EP0384044B2 - Véhicule pour le transport d'une pile de pierres séparées - Google Patents

Véhicule pour le transport d'une pile de pierres séparées Download PDFInfo

- Publication number

- EP0384044B2 EP0384044B2 EP89202014A EP89202014A EP0384044B2 EP 0384044 B2 EP0384044 B2 EP 0384044B2 EP 89202014 A EP89202014 A EP 89202014A EP 89202014 A EP89202014 A EP 89202014A EP 0384044 B2 EP0384044 B2 EP 0384044B2

- Authority

- EP

- European Patent Office

- Prior art keywords

- arms

- frame

- stones

- front wheels

- support

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 239000004575 stone Substances 0.000 title claims abstract description 46

- 230000007246 mechanism Effects 0.000 claims description 9

- 230000001360 synchronised effect Effects 0.000 claims 1

- 239000011449 brick Substances 0.000 abstract 3

- 238000010276 construction Methods 0.000 description 3

- 230000005484 gravity Effects 0.000 description 2

- 239000000446 fuel Substances 0.000 description 1

- 239000002828 fuel tank Substances 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 239000000203 mixture Substances 0.000 description 1

- 239000004576 sand Substances 0.000 description 1

- 239000000725 suspension Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B66—HOISTING; LIFTING; HAULING

- B66F—HOISTING, LIFTING, HAULING OR PUSHING, NOT OTHERWISE PROVIDED FOR, e.g. DEVICES WHICH APPLY A LIFTING OR PUSHING FORCE DIRECTLY TO THE SURFACE OF A LOAD

- B66F9/00—Devices for lifting or lowering bulky or heavy goods for loading or unloading purposes

- B66F9/06—Devices for lifting or lowering bulky or heavy goods for loading or unloading purposes movable, with their loads, on wheels or the like, e.g. fork-lift trucks

- B66F9/065—Devices for lifting or lowering bulky or heavy goods for loading or unloading purposes movable, with their loads, on wheels or the like, e.g. fork-lift trucks non-masted

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B66—HOISTING; LIFTING; HAULING

- B66F—HOISTING, LIFTING, HAULING OR PUSHING, NOT OTHERWISE PROVIDED FOR, e.g. DEVICES WHICH APPLY A LIFTING OR PUSHING FORCE DIRECTLY TO THE SURFACE OF A LOAD

- B66F9/00—Devices for lifting or lowering bulky or heavy goods for loading or unloading purposes

- B66F9/06—Devices for lifting or lowering bulky or heavy goods for loading or unloading purposes movable, with their loads, on wheels or the like, e.g. fork-lift trucks

- B66F9/075—Constructional features or details

- B66F9/12—Platforms; Forks; Other load supporting or gripping members

- B66F9/18—Load gripping or retaining means

- B66F9/188—Stacked-bricks lifting devices

Definitions

- the invention relates to a vehicle for transporting a stack of loose stones, which has a frame which is supported by two front wheels and at least one rear wheel, means mounted on this frame for driving at least the front wheels, one in front of the front wheels the frame-mounted device for carrying the stones, which device comprises two arms which protrude forward and move sideways away from one another and can be adjusted towards one another for clamping one or more rows of stones at the bottom of the stack and means for adjusting these arms laterally relative to one another and means for Moving this facility includes.

- the holding device for carrying stone sits vertically slidably mounted on a mast frame, which can be pivoted a little even with respect to the other parts of the frame is.

- This construction allows the stones to be displaced in great heights, but it is complicated and in no way compact.

- the stones are normally moved purely vertically, without the need for a support on the rear side of the holding device.

- GB-A-965 601 describes a device for carrying stones which has a straight standing back wall. But even in this case, the device is designed to be mounted on a mast that can only be moved vertically. This device also does not include a pair of adjustable arms, but fork fingers, and the back wall mainly forms a stop for the stones when the fork fingers are inserted through openings in a stack of stones.

- a vehicle for transporting cuboid containers is known, with a holding device which has two arms which grip the bottom container in a clamp handle and a back support. At the lower end of this holding device is a bearing, around which the loaded device can be pivoted backwards so that its center of gravity lies in the center of gravity of the axis of the front wheel.

- the vehicle itself is a work vehicle with driven rear wheels that is hand-guided by an attendant operator and is not suitable for transporting objects as heavy as stones.

- the proximity of the pivot point of the holding device to this leads to the fact that at the beginning of the pivoting the underside, in particular its corner area, predominantly slides horizontally on the ground and only detaches from it after a significant pivot angle has been reached. In the case of flexible suspension or tires, the pivoting may even become impossible with heavy loads, or the vehicle is thereby reset by one step, with a corresponding risk of an accident.

