WO2024029346A1 - 離型フィルム - Google Patents

離型フィルム Download PDFInfo

- Publication number

- WO2024029346A1 WO2024029346A1 PCT/JP2023/026510 JP2023026510W WO2024029346A1 WO 2024029346 A1 WO2024029346 A1 WO 2024029346A1 JP 2023026510 W JP2023026510 W JP 2023026510W WO 2024029346 A1 WO2024029346 A1 WO 2024029346A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- resin layer

- layer

- release

- resin

- release film

- Prior art date

Links

- 229920005989 resin Polymers 0.000 claims abstract description 313

- 239000011347 resin Substances 0.000 claims abstract description 313

- 229920002050 silicone resin Polymers 0.000 claims abstract description 67

- 239000000853 adhesive Substances 0.000 claims abstract description 47

- 239000003795 chemical substances by application Substances 0.000 claims abstract description 43

- 239000010410 layer Substances 0.000 claims description 460

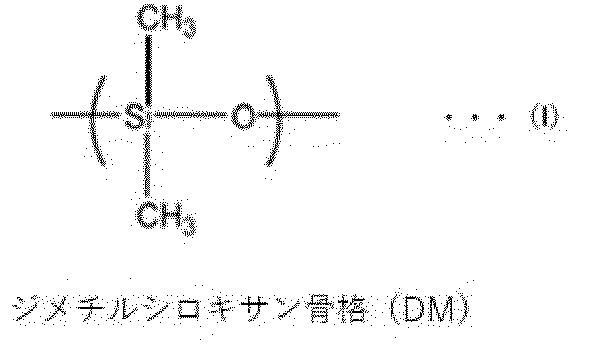

- -1 dimethylsiloxane skeleton Chemical group 0.000 claims description 120

- 150000001875 compounds Chemical class 0.000 claims description 96

- 239000012790 adhesive layer Substances 0.000 claims description 76

- 239000000203 mixture Substances 0.000 claims description 75

- 229920000728 polyester Polymers 0.000 claims description 72

- 239000002245 particle Substances 0.000 claims description 67

- 238000000034 method Methods 0.000 claims description 64

- 229920000642 polymer Polymers 0.000 claims description 50

- 230000001070 adhesive effect Effects 0.000 claims description 47

- 125000000217 alkyl group Chemical group 0.000 claims description 44

- 229920006267 polyester film Polymers 0.000 claims description 44

- YTPLMLYBLZKORZ-UHFFFAOYSA-N Thiophene Chemical compound C=1C=CSC=1 YTPLMLYBLZKORZ-UHFFFAOYSA-N 0.000 claims description 36

- 238000011156 evaluation Methods 0.000 claims description 24

- 229920000178 Acrylic resin Polymers 0.000 claims description 19

- 239000004925 Acrylic resin Substances 0.000 claims description 19

- 239000004820 Pressure-sensitive adhesive Substances 0.000 claims description 19

- 230000003287 optical effect Effects 0.000 claims description 18

- 229930192474 thiophene Natural products 0.000 claims description 18

- 229920001225 polyester resin Polymers 0.000 claims description 17

- 239000004645 polyester resin Substances 0.000 claims description 17

- 238000003825 pressing Methods 0.000 claims description 17

- 150000003577 thiophenes Chemical class 0.000 claims description 17

- 239000006082 mold release agent Substances 0.000 claims description 16

- 239000003522 acrylic cement Substances 0.000 claims description 12

- 150000001449 anionic compounds Chemical class 0.000 claims description 6

- 150000002222 fluorine compounds Chemical class 0.000 claims description 5

- 229920005749 polyurethane resin Polymers 0.000 claims description 5

- GOXQRTZXKQZDDN-UHFFFAOYSA-N 2-Ethylhexyl acrylate Chemical compound CCCCC(CC)COC(=O)C=C GOXQRTZXKQZDDN-UHFFFAOYSA-N 0.000 claims description 4

- CQEYYJKEWSMYFG-UHFFFAOYSA-N butyl acrylate Chemical compound CCCCOC(=O)C=C CQEYYJKEWSMYFG-UHFFFAOYSA-N 0.000 claims description 4

- 125000000129 anionic group Chemical group 0.000 claims description 3

- 230000000903 blocking effect Effects 0.000 abstract description 33

- 239000000463 material Substances 0.000 abstract description 16

- 230000008859 change Effects 0.000 abstract description 4

- 239000010408 film Substances 0.000 description 326

- NIXOWILDQLNWCW-UHFFFAOYSA-M Acrylate Chemical compound [O-]C(=O)C=C NIXOWILDQLNWCW-UHFFFAOYSA-M 0.000 description 78

- 238000000576 coating method Methods 0.000 description 71

- 239000011248 coating agent Substances 0.000 description 69

- LYCAIKOWRPUZTN-UHFFFAOYSA-N Ethylene glycol Chemical compound OCCO LYCAIKOWRPUZTN-UHFFFAOYSA-N 0.000 description 67

- 239000000178 monomer Substances 0.000 description 62

- 239000003431 cross linking reagent Substances 0.000 description 43

- 239000001993 wax Substances 0.000 description 34

- 239000002585 base Substances 0.000 description 33

- 229920001296 polysiloxane Polymers 0.000 description 32

- 238000006243 chemical reaction Methods 0.000 description 30

- 238000004519 manufacturing process Methods 0.000 description 28

- 238000005259 measurement Methods 0.000 description 27

- MTHSVFCYNBDYFN-UHFFFAOYSA-N diethylene glycol Chemical compound OCCOCCO MTHSVFCYNBDYFN-UHFFFAOYSA-N 0.000 description 24

- 239000002253 acid Substances 0.000 description 21

- 125000002887 hydroxy group Chemical group [H]O* 0.000 description 20

- 229920002803 thermoplastic polyurethane Polymers 0.000 description 20

- 230000000052 comparative effect Effects 0.000 description 19

- 125000004432 carbon atom Chemical group C* 0.000 description 17

- 239000002904 solvent Substances 0.000 description 17

- IMNFDUFMRHMDMM-UHFFFAOYSA-N N-Heptane Chemical compound CCCCCCC IMNFDUFMRHMDMM-UHFFFAOYSA-N 0.000 description 16

- DNIAPMSPPWPWGF-UHFFFAOYSA-N Propylene glycol Chemical compound CC(O)CO DNIAPMSPPWPWGF-UHFFFAOYSA-N 0.000 description 16

- WYURNTSHIVDZCO-UHFFFAOYSA-N Tetrahydrofuran Chemical compound C1CCOC1 WYURNTSHIVDZCO-UHFFFAOYSA-N 0.000 description 16

- NIXOWILDQLNWCW-UHFFFAOYSA-N acrylic acid group Chemical group C(C=C)(=O)O NIXOWILDQLNWCW-UHFFFAOYSA-N 0.000 description 16

- 239000003054 catalyst Substances 0.000 description 16

- 238000001723 curing Methods 0.000 description 15

- 239000007788 liquid Substances 0.000 description 15

- 230000005012 migration Effects 0.000 description 15

- 238000013508 migration Methods 0.000 description 15

- BASFCYQUMIYNBI-UHFFFAOYSA-N platinum Chemical compound [Pt] BASFCYQUMIYNBI-UHFFFAOYSA-N 0.000 description 15

- 125000002947 alkylene group Chemical group 0.000 description 14

- 239000011572 manganese Substances 0.000 description 14

- 125000003342 alkenyl group Chemical group 0.000 description 13

- 238000001035 drying Methods 0.000 description 13

- 229920005862 polyol Polymers 0.000 description 13

- ZWEHNKRNPOVVGH-UHFFFAOYSA-N 2-Butanone Chemical compound CCC(C)=O ZWEHNKRNPOVVGH-UHFFFAOYSA-N 0.000 description 12

- PPBRXRYQALVLMV-UHFFFAOYSA-N Styrene Chemical compound C=CC1=CC=CC=C1 PPBRXRYQALVLMV-UHFFFAOYSA-N 0.000 description 12

- KKEYFWRCBNTPAC-UHFFFAOYSA-N Terephthalic acid Chemical compound OC(=O)C1=CC=C(C(O)=O)C=C1 KKEYFWRCBNTPAC-UHFFFAOYSA-N 0.000 description 12

- 239000002216 antistatic agent Substances 0.000 description 12

- 238000010438 heat treatment Methods 0.000 description 12

- 150000003077 polyols Chemical class 0.000 description 12

- 239000000243 solution Substances 0.000 description 12

- 239000000126 substance Substances 0.000 description 12

- 125000000391 vinyl group Chemical group [H]C([*])=C([H])[H] 0.000 description 12

- 230000015572 biosynthetic process Effects 0.000 description 11

- 125000003178 carboxy group Chemical group [H]OC(*)=O 0.000 description 11

- 229920001577 copolymer Polymers 0.000 description 11

- 229920000058 polyacrylate Polymers 0.000 description 11

- 230000008569 process Effects 0.000 description 11

- 239000002994 raw material Substances 0.000 description 11

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 11

- OFOBLEOULBTSOW-UHFFFAOYSA-N Malonic acid Chemical compound OC(=O)CC(O)=O OFOBLEOULBTSOW-UHFFFAOYSA-N 0.000 description 10

- QQVIHTHCMHWDBS-UHFFFAOYSA-N isophthalic acid Chemical compound OC(=O)C1=CC=CC(C(O)=O)=C1 QQVIHTHCMHWDBS-UHFFFAOYSA-N 0.000 description 10

- 125000002496 methyl group Chemical group [H]C([H])([H])* 0.000 description 10

- 239000002344 surface layer Substances 0.000 description 10

- OKKJLVBELUTLKV-UHFFFAOYSA-N Methanol Chemical compound OC OKKJLVBELUTLKV-UHFFFAOYSA-N 0.000 description 9

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N Silicium dioxide Chemical compound O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 description 9

- YXFVVABEGXRONW-UHFFFAOYSA-N Toluene Chemical compound CC1=CC=CC=C1 YXFVVABEGXRONW-UHFFFAOYSA-N 0.000 description 9

- 150000001252 acrylic acid derivatives Chemical class 0.000 description 9

- 125000003277 amino group Chemical group 0.000 description 9

- 239000011230 binding agent Substances 0.000 description 9

- WGCNASOHLSPBMP-UHFFFAOYSA-N hydroxyacetaldehyde Natural products OCC=O WGCNASOHLSPBMP-UHFFFAOYSA-N 0.000 description 9

- VZSRBBMJRBPUNF-UHFFFAOYSA-N 2-(2,3-dihydro-1H-inden-2-ylamino)-N-[3-oxo-3-(2,4,6,7-tetrahydrotriazolo[4,5-c]pyridin-5-yl)propyl]pyrimidine-5-carboxamide Chemical compound C1C(CC2=CC=CC=C12)NC1=NC=C(C=N1)C(=O)NCCC(N1CC2=C(CC1)NN=N2)=O VZSRBBMJRBPUNF-UHFFFAOYSA-N 0.000 description 8

- QGZKDVFQNNGYKY-UHFFFAOYSA-N Ammonia Chemical compound N QGZKDVFQNNGYKY-UHFFFAOYSA-N 0.000 description 8

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 8

- 229920000877 Melamine resin Polymers 0.000 description 8

- 239000006096 absorbing agent Substances 0.000 description 8

- 239000002390 adhesive tape Substances 0.000 description 8

- WNLRTRBMVRJNCN-UHFFFAOYSA-N adipic acid Chemical compound OC(=O)CCCCC(O)=O WNLRTRBMVRJNCN-UHFFFAOYSA-N 0.000 description 8

- 238000004458 analytical method Methods 0.000 description 8

- ADCOVFLJGNWWNZ-UHFFFAOYSA-N antimony trioxide Chemical compound O=[Sb]O[Sb]=O ADCOVFLJGNWWNZ-UHFFFAOYSA-N 0.000 description 8

- 239000006185 dispersion Substances 0.000 description 8

- 230000000694 effects Effects 0.000 description 8

- 125000001495 ethyl group Chemical group [H]C([H])([H])C([H])([H])* 0.000 description 8

- 125000000524 functional group Chemical group 0.000 description 8

- 125000005010 perfluoroalkyl group Chemical group 0.000 description 8

- 125000001997 phenyl group Chemical group [H]C1=C([H])C([H])=C(*)C([H])=C1[H] 0.000 description 8

- CXMXRPHRNRROMY-UHFFFAOYSA-N sebacic acid Chemical compound OC(=O)CCCCCCCCC(O)=O CXMXRPHRNRROMY-UHFFFAOYSA-N 0.000 description 8

- YLQBMQCUIZJEEH-UHFFFAOYSA-N tetrahydrofuran Natural products C=1C=COC=1 YLQBMQCUIZJEEH-UHFFFAOYSA-N 0.000 description 8

- 150000003609 titanium compounds Chemical class 0.000 description 8

- 239000004372 Polyvinyl alcohol Substances 0.000 description 7

- 238000007792 addition Methods 0.000 description 7

- 125000003118 aryl group Chemical group 0.000 description 7

- 238000001816 cooling Methods 0.000 description 7

- 230000006866 deterioration Effects 0.000 description 7

- 229920001971 elastomer Polymers 0.000 description 7

- 150000002430 hydrocarbons Chemical group 0.000 description 7

- 239000012948 isocyanate Substances 0.000 description 7

- XNGIFLGASWRNHJ-UHFFFAOYSA-N phthalic acid Chemical compound OC(=O)C1=CC=CC=C1C(O)=O XNGIFLGASWRNHJ-UHFFFAOYSA-N 0.000 description 7

