EP0456147B1 - Structure de voie ferrée - Google Patents

Structure de voie ferrée Download PDFInfo

- Publication number

- EP0456147B1 EP0456147B1 EP19910107297 EP91107297A EP0456147B1 EP 0456147 B1 EP0456147 B1 EP 0456147B1 EP 19910107297 EP19910107297 EP 19910107297 EP 91107297 A EP91107297 A EP 91107297A EP 0456147 B1 EP0456147 B1 EP 0456147B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- wedge

- accordance

- track member

- trough

- structural part

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 239000004567 concrete Substances 0.000 claims description 18

- 241001669679 Eleotris Species 0.000 claims description 13

- 239000000463 material Substances 0.000 claims description 6

- 230000037431 insertion Effects 0.000 claims 4

- 238000003780 insertion Methods 0.000 claims 4

- 239000012858 resilient material Substances 0.000 claims 1

- 230000000284 resting effect Effects 0.000 claims 1

- 239000007779 soft material Substances 0.000 claims 1

- 229910000831 Steel Inorganic materials 0.000 description 5

- 239000010959 steel Substances 0.000 description 5

- 238000009415 formwork Methods 0.000 description 4

- 239000010426 asphalt Substances 0.000 description 3

- 150000001875 compounds Chemical class 0.000 description 3

- 238000004873 anchoring Methods 0.000 description 2

- 238000005266 casting Methods 0.000 description 2

- 238000010276 construction Methods 0.000 description 2

- 239000013013 elastic material Substances 0.000 description 2

- 238000011065 in-situ storage Methods 0.000 description 2

- 239000013521 mastic Substances 0.000 description 2

- 239000011178 precast concrete Substances 0.000 description 2

- 230000001133 acceleration Effects 0.000 description 1

- 238000012423 maintenance Methods 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 238000005096 rolling process Methods 0.000 description 1

- 238000007789 sealing Methods 0.000 description 1

- 238000003892 spreading Methods 0.000 description 1

- 238000003860 storage Methods 0.000 description 1

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E01—CONSTRUCTION OF ROADS, RAILWAYS, OR BRIDGES

- E01B—PERMANENT WAY; PERMANENT-WAY TOOLS; MACHINES FOR MAKING RAILWAYS OF ALL KINDS

- E01B29/00—Laying, rebuilding, or taking-up tracks; Tools or machines therefor

- E01B29/005—Making of concrete parts of the track in situ

-

- E—FIXED CONSTRUCTIONS

- E01—CONSTRUCTION OF ROADS, RAILWAYS, OR BRIDGES

- E01B—PERMANENT WAY; PERMANENT-WAY TOOLS; MACHINES FOR MAKING RAILWAYS OF ALL KINDS

- E01B1/00—Ballastway; Other means for supporting the sleepers or the track; Drainage of the ballastway

- E01B1/002—Ballastless track, e.g. concrete slab trackway, or with asphalt layers

-

- E—FIXED CONSTRUCTIONS

- E01—CONSTRUCTION OF ROADS, RAILWAYS, OR BRIDGES

- E01B—PERMANENT WAY; PERMANENT-WAY TOOLS; MACHINES FOR MAKING RAILWAYS OF ALL KINDS

- E01B2204/00—Characteristics of the track and its foundations

- E01B2204/01—Elastic layers other than rail-pads, e.g. sleeper-shoes, bituconcrete

-

- E—FIXED CONSTRUCTIONS

- E01—CONSTRUCTION OF ROADS, RAILWAYS, OR BRIDGES

- E01B—PERMANENT WAY; PERMANENT-WAY TOOLS; MACHINES FOR MAKING RAILWAYS OF ALL KINDS

- E01B2204/00—Characteristics of the track and its foundations

- E01B2204/09—Ballastless systems

Definitions

- the invention relates to a track body with rails arranged in pairs and transversely to sleepers, and to a device for its production, the sleepers with their end portions with the interposition of elastic documents in trough-like recesses of a rigid base are adopted.

- Such track bodies are known and described, for example, in the following publications: Austrian patent specifications 304 598, 308 168 and 316 607; European patent application 49 879; British Patent 1,033,350. It is also known from these publications to further subdivide the rigid underlay made from in-situ concrete, the individual plate-like elements of these underlays being separated from one another by insulating layers.

