EP0331918A2 - Méthode pour actionner un dispositif de chauffage et dispositif de chauffage - Google Patents

Méthode pour actionner un dispositif de chauffage et dispositif de chauffage Download PDFInfo

- Publication number

- EP0331918A2 EP0331918A2 EP89102180A EP89102180A EP0331918A2 EP 0331918 A2 EP0331918 A2 EP 0331918A2 EP 89102180 A EP89102180 A EP 89102180A EP 89102180 A EP89102180 A EP 89102180A EP 0331918 A2 EP0331918 A2 EP 0331918A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- flame temperature

- air ratio

- heater

- flame

- combustion

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23N—REGULATING OR CONTROLLING COMBUSTION

- F23N5/00—Systems for controlling combustion

- F23N5/02—Systems for controlling combustion using devices responsive to thermal changes or to thermal expansion of a medium

- F23N5/10—Systems for controlling combustion using devices responsive to thermal changes or to thermal expansion of a medium using thermocouples

- F23N5/102—Systems for controlling combustion using devices responsive to thermal changes or to thermal expansion of a medium using thermocouples using electronic means

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23N—REGULATING OR CONTROLLING COMBUSTION

- F23N1/00—Regulating fuel supply

- F23N1/02—Regulating fuel supply conjointly with air supply

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23N—REGULATING OR CONTROLLING COMBUSTION

- F23N1/00—Regulating fuel supply

- F23N1/08—Regulating fuel supply conjointly with another medium, e.g. boiler water

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23N—REGULATING OR CONTROLLING COMBUSTION

- F23N2225/00—Measuring

- F23N2225/08—Measuring temperature

- F23N2225/16—Measuring temperature burner temperature

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23N—REGULATING OR CONTROLLING COMBUSTION

- F23N2225/00—Measuring

- F23N2225/26—Measuring humidity

- F23N2225/30—Measuring humidity measuring lambda

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23N—REGULATING OR CONTROLLING COMBUSTION

- F23N2241/00—Applications

- F23N2241/14—Vehicle heating, the heat being derived otherwise than from the propulsion plant

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23N—REGULATING OR CONTROLLING COMBUSTION

- F23N5/00—Systems for controlling combustion

- F23N5/02—Systems for controlling combustion using devices responsive to thermal changes or to thermal expansion of a medium

- F23N5/14—Systems for controlling combustion using devices responsive to thermal changes or to thermal expansion of a medium using thermo-sensitive resistors

Definitions

- the invention relates to a method for operating a heater, in particular a vehicle auxiliary heater, in which combustion air and fuel are supplied to a burner and a flame is generated in a combustion chamber, and to a heater, in particular a vehicle auxiliary heater, which has a burner in a combustion chamber , has a fuel supply device and a combustion air supply device.

- the invention aims to provide a method for operating a heater, in particular a vehicle heater of the generic type and a correspondingly designed heater, in which a stable and low-pollutant combustion is reliably guaranteed in a simple manner while overcoming the difficulties described above.

- a method for operating a heater in particular a vehicle auxiliary heater, in which combustion air and fuel are supplied to a burner and a flame is generated in a combustion chamber, is carried out in such a way that the air ratio, which is generally referred to in the art as ⁇ , is determined on the basis of the flame temperature measured in the combustion chamber.

- the method according to the invention makes use of the fact that when a combustion occurs in such a heater, there is a clear physical relationship between the air ratio ⁇ and the adiabatic combustion temperature, ie the flame temperature.

- the flame temperature is thus detected and measured, and the corresponding air ratio ⁇ is determined from this, taking into account the predetermined clear physical relationship, which provides information about the ratio of the amount of combustion air supplied and the amount of fuel supplied. If this air ratio ⁇ is kept within predetermined limit values, stable and low-pollution combustion can be ensured.