- the invention is intended to create a vehicle for transporting a stack of loose stones, which has a relatively simple construction, but can be transported very quickly with the stack of loose stones can also be carried out very easily and can drive over it without risk of damage to the paving already laid.

- the device for carrying the stones is a holding device which, in addition to the arms and the means, also has an almost flat support which rises from the bottom upwards on the back of the arms in front of the front wheels and about a horizontal axis which is in one Distance behind the support is located near the axis of rotation of the front wheels, is pivotally mounted directly on the frame, the support being inclined upwards and backwards when the device is rotated, around the rows of stones clamped between the arms and rows above them Supporting stones and the two arms for distributing the pressure of the rows of stones gripped between the arms are provided on their mutually facing side with feet, which are articulated about a vertical axis on the arms.

- the stones can thereby be lifted in a very simple manner by simply rotating the holding device at the same time and stored stably for transport, the feet ensuring that the stones are held securely at their prescribed height in a sufficiently secure manner that parts protruding below and grinding when angled Stones are avoided. This is particularly advantageous when paving stones are loaded onto pavement that has already been laid.

- the front wheels are rigid with respect to the frame, that is to say they cannot be pivoted, and the means which drive at least the front wheels are those which drive the front wheels separately.

- the rear wheel is preferably a steering wheel.

- the vehicle is very easy to steer and can turn quite closely.

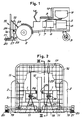

- the vehicle shown in Fig. 1 for transporting a stack of loose stones comprises a frame 1 which is supported by two rigid front wheels 2 and two rear steering wheels 3.

- the vehicle is a self-propelled vehicle with a fuel engine 4, which is fed by an overhead fuel tank 5.

- This motor 4 drives a hydraulic compressor 6.

- the compressor 6 is connected via a distributor 7 on the one hand via a line 8 to an oil tank 9 and on the other hand via lines not shown in the drawing with two hydraulic motors 10 and cylinder-piston mechanisms 11 and 12, as will be described below.

- the front wheels 2 are each driven by one of the hydraulic motors 10, which are fastened to cross members, which are parts of the frame 1. They are steered separately by a driver sitting on a seat 13 by means of two levers 14.

- the vehicle When the two motors 10 are running at the same speed, the vehicle is traveling straight. By increasing the speed of one of the motors 10, one can steer the vehicle, also thanks to the fact that the rear wheels are steering wheels 3. The vehicle can turn very tightly and almost on the spot, without damaging any pavement that the vehicle has already laid over.

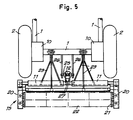

- a holding device 15 is pivotally mounted on the frame 1.

- This holding device 15 contains one from below top-extending, almost flat support, which consists of a frame 16 made of metal tubes and a net 17 welded thereon.

- the underside of the frame is formed from a horizontal, hollow square tube 18 which extends in the transverse direction of the vehicle.

- a square support tube 19 is displaceable, which carries an arm 20 at its end.

- the two arms 20 on the two support tubes 19 extend on both sides of the support 16, 17 to the front, practically at right angles to the level of the support 16, 17. They are each provided on their mutually facing sides with two feet 21 articulated about a vertical axis , which match two rows of stones.

- these stones are drawn in dash-dotted lines and given the reference number 22. Because the feet 21 are articulated, the pressure exerted by the two arms 20 on the rows of stones 22 is distributed evenly over the two rows, even if the row lengths are not exactly the same.

- the two arms 20 can be moved towards and from each other by means of the two cylinder-piston mechanisms 11, the cylinders of which are fastened on top of the tube 18 and the pistons of which are connected to ends of the respective two arms 20 projecting from the rear of the support 16, 17 be pushed away.

- the two cylinder-piston mechanisms are of course operated together, so that the two arms 20 are pushed towards or away from each other at the same time.

- the pivoting of the support 16, 17 and thus the complete holding device 15 is effected by the cylinder-piston mechanism 12, the cylinder of which is articulated at a small distance behind the support 16, 17 on the horizontal axis 24, specifically via two horizontal arms 26 welded to the top of two profile frames, which are extend between the wheels 2 at the front of the frame 1.

- the piston is articulated to two small arms 27 which are welded to the back of the hollow tube 18.

- the holding device 15 can be pivoted between the position shown in FIGS. 1 to 3 and the position shown in FIG. 4.