- 229910052697 platinum Inorganic materials 0.000 description 7

- 238000006116 polymerization reaction Methods 0.000 description 7

- 229920002451 polyvinyl alcohol Polymers 0.000 description 7

- VZCYOOQTPOCHFL-UHFFFAOYSA-N trans-butenedioic acid Natural products OC(=O)C=CC(O)=O VZCYOOQTPOCHFL-UHFFFAOYSA-N 0.000 description 7

- 239000004970 Chain extender Substances 0.000 description 6

- KWYUFKZDYYNOTN-UHFFFAOYSA-M Potassium hydroxide Chemical compound [OH-].[K+] KWYUFKZDYYNOTN-UHFFFAOYSA-M 0.000 description 6

- ZMANZCXQSJIPKH-UHFFFAOYSA-N Triethylamine Chemical compound CCN(CC)CC ZMANZCXQSJIPKH-UHFFFAOYSA-N 0.000 description 6

- WERYXYBDKMZEQL-UHFFFAOYSA-N butane-1,4-diol Chemical compound OCCCCO WERYXYBDKMZEQL-UHFFFAOYSA-N 0.000 description 6

- 238000004132 cross linking Methods 0.000 description 6

- 238000007865 diluting Methods 0.000 description 6

- WOZVHXUHUFLZGK-UHFFFAOYSA-N dimethyl terephthalate Chemical compound COC(=O)C1=CC=C(C(=O)OC)C=C1 WOZVHXUHUFLZGK-UHFFFAOYSA-N 0.000 description 6

- 150000002009 diols Chemical class 0.000 description 6

- KPUWHANPEXNPJT-UHFFFAOYSA-N disiloxane Chemical class [SiH3]O[SiH3] KPUWHANPEXNPJT-UHFFFAOYSA-N 0.000 description 6

- 238000005227 gel permeation chromatography Methods 0.000 description 6

- 230000009477 glass transition Effects 0.000 description 6

- 229920001519 homopolymer Polymers 0.000 description 6

- 229910052751 metal Inorganic materials 0.000 description 6

- SLCVBVWXLSEKPL-UHFFFAOYSA-N neopentyl glycol Chemical compound OCC(C)(C)CO SLCVBVWXLSEKPL-UHFFFAOYSA-N 0.000 description 6

- 239000013500 performance material Substances 0.000 description 6

- 238000006068 polycondensation reaction Methods 0.000 description 6

- HRPVXLWXLXDGHG-UHFFFAOYSA-N Acrylamide Chemical compound NC(=O)C=C HRPVXLWXLXDGHG-UHFFFAOYSA-N 0.000 description 5

- VZCYOOQTPOCHFL-OWOJBTEDSA-N Fumaric acid Chemical compound OC(=O)\C=C\C(O)=O VZCYOOQTPOCHFL-OWOJBTEDSA-N 0.000 description 5

- 239000002202 Polyethylene glycol Substances 0.000 description 5

- YIMQCDZDWXUDCA-UHFFFAOYSA-N [4-(hydroxymethyl)cyclohexyl]methanol Chemical compound OCC1CCC(CO)CC1 YIMQCDZDWXUDCA-UHFFFAOYSA-N 0.000 description 5

- 150000001412 amines Chemical class 0.000 description 5

- 239000000975 dye Substances 0.000 description 5

- 150000002148 esters Chemical class 0.000 description 5

- 238000001125 extrusion Methods 0.000 description 5

- 125000004435 hydrogen atom Chemical group [H]* 0.000 description 5

- 150000002500 ions Chemical class 0.000 description 5

- 150000002513 isocyanates Chemical class 0.000 description 5

- 239000002184 metal Substances 0.000 description 5

- RXOHFPCZGPKIRD-UHFFFAOYSA-N naphthalene-2,6-dicarboxylic acid Chemical compound C1=C(C(O)=O)C=CC2=CC(C(=O)O)=CC=C21 RXOHFPCZGPKIRD-UHFFFAOYSA-N 0.000 description 5

- 229910052698 phosphorus Inorganic materials 0.000 description 5

- 239000011574 phosphorus Substances 0.000 description 5

- 229920000515 polycarbonate Polymers 0.000 description 5

- 239000004417 polycarbonate Substances 0.000 description 5

- 229920001223 polyethylene glycol Polymers 0.000 description 5

- 230000000379 polymerizing effect Effects 0.000 description 5

- 229920002635 polyurethane Polymers 0.000 description 5

- 239000004814 polyurethane Substances 0.000 description 5

- YPFDHNVEDLHUCE-UHFFFAOYSA-N propane-1,3-diol Chemical compound OCCCO YPFDHNVEDLHUCE-UHFFFAOYSA-N 0.000 description 5

- 238000007789 sealing Methods 0.000 description 5

- 238000003756 stirring Methods 0.000 description 5

- 230000003746 surface roughness Effects 0.000 description 5

- 238000005809 transesterification reaction Methods 0.000 description 5

- 238000012546 transfer Methods 0.000 description 5

- PUPZLCDOIYMWBV-UHFFFAOYSA-N (+/-)-1,3-Butanediol Chemical compound CC(O)CCO PUPZLCDOIYMWBV-UHFFFAOYSA-N 0.000 description 4

- 238000005160 1H NMR spectroscopy Methods 0.000 description 4

- 229920002799 BoPET Polymers 0.000 description 4

- VTYYLEPIZMXCLO-UHFFFAOYSA-L Calcium carbonate Chemical compound [Ca+2].[O-]C([O-])=O VTYYLEPIZMXCLO-UHFFFAOYSA-L 0.000 description 4

- RTZKZFJDLAIYFH-UHFFFAOYSA-N Diethyl ether Chemical compound CCOCC RTZKZFJDLAIYFH-UHFFFAOYSA-N 0.000 description 4

- PEDCQBHIVMGVHV-UHFFFAOYSA-N Glycerine Chemical compound OCC(O)CO PEDCQBHIVMGVHV-UHFFFAOYSA-N 0.000 description 4

- CTQNGGLPUBDAKN-UHFFFAOYSA-N O-Xylene Chemical compound CC1=CC=CC=C1C CTQNGGLPUBDAKN-UHFFFAOYSA-N 0.000 description 4

- 229910019142 PO4 Inorganic materials 0.000 description 4

- NBIIXXVUZAFLBC-UHFFFAOYSA-N Phosphoric acid Chemical compound OP(O)(O)=O NBIIXXVUZAFLBC-UHFFFAOYSA-N 0.000 description 4

- 239000004793 Polystyrene Substances 0.000 description 4

- QAOWNCQODCNURD-UHFFFAOYSA-N Sulfuric acid Chemical compound OS(O)(=O)=O QAOWNCQODCNURD-UHFFFAOYSA-N 0.000 description 4

- 239000000654 additive Substances 0.000 description 4

- 239000001361 adipic acid Substances 0.000 description 4

- 235000011037 adipic acid Nutrition 0.000 description 4

- 125000001931 aliphatic group Chemical group 0.000 description 4

- 229910021529 ammonia Inorganic materials 0.000 description 4

- 239000012298 atmosphere Substances 0.000 description 4

- CDQSJQSWAWPGKG-UHFFFAOYSA-N butane-1,1-diol Chemical compound CCCC(O)O CDQSJQSWAWPGKG-UHFFFAOYSA-N 0.000 description 4

- 238000007334 copolymerization reaction Methods 0.000 description 4

- 125000003055 glycidyl group Chemical group C(C1CO1)* 0.000 description 4

- 238000009998 heat setting Methods 0.000 description 4

- 150000002440 hydroxy compounds Chemical class 0.000 description 4

- 239000004973 liquid crystal related substance Substances 0.000 description 4

- VZCYOOQTPOCHFL-UPHRSURJSA-N maleic acid Chemical compound OC(=O)\C=C/C(O)=O VZCYOOQTPOCHFL-UPHRSURJSA-N 0.000 description 4

- 150000007974 melamines Chemical class 0.000 description 4

- 229910052757 nitrogen Inorganic materials 0.000 description 4

- 150000003961 organosilicon compounds Chemical class 0.000 description 4

- NBIIXXVUZAFLBC-UHFFFAOYSA-K phosphate Chemical compound [O-]P([O-])([O-])=O NBIIXXVUZAFLBC-UHFFFAOYSA-K 0.000 description 4

- 239000010452 phosphate Substances 0.000 description 4

- 239000000049 pigment Substances 0.000 description 4

- 229920000172 poly(styrenesulfonic acid) Polymers 0.000 description 4

- 229920000447 polyanionic polymer Polymers 0.000 description 4

- 229920005906 polyester polyol Polymers 0.000 description 4

- 229920001451 polypropylene glycol Polymers 0.000 description 4

- 229920002223 polystyrene Polymers 0.000 description 4

- 229940005642 polystyrene sulfonic acid Drugs 0.000 description 4

- 239000002244 precipitate Substances 0.000 description 4

- 239000011541 reaction mixture Substances 0.000 description 4

- 230000009257 reactivity Effects 0.000 description 4

- 150000003839 salts Chemical class 0.000 description 4

- 239000002356 single layer Substances 0.000 description 4

- 239000000758 substrate Substances 0.000 description 4

- 239000006097 ultraviolet radiation absorber Substances 0.000 description 4

- 239000008096 xylene Substances 0.000 description 4

- HMUNWXXNJPVALC-UHFFFAOYSA-N 1-[4-[2-(2,3-dihydro-1H-inden-2-ylamino)pyrimidin-5-yl]piperazin-1-yl]-2-(2,4,6,7-tetrahydrotriazolo[4,5-c]pyridin-5-yl)ethanone Chemical compound C1C(CC2=CC=CC=C12)NC1=NC=C(C=N1)N1CCN(CC1)C(CN1CC2=C(CC1)NN=N2)=O HMUNWXXNJPVALC-UHFFFAOYSA-N 0.000 description 3

- QWDQYHPOSSHSAW-UHFFFAOYSA-N 1-isocyanatooctadecane Chemical compound CCCCCCCCCCCCCCCCCCN=C=O QWDQYHPOSSHSAW-UHFFFAOYSA-N 0.000 description 3

- PTBDIHRZYDMNKB-UHFFFAOYSA-N 2,2-Bis(hydroxymethyl)propionic acid Chemical compound OCC(C)(CO)C(O)=O PTBDIHRZYDMNKB-UHFFFAOYSA-N 0.000 description 3

- 125000000954 2-hydroxyethyl group Chemical group [H]C([*])([H])C([H])([H])O[H] 0.000 description 3

- OMIGHNLMNHATMP-UHFFFAOYSA-N 2-hydroxyethyl prop-2-enoate Chemical compound OCCOC(=O)C=C OMIGHNLMNHATMP-UHFFFAOYSA-N 0.000 description 3

- RSWGJHLUYNHPMX-UHFFFAOYSA-N Abietic-Saeure Natural products C12CCC(C(C)C)=CC2=CCC2C1(C)CCCC2(C)C(O)=O RSWGJHLUYNHPMX-UHFFFAOYSA-N 0.000 description 3

- QTBSBXVTEAMEQO-UHFFFAOYSA-N Acetic acid Chemical compound CC(O)=O QTBSBXVTEAMEQO-UHFFFAOYSA-N 0.000 description 3

- 239000004593 Epoxy Chemical class 0.000 description 3

- LFQSCWFLJHTTHZ-UHFFFAOYSA-N Ethanol Chemical compound CCO LFQSCWFLJHTTHZ-UHFFFAOYSA-N 0.000 description 3

- XEKOWRVHYACXOJ-UHFFFAOYSA-N Ethyl acetate Chemical compound CCOC(C)=O XEKOWRVHYACXOJ-UHFFFAOYSA-N 0.000 description 3

- IAYPIBMASNFSPL-UHFFFAOYSA-N Ethylene oxide Chemical compound C1CO1 IAYPIBMASNFSPL-UHFFFAOYSA-N 0.000 description 3

- KFZMGEQAYNKOFK-UHFFFAOYSA-N Isopropanol Chemical compound CC(C)O KFZMGEQAYNKOFK-UHFFFAOYSA-N 0.000 description 3

- CERQOIWHTDAKMF-UHFFFAOYSA-N Methacrylic acid Chemical compound CC(=C)C(O)=O CERQOIWHTDAKMF-UHFFFAOYSA-N 0.000 description 3

- 239000004698 Polyethylene Substances 0.000 description 3

- KHPCPRHQVVSZAH-HUOMCSJISA-N Rosin Natural products O(C/C=C/c1ccccc1)[C@H]1[C@H](O)[C@@H](O)[C@@H](O)[C@@H](CO)O1 KHPCPRHQVVSZAH-HUOMCSJISA-N 0.000 description 3

- BZHJMEDXRYGGRV-UHFFFAOYSA-N Vinyl chloride Chemical compound ClC=C BZHJMEDXRYGGRV-UHFFFAOYSA-N 0.000 description 3

- 150000001735 carboxylic acids Chemical class 0.000 description 3

- KRKNYBCHXYNGOX-UHFFFAOYSA-N citric acid Chemical compound OC(=O)CC(O)(C(O)=O)CC(O)=O KRKNYBCHXYNGOX-UHFFFAOYSA-N 0.000 description 3

- 239000011247 coating layer Substances 0.000 description 3

- 239000006258 conductive agent Substances 0.000 description 3

- 125000004122 cyclic group Chemical group 0.000 description 3

- 230000003247 decreasing effect Effects 0.000 description 3

- 125000003438 dodecyl group Chemical group [H]C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])* 0.000 description 3