- the disturbance variables influencing the combustion in the combustion chamber such as differential pressure between the air inlet and exhaust gas outlet, variable resistances in the intake and exhaust systems, temperature influences and the like with regard to the influences on the combustion behavior of the heater taken into account directly or indirectly by measuring the flame temperature, so that increased pollutant emissions and heater defects can be effectively avoided.

- the air ratio ⁇ is regulated to a predetermined setpoint by changing the combustion air and / or fuel supply in accordance with the determined flame temperature until the flame temperature reaches a predetermined setpoint for the Air ratio assigned setpoint for the flame temperature reached.

- the air ratio ⁇ is regulated via the flame temperature to a predetermined setpoint, which can be determined in advance in a device-dependent manner in such a way that combustion which is as stable and low-pollutant as possible is guaranteed under all operating conditions of the heater.

- control is regulated at an air ratio ⁇ of greater than 1 of this air ratio to the setpoint value in that the quantity of combustion air supplied is increased or the quantity of fuel supplied is increased at a flame temperature measured above the setpoint for the flame temperature and at a value below the setpoint for the flame temperature measured flame temperature, the quantity of combustion air supplied is reduced and the quantity of fuel supplied is increased.

- the combustion in the heater is influenced by the corresponding influencing of the quantity of combustion air supplied or the quantity of fuel supplied in such a way that the combustion is returned to the predetermined air ratio in accordance with the predetermined desired value for this purpose.

- a check is made as to whether within a predetermined period of time the detected flame temperature meets the following condition: T max > T F > T min (corresponds to ⁇ min ⁇ ⁇ max ) where T max the maximum permissible flame temperature, T F the detected flame temperature, T min the minimum permissible flame temperature, ⁇ min the permissible minimum air ratio, ⁇ the air ratio determined via the flame temperature T F and ⁇ max the maximum permissible air ratio.

- the heater is switched off. If this procedure is used in the method for operating the heater without regulating the predetermined setpoint value of the air ratio ⁇ , the operating method according to the invention enables flame monitoring without the additional use of a flame detector, namely if the above-mentioned condition is not met within the predetermined period of time the temperature detection of the flame temperature is recognized that no flame has formed in the combustion chamber of the heater, so that, depending on this, a forced shutdown or lockout of the heater is carried out. By monitoring the area limits, the flame monitor function is also taken over in the control.

- a heater in particular a vehicle auxiliary heater, with a burner in a combustion chamber, a combustion air supply device and a fuel supply device is distinguished in that a temperature detection device is arranged in the flame region of the combustion chamber for load-independent detection of the flame temperature, which is provided with a device for determining the Air ratio is connected.

- the solution created according to the invention in terms of device technology can be implemented in a structurally simple manner and a heater is provided which can be operated reliably and with low pollutants and is stable and can be produced inexpensively.

- a spatially integrating sensor such as a resistance thermometer, can be provided as the temperature detection device, which is expediently arranged in the combustion chamber in such a way that it starts from the flame root and extends into the flame region in the combustion chamber.

- thermocouple a point-acting sensor, such as a thermocouple, can be provided as the temperature detection device, which expediently protrudes into the combustion chamber near the end of the burnout length of the flame.

- the device for determining the air ratio switches the heater off if after a predetermined period of time the operating range determined by the following condition has not been reached: T max > T F > T min (corresponds to ⁇ min ⁇ ⁇ max ) these variables have the meaning explained above in connection with the operating method according to the invention.

- the temperature detection device and the associated device for determining the air ratio at the same time take over the function of a previously usual flame detector, so that this flame detector, which was previously a special component, can be omitted.

- the heater is also switched off when there is a risk that the heater may enter an inadmissible operating range when the amount of combustion air and / or fuel supplied is changed.

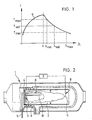

- Fig. 1 serves to illustrate the procedures for operating a heater shown in more detail in Fig. 2.

- the flame temperature T F is plotted against the air ratio ⁇ and the course of the curve a given there represents the empirically determined clear physical relationship between the flame temperature and air ratio at the firing temperature of a heater.

