EP0551146B1 - Tête de pulvérisateur pour distribuer de la mousse - Google Patents

Tête de pulvérisateur pour distribuer de la mousse Download PDFInfo

- Publication number

- EP0551146B1 EP0551146B1 EP93103461A EP93103461A EP0551146B1 EP 0551146 B1 EP0551146 B1 EP 0551146B1 EP 93103461 A EP93103461 A EP 93103461A EP 93103461 A EP93103461 A EP 93103461A EP 0551146 B1 EP0551146 B1 EP 0551146B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- closure element

- foam

- dispensing valve

- discharge passage

- spray head

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 239000006260 foam Substances 0.000 title claims description 29

- 239000007921 spray Substances 0.000 title claims description 24

- 235000001674 Agaricus brunnescens Nutrition 0.000 claims description 10

- 239000007788 liquid Substances 0.000 claims description 6

- 230000003111 delayed effect Effects 0.000 claims description 5

- 239000000463 material Substances 0.000 claims description 5

- 239000007789 gas Substances 0.000 claims description 4

- 239000000443 aerosol Substances 0.000 description 4

- 239000011324 bead Substances 0.000 description 2

- 230000000881 depressing effect Effects 0.000 description 2

- 238000005187 foaming Methods 0.000 description 2

- 230000007423 decrease Effects 0.000 description 1

- 230000003247 decreasing effect Effects 0.000 description 1

- 230000000994 depressogenic effect Effects 0.000 description 1

- 238000011161 development Methods 0.000 description 1

- 230000018109 developmental process Effects 0.000 description 1

- 230000005484 gravity Effects 0.000 description 1

- 230000002093 peripheral effect Effects 0.000 description 1

- 239000003380 propellant Substances 0.000 description 1

- 230000001681 protective effect Effects 0.000 description 1

- 230000000717 retained effect Effects 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05B—SPRAYING APPARATUS; ATOMISING APPARATUS; NOZZLES

- B05B11/00—Single-unit hand-held apparatus in which flow of contents is produced by the muscular force of the operator at the moment of use

- B05B11/0005—Components or details

- B05B11/0062—Outlet valves actuated by the pressure of the fluid to be sprayed

- B05B11/007—Outlet valves actuated by the pressure of the fluid to be sprayed being opened by deformation of a sealing element made of resiliently deformable material, e.g. flaps, skirts, duck-bill valves

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05B—SPRAYING APPARATUS; ATOMISING APPARATUS; NOZZLES

- B05B11/00—Single-unit hand-held apparatus in which flow of contents is produced by the muscular force of the operator at the moment of use

- B05B11/0005—Components or details

- B05B11/0062—Outlet valves actuated by the pressure of the fluid to be sprayed

- B05B11/0072—A valve member forming part of an outlet opening

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05B—SPRAYING APPARATUS; ATOMISING APPARATUS; NOZZLES

- B05B7/00—Spraying apparatus for discharge of liquids or other fluent materials from two or more sources, e.g. of liquid and air, of powder and gas

- B05B7/0018—Spraying apparatus for discharge of liquids or other fluent materials from two or more sources, e.g. of liquid and air, of powder and gas with devices for making foam

- B05B7/0025—Spraying apparatus for discharge of liquids or other fluent materials from two or more sources, e.g. of liquid and air, of powder and gas with devices for making foam with a compressed gas supply

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D83/00—Containers or packages with special means for dispensing contents

- B65D83/14—Containers or packages with special means for dispensing contents for delivery of liquid or semi-liquid contents by internal gaseous pressure, i.e. aerosol containers comprising propellant for a product delivered by a propellant

- B65D83/16—Containers or packages with special means for dispensing contents for delivery of liquid or semi-liquid contents by internal gaseous pressure, i.e. aerosol containers comprising propellant for a product delivered by a propellant characterised by the actuating means

- B65D83/20—Containers or packages with special means for dispensing contents for delivery of liquid or semi-liquid contents by internal gaseous pressure, i.e. aerosol containers comprising propellant for a product delivered by a propellant characterised by the actuating means operated by manual action, e.g. button-type actuator or actuator caps