- 238000004945 emulsification Methods 0.000 description 3

- 239000003822 epoxy resin Substances 0.000 description 3

- 230000032050 esterification Effects 0.000 description 3

- 238000005886 esterification reaction Methods 0.000 description 3

- 239000010419 fine particle Substances 0.000 description 3

- 229910052731 fluorine Inorganic materials 0.000 description 3

- 125000001153 fluoro group Chemical group F* 0.000 description 3

- 230000006870 function Effects 0.000 description 3

- 150000002291 germanium compounds Chemical class 0.000 description 3

- 238000007756 gravure coating Methods 0.000 description 3

- XXMIOPMDWAUFGU-UHFFFAOYSA-N hexane-1,6-diol Chemical compound OCCCCCCO XXMIOPMDWAUFGU-UHFFFAOYSA-N 0.000 description 3

- 125000003010 ionic group Chemical group 0.000 description 3

- IQPQWNKOIGAROB-UHFFFAOYSA-N isocyanate group Chemical group [N-]=C=O IQPQWNKOIGAROB-UHFFFAOYSA-N 0.000 description 3

- 239000000314 lubricant Substances 0.000 description 3

- 229940097364 magnesium acetate tetrahydrate Drugs 0.000 description 3

- XKPKPGCRSHFTKM-UHFFFAOYSA-L magnesium;diacetate;tetrahydrate Chemical compound O.O.O.O.[Mg+2].CC([O-])=O.CC([O-])=O XKPKPGCRSHFTKM-UHFFFAOYSA-L 0.000 description 3

- 239000011976 maleic acid Substances 0.000 description 3

- VLKZOEOYAKHREP-UHFFFAOYSA-N n-Hexane Chemical compound CCCCCC VLKZOEOYAKHREP-UHFFFAOYSA-N 0.000 description 3

- 125000000962 organic group Chemical group 0.000 description 3

- WXZMFSXDPGVJKK-UHFFFAOYSA-N pentaerythritol Chemical compound OCC(CO)(CO)CO WXZMFSXDPGVJKK-UHFFFAOYSA-N 0.000 description 3

- 235000019271 petrolatum Nutrition 0.000 description 3

- 235000011007 phosphoric acid Nutrition 0.000 description 3

- 229920003216 poly(methylphenylsiloxane) Polymers 0.000 description 3

- 229920000647 polyepoxide Polymers 0.000 description 3

- 229920000573 polyethylene Polymers 0.000 description 3

- 239000000047 product Substances 0.000 description 3

- 125000001436 propyl group Chemical group [H]C([*])([H])C([H])([H])C([H])([H])[H] 0.000 description 3

- 239000007858 starting material Substances 0.000 description 3

- 150000005846 sugar alcohols Polymers 0.000 description 3

- KHPCPRHQVVSZAH-UHFFFAOYSA-N trans-cinnamyl beta-D-glucopyranoside Natural products OC1C(O)C(O)C(CO)OC1OCC=CC1=CC=CC=C1 KHPCPRHQVVSZAH-UHFFFAOYSA-N 0.000 description 3

- ARCGXLSVLAOJQL-UHFFFAOYSA-N trimellitic acid Chemical compound OC(=O)C1=CC=C(C(O)=O)C(C(O)=O)=C1 ARCGXLSVLAOJQL-UHFFFAOYSA-N 0.000 description 3

- 239000003981 vehicle Substances 0.000 description 3

- 229920002554 vinyl polymer Polymers 0.000 description 3

- 238000004804 winding Methods 0.000 description 3

- DSEKYWAQQVUQTP-XEWMWGOFSA-N (2r,4r,4as,6as,6as,6br,8ar,12ar,14as,14bs)-2-hydroxy-4,4a,6a,6b,8a,11,11,14a-octamethyl-2,4,5,6,6a,7,8,9,10,12,12a,13,14,14b-tetradecahydro-1h-picen-3-one Chemical compound C([C@H]1[C@]2(C)CC[C@@]34C)C(C)(C)CC[C@]1(C)CC[C@]2(C)[C@H]4CC[C@@]1(C)[C@H]3C[C@@H](O)C(=O)[C@@H]1C DSEKYWAQQVUQTP-XEWMWGOFSA-N 0.000 description 2

- QPFMBZIOSGYJDE-UHFFFAOYSA-N 1,1,2,2-tetrachloroethane Chemical compound ClC(Cl)C(Cl)Cl QPFMBZIOSGYJDE-UHFFFAOYSA-N 0.000 description 2

- MYRTYDVEIRVNKP-UHFFFAOYSA-N 1,2-Divinylbenzene Chemical compound C=CC1=CC=CC=C1C=C MYRTYDVEIRVNKP-UHFFFAOYSA-N 0.000 description 2

- ALVZNPYWJMLXKV-UHFFFAOYSA-N 1,9-Nonanediol Chemical compound OCCCCCCCCCO ALVZNPYWJMLXKV-UHFFFAOYSA-N 0.000 description 2

- UAJRSHJHFRVGMG-UHFFFAOYSA-N 1-ethenyl-4-methoxybenzene Chemical compound COC1=CC=C(C=C)C=C1 UAJRSHJHFRVGMG-UHFFFAOYSA-N 0.000 description 2

- SMZOUWXMTYCWNB-UHFFFAOYSA-N 2-(2-methoxy-5-methylphenyl)ethanamine Chemical compound COC1=CC=C(C)C=C1CCN SMZOUWXMTYCWNB-UHFFFAOYSA-N 0.000 description 2

- IAXFZZHBFXRZMT-UHFFFAOYSA-N 2-[3-(2-hydroxyethoxy)phenoxy]ethanol Chemical compound OCCOC1=CC=CC(OCCO)=C1 IAXFZZHBFXRZMT-UHFFFAOYSA-N 0.000 description 2

- DSKYSDCYIODJPC-UHFFFAOYSA-N 2-butyl-2-ethylpropane-1,3-diol Chemical compound CCCCC(CC)(CO)CO DSKYSDCYIODJPC-UHFFFAOYSA-N 0.000 description 2

- SVTBMSDMJJWYQN-UHFFFAOYSA-N 2-methylpentane-2,4-diol Chemical compound CC(O)CC(C)(C)O SVTBMSDMJJWYQN-UHFFFAOYSA-N 0.000 description 2

- 125000003504 2-oxazolinyl group Chemical group O1C(=NCC1)* 0.000 description 2

- YLZOPXRUQYQQID-UHFFFAOYSA-N 3-(2,4,6,7-tetrahydrotriazolo[4,5-c]pyridin-5-yl)-1-[4-[2-[[3-(trifluoromethoxy)phenyl]methylamino]pyrimidin-5-yl]piperazin-1-yl]propan-1-one Chemical compound N1N=NC=2CN(CCC=21)CCC(=O)N1CCN(CC1)C=1C=NC(=NC=1)NCC1=CC(=CC=C1)OC(F)(F)F YLZOPXRUQYQQID-UHFFFAOYSA-N 0.000 description 2

- SXFJDZNJHVPHPH-UHFFFAOYSA-N 3-methylpentane-1,5-diol Chemical compound OCCC(C)CCO SXFJDZNJHVPHPH-UHFFFAOYSA-N 0.000 description 2

- XDLMVUHYZWKMMD-UHFFFAOYSA-N 3-trimethoxysilylpropyl 2-methylprop-2-enoate Chemical compound CO[Si](OC)(OC)CCCOC(=O)C(C)=C XDLMVUHYZWKMMD-UHFFFAOYSA-N 0.000 description 2

- YEJRWHAVMIAJKC-UHFFFAOYSA-N 4-Butyrolactone Chemical compound O=C1CCCO1 YEJRWHAVMIAJKC-UHFFFAOYSA-N 0.000 description 2

- SXIFAEWFOJETOA-UHFFFAOYSA-N 4-hydroxy-butyl Chemical group [CH2]CCCO SXIFAEWFOJETOA-UHFFFAOYSA-N 0.000 description 2

- FJKROLUGYXJWQN-UHFFFAOYSA-N 4-hydroxybenzoic acid Chemical compound OC(=O)C1=CC=C(O)C=C1 FJKROLUGYXJWQN-UHFFFAOYSA-N 0.000 description 2

- NLHHRLWOUZZQLW-UHFFFAOYSA-N Acrylonitrile Chemical compound C=CC#N NLHHRLWOUZZQLW-UHFFFAOYSA-N 0.000 description 2

- VHUUQVKOLVNVRT-UHFFFAOYSA-N Ammonium hydroxide Chemical compound [NH4+].[OH-] VHUUQVKOLVNVRT-UHFFFAOYSA-N 0.000 description 2

- 239000004604 Blowing Agent Substances 0.000 description 2

- KAKZBPTYRLMSJV-UHFFFAOYSA-N Butadiene Chemical compound C=CC=C KAKZBPTYRLMSJV-UHFFFAOYSA-N 0.000 description 2

- FERIUCNNQQJTOY-UHFFFAOYSA-N Butyric acid Chemical compound CCCC(O)=O FERIUCNNQQJTOY-UHFFFAOYSA-N 0.000 description 2

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 2

- 229920002284 Cellulose triacetate Polymers 0.000 description 2

- VEXZGXHMUGYJMC-UHFFFAOYSA-N Hydrochloric acid Chemical compound Cl VEXZGXHMUGYJMC-UHFFFAOYSA-N 0.000 description 2

- 238000005481 NMR spectroscopy Methods 0.000 description 2

- ISWSIDIOOBJBQZ-UHFFFAOYSA-N Phenol Chemical compound OC1=CC=CC=C1 ISWSIDIOOBJBQZ-UHFFFAOYSA-N 0.000 description 2

- OAICVXFJPJFONN-UHFFFAOYSA-N Phosphorus Chemical compound [P] OAICVXFJPJFONN-UHFFFAOYSA-N 0.000 description 2

- 229920003171 Poly (ethylene oxide) Polymers 0.000 description 2

- 229920001609 Poly(3,4-ethylenedioxythiophene) Polymers 0.000 description 2

- 229920002873 Polyethylenimine Polymers 0.000 description 2

- 239000004721 Polyphenylene oxide Substances 0.000 description 2

- XUIMIQQOPSSXEZ-UHFFFAOYSA-N Silicon Chemical group [Si] XUIMIQQOPSSXEZ-UHFFFAOYSA-N 0.000 description 2

- KDYFGRWQOYBRFD-UHFFFAOYSA-N Succinic acid Natural products OC(=O)CCC(O)=O KDYFGRWQOYBRFD-UHFFFAOYSA-N 0.000 description 2

- RTAQQCXQSZGOHL-UHFFFAOYSA-N Titanium Chemical compound [Ti] RTAQQCXQSZGOHL-UHFFFAOYSA-N 0.000 description 2

- ZJCCRDAZUWHFQH-UHFFFAOYSA-N Trimethylolpropane Chemical compound CCC(CO)(CO)CO ZJCCRDAZUWHFQH-UHFFFAOYSA-N 0.000 description 2

- QYKIQEUNHZKYBP-UHFFFAOYSA-N Vinyl ether Chemical compound C=COC=C QYKIQEUNHZKYBP-UHFFFAOYSA-N 0.000 description 2

- NNLVGZFZQQXQNW-ADJNRHBOSA-N [(2r,3r,4s,5r,6s)-4,5-diacetyloxy-3-[(2s,3r,4s,5r,6r)-3,4,5-triacetyloxy-6-(acetyloxymethyl)oxan-2-yl]oxy-6-[(2r,3r,4s,5r,6s)-4,5,6-triacetyloxy-2-(acetyloxymethyl)oxan-3-yl]oxyoxan-2-yl]methyl acetate Chemical compound O([C@@H]1O[C@@H]([C@H]([C@H](OC(C)=O)[C@H]1OC(C)=O)O[C@H]1[C@@H]([C@@H](OC(C)=O)[C@H](OC(C)=O)[C@@H](COC(C)=O)O1)OC(C)=O)COC(=O)C)[C@@H]1[C@@H](COC(C)=O)O[C@@H](OC(C)=O)[C@H](OC(C)=O)[C@H]1OC(C)=O NNLVGZFZQQXQNW-ADJNRHBOSA-N 0.000 description 2

- 125000002339 acetoacetyl group Chemical group O=C([*])C([H])([H])C(=O)C([H])([H])[H] 0.000 description 2

- 150000008065 acid anhydrides Chemical class 0.000 description 2

- 150000001298 alcohols Chemical class 0.000 description 2

- 125000002723 alicyclic group Chemical group 0.000 description 2

- XXROGKLTLUQVRX-UHFFFAOYSA-N allyl alcohol Chemical compound OCC=C XXROGKLTLUQVRX-UHFFFAOYSA-N 0.000 description 2

- XYLMUPLGERFSHI-UHFFFAOYSA-N alpha-Methylstyrene Chemical compound CC(=C)C1=CC=CC=C1 XYLMUPLGERFSHI-UHFFFAOYSA-N 0.000 description 2

- 150000001408 amides Chemical class 0.000 description 2

- 235000011114 ammonium hydroxide Nutrition 0.000 description 2

- 239000012164 animal wax Substances 0.000 description 2

- 239000002518 antifoaming agent Substances 0.000 description 2

- 239000003963 antioxidant agent Substances 0.000 description 2

- 239000007864 aqueous solution Substances 0.000 description 2

- 125000004429 atom Chemical group 0.000 description 2

- 238000007611 bar coating method Methods 0.000 description 2

- 125000002511 behenyl group Chemical group [H]C([*])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])[H] 0.000 description 2

