EP0334802A2 - Installation de coulée pour la fabrication continue de bande métallique et procédé - Google Patents

Installation de coulée pour la fabrication continue de bande métallique et procédé Download PDFInfo

- Publication number

- EP0334802A2 EP0334802A2 EP89730066A EP89730066A EP0334802A2 EP 0334802 A2 EP0334802 A2 EP 0334802A2 EP 89730066 A EP89730066 A EP 89730066A EP 89730066 A EP89730066 A EP 89730066A EP 0334802 A2 EP0334802 A2 EP 0334802A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- pouring

- nozzle

- casting

- distributor

- cooling belt

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 238000005266 casting Methods 0.000 title claims abstract description 39

- 239000002184 metal Substances 0.000 title claims abstract description 14

- 238000000034 method Methods 0.000 title claims description 9

- 238000001816 cooling Methods 0.000 claims abstract description 43

- 238000010924 continuous production Methods 0.000 claims abstract description 8

- 230000001105 regulatory effect Effects 0.000 claims abstract description 5

- 239000000155 melt Substances 0.000 claims description 10

- 238000009530 blood pressure measurement Methods 0.000 claims description 3

- 238000009499 grossing Methods 0.000 claims description 3

- 229910000831 Steel Inorganic materials 0.000 abstract description 3

- 239000010959 steel Substances 0.000 abstract description 3

- 238000009434 installation Methods 0.000 abstract 1

- 238000005259 measurement Methods 0.000 abstract 1

- 230000001154 acute effect Effects 0.000 description 1

- 230000015556 catabolic process Effects 0.000 description 1

- 230000001276 controlling effect Effects 0.000 description 1

- 238000009826 distribution Methods 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22D—CASTING OF METALS; CASTING OF OTHER SUBSTANCES BY THE SAME PROCESSES OR DEVICES

- B22D11/00—Continuous casting of metals, i.e. casting in indefinite lengths

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22D—CASTING OF METALS; CASTING OF OTHER SUBSTANCES BY THE SAME PROCESSES OR DEVICES

- B22D11/00—Continuous casting of metals, i.e. casting in indefinite lengths

- B22D11/16—Controlling or regulating processes or operations

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22D—CASTING OF METALS; CASTING OF OTHER SUBSTANCES BY THE SAME PROCESSES OR DEVICES

- B22D11/00—Continuous casting of metals, i.e. casting in indefinite lengths

- B22D11/06—Continuous casting of metals, i.e. casting in indefinite lengths into moulds with travelling walls, e.g. with rolls, plates, belts, caterpillars

- B22D11/0602—Continuous casting of metals, i.e. casting in indefinite lengths into moulds with travelling walls, e.g. with rolls, plates, belts, caterpillars formed by a casting wheel and belt, e.g. Properzi-process

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22D—CASTING OF METALS; CASTING OF OTHER SUBSTANCES BY THE SAME PROCESSES OR DEVICES

- B22D11/00—Continuous casting of metals, i.e. casting in indefinite lengths

- B22D11/06—Continuous casting of metals, i.e. casting in indefinite lengths into moulds with travelling walls, e.g. with rolls, plates, belts, caterpillars

- B22D11/0631—Continuous casting of metals, i.e. casting in indefinite lengths into moulds with travelling walls, e.g. with rolls, plates, belts, caterpillars formed by a travelling straight surface, e.g. through-like moulds, a belt

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22D—CASTING OF METALS; CASTING OF OTHER SUBSTANCES BY THE SAME PROCESSES OR DEVICES

- B22D11/00—Continuous casting of metals, i.e. casting in indefinite lengths

- B22D11/06—Continuous casting of metals, i.e. casting in indefinite lengths into moulds with travelling walls, e.g. with rolls, plates, belts, caterpillars

- B22D11/0637—Accessories therefor

- B22D11/064—Accessories therefor for supplying molten metal

Definitions

- the present invention relates to an apparatus and a method for casting strips of metal, in particular steel, in which the molten metal is fed from a pouring nozzle, which preferably corresponds to the strip width, onto a continuously moving, cooled conveyor belt and the nozzle mouth with its plane to the thickness of the metal strip to be cast, ie is adjustable to an acute angle to the conveyor belt level.

