EP0893366A2 - Dispositif pour transporter des véhicules, en particulier pour voitures particulières, petites véhicules ou similaires - Google Patents

Dispositif pour transporter des véhicules, en particulier pour voitures particulières, petites véhicules ou similaires Download PDFInfo

- Publication number

- EP0893366A2 EP0893366A2 EP98113029A EP98113029A EP0893366A2 EP 0893366 A2 EP0893366 A2 EP 0893366A2 EP 98113029 A EP98113029 A EP 98113029A EP 98113029 A EP98113029 A EP 98113029A EP 0893366 A2 EP0893366 A2 EP 0893366A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- floor

- stacking columns

- flap

- vehicles

- folded

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D88/00—Large containers

- B65D88/02—Large containers rigid

- B65D88/12—Large containers rigid specially adapted for transport

- B65D88/122—Large containers rigid specially adapted for transport with access from above

- B65D88/123—Large containers rigid specially adapted for transport with access from above open top

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D88/00—Large containers

- B65D88/02—Large containers rigid

- B65D88/12—Large containers rigid specially adapted for transport

- B65D88/127—Large containers rigid specially adapted for transport open-sided container, i.e. having substantially the whole side free to provide access, with or without closures

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D88/00—Large containers

- B65D88/02—Large containers rigid

- B65D88/12—Large containers rigid specially adapted for transport

- B65D88/129—Transporter frames for containers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D88/00—Large containers

- B65D88/54—Large containers characterised by means facilitating filling or emptying

- B65D88/542—Ramps forming part of the container

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2585/00—Containers, packaging elements or packages specially adapted for particular articles or materials

- B65D2585/68—Containers, packaging elements or packages specially adapted for particular articles or materials for machines, engines, or vehicles in assembled or dismantled form

- B65D2585/6802—Containers, packaging elements or packages specially adapted for particular articles or materials for machines, engines, or vehicles in assembled or dismantled form specific machines, engines or vehicles

- B65D2585/686—Containers, packaging elements or packages specially adapted for particular articles or materials for machines, engines, or vehicles in assembled or dismantled form specific machines, engines or vehicles vehicles

- B65D2585/6867—Containers, packaging elements or packages specially adapted for particular articles or materials for machines, engines, or vehicles in assembled or dismantled form specific machines, engines or vehicles vehicles automobiles

Definitions

- the invention relates to a device for transporting vehicles, especially passenger cars, vans or the like, according to the preamble of claim 1, 6, 12 and / or 18.

- the known transport cage-like devices have a relatively high weight and show deficiencies in their Handling on. Also driving on the known Devices with the vehicles to be transported in multiple Proven problematic.

- the object of the invention is Devices (transport cages) for the transport of vehicles, in particular motor vehicles, vans or the like to create a low with sufficient stability

- Devices transport cages for the transport of vehicles, in particular motor vehicles, vans or the like to create a low with sufficient stability

- a device for solving this problem has the features of claim 1.

- the upright, transverse to the level of the floor trending walls have a relatively large resistance moment so that the weight of the walls is less than that Material to be saved to stiffen the floor.

- the hands or hand sections are preferably pivotable with longitudinal or transverse edges, in particular longitudinal edges, of the floor connected. In this way it is possible to cover the walls to pivot empty devices against the floor surface, thereby several devices are stacked to save space stack it. In addition, by pivoting the Walls or wall sections of the devices from the side fully or partially freely accessible, which opens doors to the the device driven vehicles to enter or exit the Allow driver to open fully and risk of damage of the doors due to a collision with parts of the device excluded are.

- the hand sections can be moved with the corresponding ones Edges of the ground. That’s it possible, individual, namely currently disturbing, wall sections push away.

- the wall sections keep their vertical position to the level of the ground, thereby reinforcing the Basically even with wall sections pushed away remains.

- both the long and the front sides of the Assign hands or hand sections to the floor. At least have the longitudinal side edges of the floor over side walls or Sidewall parts. The end faces of the floor then remain open, whereby the device can be used by vehicles at any time can.

- Another device for solving the basis of the invention Task which is also a cheerfulness of the device having the features described above can act, has the features of claim 6.

