EP0825000B1 - Trockenrasierapparat mit Schutzkappe - Google Patents

Trockenrasierapparat mit Schutzkappe Download PDFInfo

- Publication number

- EP0825000B1 EP0825000B1 EP97111455A EP97111455A EP0825000B1 EP 0825000 B1 EP0825000 B1 EP 0825000B1 EP 97111455 A EP97111455 A EP 97111455A EP 97111455 A EP97111455 A EP 97111455A EP 0825000 B1 EP0825000 B1 EP 0825000B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- shaving apparatus

- dry shaving

- wall

- guard

- recess

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 230000001681 protective effect Effects 0.000 title description 18

- 230000008878 coupling Effects 0.000 description 4

- 238000010168 coupling process Methods 0.000 description 4

- 238000005859 coupling reaction Methods 0.000 description 4

- 238000006073 displacement reaction Methods 0.000 description 3

- 238000009966 trimming Methods 0.000 description 3

- 230000000149 penetrating effect Effects 0.000 description 2

- 241000950638 Symphysodon discus Species 0.000 description 1

- 230000006978 adaptation Effects 0.000 description 1

- 230000008901 benefit Effects 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 230000008859 change Effects 0.000 description 1

- 230000010354 integration Effects 0.000 description 1

- 230000003993 interaction Effects 0.000 description 1

- HOQADATXFBOEGG-UHFFFAOYSA-N isofenphos Chemical compound CCOP(=S)(NC(C)C)OC1=CC=CC=C1C(=O)OC(C)C HOQADATXFBOEGG-UHFFFAOYSA-N 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 230000009467 reduction Effects 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B26—HAND CUTTING TOOLS; CUTTING; SEVERING

- B26B—HAND-HELD CUTTING TOOLS NOT OTHERWISE PROVIDED FOR

- B26B19/00—Clippers or shavers operating with a plurality of cutting edges, e.g. hair clippers, dry shavers

- B26B19/38—Details of, or accessories for, hair clippers, or dry shavers, e.g. housings, casings, grips, guards

- B26B19/3806—Accessories

- B26B19/382—Built-in accessories

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B26—HAND CUTTING TOOLS; CUTTING; SEVERING

- B26B—HAND-HELD CUTTING TOOLS NOT OTHERWISE PROVIDED FOR

- B26B19/00—Clippers or shavers operating with a plurality of cutting edges, e.g. hair clippers, dry shavers

- B26B19/38—Details of, or accessories for, hair clippers, or dry shavers, e.g. housings, casings, grips, guards

- B26B19/3853—Housing or handle

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B26—HAND CUTTING TOOLS; CUTTING; SEVERING

- B26B—HAND-HELD CUTTING TOOLS NOT OTHERWISE PROVIDED FOR

- B26B19/00—Clippers or shavers operating with a plurality of cutting edges, e.g. hair clippers, dry shavers

- B26B19/38—Details of, or accessories for, hair clippers, or dry shavers, e.g. housings, casings, grips, guards

- B26B19/3886—Actuating members, e.g. switches or control knobs

Definitions

- the invention relates to a dry shaver with a wide side walls and narrow side walls formed housing, with an electric drive for at least one cutting system, with at least one actuation switch and with one Protective cap pivoted on the housing with a protective shear system essentially U-shaped cap part.

- a dry shaver of the type mentioned is from the Japanese utility model JP-2-17558 (Y2) known.

- narrow support arms are formed, each using a sliding swivel joint on the two narrow sides of the housing of the dry shaver both are articulated as well as rotatable.

- a hinge pin resiliently mounted in one in the end walls the support arm provided elongated groove engages.

- the sliding path of the protective cap is determined by the intended length of the grooves, i.e. by applying the hinge pin to the End walls of the grooves determined.