- a pouring nozzle which preferably corresponds to the strip width

- a continuously moving, cooled conveyor belt and the nozzle mouth with its plane to the thickness of the metal strip to be cast ie is adjustable to an acute angle to the conveyor belt level.

- the object of the present invention is to improve the quality of the thin steel strips that can be produced with such a system and to improve the system in terms of manageability and operational safety.

- the invention therefore proposes that the Distributor designed as a double chamber vessel, at least the pouring chamber provided with the pouring nozzle is sealed gas-tight above the melt and is connected to a pressure-controllable gas source, that the pouring nozzle is followed by a position-adjustable, adjustable smoothing roller, at least one distance measuring device on the pouring nozzle for determining the position of the pouring nozzle Cooling belt is provided and is connected via a controller with means for changing the position of the distributor.

- the Distributor designed as a double chamber vessel, at least the pouring chamber provided with the pouring nozzle is sealed gas-tight above the melt and is connected to a pressure-controllable gas source, that the pouring nozzle is followed by a position-adjustable, adjustable smoothing roller, at least one distance measuring device on the pouring nozzle for determining the position of the pouring nozzle Cooling belt is provided and is connected via a controller with means for changing the position of the distributor.

- the distance measuring device is a dynamic pressure measuring device and the measuring opening is arranged in the plane of the outlet opening of the casting nozzle in the wall of the casting nozzle which is assigned to the strip inlet side and which Outlet opening of the pouring nozzle is arranged inclined to the surface of the cooling belt and the angle of inclination opens in the direction of strip withdrawal.

- means are arranged in the strip take-off direction behind the casting nozzle, with which the thickness of the cast strip can be detected and that the measured values are compared in a control unit with predetermined target values and the regulator on the gas source in the sense of a Pressure change acts to regulate the intended strip thickness by controlling the melt flow rate.

- the means for determining the strip thickness is in particular a radiometric measuring device.

- the radiometric measuring device can be connected to a further controller, which is connected to actuators by a height-adjustable support element arranged below the cooling belt. This support element is in particular below the pouring nozzle and can also be used to control the strip thickness.

- each measuring device is connected to the corresponding actuating drives of one supporting element each via a controller.

- the distance measuring devices mentioned at the outset are arranged in the outer region of the pouring nozzle in order to prevent the strip from tilting relative to the pouring nozzle and to create a thick band that is uniform across the entire width.

- the thickness of the cast strip is measured, the measured value is fed to a regulator and, after comparison with a predetermined setpoint characterizing the thickness of the strip, the gas pressure in the pouring chamber of the distributor vessel in connection is regulated with the flow rate of the melt into the pouring chamber.

- the above-described method for operating a pouring device can be characterized in a further embodiment of the invention, starting from the previously described generic type, in that the distance of the pouring nozzle is measured by means of a dynamic pressure measurement of a gas jet emerging from a measuring opening in the plane in the outlet opening, a the measured value of Signal corresponding to the dynamic pressure is fed to a controller and, after comparison with a target value which characterizes the distance of the nozzle from the cooling belt, actuating means acting on the distributor are actuated in the sense of keeping the measured value constant or the distance between the casting nozzle and the cooling belt surface.

- the thickness of the cast strip is measured by means of several thickness gauges in the vicinity of the pouring nozzle distributed over the bandwidth, the measured values of the individual measuring instruments with a predetermined setpoint characterizing the thickness of the strip in one measuring device each assigned controller and, in the event of deviations from the setpoint, supplied to the actuator of the respective support element assigned to the thickness measuring device and opposite the casting nozzle for setting a desired profile and is set.

- Fig. 1 shows a casting device for the continuous production of metal strip 19, consisting of the endless cooling belt 9, which is guided over transport rollers 20, 21 and driven in rotation.

- a cooling or smoothing roller 1 is arranged above the cooling belt 9 and its position relative to the cooling belt 9 can be changed by actuating cylinders 22.

- the cooling belt 9 including the transport rollers 20, 21 is mounted on a frame 2 which is adjustable in the inclination to the horizontal.

- the frame 2 is articulated on one side, with an articulated axis 4, which extends transversely to the tape take-off direction and rests on the opposite side on vertically arranged hydraulically operated actuating cylinders 16.

- a gas source is designated, which is connected to the outlet chamber 3 ⁇ .

- the distribution vessel 3 is also adjustable in position.

