EP0596289B1 - Stoffknetmaschine - Google Patents

Stoffknetmaschine Download PDFInfo

- Publication number

- EP0596289B1 EP0596289B1 EP93116596A EP93116596A EP0596289B1 EP 0596289 B1 EP0596289 B1 EP 0596289B1 EP 93116596 A EP93116596 A EP 93116596A EP 93116596 A EP93116596 A EP 93116596A EP 0596289 B1 EP0596289 B1 EP 0596289B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- rotor

- kneading machine

- housing

- machine according

- kneading

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- D—TEXTILES; PAPER

- D21—PAPER-MAKING; PRODUCTION OF CELLULOSE

- D21B—FIBROUS RAW MATERIALS OR THEIR MECHANICAL TREATMENT

- D21B1/00—Fibrous raw materials or their mechanical treatment

- D21B1/04—Fibrous raw materials or their mechanical treatment by dividing raw materials into small particles, e.g. fibres

- D21B1/12—Fibrous raw materials or their mechanical treatment by dividing raw materials into small particles, e.g. fibres by wet methods, by the use of steam

- D21B1/30—Defibrating by other means

- D21B1/34—Kneading or mixing; Pulpers

- D21B1/342—Mixing apparatus

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F33/00—Other mixers; Mixing plants; Combinations of mixers

- B01F33/80—Mixing plants; Combinations of mixers

- B01F33/81—Combinations of similar mixers, e.g. with rotary stirring devices in two or more receptacles

Definitions

- the invention relates to a kneading machine according to the preamble of claim 1.

- a kneading machine is known from Paper Technology, July, 1973, pages 196 to 202 and T 136 to T 142.

- Such machines process fiber materials with consistencies between generally 26 to 35%. and increased temperature generated by the supply of steam.

- a feed screw is provided, which feeds the material to the kneading machine, and a compression screw which is connected directly upstream of the kneading elements of the rotor.

- They are machines with a housing that has an inlet at one end and an outlet at its opposite end.

- the object of the invention is to provide a kneading machine which also enables high throughputs at very high processing pressures. This object is achieved by the features of the characterizing part of claim 1.

- the discharge screws enable the throughput quantities or, in particular, the processing time of the fibers to be set precisely. It goes without saying that due to the essentially symmetrical design of the machine, the loads caused by the axial forces of the rotor on the bearings become very low. It is ensured that all fibers are exposed to essentially the same specific workload.

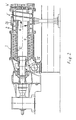

- a rotor consisting of the rotor parts 4, 4 'and 5 is arranged centrally or concentrically in the housing 1.

- the rotor parts 4 and 4 ' carry the kneading elements 12.

- the rotor part 5 essentially has a screw conveyor 2, 2' for the rotor parts 4 and 4 ', respectively.

- the inlet opening 8 is arranged symmetrically to the region of the screw conveyor located between the rotor parts 4 and 4 '; it is preceded by a feed screw 10.

- In this housing area there is also a closable opening 13 for the supply of steam and chemicals.

- the discharge openings 15 and 15 'at the axial ends of the housing are arranged more axially than radially in the lower region in the form of a ring sector. In this area, a discharge screw 5 or 5 'runs transversely to the axis of rotation of the rotor.

- the feed screw also achieves the following: There is a grafting of the fiber suspension of fairly high consistency (see as indicated above), so that the screw conveyors 2 and 2 'then uniformly spread the entire throughput onto the two rotor parts 4 and 4' or the corresponding ones Can split knee rooms.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Life Sciences & Earth Sciences (AREA)

- Wood Science & Technology (AREA)

- Mechanical Engineering (AREA)

- Chemical & Material Sciences (AREA)

- Processing And Handling Of Plastics And Other Materials For Molding In General (AREA)

- Mixers Of The Rotary Stirring Type (AREA)

- Paper (AREA)

- Manufacturing And Processing Devices For Dough (AREA)

- Preparation Of Clay, And Manufacture Of Mixtures Containing Clay Or Cement (AREA)

- Bakery Products And Manufacturing Methods Therefor (AREA)

- Transition And Organic Metals Composition Catalysts For Addition Polymerization (AREA)

- Formation And Processing Of Food Products (AREA)