- B65D83/205—Actuator caps, or peripheral actuator skirts, attachable to the aerosol container

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D83/00—Containers or packages with special means for dispensing contents

- B65D83/14—Containers or packages with special means for dispensing contents for delivery of liquid or semi-liquid contents by internal gaseous pressure, i.e. aerosol containers comprising propellant for a product delivered by a propellant

- B65D83/28—Nozzles, nozzle fittings or accessories specially adapted therefor

- B65D83/30—Nozzles, nozzle fittings or accessories specially adapted therefor for guiding the flow of spray, e.g. funnels, hoods

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D83/00—Containers or packages with special means for dispensing contents

- B65D83/14—Containers or packages with special means for dispensing contents for delivery of liquid or semi-liquid contents by internal gaseous pressure, i.e. aerosol containers comprising propellant for a product delivered by a propellant

- B65D83/40—Closure caps

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D83/00—Containers or packages with special means for dispensing contents

- B65D83/14—Containers or packages with special means for dispensing contents for delivery of liquid or semi-liquid contents by internal gaseous pressure, i.e. aerosol containers comprising propellant for a product delivered by a propellant

- B65D83/75—Aerosol containers not provided for in groups B65D83/16 - B65D83/74

- B65D83/753—Aerosol containers not provided for in groups B65D83/16 - B65D83/74 characterised by details or accessories associated with outlets

- B65D83/7535—Outlet valves opened by the product to be delivered

Definitions

- the invention relates to a spray head for a spray container for dispensing foam, the spray container having a manually operable dispensing valve in an outlet channel of the spray head and the spray head having a closure element which closes the outlet channel automatically and with a delay relative to the dispensing valve, downstream of the dispensing valve, and the closure element is somewhat mushroom-like is formed, with its stem axially inserted into the outlet channel and in the closed position with the edge of its mushroom head on the edge of the outlet opening of the outlet channel and with a radial projection of the stem against an undercut in the outlet channel, engaging under it.

- the closure element hermetically closes, the product residue remaining between the dispensing valve and the outlet opening can re-foam in the closed outlet channel and, if appropriate, open the closure element again under the pressure of the foam, so that foam continues to flow out.

- the invention has for its object to provide a spray head of the generic type, in which the emerging foam has a higher strength and an outflow of foam is avoided after closing the closure element.

- this object is achieved in that the opening of the closure element is delayed compared to the opening of the dispensing valve and the closure element in its closed position allows gases but no liquids to escape, and that at least the mushroom head consists of an elastically flexible material.

- the delayed-opening closure element initially acts like a foam outlet brake, so that the foam strength is increased. Due to the non-hermetic closing and the still possible gas outlet, after-foaming and outflow of foam is avoided at the same time.

- the edge of the mushroom head bends under the pressure of the foam delayed away from the edge of the outlet opening of the outlet channel in order to expose the outlet of the foam. After the dispensing valve is closed, the edge of the mushroom head moves with a delay due to its inherent elasticity decreasing pressure of the foam back to the closed position.

- the outlet channel can be divided into a first section and a second section which can be plugged together and has the closure element.

- the first section can form the conventional outlet channel, into which the second section can simply be inserted in the desired configuration.

- the actuating attachment 1 has a vertical outlet pipe 5, which forms a first section of an outlet channel 6 and into which a pipe socket 7 of the closure cap 2 is inserted, the pipe socket 7 forming a second section of the outlet channel 6.

- the outlet pipe 5 and the pipe socket 7 are held tightly together in the frictional engagement.

- the axially lower section of the outlet tube 5 forms a socket 8 for receiving the outlet end of an outlet tube of the outlet valve.

- the outlet channel 6 is partially blocked by a baffle 9 extending transversely therein, on which the aqueous aerosol liquid released from the spray container can initially foam.