- the distributor vessel 3 consists of an inlet chamber 3 'and an outlet chamber 3 ⁇ . At the outlet chamber 3 ⁇ , the pouring nozzle 7 is arranged.

- the pouring chamber 3 is sealed gas-tight above the melt.

- the distributor 3, which is designed as a double-chamber vessel, is separated into the areas of the pouring chamber 3 'and the pouring chamber 3' by a central wall 23 which projects from above into the distributor and into the melt.

- the movable carriage 6 carrying the distributor 3 is mounted on the frame 2.

- the distributor 3 can be adjusted in height by means of a hydraulic cylinder 13.

- the hydraulic cylinder 13 is included in a control circuit which includes the regulator R1 and a dynamic pressure measurement of a gas jet emerging at the casting nozzle 7, as shown in more detail in FIG. 3.

- the distance measuring device 11 with the measuring opening 11 ' is arranged on or in the wall of the casting nozzle 7 assigned to the belt inlet side.

- the dynamic pressure of the gas emerging at 11 'as a measure of the distance of the pouring nozzle 7 from the cooling belt 9 is fed to the controller R1.

- the controller R1 controls the hydraulic cylinder 13 in the sense of keeping the distance of the pouring nozzle 7 from the surface of the cooling belt 9 constant.

- the pouring nozzle 7 is immediately downstream of a thickness measuring device 14 in the direction of strip travel for determining the thickness of the metal strip 19 produced.

- the thickness measuring device works according to the radiographic method and accordingly has transmitters and receivers which are arranged above or below the strip.

- the measuring device 14 is connected to the pressure-controllable gas source 24 via the regulator R2.

- the bath level of the melt 25 can be regulated via the gas pressure in the pouring chamber 3 ⁇ and thus the amount of outflow from the pouring nozzle 7 leaking metal.

- the “gas source” is operated as a connection to a vacuum chamber.

- the measuring device 14 is also connected to a further controller R4, which carries adjusting means for influencing the distance from the support elements 18 arranged below the cooling belt 9.

- the support elements 18 in the form of a continuous roll or a roll consisting of individual sections are arranged in the region of the outlet opening of the pouring nozzle 7.

- the controllable position of the support elements 18 also makes it possible to influence the thickness of the band 19 to be produced. In the event that the support element 18 consists of several individual rollers, a corresponding number of adjusting elements 15 are of course required.

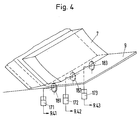

- FIG. 4. 4 shows the pouring nozzle 7 with individual rollers 181, 182, 183 arranged below the belt 9.

- Each roller is assigned a corresponding actuating means 171, 172, 173, each of which is connected to its own controller R41, R42, R43.

- R41, R42, R43 Such a breakdown of the support elements naturally makes it necessary for a corresponding number of thickness measuring devices 14 to also be present, so that each thickness measuring device 14 is assigned a corresponding supporting roller. This division makes it possible to achieve a finer adjustment and influencing of the strip thickness over the strip width.

- FIG. 2 which detects the belt speed of the cooling belt 9, feeds the belt speed to a controller R3 and acts on an actuating cylinder 16, with the aid of which the inclination of the casting belt can be regulated as a function of the belt speed.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Continuous Casting (AREA)

- Treatment Of Steel In Its Molten State (AREA)

- Forging (AREA)

- Manufacture Of Alloys Or Alloy Compounds (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT89730066T ATE89770T1 (de) | 1988-03-24 | 1989-03-14 | Giesseinrichtung zur kontinuierlichen herstellung von metallband und verfahren. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE3810302A DE3810302A1 (de) | 1988-03-24 | 1988-03-24 | Giesseinrichtung zur kontinuierlichen herstellung von metallband |

| DE3810302 | 1988-03-24 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0334802A2 true EP0334802A2 (fr) | 1989-09-27 |

| EP0334802A3 EP0334802A3 (en) | 1990-11-22 |

| EP0334802B1 EP0334802B1 (fr) | 1993-05-26 |

Family

ID=6350766

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP89730066A Expired - Lifetime EP0334802B1 (fr) | 1988-03-24 | 1989-03-14 | Installation de coulée pour la fabrication continue de bande métallique et procédé |