- the protective cap To release one protected by the protective cap Schersystems the protective cap with the molded support arms so far pushed beyond that of the shaving system until a pivoting movement of the support arms around the hinge pin is feasible. After executing such a pivoting movement the protective cap is below the parallel to the shaving system by 180 ° extending bottom part of the housing of the dry shaver and can in be pushed and locked in this position on the housing.

- the arrangement of the Sliding and swivel joint in the narrow sides of the housing and the narrow ones Support arms of the cap part inevitably lead to a lack of sufficient space a relatively small dimensioning of the components of the sliding and rotating joint with the consequence of an increased risk of breakage during use of the dry shaver.

- the handling of such, on the narrow sides of a housing both slidably and rotatably mounted protective cap means is difficult and often leads to canting of the components in engagement with one another of the sliding and swivel joint.

- the object of the invention is to provide a dry shaver of the type mentioned improve.

- a major advantage of the invention is that both to protect the Shear system and only to release the shear system through the protective cap a movement of the pivoted protective cap in one of the pivot directions - To be carried out in or counterclockwise.

- the pending the broad side walls of the protective cap mounted much more space for the dimensioning and the structural design of the swivel joint (s) available stable storage of the cap part of the protective cap by means of or both cap walls on the respective broad side wall of the housing is guaranteed.

- the swivel is through on the Broad side wall and cooperating positive locking elements provided on the cap wall educated.

- the form-locking elements are preferably in the form of a round recess and a round pin engaging in it. Training the Swivel joint on the broad side wall and on the cap wall allows one relatively large-sized design of the form-locking elements, which causes the sliding movement a round recess on a round pin engaging in this relative runs smoothly.

- Round pins are provided on a wide side wall of the housing.

- the round recess is provided in the cap wall.

- the round pin is on the Cap wall provided.

- the round pin corresponds to the round pin Recess provided in a wide side wall of the housing.

- the round recess is the round recess as one that Opening formed through the cap wall.

- the round recess is the round recess as a the broad side wall of the housing through opening formed.

- a very simple and inexpensive coupling of the positive locking elements is distinguished according to the invention in that the positive locking elements of the wide side wall and Cap wall are held cooperable by means of a clip connection.

- the clip connection through a circumferential groove and a spring which can be snapped into this groove and is resilient trained spring arm is formed.

- the groove is preferably on a round pin provided and the spring arm with the spring on the wall of the round recess molded resiliently by means of a film hinge.

- sliding ribs are provided between the round pin and the round opening.

- the sliding ribs are on molded onto the inner wall of the round opening.

- the sliding ribs are formed on the outer wall of the round pin.

- the positive locking elements of Broad side wall and cap wall can be interacted by means of a plug connection held.

- the invention is the protective cap by two cap walls and the cap walls connecting cap part formed.

- An inexpensive to manufacture embodiment The invention is characterized in that the protective cap by a cap wall and a cap part provided on the cap wall is formed.

- the protective caps is held in at least one pivoting position by means of spring-loaded latching means.

- the actuation switch is in the cap wall arranged. In a further embodiment of this embodiment is according to the Invention of the actuation switch with the cap wall by means of the swivel joint pivoted.

- the actuation switch provided in a form-locking element penetrating the cap wall.

- the actuation switch is preferably designed as a slide switch.

- a recess for at least an actuating movement of the slide switch is provided.

- the Recess provided in a pivoted cap wall.

- a positioning the recess in the cap wall such that at an opposite to Cap system located shear system use of the recess by displacement the actuation switch into the recess, the electric drive of the dry shaver is switched on automatically has the consequence that when swiveling the cap wall by 180 ° - after its execution, the cap part of the protective cap embraces the shaving system in a U-shape - that which is in the switched-off state Actuation switch against displacement into that provided in the cap wall Switch position ON is locked without the need for additional components are.

- the recess is in a broad side wall of the housing provided.

- the recess in a circular ring wall Form-locking element molded.

- a movable pin in the recess provided on the actuating switch a movable pin in the recess.