- This relationship between the flame temperature T F and the air ratio ⁇ is verified by the flame temperature T F measured in the combustion chamber in the method according to the invention.

- Is intended with ⁇ is designated for the air ratio of the target value, which is assigned to the Flammtemperaturkoordinate taking into account the physical unique relationship, a target value for the flame temperature T set.

- an empirically ascertainable minimum value for the air ratio ⁇ min and a corresponding empirically ascertainable maximum value for the air ratio ⁇ max are specified, these limit values ⁇ min and ⁇ max being given a corresponding maximum flame temperature value T max and minimum flame temperature value T min assigned.

- T max > T F > T min (corresponds to ⁇ min ⁇ ⁇ max ).

- T max maximum permissible flame temperature

- T F detected or measured flame temperature

- T min minimum permissible flame temperature

- ⁇ min minimum permissible air ratio

- ⁇ air ratio derived from detected or measured flame temperature

- T F ⁇ max maximum permissible air ratio.

- the heater is forced to shutdown or lock out. This can in the case of rain the air ratio ⁇ to the predetermined target value ⁇ , operation of the heater in an impermissible functional range is to be effectively avoided, as has been explained above.

- the control in the form of self-monitoring can be continuously checked in the operating method of the heater with control. When monitoring the area limits, the operating procedure enables the flame detector function to be implemented.

- the CO2 value in the exhaust gas of the heater which is clearly related to the air ratio, can be kept constant within narrow limits, so that one obtains a low-pollutant, but stable operation of the heater.

- a preferred embodiment of a heater designed according to the invention is explained with reference to FIG. 2.

- the heater as a whole is labeled 1.

- a combustion chamber 2 is provided in the heater 1.

- a so-called evaporation burner is illustrated as the burner 3, which has a nonwoven material 4, which serves to evaporate the fuel, such as liquid fuel, supplied via a fuel supply device 5.

- Combustion air is introduced into the combustion chamber 2 from a combustion air supply device, not shown, via schematically illustrated openings 6, as indicated by arrows.

- a combustion air supply device not shown, via schematically illustrated openings 6, as indicated by arrows.

- the flame curve for full-load operation is shown in solid lines and the flame curve for partial-load operation in broken lines.

- a total of 8 denotes a flame temperature detection device which is arranged in the flame area of the combustion chamber 2 in such a way that the temperature of the respective flame is always reliably and unambiguously detected regardless of the operating load of the heater, ie independently of full-load operation or part-load operation, for example.

- a device 9 shown schematically in block form, for determining the air ratio, which is designated by ⁇ .

- a spatially integrating sensor 10 is shown as flame temperature detection device 8, which sensor can be formed, for example, by a resistance thermometer. This spatially integrating sensor 10 starts from the flame root in the combustion chamber 2 and then extends in the direction of the burnout end of the flame.

- thermocouple An alternative embodiment of the flame temperature detection device 8, which is formed by a point-acting sensor 11, which can be, for example, a thermocouple, is illustrated with broken lines.

- This selective sensor 11 protrudes into the combustion chamber 2 in such a way that it is located in the combustion chamber 2 near the end of the burnout length of the flame.

- the method for operating a heater described in accordance with the invention is generally also suitable for stationary heating systems and not only for vehicle heaters.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Control Of Combustion (AREA)