Country Status (10)

| Country | Link |

|---|---|

| US (1) | US5000250A (fr) |

| EP (1) | EP0334802B1 (fr) |

| JP (1) | JP2925568B2 (fr) |

| KR (1) | KR960007493B1 (fr) |

| AT (1) | ATE89770T1 (fr) |

| BR (1) | BR8901364A (fr) |

| DE (2) | DE3810302A1 (fr) |

| DK (1) | DK137189A (fr) |

| ES (1) | ES2040497T3 (fr) |

| ZA (1) | ZA892180B (fr) |

Cited By (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0463255A2 (fr) * | 1990-06-22 | 1992-01-02 | Armco Inc. | Procédé et dispositif pneumatique de mesure d'une fente |

| EP0463256A2 (fr) * | 1990-06-22 | 1992-01-02 | Armco Inc. | Méthode et capteur électronique de fente |

| EP0534174A1 (fr) * | 1991-09-27 | 1993-03-31 | Wieland-Werke Ag | Procédé et dispositif de fabrication d'une bande de métal proche de sa mesure finale |

| WO1994008742A1 (fr) * | 1992-10-10 | 1994-04-28 | Sundwiger Eisenhütte Maschinenfabrik Gmbh & Co. | Machine a couler les feuillards, constituee d'au moins une surface de refroidissement mobile, en particulier une roue de coulee precedee d'une buse de coulee ou d'un avant-creuset |

| EP0613744A1 (fr) * | 1993-03-05 | 1994-09-07 | Wieland-Werke Ag | Installation de coulée pour la fabrication continue de bande métallique |

| US5538071A (en) * | 1991-07-01 | 1996-07-23 | Mannesmann Aktiengesellschaft | Machine and method of continuously casting a metal strip |

| WO2008110330A1 (fr) * | 2007-03-09 | 2008-09-18 | Sms Siemag Ag | Dispositif de mesure d'épaisseur et procédé associé |

| WO2012080191A1 (fr) * | 2010-12-15 | 2012-06-21 | Sms Siemag Ag | Dispositif et procédé pour la coulée horizontale de bandes métalliques |

Families Citing this family (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5092392A (en) * | 1990-06-22 | 1992-03-03 | Armco, Inc. | Pneumatic gap sensor and method |

| DE4039959C1 (fr) * | 1990-12-14 | 1992-01-23 | Wieland-Werke Ag, 7900 Ulm, De | |

| DE4132189C1 (en) * | 1991-09-27 | 1993-02-04 | Wieland-Werke Ag, 7900 Ulm, De | Metal strip prodn. - by feeding molten metal from tundish via casting nozzle onto cooled conveyor belt |

| DE4344953C2 (de) * | 1993-12-27 | 1996-10-02 | Mannesmann Ag | Verfahren und Vorrichtung zum Angießen eines endabmessungsnahen Metallbandes |

| DE4407873C2 (de) * | 1994-03-04 | 1997-04-10 | Mannesmann Ag | Verfahren und Vorrichtung zum Kühlen schmelzflüssigen Stahls |

| US6026887A (en) * | 1997-03-04 | 2000-02-22 | Hazelett Strip-Casting Corporation | Steering, tensing and driving a revolving casting belt using an exit-pulley drum for achieving all three functions |

| DE19811434C2 (de) * | 1998-03-17 | 2002-05-16 | Mannesmann Ag | Verfahren und Vorrichtung zum Vergleichmäßigen eines schmelzflüssigen Metallfilmes |

| EP1506827B1 (fr) * | 2003-08-01 | 2005-10-05 | Hof Te Fiennes N.V. | Système et procédé de coulée métaux non-ferreux |

| DE102008005727B3 (de) * | 2008-01-23 | 2009-10-01 | Technische Universität Clausthal | Zuführeinrichtung für eine Metallschmelze und eine mit einer solchen Vorrichtung ausgestattete Bandgießeinrichtung |

| CN103286291B (zh) * | 2013-05-27 | 2015-04-29 | 平湖东创新材料科技有限公司 | 板材成型设备 |

| DE102015114725B3 (de) * | 2015-09-03 | 2016-12-08 | Salzgitter Flachstahl Gmbh | Schmelzenaufgabesystem für eine horizontale Bandgießanlage |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5841654A (ja) * | 1981-09-02 | 1983-03-10 | Hitachi Metals Ltd | 合金薄板製造装置 |

| GB2140720A (en) * | 1983-06-01 | 1984-12-05 | Alusuisse | Feeding molten metal through a nozzle to a casting mould |

| JPS6021158A (ja) * | 1983-07-15 | 1985-02-02 | Nisshin Steel Co Ltd | 薄板連続鋳造装置 |

| JPS61137658A (ja) * | 1984-12-10 | 1986-06-25 | Kawasaki Steel Corp | 急冷薄帯の板厚推定方法 |

| DE3707897A1 (de) * | 1987-03-12 | 1988-09-22 | Mannesmann Ag | Verfahren und giessvorrichtung zum giessen von baendern aus metall, insbesondere aus stahl |