- This underlay made of concrete on site is manufactured in at least two work steps. First, the actual foundation plate is poured, on which the track body is then placed and aligned, and in which the end sections of the sleepers are fitted with sleeper shoes in the form of open half-boxes made of elastic material (Austrian patent specification 316 607).

- a track body is known from DE-OS 38 09 466, which consists of rails screwed to precast concrete sleepers.

- This track body is laid on support plates, which can be parts of a bridge structure, for example.

- the cross section of the precast concrete sleepers is trapezoidal and tapers upwards.

- the sleepers are not directly on the support plates on, rather they are glued to the support plate by a casting compound based on bitumen or plastic.

- Edge boundaries are arranged along the track body and at a distance from it. Both the sleeper compartments as well as the areas between the front sides of the sleepers and the mentioned edge boundaries are filled with an asphalt mastic or with mastic asphalt, the surface of this sealing compound being only slightly below the upper edge of the sleepers.

- a track body with such a structure is not very expedient, since repair and revision work, which is usually unavoidable at frequent intervals in the case of a busy track body, can only be carried out with extraordinary effort. Since all sleepers are practically cast in, the entire casting compound must first be removed over a long distance in such work so that the track body can be raised at all for such repair work and revision work. That should also be the reason why a track body with such a structure has so far not found a way into practice.

- SU-PS 1 131 954 which describes a track body with sleepers, on one side of which a wedge bevel is formed, so that the cross section through the sleeper is approximately trapezoidal in this area.

- These end sections of the threshold lie in a concrete body with corresponding recesses for receiving these sections.

- elastic insert plates are provided, on which these threshold sections should rest.

- a construction of this kind is not expedient, since it requires a double fit, which probably cannot be achieved with a concrete body manufactured on site.

- the threshold with its molded-on side wedge slope either hangs in this recess in the concrete body and does not rest on the elastic intermediate layer, so that this elastic intermediate layer cannot perform the function intended for it, or it lies on the elastic one Intermediate layer on, but then the wedge bevel has play with respect to the cheek of the recess and the threshold is therefore not sufficiently securely and firmly held in this recess.

- the invention aims at a track body of the type mentioned not only to be soundproofed, but also to anchor it on its base in such a way that the means used for its anchoring, despite the high mechanical vibration stress to which such a track body is subjected, maintain their position safely and reliably.

- the invention proposes those measures that are the content and subject of claim 1.

- a device serving this purpose has those features that are the content and subject of claim 9.

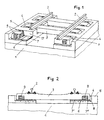

- the base plate 1 and 2 has a base plate 1 made on site and running along the route, which is cast from concrete.

- the rails 2 are fastened to sleepers 3, which are also made of concrete.

- the fastening means provided for this purpose are not shown for the sake of clarity.

- the end sections of the sleepers 3 lie in trough-like recesses 4 of a concrete body 5, which is also cast on site, plate-shaped elastic intermediate layers 7 being arranged between the underside of the end sections of the sleepers 3 and the bottom 6 of the trough-like recesses 4.

- these elastic intermediate layers 7 can consist of several parts 7 'and 7' 'of different elasticity.

- the bottom 6 of the trough-like recess 4 has a channel 8 surrounding the intermediate layer 7 (FIG. 2), which has a slope towards the center of the track body 2.

- the length and width of the trough-like recess 4 is dimensioned such that it encloses the end section of each threshold at a distance. Since considerable forces act on the track body during operational use both in the longitudinal direction and transversely thereto (braking and acceleration forces), the end sections of the sleeper 3 are fixed by wedges 9.

- wedges 9 are arranged in pairs on both sides of the respective end section of a threshold. It should be noted at this point that such wedges can also be arranged on the front end at the end sections of the threshold 3, and everything that is said in the following about the wedges shown in FIG. 1 also applies in an analogous manner to those wedges which are to be attached at the front to the end sections of the sleepers 3.

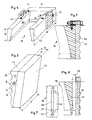

- Such a wedge is shown in an oblique view in FIG. 3. Its back 10 is profiled and has a plurality of horizontally running steps 11.