- Air-Conditioning For Vehicles (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE3807388A DE3807388A1 (de) | 1988-03-07 | 1988-03-07 | Verfahren zum betreiben eines heizgeraets und heizgeraet |

| DE3807388 | 1988-03-07 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0331918A2 true EP0331918A2 (fr) | 1989-09-13 |

| EP0331918A3 EP0331918A3 (fr) | 1990-09-05 |

Family

ID=6349036

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP19890102180 Withdrawn EP0331918A3 (fr) | 1988-03-07 | 1989-02-09 | Méthode pour actionner un dispositif de chauffage et dispositif de chauffage |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP0331918A3 (fr) |

| JP (1) | JPH01262214A (fr) |

| DE (1) | DE3807388A1 (fr) |

Cited By (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO1996021127A1 (fr) * | 1994-12-30 | 1996-07-11 | Firma J. Eberspächer | Appareil de chauffage pour vehicule |

| US5616021A (en) * | 1994-09-19 | 1997-04-01 | Nippon Soken Inc. | Fuel burning heater |

| WO2004015333A2 (fr) * | 2002-08-05 | 2004-02-19 | Merloni Termosanitari S.P.A. | Systeme de regulation de combustion a capteur $g(l) virtuel |

| EP1612480A2 (fr) | 2004-06-28 | 2006-01-04 | J. Eberspächer GmbH & Co. KG | Brûleur à vaporisation |

| WO2006000367A1 (fr) * | 2004-06-23 | 2006-01-05 | Ebm-Papst Landshut Gmbh | Procede de reglage du coefficient d'air sur un dispositif de chauffage et dispositif de chauffage |

| DE102006015771A1 (de) * | 2006-04-04 | 2007-10-11 | J. Eberspächer GmbH & Co. KG | Verfahren zum Betreiben eines brennstoffbetriebenen Fahrzeugheizgerätes |

| WO2008058408A2 (fr) * | 2006-11-17 | 2008-05-22 | Toby Ag | Procédé de commande d'un brûleur à vaporisation |

| EP4174375A1 (fr) * | 2021-10-27 | 2023-05-03 | Vaillant GmbH | Procédé de validation d'un signal d'un dispositif de surveillance de flamme d'un appareil de chauffage, programme informatique, support de stockage, appareil de commande et utilisation d'un capteur de température |

Families Citing this family (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE4141116C1 (en) * | 1991-12-13 | 1993-04-08 | Webasto Ag Fahrzeugtechnik, 8035 Stockdorf, De | Operating burner receiving exhaust gas of IC engine - regenerating particle filter installation producing flame in variable manner |

| US5722588A (en) * | 1994-04-13 | 1998-03-03 | Nippon Soken Inc. | Combustion heater |

| US5617995A (en) * | 1994-04-22 | 1997-04-08 | Nippon Soken Inc | Combustion heater |

| DE4433210C2 (de) * | 1994-09-17 | 1999-07-01 | Webasto Thermosysteme Gmbh | Fahrzeugzusatzheizgerät |

| DE19636430C2 (de) * | 1996-09-07 | 2002-02-14 | Webasto Thermosysteme Gmbh | Verfahren und Vorrichtung zum Betreiben eines motorunabhängigen Fahrzeug-Heizgeräts |

| DE29924803U1 (de) * | 1999-10-23 | 2005-12-01 | Webasto Ag | Brennerbetriebenes Heizgerät mit Flammwächter in Gestalt eines Thermoelements |

| DE102016122821B3 (de) * | 2016-11-25 | 2018-02-08 | Webasto SE | Brennstoffbetriebenes Fahrzeugheizgerät und Verfahren zum Betreiben eines brennstoffbetriebenen Fahrzeugheizgerätes |

| DE102017119077A1 (de) * | 2017-08-21 | 2019-02-21 | Eberspächer Climate Control Systems GmbH & Co. KG | Fahrzeugheizgerät |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4033712A (en) * | 1976-02-26 | 1977-07-05 | Edmund D. Hollon | Fuel supply systems |

| US4480986A (en) * | 1983-09-14 | 1984-11-06 | Sea-Labs, Inc. | Liquid fuel vaporizing burner |

| JPS61197914A (ja) * | 1985-02-27 | 1986-09-02 | Matsushita Electric Ind Co Ltd | 燃焼器の制御回路 |

| GB2191022A (en) * | 1986-05-27 | 1987-12-02 | Rinnai Kk | A fluid heating apparatus |

| JPS6349624A (ja) * | 1986-08-18 | 1988-03-02 | Matsushita Electric Ind Co Ltd | 燃焼装置 |