- the upper wall 10 of the actuating attachment 1 is connected in one piece only on one side (in FIG. 1) of the outlet pipe 5 to the upper edge of a radially outer peripheral wall 11 of the actuating attachment 1 which can be snapped onto the upper edge of the spray container.

- the wall 10 is made of flexible material. Therefore, by depressing one of the connection points between the walls 10 and 11 diametrically opposite actuating step 12, pressure can be exerted on the dispensing tube of the dispensing valve which engages in the socket 8.

- the dispensing valve is opened by depressing the dispensing tube, which at the same time forms a closure part of the dispensing valve.

- the closure element 3 is shaped like a mushroom and axially inserted into the outlet channel 6 with its stem 13.

- the handle 13 has a radial projection 14 in the form of a circumferential bead, which engages under an undercut 15, which is also formed by a bead protruding radially inwards in the outlet channel 6.

- the radial projection 14 In the closed position of the closure element 3 shown in FIG. 1, this lies with the edge 16 of its mushroom head 17 on the edge 18 of the outlet opening of the outlet channel 6.

- the radial projection 14 has an axial distance d from the undercut 15, through which the stroke of the closure element 3, which is made of rigid material, is determined and limited.

- Axial through channels 19 penetrate the radial projection 14 up to the upper side of the projection forming the undercut 15.

- the mushroom head 17 of the closure element 3 is sunk largely flush in an axial recess 20 in the mushroom-like extension of the closure attachment 2.

- the dispensing valve closes, while the closure element 3 continues to maintain the open position under the pressure of the foam.

- the closure element 3 In the upright position of the spray container and accordingly the vertical position of the outlet channel 6, the closure element 3 now sinks back into the closed position when the foam pressure decreases. Alternatively, the closure element 3 can also be manually stripped of the leaked Foam are pushed back into the closed position. In the closed position, gas can continue to escape through the non-hermetically sealed closing gap between the closure element 3 and the closure attachment 2, while the foam or liquid which forms in the outlet channel 6 is retained and at the same time it is prevented that the product residue remaining in the outlet channel can change under air access .

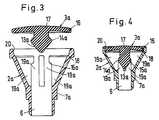

- FIG. 3 and 4 show a modified closure attachment 2a, which can be used together with the actuating attachment 1 and in which the likewise mushroom-shaped closure element 3a is not rigid, but is made of an elastically flexible material.

- the through-channels 19a are not formed in the stem 13a, but in a conically widening part of the pipe socket 7a. Accordingly, the radial projection 14a of the stem 13a is continuous in the circumferential direction and the undercut 15a is interrupted in the circumferential direction by the through channels 19a.

- the projection 14a has no axial distance from the undercut 15a, but is constantly in contact with it.

- the closure element 3a When the dispensing valve is opened, the closure element 3a is therefore not raised, but rather only its edge 16 is bent axially upward by the pressure of the foam, and in this way the closure element 3a is brought into the open position (not shown) with a delay. After the dispensing valve is closed, the opening edge 16 is bent back again until it rests against the edge 18 due to its return spring force and brought into the closed position. The opening and closing of the closure element 3a is therefore also delayed compared to the opening and closing of the dispensing valve.

- polygonal, e.g. quadrangular, closure elements and correspondingly adapted actuating attachments with the same design, as shown, can be provided.

Landscapes

- Chemical & Material Sciences (AREA)

- Dispersion Chemistry (AREA)

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Containers And Packaging Bodies Having A Special Means To Remove Contents (AREA)

- Nozzles (AREA)

Claims (2)