- 238000005452 bending Methods 0.000 description 2

- QMKYBPDZANOJGF-UHFFFAOYSA-N benzene-1,3,5-tricarboxylic acid Chemical compound OC(=O)C1=CC(C(O)=O)=CC(C(O)=O)=C1 QMKYBPDZANOJGF-UHFFFAOYSA-N 0.000 description 2

- 125000001797 benzyl group Chemical group [H]C1=C([H])C([H])=C(C([H])=C1[H])C([H])([H])* 0.000 description 2

- 229920001400 block copolymer Polymers 0.000 description 2

- KDYFGRWQOYBRFD-NUQCWPJISA-N butanedioic acid Chemical compound O[14C](=O)CC[14C](O)=O KDYFGRWQOYBRFD-NUQCWPJISA-N 0.000 description 2

- 125000000484 butyl group Chemical group [H]C([*])([H])C([H])([H])C([H])([H])C([H])([H])[H] 0.000 description 2

- 229910000019 calcium carbonate Inorganic materials 0.000 description 2

- 238000011088 calibration curve Methods 0.000 description 2

- 150000004649 carbonic acid derivatives Chemical class 0.000 description 2

- 239000004359 castor oil Substances 0.000 description 2

- 235000019438 castor oil Nutrition 0.000 description 2

- 238000006482 condensation reaction Methods 0.000 description 2

- 238000011109 contamination Methods 0.000 description 2

- 238000003851 corona treatment Methods 0.000 description 2

- 230000001186 cumulative effect Effects 0.000 description 2

- 238000007766 curtain coating Methods 0.000 description 2

- 125000002704 decyl group Chemical group [H]C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])* 0.000 description 2

- 238000001514 detection method Methods 0.000 description 2

- 230000002542 deteriorative effect Effects 0.000 description 2

- AYOHIQLKSOJJQH-UHFFFAOYSA-N dibutyltin Chemical compound CCCC[Sn]CCCC AYOHIQLKSOJJQH-UHFFFAOYSA-N 0.000 description 2

- NZZFYRREKKOMAT-UHFFFAOYSA-N diiodomethane Chemical compound ICI NZZFYRREKKOMAT-UHFFFAOYSA-N 0.000 description 2

- 125000000118 dimethyl group Chemical group [H]C([H])([H])* 0.000 description 2

- 125000005388 dimethylhydrogensiloxy group Chemical group 0.000 description 2

- 238000009826 distribution Methods 0.000 description 2

- 239000003480 eluent Substances 0.000 description 2

- 239000000839 emulsion Substances 0.000 description 2

- 125000003700 epoxy group Chemical group 0.000 description 2

- UIWXSTHGICQLQT-UHFFFAOYSA-N ethenyl propanoate Chemical compound CCC(=O)OC=C UIWXSTHGICQLQT-UHFFFAOYSA-N 0.000 description 2

- NKSJNEHGWDZZQF-UHFFFAOYSA-N ethenyl(trimethoxy)silane Chemical compound CO[Si](OC)(OC)C=C NKSJNEHGWDZZQF-UHFFFAOYSA-N 0.000 description 2

- 150000002170 ethers Chemical class 0.000 description 2

- 125000001301 ethoxy group Chemical group [H]C([H])([H])C([H])([H])O* 0.000 description 2

- 239000011737 fluorine Substances 0.000 description 2

- 239000001530 fumaric acid Substances 0.000 description 2

- 239000011521 glass Substances 0.000 description 2

- JFCQEDHGNNZCLN-UHFFFAOYSA-N glutaric acid Chemical class OC(=O)CCCC(O)=O JFCQEDHGNNZCLN-UHFFFAOYSA-N 0.000 description 2

- 235000011187 glycerol Nutrition 0.000 description 2

- ZEMPKEQAKRGZGQ-XOQCFJPHSA-N glycerol triricinoleate Natural products CCCCCC[C@@H](O)CC=CCCCCCCCC(=O)OC[C@@H](COC(=O)CCCCCCCC=CC[C@@H](O)CCCCCC)OC(=O)CCCCCCCC=CC[C@H](O)CCCCCC ZEMPKEQAKRGZGQ-XOQCFJPHSA-N 0.000 description 2

- 125000006038 hexenyl group Chemical group 0.000 description 2

- 125000004051 hexyl group Chemical group [H]C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])* 0.000 description 2

- 229930195733 hydrocarbon Natural products 0.000 description 2

- 239000001257 hydrogen Substances 0.000 description 2

- 229910052739 hydrogen Inorganic materials 0.000 description 2

- 230000007062 hydrolysis Effects 0.000 description 2

- 238000006460 hydrolysis reaction Methods 0.000 description 2

- 125000002768 hydroxyalkyl group Chemical group 0.000 description 2

- 239000012535 impurity Substances 0.000 description 2

- 238000007373 indentation Methods 0.000 description 2

- 230000001678 irradiating effect Effects 0.000 description 2

- 150000002576 ketones Chemical class 0.000 description 2

- 239000002346 layers by function Substances 0.000 description 2

- 239000002075 main ingredient Substances 0.000 description 2

- 230000008018 melting Effects 0.000 description 2

- 238000002844 melting Methods 0.000 description 2

- 125000005395 methacrylic acid group Chemical group 0.000 description 2

- 125000000956 methoxy group Chemical group [H]C([H])([H])O* 0.000 description 2

- LVHBHZANLOWSRM-UHFFFAOYSA-N methylenebutanedioic acid Natural products OC(=O)CC(=C)C(O)=O LVHBHZANLOWSRM-UHFFFAOYSA-N 0.000 description 2

- 239000004200 microcrystalline wax Substances 0.000 description 2

- 235000019808 microcrystalline wax Nutrition 0.000 description 2

- 230000001617 migratory effect Effects 0.000 description 2

- 239000012184 mineral wax Substances 0.000 description 2

- 238000002156 mixing Methods 0.000 description 2

- 239000012170 montan wax Substances 0.000 description 2

- BDJRBEYXGGNYIS-UHFFFAOYSA-N nonanedioic acid Chemical compound OC(=O)CCCCCCCC(O)=O BDJRBEYXGGNYIS-UHFFFAOYSA-N 0.000 description 2

- OEIJHBUUFURJLI-UHFFFAOYSA-N octane-1,8-diol Chemical compound OCCCCCCCCO OEIJHBUUFURJLI-UHFFFAOYSA-N 0.000 description 2

- 125000002347 octyl group Chemical group [H]C([*])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])[H] 0.000 description 2

- 150000002894 organic compounds Chemical class 0.000 description 2

- 239000011146 organic particle Substances 0.000 description 2

- 239000003960 organic solvent Substances 0.000 description 2

- 150000002918 oxazolines Chemical class 0.000 description 2

- 235000013873 oxidized polyethylene wax Nutrition 0.000 description 2

- 239000012188 paraffin wax Substances 0.000 description 2

- 230000002093 peripheral effect Effects 0.000 description 2

- 239000003208 petroleum Substances 0.000 description 2

- 239000012169 petroleum derived wax Substances 0.000 description 2

- 235000019381 petroleum wax Nutrition 0.000 description 2

- 239000005011 phenolic resin Substances 0.000 description 2

- WLJVNTCWHIRURA-UHFFFAOYSA-N pimelic acid Chemical compound OC(=O)CCCCCC(O)=O WLJVNTCWHIRURA-UHFFFAOYSA-N 0.000 description 2

- 238000009832 plasma treatment Methods 0.000 description 2

- 229920000570 polyether Polymers 0.000 description 2

- 229920000139 polyethylene terephthalate Polymers 0.000 description 2

- 239000005020 polyethylene terephthalate Substances 0.000 description 2

- 239000005056 polyisocyanate Substances 0.000 description 2

- 229920001228 polyisocyanate Polymers 0.000 description 2

- 229920002959 polymer blend Polymers 0.000 description 2

- 229920001843 polymethylhydrosiloxane Polymers 0.000 description 2

- 238000001556 precipitation Methods 0.000 description 2

- HJWLCRVIBGQPNF-UHFFFAOYSA-N prop-2-enylbenzene Chemical compound C=CCC1=CC=CC=C1 HJWLCRVIBGQPNF-UHFFFAOYSA-N 0.000 description 2

- CYIDZMCFTVVTJO-UHFFFAOYSA-N pyromellitic acid Chemical compound OC(=O)C1=CC(C(O)=O)=C(C(O)=O)C=C1C(O)=O CYIDZMCFTVVTJO-UHFFFAOYSA-N 0.000 description 2

- 150000003242 quaternary ammonium salts Chemical class 0.000 description 2

- 238000010992 reflux Methods 0.000 description 2

- 239000011342 resin composition Substances 0.000 description 2

- 238000007127 saponification reaction Methods 0.000 description 2

- 239000000377 silicon dioxide Substances 0.000 description 2

- 239000013464 silicone adhesive Substances 0.000 description 2

- 238000007711 solidification Methods 0.000 description 2

- 230000008023 solidification Effects 0.000 description 2

- 125000004079 stearyl group Chemical group [H]C([*])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])[H] 0.000 description 2

- 238000003860 storage Methods 0.000 description 2

- 150000003440 styrenes Chemical class 0.000 description 2

- TYFQFVWCELRYAO-UHFFFAOYSA-N suberic acid Chemical compound OC(=O)CCCCCCC(O)=O TYFQFVWCELRYAO-UHFFFAOYSA-N 0.000 description 2

- 125000001424 substituent group Chemical group 0.000 description 2

- 238000004381 surface treatment Methods 0.000 description 2

- 239000004094 surface-active agent Substances 0.000 description 2

- 239000002562 thickening agent Substances 0.000 description 2

- DVKJHBMWWAPEIU-UHFFFAOYSA-N toluene 2,4-diisocyanate Chemical compound CC1=CC=C(N=C=O)C=C1N=C=O DVKJHBMWWAPEIU-UHFFFAOYSA-N 0.000 description 2

- ZIBGPFATKBEMQZ-UHFFFAOYSA-N triethylene glycol Chemical compound OCCOCCOCCO ZIBGPFATKBEMQZ-UHFFFAOYSA-N 0.000 description 2

- GETQZCLCWQTVFV-UHFFFAOYSA-N trimethylamine Chemical compound CN(C)C GETQZCLCWQTVFV-UHFFFAOYSA-N 0.000 description 2

- 239000012178 vegetable wax Substances 0.000 description 2

- DTGKSKDOIYIVQL-WEDXCCLWSA-N (+)-borneol Chemical group C1C[C@@]2(C)[C@@H](O)C[C@@H]1C2(C)C DTGKSKDOIYIVQL-WEDXCCLWSA-N 0.000 description 1

- DNIAPMSPPWPWGF-VKHMYHEASA-N (+)-propylene glycol Chemical compound C[C@H](O)CO DNIAPMSPPWPWGF-VKHMYHEASA-N 0.000 description 1

- WYTZZXDRDKSJID-UHFFFAOYSA-N (3-aminopropyl)triethoxysilane Chemical compound CCO[Si](OCC)(OCC)CCCN WYTZZXDRDKSJID-UHFFFAOYSA-N 0.000 description 1

- SZCWBURCISJFEZ-UHFFFAOYSA-N (3-hydroxy-2,2-dimethylpropyl) 3-hydroxy-2,2-dimethylpropanoate Chemical compound OCC(C)(C)COC(=O)C(C)(C)CO SZCWBURCISJFEZ-UHFFFAOYSA-N 0.000 description 1

- GHKBRNPRJNJGIM-SNAWJCMRSA-N (e)-4-butoxy-4-oxobut-2-eneperoxoic acid Chemical compound CCCCOC(=O)\C=C\C(=O)OO GHKBRNPRJNJGIM-SNAWJCMRSA-N 0.000 description 1

- NNOZGCICXAYKLW-UHFFFAOYSA-N 1,2-bis(2-isocyanatopropan-2-yl)benzene Chemical group O=C=NC(C)(C)C1=CC=CC=C1C(C)(C)N=C=O NNOZGCICXAYKLW-UHFFFAOYSA-N 0.000 description 1

- CHRJZRDFSQHIFI-UHFFFAOYSA-N 1,2-bis(ethenyl)benzene;styrene Chemical compound C=CC1=CC=CC=C1.C=CC1=CC=CC=C1C=C CHRJZRDFSQHIFI-UHFFFAOYSA-N 0.000 description 1

- FKTHNVSLHLHISI-UHFFFAOYSA-N 1,2-bis(isocyanatomethyl)benzene Chemical compound O=C=NCC1=CC=CC=C1CN=C=O FKTHNVSLHLHISI-UHFFFAOYSA-N 0.000 description 1

- MTZUIIAIAKMWLI-UHFFFAOYSA-N 1,2-diisocyanatobenzene Chemical compound O=C=NC1=CC=CC=C1N=C=O MTZUIIAIAKMWLI-UHFFFAOYSA-N 0.000 description 1

- ZXHZWRZAWJVPIC-UHFFFAOYSA-N 1,2-diisocyanatonaphthalene Chemical compound C1=CC=CC2=C(N=C=O)C(N=C=O)=CC=C21 ZXHZWRZAWJVPIC-UHFFFAOYSA-N 0.000 description 1

- ZGDSDWSIFQBAJS-UHFFFAOYSA-N 1,2-diisocyanatopropane Chemical group O=C=NC(C)CN=C=O ZGDSDWSIFQBAJS-UHFFFAOYSA-N 0.000 description 1

- PXGZQGDTEZPERC-UHFFFAOYSA-N 1,4-cyclohexanedicarboxylic acid Chemical compound OC(=O)C1CCC(C(O)=O)CC1 PXGZQGDTEZPERC-UHFFFAOYSA-N 0.000 description 1