- the wedge is made in two parts. over its strength is in areas 13 and 14 of different elasticity.

- the area 13 of the wedge 9 provided for contacting the wall 17 of the trough-like recess 4 is made of a hard

- the area 14 provided for contacting the threshold 3 is made of a soft plastic material.

- bores 16 are provided in pairs on both sides, to which a lever-like tool can be attached in order to lift the wedge out of its operational position.

- the width 12 of the wedge 9 is smaller than the length of the end section of the threshold 3 and is approximately half or less of the same.

- the profiling on the back 10 of the wedge 9 interacts with a corresponding profiling on the wall 17 of the trough-like recess 4 and thereby secures the seat of the driven wedge 9.

- Fig. 4 now illustrates a U-shaped molded part 18, the axial extent 19 corresponds approximately to the height of the end portion of the threshold 3 and the cheek height 20 of the length of the trough-like recess 4.

- the molded part is expediently made of plastic.

- the inner cross-sectional profile of the shaped piece 18, viewed in the direction of its height 20, is approximately corresponding to the cross-sectional profile of the end section of the threshold 3.

- Such an assembly aid can be designed as a bracket that engages over the molded part 18.

- Insert plates 24 are arranged on the outside of the cheeks 22, the outside of which are correspondingly designed for profiling the rear side 10 of the wedges 9.

- the insert plate 24 (FIG. 5) lies flat against the cheeks 22 of the molded part 18.

- the insert plate 24 protrudes above the molded part 18 and is with its outstanding Section releasably connected to the molded part.

- Shafts can be arranged on the upper edge of the molded part, which carry bores through which horizontally lying fastening screws can be threaded.

- the insert plates 24 are arranged in vertically extending groove-like recesses 25 in the cheeks 22 of the molded part 19 and are guided through these undercut recesses 25.

- Spreading wedges 26 secure and fix their position.

- the width of these insert plates 24 corresponds approximately to the width 12 of the wedges 9 or is somewhat larger than this.

- the track body of the type shown in FIGS. 1 and 2 is now erected as follows: After the foundation plate 1 has been poured along the track route, the track grating assembled from the rails 2 and the sleepers 3 is placed and opposite the foundation plate 1 with length-adjustable spindles supported, aligned and leveled. At the end sections of the sleepers 3, the elastic intermediate layers 7 are already attached, preferably glued, at the factory. If the track grate is aligned and leveled in the manner described, a formwork is built parallel to and below the rails 3 for the concrete body 5 to be cast on site.

- the assembly aids for the molded parts 18 are removed, the fasteners between the molded part 18 and the insert plate 24 or the expansion wedge 26 are pulled out, and then the molded parts and then the insert plates 24 can be pulled out and removed and used again on a subsequent track section .

- the wedges 9 are then inserted and driven in. 1 and 2 show a track body erected in this way. During revision work on the track body, the wedges 9 are first pulled out. For this purpose, a lever-like tool, not shown here, is used, which is attached to the bores 16 of the wedges 9 and with which the wedges 9 are lifted out of their anchoring given by the profiling and then pulled out.

- the track grate consisting of the rails 2 and the sleepers 3 can be lifted up by means of threaded spindles or other lifting tools, so that, inter alia, the underside of the end sections of the sleepers 3 can be accessed, so that the elastic, possibly multi-part intermediate layer can be replaced .

- the wedge 9 is narrower than the length of the recess 4. It is conceivable to make the wedge 9 as long as the recess 4.

Landscapes

- Engineering & Computer Science (AREA)

- Architecture (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Machines For Laying And Maintaining Railways (AREA)

- Railway Tracks (AREA)

- Forms Removed On Construction Sites Or Auxiliary Members Thereof (AREA)

Claims (14)