- the floor can therefore be extended. This gives the device in the longitudinal direction or direction of travel of the vehicles greater absorption capacity. In this way it is possible Devices usually, namely in the unextended state, correspond to the grid dimension of 40 'containers, where the space available allows for a pitch of 45 ' Enlarge containers. It is also extendable of the floor possible to enlarge the device so that such a number of longer vehicles can be stowed, which corresponds to the number of vehicles of shorter length.

- the device is preferably extended in such a way that at least one front edge of the floor is a ramp-like Flap is assigned, which can be designed as a hand.

- the ramp-like flap enables the device to be driven on without additional ramps. If the or each flap for transportation folded up, it serves as a front protection for yourself vehicles located on the floor of the device.

- the or each ramp be in several parts to train.

- the individual parts of the ramp are preferably connected by a pivot axis that is parallel to the corresponding end edge of the floor runs on the turn the entire ramp can be swiveled by a further swivel axis is articulated.

- the respective ramp can be folded in this way. This allows the ramp to be partially extended by using a Part of the ramp that is pivotally connected directly to the floor is swung down into the plane of the floor during the other, unneeded part of the ramp is folded up for Stabilization of the device and for simultaneous Front protection of the vehicles on it.

- the or each ramp or parts thereof in the folded up position State to connect with neighboring stacking columns.

- the longitudinal central axis of the bottom is provided, at least one Lane on at least one side with a guide or the like to provide.

- a guide or the like By driving along the guide the respective vehicle in an off-center position the floor, which has a slight entry and exit on one side of the vehicle Exit possible.

- the stands preferably Lane extending over the entire length of the floor opposite the level of the ground.

- the or each guide is preferably at a distance from the longitudinal central axis of the soil changeable.

- the leadership can thereby the respective width of that provided for loading the device Vehicle adjusted so that one side of the vehicle is located close to a longitudinal slope of the floor. On the other side of the vehicle is thus a maximum possible Distance to the corresponding side of the floor is available, which makes the best possible use of the remaining space becomes.

- the guide is firmly attached to the floor connect.

- the leadership takes over one. static stabilization of the floor, which means that it does not add anything to the device Gives weight; rather contributes to weight optimization.

- the device according to claim 18 provides for the floor To provide anchoring openings when the stacking columns are folded down lie free.

- Stacking columns can add these anchoring openings serve, by coupling pieces, for example twistlocks, a Connection to corresponding anchoring openings on the Manufacture underside of the respective stacking column and thereby the respective stacking column in the folded up position lock.

- the devices are empty, they are folded down on the floor Stacking columns form the anchoring openings thus exposed on the floor means for connecting the device with hoists, for example spreaders.

- Anchoring openings on the floor serve several devices, especially empty devices to connect suitable coupling pieces or the like.

- the device shown here is used to transport from the 1, 3 and 8 motor vehicles shown in particular Trucks, railway wagons, inland or sea ships.

- 2 shows 10 loaded devices on board with motor vehicles of an inland waterway vessel 11.

- the devices shown here are used as transport cages Recording of two motor vehicles 10 each.

- the unextended version shown in FIG. 1 corresponds to the external dimensions each device approximately the outer dimension of one 40 'containers.

- the transport cage type devices are together with the motor vehicles thereon 10 like Container can be handled.

- the loaded devices can be together with the motor vehicles 10 thereon such as containers one above the other and side by side on board the inland waterway vessel 11 to be stowed.

- On trucks or railroad cars are preferred two transport cages with motor vehicles on them 10 transported stacked one above the other.

- the devices are collapsible when unloaded, so that a larger number of stacked transport cage-like Devices can be transported to save space can.

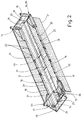

- Each transport cage-like device has a rectangular top Base 12 with two parallel longitudinal side edges 13 and two parallel (shorter) transverse edges 14 as well as giftable ones Stacking columns 15.

- the floor 12 is constructed like a frame, has namely, along the longitudinal side edges 13 Side members 18 and cross members 14 running along the transverse edges 19. The of the side members 18 and the cross members 19th enclosed area can with additional stiffening beams, not shown be provided.

- On the one made by the bearers There are two frames in the longitudinal direction of the floor 12 running parallel lanes 16 and 17 for those on the Devices to accommodate devices 10.

- Each of the four corner points of the rectangular bottom 12 is a stacking column 15 assigned. The stacking columns are in the transport position 15 folded up, so run perpendicular to the approximately horizontal Bottom 12.