- the distance R1 of the axis of rotation D is both narrow side walls the same size.

- the distance R1 of the axis of rotation D to the outermost point P of the shear system S larger than the distance R3 to the outermost point P1 of the shear system S. opposite part of the housing.

- the invention is the distance R1 of the axis of rotation D to the outermost point P. of the shear system S is equal to the distance R1 to the outermost point P1 of the shear system S opposite part of the housing.

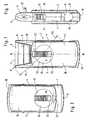

- Fig. 1 shows the front view of a dry shaver with a housing 7, the essentially by two broad side walls 1 and 2 and four narrow side walls 3, 4,5, 6 is formed, on the narrow side wall 6 as a short hair cutting system trained cutting system S is arranged.

- the short hair cutting system consists of an upper knife 8, which is clamped in an arc shape in a shaving head frame 9, and a lower knife assigned to the upper knife 8 - not shown.

- the shaving head frame 9 is detachably coupled to the housing 1. Below the shaving head frame 9 is in the housing 7 a pivotable out of the broad side wall 2 Long hair cutting system 10 extending parallel to the cutting system S.

- the long hair cutting system is arranged by means of a switch 11 arranged in the narrow side wall 4 10 in the trimming position shown in Fig. 3 pivotable and after actuating the switch 11 again in the opposite direction into the housing 7 swivels into a protected rest position.

- a form-locking element 13 is formed on the broad side wall 1 of the housing 7.

- a cap wall 16 On the form-locking element 13, which is designed as a round pin, is a cap wall 16 by means of a form-locking element 12, which penetrates as the cap wall 16 round opening is formed, rotatably mounted.

- On the cap wall 16 is a cap part 18 molded - see Fig. 3 -.

- the cap part 18 is by means of another cap wall 17 and other positive locking elements 14 and 15 - see sectional view according to Fig. 4 - pivotally mounted on the wide side wall 2 of the housing 7.

- the dry shaver is in use for a user depicted state.

- the cap part 18 is in one pivoting position opposite the cutting system S, i.e. in a position that runs parallel to the narrow side wall 5 of the housing 7 which acts as a base part.

- the outer wall of the form-locking element 13 which is part of the broad side wall 1 of the housing 7 - more assertive Operating switch 20 arranged for switching the electric drive.

- the Operating switch 20 is designed as a slide switch.

- the switching path 21 of the Actuator switch 20 is mounted on the round form-locking element 13 Cap wall 16 molded in such a way that the actuating switch 20 only at one of the Cap part 18 released cutting system S in the switching path 21 slidably is to by means of this switching movement the electric drive of the dry shaver turn on.

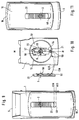

- the Housing 7 is on both broad side walls 1 and 2 of the Housing 7 formed as a round pin form-fit element 13, 15 each with a circumferential groove 22.

- the closed outer wall of the form-locking element 13 lies, for example, in one plane with the outer wall of the cap wall 16.

- the Cap walls 16 and 17 are the positive locking elements 12 and 14 as the cap walls 16 and 17 penetrating round openings are formed.

- spring arms 32 At the opening edge of the Form-locking elements 12 and 14 are spring arms 32 with one engaging in the groove 22 Spring 33 molded resiliently, whereby a clip connection between the positive locking elements 12, 13, 14 and 15 is produced.

- this clip connection are the cap walls 16, 17, rotatably coupled to the form-locking elements 13, 15 and held.

- Fig. 5 shows the embodiment of a dry shaver with only one a broad side wall 2 of the housing 7 molded form-locking element 15 and one a cap wall 17 carrying the cap part 18, which by means of a positive locking element 14 is rotatably coupled to the form-locking element 15.

- the embodiment according to FIG. 6 differs from the embodiment according to FIG. 5 by the arrangement of a further parallel to the broad side wall 1 of the housing 7 extending on the cap part 18 molded cap wall 16. A positive Coupling the broad side wall 1 with the cap wall 16 is in the embodiment 6 is not provided.

