresponds to: |

Ref document number: 69900423 Country of ref document: DE Date of ref document: 20011213 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20020115 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20020207 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20020207 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20020207 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20020319 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20020319 |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| PLBQ | Unpublished change to opponent data |

Free format text: ORIGINAL CODE: EPIDOS OPPO |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20020530 |

|

| 26 | Opposition filed |

Opponent name: WAYNE-DALTON CORPORATION Effective date: 20020515 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| NLR1 | Nl: opposition has been filed with the epo |

Opponent name: WAYNE-DALTON CORPORATION |

|

| PLBF | Reply of patent proprietor to notice(s) of opposition |

Free format text: ORIGINAL CODE: EPIDOS OBSO |

|

| PLBF | Reply of patent proprietor to notice(s) of opposition |

Free format text: ORIGINAL CODE: EPIDOS OBSO |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20030331 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20030331 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| APBP | Date of receipt of notice of appeal recorded |

Free format text: ORIGINAL CODE: EPIDOSNNOA2O |

|

| APAH | Appeal reference modified |

Free format text: ORIGINAL CODE: EPIDOSCREFNO |

|

| APBQ | Date of receipt of statement of grounds of appeal recorded |

Free format text: ORIGINAL CODE: EPIDOSNNOA3O |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: 732E |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: TP |

|

| NLS | Nl: assignments of ep-patents |

Owner name: NOVOFERM FRANCE SAS Effective date: 20070611 |

|

| APBU | Appeal procedure closed |

Free format text: ORIGINAL CODE: EPIDOSNNOA9O |

|

| PUAH | Patent maintained in amended form |

Free format text: ORIGINAL CODE: 0009272 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: PATENT MAINTAINED AS AMENDED |

|

| 27A | Patent maintained in amended form |

Effective date: 20090218 |

|

| AK | Designated contracting states |

Kind code of ref document: B2 Designated state(s): AT BE CH DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20020320 |

|

| NLR2 | Nl: decision of opposition |

Effective date: 20090218 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20090303 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20090318 Year of fee payment: 11 |

|

| NLR3 | Nl: receipt of modified translations in the netherlands language after an opposition procedure | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20090316 Year of fee payment: 11 Ref country code: DE Payment date: 20090313 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 20090401 Year of fee payment: 11 |

|

| BERE | Be: lapsed |

Owner name: *NOVOFERM FRANCE Effective date: 20100331 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: V1 Effective date: 20101001 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20100319 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20101001 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20101001 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100319 Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100319 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 18 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 19 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20180130 Year of fee payment: 20 |