Family Cites Families (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4449568A (en) * | 1980-02-28 | 1984-05-22 | Allied Corporation | Continuous casting controller |

| JPS57142748A (en) * | 1981-02-27 | 1982-09-03 | Hitachi Ltd | Molding device for thin plate |

| JPS59150646A (ja) * | 1983-02-17 | 1984-08-28 | Kawasaki Steel Corp | 金属板の連続鋳造方法およびその装置 |

| CH661882A5 (de) * | 1983-06-01 | 1987-08-31 | Lauener W F Ag | Verfahren zum zufuehren einer metallschmelze in den giessspalt einer giessmaschine und giessmaschine zur durchfuehrung des verfahrens. |

| DE3403152C2 (de) * | 1984-01-31 | 1986-02-20 | Fried. Krupp Gmbh, 4300 Essen | Verfahren zum Zuführen von Stahlschmelze aus einem Zwischenbehälter in eine Doppelbandstranggießkokille und Zwischenbehälter zur Durchführung des Verfahrens |

| DE3440237C2 (de) * | 1984-11-03 | 1986-11-06 | Mannesmann AG, 4000 Düsseldorf | Vorrichtung zum Bandstranggießen von Metallen, insbesondere von Stahl |

| JPS61144251A (ja) * | 1984-12-18 | 1986-07-01 | Kawasaki Heavy Ind Ltd | 連続鋳造設備のノズル交換方法および装置 |

| US4646812A (en) | 1985-09-20 | 1987-03-03 | Battelle Development Corporation | Flow casting |

-

1988

- 1988-03-24 DE DE3810302A patent/DE3810302A1/de active Granted

-

1989

- 1989-03-14 ES ES198989730066T patent/ES2040497T3/es not_active Expired - Lifetime

- 1989-03-14 DE DE8989730066T patent/DE58904455D1/de not_active Expired - Lifetime

- 1989-03-14 AT AT89730066T patent/ATE89770T1/de not_active IP Right Cessation

- 1989-03-14 EP EP89730066A patent/EP0334802B1/fr not_active Expired - Lifetime

- 1989-03-21 DK DK137189A patent/DK137189A/da not_active Application Discontinuation

- 1989-03-22 BR BR898901364A patent/BR8901364A/pt not_active IP Right Cessation

- 1989-03-22 JP JP1070328A patent/JP2925568B2/ja not_active Expired - Lifetime

- 1989-03-22 ZA ZA892180A patent/ZA892180B/xx unknown

- 1989-03-23 KR KR1019890003653A patent/KR960007493B1/ko not_active IP Right Cessation

- 1989-03-24 US US07/328,161 patent/US5000250A/en not_active Expired - Lifetime

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5841654A (ja) * | 1981-09-02 | 1983-03-10 | Hitachi Metals Ltd | 合金薄板製造装置 |

| GB2140720A (en) * | 1983-06-01 | 1984-12-05 | Alusuisse | Feeding molten metal through a nozzle to a casting mould |

| JPS6021158A (ja) * | 1983-07-15 | 1985-02-02 | Nisshin Steel Co Ltd | 薄板連続鋳造装置 |

| JPS61137658A (ja) * | 1984-12-10 | 1986-06-25 | Kawasaki Steel Corp | 急冷薄帯の板厚推定方法 |

| DE3707897A1 (de) * | 1987-03-12 | 1988-09-22 | Mannesmann Ag | Verfahren und giessvorrichtung zum giessen von baendern aus metall, insbesondere aus stahl |