- Pivot axis 20 is each stacking column 15 against the corresponding one Longitudinal edge 13 pivotable.

- each longitudinal side edge 13 of the Bottom 12 is associated with a side wall 21.

- Each of the same trained over the entire length of the device between two stacking columns 15 arranged on the same side Side wall 21 is pivotable on the corresponding Longitudinal edge 13 of the bottom 12 articulated. To this end serve several at a distance on the longitudinal side edge 13 of the bottom 12 distributed hinges 22.

- folded up State (left representation of Fig. 2) are vertical front edges 23 of the corresponding side wall 21 with the associated Stacking columns 15 can be connected by means of corresponding bars.

- the respective side wall 21 is folded up Locked position and at the same time a stable connection of the respective side wall 20 with the opposite end edges 23 of the same associated stacking columns 15 are produced. Consequently forms each side wall 21 with the two associated with it Stacking columns 15 and the hinges 22 with the corresponding Longitudinal edge 13 of the bottom 12 one unit.

- the side walls 21 contribute to stabilization of the bottom 12, in particular by the Side walls 21 with the bottom 12 hinges 22.

- Die Sidewalls 21 form when folded up (left illustration 2) a lateral protection for the on the transport cage-like Device for motor vehicles 10.

- the side walls 21 expose the long sides of the device, whereby the motor vehicles 10 on the device from the side are accessible here, especially the doors of the Motor vehicles 10 for getting in and out of drivers almost let it open completely.

- An alternative embodiment of the device not shown has side walls with one as in the embodiment 2 foldable on the longitudinal side edges 13 of the floor 12 hinged frame.

- side wall part forming sliding doors arranged to each other can be moved that the loaded device frame-like side wall is completely closed.

- Sliding doors are moved that in the corresponding area only the side wall frame remains. Through the open The inner surface of the same can then be opened doors of the Swing vehicle through, making it easy for a driver to get out of his Vehicle can get in or out.

- each side wall from load-bearing or load-bearing side wall parts provides for each side wall from load-bearing or load-bearing side wall parts to form the slidably on the longitudinal side edges 13 of the bottom 12 are arranged.

- This displaceability of the side wall parts takes place in the same way as for example in sliding door wardrobes is known.

- the leadership of the sliding and resilient or load-bearing side wall parts on the respective longitudinal side edge 13 of the base 12 stored. This is a positive and non-positive Storage that makes it possible to exercise on the floor 12 To transfer loads to the sliding side wall parts, whereby these intercept possible deflections of the floor 12 or reduce.

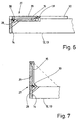

- the device according to FIG. 2 also has its Cross edges 14 over hands, namely transverse walls, which act as flaps 24 are trained.

- the flaps 24 are preferably of the Motor vehicles 10 passable.

- Each flap 24 is via a hinge 25 or possibly Several hinges can also be folded around a horizontal swivel axis connected to the respective transverse edge of the bottom 12.

- the Flap 24 thus forms a ramp for driving one behind the other arranged devices.

- the respective forms Flap 24 but also an extension of the bottom 12 of the Device, making the device with longer motor vehicles 10 can be loaded, if necessary during the Transport with rear or front wheels stop on the flap 24 can.

- the stability of the flap 24 required for this in the extended, horizontal position is achieved by retractable struts 26 of two hinged together Arms poor. With the flap swung into the horizontal position 24 (left representation of FIG. 2) the lever arms reach Strut 26 in an extended position, creating a reliable Securing the position of the respective flap 24 in the bottom 12 extending horizontal position is guaranteed.

- the device is loaded with vehicles that only cover the area of the floor 12 can take up after loading the flaps 24 are pivoted up into a transport position (Right representation of Fig. 2).

- the superscript Flaps 24 form end walls of the device in the transport position, which on the one hand serve to protect the vehicles on the front or rear from the outside and on the other hand the Stabilize the device.

- the swung up Flaps 24 by positive locking elements associated with the opposite sides of the flaps 24 Stacking columns 15 form-fitting (but detachable) connectable. This creates a stabilizing connection between the Flaps 24, the bottom 12 and those associated with the flaps 24 Stacking columns 15.