- Disintegrating Or Milling (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE4237433A DE4237433C2 (de) | 1992-11-06 | 1992-11-06 | Stoffknetmaschine |

| DE4237433 | 1992-11-06 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0596289A1 EP0596289A1 (de) | 1994-05-11 |

| EP0596289B1 true EP0596289B1 (de) | 1995-08-09 |

Family

ID=6472212

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP93116596A Expired - Lifetime EP0596289B1 (de) | 1992-11-06 | 1993-10-14 | Stoffknetmaschine |

Country Status (11)

| Country | Link |

|---|---|

| US (1) | US5407268A (enExample) |

| EP (1) | EP0596289B1 (enExample) |

| JP (1) | JPH06212583A (enExample) |

| KR (1) | KR940011698A (enExample) |

| AT (1) | ATE126293T1 (enExample) |

| BR (1) | BR9304504A (enExample) |

| CA (1) | CA2102059A1 (enExample) |

| DE (2) | DE4237433C2 (enExample) |

| ES (1) | ES2075752T3 (enExample) |

| FI (1) | FI934788A7 (enExample) |

| NO (1) | NO933991L (enExample) |

Families Citing this family (20)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE4237433C2 (de) * | 1992-11-06 | 1994-05-11 | Voith Gmbh J M | Stoffknetmaschine |

| AT409130B (de) * | 1995-04-25 | 2002-05-27 | Chemiefaser Lenzing Ag | Verwendung einer vorrichtung zum halten und abgeben einer homogenen cellulosesuspension |

| DE59703888D1 (de) * | 1996-05-10 | 2001-08-02 | Voith Sulzer Stoffaufbereitung | Vorrichtung zum Kneten von hochkonsistentem Faserstoff |

| DE19618887A1 (de) * | 1996-05-10 | 1997-06-19 | Voith Sulzer Stoffaufbereitung | Verfahren und Vorrichtung zum Kneten von hochkonsistentem Faserstoff |

| KR100394481B1 (ko) * | 2001-03-06 | 2003-08-21 | 이남훈 | 전등부하 제어회로 |

| US6719448B2 (en) * | 2002-06-13 | 2004-04-13 | Wenger Manufacturing, Inc. | Method and apparatus for the simultaneous production of differently characterized extrudates |

| DE10337821B3 (de) * | 2003-08-18 | 2005-01-13 | Voith Paper Patent Gmbh | Verfahren zur Behandlung von störende Gefäßzellen enthaltendem Zellstoff |

| US8172545B2 (en) * | 2003-08-20 | 2012-05-08 | Kraft Foods Global Brands Llc | Method for controlling ground meat flow rates |

| US20050255224A1 (en) * | 2003-08-20 | 2005-11-17 | Kraft Foods Holdings, Inc. | Integrated continuous meat processing system |

| US7857500B2 (en) * | 2003-08-20 | 2010-12-28 | Kraft Foods Global Brands Llc | Apparatus for vacuum-less meat processing |

| US7488502B2 (en) * | 2003-08-20 | 2009-02-10 | Kraft Foods Global Brands Llc | Method of making processed meat products |

| US7871655B2 (en) * | 2003-08-20 | 2011-01-18 | Kraft Foods Global Brands Llc | Method and apparatus for accelerating formation of functional meat mixtures |

| US20050255222A1 (en) * | 2003-08-20 | 2005-11-17 | Kraft Foods Holdings, Inc. | Method and apparatus for acceleration ingredient diffusion in meat |

| US7731998B2 (en) * | 2003-08-20 | 2010-06-08 | Kraft Foods Global Brands Llc | Method for reducing protein exudate on meat product |

| US20050276903A1 (en) * | 2003-08-20 | 2005-12-15 | Kraft Foods Holdings, Inc. | Method and apparatus for meat product manufacturing |

| US7169421B2 (en) * | 2003-08-20 | 2007-01-30 | Kraft Foods Holdings, Inc. | Method of making processed meat products |

| US20050249862A1 (en) * | 2003-08-20 | 2005-11-10 | Kraft Foods Holdings, Inc. | Method and apparatus for controlling texture of meat products |

| US8641263B2 (en) | 2008-11-24 | 2014-02-04 | Kraft Foods Group Brands Llc | Method and apparatus for continuous processing of whole muscle meat products |

| US8187651B2 (en) * | 2008-11-24 | 2012-05-29 | Kraft Foods Global Brands Llc | Method and apparatus for continuous processing of whole muscle meat products |

| US8308342B2 (en) | 2008-11-24 | 2012-11-13 | Kraft Foods Global Brands Llc | Processing elements for mixing meat products |