-

1988

- 1988-03-07 DE DE3807388A patent/DE3807388A1/de not_active Withdrawn

-

1989

- 1989-02-09 EP EP19890102180 patent/EP0331918A3/fr not_active Withdrawn

- 1989-03-03 JP JP1051846A patent/JPH01262214A/ja active Pending

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4033712A (en) * | 1976-02-26 | 1977-07-05 | Edmund D. Hollon | Fuel supply systems |

| US4480986A (en) * | 1983-09-14 | 1984-11-06 | Sea-Labs, Inc. | Liquid fuel vaporizing burner |

| JPS61197914A (ja) * | 1985-02-27 | 1986-09-02 | Matsushita Electric Ind Co Ltd | 燃焼器の制御回路 |

| GB2191022A (en) * | 1986-05-27 | 1987-12-02 | Rinnai Kk | A fluid heating apparatus |

| JPS6349624A (ja) * | 1986-08-18 | 1988-03-02 | Matsushita Electric Ind Co Ltd | 燃焼装置 |

Non-Patent Citations (2)

| Title |

|---|

| PATENT ABSTRACTS OF JAPAN vol. 11, no. 25 (M-556)(2472) 23 Januar 1987, & JP-A-61 197914 (MATSUSHITA ELECTRIC) 02 September 1986, * |

| PATENT ABSTRACTS OF JAPAN vol. 12, no. 267 (M-722)(3114) 26 Juli 1988, & JP-A-63 49624 (MATSUSHITA ELECTRIC) 02 März 1988, * |

Cited By (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5616021A (en) * | 1994-09-19 | 1997-04-01 | Nippon Soken Inc. | Fuel burning heater |

| WO1996021127A1 (fr) * | 1994-12-30 | 1996-07-11 | Firma J. Eberspächer | Appareil de chauffage pour vehicule |

| WO2004015333A2 (fr) * | 2002-08-05 | 2004-02-19 | Merloni Termosanitari S.P.A. | Systeme de regulation de combustion a capteur $g(l) virtuel |

| WO2004015333A3 (fr) * | 2002-08-05 | 2004-06-03 | Merloni Termosanitari Spa | Systeme de regulation de combustion a capteur $g(l) virtuel |

| CN100570218C (zh) * | 2002-08-05 | 2009-12-16 | 默洛尼卫生洁具有限公司 | 带虚拟λ传感器的燃料控制系统 |

| US7922481B2 (en) | 2004-06-23 | 2011-04-12 | EBM—Papst Landshut GmbH | Method for setting the air ratio on a firing device and a firing device |

| WO2006000367A1 (fr) * | 2004-06-23 | 2006-01-05 | Ebm-Papst Landshut Gmbh | Procede de reglage du coefficient d'air sur un dispositif de chauffage et dispositif de chauffage |

| EP1612480A3 (fr) * | 2004-06-28 | 2008-12-10 | J. Eberspächer GmbH & Co. KG | Brûleur à vaporisation |

| EP1612480A2 (fr) | 2004-06-28 | 2006-01-04 | J. Eberspächer GmbH & Co. KG | Brûleur à vaporisation |

| DE102006015771A1 (de) * | 2006-04-04 | 2007-10-11 | J. Eberspächer GmbH & Co. KG | Verfahren zum Betreiben eines brennstoffbetriebenen Fahrzeugheizgerätes |

| WO2008058408A3 (fr) * | 2006-11-17 | 2008-07-17 | Toby Ag | Procédé de commande d'un brûleur à vaporisation |

| WO2008058408A2 (fr) * | 2006-11-17 | 2008-05-22 | Toby Ag | Procédé de commande d'un brûleur à vaporisation |

| EP4174375A1 (fr) * | 2021-10-27 | 2023-05-03 | Vaillant GmbH | Procédé de validation d'un signal d'un dispositif de surveillance de flamme d'un appareil de chauffage, programme informatique, support de stockage, appareil de commande et utilisation d'un capteur de température |

