EP0417406B1 - Machine de fabrication de tablettes à table tournante - Google Patents

Machine de fabrication de tablettes à table tournante Download PDFInfo

- Publication number

- EP0417406B1 EP0417406B1 EP90111313A EP90111313A EP0417406B1 EP 0417406 B1 EP0417406 B1 EP 0417406B1 EP 90111313 A EP90111313 A EP 90111313A EP 90111313 A EP90111313 A EP 90111313A EP 0417406 B1 EP0417406 B1 EP 0417406B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- tabletting machine

- punches

- machine according

- cam ring

- guided

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 239000000314 lubricant Substances 0.000 claims abstract description 13

- 239000011159 matrix material Substances 0.000 claims abstract 4

- 238000005096 rolling process Methods 0.000 claims 1

- 239000000463 material Substances 0.000 description 6

- 238000005259 measurement Methods 0.000 description 4

- 238000011109 contamination Methods 0.000 description 3

- 238000011156 evaluation Methods 0.000 description 3

- 238000005461 lubrication Methods 0.000 description 2

- 238000004140 cleaning Methods 0.000 description 1

- 230000006835 compression Effects 0.000 description 1

- 238000007906 compression Methods 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- 238000000034 method Methods 0.000 description 1

- 230000003287 optical effect Effects 0.000 description 1

- 230000001960 triggered effect Effects 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B30—PRESSES

- B30B—PRESSES IN GENERAL

- B30B11/00—Presses specially adapted for forming shaped articles from material in particulate or plastic state, e.g. briquetting presses, tabletting presses

- B30B11/005—Control arrangements

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B30—PRESSES

- B30B—PRESSES IN GENERAL

- B30B15/00—Details of, or accessories for, presses; Auxiliary measures in connection with pressing

- B30B15/0094—Press load monitoring means

Definitions

- the invention relates to a rotary tableting machine with a die plate rotatably mounted in a housing and connected to a drive shaft, in which upper and lower punches are guided, the position of which is controlled by annular curves when the die plate rotates.

- They are designed as cam rings, each of which is provided with an annular groove in the manner of a control cam in which the stamp heads are guided.

- the cam rings and control cams are used to move the individual punches up and down in the guides of a rotor, that is to say in their axial direction, when a die disk rotates. These movements However, they are stiff when the stamps and their stamp guides are dusty due to the press material to be pressed by the stamps. Lubricants, which are used for smooth movement of the punches, also contribute to such contamination.

- the object of the invention is to provide an arrangement which makes it possible to continuously reduce the frictional resistance of the punches during the rotation of a die plate to be able to determine in order to be able to take appropriate measures, such as for example a lubricant supply, in good time with a relatively high frictional resistance and thus to improve the operational safety of the machine with little effort.

- the upper punches are guided in a cam ring which is rotatably mounted to the housing and the drive shaft and is connected to a measuring device for its torque.

- the invention is therefore based on the knowledge that the greater the friction of the punches in their guides, the greater the forces exerted by the punches when they rotate on the guides or directly on the cam rings, in particular also in their bores intended for axial guidance in the rotor. These forces and thus the frictional resistance that the punches have to overcome during their movements can be measured as the torque of the cam ring when it is rotatably mounted.

- the cam ring can be connected to an inner support ring which is roller-mounted on the drive shaft and carries a lever arm which is connected to a load cell.

- the lever arm is also arranged, for example, directly on the cam ring can be. Rather, the decisive factor is that the cam ring itself is easily rotatable on the one hand relative to the housing, and on the other hand is rotatably mounted with respect to the drive shaft so that it is not carried along by it, but solely through the influence of the frictional forces.

- the solution according to the invention can also be used in the same way for the lower punches.

- the upper punches normally have to be driven with very little lubrication in order to avoid that the material to be pressed below the upper punches is contaminated by lubricants, the measurement of the friction of the upper punches is of relatively greater importance compared to the lower punches.

- the solution according to the invention has the particular advantage that the frictional resistance is measured not only at a specific point on a control curve or the continuous curve in order to measure the stiffness of individual stamps, but across the entire curve. It is possible to electronically evaluate the measured torque using a computer and to control the lubricant supply to the punches as a function of the measurement results obtained.

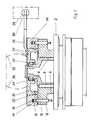

- the rotary tablet machine shown in the drawing has a rotatable driven die plate 2 which is connected to a drive shaft 4.