- Tête de pulvérisation d'un récipient de pulvérisation pour la distribution de mousse, le récipient de pulvérisation présentant une soupape de distribution pouvant être actionnée manuellement, dans un canal de sortie (6) de la tête de pulvérisation et la tête de pulvérisation présentant, en aval de la soupape de distribution, un élément de fermeture (3a) fermant le canal de sortie (6) de façon automatique et de façon temporisée par rapport à la soupape de distribution et l'élément de fermeture (3a) présentant sensiblement la forme d'un champignon et étant introduit, avec sa tige (13a), axialement dans le canal de sortie (6) et appuyant, dans la position de fermeture, avec le bord (16) de sa tête en forme de champignon (17) contre le bord (18) de l'orifice de sortie du canal de sortie (6), et avec une saillie radiale (14a) de la tige (13a) entrant en prise par en dessous avec une contre-dépouille (15a) dans le canal de sortie (6), caractérisée en ce que l'ouverture de l'élément de fermeture (3a) est temporisée par rapport à l'ouverture de la soupape de distribution et en ce que l'élément de fermeture (3a), dans sa position de fermeture, laisse sortir des gaz mais aucun liquide et en ce que au moins la tête en forme de champignon (17) est réalisée dans un matériau flexible de façon élastique.

- Tête de pulvérisation selon la revendication 1, caractérisée en ce que le canal de sortie (6) est divisé en un premier tronçon (5) et en un deuxième tronçon (7a) présentant l'élément de fermeture (3a) et pouvant être assemblé avec le premier tronçon par enfichage.

Applications Claiming Priority (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE3909792 | 1989-03-24 | ||

| DE3909792 | 1989-03-24 | ||

| DE3931679 | 1989-09-22 | ||

| DE3931679A DE3931679A1 (de) | 1989-03-24 | 1989-09-22 | Spruehkopf fuer einen spruehbehaelter zur ausgabe von schaum |

| EP90105423A EP0388947B1 (fr) | 1989-03-24 | 1990-03-22 | Tête de pulvérisateur pour distribuer de la mousse |

Related Parent Applications (3)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP90105423.9 Division | 1990-03-22 | ||

| EP90105423A Division EP0388947B1 (fr) | 1989-03-24 | 1990-03-22 | Tête de pulvérisateur pour distribuer de la mousse |

| EP90105423A Division-Into EP0388947B1 (fr) | 1989-03-24 | 1990-03-22 | Tête de pulvérisateur pour distribuer de la mousse |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0551146A1 EP0551146A1 (fr) | 1993-07-14 |

| EP0551146B1 true EP0551146B1 (fr) | 1995-04-26 |

Family

ID=25879177

Family Applications (3)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP93103461A Expired - Lifetime EP0551146B1 (fr) | 1989-03-24 | 1990-03-22 | Tête de pulvérisateur pour distribuer de la mousse |

| EP90105423A Expired - Lifetime EP0388947B1 (fr) | 1989-03-24 | 1990-03-22 | Tête de pulvérisateur pour distribuer de la mousse |

| EP93103462A Expired - Lifetime EP0550409B1 (fr) | 1989-03-24 | 1990-03-22 | Tête de pulvérisateur pour distribuer de la mousse |

Family Applications After (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP90105423A Expired - Lifetime EP0388947B1 (fr) | 1989-03-24 | 1990-03-22 | Tête de pulvérisateur pour distribuer de la mousse |

| EP93103462A Expired - Lifetime EP0550409B1 (fr) | 1989-03-24 | 1990-03-22 | Tête de pulvérisateur pour distribuer de la mousse |

Country Status (10)

| Country | Link |

|---|---|

| EP (3) | EP0551146B1 (fr) |

| JP (1) | JP2867179B2 (fr) |

| AR (1) | AR244577A1 (fr) |

| AU (1) | AU624933B2 (fr) |

| BR (1) | BR9005967A (fr) |

| CA (1) | CA2028850A1 (fr) |

| DE (4) | DE3931679A1 (fr) |

| ES (3) | ES2080545T3 (fr) |

| HU (1) | HU214724B (fr) |

| WO (1) | WO1990011236A1 (fr) |

Families Citing this family (21)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2660635B1 (fr) * | 1990-04-10 | 1994-01-14 | Marthe Lucas | Coiffe distributrice de creme moussante. |

| DE4108428A1 (de) * | 1991-03-15 | 1992-09-17 | Wiegner Georg Dipl Kaufm | Vorrichtung zur dosierten abgabe von unter druck stehenden inhaltstoffen |