- VZXPHDGHQXLXJC-UHFFFAOYSA-N 1,6-diisocyanato-5,6-dimethylheptane Chemical group O=C=NC(C)(C)C(C)CCCCN=C=O VZXPHDGHQXLXJC-UHFFFAOYSA-N 0.000 description 1

- PWGJDPKCLMLPJW-UHFFFAOYSA-N 1,8-diaminooctane Chemical compound NCCCCCCCCN PWGJDPKCLMLPJW-UHFFFAOYSA-N 0.000 description 1

- DURPTKYDGMDSBL-UHFFFAOYSA-N 1-butoxybutane Chemical compound CCCCOCCCC DURPTKYDGMDSBL-UHFFFAOYSA-N 0.000 description 1

- ZTEHOZMYMCEYRM-UHFFFAOYSA-N 1-chlorodecane Chemical compound CCCCCCCCCCCl ZTEHOZMYMCEYRM-UHFFFAOYSA-N 0.000 description 1

- OACXFSZVCDOBKF-UHFFFAOYSA-N 1-chlorodocosane Chemical compound CCCCCCCCCCCCCCCCCCCCCCCl OACXFSZVCDOBKF-UHFFFAOYSA-N 0.000 description 1

- YAYNEUUHHLGGAH-UHFFFAOYSA-N 1-chlorododecane Chemical compound CCCCCCCCCCCCCl YAYNEUUHHLGGAH-UHFFFAOYSA-N 0.000 description 1

- MLRVZFYXUZQSRU-UHFFFAOYSA-N 1-chlorohexane Chemical compound CCCCCCCl MLRVZFYXUZQSRU-UHFFFAOYSA-N 0.000 description 1

- VUQPJRPDRDVQMN-UHFFFAOYSA-N 1-chlorooctadecane Chemical compound CCCCCCCCCCCCCCCCCCCl VUQPJRPDRDVQMN-UHFFFAOYSA-N 0.000 description 1

- CNDHHGUSRIZDSL-UHFFFAOYSA-N 1-chlorooctane Chemical compound CCCCCCCCCl CNDHHGUSRIZDSL-UHFFFAOYSA-N 0.000 description 1

- QIVRKSLMUAURGI-UHFFFAOYSA-N 1-isocyanato-1-[2-(1-isocyanatocyclohexyl)propan-2-yl]cyclohexane Chemical compound C1CCCCC1(N=C=O)C(C)(C)C1(N=C=O)CCCCC1 QIVRKSLMUAURGI-UHFFFAOYSA-N 0.000 description 1

- XFEWMFDVBLLXFE-UHFFFAOYSA-N 1-isocyanatodecane Chemical compound CCCCCCCCCCN=C=O XFEWMFDVBLLXFE-UHFFFAOYSA-N 0.000 description 1

- ODDFKRTWSQGENK-UHFFFAOYSA-N 1-isocyanatodocosane Chemical compound CCCCCCCCCCCCCCCCCCCCCCN=C=O ODDFKRTWSQGENK-UHFFFAOYSA-N 0.000 description 1

- YIDSTEJLDQMWBR-UHFFFAOYSA-N 1-isocyanatododecane Chemical compound CCCCCCCCCCCCN=C=O YIDSTEJLDQMWBR-UHFFFAOYSA-N 0.000 description 1

- DYQFCTCUULUMTQ-UHFFFAOYSA-N 1-isocyanatooctane Chemical compound CCCCCCCCN=C=O DYQFCTCUULUMTQ-UHFFFAOYSA-N 0.000 description 1

- RTBFRGCFXZNCOE-UHFFFAOYSA-N 1-methylsulfonylpiperidin-4-one Chemical compound CS(=O)(=O)N1CCC(=O)CC1 RTBFRGCFXZNCOE-UHFFFAOYSA-N 0.000 description 1

- XLPJNCYCZORXHG-UHFFFAOYSA-N 1-morpholin-4-ylprop-2-en-1-one Chemical compound C=CC(=O)N1CCOCC1 XLPJNCYCZORXHG-UHFFFAOYSA-N 0.000 description 1

- JCTXKRPTIMZBJT-UHFFFAOYSA-N 2,2,4-trimethylpentane-1,3-diol Chemical compound CC(C)C(O)C(C)(C)CO JCTXKRPTIMZBJT-UHFFFAOYSA-N 0.000 description 1

- JVYDLYGCSIHCMR-UHFFFAOYSA-N 2,2-bis(hydroxymethyl)butanoic acid Chemical compound CCC(CO)(CO)C(O)=O JVYDLYGCSIHCMR-UHFFFAOYSA-N 0.000 description 1

- DDHUNHGZUHZNKB-UHFFFAOYSA-N 2,2-dimethylpropane-1,3-diamine Chemical compound NCC(C)(C)CN DDHUNHGZUHZNKB-UHFFFAOYSA-N 0.000 description 1

- ZWNMRZQYWRLGMM-UHFFFAOYSA-N 2,5-dimethylhexane-2,5-diol Chemical compound CC(C)(O)CCC(C)(C)O ZWNMRZQYWRLGMM-UHFFFAOYSA-N 0.000 description 1

- LDXJRKWFNNFDSA-UHFFFAOYSA-N 2-(2,4,6,7-tetrahydrotriazolo[4,5-c]pyridin-5-yl)-1-[4-[2-[[3-(trifluoromethoxy)phenyl]methylamino]pyrimidin-5-yl]piperazin-1-yl]ethanone Chemical compound C1CN(CC2=NNN=C21)CC(=O)N3CCN(CC3)C4=CN=C(N=C4)NCC5=CC(=CC=C5)OC(F)(F)F LDXJRKWFNNFDSA-UHFFFAOYSA-N 0.000 description 1

- HLIQLHSBZXDKLV-UHFFFAOYSA-N 2-(2-hydroxyethoxy)-1-phenoxyethanol Chemical compound OCCOCC(O)OC1=CC=CC=C1 HLIQLHSBZXDKLV-UHFFFAOYSA-N 0.000 description 1

- JAHNSTQSQJOJLO-UHFFFAOYSA-N 2-(3-fluorophenyl)-1h-imidazole Chemical compound FC1=CC=CC(C=2NC=CN=2)=C1 JAHNSTQSQJOJLO-UHFFFAOYSA-N 0.000 description 1

- OEPOKWHJYJXUGD-UHFFFAOYSA-N 2-(3-phenylmethoxyphenyl)-1,3-thiazole-4-carbaldehyde Chemical compound O=CC1=CSC(C=2C=C(OCC=3C=CC=CC=3)C=CC=2)=N1 OEPOKWHJYJXUGD-UHFFFAOYSA-N 0.000 description 1

- RWLALWYNXFYRGW-UHFFFAOYSA-N 2-Ethyl-1,3-hexanediol Chemical compound CCCC(O)C(CC)CO RWLALWYNXFYRGW-UHFFFAOYSA-N 0.000 description 1

- LCZVSXRMYJUNFX-UHFFFAOYSA-N 2-[2-(2-hydroxypropoxy)propoxy]propan-1-ol Chemical compound CC(O)COC(C)COC(C)CO LCZVSXRMYJUNFX-UHFFFAOYSA-N 0.000 description 1

- TXBCBTDQIULDIA-UHFFFAOYSA-N 2-[[3-hydroxy-2,2-bis(hydroxymethyl)propoxy]methyl]-2-(hydroxymethyl)propane-1,3-diol Chemical compound OCC(CO)(CO)COCC(CO)(CO)CO TXBCBTDQIULDIA-UHFFFAOYSA-N 0.000 description 1

- NDXNCTAJOQSKIO-UHFFFAOYSA-N 2-butyl-2-ethylpentane-1,5-diamine Chemical compound CCCCC(CC)(CN)CCCN NDXNCTAJOQSKIO-UHFFFAOYSA-N 0.000 description 1

- TUQYFIFPADMJFJ-UHFFFAOYSA-N 2-butyl-2-hexylpropane-1,3-diol Chemical compound CCCCCCC(CO)(CO)CCCC TUQYFIFPADMJFJ-UHFFFAOYSA-N 0.000 description 1

- IPJGPNZOIMZKEK-UHFFFAOYSA-N 2-ethyl-4-hydroxy-2-(2-hydroxyethyl)butanoic acid Chemical compound OCCC(CC)(CCO)C(O)=O IPJGPNZOIMZKEK-UHFFFAOYSA-N 0.000 description 1

- GWZMWHWAWHPNHN-UHFFFAOYSA-N 2-hydroxypropyl prop-2-enoate Chemical compound CC(O)COC(=O)C=C GWZMWHWAWHPNHN-UHFFFAOYSA-N 0.000 description 1

- DPNXHTDWGGVXID-UHFFFAOYSA-N 2-isocyanatoethyl prop-2-enoate Chemical compound C=CC(=O)OCCN=C=O DPNXHTDWGGVXID-UHFFFAOYSA-N 0.000 description 1

- JVZZUPJFERSVRN-UHFFFAOYSA-N 2-methyl-2-propylpropane-1,3-diol Chemical compound CCCC(C)(CO)CO JVZZUPJFERSVRN-UHFFFAOYSA-N 0.000 description 1

- CEBKHWWANWSNTI-UHFFFAOYSA-N 2-methylbut-3-yn-2-ol Chemical compound CC(C)(O)C#C CEBKHWWANWSNTI-UHFFFAOYSA-N 0.000 description 1

- SDQROPCSKIYYAV-UHFFFAOYSA-N 2-methyloctane-1,8-diol Chemical compound OCC(C)CCCCCCO SDQROPCSKIYYAV-UHFFFAOYSA-N 0.000 description 1

- JZUHIOJYCPIVLQ-UHFFFAOYSA-N 2-methylpentane-1,5-diamine Chemical compound NCC(C)CCCN JZUHIOJYCPIVLQ-UHFFFAOYSA-N 0.000 description 1

- AAAWJUMVTPNRDT-UHFFFAOYSA-N 2-methylpentane-1,5-diol Chemical compound OCC(C)CCCO AAAWJUMVTPNRDT-UHFFFAOYSA-N 0.000 description 1

- QWGRWMMWNDWRQN-UHFFFAOYSA-N 2-methylpropane-1,3-diol Chemical compound OCC(C)CO QWGRWMMWNDWRQN-UHFFFAOYSA-N 0.000 description 1

- 125000003903 2-propenyl group Chemical group [H]C([*])([H])C([H])=C([H])[H] 0.000 description 1

- RAADBCJYJHQQBI-UHFFFAOYSA-N 2-sulfoterephthalic acid Chemical compound OC(=O)C1=CC=C(C(O)=O)C(S(O)(=O)=O)=C1 RAADBCJYJHQQBI-UHFFFAOYSA-N 0.000 description 1

- WMRCTEPOPAZMMN-UHFFFAOYSA-N 2-undecylpropanedioic acid Chemical compound CCCCCCCCCCCC(C(O)=O)C(O)=O WMRCTEPOPAZMMN-UHFFFAOYSA-N 0.000 description 1

- KGIGUEBEKRSTEW-UHFFFAOYSA-N 2-vinylpyridine Chemical compound C=CC1=CC=CC=N1 KGIGUEBEKRSTEW-UHFFFAOYSA-N 0.000 description 1

- NECRQCBKTGZNMH-UHFFFAOYSA-N 3,5-dimethylhex-1-yn-3-ol Chemical compound CC(C)CC(C)(O)C#C NECRQCBKTGZNMH-UHFFFAOYSA-N 0.000 description 1

- RNLHGQLZWXBQNY-UHFFFAOYSA-N 3-(aminomethyl)-3,5,5-trimethylcyclohexan-1-amine Chemical compound CC1(C)CC(N)CC(C)(CN)C1 RNLHGQLZWXBQNY-UHFFFAOYSA-N 0.000 description 1

- SDOFNQUTVKJYKH-UHFFFAOYSA-N 3-butoxycarbonylbut-3-eneperoxoic acid Chemical compound C(C(=C)CC(=O)OO)(=O)OCCCC SDOFNQUTVKJYKH-UHFFFAOYSA-N 0.000 description 1

- ZCNAVPLNWUDRJK-UHFFFAOYSA-N 3-hydroxy-2-(hydroxymethyl)-2-methylpropanoic acid;potassium Chemical compound [K].OCC(C)(CO)C(O)=O ZCNAVPLNWUDRJK-UHFFFAOYSA-N 0.000 description 1

- WHNPOQXWAMXPTA-UHFFFAOYSA-N 3-methylbut-2-enamide Chemical compound CC(C)=CC(N)=O WHNPOQXWAMXPTA-UHFFFAOYSA-N 0.000 description 1

- UUEWCQRISZBELL-UHFFFAOYSA-N 3-trimethoxysilylpropane-1-thiol Chemical compound CO[Si](OC)(OC)CCCS UUEWCQRISZBELL-UHFFFAOYSA-N 0.000 description 1

- KBQVDAIIQCXKPI-UHFFFAOYSA-N 3-trimethoxysilylpropyl prop-2-enoate Chemical compound CO[Si](OC)(OC)CCCOC(=O)C=C KBQVDAIIQCXKPI-UHFFFAOYSA-N 0.000 description 1

- UPMLOUAZCHDJJD-UHFFFAOYSA-N 4,4'-Diphenylmethane Diisocyanate Chemical compound C1=CC(N=C=O)=CC=C1CC1=CC=C(N=C=O)C=C1 UPMLOUAZCHDJJD-UHFFFAOYSA-N 0.000 description 1