- the die plate 2 is provided with a plurality of dies not shown in the drawing, which are arranged evenly distributed over the circumference.

- compressed material from tablets with lower punches and upper punches 12 is pressed together.

- the upper punches are guided axially adjustable in bores 10 which are located in a rotor 6 which is connected to the drive shaft 4 by a driver 8.

- a cam ring 14 is provided, which has an annular groove 16, which is effective as a control curve for the stamp heads 18 and the stamp 12.

- the cam ring 14 is designed as a partial ring, as can be seen in FIG. 2.

- the pre-printing station with the pre-pressure roller 36 and the main printing station with the main pressure roller 38.

- the compression material 36 is pressed first by the pre-pressure roller 36 and then by the main pressure roller 38.

- the die plate 2 with the rotor 6 and the punches 12 rotate in the guides 10 according to the arrow 32 in FIG. 2 counterclockwise.

- the cam ring 14 is connected by screws 20 to a support ring 22 which is roller-mounted on the drive shaft 4 by a bearing 24.

- This support ring carries a lever arm 26 which extends radially outward beyond the cam ring 14 and interacts with a load cell 28 which is mounted on a stationary housing part 30.

- the lever arm 26 is connected to the support ring 22 with screws 34.

- stamp If a stamp is subjected to greater friction during its movement, a force has to be exerted to overcome the resistance, which is symbolically represented in FIG. 2 by the arrow 40.

- the sum of the resistance forces of all stamps which have to be overcome when the stamp is moved Stamp during the rotation of the die plate 2 acts as a torque via the lever 26 on the load cell 28. Via this load cell, the frictional resistance can thus be measured, namely continuously over the entire course of the curve of the annular groove 16 or control curve and the guide bores 10, within which the stamp 12 move as it rotates.

- the measurement result to be determined continuously can be used, among other things, for controlling the supply of lubricants, in particular for the bores 10 of the rotor 6, but also for the supply of lubricants for the heads 18 of the stamps 12.

- the load cell 28 has, for example, a known strain gauge for this purpose, which outputs a signal to an amplifier 44 for the purpose of further electronic evaluation.

- the load cell 28 thus corresponds in principle to a known Wheatstone bridge 42. According to FIG. 3, the amplifier sends the signal to an analog-to-digital converter 46, which inputs the digital result into a computer 48, in which an evaluation takes place.

- a signal can be triggered via the computer 48 via a signal transmitter 50, for example, in such a way that lubricants are added or, for example, the machine is stopped for the purpose of cleaning.

- a signal transmitter 50 for example, in such a way that lubricants are added or, for example, the machine is stopped for the purpose of cleaning.

- an alarm system of an optical or acoustic type There is also the possibility of triggering an alarm system of an optical or acoustic type.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Medical Preparation Storing Or Oral Administration Devices (AREA)

- Medicinal Preparation (AREA)

- Formation And Processing Of Food Products (AREA)

- Processing And Handling Of Plastics And Other Materials For Molding In General (AREA)

- Basic Packing Technique (AREA)

- Forging (AREA)

- Encapsulation Of And Coatings For Semiconductor Or Solid State Devices (AREA)

Claims (6)

- Machine de fabrication de tablettes à table tournante avec un disque de matrice positionné en étant rotatif dans un bâti et relié à un arbre primaire, disque de matrice dans lequel des poinçons supérieurs et inférieurs sont guidés dont la position est commandée, lors de la rotation du disque de matrice, par des cames annulaires, caractérisée en ce que les poinçons supérieurs (12) sont guidés dans un anneau à cames (14) qui est positionné en étant mobile en rotation par rapport au bâti (30) et à l'arbre primaire (4) et qui est relié à un dispositif de mesure (28, 42) pour son couple de rotation.

- Machine de fabrication de tablettes selon la revendication 1, caractérisée en ce que l'anneau à cames (14) est relié à un anneau porteur situé à l'intérieur (22) qui est positionné sur un palier à roulement sur l'arbre primaire (4).

- Machine de fabrication de tablettes selon la revendication 2, caractérisée en ce que l'anneau porteur (22) porte un bras de levier (26) qui est raccordé à une boîte dynamométrique (28).

- Machine de fabrication de tablettes selon la revendication 3, caractérisée en ce que la boîte dynamométrique (28) est pourvue d'un pont de Wheatstone (42).

