EP0271106B1 - Dispositif de verrouillage pour portes relevables de véhicules à moteur, en particulier voitures particulières - Google Patents

Dispositif de verrouillage pour portes relevables de véhicules à moteur, en particulier voitures particulières Download PDFInfo

- Publication number

- EP0271106B1 EP0271106B1 EP87118346A EP87118346A EP0271106B1 EP 0271106 B1 EP0271106 B1 EP 0271106B1 EP 87118346 A EP87118346 A EP 87118346A EP 87118346 A EP87118346 A EP 87118346A EP 0271106 B1 EP0271106 B1 EP 0271106B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- door

- rotary

- locking device

- closed position

- locking

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 230000006978 adaptation Effects 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 230000008439 repair process Effects 0.000 description 1

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05B—LOCKS; ACCESSORIES THEREFOR; HANDCUFFS

- E05B83/00—Vehicle locks specially adapted for particular types of wing or vehicle

- E05B83/36—Locks for passenger or like doors

Definitions

- the invention relates to a locking device for lifting doors of motor vehicles, in particular passenger cars, which can be displaced in the vertical direction.

- the window pane which is carried by the lifting door and can be lowered into the lifting door, must be lowered into the latter. It runs in the lower position Window pane on the latch and pushes it back into the door. The locking lugs slide out of the corresponding receiving openings in the door jamb so that the door is unlocked and can be opened. A lock for the open position of the lifting door is not provided.

- a sliding door for motor vehicles is known from DE-AS 1 235 768, which can be moved along a horizontal path and can be locked both in the closed position and in the open position.

- This known sliding door carries at its front end on the inside of the door a gear latch which engages in a locking block on the front door jamb in the closed position and in a locking block on the rear door jamb in the open position.

- the gear latch is rotatably connected by a rotary latch shaft, the axis of which is perpendicular to the door plane, with a ratchet wheel which cooperates with a spring-loaded pawl which can be actuated by a linkage from a door handle.

- a locking device is provided on one of the two door wings, one at the upper door end and one at the lower door end has a rotary latch designed as a fork latch with a radial engagement recess, which engages around locking bolts in the closed position of the door leaf and holds the door leaf in the closed position (US Pat. No. 2,943,879).

- this known locking device are the two rotary latches, which can be arranged parallel to each other and by the locking bolt by moving the door leaf into the locking and unlocking positions are pivotable, rotatably connected to one another by a rotary latch shaft and to a common latching device.

- the locking device is arranged approximately half way up the door leaf and has a pre-locking and a main locking.

- the invention has for its object to provide a locking device of the type mentioned, which ensures a secure hold of the lifting door both in the closed position and in the open position with a simple structure.

- the rotary latches can be permanently connected to the rotary latch shaft, e.g. welded or riveted.

- the rotary latches can also advantageously be detachably connected to the rotary latch shaft. This enables the rotary latches to be adjusted according to the respective requirements, so that the contact pressure and surface alignment reach the desired level. Adjusting the rotary latches also makes it possible to compensate for any position deviations of the locking bolts, which can be advantageous, for example, after any vehicle repairs. Furthermore, the adjustment enables adaptation to any wear.

- the latching device can be arranged at a spatial distance from the rotary latch shaft.

- the rotary latch shaft and the locking device can be connected to one another by a linkage.

- the latching device can act on the rotary latch shaft between the two rotary latches or on an extension of the rotary latch shaft extending beyond one of the two rotary latches. Accordingly, there is great freedom of movement for the arrangement of the latching device.

- the rotary latches with rotary latch shaft and latching device can be arranged on the lifting door to be locked.

- the locking bolts are arranged on the vehicle body.

- a reverse arrangement is also possible in which the rotary latches with rotary latch shaft and latching device on the vehicle body and the locking bolts are arranged on the lifting door to be locked. This latter arrangement has the advantage that the lifting door can be made particularly light.

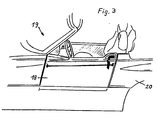

- a passenger car 1 with an open structure as a side door has a lifting door 2 which, in the closed position shown, is arranged flush with the adjoining vehicle parts and consequently assumes an essentially vertical position.

- the lifting door 2 is mounted on the vehicle body 3 so as to be displaceable in the vertical direction. It can be shifted downward from the closed position substantially into a receiving space in the side sill 4 while maintaining the vertical position. In the lower end position, the lifting door 2 assumes the open position.

- the passenger car 1 can be driven both when the lifting door 2 is closed, ie raised, and when the lifting door 2 is open, i.e. lowered.