| FR2676714B1 (fr) * | 1991-05-21 | 1993-09-24 | Oreal | Recipient muni d'un dispositif elastique de fermeture. |

| CH680359A5 (fr) * | 1991-08-28 | 1992-08-14 | Supermatic Kunststoff Ag | |

| DE9114142U1 (de) * | 1991-11-13 | 1993-03-11 | PCT Powder Coating Technologies GmbH, 7482 Krauchenwies | Vorrichtung zum Farbpulvereinzug beim Pulverlackieren |

| FR2692231B1 (fr) * | 1992-06-11 | 1996-04-26 | Avitex | Embout de diffusion et tete de diffusion pour recipient pressurise. |

| WO1994012406A1 (fr) * | 1992-11-23 | 1994-06-09 | Deutsche Präzisions Ventil Gmbh | Dispositif d'actionnement pour une bombe aerosol |

| NL9300517A (nl) * | 1993-03-23 | 1994-10-17 | Airspray Int Bv | Schuimvormingssamenstel, een daarvoor geschikte spuitkop en een spuitbus die een dergelijk samenstel omvat. |

| DE9411622U1 (de) * | 1994-07-18 | 1994-11-17 | Coster Tecnologie Speciali Spa | Vorrichtung zum dosierten Austrag eines fließfähigen Mediums |

| DE4426120A1 (de) * | 1994-07-22 | 1996-01-25 | Coster Tecnologie Speciali Spa | Sprühkopf für einen Behälter für ein unter Druck stehendes Fluid |

| FR2724154B1 (fr) * | 1994-09-05 | 1997-01-17 | Oreal | Embout distributeur de produit, notamment de mousse pour recipient pressurise a valve |

| DE4437439A1 (de) * | 1994-10-20 | 1996-04-25 | Wella Ag | Einrichtung mit mindestens einer rutschfesten Handhabungs- oder Betätigungsfläche einer Vorrichtung |

| DE9419268U1 (de) * | 1994-12-01 | 1995-01-26 | Josef Wischerath Gmbh & Co. Kg, 50259 Pulheim | Spender |

| DE19607691A1 (de) * | 1996-02-29 | 1997-09-04 | Coster Tecnologie Speciali Spa | Schaumkopf |

| US7011978B2 (en) | 2001-08-17 | 2006-03-14 | Micron Technology, Inc. | Methods of forming capacitor constructions comprising perovskite-type dielectric materials with different amount of crystallinity regions |

| DE10232863A1 (de) * | 2002-07-16 | 2004-02-05 | Hüttlin, Herbert, Dr.h.c. | Zerstäubungsdüse mit rotativem Ringspalt |

| DE10321902A1 (de) * | 2003-05-06 | 2004-12-09 | Ing. Erich Pfeiffer Gmbh | Austragvorrichtung für zumindest ein Medium |

| FR2980125B1 (fr) * | 2011-09-21 | 2016-01-22 | Oreal | Tete de distribution comportant deux buses a restriction |

| CN103286020B (zh) * | 2013-07-02 | 2016-03-02 | 江苏新天宝机械有限公司 | 一种罐体中的清洗液喷头 |

| JP6383207B2 (ja) * | 2014-07-31 | 2018-08-29 | 株式会社吉野工業所 | 吐出面に内容物を吐出する吐出容器 |

| JP6745299B2 (ja) * | 2018-08-01 | 2020-08-26 | 株式会社吉野工業所 | 吐出面に内容物を吐出する吐出容器 |

Family Cites Families (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2913749A (en) * | 1958-03-19 | 1959-11-24 | John M Wittke | Applicator for pressurized package |

| US2954904A (en) * | 1958-10-13 | 1960-10-04 | Joseph B Potoczky | Gas pressure type dispensing container cap |

| GB1226565A (fr) * | 1967-04-07 | 1971-03-31 | ||

| ES419697A1 (es) * | 1972-10-18 | 1976-03-16 | Ivanov Mantchev | Dispositivo tapon valvular para botellas y recipientes si- milares. |