- Corps de voie comportant des rails (2) agencés par paires et des traverses de retenue (3) agencées transversalement aux rails et reliées à ceux-ci, lesdites traverses reposant par leurs sections terminales sur des supports rigides (5), de préférence en béton, par-dessus des lames intermédiaires élastiques (7) intercalées et étant reçues dans des évidements en forme d'auge (4) pratiqués dans lesdits supports et entourées sur trois côtés lorsqu'on les observe du dessus, les lames intermédiaires élastiques (7) en forme de plaques étant prévues sur la partie inférieure des sections terminales des traverses (3) et au moins respectivement une clavette (9) étant prévue au moins entre les joues latérales des sections terminales des traverses (3) et la paroi respectivement voisine (17) de l'évidement en forme d'auge (4), la clavette enfichable (9) présentant sur sa partie postérieure (10) prévue pour l'application sur la paroi (17) de l'évidement en forme d'auge (4) un profilage sensiblement horizontal sous la forme d'ondulations ou de gradins (11) et la paroi (17) de l'évidement en forme d'auge (4) possédant, au moins dans la région sur laquelle la clavette enfichable (20) s'applique, un profilage correspondant à son profilage.

- Corps de voie selon la revendication 1, caractérisé en ce que la largeur (1) de la clavette (9) est inférieure à la longueur de la section terminale de la traverse (3) et atteint plus ou moins la moitié ou moins de celle-ci.

- Corps de voie selon la revendication 1, caractérisé en ce que la clavette (9) est constituée d'un matériau élastique.

- Corps de voie selon la revendication 1, caractérisé en ce que la clavette (9) présente sur ses zones épaissies (13, 14) une élasticité différente.

- Corps de voie selon la revendication 4, caractérisé en ce que la zone (13) de la clavette (9) prévue pour l'application sur la paroi (17) de l'évidement en forme d'auge (4) est constituée d'une matière plastique dure tandis que la zone (14) prévue pour l'application sur la traverse (3) est constituée d'une matière plastique relativement souple.

- Corps de voie selon la revendication 4 ou 5, caractérisé en ce que la zone (14) de la clavette (9) constituée d'un matériau souple présente sur sa longueur une épaisseur sensiblement constante (15).

- Corps de voie selon la revendication 5, caractérisé en ce que, dans la zone (13) de la clavette (9) constituée d'un matériau dur, sont prévus, par paires, sur les deux côtés de cette zone des alésages (16) pour y appliquer un outil.

- Corps de voie selon la revendication 1, caractérisé en ce que le fond (6) de l'évidement en forme d'auge (4), sur lequel s'applique la plaque intermédiaire élastique (7) de la section terminale de la traverse (3), possède une rigole (8) entourant la lame intermédiaire (7) et présentant une déclivité vis-à-vis de l'axe central longitudinal du corps de voie.

- Dispositif de fabrication d'un corps de voie selon l'une des revendications 1 à 8, caractérisé par une pièce moulée en forme de U (18), dont la dimension axiale (19) correspond plus ou moins à la hauteur de la section terminale de la traverse (3) et dont la hauteur des joues (20) correspond à la longueur de l'évidement en forme d'auge (4) et qui porte au moins sur les côtés externes de ses joues (22) des plaques rapportées (24), dont la face externe porte un profilage correspondant au profilage de la partie postérieure (10) des clavettes (9).

- Dispositif selon la revendication 9, caractérisé en ce que les plaques rapportées (24) s'appliquent sur les joues (22) de la pièce moulée (18) à plat et dépassent celles-ci vers le haut et sont raccordées de manière amovible avec la pièce moulée par leur section de transition (Fig. 4, 5).

- Dispositif selon la revendication 9, caractérisé en ce que les plaques rapportées (24) se trouvent dans des évidements (25) en forme de rainures ménagés dans les joues (22) de la pièce moulée (18) et peuvent y être fixées en place par des clavettes à écartement (26).

- Dispositif selon la revendication 9, caractérisé en ce que le profil interne en section transversale de la pièce moulée (18) - observé dans la direction de sa hauteur (20) - est conformé de manière plus ou moins correspondante au profil en section transversale de la section terminale de la traverse (3).

- Dispositif selon la revendication 9, caractérisé en ce qu'il est prévu sur le bord supérieur (21) des joues (22) de la pièce moulée (18) des douilles filetées (23) pour recevoir des vis de fixation par lesquelles des moyens de montage, par exemple, des étriers chevauchant la pièce moulée (18), peuvent être fixés de manière amovible.