- the device receives has a relatively high torsional stiffness an open box-shaped receptacle for the motor vehicles 10th

- each two-part Flap 27 is with a corresponding hinge, not shown Cross edge 14 of the base 12 with an inner part 28 pivoted. With the inner part 28 is in turn Hinges, not shown, pivot an outer part 29 of the Flap 27 hinged. Inner part 28 and outer part 29 thus form the two parts of each flap 27. In the extended position of the Flap 27 are both the inner part 28 and that Outer part 29 approximately in the plane of the bottom 12 (FIGS. 5 and 9).

- the respective flap 27 serves as an up and down ramp for the motor vehicles 10.

- both the inner parts 28 and the outer parts 29 horizontal extensions opposite sides of the floor 12

- the flap 24 is extended on both sides Bottom 12 dimensions, which correspond approximately to a 45 'container.

- the stacking columns 15 are located on grid points, which correspond to those of a 40 'container.

- the stacking columns 15 are of the same design and each have over an elongated, box-like shape.

- a lower one The end of each stacking column 15 is pivotable with the respective one Corner of the floor 12 connected by a horizontal and parallel pivot axis 30 extending to the transverse edge 14 the stacking columns 15 in a perpendicular to the respective longitudinal side edge 13 of the floor 12 extending plane pivotable (Fig. 4).

- Starting from each corner of floor 12 is one along a part of the corresponding longitudinal side edge 13 extending Recess 31 provided which corresponds to the Dimensions of a stacking column 15 are formed.

- the Recesses 31 are used in a horizontal Most of the position of the folded down stacking columns 15. In this way, the tops of the folded up protrude Stacking columns 15 not significantly above the top of the Bottom 12 out (Fig. 4).

- each stacking column 15 has one Brace 32 lockable against the floor 12.

- Each one The strut 32 assigned to the stacking column 15 is vertical with a strut extending to the respective longitudinal side edge of the bottom 12 Level arranged.

- One end of each strut 32 is pivotable the respective long side edge 13 of the bottom 12 articulated.

- the opposite end of each strut 32 is with the corresponding one folded up stack column 15 connectable (Fig. 4).

- Stacking columns 15 are the struts 32 around the articulated Articulation point on the floor 12 pivotable against the floor 12 (Fig. 4).

- each stacking column 15 is with a stacked column 15 in Arranged parallel to the floor 12 horizontal levels Provide plates, each with an anchoring opening 33 and 34 is arranged.

- the corner points of the floor 12 two parallel, horizontal plates are also assigned, in each of which there is an anchoring opening 35, 36.

- the plates with the anchoring openings 35, 36 can by commercially available container corner fittings are formed. Then are also in the upright front and side edges of the Bottom 12 anchoring openings.

- each stacking column 15 34 corresponds to that on the top of the bottom 12 arranged anchoring opening 35 such that both Anchoring openings 34 and 35 through a commercially available coupling piece, for example a twistlock 37, form-fitting with each other can be connected.

- a commercially available coupling piece for example a twistlock 37

- the pivot axis 30 for connection each stacking column 15 with the bottom 12 is placed so that at folded down stacking columns 15, the upper anchoring opening 35 exposed on floor 12. This anchoring opening 35 is therefore freely accessible for connecting several on top of each other stacked empty device with folded stacking columns 15 or also for coupling hoists.

- the anchoring opening 33 at the top of each stacking column 15 preferably also serves to receive a coupling piece, for example a twistlock 38 (Fig. 4).

- the Twistlocks 38 then serve to connect two stacked devices, by inserting the top of the into the anchor hole 33 Twistlocks inserted at the top of each stacking column 15 38 into the anchoring opening 36 on the underside of the floor 12 a device placed on the lower device intervenes.

- each stacking column 15 directly with a coupling piece to connect, preferably permanently. Then it can the anchoring openings 33 and 34 at the top and bottom the stacking columns 15 are omitted.

- the permanent on top and Bottom of each stacking column 15 attached coupling pieces can used when necessary to stack one on top of the other Devices with upright, folded-out stacking columns 15 to connect with each other and around the folded up in transport position To lock stacking columns 15 in this position ⁇ by the permanent on the undersides of the stacking columns 15 attached coupling pieces with the anchoring openings 35 the top of the bottom 12 are connected.

- the device Roads 16 and 17 with different distances from the longitudinal central axis 39 of the device or the bottom 12 provided.

- the The embodiment shown (Fig. 3) has the right lane 17 a greater distance from the longitudinal central axis 39 than the left lane 16.