- NEQFBGHQPUXOFH-UHFFFAOYSA-N 4-(4-carboxyphenyl)benzoic acid Chemical compound C1=CC(C(=O)O)=CC=C1C1=CC=C(C(O)=O)C=C1 NEQFBGHQPUXOFH-UHFFFAOYSA-N 0.000 description 1

- DNFUJUFGVPNZMP-UHFFFAOYSA-N 4-hydroxy-2-(2-hydroxyethyl)-2-methylbutanoic acid Chemical compound OCCC(C)(CCO)C(O)=O DNFUJUFGVPNZMP-UHFFFAOYSA-N 0.000 description 1

- SBVKVAIECGDBTC-UHFFFAOYSA-N 4-hydroxy-2-methylidenebutanamide Chemical compound NC(=O)C(=C)CCO SBVKVAIECGDBTC-UHFFFAOYSA-N 0.000 description 1

- 229940090248 4-hydroxybenzoic acid Drugs 0.000 description 1

- NDWUBGAGUCISDV-UHFFFAOYSA-N 4-hydroxybutyl prop-2-enoate Chemical compound OCCCCOC(=O)C=C NDWUBGAGUCISDV-UHFFFAOYSA-N 0.000 description 1

- JYOZFNMFSVAZAW-UHFFFAOYSA-N 4-phenylbut-3-yn-2-ol Chemical compound CC(O)C#CC1=CC=CC=C1 JYOZFNMFSVAZAW-UHFFFAOYSA-N 0.000 description 1

- ZWAPMFBHEQZLGK-UHFFFAOYSA-N 5-(dimethylamino)-2-methylidenepentanamide Chemical compound CN(C)CCCC(=C)C(N)=O ZWAPMFBHEQZLGK-UHFFFAOYSA-N 0.000 description 1

- GLBHAWAMATUOBB-UHFFFAOYSA-N 6,6-dimethylheptane-1,1-diamine Chemical compound CC(C)(C)CCCCC(N)N GLBHAWAMATUOBB-UHFFFAOYSA-N 0.000 description 1

- GZVHEAJQGPRDLQ-UHFFFAOYSA-N 6-phenyl-1,3,5-triazine-2,4-diamine Chemical compound NC1=NC(N)=NC(C=2C=CC=CC=2)=N1 GZVHEAJQGPRDLQ-UHFFFAOYSA-N 0.000 description 1

- ZCYVEMRRCGMTRW-UHFFFAOYSA-N 7553-56-2 Chemical compound [I] ZCYVEMRRCGMTRW-UHFFFAOYSA-N 0.000 description 1

- 239000005995 Aluminium silicate Substances 0.000 description 1

- 229920006310 Asahi-Kasei Polymers 0.000 description 1

- NOWKCMXCCJGMRR-UHFFFAOYSA-N Aziridine Chemical compound C1CN1 NOWKCMXCCJGMRR-UHFFFAOYSA-N 0.000 description 1

- 229930185605 Bisphenol Natural products 0.000 description 1

- DKPFZGUDAPQIHT-UHFFFAOYSA-N Butyl acetate Natural products CCCCOC(C)=O DKPFZGUDAPQIHT-UHFFFAOYSA-N 0.000 description 1

- OYPRJOBELJOOCE-UHFFFAOYSA-N Calcium Chemical compound [Ca] OYPRJOBELJOOCE-UHFFFAOYSA-N 0.000 description 1

- BVKZGUZCCUSVTD-UHFFFAOYSA-L Carbonate Chemical compound [O-]C([O-])=O BVKZGUZCCUSVTD-UHFFFAOYSA-L 0.000 description 1

- 241000283153 Cetacea Species 0.000 description 1

- VEXZGXHMUGYJMC-UHFFFAOYSA-M Chloride anion Chemical compound [Cl-] VEXZGXHMUGYJMC-UHFFFAOYSA-M 0.000 description 1

- 229920001634 Copolyester Polymers 0.000 description 1

- XMSXQFUHVRWGNA-UHFFFAOYSA-N Decamethylcyclopentasiloxane Chemical compound C[Si]1(C)O[Si](C)(C)O[Si](C)(C)O[Si](C)(C)O[Si](C)(C)O1 XMSXQFUHVRWGNA-UHFFFAOYSA-N 0.000 description 1

- OIFBSDVPJOWBCH-UHFFFAOYSA-N Diethyl carbonate Chemical compound CCOC(=O)OCC OIFBSDVPJOWBCH-UHFFFAOYSA-N 0.000 description 1

- ZAFNJMIOTHYJRJ-UHFFFAOYSA-N Diisopropyl ether Chemical compound CC(C)OC(C)C ZAFNJMIOTHYJRJ-UHFFFAOYSA-N 0.000 description 1

- JOYRKODLDBILNP-UHFFFAOYSA-N Ethyl urethane Chemical compound CCOC(N)=O JOYRKODLDBILNP-UHFFFAOYSA-N 0.000 description 1

- 239000005977 Ethylene Substances 0.000 description 1

- KMTRUDSVKNLOMY-UHFFFAOYSA-N Ethylene carbonate Chemical compound O=C1OCCO1 KMTRUDSVKNLOMY-UHFFFAOYSA-N 0.000 description 1

- 239000004716 Ethylene/acrylic acid copolymer Substances 0.000 description 1

- PIICEJLVQHRZGT-UHFFFAOYSA-N Ethylenediamine Chemical compound NCCN PIICEJLVQHRZGT-UHFFFAOYSA-N 0.000 description 1

- YCKRFDGAMUMZLT-UHFFFAOYSA-N Fluorine atom Chemical compound [F] YCKRFDGAMUMZLT-UHFFFAOYSA-N 0.000 description 1

- 239000005057 Hexamethylene diisocyanate Chemical group 0.000 description 1

- UFHFLCQGNIYNRP-UHFFFAOYSA-N Hydrogen Chemical compound [H][H] UFHFLCQGNIYNRP-UHFFFAOYSA-N 0.000 description 1

- NHTMVDHEPJAVLT-UHFFFAOYSA-N Isooctane Chemical compound CC(C)CC(C)(C)C NHTMVDHEPJAVLT-UHFFFAOYSA-N 0.000 description 1

- 239000005058 Isophorone diisocyanate Chemical group 0.000 description 1

- 239000004166 Lanolin Substances 0.000 description 1

- NTIZESTWPVYFNL-UHFFFAOYSA-N Methyl isobutyl ketone Chemical compound CC(C)CC(C)=O NTIZESTWPVYFNL-UHFFFAOYSA-N 0.000 description 1

- UIHCLUNTQKBZGK-UHFFFAOYSA-N Methyl isobutyl ketone Natural products CCC(C)C(C)=O UIHCLUNTQKBZGK-UHFFFAOYSA-N 0.000 description 1

- GYCMBHHDWRMZGG-UHFFFAOYSA-N Methylacrylonitrile Chemical compound CC(=C)C#N GYCMBHHDWRMZGG-UHFFFAOYSA-N 0.000 description 1

- CNCOEDDPFOAUMB-UHFFFAOYSA-N N-Methylolacrylamide Chemical compound OCNC(=O)C=C CNCOEDDPFOAUMB-UHFFFAOYSA-N 0.000 description 1

- WHNWPMSKXPGLAX-UHFFFAOYSA-N N-Vinyl-2-pyrrolidone Chemical compound C=CN1CCCC1=O WHNWPMSKXPGLAX-UHFFFAOYSA-N 0.000 description 1

- MKYBYDHXWVHEJW-UHFFFAOYSA-N N-[1-oxo-1-(2,4,6,7-tetrahydrotriazolo[4,5-c]pyridin-5-yl)propan-2-yl]-2-[[3-(trifluoromethoxy)phenyl]methylamino]pyrimidine-5-carboxamide Chemical compound O=C(C(C)NC(=O)C=1C=NC(=NC=1)NCC1=CC(=CC=C1)OC(F)(F)F)N1CC2=C(CC1)NN=N2 MKYBYDHXWVHEJW-UHFFFAOYSA-N 0.000 description 1

- NIPNSKYNPDTRPC-UHFFFAOYSA-N N-[2-oxo-2-(2,4,6,7-tetrahydrotriazolo[4,5-c]pyridin-5-yl)ethyl]-2-[[3-(trifluoromethoxy)phenyl]methylamino]pyrimidine-5-carboxamide Chemical compound O=C(CNC(=O)C=1C=NC(=NC=1)NCC1=CC(=CC=C1)OC(F)(F)F)N1CC2=C(CC1)NN=N2 NIPNSKYNPDTRPC-UHFFFAOYSA-N 0.000 description 1

- AFCARXCZXQIEQB-UHFFFAOYSA-N N-[3-oxo-3-(2,4,6,7-tetrahydrotriazolo[4,5-c]pyridin-5-yl)propyl]-2-[[3-(trifluoromethoxy)phenyl]methylamino]pyrimidine-5-carboxamide Chemical compound O=C(CCNC(=O)C=1C=NC(=NC=1)NCC1=CC(=CC=C1)OC(F)(F)F)N1CC2=C(CC1)NN=N2 AFCARXCZXQIEQB-UHFFFAOYSA-N 0.000 description 1

- OMRDSWJXRLDPBB-UHFFFAOYSA-N N=C=O.N=C=O.C1CCCCC1 Chemical group N=C=O.N=C=O.C1CCCCC1 OMRDSWJXRLDPBB-UHFFFAOYSA-N 0.000 description 1

- HDONYZHVZVCMLR-UHFFFAOYSA-N N=C=O.N=C=O.CC1CCCCC1 Chemical group N=C=O.N=C=O.CC1CCCCC1 HDONYZHVZVCMLR-UHFFFAOYSA-N 0.000 description 1

- 229910017855 NH 4 F Inorganic materials 0.000 description 1

- GRYLNZFGIOXLOG-UHFFFAOYSA-N Nitric acid Chemical compound O[N+]([O-])=O GRYLNZFGIOXLOG-UHFFFAOYSA-N 0.000 description 1

- 240000007594 Oryza sativa Species 0.000 description 1

- 235000007164 Oryza sativa Nutrition 0.000 description 1

- CBENFWSGALASAD-UHFFFAOYSA-N Ozone Chemical compound [O-][O+]=O CBENFWSGALASAD-UHFFFAOYSA-N 0.000 description 1

- ALQSHHUCVQOPAS-UHFFFAOYSA-N Pentane-1,5-diol Chemical compound OCCCCCO ALQSHHUCVQOPAS-UHFFFAOYSA-N 0.000 description 1

- 239000004264 Petrolatum Substances 0.000 description 1

- LGRFSURHDFAFJT-UHFFFAOYSA-N Phthalic anhydride Natural products C1=CC=C2C(=O)OC(=O)C2=C1 LGRFSURHDFAFJT-UHFFFAOYSA-N 0.000 description 1

- 229920002845 Poly(methacrylic acid) Polymers 0.000 description 1

- 239000004962 Polyamide-imide Substances 0.000 description 1

- 239000004695 Polyether sulfone Substances 0.000 description 1

- 239000004642 Polyimide Substances 0.000 description 1

- 239000004743 Polypropylene Substances 0.000 description 1

- GOOHAUXETOMSMM-UHFFFAOYSA-N Propylene oxide Chemical compound CC1CO1 GOOHAUXETOMSMM-UHFFFAOYSA-N 0.000 description 1

- BLRPTPMANUNPDV-UHFFFAOYSA-N Silane Chemical compound [SiH4] BLRPTPMANUNPDV-UHFFFAOYSA-N 0.000 description 1

- GWEVSGVZZGPLCZ-UHFFFAOYSA-N Titan oxide Chemical compound O=[Ti]=O GWEVSGVZZGPLCZ-UHFFFAOYSA-N 0.000 description 1

- 229920001807 Urea-formaldehyde Polymers 0.000 description 1

- XTXRWKRVRITETP-UHFFFAOYSA-N Vinyl acetate Chemical compound CC(=O)OC=C XTXRWKRVRITETP-UHFFFAOYSA-N 0.000 description 1

- 229920002433 Vinyl chloride-vinyl acetate copolymer Polymers 0.000 description 1

- 229920004482 WACKER® Polymers 0.000 description 1

- QCWXUUIWCKQGHC-UHFFFAOYSA-N Zirconium Chemical compound [Zr] QCWXUUIWCKQGHC-UHFFFAOYSA-N 0.000 description 1

- GKXVJHDEWHKBFH-UHFFFAOYSA-N [2-(aminomethyl)phenyl]methanamine Chemical compound NCC1=CC=CC=C1CN GKXVJHDEWHKBFH-UHFFFAOYSA-N 0.000 description 1

- XMUZQOKACOLCSS-UHFFFAOYSA-N [2-(hydroxymethyl)phenyl]methanol Chemical compound OCC1=CC=CC=C1CO XMUZQOKACOLCSS-UHFFFAOYSA-N 0.000 description 1

- QLBRROYTTDFLDX-UHFFFAOYSA-N [3-(aminomethyl)cyclohexyl]methanamine Chemical compound NCC1CCCC(CN)C1 QLBRROYTTDFLDX-UHFFFAOYSA-N 0.000 description 1

- ISKQADXMHQSTHK-UHFFFAOYSA-N [4-(aminomethyl)phenyl]methanamine Chemical compound NCC1=CC=C(CN)C=C1 ISKQADXMHQSTHK-UHFFFAOYSA-N 0.000 description 1

- BWVAOONFBYYRHY-UHFFFAOYSA-N [4-(hydroxymethyl)phenyl]methanol Chemical compound OCC1=CC=C(CO)C=C1 BWVAOONFBYYRHY-UHFFFAOYSA-N 0.000 description 1