- Machine de fabrication de tablettes selon la revendication 1, caractérisée en ce que le bras de levier (26) est placé en étant en saillie vers l'extérieur derrière le galet principal de pression (38) radialement au-dessus de l'anneau à cames (14).

- Machine de fabrication de tablettes selon la revendication 1, caractérisée en ce que le couple de rotation mesuré est exploité électroniquement par un ordinateur (48) pour la commande de l'amenée de lubrifiant des poinçons supérieurs (12).

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT90111313T ATE94808T1 (de) | 1989-09-09 | 1990-06-15 | Rundlauf-tablettiermaschine. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE3930127A DE3930127A1 (de) | 1989-09-09 | 1989-09-09 | Rundlauf-tablettiermaschine |

| DE3930127 | 1989-09-09 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0417406A2 EP0417406A2 (fr) | 1991-03-20 |

| EP0417406A3 EP0417406A3 (en) | 1991-08-28 |

| EP0417406B1 true EP0417406B1 (fr) | 1993-09-22 |

Family

ID=6389067

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP90111313A Expired - Lifetime EP0417406B1 (fr) | 1989-09-09 | 1990-06-15 | Machine de fabrication de tablettes à table tournante |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US5071336A (fr) |

| EP (1) | EP0417406B1 (fr) |

| AT (1) | ATE94808T1 (fr) |

| DE (2) | DE3930127A1 (fr) |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE10026731C2 (de) * | 2000-05-17 | 2002-08-14 | Fette Wilhelm Gmbh | Rundläufer-Tablettenpresse für die Herstellung von mehrschichtigen Tabletten |

| DE102005019132B4 (de) * | 2005-04-20 | 2007-08-16 | Korsch Ag | Verfahren und Vorrichtung zur Kalibrierung einer Rundläufer-Tablettiermaschine durch Simulation einer Schwergängigkeit wenigstens eines Oberstempels und/oder wenigstens eines Unterstempels |

| DE102005030312B4 (de) * | 2005-06-23 | 2011-05-05 | Korsch Ag | Rundläufer-Tablettiermaschine und Verfahren zur Herstellung einer Mehrschichttablette |

| DK177589B1 (en) | 2012-01-20 | 2013-11-04 | Kronberg Aps | Pelletizer press and method for the treatment of dust particles of metals |

| CN104443581B (zh) * | 2014-12-01 | 2016-03-09 | 舟山市鲨鱼制药机械有限公司 | 一种机械式数片机的缺粒检测装置及检测方法 |

Family Cites Families (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3158111A (en) * | 1962-06-06 | 1964-11-24 | Smith Kline French Lab | Method and apparatus for forming tablets |

| DE1627931C3 (de) * | 1967-12-11 | 1973-11-08 | Kilian & Co Gmbh, 5000 Koeln | Tablettenpresse |

| US3579217A (en) * | 1968-06-10 | 1971-05-18 | Thomas Machinery Corp | Method and apparatus for detecting and indicating malfunction of a tableting machine |

| US3891375A (en) * | 1974-01-21 | 1975-06-24 | Vector Corp | Tablet press |

| DE2628770C3 (de) * | 1976-06-26 | 1980-07-10 | Kikusui Seisakusho Ltd., Kyoto (Japan) | Tablettenpresse |

| US4047866A (en) * | 1976-11-22 | 1977-09-13 | The Dow Chemical Company | Automatic self-lubricating rotary tablet press |

| DE2742572B1 (de) * | 1977-09-22 | 1979-03-29 | Fette Wilhelm Gmbh | Verfahren zum Herstellen von Tabletten und Tablettenpresse |

| JPS5614098A (en) * | 1979-07-13 | 1981-02-10 | Takeda Chem Ind Ltd | Externally lubricating tablet making machine |

| DE3131388A1 (de) * | 1981-08-07 | 1983-02-24 | GAO Gesellschaft für Automation und Organisation mbH, 8000 München | Stapelvorrichtung fuer blattgut |

-

1989

- 1989-09-09 DE DE3930127A patent/DE3930127A1/de active Granted

-

1990

- 1990-06-15 AT AT90111313T patent/ATE94808T1/de not_active IP Right Cessation

- 1990-06-15 DE DE90111313T patent/DE59002827D1/de not_active Expired - Fee Related