- the motor vehicles 10 drive off-center on the floor 12 of the device.

- the passenger side close to the long side edge 13, while the driver side one clear distance to the opposite longitudinal side edge 13 having. This distance is especially important if the Device with the side walls 21 not shown in FIG. 3 is provided. Then you can even when closed Side walls 21, the driver's door are opened so far that the Drivers of motor vehicles 19 relatively easy on and can get out.

- an elongated guide 42 is provided.

- This guide 42 is in the embodiment shown on the outside of a Lane (in Fig. 2 the left lane 16) arranged.

- the Guide 42 is firmly connected to the floor 12 here.

- a vertical one Action 43 of the guide 42 is next to the corresponding one Lane 16 and provides a guide here left tire 44 of the respective motor vehicle 10.

- the guide 42 or the wall 43 practically have the effect of curbs.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Handcart (AREA)

- Tents Or Canopies (AREA)

- Loading Or Unloading Of Vehicles (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19730165A DE19730165A1 (de) | 1997-07-14 | 1997-07-14 | Vorrichtung zum Transport von Fahrzeugen, insbesondere Personenkraftwagen, Kleintransportern oder dergleichen |

| DE19730165 | 1997-07-14 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0893366A2 true EP0893366A2 (fr) | 1999-01-27 |

| EP0893366A3 EP0893366A3 (fr) | 2000-01-05 |

| EP0893366B1 EP0893366B1 (fr) | 2004-05-12 |

Family

ID=7835681

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP98113029A Expired - Lifetime EP0893366B1 (fr) | 1997-07-14 | 1998-07-14 | Dispositif pour transporter des véhicules, en particulier pour voitures particulières, petites véhicules ou similaires |

Country Status (4)

| Country | Link |

|---|---|

| EP (1) | EP0893366B1 (fr) |

| DE (2) | DE19730165A1 (fr) |

| DK (1) | DK0893366T3 (fr) |

| ES (1) | ES2221695T3 (fr) |

Cited By (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB2376014A (en) * | 2001-04-10 | 2002-12-04 | Martin Clive-Smith | Folding flatrack with outward bracing |

| WO2004041679A1 (fr) * | 2002-11-07 | 2004-05-21 | Martin Clive-Smith | Plate-forme droite porte-automobiles repliable |

| CN103144644A (zh) * | 2012-11-26 | 2013-06-12 | 南车长江车辆有限公司 | 一种铁路自翻车 |

| US8608415B2 (en) | 2010-09-29 | 2013-12-17 | Raildecks (2009), Inc. | Intermodal transport platform |

| US8714895B2 (en) | 2010-09-29 | 2014-05-06 | Raildecks (2009), Inc. | Collapsible intermodal transport platform |

| US9004832B1 (en) | 2012-05-14 | 2015-04-14 | Raildecks (2009), Inc. | Intermodal container |

| CN105416882A (zh) * | 2015-12-29 | 2016-03-23 | 龙口丛林中德车体系统工程有限公司 | 轨道交通车辆车体大部件一体式运输工装 |

| DE102016005417A1 (de) * | 2016-05-02 | 2017-11-02 | René Schaedler | Ladeboden |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR100744815B1 (ko) * | 2005-12-19 | 2007-08-01 | 김점규 | 차량 선적용 콘테이너 |

| EP2027007A4 (fr) * | 2006-06-14 | 2009-08-05 | Ben Alder Pty Ltd | Systeme de stockage mobile et procede de gestion de son utilisation |

| US11485573B1 (en) * | 2021-09-20 | 2022-11-01 | Ramp Container LLC | Container with at least one ramp wall |

Citations (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR1254559A (fr) * | 1960-01-15 | 1961-02-24 | Venissieux Atel | Wagon plat pour le transport de véhicules automobiles |

| DE1284610B (de) * | 1966-11-04 | 1968-12-05 | Karl Haegele Dipl Ing | Buehne zum Abstellen eines Kraftfahrzeuges ueber einem anderen |

| GB1258284A (fr) * | 1968-10-02 | 1971-12-30 | ||

| US3801177A (en) * | 1971-06-04 | 1974-04-02 | Fmc Corp | Frameless shipping container |

| EP0139537A2 (fr) * | 1983-10-20 | 1985-05-02 | Lawrence David Ltd. | Conteneur avec portes glissantes |