- the interlocking elements are in engagement 12, 13, 14, 15 of the broad side walls 1, 2 and the cap part 18 carrying cap walls 16, 17 in comparison to the embodiments accommodating an actuation switch 20 for example according to FIGS. 4 to 6 in diameter smaller, however larger and consequently more stable than in the known dry shaver according to JP-Y2-2-17558.

- the actuation switch 20 for commissioning the dry shaver is provided in one of the narrow side walls 4 of the housing 7.

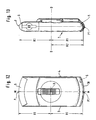

- the dry shaver according to FIG. 12 has a essentially from one narrow side wall 3 to an opposite one Narrow side wall 4 extending, elongated shear system S, which extends on both sides of the vertical center axis M and is designed in an arc shape.

- the distance R1 of the outermost point P is the arcuate Shear system S to the axis of rotation D is equal to the distance R1 of the axis of rotation D to the extreme Point P1 of the arcuate narrow side wall 5, which the Bottom wall of the housing 7 represents.

- the inner wall of the pivoted Kapppenteils 18 has a distance R2 to the axis of rotation D, which is slightly larger than the distance R1 to both a pivoting movement of the cap part 18 around the Rotation axis D to protect the shear system S via the shear system S as well Swiveling movement to release the shear system S over the narrow side wall 5 of the To ensure housing 7.

- the distance R3 is the narrow side wall 5 to the axis of rotation D smaller than the distance R1 of the axis of rotation to the outermost Point P of the shear system S.

- a linear shear system S - see Fig. 1 - are the design points for the distance R1 on the one hand the axis of rotation D and on the other hand, the outermost point P on the housing 7 of the dry shaver arranged, essentially from a narrow side wall 3 to an opposite Sidewall 4 linearly extending shear system S.

- the dry shaver in an unusable Condition of the dry shaver the dry shaver is a very small and maintains handy size, while with a dry shaver in the operating state, in which the cap part 18 is parallel to the narrow side wall 5 of the Housing 7 is located, the dry shaver by means of the cap walls 16, 17 and the cap part 18 extended, i.e. is enlarged, and thus the handling of a such reduced dry shavers much easier during shaving.

- the broad side wall 1 of the housing 7 with a cooperating Cap wall 16 shown in the removed state.

- the actuating switch 20 is arranged.

- a recess 24 for receiving a spring element 25 and a ball 26 molded.

- These locking means are operatively connected to a first locking recess 28 and a second locking recess 27 in the inner wall of the cap wall 16 Definition of a cap wall 16 carrying the cap part 18, in one the shear system S releasing and in a position protecting the S shaving system.

- the recesses 27 and 28 offset by 180 ° to each other on one Circular arc provided around the axis of rotation D.

- On the inside wall as a round A plurality of sliding ribs 36 are integrally formed, by means of which the friction upon rotation of the cap wall 16 on the round pin trained positive locking element 13 is significantly reduced.

- 9 and 11 is a dry shaver with a through the cap wall 16th concealed arranged - formed by positive locking elements 12, 13, 14, 15 - swivel shown.

- the design of the swivel joint (s) corresponds to essential of the embodiment of FIG. 4 and the associated description. in the The difference from the embodiment according to FIG. 4 is on the inside of the cap wall 16 a round recess designed as a form-locking element 12 and not a round one through opening provided so that on the broad side wall 1 as a round Shaped form-fitting element 13 from the pivoted cap wall 16 is covered.

- the dry shaver is free to use given shear system S.

- FIG. 10 shows a broad side wall 1 of the housing 7 with a form-locking element 13, that can be coupled to another form-locking element 12 of the cap wall 16 and around the axis of rotation D is rotatable, and an actuation switch 20 with a pin 50, that in the course of the pivoting movement of the cap part 16 and the actuating switch 20 about the axis of rotation D on the annular ring wall of the form-locking element 13 slides along and into the area as a switching path for the operating switch 20 provided recess formed in the ring wall. This recess is located on the vertical wall dividing the broad side wall 1 into two congruent halves Center axis.