- the two locking bolts 5, 6 are arranged in the lower region of the lifting door 2. They serve to lock the lifting door 2 in the closed position.

- the two locking bolts 7, 8 are arranged in the upper region of the lifting door 2. They serve to lock the lift door 2 in the open position.

- the locking bolts 5 to 8 are arranged in the two side door areas, that is to say at the front and at the rear end of the lifting door 2.

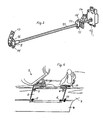

- a device shown in FIG. 2 with two rotary latches 9, 10, a rotary latch shaft 11 and a latching device 12 is fastened to the vehicle body 3.

- the attachment to the vehicle body 3 serve two holders 13, 14.

- the rotary latches 9, 10 are arranged in the two side door areas, that is to say at the front end and at the rear end of the lifting door 2, so that they cooperate with the locking bolts 5 to 8 can.

- the at least approximately horizontally arranged rotary latch shaft 11 not only extends between the two rotary latches 9, 10, but also protrudes beyond them with their two ends. With its front end, it is rotatably supported in the front holder 13.

- the two rotary latches 9, 10 are plate-shaped, arranged parallel to one another and designed as fork latches.

- Each of the two rotary latches 9, 10 is provided with two radial engagement recesses 15, 16 which are arranged offset from one another by an angle of rotation, the apex of which lies on the axis of the rotary latch shaft 11.

- the engagement recesses 15, 16 of the two rotary latches 9, 10 are aligned with one another in the same way.

- the two engagement recesses 15 pointing obliquely downward in FIG. 2 cooperate with the two locking bolts 5, 6 for the closed position.

- the two engagement recesses 16 which point obliquely upwards in FIG. 2 work together with the two locking bolts 7, 8 for the open position.

- the angle of rotation enclosed by the engagement recesses 15, 16 is 90 °.

- the locking bolts 5, 6 for the closed position are located in the engagement recesses 15 for the closed position.

- the rotary latches 9, 10 with the rotary latch shaft 11 are pivoted by approximately 45 ° relative to the position shown in FIG. 2, the unlocking position, such that the engagement recesses 15 for the closed position extend at least approximately horizontally.

- the locking device and thus the lifting door 2 is held by the locking device 12.

- the locking device 12 is actuated, for example by a linkage, not shown, which can be actuated by a handle 17 arranged on the vehicle body 3.

- the lifting door 2 can be opened, ie pushed down.

- the locking bolts 5, 6 pivot the rotary latches 9, 10 for the closed position about the axis of the rotary latch shaft 11 and finally emerge from the engagement recesses 15 for the closed position downward.

- the locking bolts 7, 8 for the open position come into the engaging recesses 16 pivoted into their receiving position the open position and pivot when the lifting door 2 is lowered into the open position, the rotary latches 9, 10 such that the engagement recesses 16 for the open position now extend at least approximately horizontally.

- the locking device 12 locks again.

- the lifting door 2 can be raised again and locked in the closed position.

- the rotary latches with rotary latch shaft and latching device are arranged on a side lifting door 18 of a passenger car 19 with an open structure.

- the rotary latch shaft extends in the upper door area at least approximately in the horizontal direction approximately over the entire length of the lifting door 18, in whose two lateral areas the two rotary latches are arranged.

- the latching device is arranged in the vicinity of the rear rotary latch in the region of the door handle arranged at the rear door end between the two rotary latches.

- upper locking bolts (not shown) for the closed position and lower locking bolts (also not shown) for the open position are provided on the vehicle body 20.

- a spring can be provided which tries to turn the rotary latches into the unlocking position and to hold them in this position.

- the locking device on the right side door is in each case a mirror image of the locking device explained on the left side door.

- a one-piece rotary latch shaft can be used instead of the assembled rotary latch shaft. It is also possible to provide both the closed position and the open position in the locking device forward and main detent.