| JPH02139381A (ja) * | 1988-07-20 | 1990-05-29 | Shigenobu Furukawa | 乗用車輸送用コンテナ |

| DE9010938U1 (de) * | 1990-07-24 | 1990-10-18 | Kimm, Bruno, 3500 Kassel | Vorrichtung zur Lagerung und zum Transport von Kraftfahrzeugen, insbesondere von Pkw |

| US5265748A (en) * | 1987-12-10 | 1993-11-30 | Shigenobu Furukawa | Multi-purpose container |

| US5344203A (en) * | 1992-03-09 | 1994-09-06 | Tollenaere Donald J | Aerodynamically-stabilized collapsible personnel and cargo basket for helicopters |

| GB2298842A (en) * | 1995-02-28 | 1996-09-18 | Treton Developments Inc | Motor vehicle transportation |

| EP0776786A1 (fr) * | 1995-11-30 | 1997-06-04 | Wabash National Corporation | Dispositif de levage pour un transporteur à deux étages |

Family Cites Families (17)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE8007586U1 (de) * | 1980-07-03 | Kaufmann & Lindgens Gmbh & Co Kg, 5144 Wegberg | Zusammenlegbare Langgutkassette | |

| DE8216085U1 (de) * | 1982-11-25 | Eloxal Becker & Oswald GmbH & Co KG, 6544 Kirchberg | Zusammenklappbarer Langgut-Container | |

| FR1212465A (fr) * | 1959-06-08 | 1960-03-24 | Botrans | Dispositif d'assujettissement de véhicules sur wagons |

| DE7713630U1 (de) * | 1977-04-29 | 1977-09-29 | Plan Transport Equipment Ltd | Vorrichtung zum Verriegeln der Ecksaeulen eines Transportgeraetes (Klappflat) oder zum Verriegeln des Transportgeraetes mit einem gleichartigen Geraet |

| FR2419191A1 (fr) * | 1978-03-07 | 1979-10-05 | Jige Remorques Indles | Procede de chargement et de dechargement d'un vehicule porteur a plateau de chargement solidaire du chassis et vehicule porteur pour la mise en oeuvre de ce procede |

| US4966510A (en) * | 1989-06-06 | 1990-10-30 | Johnson Jr James N | Trailer for transporting golf carts and the like |

| DE9103785U1 (de) * | 1991-03-14 | 1991-06-20 | Lokomotivbau-Elektrotechnische Werke Hennigsdorf GmbH, O-1422 Hennigsdorf | Notausstiegstür für Schienenfahrzeuge |

| FR2677622B1 (fr) * | 1991-06-11 | 1995-01-06 | Lohr Ind | Conteneur universel multiusage a capacite maximale. |

| FR2695087B1 (fr) * | 1992-09-03 | 1994-09-30 | Lohr Ind | Plancher double mixte transformable en une structure porte-véhicules pour unité de transport. |

| DE9214306U1 (de) * | 1992-10-23 | 1993-06-17 | BWR Werkstoff-Systeme und Fahrzeugbau GmbH, 7550 Rastatt | Ladeplattform |

| DE9307281U1 (de) * | 1993-02-22 | 1993-07-15 | Hagemann & Partner Gesellschaft für Umwelttechnik mbH, 1000 Berlin | Sammelbehälter |

| US5690453A (en) * | 1994-04-15 | 1997-11-25 | Global Transport Systems, Inc. | Method and apparatus for transporting cars |

| DE29516152U1 (de) * | 1994-10-11 | 1995-11-30 | Bodack, Karl-Dieter, 82194 Gröbenzell | Autotransportwagen |

| GB9421349D0 (en) * | 1994-10-24 | 1994-12-07 | Clive Smith Martin | Collapsible flatrack with removable walls |

| GB2303360B (en) * | 1995-07-19 | 1999-12-08 | Clive Smith Martin | Collapsible Shipping Container |

| DE19620909A1 (de) * | 1995-10-24 | 1997-04-30 | Clive Smith Martin | Zusammenklappbares Flachgestell mit Auffahrt und Wandungen |

| ES2130032B1 (es) * | 1995-11-29 | 2000-01-16 | Fine Products S A | Mejoras en el objeto de la patente 9600259 relativa a un conjunto de puerta y rampa de evacuacion para medios de transporte de viajeros. |