Family Cites Families (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1827710A (en) * | 1928-07-28 | 1931-10-13 | Leyst-Kuchenmeister Carl | Process for treating fibrous materials |

| US2377069A (en) * | 1941-06-14 | 1945-05-29 | John T Brubaker | Meat grinding and condiment admixing machine |

| FI24728A (fi) * | 1948-02-28 | 1950-11-10 | Paper And Ind Appliances | Förfaringssätt för behandling av cellulosamaterial |

| US3575791A (en) * | 1967-05-01 | 1971-04-20 | Mary Agnes Messing | Inclined continuous digester with mechanical conveying screws of decreasing pitch |

| GB1340219A (en) * | 1970-08-01 | 1973-12-12 | Scheer & Cie C F | Devices for plasticising and extruding plastics material |

| SU426006A1 (enExample) * | 1971-03-29 | 1974-04-30 | А. М. Лысенко, Н. У. Ризаев, У. Усманов, Л. Ускова , А. К. Хаджиев | |

| CH570780A5 (enExample) * | 1972-05-16 | 1975-12-31 | Buehler Ag Geb | |

| US3869111A (en) * | 1973-12-10 | 1975-03-04 | Intercole Automation Inc | Apparatus for mixing rubber, elastomer, plastic and the like |

| DE2408936A1 (de) * | 1974-02-25 | 1975-09-11 | Ludwig Wittrock | Vorrichtung zur verformung von thermoplastrohstoffen und aehnlichen massen mittels rotierender mastifizierwerkzeuge z.b. schnecken oder walzen |

| DE2738776C2 (de) * | 1977-08-27 | 1983-05-19 | Hermann Berstorff Maschinenbau Gmbh, 3000 Hannover | Temperierbare Schneckenpresse zum kontinuierlichen Extrudieren von thermoplastischem Schaumstoff |

| US4295925A (en) * | 1979-06-15 | 1981-10-20 | Weyerhaeuser Company | Treating pulp with oxygen |

| DE3519349A1 (de) * | 1985-05-30 | 1986-12-04 | IKA-Maschinenbau Janke & Kunkel GmbH & Co KG, 7812 Bad Krozingen | Knetmaschine |

| AT394588B (de) * | 1990-01-23 | 1992-05-11 | Andritz Ag Maschf | Zerkleinerungsflaechen aufweisendes segment fuer trommelrefiner und hiemit versehene anordnung |

| DE4237433C2 (de) * | 1992-11-06 | 1994-05-11 | Voith Gmbh J M | Stoffknetmaschine |

-

1992

- 1992-11-06 DE DE4237433A patent/DE4237433C2/de not_active Expired - Fee Related

-

1993

- 1993-10-14 AT AT93116596T patent/ATE126293T1/de not_active IP Right Cessation

- 1993-10-14 EP EP93116596A patent/EP0596289B1/de not_active Expired - Lifetime

- 1993-10-14 DE DE59300456T patent/DE59300456D1/de not_active Expired - Fee Related

- 1993-10-14 ES ES93116596T patent/ES2075752T3/es not_active Expired - Lifetime

- 1993-10-28 FI FI934788A patent/FI934788A7/fi unknown

- 1993-10-29 JP JP5294714A patent/JPH06212583A/ja active Pending

- 1993-10-29 CA CA002102059A patent/CA2102059A1/en not_active Abandoned

- 1993-11-03 KR KR1019930022176A patent/KR940011698A/ko not_active Expired - Lifetime

- 1993-11-04 NO NO933991A patent/NO933991L/no unknown

- 1993-11-05 BR BR9304504A patent/BR9304504A/pt not_active IP Right Cessation

-

1994

- 1994-08-22 US US08/293,747 patent/US5407268A/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| KR940011698A (ko) | 1994-06-21 |

| ATE126293T1 (de) | 1995-08-15 |

| BR9304504A (pt) | 1994-05-10 |

| ES2075752T3 (es) | 1995-10-01 |

| DE59300456D1 (de) | 1995-09-14 |

| JPH06212583A (ja) | 1994-08-02 |

| US5407268A (en) | 1995-04-18 |

| EP0596289A1 (de) | 1994-05-11 |

| NO933991L (no) | 1994-05-09 |

| FI934788L (fi) | 1994-05-07 |

| DE4237433C2 (de) | 1994-05-11 |

| NO933991D0 (no) | 1993-11-04 |

| DE4237433A1 (enExample) | 1993-05-06 |

| CA2102059A1 (en) | 1994-05-07 |

| FI934788A0 (fi) | 1993-10-28 |

| FI934788A7 (fi) | 1994-05-07 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0596289B1 (de) | Stoffknetmaschine | |