- a slide valve 55 in an elongated slot 54 slidably supported in a vertical direction with the position of the slide valve 55 can be fixed by means of two interacting form-locking elements 56, 57.

- the Actuation switch 20 is by means of plug-in connection elements 58, 59 with the slide valve 55 can be coupled.

- the pin 50 After coupling the operating switch 20 with the slide valve 55 the pin 50 is in a position in the off position Actuation switch 20 and a shaving system S released by the cap part 18 outside the ring wall of the form-locking element 13 and can for the purpose of Switching on the dry shaving apparatus can be moved into the switching path 21, the positive locking elements 56 and 57 from the first positive locking position in a second positive locking position are brought.

- the actuation switch 20 is first from the on position to the off position. In the course of this movement the pin 50 slides out of the switching path 21 and then slides in the course the further rotational movement about the axis of rotation D on the annular ring wall of the Form-locking element 13 along until the shear system S from the cap part 18th is covered. The pin 50 is then offset by 180 ° to the position of the Switching path 21 and is in this position against any displacement in and against a vertical direction through the annular ring wall of the form-locking element 13 hindered. The result of this is that the actuating switch 20 according to FIG. 11 is locked OFF in the switching position shown, i.e. not in the switching path 40 can be moved into it.

Landscapes

- Life Sciences & Earth Sciences (AREA)

- Forests & Forestry (AREA)

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Dry Shavers And Clippers (AREA)

- Connector Housings Or Holding Contact Members (AREA)

- Processing Of Meat And Fish (AREA)

- Professional, Industrial, Or Sporting Protective Garments (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19633037 | 1996-08-16 | ||

| DE19633037A DE19633037C1 (de) | 1996-08-16 | 1996-08-16 | Trockenrasierapparat mit Schutzkappe |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0825000A2 EP0825000A2 (de) | 1998-02-25 |

| EP0825000A3 EP0825000A3 (de) | 1999-01-13 |

| EP0825000B1 true EP0825000B1 (de) | 2000-08-30 |

Family

ID=7802792

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP97111455A Expired - Lifetime EP0825000B1 (de) | 1996-08-16 | 1997-07-07 | Trockenrasierapparat mit Schutzkappe |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US6000135A (ja) |

| EP (1) | EP0825000B1 (ja) |

| JP (1) | JP3992331B2 (ja) |

| CN (1) | CN1102483C (ja) |

| AT (1) | ATE195898T1 (ja) |

| DE (2) | DE19633037C1 (ja) |

| HK (1) | HK1009110A1 (ja) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2006131171A1 (de) | 2005-06-10 | 2006-12-14 | Braun Gmbh | Elektrisches haarentfernungsgerät |

| US7937837B2 (en) * | 2004-07-22 | 2011-05-10 | Bic-Violex Sa | Razor head having two shaving heads |

Families Citing this family (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP3769957B2 (ja) * | 1998-06-15 | 2006-04-26 | 松下電工株式会社 | ヘアカッター |

| US6277129B1 (en) * | 2000-06-22 | 2001-08-21 | Epilady 2000, L.L.C. | Dual ended hair remover |

| KR100563481B1 (ko) * | 2002-06-17 | 2006-03-27 | 마츠시다 덴코 가부시키가이샤 | 전기면도기의 가동헤드 유지구조 |

| US6782625B1 (en) * | 2002-06-20 | 2004-08-31 | Raymond Electric (China) Ltd. | Encased electric shaver |

| KR100796307B1 (ko) * | 2003-11-11 | 2008-01-21 | 마츠시다 덴코 가부시키가이샤 | 전기 면도기 |

| KR200396688Y1 (ko) * | 2005-06-21 | 2005-09-26 | 오태준 | 슬림형 전기면도기 |

| US7900359B2 (en) * | 2007-08-31 | 2011-03-08 | The Gillette Company | Hair trimmer |