Non-Patent Citations (3)

| Title |

|---|

| PATENT ABSTRACTS OF JAPAN, vol. 10, no. 333 (M-534)(2389), 12 November 1986; & JP-A-61137658 (Kawasaki Steel) 25.06.1986 * |

| PATENT ABSTRACTS OF JAPAN, vol. 7, no. 124 (M-218)(1269), 28 May 1983; & JP-A-58 041654 (Hitachi) 10.03.1983 * |

| PATENT ABSTRACTS OF JAPAN, vol. 9, no. 142 (M-388)(1865), 18 June 1985; & JP-A-60 021158 (Nitsushin) 02.02.1985 * |

Cited By (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0463255A2 (fr) * | 1990-06-22 | 1992-01-02 | Armco Inc. | Procédé et dispositif pneumatique de mesure d'une fente |

| EP0463256A2 (fr) * | 1990-06-22 | 1992-01-02 | Armco Inc. | Méthode et capteur électronique de fente |

| EP0463255A3 (en) * | 1990-06-22 | 1992-09-23 | Armco Inc. | Pneumatic gap sensor and method |

| EP0463256A3 (en) * | 1990-06-22 | 1992-10-14 | Armco Inc. | Electronic gap sensor and method |

| AU644112B2 (en) * | 1990-06-22 | 1993-12-02 | Armco Inc. | Pneumatic gap sensor and method |

| US5538071A (en) * | 1991-07-01 | 1996-07-23 | Mannesmann Aktiengesellschaft | Machine and method of continuously casting a metal strip |

| EP0534174A1 (fr) * | 1991-09-27 | 1993-03-31 | Wieland-Werke Ag | Procédé et dispositif de fabrication d'une bande de métal proche de sa mesure finale |

| WO1994008742A1 (fr) * | 1992-10-10 | 1994-04-28 | Sundwiger Eisenhütte Maschinenfabrik Gmbh & Co. | Machine a couler les feuillards, constituee d'au moins une surface de refroidissement mobile, en particulier une roue de coulee precedee d'une buse de coulee ou d'un avant-creuset |

| EP0613744A1 (fr) * | 1993-03-05 | 1994-09-07 | Wieland-Werke Ag | Installation de coulée pour la fabrication continue de bande métallique |

| WO2008110330A1 (fr) * | 2007-03-09 | 2008-09-18 | Sms Siemag Ag | Dispositif de mesure d'épaisseur et procédé associé |

| US9335164B2 (en) | 2007-03-09 | 2016-05-10 | Sms Group Gmbh | Device for thickness measurement and method therefor |

| WO2012080191A1 (fr) * | 2010-12-15 | 2012-06-21 | Sms Siemag Ag | Dispositif et procédé pour la coulée horizontale de bandes métalliques |

Also Published As

| Publication number | Publication date |

|---|---|

| BR8901364A (pt) | 1989-11-07 |

| EP0334802A3 (en) | 1990-11-22 |

| ATE89770T1 (de) | 1993-06-15 |

| DK137189A (da) | 1989-09-25 |

| EP0334802B1 (fr) | 1993-05-26 |

| DE58904455D1 (de) | 1993-07-01 |

| KR960007493B1 (ko) | 1996-06-05 |

| JPH01278946A (ja) | 1989-11-09 |

| JP2925568B2 (ja) | 1999-07-28 |

| US5000250A (en) | 1991-03-19 |

| DE3810302A1 (de) | 1989-10-12 |

| ZA892180B (en) | 1989-11-29 |

| ES2040497T3 (es) | 1993-10-16 |

| DK137189D0 (da) | 1989-03-21 |

| DE3810302C2 (fr) | 1990-07-05 |

| KR890014189A (ko) | 1989-10-23 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0334802B1 (fr) | Installation de coulée pour la fabrication continue de bande métallique et procédé | |

| DE69503742T2 (de) | Vorrichtung zum Stranggiessen zwischen Giesswalzen mit Inertgasschutz | |

| DE2757052A1 (de) | Vorrichtung zur niveauueberwachung und -steuerung des geschmolzenen metalls in der gussform einer strang-gussmaschine | |

| DE3532763A1 (de) | Verfahren und vorrichtung zum automatischen vergiessen von fluessigem metall | |

| EP0114293B1 (fr) | Procédé et dispositif de réglage de la conicité des petits côtés de lingotières de coulée continue | |

| EP0019114B1 (fr) | Procédé et dispositif pour la coulée continue de plusieurs barres | |