- Dispositif selon la revendication 9, caractérisé en ce que la pièce moulée (18) et/ou la plaque rapportée (24) est ou sont constitués de matière plastique.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT102090A AT402210B (de) | 1990-05-07 | 1990-05-07 | Gleiskörper |

| AT1020/90 | 1990-05-07 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0456147A1 EP0456147A1 (fr) | 1991-11-13 |

| EP0456147B1 true EP0456147B1 (fr) | 1994-03-30 |

Family

ID=3505017

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP19910107297 Expired - Lifetime EP0456147B1 (fr) | 1990-05-07 | 1991-05-06 | Structure de voie ferrée |

Country Status (4)

| Country | Link |

|---|---|

| EP (1) | EP0456147B1 (fr) |

| AT (1) | AT402210B (fr) |

| DE (1) | DE59101256D1 (fr) |

| ES (1) | ES2054396T3 (fr) |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5826404A (en) * | 1993-08-02 | 1998-10-27 | Fuss; Gunter G. | System and method for use of loose fill packing materials |

| DE10325166B4 (de) | 2003-06-04 | 2006-11-23 | Graf von der Schulenburg-Wolfsburg, Günzel, Dr. | Gleisaufbau für schienengebundene Fahrzeuge, insbesondere Eisenbahnen |

| CN102979010B (zh) * | 2012-12-25 | 2015-05-20 | 西南交通大学 | 可抑制波磨的铁路小半径曲线轨道系统 |

| CN103437252B (zh) * | 2013-08-05 | 2016-02-03 | 北京市轨道交通设计研究院有限公司 | 一种轨道路基结构及其施工方法 |

| CN108396596A (zh) * | 2018-04-23 | 2018-08-14 | 杭州唐普徕科技有限公司 | 用于铁路轨道领域隧道的新型全预制装配式轨道结构 |

Family Cites Families (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR1387179A (fr) * | 1963-12-12 | 1965-01-29 | Ferroviaires Soc | Voie ferrée sans ballast et dispositif pour sa pose |

| AT304598B (de) * | 1971-01-21 | 1973-01-10 | Johann Hofer Dipl Ing | Elastische Lagerung von Bahnschwellen |

| AT308168B (de) * | 1971-12-06 | 1973-06-25 | Josef Sailler Dipl Ing | Elastische Lagerung von Bahnschwellen |

| AT316607B (de) * | 1972-01-13 | 1974-07-25 | Semperit Ag | Schwellenschuh |

| DE2926658A1 (de) * | 1978-08-10 | 1980-02-21 | Krems Huette Gmbh | Schotterloser bahnoberbau |

| US4303199A (en) * | 1978-08-22 | 1981-12-01 | Eisses Jacobus A | Restored vibration isolation for railway tracks |

| US4356968A (en) * | 1980-10-10 | 1982-11-02 | Stedef S.A. | Railroad tie cover |

| DE3315697A1 (de) * | 1983-04-29 | 1984-11-08 | Klöckner-Werke AG, 4100 Duisburg | Schallminderndes gleiselement |

| SU1131954A1 (ru) * | 1983-06-17 | 1984-12-30 | Государственный Ордена Трудового Красного Знамени Проектно-Изыскательский Институт "Метрогипротранс" | Путь метрополитена |

| AT382178B (de) * | 1985-10-02 | 1987-01-26 | Getzner Chemie Gmbh & Co | Gleiskoerper |

| DE3809466A1 (de) * | 1988-02-29 | 1989-09-07 | Kunz Alfred & Co | Oberbau fuer schienenbahnen |

-

1990

- 1990-05-07 AT AT102090A patent/AT402210B/de not_active IP Right Cessation

-

1991

- 1991-05-06 ES ES91107297T patent/ES2054396T3/es not_active Expired - Lifetime

- 1991-05-06 DE DE91107297T patent/DE59101256D1/de not_active Expired - Fee Related

- 1991-05-06 EP EP19910107297 patent/EP0456147B1/fr not_active Expired - Lifetime