| JP5224348B2 (ja) * | 2008-07-03 | 2013-07-03 | 日立マクセル株式会社 | 電気かみそり |

| JP5259364B2 (ja) * | 2008-12-05 | 2013-08-07 | 株式会社貝印刃物開発センター | 安全カミソリ |

| US20150251326A1 (en) * | 2014-03-04 | 2015-09-10 | LoriAnn Lombardo | Hair trimming apparatus |

| GB2573289B (en) * | 2018-04-30 | 2021-06-30 | Lister Shearing Equip Ltd | Improvement in or Relating to Clippers |

Family Cites Families (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2691216A (en) * | 1952-06-03 | 1954-10-12 | Remington Rand Inc | Shaver head guard |

| US2803874A (en) * | 1954-10-12 | 1957-08-27 | Jordan Kunik I | Shaving instrument and enclosureholder therefor |

| US2787830A (en) * | 1954-11-19 | 1957-04-09 | Schick Inc | Shaving device and rotatable guard means therefor |

| JPS6091176U (ja) * | 1983-11-28 | 1985-06-21 | 東芝テック株式会社 | 電気かみそり |

| US4751781A (en) * | 1986-09-17 | 1988-06-21 | Remington Products, Inc. | Electric dry shaver having an improved head guard |

| AT388530B (de) * | 1987-04-24 | 1989-07-25 | Philips Nv | Trockenrasierapparat mit einem verschiebbaren rolladen |

| JPH0217558A (ja) * | 1988-07-06 | 1990-01-22 | Nec Corp | 入出力制御方式 |

| US5193275A (en) * | 1990-08-28 | 1993-03-16 | Matsushita Electric Works, Ltd. | Flat-shaped dry shaver |

| CN1021810C (zh) * | 1991-07-04 | 1993-08-18 | 东北煤气化设计研究所 | 煤气污水萃取脱酚、蒸氨处理方法 |

-

1996

- 1996-08-16 DE DE19633037A patent/DE19633037C1/de not_active Expired - Fee Related

-

1997

- 1997-07-07 US US08/888,428 patent/US6000135A/en not_active Expired - Lifetime

- 1997-07-07 AT AT97111455T patent/ATE195898T1/de not_active IP Right Cessation

- 1997-07-07 EP EP97111455A patent/EP0825000B1/de not_active Expired - Lifetime

- 1997-07-07 DE DE59702276T patent/DE59702276D1/de not_active Expired - Lifetime

- 1997-08-14 CN CN97116346A patent/CN1102483C/zh not_active Expired - Lifetime

- 1997-08-15 JP JP22045197A patent/JP3992331B2/ja not_active Expired - Fee Related

-

1998

- 1998-08-13 HK HK98109890A patent/HK1009110A1/xx not_active IP Right Cessation

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US7937837B2 (en) * | 2004-07-22 | 2011-05-10 | Bic-Violex Sa | Razor head having two shaving heads |

| WO2006131171A1 (de) | 2005-06-10 | 2006-12-14 | Braun Gmbh | Elektrisches haarentfernungsgerät |

| DE102005026800A1 (de) * | 2005-06-10 | 2006-12-21 | Braun Gmbh | Elektrisches Haarentfernungsgerät |

| DE102005026800B4 (de) * | 2005-06-10 | 2012-02-23 | Braun Gmbh | Elektrisches Haarentfernungsgerät |