- the vehicle is relatively compact and easy to steer.

Landscapes

- Engineering & Computer Science (AREA)

- Transportation (AREA)

- Structural Engineering (AREA)

- Civil Engineering (AREA)

- Life Sciences & Earth Sciences (AREA)

- Geology (AREA)

- Mechanical Engineering (AREA)

- Handcart (AREA)

- Machines For Laying And Maintaining Railways (AREA)

- Forklifts And Lifting Vehicles (AREA)

Claims (7)

- Véhicule pour transporter un tas de pierres en vrac (22), qui comprend un châssis (1) qui est porté par deux roues avant (12) et par au moins une roue arrière (3), des moyens (4, 6, 10) montés sur ce châssis (1) pour entraîner au moins les roues avant (2), un mécanisme (15) disposé devant les roues avant (2) et monté en mobilité sur le châssis (1), pour le transport des pierres (22) - ledit mécanisme comprenant deux bras (20) faisant saillie vers l'avant et aptes à se déplacer l'un par-dessus l'autre et l'un à l'écart de l'autre en direction latérale pour enserrer entre eux une ou plusieurs rangées de pierres (22) se trouvant à la base du tas, et des moyens (11) pour déplacer ces bras (20) l'un par rapport à l'autre en direction latérale - ainsi que des agents (10) pour déplacer ce mécanisme, caractérisé en ce que le mécanisme (15) est un dispositif de retenue qui possède, en dehors des bras (20) et des moyens (11), également un support pratiquement plat (16, 17) faisant saillie de bas en haut devant les roues avant (2) sur le côté dorsal des bras (20) et qui est monté directement sur le châssis (1) en pivotement autour d'un axe horizontal (24) qui se trouve à une certaine distance derrière le support (16, 17) à proximité de l'axe de rotation des roues avant, en ce que le support (16, 17), dans la position du dispositif de retenue (15) dans laquelle ce dernier a effectué une rotation, est orienté en inclinaison vers le haut et vers l'arrière pour soutenir les rangées de pierres (22) enserrées entre les bras (20) et des rangées de pierres (22) disposées par-dessus, et en ce que les deux bras (20) sont munis, sur leurs côtés orientés l'un vers l'autre, de petits pieds (21) pour répartir la pression des rangées de pierres (22) saisies entre les bras, qui sont fixés aux bras (20) en articulation autour d'un axe vertical.

- Véhicule selon la revendication 1, caractérisé en ce que les moyens (12) pour faire tourner le dispositif de retenue (15) contiennent un mécanisme (12) à piston-cylindre dont la partie stationnaire est fixée en articulation sur le châssis (1) entre le support (16, 17) et l'axe horizontal (24), respectivement dont la partie déplaçable est fixée en bas en articulation (en 25) au dispositif de retenue (15).

- Véhicule selon la revendication 1 ou 2, caractérisé en ce que le support (16, 17) du dispositif de retenue (15) contient un cadre (16) et un treillis (17) fixé par-dessus, le cadre (16) étant soudé à demeure à deux groupes de barres (23) qui sont montées en rotation derrière le cadre sur l'axe horizontal (24).

- Véhicule selon l'une quelconque des revendications 1 à 3, caractérisé en ce que les roues avant (2) ne sont pas à même de pivoter par rapport au châssis (1), les moyens (4, 6, 10) qui entraînent au moins les roues avant (2) entraînant ces dernières respectivement de manière séparée.

- Véhicule selon la revendication 4, caractérisé en ce que la roue arrière (3) est une roue directrice.

- Véhicule selon l'une quelconque des revendications 4 à 5, caractérisé en ce que les moyens d'entraînement (4, 6, 10) des roues avant (2) contiennent des moteurs hydrauliques (10).

- Véhicule selon l'une quelconque des revendications 1 à 6, caractérisé en ce que les moyens pour déplacer les bras contiennent un mécanisme (11) à piston-cylindre pour chacun des bras (20), ces mécanismes travaillant de manière synchrone pour les deux bras (20).