Landscapes

- Lock And Its Accessories (AREA)

- Elevator Door Apparatuses (AREA)

Claims (6)

- Dispositif de verrouillage pour les portières relevables (18) de véhicules, en particulier de voitures particulières, pouvant coulisser dans le sens de la hauteur et prendre en position de fermeture, une position essentiellement verticale, avec des verrous pour la position de fermeture disposés dans les deux zones latérales des portières, caractérisé en ce que dans chacune des deux zones latérales des portières, est disposé un crochet tournant (9, 10) constitué comme un crochet à fourche avec un évidement radial d'agrippage (15) pour la position de fermeture et un évidement radial d'agrippage (16) pour la position d'ouverture disposé par rapport au précédent de façon décalée d'un certain angle de rotation, crochets tournants qui coopèrent pour la position de fermeture avec un téton de fermeture (5, 6) et pour la position d'ouverture avec un téton de fermeture (7, 8) disposé à une certaine distance du premier dans le sens de la hauteur et qui peuvent pivoter dans la position de verrouillage et dans la position de déverrouillage, grâce aux tétons de fermeture (5, 6, 7, 8) lors du mouvement de la portière relevable (2, 18) et en ce que les crochets tournants (9, 10) sont disposés parallèlement l'un à l'autre et sont reliés solidairement en rotation à un arbre à crochets tournants (11) et à une gâche automatique commune (12).

- Dispositif de verrouillage selon la revendication 1, caractérisé en ce que l'angle de rotation est un angle droit.

- Dispositif de verrouillage selon les revendications 1 ou 2, caractérisé en ce que les crochets tournants (9, 10) indépendamment l'un de l'autre, peuvent être montés de façon réglable sur l'arbre à crochets tournants (11).

- Dispositif de verrouillage selon les revendications 1 ou 2, caractérisé en ce que la gâche automatique (12) est disposée en dehors de l'espace compris entre les deux crochets tournants (9, 10).

- Dispositif de verrouillage selon l'une des revendications 1 à 3, caractérisé en ce que la gâche automatique est disposée entre les deux crochets tournants.

- Dispositif de verrouillage selon l'une des revendications précédentes, caractérisé en ce que les crochets tournants (9, 10) sont prévus sur la carrosserie du véhicule (3) et les tétons de fermeture (5, 6, 7, 8) sur la portière relevable (2).

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19863642242 DE3642242A1 (de) | 1986-12-10 | 1986-12-10 | Verriegelungseinrichtung fuer tueren, hauben, klappen o.dgl. von fahrzeugen, insbesondere kraftfahrzeugen |

| DE3642242 | 1986-12-10 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0271106A2 EP0271106A2 (fr) | 1988-06-15 |

| EP0271106A3 EP0271106A3 (en) | 1989-05-03 |

| EP0271106B1 true EP0271106B1 (fr) | 1991-08-14 |

Family

ID=6315914

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP87118346A Expired - Lifetime EP0271106B1 (fr) | 1986-12-10 | 1987-12-10 | Dispositif de verrouillage pour portes relevables de véhicules à moteur, en particulier voitures particulières |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP0271106B1 (fr) |

| DE (2) | DE3642242A1 (fr) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN111911015A (zh) * | 2019-05-08 | 2020-11-10 | 丰田自动车株式会社 | 车门结构 |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3921314C1 (fr) * | 1989-06-29 | 1990-08-23 | Daimler-Benz Aktiengesellschaft, 7000 Stuttgart, De | |

| DE4305738A1 (de) * | 1993-02-25 | 1994-10-13 | Scharwaechter Gmbh Co Kg | Türschließeinrichtung für Kraftwagentüren |

| DE4325266A1 (de) * | 1993-07-28 | 1995-02-02 | Scharwaechter Gmbh Co Kg | Türschließeinrichtung für Kraftwagentüren |

Family Cites Families (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE717946C (de) * | 1935-11-24 | 1942-02-26 | Wilhelm Hautau | Ruderverschluss fuer Fenster und Tueren |

| DE895409C (de) * | 1951-09-04 | 1953-11-02 | Helmut Petermann | Fahrzeugtuer, insbesondere Kraftfahrzeugtuer |

| US2943879A (en) * | 1957-05-10 | 1960-07-05 | Lisle W Menzimer | Latch mechanism |

| DE1235768B (de) * | 1961-12-21 | 1967-03-02 | Ford Werke Ag | Verschluss zum Festhalten einer Schiebetuer in geoeffneter oder geschlossener Stellung mittels einer in beidseitig angeordnete Schliesskloben eingreifenden Falle, deren Achse quer zur Bewegung der Schiebetuer angeordnet ist |

| DE1952334U (de) * | 1966-10-28 | 1966-12-22 | Schulte Schlagbaum Schlossfab | Drehstangenschloss. |

| DE1807388A1 (de) * | 1968-11-07 | 1970-05-27 | Guenter Mueller | Container mit abnehmbarem Dach |

| DE1813410A1 (de) * | 1968-12-07 | 1970-06-11 | Kiekert Soehne Arn | Schliessvorrichtung fuer Kraftfahrzeugtueren |

| JPS5850268A (ja) * | 1981-09-22 | 1983-03-24 | 株式会社大井製作所 | 自動車用ドアロツクの操作装置 |

-

1986

- 1986-12-10 DE DE19863642242 patent/DE3642242A1/de active Granted

-

1987

- 1987-12-10 DE DE8787118346T patent/DE3772170D1/de not_active Expired - Lifetime