| US3874563A (en) * | 1973-06-19 | 1975-04-01 | Gilbert Schwartzman | Applicator having multiple valve assemblies |

| US3976216A (en) * | 1974-12-26 | 1976-08-24 | Thermo Electron Corporation | Sterile bottle closure |

| CA1166203A (fr) * | 1979-12-21 | 1984-04-24 | Luigi Del Bon | Commande a fermeture automatique sur decharge de contenant sous pression |

| US4314658A (en) * | 1980-01-30 | 1982-02-09 | Laauwe Robert H | Viscous product dispensing squeeze bottle having a self-venting automatic shut-off valve |

| ATE49716T1 (de) * | 1985-01-28 | 1990-02-15 | Earl Wright Co | Schaumerzeuger. |

| DE8524966U1 (de) * | 1985-08-31 | 1987-01-22 | Bramlage Gmbh, 2842 Lohne | Schraubverschlußkappe für Flaschen oder dgl. |

| US4813577A (en) * | 1988-03-04 | 1989-03-21 | Carow International, Inc. | Multiple flow dispensing cap |

-

1989

- 1989-09-22 DE DE3931679A patent/DE3931679A1/de not_active Ceased

-

1990

- 1990-03-01 AR AR90316305A patent/AR244577A1/es active

- 1990-03-21 WO PCT/EP1990/000460 patent/WO1990011236A1/fr active Application Filing

- 1990-03-21 JP JP2504726A patent/JP2867179B2/ja not_active Expired - Fee Related

- 1990-03-21 BR BR909005967A patent/BR9005967A/pt not_active IP Right Cessation

- 1990-03-21 HU HU902832A patent/HU214724B/hu not_active IP Right Cessation

- 1990-03-21 CA CA002028850A patent/CA2028850A1/fr not_active Abandoned

- 1990-03-21 AU AU52737/90A patent/AU624933B2/en not_active Ceased

- 1990-03-22 DE DE90105423T patent/DE59002788D1/de not_active Expired - Fee Related

- 1990-03-22 DE DE59008985T patent/DE59008985D1/de not_active Expired - Fee Related

- 1990-03-22 ES ES93103462T patent/ES2080545T3/es not_active Expired - Lifetime

- 1990-03-22 EP EP93103461A patent/EP0551146B1/fr not_active Expired - Lifetime

- 1990-03-22 ES ES93103461T patent/ES2071521T3/es not_active Expired - Lifetime

- 1990-03-22 DE DE59009931T patent/DE59009931D1/de not_active Expired - Fee Related

- 1990-03-22 ES ES90105423T patent/ES2045604T3/es not_active Expired - Lifetime

- 1990-03-22 EP EP90105423A patent/EP0388947B1/fr not_active Expired - Lifetime

- 1990-03-22 EP EP93103462A patent/EP0550409B1/fr not_active Expired - Lifetime

Also Published As

| Publication number | Publication date |

|---|---|

| CA2028850A1 (fr) | 1990-09-25 |

| ES2071521T3 (es) | 1995-06-16 |

| HUT56036A (en) | 1991-07-29 |

| DE59008985D1 (de) | 1995-06-01 |

| AU5273790A (en) | 1990-10-22 |

| HU214724B (hu) | 1998-05-28 |

| EP0550409B1 (fr) | 1995-11-29 |

| BR9005967A (pt) | 1991-08-06 |

| AR244577A1 (es) | 1993-11-30 |

| AU624933B2 (en) | 1992-06-25 |

| ES2080545T3 (es) | 1996-02-01 |

| DE59009931D1 (de) | 1996-01-11 |

| ES2045604T3 (es) | 1994-01-16 |

| JPH03504826A (ja) | 1991-10-24 |

| JP2867179B2 (ja) | 1999-03-08 |

| EP0551146A1 (fr) | 1993-07-14 |

| EP0388947B1 (fr) | 1993-09-22 |

| DE59002788D1 (de) | 1993-10-28 |

| EP0388947A1 (fr) | 1990-09-26 |

| HU902832D0 (en) | 1991-06-28 |

| DE3931679A1 (de) | 1990-09-27 |

| WO1990011236A1 (fr) | 1990-10-04 |

| EP0550409A1 (fr) | 1993-07-07 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0551146B1 (fr) | Tête de pulvérisateur pour distribuer de la mousse | |