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT89202014T ATE97386T1 (de) | 1989-02-22 | 1989-08-02 | Fahrzeug zum transportieren eines stapels loser steine. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| BE8900183A BE1002858A6 (nl) | 1989-02-22 | 1989-02-22 | Voertuig voor het transport van een stapel losse stenen. |

| BE8900183 | 1989-02-22 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0384044A1 EP0384044A1 (fr) | 1990-08-29 |

| EP0384044B1 EP0384044B1 (fr) | 1993-11-18 |

| EP0384044B2 true EP0384044B2 (fr) | 1997-10-01 |

Family

ID=3884029

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP89202014A Expired - Lifetime EP0384044B2 (fr) | 1989-02-22 | 1989-08-02 | Véhicule pour le transport d'une pile de pierres séparées |

Country Status (5)

| Country | Link |

|---|---|

| EP (1) | EP0384044B2 (fr) |

| AT (1) | ATE97386T1 (fr) |

| BE (1) | BE1002858A6 (fr) |

| DE (1) | DE58906212D1 (fr) |

| ES (1) | ES2046452T5 (fr) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| IT1306433B1 (it) | 1998-10-13 | 2001-06-06 | Biase Mario Di | Macchina operatrice per posa in opera del pave' modello elefante |

| CN202297037U (zh) | 2011-09-16 | 2012-07-04 | 卡斯卡特(厦门)叉车属具有限公司 | 叉车夹臂 |

| CN112110388B (zh) * | 2020-09-17 | 2022-01-28 | 河南省宾康绿色能源科技有限公司 | 一种节能环保型建筑砖块运输设备 |

Family Cites Families (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB709427A (en) * | 1951-03-28 | 1954-05-26 | Samuel Edgar Rodman | Improvements in or relating to self-loading transporting devices |

| US2896994A (en) * | 1954-03-24 | 1959-07-28 | Ruhr Intrans Hubstapler G M B | Clamping device for industrial trucks |

| DE1060270B (de) * | 1955-02-15 | 1959-06-25 | Kurt Gunnar Schultz | Kraftfahrzeug mit Be- und Entladevorrichtung |

| US2836317A (en) * | 1956-09-10 | 1958-05-27 | Oury John Foster | Brick handling apparatus |

| GB965601A (en) * | 1962-04-12 | 1964-08-06 | John Henry Parry | Improvements in or relating to forks for handling stacks of articles |

| FR1438629A (fr) * | 1965-04-29 | 1966-05-13 | Entwicklungs Und Musterbau Bau | Fourche hydraulique serre-briques pouvant être montée sur des élévateurs à fourche |

| US3380606A (en) * | 1966-01-04 | 1968-04-30 | Lawrence R. Trumpore | Lift truck |

| FR1587515A (fr) * | 1967-12-08 | 1970-03-20 | ||

| DE2503198C3 (de) * | 1975-01-27 | 1983-01-13 | Josef 7989 Amtzell Ott Jun. | Krangabel mit hydraulischer Klemmvorrichtung |

| FR2397364A1 (fr) * | 1977-07-13 | 1979-02-09 | Equipman | Pince a bras developpable pour chariot elevateur |

-

1989

- 1989-02-22 BE BE8900183A patent/BE1002858A6/nl not_active IP Right Cessation

- 1989-08-02 DE DE89202014T patent/DE58906212D1/de not_active Expired - Fee Related

- 1989-08-02 EP EP89202014A patent/EP0384044B2/fr not_active Expired - Lifetime

- 1989-08-02 ES ES89202014T patent/ES2046452T5/es not_active Expired - Fee Related

- 1989-08-02 AT AT89202014T patent/ATE97386T1/de not_active IP Right Cessation

Also Published As

| Publication number | Publication date |

|---|---|

| BE1002858A6 (nl) | 1991-07-02 |

| DE58906212D1 (de) | 1993-12-23 |

| EP0384044A1 (fr) | 1990-08-29 |

| EP0384044B1 (fr) | 1993-11-18 |

| ES2046452T3 (es) | 1994-02-01 |

| ES2046452T5 (es) | 1998-01-16 |

| ATE97386T1 (de) | 1993-12-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE1192531B (de) | Lenkeinrichtung fuer Flurfoerder- und Stapelgeraete | |

| EP0394534A1 (fr) | Remorqueur d'avion sans barre de remorquage (palette tournante) | |

| DE102011010727B4 (de) | Schleppfahrzeug für Flugzeuge, das auf der Stelle drehen kann mit frei drehbarer Bugradaufnahmevorrichtung | |

| DE1756907B2 (de) | Baumstamm-Greiffahrzeug | |

| DE3017456A1 (de) | Hochregalstapler | |

| DE7338262U (de) | Landwirtschaftliche arbeitsmaschine | |

| DE3047132A1 (de) | Mehrzweckfahrzeug | |

| DE19602972A1 (de) | Kran | |

| EP0384044B2 (fr) | Véhicule pour le transport d'une pile de pierres séparées | |