-

1997

- 1997-07-14 DE DE19730165A patent/DE19730165A1/de not_active Withdrawn

-

1998

- 1998-07-14 EP EP98113029A patent/EP0893366B1/fr not_active Expired - Lifetime

- 1998-07-14 DK DK98113029T patent/DK0893366T3/da active

- 1998-07-14 DE DE59811360T patent/DE59811360D1/de not_active Expired - Lifetime

- 1998-07-14 ES ES98113029T patent/ES2221695T3/es not_active Expired - Lifetime

Patent Citations (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR1254559A (fr) * | 1960-01-15 | 1961-02-24 | Venissieux Atel | Wagon plat pour le transport de véhicules automobiles |

| DE1284610B (de) * | 1966-11-04 | 1968-12-05 | Karl Haegele Dipl Ing | Buehne zum Abstellen eines Kraftfahrzeuges ueber einem anderen |

| GB1258284A (fr) * | 1968-10-02 | 1971-12-30 | ||

| US3801177A (en) * | 1971-06-04 | 1974-04-02 | Fmc Corp | Frameless shipping container |

| EP0139537A2 (fr) * | 1983-10-20 | 1985-05-02 | Lawrence David Ltd. | Conteneur avec portes glissantes |

| US5265748A (en) * | 1987-12-10 | 1993-11-30 | Shigenobu Furukawa | Multi-purpose container |

| JPH02139381A (ja) * | 1988-07-20 | 1990-05-29 | Shigenobu Furukawa | 乗用車輸送用コンテナ |

| DE9010938U1 (de) * | 1990-07-24 | 1990-10-18 | Kimm, Bruno, 3500 Kassel | Vorrichtung zur Lagerung und zum Transport von Kraftfahrzeugen, insbesondere von Pkw |

| US5344203A (en) * | 1992-03-09 | 1994-09-06 | Tollenaere Donald J | Aerodynamically-stabilized collapsible personnel and cargo basket for helicopters |

| GB2298842A (en) * | 1995-02-28 | 1996-09-18 | Treton Developments Inc | Motor vehicle transportation |

| EP0776786A1 (fr) * | 1995-11-30 | 1997-06-04 | Wabash National Corporation | Dispositif de levage pour un transporteur à deux étages |

Non-Patent Citations (1)

| Title |

|---|

| PATENT ABSTRACTS OF JAPAN vol. 014, no. 378 (M-1011), 15. August 1990 (1990-08-15) & JP 02 139381 A (SHIGENOBU FURUKAWA), 29. Mai 1990 (1990-05-29) * |

Cited By (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB2376014A (en) * | 2001-04-10 | 2002-12-04 | Martin Clive-Smith | Folding flatrack with outward bracing |

| WO2004041679A1 (fr) * | 2002-11-07 | 2004-05-21 | Martin Clive-Smith | Plate-forme droite porte-automobiles repliable |

| CN100463817C (zh) * | 2002-11-07 | 2009-02-25 | 马丁·克莱夫-史密斯 | 可折叠的平台甲板 |

| US9227756B2 (en) | 2010-09-29 | 2016-01-05 | Raildecks (2009), Inc. | Intermodal transport platform |

| US8608415B2 (en) | 2010-09-29 | 2013-12-17 | Raildecks (2009), Inc. | Intermodal transport platform |

| US8678727B2 (en) | 2010-09-29 | 2014-03-25 | Raildecks (2009), Inc. | Stacking system for intermodal platforms |

| US8714895B2 (en) | 2010-09-29 | 2014-05-06 | Raildecks (2009), Inc. | Collapsible intermodal transport platform |

| US8757943B2 (en) | 2010-09-29 | 2014-06-24 | Raildecks (2009), Inc. | Intermodal transport platform |

| US9004832B1 (en) | 2012-05-14 | 2015-04-14 | Raildecks (2009), Inc. | Intermodal container |

| CN103144644A (zh) * | 2012-11-26 | 2013-06-12 | 南车长江车辆有限公司 | 一种铁路自翻车 |

| CN103144644B (zh) * | 2012-11-26 | 2015-12-23 | 南车长江车辆有限公司 | 一种铁路自翻车 |

| CN105416882A (zh) * | 2015-12-29 | 2016-03-23 | 龙口丛林中德车体系统工程有限公司 | 轨道交通车辆车体大部件一体式运输工装 |

| CN105416882B (zh) * | 2015-12-29 | 2017-09-19 | 山东诺维科轻量化装备有限公司 | 轨道交通车辆车体大部件一体式运输工装 |

| DE102016005417A1 (de) * | 2016-05-02 | 2017-11-02 | René Schaedler | Ladeboden |