- MZVQCMJNVPIDEA-UHFFFAOYSA-N [CH2]CN(CC)CC Chemical group [CH2]CN(CC)CC MZVQCMJNVPIDEA-UHFFFAOYSA-N 0.000 description 1

- BJSBGAIKEORPFG-UHFFFAOYSA-N [[6-amino-1,2,3,4-tetramethoxy-4-(methoxyamino)-1,3,5-triazin-2-yl]-methoxyamino]methanol Chemical compound CONC1(N(C(N(C(=N1)N)OC)(N(CO)OC)OC)OC)OC BJSBGAIKEORPFG-UHFFFAOYSA-N 0.000 description 1

- VXPYSZQGFPMWQU-UHFFFAOYSA-L [acetyloxy(diphenyl)stannyl] acetate Chemical compound CC([O-])=O.CC([O-])=O.C=1C=CC=CC=1[Sn+2]C1=CC=CC=C1 VXPYSZQGFPMWQU-UHFFFAOYSA-L 0.000 description 1

- UKLDJPRMSDWDSL-UHFFFAOYSA-L [dibutyl(dodecanoyloxy)stannyl] dodecanoate Chemical compound CCCCCCCCCCCC(=O)O[Sn](CCCC)(CCCC)OC(=O)CCCCCCCCCCC UKLDJPRMSDWDSL-UHFFFAOYSA-L 0.000 description 1

- 230000001133 acceleration Effects 0.000 description 1

- 125000003668 acetyloxy group Chemical group [H]C([H])([H])C(=O)O[*] 0.000 description 1

- 230000002378 acidificating effect Effects 0.000 description 1

- 150000007513 acids Chemical class 0.000 description 1

- 150000003926 acrylamides Chemical class 0.000 description 1

- 150000001253 acrylic acids Chemical class 0.000 description 1

- HFBMWMNUJJDEQZ-UHFFFAOYSA-N acryloyl chloride Chemical compound ClC(=O)C=C HFBMWMNUJJDEQZ-UHFFFAOYSA-N 0.000 description 1

- 125000003647 acryloyl group Chemical group O=C([*])C([H])=C([H])[H] 0.000 description 1

- 125000005073 adamantyl group Chemical group C12(CC3CC(CC(C1)C3)C2)* 0.000 description 1

- 230000000996 additive effect Effects 0.000 description 1

- 230000001476 alcoholic effect Effects 0.000 description 1

- 150000001299 aldehydes Chemical class 0.000 description 1

- 150000001338 aliphatic hydrocarbons Chemical class 0.000 description 1

- 229910052783 alkali metal Inorganic materials 0.000 description 1

- 150000008044 alkali metal hydroxides Chemical class 0.000 description 1

- 150000001340 alkali metals Chemical class 0.000 description 1

- 150000001336 alkenes Chemical class 0.000 description 1

- 229920000180 alkyd Polymers 0.000 description 1

- HSFWRNGVRCDJHI-UHFFFAOYSA-N alpha-acetylene Natural products C#C HSFWRNGVRCDJHI-UHFFFAOYSA-N 0.000 description 1

- AZDRQVAHHNSJOQ-UHFFFAOYSA-N alumane Chemical class [AlH3] AZDRQVAHHNSJOQ-UHFFFAOYSA-N 0.000 description 1

- 229910052782 aluminium Inorganic materials 0.000 description 1

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 1

- 229910000147 aluminium phosphate Inorganic materials 0.000 description 1

- 235000012211 aluminium silicate Nutrition 0.000 description 1

- 150000001450 anions Chemical group 0.000 description 1

- 230000003712 anti-aging effect Effects 0.000 description 1

- 229940058905 antimony compound for treatment of leishmaniasis and trypanosomiasis Drugs 0.000 description 1

- 150000001463 antimony compounds Chemical class 0.000 description 1

- 150000004984 aromatic diamines Chemical class 0.000 description 1

- 125000002029 aromatic hydrocarbon group Chemical group 0.000 description 1

- 150000004945 aromatic hydrocarbons Chemical class 0.000 description 1

- AYJRCSIUFZENHW-DEQYMQKBSA-L barium(2+);oxomethanediolate Chemical compound [Ba+2].[O-][14C]([O-])=O AYJRCSIUFZENHW-DEQYMQKBSA-L 0.000 description 1

- 150000007514 bases Chemical class 0.000 description 1

- 235000013871 bee wax Nutrition 0.000 description 1

- 239000012166 beeswax Substances 0.000 description 1

- 239000012965 benzophenone Substances 0.000 description 1

- 150000008366 benzophenones Chemical class 0.000 description 1

- QRUDEWIWKLJBPS-UHFFFAOYSA-N benzotriazole Chemical compound C1=CC=C2N[N][N]C2=C1 QRUDEWIWKLJBPS-UHFFFAOYSA-N 0.000 description 1

- 239000012964 benzotriazole Substances 0.000 description 1

- 150000001565 benzotriazoles Chemical class 0.000 description 1

- IISBACLAFKSPIT-UHFFFAOYSA-N bisphenol A Chemical compound C=1C=C(O)C=CC=1C(C)(C)C1=CC=C(O)C=C1 IISBACLAFKSPIT-UHFFFAOYSA-N 0.000 description 1

- 238000009835 boiling Methods 0.000 description 1

- YHWCPXVTRSHPNY-UHFFFAOYSA-N butan-1-olate;titanium(4+) Chemical compound [Ti+4].CCCC[O-].CCCC[O-].CCCC[O-].CCCC[O-] YHWCPXVTRSHPNY-UHFFFAOYSA-N 0.000 description 1

- BMRWNKZVCUKKSR-UHFFFAOYSA-N butane-1,2-diol Chemical compound CCC(O)CO BMRWNKZVCUKKSR-UHFFFAOYSA-N 0.000 description 1

- OWBTYPJTUOEWEK-UHFFFAOYSA-N butane-2,3-diol Chemical compound CC(O)C(C)O OWBTYPJTUOEWEK-UHFFFAOYSA-N 0.000 description 1

- 125000004106 butoxy group Chemical group [*]OC([H])([H])C([H])([H])C(C([H])([H])[H])([H])[H] 0.000 description 1

- JHIWVOJDXOSYLW-UHFFFAOYSA-N butyl 2,2-difluorocyclopropane-1-carboxylate Chemical compound CCCCOC(=O)C1CC1(F)F JHIWVOJDXOSYLW-UHFFFAOYSA-N 0.000 description 1

- 239000011575 calcium Substances 0.000 description 1

- 229910052791 calcium Inorganic materials 0.000 description 1

- 235000001465 calcium Nutrition 0.000 description 1

- 229940043430 calcium compound Drugs 0.000 description 1

- 150000001674 calcium compounds Chemical class 0.000 description 1

- 239000001506 calcium phosphate Substances 0.000 description 1

- 229910000389 calcium phosphate Inorganic materials 0.000 description 1

- 235000011010 calcium phosphates Nutrition 0.000 description 1

- 239000004204 candelilla wax Substances 0.000 description 1

- 235000013868 candelilla wax Nutrition 0.000 description 1

- 229940073532 candelilla wax Drugs 0.000 description 1

- 229910052799 carbon Inorganic materials 0.000 description 1

- 239000011203 carbon fibre reinforced carbon Substances 0.000 description 1

- 150000001732 carboxylic acid derivatives Chemical class 0.000 description 1

- 125000002843 carboxylic acid group Chemical group 0.000 description 1

- 239000004203 carnauba wax Substances 0.000 description 1

- 235000013869 carnauba wax Nutrition 0.000 description 1

- 230000003197 catalytic effect Effects 0.000 description 1

- 239000007795 chemical reaction product Substances 0.000 description 1

- 238000006757 chemical reactions by type Methods 0.000 description 1

- 150000001805 chlorine compounds Chemical class 0.000 description 1

- PMMYEEVYMWASQN-IMJSIDKUSA-N cis-4-Hydroxy-L-proline Chemical compound O[C@@H]1CN[C@H](C(O)=O)C1 PMMYEEVYMWASQN-IMJSIDKUSA-N 0.000 description 1

- HNEGQIOMVPPMNR-IHWYPQMZSA-N citraconic acid Chemical compound OC(=O)C(/C)=C\C(O)=O HNEGQIOMVPPMNR-IHWYPQMZSA-N 0.000 description 1

- 229940018557 citraconic acid Drugs 0.000 description 1

- 239000003086 colorant Substances 0.000 description 1

- 239000002131 composite material Substances 0.000 description 1

- 238000009833 condensation Methods 0.000 description 1

- 230000005494 condensation Effects 0.000 description 1

- 239000000470 constituent Substances 0.000 description 1

- 230000008878 coupling Effects 0.000 description 1

- 238000010168 coupling process Methods 0.000 description 1

- 238000005859 coupling reaction Methods 0.000 description 1

- LDHQCZJRKDOVOX-NSCUHMNNSA-N crotonic acid Chemical compound C\C=C\C(O)=O LDHQCZJRKDOVOX-NSCUHMNNSA-N 0.000 description 1

- 125000000753 cycloalkyl group Chemical group 0.000 description 1

- PDXRQENMIVHKPI-UHFFFAOYSA-N cyclohexane-1,1-diol Chemical compound OC1(O)CCCCC1 PDXRQENMIVHKPI-UHFFFAOYSA-N 0.000 description 1

- VKIRRGRTJUUZHS-UHFFFAOYSA-N cyclohexane-1,4-diamine Chemical compound NC1CCC(N)CC1 VKIRRGRTJUUZHS-UHFFFAOYSA-N 0.000 description 1

- 125000000113 cyclohexyl group Chemical group [H]C1([H])C([H])([H])C([H])([H])C([H])(*)C([H])([H])C1([H])[H] 0.000 description 1

- 230000007423 decrease Effects 0.000 description 1

- JGFBRKRYDCGYKD-UHFFFAOYSA-N dibutyl(oxo)tin Chemical compound CCCC[Sn](=O)CCCC JGFBRKRYDCGYKD-UHFFFAOYSA-N 0.000 description 1

- 239000012975 dibutyltin dilaurate Substances 0.000 description 1

- ZXDVQYBUEVYUCG-UHFFFAOYSA-N dibutyltin(2+);methanolate Chemical compound CCCC[Sn](OC)(OC)CCCC ZXDVQYBUEVYUCG-UHFFFAOYSA-N 0.000 description 1

- KEIQPMUPONZJJH-UHFFFAOYSA-N dicyclohexylmethanediamine Chemical compound C1CCCCC1C(N)(N)C1CCCCC1 KEIQPMUPONZJJH-UHFFFAOYSA-N 0.000 description 1

- 238000007607 die coating method Methods 0.000 description 1

- 150000001993 dienes Chemical class 0.000 description 1

- 235000014113 dietary fatty acids Nutrition 0.000 description 1

- OTARVPUIYXHRRB-UHFFFAOYSA-N diethoxy-methyl-[3-(oxiran-2-ylmethoxy)propyl]silane Chemical compound CCO[Si](C)(OCC)CCCOCC1CO1 OTARVPUIYXHRRB-UHFFFAOYSA-N 0.000 description 1

- 125000004177 diethyl group Chemical group [H]C([H])([H])C([H])([H])* 0.000 description 1

- 125000005442 diisocyanate group Chemical group 0.000 description 1

- KIQKWYUGPPFMBV-UHFFFAOYSA-N diisocyanatomethane Chemical group O=C=NCN=C=O KIQKWYUGPPFMBV-UHFFFAOYSA-N 0.000 description 1

- 239000003085 diluting agent Substances 0.000 description 1

- IEJIGPNLZYLLBP-UHFFFAOYSA-N dimethyl carbonate Chemical compound COC(=O)OC IEJIGPNLZYLLBP-UHFFFAOYSA-N 0.000 description 1

- 239000004205 dimethyl polysiloxane Substances 0.000 description 1

- JVSWJIKNEAIKJW-UHFFFAOYSA-N dimethyl-hexane Natural products CCCCCC(C)C JVSWJIKNEAIKJW-UHFFFAOYSA-N 0.000 description 1

- 229920005645 diorganopolysiloxane polymer Polymers 0.000 description 1

- ROORDVPLFPIABK-UHFFFAOYSA-N diphenyl carbonate Chemical compound C=1C=CC=CC=1OC(=O)OC1=CC=CC=C1 ROORDVPLFPIABK-UHFFFAOYSA-N 0.000 description 1

- ZZTCPWRAHWXWCH-UHFFFAOYSA-N diphenylmethanediamine Chemical compound C=1C=CC=CC=1C(N)(N)C1=CC=CC=C1 ZZTCPWRAHWXWCH-UHFFFAOYSA-N 0.000 description 1

- SZXQTJUDPRGNJN-UHFFFAOYSA-N dipropylene glycol Chemical compound OCCCOCCCO SZXQTJUDPRGNJN-UHFFFAOYSA-N 0.000 description 1

- 238000002845 discoloration Methods 0.000 description 1

- 238000005401 electroluminescence Methods 0.000 description 1

- 238000001227 electron beam curing Methods 0.000 description 1

- 239000003995 emulsifying agent Substances 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- AFSIMBWBBOJPJG-UHFFFAOYSA-N ethenyl octadecanoate Chemical compound CCCCCCCCCCCCCCCCCC(=O)OC=C AFSIMBWBBOJPJG-UHFFFAOYSA-N 0.000 description 1

- 125000001033 ether group Chemical group 0.000 description 1

- 125000005448 ethoxyethyl group Chemical group [H]C([H])([H])C([H])([H])OC([H])([H])C([H])([H])* 0.000 description 1

- 125000005745 ethoxymethyl group Chemical group [H]C([H])([H])C([H])([H])OC([H])([H])* 0.000 description 1