Also Published As

| Publication number | Publication date |

|---|---|

| JPH1076080A (ja) | 1998-03-24 |

| ATE195898T1 (de) | 2000-09-15 |

| DE19633037C1 (de) | 1997-05-28 |

| JP3992331B2 (ja) | 2007-10-17 |

| CN1175494A (zh) | 1998-03-11 |

| EP0825000A3 (de) | 1999-01-13 |

| DE59702276D1 (de) | 2000-10-05 |

| EP0825000A2 (de) | 1998-02-25 |

| CN1102483C (zh) | 2003-03-05 |

| HK1009110A1 (en) | 1999-05-28 |

| US6000135A (en) | 1999-12-14 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0825000B1 (de) | Trockenrasierapparat mit Schutzkappe | |

| DE3726354C2 (ja) | ||

| EP1641601B1 (de) | Elektrisches haarschneidegerät | |

| DE19540304C2 (de) | Gerätestecker für Elektrogeräte | |

| DE19521299C1 (de) | Trockenrasierapparat mit schwenkbar gelagertem Langhaarschneider | |

| DE69209091T2 (de) | Trockenrasiergerät | |

| EP2035195B1 (de) | Elektrischer trockenrasierapparat | |

| EP0857100A1 (de) | Trockenrasierapparat | |

| DE2949301A1 (de) | Trockenrasiergeraet | |

| DE3529516A1 (de) | Haarschneidemaschine, insbesondere elektrische haarschneidemaschine | |

| DE1086782B (de) | Fuer ein elektrisches Werkzeug bestimmter Schalterantriebsmechanismus | |

| DE112007001273T5 (de) | Hand-Haarschneidegerät | |

| EP3843959A1 (de) | Messer mit einem messergriff und einer klinge | |

| DE3111871C2 (ja) | ||

| DE19633824C1 (de) | Elektrisch betreibbarer Rasierapparat | |

| DE1553803C3 (de) | Elektrisches Trockenrasiergerät | |

| DE60100298T2 (de) | Pflanzenschneidevorrichtung | |

| EP1888303B1 (de) | Elektrisches haarentfernungsgerät | |

| EP0571020B1 (de) | Rasierapparat mit einer verstellbaren Zahnschneideinrichtung | |

| EP0434781B1 (de) | Elektromotorisch angetriebene handgrasschere | |

| EP0846042B1 (de) | Trockenrasierapparat | |

| DE2033199B2 (de) | Scherkopf für Trockenrasierapparate | |

| EP2185326A1 (de) | Schneidvorrichtung mit wenigstens einem beweglichen von einem motor antreibbaren schneidkopf | |

| EP1098560B1 (de) | Scheren-verriegelungsvorrichtung | |

| DE733524C (de) | Handschalter fuer Elektromotoren, insbesondere ortsveraenderliche Elektromotoren, wie z.B. Elektrolaufkatzen u. dgl. |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT CH DE DK FR GB IT LI NL |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;RO;SI |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;RO;SI |

|

| 17P | Request for examination filed |

Effective date: 19990123 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| AKX | Designation fees paid |

Free format text: AT CH DE DK FR GB IT LI NL |

|

| 17Q | First examination report despatched |

Effective date: 19990910 |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: BRAUN GMBH |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| ITF | It: translation for a ep patent filed | ||

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT CH DE DK FR GB IT LI NL |

|

| REF | Corresponds to: |

Ref document number: 195898 Country of ref document: AT Date of ref document: 20000915 Kind code of ref document: T |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: LUCHS & PARTNER PATENTANWAELTE |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20000831 |

|

| REF | Corresponds to: |

Ref document number: 59702276 Country of ref document: DE Date of ref document: 20001005 |

|

| ET | Fr: translation filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20001130 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20050713 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20050718 Year of fee payment: 9 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20060731 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20060731 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20060731 Year of fee payment: 10 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20070330 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20060731 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070707 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20090730 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20100616 Year of fee payment: 14 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: V1 Effective date: 20110201 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110201 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20110622 Year of fee payment: 15 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 195898 Country of ref document: AT Kind code of ref document: T Effective date: 20110707 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110707 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20120707 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120707 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20160801 Year of fee payment: 20 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R071 Ref document number: 59702276 Country of ref document: DE |