Also Published As

| Publication number | Publication date |

|---|---|

| DE19730165A1 (de) | 1999-01-21 |

| DE59811360D1 (de) | 2004-06-17 |

| EP0893366B1 (fr) | 2004-05-12 |

| ES2221695T3 (es) | 2005-01-01 |

| DK0893366T3 (da) | 2004-09-06 |

| EP0893366A3 (fr) | 2000-01-05 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1495937B1 (fr) | Chariot de transport | |

| DE2731386C2 (fr) | ||

| EP2684757B1 (fr) | Wagon de marchandises | |

| EP0893366A2 (fr) | Dispositif pour transporter des véhicules, en particulier pour voitures particulières, petites véhicules ou similaires | |

| EP1884438A2 (fr) | Chariot pour pièces de petite taille | |

| CH617133A5 (fr) | ||

| EP1690810A2 (fr) | Conteneur repliable et dispositif de vidage | |

| EP0215227B1 (fr) | Véhicule pour la livraison de boissons | |

| DE69308971T2 (de) | Umstellbarer, doppelter Boden für Kraftfahrzeuge in einer Transporteinheit | |

| DE29801555U1 (de) | Aufbau für ein Transportfahrzeug | |

| DE60202890T2 (de) | Schienenfahrzeug zur wechselweisen Verwendung für den Schienen- und Stras- sentransport von Straßenfahrzeugen | |

| DE3805375C2 (fr) | ||

| EP2955086B1 (fr) | Montage d'un véhicule utilitaire doté d'élément de hayon pivotant | |

| EP0508404A1 (fr) | Dispositif de sécurité pour support de transport | |

| DE202008017410U1 (de) | Container | |

| DE10051678C2 (de) | Ausrüstung für Transportbehälter, insbesongere Gitterbox-Transportpaletten | |

| DE102005042243A1 (de) | Klappbarer Transportcontainer | |

| CH621095A5 (fr) | ||

| EP2388208A2 (fr) | Conteneur de transport doté d'un recouvrement supérieur | |

| DE19529045B4 (de) | Wechselbehälter für Transportfahrzeuge | |

| DE10314378A1 (de) | Aufbau für einen Lastkraftwagen oder einen Anhänger für Lastkraftwagen | |

| WO2020240045A1 (fr) | Véhicule à voies multiples pour le transport de charges | |

| DE202016104821U1 (de) | Transport- und/oder Lagerbox für ein Kraftfahrzeug | |

| DE8903451U1 (de) | Mit entsprechenden Wagen schachtelbarer Schubgepäckwagen | |

| DE1956392A1 (de) | Schiebeverdeck,insbesondere fuer Lastkraftwagen und Anhaenger |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): DE DK ES FR GB |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| RTI1 | Title (correction) |

Free format text: DEVICE FOR TRANSPORTING VEHICLES, ESPECIALLY FOR ESTATE CARS, SMALL VEHICLES OR SIMILAR |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| 17P | Request for examination filed |

Effective date: 20000328 |

|

| AKX | Designation fees paid |

Free format text: DE DK ES FR GB |

|

| 17Q | First examination report despatched |

Effective date: 20011207 |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: MACGREGOR-CONVER GMBH |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: GLOYSTEIN, JUERGEN, DIPL.-ING. |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): DE DK ES FR GB |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REF | Corresponds to: |

Ref document number: 59811360 Country of ref document: DE Date of ref document: 20040617 Kind code of ref document: P |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: T3 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20040818 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2221695 Country of ref document: ES Kind code of ref document: T3 |

|

| ET | Fr: translation filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20050215 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20080821 Year of fee payment: 11 Ref country code: DK Payment date: 20080721 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20080718 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20080716 Year of fee payment: 11 |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: EBP |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20090714 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20100331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090731 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090714 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090731 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20090715 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090715 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20100821 Year of fee payment: 13 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120201 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 59811360 Country of ref document: DE Effective date: 20120201 |