- 238000007765 extrusion coating Methods 0.000 description 1

- 239000000194 fatty acid Substances 0.000 description 1

- 229930195729 fatty acid Natural products 0.000 description 1

- 150000004665 fatty acids Chemical class 0.000 description 1

- 239000000945 filler Substances 0.000 description 1

- 238000011049 filling Methods 0.000 description 1

- 238000009501 film coating Methods 0.000 description 1

- 230000004927 fusion Effects 0.000 description 1

- 238000001879 gelation Methods 0.000 description 1

- 150000002334 glycols Chemical class 0.000 description 1

- 229920000578 graft copolymer Polymers 0.000 description 1

- 238000010559 graft polymerization reaction Methods 0.000 description 1

- 230000005484 gravity Effects 0.000 description 1

- 125000001188 haloalkyl group Chemical group 0.000 description 1

- 125000005843 halogen group Chemical group 0.000 description 1

- 238000013007 heat curing Methods 0.000 description 1

- 239000012760 heat stabilizer Substances 0.000 description 1

- IUJAMGNYPWYUPM-UHFFFAOYSA-N hentriacontane Chemical compound CCCCCCCCCCCCCCCCCCCCCCCCCCCCCCC IUJAMGNYPWYUPM-UHFFFAOYSA-N 0.000 description 1

- YCOZIPAWZNQLMR-UHFFFAOYSA-N heptane - octane Natural products CCCCCCCCCCCCCCC YCOZIPAWZNQLMR-UHFFFAOYSA-N 0.000 description 1

- SXCBDZAEHILGLM-UHFFFAOYSA-N heptane-1,7-diol Chemical compound OCCCCCCCO SXCBDZAEHILGLM-UHFFFAOYSA-N 0.000 description 1

- CGQIJXYITMTOBI-UHFFFAOYSA-N hex-5-enyl(trimethoxy)silane Chemical compound CO[Si](OC)(OC)CCCCC=C CGQIJXYITMTOBI-UHFFFAOYSA-N 0.000 description 1

- HTDJPCNNEPUOOQ-UHFFFAOYSA-N hexamethylcyclotrisiloxane Chemical compound C[Si]1(C)O[Si](C)(C)O[Si](C)(C)O1 HTDJPCNNEPUOOQ-UHFFFAOYSA-N 0.000 description 1

- RRAMGCGOFNQTLD-UHFFFAOYSA-N hexamethylene diisocyanate Chemical group O=C=NCCCCCCN=C=O RRAMGCGOFNQTLD-UHFFFAOYSA-N 0.000 description 1

- SYECJBOWSGTPLU-UHFFFAOYSA-N hexane-1,1-diamine Chemical compound CCCCCC(N)N SYECJBOWSGTPLU-UHFFFAOYSA-N 0.000 description 1

- FUZZWVXGSFPDMH-UHFFFAOYSA-M hexanoate Chemical compound CCCCCC([O-])=O FUZZWVXGSFPDMH-UHFFFAOYSA-M 0.000 description 1

- ANJPRQPHZGHVQB-UHFFFAOYSA-N hexyl isocyanate Chemical compound CCCCCCN=C=O ANJPRQPHZGHVQB-UHFFFAOYSA-N 0.000 description 1

- 150000003949 imides Chemical class 0.000 description 1

- 238000005470 impregnation Methods 0.000 description 1

- 239000003112 inhibitor Substances 0.000 description 1

- 239000010954 inorganic particle Substances 0.000 description 1

- 229910052740 iodine Inorganic materials 0.000 description 1

- 239000011630 iodine Substances 0.000 description 1

- 238000005342 ion exchange Methods 0.000 description 1

- 229920000554 ionomer Polymers 0.000 description 1

- 125000000959 isobutyl group Chemical group [H]C([H])([H])C([H])(C([H])([H])[H])C([H])([H])* 0.000 description 1

- XJRAOMZCVTUHFI-UHFFFAOYSA-N isocyanic acid;methane Chemical compound C.N=C=O.N=C=O XJRAOMZCVTUHFI-UHFFFAOYSA-N 0.000 description 1

- NIMLQBUJDJZYEJ-UHFFFAOYSA-N isophorone diisocyanate Chemical group CC1(C)CC(N=C=O)CC(C)(CN=C=O)C1 NIMLQBUJDJZYEJ-UHFFFAOYSA-N 0.000 description 1

- 125000001449 isopropyl group Chemical group [H]C([H])([H])C([H])(*)C([H])([H])[H] 0.000 description 1

- 229940119170 jojoba wax Drugs 0.000 description 1

- NLYAJNPCOHFWQQ-UHFFFAOYSA-N kaolin Chemical compound O.O.O=[Al]O[Si](=O)O[Si](=O)O[Al]=O NLYAJNPCOHFWQQ-UHFFFAOYSA-N 0.000 description 1

- 235000019388 lanolin Nutrition 0.000 description 1

- 229940039717 lanolin Drugs 0.000 description 1

- ZLNQQNXFFQJAID-UHFFFAOYSA-L magnesium carbonate Chemical compound [Mg+2].[O-]C([O-])=O ZLNQQNXFFQJAID-UHFFFAOYSA-L 0.000 description 1

- 239000001095 magnesium carbonate Substances 0.000 description 1

- 229910000021 magnesium carbonate Inorganic materials 0.000 description 1

- 150000002681 magnesium compounds Chemical class 0.000 description 1

- GVALZJMUIHGIMD-UHFFFAOYSA-H magnesium phosphate Chemical compound [Mg+2].[Mg+2].[Mg+2].[O-]P([O-])([O-])=O.[O-]P([O-])([O-])=O GVALZJMUIHGIMD-UHFFFAOYSA-H 0.000 description 1

- 239000004137 magnesium phosphate Substances 0.000 description 1

- 229910000157 magnesium phosphate Inorganic materials 0.000 description 1

- 229960002261 magnesium phosphate Drugs 0.000 description 1

- 235000010994 magnesium phosphates Nutrition 0.000 description 1

- FPYJFEHAWHCUMM-UHFFFAOYSA-N maleic anhydride Chemical compound O=C1OC(=O)C=C1 FPYJFEHAWHCUMM-UHFFFAOYSA-N 0.000 description 1

- 150000002697 manganese compounds Chemical class 0.000 description 1

- 238000000691 measurement method Methods 0.000 description 1

- JDSHMPZPIAZGSV-UHFFFAOYSA-N melamine Chemical compound NC1=NC(N)=NC(N)=N1 JDSHMPZPIAZGSV-UHFFFAOYSA-N 0.000 description 1

- 239000000155 melt Substances 0.000 description 1

- 239000012528 membrane Substances 0.000 description 1

- QSHDDOUJBYECFT-UHFFFAOYSA-N mercury Chemical compound [Hg] QSHDDOUJBYECFT-UHFFFAOYSA-N 0.000 description 1

- 229910052753 mercury Inorganic materials 0.000 description 1

- 150000002736 metal compounds Chemical class 0.000 description 1

- 229910001507 metal halide Inorganic materials 0.000 description 1

- 150000005309 metal halides Chemical class 0.000 description 1

- RBQRWNWVPQDTJJ-UHFFFAOYSA-N methacryloyloxyethyl isocyanate Chemical compound CC(=C)C(=O)OCCN=C=O RBQRWNWVPQDTJJ-UHFFFAOYSA-N 0.000 description 1

- 125000004184 methoxymethyl group Chemical group [H]C([H])([H])OC([H])([H])* 0.000 description 1

- AYLRODJJLADBOB-QMMMGPOBSA-N methyl (2s)-2,6-diisocyanatohexanoate Chemical group COC(=O)[C@@H](N=C=O)CCCCN=C=O AYLRODJJLADBOB-QMMMGPOBSA-N 0.000 description 1

- ICCDZMWNLNRHGP-UHFFFAOYSA-N methyl-[3-(oxiran-2-ylmethoxy)propyl]-bis(prop-1-en-2-yloxy)silane Chemical compound CC(=C)O[Si](C)(OC(C)=C)CCCOCC1CO1 ICCDZMWNLNRHGP-UHFFFAOYSA-N 0.000 description 1

- 150000007522 mineralic acids Chemical class 0.000 description 1

- 239000012046 mixed solvent Substances 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- PYLWMHQQBFSUBP-UHFFFAOYSA-N monofluorobenzene Chemical compound FC1=CC=CC=C1 PYLWMHQQBFSUBP-UHFFFAOYSA-N 0.000 description 1

- OMNKZBIFPJNNIO-UHFFFAOYSA-N n-(2-methyl-4-oxopentan-2-yl)prop-2-enamide Chemical compound CC(=O)CC(C)(C)NC(=O)C=C OMNKZBIFPJNNIO-UHFFFAOYSA-N 0.000 description 1

- 125000004108 n-butyl group Chemical group [H]C([H])([H])C([H])([H])C([H])([H])C([H])([H])* 0.000 description 1

- 125000001280 n-hexyl group Chemical group C(CCCCC)* 0.000 description 1

- 125000000740 n-pentyl group Chemical group [H]C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])* 0.000 description 1

- 125000004123 n-propyl group Chemical group [H]C([H])([H])C([H])([H])C([H])([H])* 0.000 description 1

- DFFZOPXDTCDZDP-UHFFFAOYSA-N naphthalene-1,5-dicarboxylic acid Chemical compound C1=CC=C2C(C(=O)O)=CC=CC2=C1C(O)=O DFFZOPXDTCDZDP-UHFFFAOYSA-N 0.000 description 1

- VAWFFNJAPKXVPH-UHFFFAOYSA-N naphthalene-1,6-dicarboxylic acid Chemical compound OC(=O)C1=CC=CC2=CC(C(=O)O)=CC=C21 VAWFFNJAPKXVPH-UHFFFAOYSA-N 0.000 description 1

- WPUMVKJOWWJPRK-UHFFFAOYSA-N naphthalene-2,7-dicarboxylic acid Chemical compound C1=CC(C(O)=O)=CC2=CC(C(=O)O)=CC=C21 WPUMVKJOWWJPRK-UHFFFAOYSA-N 0.000 description 1

- 238000006386 neutralization reaction Methods 0.000 description 1

- 230000003472 neutralizing effect Effects 0.000 description 1

- 229910017604 nitric acid Inorganic materials 0.000 description 1

- QJGQUHMNIGDVPM-UHFFFAOYSA-N nitrogen group Chemical group [N] QJGQUHMNIGDVPM-UHFFFAOYSA-N 0.000 description 1

- SXJVFQLYZSNZBT-UHFFFAOYSA-N nonane-1,9-diamine Chemical compound NCCCCCCCCCN SXJVFQLYZSNZBT-UHFFFAOYSA-N 0.000 description 1

- 239000002736 nonionic surfactant Substances 0.000 description 1

- HMMGMWAXVFQUOA-UHFFFAOYSA-N octamethylcyclotetrasiloxane Chemical compound C[Si]1(C)O[Si](C)(C)O[Si](C)(C)O[Si](C)(C)O1 HMMGMWAXVFQUOA-UHFFFAOYSA-N 0.000 description 1

- 125000004365 octenyl group Chemical group C(=CCCCCCC)* 0.000 description 1

- 238000010943 off-gassing Methods 0.000 description 1

- 239000003921 oil Substances 0.000 description 1

- JRZJOMJEPLMPRA-UHFFFAOYSA-N olefin Natural products CCCCCCCC=C JRZJOMJEPLMPRA-UHFFFAOYSA-N 0.000 description 1

- 150000007524 organic acids Chemical class 0.000 description 1

- 235000005985 organic acids Nutrition 0.000 description 1

- 150000004812 organic fluorine compounds Chemical class 0.000 description 1

- 229920006136 organohydrogenpolysiloxane Polymers 0.000 description 1

- 239000007800 oxidant agent Substances 0.000 description 1

- 230000003647 oxidation Effects 0.000 description 1

- 238000007254 oxidation reaction Methods 0.000 description 1

- 239000004209 oxidized polyethylene wax Substances 0.000 description 1

- TWNQGVIAIRXVLR-UHFFFAOYSA-N oxo(oxoalumanyloxy)alumane Chemical compound O=[Al]O[Al]=O TWNQGVIAIRXVLR-UHFFFAOYSA-N 0.000 description 1

- RVTZCBVAJQQJTK-UHFFFAOYSA-N oxygen(2-);zirconium(4+) Chemical compound [O-2].[O-2].[Zr+4] RVTZCBVAJQQJTK-UHFFFAOYSA-N 0.000 description 1

- 239000005022 packaging material Substances 0.000 description 1

- 239000003973 paint Substances 0.000 description 1

- 239000000123 paper Substances 0.000 description 1

- 235000019809 paraffin wax Nutrition 0.000 description 1

- UCUUFSAXZMGPGH-UHFFFAOYSA-N penta-1,4-dien-3-one Chemical compound C=CC(=O)C=C UCUUFSAXZMGPGH-UHFFFAOYSA-N 0.000 description 1

- 230000035699 permeability Effects 0.000 description 1

- 229940066842 petrolatum Drugs 0.000 description 1

- 150000003009 phosphonic acids Chemical class 0.000 description 1

- 150000003016 phosphoric acids Chemical class 0.000 description 1

- 238000000016 photochemical curing Methods 0.000 description 1

- 230000000704 physical effect Effects 0.000 description 1

- 229920000233 poly(alkylene oxides) Chemical group 0.000 description 1

- 229920000435 poly(dimethylsiloxane) Polymers 0.000 description 1

- 229920002312 polyamide-imide Polymers 0.000 description 1