| DE4138655C2 (de) | Ausflußregler für Zwischengefäß | |

| DE3707897C2 (fr) | ||

| DE69801945T2 (de) | Giessen von Metallbändern | |

| DE2939322C2 (de) | Vorrichtung zur Änderung des Abstandes von Spritzbalken einer Stranggießanlage | |

| DE4313041A1 (de) | Gießen von Metallband | |

| DE3440236C2 (fr) | ||

| EP1057557B1 (fr) | Procédé et dispositif pour la coulée continue de métal | |

| WO2022058152A1 (fr) | Procédé et appareil de pulvérisation pour le traitement thermique de surface d'un produit métallique | |

| EP0613744B1 (fr) | Installation de coulée pour la fabrication continue de bande métallique | |

| EP0383413A2 (fr) | Procédé de coulée continue | |

| DE10122118A1 (de) | Verfahren und Vorrichtung zum Stranggiessen von Blöcken, Brammen und Dünnbrammen | |

| EP1827735A1 (fr) | Procede et dispositif de coulee en bande de metaux | |

| DE2830840B2 (de) | Verfahren und Vorrichtung zum Regeln des Badspiegels beim Stranggießen | |

| DE3241405A1 (de) | Kokillen- oder induktions-stranggiessverfahren | |

| DE102008005727B3 (de) | Zuführeinrichtung für eine Metallschmelze und eine mit einer solchen Vorrichtung ausgestattete Bandgießeinrichtung | |

| EP0083916A1 (fr) | Dispositif pour la coulée continue horizontale de métaux et d'alliages, notamment d'acier | |

| DE10311280A1 (de) | Stranggießanlage zum Gießen von Strängen aus flüssigem Metall, insbesondere aus flüssigem Stahlwerkstoff mit einem Verteilerrinnen-Wagen | |

| DE3934975A1 (de) | Verfahren zur regelung der lage des giessspiegels in einer bandstranggiessanlage und einrichtung hierzu | |

| EP3486001B1 (fr) | Installation de coulée de brames minces pourvue de tête de machine interchangeable |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH DE ES FR GB GR IT LI LU NL SE |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH DE ES FR GB GR IT LI LU NL SE |

|

| 17P | Request for examination filed |

Effective date: 19910516 |

|

| 17Q | First examination report despatched |

Effective date: 19920714 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE ES FR GB GR IT LI LU NL SE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 19930526 |

|

| REF | Corresponds to: |

Ref document number: 89770 Country of ref document: AT Date of ref document: 19930615 Kind code of ref document: T |

|

| ITF | It: translation for a ep patent filed | ||

| ET | Fr: translation filed | ||

| REF | Corresponds to: |

Ref document number: 58904455 Country of ref document: DE Date of ref document: 19930701 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 19930812 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2040497 Country of ref document: ES Kind code of ref document: T3 |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| EPTA | Lu: last paid annual fee | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Effective date: 19940331 Ref country code: LI Effective date: 19940331 |

|

| 26 | Opposition filed |

Opponent name: SUNDWIGER EISENHUETTE MASCHINENFABRIK Effective date: 19940224 |

|

| NLR1 | Nl: opposition has been filed with the epo |

Opponent name: SUNDWIGER EISENHUETTE MASCHINENFABRIK. |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| EAL | Se: european patent in force in sweden |

Ref document number: 89730066.1 |

|

| PLBN | Opposition rejected |

Free format text: ORIGINAL CODE: 0009273 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: OPPOSITION REJECTED |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: LU Payment date: 19960201 Year of fee payment: 8 |

|

| 27O | Opposition rejected |

Effective date: 19951026 |

|

| NLR2 | Nl: decision of opposition | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19970314 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20080328 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20080318 Year of fee payment: 20 Ref country code: SE Payment date: 20080313 Year of fee payment: 20 Ref country code: GB Payment date: 20080320 Year of fee payment: 20 Ref country code: IT Payment date: 20080321 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20080314 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20080314 Year of fee payment: 20 Ref country code: DE Payment date: 20080321 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 20080430 Year of fee payment: 20 |

|

| BE20 | Be: patent expired |

Owner name: *MANNESMANN A.G. Effective date: 20090314 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: PE20 Expiry date: 20090313 |

|

| NLV7 | Nl: ceased due to reaching the maximum lifetime of a patent |

Effective date: 20090314 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20090316 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20090314 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20090313 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20090316 |