| DE60301829T2 (de) | Ausgabevorrichtung für einen Behälter mit einem Ventil | |

| DE3244645C2 (fr) | ||

| EP0850177B1 (fr) | Obturateur se fermant de lui-meme pourvu d'une membrane d'obturation | |

| EP0084638B1 (fr) | Distributeur pour produits pâteux | |

| DE69206988T2 (de) | Vorrichtung zum Spritzen einer vorbestimmten Dosis eines Mediums und Verfahren zum Füllen dieser Vorrichtung | |

| DE69706478T2 (de) | Behälter zum Mischen und Entnehmen von zwei darin enthaltenen Komponenten | |

| CH617146A5 (fr) | ||

| DE69413845T2 (de) | Knebelbetätigter spenderverschluss | |

| EP0097972A1 (fr) | Dispositif distributeur de produits pâteux | |

| DE2529139A1 (de) | Selbsttaetiger verschluss fuer einen druckbehaelter zur ausgabe von produkt in schaumform | |

| DE202006021269U1 (de) | Aerosolsprühaktuator | |

| DE3125187A1 (de) | Kindersichere schutzkappe fuer einen unter druck stehenden behaelter | |

| WO2004000066A1 (fr) | Tete de diffusion dotee d'une valve d'arret | |

| EP0347546A2 (fr) | Distributeur pour produits pâteux | |

| DE68903116T2 (de) | Spender fuer pastoese produkte, versehen mit einem zur seitlichen ausgabe dienenden axialen betaetigungskopf, und verhuellungselement fuer seine ausgabeoeffnung. | |

| DE3425900A1 (de) | Vorrichtung mit tropfenzaehler zum abgeben einer fluessigen oder pastoesen substanz | |

| DE60310319T2 (de) | Aerosol Abgabe-Vorrichtung | |

| WO2001094230A1 (fr) | Fermeture de buse basculante destinee a un recipient | |

| DE2153445A1 (de) | Betätigungsvorrichtung zum Steuern der Abgabe von Material aus einem Druckbehälter | |

| EP0691284B1 (fr) | Distributeur pour masses pâteuses | |

| DE69500279T2 (de) | Flüssigkeitsspender mit einem Abgabeventil und einem Druckknopf | |

| EP1118554A1 (fr) | Capuchon de pulvérisation avec tête intégrée | |

| DE1930969A1 (de) | Kappe fuer Aerosol-Spruehdosen | |

| EP1481734B1 (fr) | Fermeture par une tête de pulvérisation |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AC | Divisional application: reference to earlier application |

Ref document number: 388947 Country of ref document: EP |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): DE ES FR GB IT |

|

| 17P | Request for examination filed |

Effective date: 19930529 |

|

| 17Q | First examination report despatched |

Effective date: 19940301 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AC | Divisional application: reference to earlier application |

Ref document number: 388947 Country of ref document: EP |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): DE ES FR GB IT |

|

| ITF | It: translation for a ep patent filed | ||

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 19950501 |

|

| REF | Corresponds to: |

Ref document number: 59008985 Country of ref document: DE Date of ref document: 19950601 |

|

| ET | Fr: translation filed | ||

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2071521 Country of ref document: ES Kind code of ref document: T3 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20080326 Year of fee payment: 19 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20080327 Year of fee payment: 19 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20080317 Year of fee payment: 19 Ref country code: DE Payment date: 20080430 Year of fee payment: 19 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20080329 Year of fee payment: 19 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20090322 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20091130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091001 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090322 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091123 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20090323 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090323 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090322 |