Also Published As

| Publication number | Publication date |

|---|---|

| EP0456147A1 (fr) | 1991-11-13 |

| ES2054396T3 (es) | 1994-08-01 |

| DE59101256D1 (de) | 1994-05-05 |

| ATA102090A (de) | 1996-07-15 |

| AT402210B (de) | 1997-03-25 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0510497B1 (fr) | Superstructure de voie-ferrée sans ballast | |

| DE4415363C1 (de) | Eine feste Fahrbahn bildender Oberbau für Schienenbahnen, insb. für Brücken und Verfahren zu seiner Herstellung | |

| DE19519745C2 (de) | Schotterloser Gleisoberbau | |

| AT410329B (de) | Schotterloser oberbau | |

| EP0456147B1 (fr) | Structure de voie ferrée | |

| DE4205192C2 (de) | Bahnsteig | |

| EP0894897A1 (fr) | Procédé de réalisation d'une voie | |

| EP0637645B1 (fr) | Voie rigide pour circulation sur rails | |

| DD284066A5 (de) | Anordnung zur ausbildung von eisenbahnoberbauten | |

| AT409641B (de) | Schotterloser oberbau mit vorgefertigten betontragplatten sowie verfahren zum ersatz derselben | |

| EP0546380B1 (fr) | Structure de voie ferrée | |

| DE7830516U1 (de) | Vorgefertigtes bauelement fuer mauern | |

| CH715209B1 (de) | Gleiskörperübergangseinheit zwischen einem Schottergleisabschnitt und einem schotterlosen Gleisabschnitt. | |

| AT404742B (de) | Gleis mit schienen für schienengebundene fahrzeuge | |

| AT411694B (de) | Einrichtung zur elastischen lagerung einer rillenschiene | |

| EP3617404B1 (fr) | Rail de roulement et structure de voie dotée du rail de roulement | |

| DE3440247A1 (de) | Schalung fuer serienfertigteile aus stahlbeton, vornehmlich fuer vorgespannte weichenschwellen | |

| EP0826827A2 (fr) | Elément en caoutchouc pour l'habillage d'une traverse de chemin de fer en béton et procédé d'installation de l'élément en caoutchouc dans une traverse de chemin de fer | |

| DE1534073C3 (de) | Vorrichtung zum Abstützen einer Schiene | |

| DE4236191A1 (de) | Bahnkörper | |

| DE4335877A1 (de) | Schotterloser Oberbau mit Betonschwellen | |

| AT409391B (de) | Schotterloser oberbau sowie verfahren zur herstellung desselben | |

| DE19538712A1 (de) | Eisenbahnschwelle aus Spannbeton sowie unter Verwendung dieser Schwelle hergestellter Eisenbahnoberbau | |

| DE19920075A1 (de) | Lagerung einer Schiene für Schienenfahrzeuge | |

| EP2800833A1 (fr) | Voie ferrée sans ballast |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): BE CH DE ES FR GB IT LI LU NL SE |

|

| 17P | Request for examination filed |

Effective date: 19920116 |

|

| 17Q | First examination report despatched |

Effective date: 19921223 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): BE CH DE ES FR GB IT LI LU NL SE |

|

| REF | Corresponds to: |

Ref document number: 59101256 Country of ref document: DE Date of ref document: 19940505 |

|

| ITF | It: translation for a ep patent filed | ||

| EPTA | Lu: last paid annual fee | ||

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2054396 Country of ref document: ES Kind code of ref document: T3 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 19940706 |

|

| ET | Fr: translation filed | ||

| EAL | Se: european patent in force in sweden |

Ref document number: 91107297.3 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 19990420 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 19990427 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 19990429 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19990505 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 19990517 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: LU Payment date: 19990518 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19990528 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 19990531 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19990717 Year of fee payment: 9 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20000506 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20000506 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20000507 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: THE PATENT HAS BEEN ANNULLED BY A DECISION OF A NATIONAL AUTHORITY Effective date: 20000508 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20000531 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20000531 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20000531 |

|

| BERE | Be: lapsed |

Owner name: GETZNER-CHEMIE G.M.B.H. Effective date: 20000531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20001201 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20000506 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| EUG | Se: european patent has lapsed |

Ref document number: 91107297.3 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20010131 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee |

Effective date: 20001201 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20010301 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20020204 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20050506 |