Also Published As

| Publication number | Publication date |

|---|---|

| EP0331918A3 (fr) | 1990-09-05 |

| DE3807388A1 (de) | 1989-09-21 |

| JPH01262214A (ja) | 1989-10-19 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0331918A2 (fr) | Méthode pour actionner un dispositif de chauffage et dispositif de chauffage | |

| EP2594848B1 (fr) | Procédé de commande d'un appareil à combustion et appareil à combustion | |

| EP1621811B1 (fr) | Procédé de fonctionnement pour un dispositif de combustion | |

| DE4417199C2 (de) | Vorrichtung zum Steuern von Gasturbinen | |

| EP2005066B1 (fr) | Procédé pour mettre en marche un système de chauffage dans des conditions générales inconnues | |

| DE2656840A1 (de) | Verfahren und vorrichtung zur regelung der energiezufuhr zu einer heizvorrichtung | |

| EP0833106B1 (fr) | Procédé et dispositif d'optimisation du fonctionnement d'un brûleur à gaz | |

| EP2017531B1 (fr) | Procédé de vérification d'un signal issu d'électrodes d'ionisation pour brûleurs | |

| EP3593047B1 (fr) | Procédé d'identification de types de gaz combustibles lors du processus de démarrage d'un appareil de chauffage fonctionnant au gaz combustible et appareil de chauffage fonctionnant au gaz combustible | |

| DE69504541T2 (de) | Fehlererkennung eines Fühlers | |

| DE60021779T2 (de) | Ein modulierendes Brennersystem zur Verhinderung der Benutzung von nicht-inbetriebgesetzten Bauelementen und Prüfung der Funktionsfähigkeit von inbetriebgesetzten Bauelementen | |

| EP0615095B1 (fr) | Commande de brûleur | |

| DE19734574B4 (de) | Verfahren und Vorrichtung zum Regeln eines Brenners, insbesondere eines vollvormischenden Gasbrenners | |

| EP3182007B1 (fr) | Système d'appareil de chauffage et procédé faisant appel à un système d'appareil de chauffage | |

| DE19921045B4 (de) | Brenner zur Verbrennung von flüssigen und/oder gasförmigen Brennstoffen in Feuerungsanlagen | |

| EP1519113A2 (fr) | Procédé pour adapter la puissance de chauffage d'un appareil de chauffage à ventilation forcée aux pertes de pression individuelles d'une conduite d'amenée d'air frais et d'évacuation de gaz d'échappement | |

| EP0614051B1 (fr) | Automate à brûleur | |

| EP4060235A1 (fr) | Procédé de fonctionnement d'un appareil de chauffage pourvu d'ensemble électronique gaz-air | |

| DE3114942A1 (de) | Regeleinrichtung fuer den gasbefeuerten heizkessel einer warmwasser-heizungsanlage | |

| EP0321858A2 (fr) | Installation de combustion | |

| EP1752708B1 (fr) | Procédé de détection de flamme dans un dispositif de chauffage de véhicule | |

| DE4331048A1 (de) | Verfahren und Vorrichtung zum Betreiben eines überstöchiometrisch vormischenden Gasbrenners | |

| DE102004063992B4 (de) | Verfahren zur Steuerung einer Feuerungseinrichtung und Feuerungseinrichtung | |

| DE102022122811A1 (de) | Verfahren zum Betreiben eines Heizgerätes, Computerprogramm, Regel- und Steuer-gerät, Brennstoffdurchflussregler und Heizgerät | |

| EP1260766B1 (fr) | Procédé d'adaptation d' un appareil de chauffage à brûleur à la cheminée d'air/fumée |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): DE FR GB SE |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): DE FR GB SE |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 19910306 |