| DE3621366A1 (de) | Nutzfahrzeug mit wechselaufbau | |

| DE2837398A1 (de) | Fahrzeugkran | |

| DE19518618A1 (de) | Maschinelle Handhabungsvorrichtung mit einer Gabel | |

| WO1998050252A1 (fr) | Vehicule et dispositif pour le transport de conteneurs | |

| DE19623444A1 (de) | Einrichtung zum Schneiden von Hecken und dergleichen | |

| EP1077169B1 (fr) | Chariot de manutention comprenant des roues de support | |

| DE2051286A1 (de) | Hebevorrichtung an Fahrzeugen | |

| DE3034766A1 (de) | Regalstapelfahrzeug | |

| DE2825130C3 (de) | Ersatzrad-Halterung für Lastfahrzeuge | |

| DE1281863B (de) | Absetzkipper mit zwei miteinander verbundenen, hydraulisch betaetigten starren Schwenkarmen | |

| DE951036C (de) | Dreiraedriger Hubwagen | |

| DE202011101157U1 (de) | Landwirtschaftliche Maschine | |

| DE2722633A1 (de) | Vorrichtung zum heben von gebuendelten brettern | |

| DE547688C (de) | Fahrbarer Hoehenfoerderer | |

| DE579755C (de) | Wagenkasten | |

| DE1480858A1 (de) | Fahrbarer Montagebock |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH DE ES FR GB GR IT LI LU NL SE |

|

| 17P | Request for examination filed |

Effective date: 19910108 |

|

| 17Q | First examination report despatched |

Effective date: 19920702 |

|

| TCNL | Nl: translation of patent claims filed | ||

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE ES FR GB GR IT LI LU NL SE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 19931118 Ref country code: SE Effective date: 19931118 |

|

| REF | Corresponds to: |

Ref document number: 97386 Country of ref document: AT Date of ref document: 19931215 Kind code of ref document: T |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 19931118 |

|

| REF | Corresponds to: |

Ref document number: 58906212 Country of ref document: DE Date of ref document: 19931223 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2046452 Country of ref document: ES Kind code of ref document: T3 |

|

| ITF | It: translation for a ep patent filed | ||

| ET | Fr: translation filed | ||

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| ITTA | It: last paid annual fee | ||

| 26 | Opposition filed |

Opponent name: PROBST, GREIF- UND FOERDERTECHNIK GMBH, Effective date: 19940818 |

|

| NLR1 | Nl: opposition has been filed with the epo |

Opponent name: PROBST, GREIF- UND FOERDERTECHNIK GMBH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: AEN |

|

| PLAW | Interlocutory decision in opposition |

Free format text: ORIGINAL CODE: EPIDOS IDOP |

|

| PLAW | Interlocutory decision in opposition |

Free format text: ORIGINAL CODE: EPIDOS IDOP |

|

| PUAH | Patent maintained in amended form |

Free format text: ORIGINAL CODE: 0009272 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: PATENT MAINTAINED AS AMENDED |

|

| 27A | Patent maintained in amended form |

Effective date: 19971001 |

|

| AK | Designated contracting states |

Kind code of ref document: B2 Designated state(s): AT BE CH DE ES FR GB GR IT LI LU NL SE |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: AEN Free format text: AUFRECHTERHALTUNG DES PATENTES IN GEAENDERTER FORM |

|

| NLR2 | Nl: decision of opposition | ||

| ITF | It: translation for a ep patent filed | ||

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: DC2A Kind code of ref document: T5 Effective date: 19971210 |

|

| ET3 | Fr: translation filed ** decision concerning opposition | ||

| NLR3 | Nl: receipt of modified translations in the netherlands language after an opposition procedure | ||

| GBTA | Gb: translation of amended ep patent filed (gb section 77(6)(b)/1977) | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20000811 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20010801 Year of fee payment: 13 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20010802 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20010810 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20010824 Year of fee payment: 13 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20020802 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20020802 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20020803 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20020831 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20020831 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: LU Payment date: 20030102 Year of fee payment: 13 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20020802 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20030512 Year of fee payment: 15 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20030912 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20050429 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20050608 Year of fee payment: 17 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20050802 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20050831 Year of fee payment: 17 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070301 Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070301 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee |

Effective date: 20070301 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 20080717 Year of fee payment: 20 |

|

| BE20 | Be: patent expired |

Owner name: *GEENS FRANS JOZEF JOHANNA Effective date: 20090802 Owner name: *GYSBRECHTS CORNEEL FRANS Effective date: 20090802 |