- 1987-12-10 EP EP87118346A patent/EP0271106B1/fr not_active Expired - Lifetime

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN111911015A (zh) * | 2019-05-08 | 2020-11-10 | 丰田自动车株式会社 | 车门结构 |

Also Published As

| Publication number | Publication date |

|---|---|

| EP0271106A2 (fr) | 1988-06-15 |

| DE3642242A1 (de) | 1988-06-23 |

| DE3642242C2 (fr) | 1990-06-28 |

| EP0271106A3 (en) | 1989-05-03 |

| DE3772170D1 (de) | 1991-09-19 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0826539B1 (fr) | Construction de toit mobile pour voiture automobile transformable | |

| DE4329997B4 (de) | Einrichtung zum Ent- und Verriegeln von zumindest zwei mit Abstand zueinander angeordneten, schwenkbaren Hauben eines Kraftfahrzeuges | |

| EP1717392B1 (fr) | Arrangement de serrure supplémentaire pour porte coulissante de véhicule automobile | |

| DE19803871A1 (de) | Schloß für ein bewegliches Karosserieteil eines Kraftfahrzeuges | |

| DE3310020A1 (de) | Beschlag fuer einen zumindest kippbaren und parallelabstellbaren fluegel eines fensters, einer tuer od. dgl. | |

| DE1780577A1 (de) | Schiebetuer,insbesondere fuer Kraftwagen | |

| EP0433623B1 (fr) | Dispositif de verrouillage d'une fenêtre, d'une porte ou similaires | |

| DE60118036T2 (de) | Öffnungsmechanismus für die seitenschiebetür eines kraftfahrzeugs | |

| EP0271106B1 (fr) | Dispositif de verrouillage pour portes relevables de véhicules à moteur, en particulier voitures particulières | |

| DE102018108180A1 (de) | Türlaufrolle und Einbaukörper | |

| WO2023143823A1 (fr) | Dispositif de déplacement pour le déplacement forcé d'un battant, en particulier d'un battant coulissant, d'une fenêtre ou d'une porte | |

| EP3425149A1 (fr) | Construction levante-coulissante, notamment porte levante-coulissante ou fenêtre levante-coulissante | |

| DE69402465T2 (de) | Fensterrahmen mit Betätigungsvorrichtung für Riegelstangenverschlüsse | |

| EP1008713A1 (fr) | Dispositif de verrouillage | |

| EP1116845B1 (fr) | Verrouillage de fausse manoeuvre | |

| EP0611863B1 (fr) | Coffre à verrouillage automatique | |

| DE3234103C2 (fr) | ||

| DE3221110A1 (de) | Beschlag fuer einen kipp- und nachfolgend mindestens parallelabstellbaren fluegel eines fensters, einer tuer od. dgl. | |

| EP0668427B1 (fr) | Ferrure pour portes, fenêtres ou analoques | |

| DE19933576A1 (de) | Beschlag für Fenster oder Türen | |

| DE19538320A1 (de) | Verriegelungsschloß | |

| EP1231345B1 (fr) | Dispositif de verrouillage et renvoi d'angle contrôlés | |

| EP0307570B1 (fr) | Dispositif de verrouillage pour un capot de véhicule | |

| EP4363681B1 (fr) | Agencement de barre de verrouillage | |

| DE2552939C2 (fr) |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): DE FR GB IT SE |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): DE FR GB IT SE |

|

| 17P | Request for examination filed |

Effective date: 19890523 |

|

| 17Q | First examination report despatched |

Effective date: 19910129 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): DE FR GB IT SE |

|

| ET | Fr: translation filed | ||

| REF | Corresponds to: |

Ref document number: 3772170 Country of ref document: DE Date of ref document: 19910919 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) | ||

| ITF | It: translation for a ep patent filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Effective date: 19911210 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19911211 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| GBPC | Gb: european patent ceased through non-payment of renewal fee | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Effective date: 19920831 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19920901 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| EUG | Se: european patent has lapsed |

Ref document number: 87118346.3 Effective date: 19920704 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20051210 |