- 1990-06-15 EP EP90111313A patent/EP0417406B1/fr not_active Expired - Lifetime

- 1990-08-31 US US07/577,924 patent/US5071336A/en not_active Expired - Lifetime

Also Published As

| Publication number | Publication date |

|---|---|

| DE3930127C2 (fr) | 1991-11-14 |

| US5071336A (en) | 1991-12-10 |

| EP0417406A2 (fr) | 1991-03-20 |

| DE59002827D1 (de) | 1993-10-28 |

| EP0417406A3 (en) | 1991-08-28 |

| ATE94808T1 (de) | 1993-10-15 |

| DE3930127A1 (de) | 1991-03-21 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1754566B1 (fr) | Table à transfert circulaire munie d'un dispositif de commande | |

| DE2703535C2 (de) | Wälzmühle | |

| EP0431269B1 (fr) | Procédé et dispositif de surveillance des forces de compression d'une machine de production des comprimés | |

| EP0204266B1 (fr) | Presse à tablettes | |

| EP0723858B1 (fr) | Procédé pour la génération d'un diagramme force-distance des pistons d'une presse rotative à comprimées | |

| EP0417406B1 (fr) | Machine de fabrication de tablettes à table tournante | |

| DE2530365B2 (de) | Einrichtung zur Durchmesserverstellung eines Zylinders | |

| DE2110294B2 (de) | Vorrichtung zum Pressen pulverisierten Materials | |

| DE2743561B2 (de) | Vorrichtung zum Außerbetriebsetzen des Schneidbetriebes an einem Rotationsquerschneider | |

| DE8910771U1 (de) | Rundlauf-Tablettiermaschine | |

| DE2245866A1 (de) | Vorrichtung zum ausgleich der spindelbelastungen bei zweistaender-maschinen | |

| DE19940701C2 (de) | Rundlaufpresse | |

| DE874942C (de) | Rundstrickmaschine mit einem oder mehreren Nadelbetten | |

| DE711160C (de) | Vorrichtung zum Erzielen einer gleichmaessigen Beruehrung und eines gleichmaessig verteilten Anpressdruckes zwischen zwei annaehernd achsparallel angeordneten Walzen | |

| DE2141382A1 (de) | Tablettenmaschine mit vorrichtung zur messung der presskraft und ausstosskraft | |

| EP2012967B1 (fr) | Entraînement pour une unité de transfert circulaire | |

| DE2519508A1 (de) | Einstellvorrichtung fuer den abstand zwischen walzen | |

| DE2450973A1 (de) | Vorrichtung zur vollautomatischen hubverstellung bei doppelstaenderpressen mit zweipunktantrieb in sogenannter querwellenausfuehrung | |

| EP3437846B1 (fr) | Poinçon servant à la production de comprimés | |

| DE1627931A1 (de) | Tablettierpresse | |

| EP3517289B1 (fr) | Pression rail réglable pour presse à table tournante à mesure de la force de pression intégrée | |

| DE2424311C3 (de) | Druckwerk | |

| DE1962427A1 (de) | Walzgeruest mit Anstellvorrichtung sowie Verfahren zum Walzen und Dressieren | |

| DE607146C (de) | Selbsttaetig arbeitende Presse fuer pulverfoermiges Arbeitsgut mit in einer Trommel radial angeordneten Pressstellen | |

| DE1577395C (de) | Vorrichtung zum Hinterschleifen von Werkzeugen |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH DE FR GB IT LI |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH DE FR GB IT LI |

|

| 17P | Request for examination filed |

Effective date: 19910904 |

|

| 17Q | First examination report despatched |

Effective date: 19921120 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE FR GB IT LI |

|

| REF | Corresponds to: |

Ref document number: 94808 Country of ref document: AT Date of ref document: 19931015 Kind code of ref document: T |

|

| ITF | It: translation for a ep patent filed | ||

| REF | Corresponds to: |

Ref document number: 59002827 Country of ref document: DE Date of ref document: 19931028 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 19931013 |

|

| ET | Fr: translation filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 19940803 Year of fee payment: 5 |

|

| 26N | No opposition filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 19950613 Year of fee payment: 6 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Effective date: 19950630 |

|

| BERE | Be: lapsed |

Owner name: WILHELM FETTE G.M.B.H. Effective date: 19950630 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Effective date: 19960615 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20080522 Year of fee payment: 19 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20080423 Year of fee payment: 19 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20080408 Year of fee payment: 19 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20080617 Year of fee payment: 19 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20080618 Year of fee payment: 19 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20090615 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20100226 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090630 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090630 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090630 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090615 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100101 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090615 |