| US5730376A (en) | Apparatus for regulated dispersion treatment of highly consistent fibrous substances | |

| DE69106392T2 (de) | Hochgeschwindigkeits-doppelscheibenrefiner mit kontrollierbarer intensität. | |

| DE69833001T2 (de) | Vorrichtung und verfahren zur steuerung eines raffineurs für papierbreie | |

| DE3617871C2 (enExample) | ||

| DE69404661T2 (de) | Zwei-zonen refiner mit getrennter entladeflussregelung | |

| DE69513276T2 (de) | Siebplatte für die Papierherstellung | |

| DE3135509A1 (de) | Verfahren und vorrichtung zum vermahlen von faserigem ausgangsgut in mahlapparaten der doppelumlaufscheiben-bauart | |

| EP1122356B1 (de) | Refiner | |

| DE19715173A1 (de) | Schneckenpresse zum Abtrennen von Flüssigkeiten aus Feststoff-Flüssigkeits-Mischungen | |

| EP0731210B1 (de) | Mahlmaschine und Mahlwerkzeug zum Mahlen von suspendiertem Faserstoffmaterial | |

| DE102004039986A1 (de) | Verfahren zur Mahlung von Fasern, insbesondere Papierfasern | |

| EP1122357B1 (de) | Refiner zur Zerkleinerung von Faserstoffen | |

| AT395325B (de) | Vorrichtung zum auftrennen einer zellulosefaserbrei-suspension | |

| EP3914768B1 (de) | Verfahren zur steuerung einer vorrichtung zur behandlung von hochkonsistem faserstoff | |

| DE10102449C1 (de) | Vorrichtung zur Heiß-Dispergierung eines Papierfaserstoffes | |

| EP1702103A1 (de) | Verfahren zur mahlung von wässrig suspendierten papier- oder zellstofffasern | |

| AT404847B (de) | Verfahren und vorrichtung zur verteilung einer, insbesondere mittelkonsistenten, faserstoffsuspension | |

| EP1359250B1 (de) | Verfahren zur Dispergierung eines Papierfaserstoffes | |

| CH617735A5 (en) | Unit for defiberising fibre material suspensions for paper machines | |

| EP0931584A1 (de) | Vorrichtung zur mechanischen Behandlung von hochkonsistenten Faserstoff | |

| DE102017127772A1 (de) | Mahlvorrichtung | |

| EP4065766A1 (de) | Faserstoff-behandlungsvorrichtung | |

| EP1146168A2 (de) | Vorrichtung zur Dispergierung von hochkonsistentem Papierfaserstoff | |

| EP1147804A1 (de) | Vorrichtung zur Dispergierung von hochkonsistentem Papierfaserstoff sowie Garnituren für diese Vorrichtung |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 19931014 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH DE ES FR GB IT LI NL SE |

|

| 17Q | First examination report despatched |

Effective date: 19950126 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE ES FR GB IT LI NL SE |

|

| REF | Corresponds to: |

Ref document number: 126293 Country of ref document: AT Date of ref document: 19950815 Kind code of ref document: T |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 19950812 |

|

| REF | Corresponds to: |

Ref document number: 59300456 Country of ref document: DE Date of ref document: 19950914 |

|

| ET | Fr: translation filed | ||

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2075752 Country of ref document: ES Kind code of ref document: T3 |

|

| ITF | It: translation for a ep patent filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19960702 |

|

| 26N | No opposition filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19990921 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 19991007 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 19991022 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 19991025 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 19991027 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 19991116 Year of fee payment: 7 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20001014 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20001015 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: THE PATENT HAS BEEN ANNULLED BY A DECISION OF A NATIONAL AUTHORITY Effective date: 20001030 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20001031 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20001031 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20001031 |

|

| BERE | Be: lapsed |

Owner name: J.M. VOITH G.M.B.H. Effective date: 20001031 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20010501 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20001014 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| EUG | Se: european patent has lapsed |

Ref document number: 93116596.3 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee |

Effective date: 20010501 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20031022 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20031028 Year of fee payment: 11 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20011113 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20041014 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20050630 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20051014 |