WO2021075149A1 - レバー式コネクタ - Google Patents

レバー式コネクタ Download PDFInfo

- Publication number

- WO2021075149A1 WO2021075149A1 PCT/JP2020/031610 JP2020031610W WO2021075149A1 WO 2021075149 A1 WO2021075149 A1 WO 2021075149A1 JP 2020031610 W JP2020031610 W JP 2020031610W WO 2021075149 A1 WO2021075149 A1 WO 2021075149A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- lever

- housing

- axis

- fitting

- shaft

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R13/00—Details of coupling devices of the kinds covered by groups H01R12/70 or H01R24/00 - H01R33/00

- H01R13/62—Means for facilitating engagement or disengagement of coupling parts or for holding them in engagement

- H01R13/629—Additional means for facilitating engagement or disengagement of coupling parts, e.g. aligning or guiding means, levers, gas pressure electrical locking indicators, manufacturing tolerances

- H01R13/62933—Comprising exclusively pivoting lever

- H01R13/62966—Comprising two pivoting levers

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R13/00—Details of coupling devices of the kinds covered by groups H01R12/70 or H01R24/00 - H01R33/00

- H01R13/62—Means for facilitating engagement or disengagement of coupling parts or for holding them in engagement

- H01R13/629—Additional means for facilitating engagement or disengagement of coupling parts, e.g. aligning or guiding means, levers, gas pressure electrical locking indicators, manufacturing tolerances

- H01R13/62933—Comprising exclusively pivoting lever

- H01R13/62938—Pivoting lever comprising own camming means

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R13/00—Details of coupling devices of the kinds covered by groups H01R12/70 or H01R24/00 - H01R33/00

- H01R13/62—Means for facilitating engagement or disengagement of coupling parts or for holding them in engagement

- H01R13/629—Additional means for facilitating engagement or disengagement of coupling parts, e.g. aligning or guiding means, levers, gas pressure electrical locking indicators, manufacturing tolerances

- H01R13/62977—Pivoting levers actuating linearly camming means

Definitions

- This disclosure relates to a lever type connector.

- Patent Document 1 discloses a lever fitting type connector in which a rotatable lever is attached to a connector housing. When mating the lever fitting type connector with the mating connector, the lever is rotated while the driven pin of the mating connector is inserted into the cam hole of the lever. When the lever is operated to slide the cam hole and the driven pin into contact with each other, a boosting effect is exerted by the lever action, and the lever fitting type connector and the mating connector are fitted.

- the lever type connector of the present disclosure is completed based on the above circumstances, and an object thereof is to reduce the operating force without increasing the size.

- the lever type connector of the present disclosure is With the housing A first lever attached to the housing so that it can rotate about the first axis, A second lever attached to the housing so that it can rotate about the second axis, It is provided with a boosting function unit that exerts a boosting function by interlocking with the rotation of the second lever.

- the first lever has a guide portion extending from the operation portion of the first lever toward the first axis.

- the second lever has a connecting portion that is connected to the first lever so that it can be displaced relative to the guide portion.

- the first lever and the second lever are interlocked between an initial position at which the housing and the mating housing start to be fitted and a fitting position at which the housing and the mating housing are completed. It is rotatable and can be rotated. When a virtual line passing through the second axis and the connecting portion is set with the second lever in the initial position, the first axis is located closer to the fitting position than the virtual line.

- the operating force can be reduced without increasing the size.

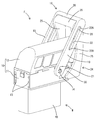

- FIG. 1 is a perspective view showing a state in which the lever type connector of the first embodiment and the mating connector are started to be fitted.

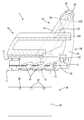

- FIG. 2 is a side view showing a state in which the first lever and the second lever are in the initial positions.

- FIG. 3 is a side view showing a state in which the first lever and the second lever are located between the initial position and the fitting position.

- FIG. 4 is a side view showing a state in which the first lever and the second lever are in the mating position.

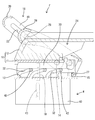

- FIG. 5 is a side sectional view showing a state in which the first lever and the second lever are in the initial positions and the lever type connector and the mating side connector are separated from each other.

- FIG. 6 is a side sectional view showing a state in which the first lever and the second lever are in the fitting position and the lever type connector and the mating side connector are fitted.

- the lever type connector of the present disclosure is (1) A housing, a first lever attached to the housing so as to rotate about the first axis, and a second lever attached to the housing so as to rotate about the second axis.

- a boosting function unit that exerts a boosting function by interlocking with the rotation of the second lever is provided, and the first lever is a guide portion extending from the operating portion of the first lever toward the first axis.

- the second lever has a connecting portion connected to the first lever so as to be relatively displaced along the guide portion, and the first lever and the second lever are the housing.

- the second lever can rotate in conjunction with the initial position at which the mating with the mating housing starts and the mating position at which the mating between the housing and the mating housing is completed.

- the first axis is located closer to the fitting position than the virtual line.

- the operating force applied to the operating portion is applied to the operating portion via the connecting portion and the second lever.

- the boosting function is exerted.

- the connecting portion is displaced relative to the first axis side from the operating portion side along the guide portion, so that the operating portion is displaced so as to move away from the second axis. Therefore, the operating force required to rotate the second shaft can be small. Since it is not necessary to lengthen the first lever and the second lever, the operating force can be reduced without increasing the size.

- the connecting portion is arranged at the tip end portion on the side opposite to the second axis in the length direction of the second lever. According to this configuration, the tip of the second lever does not protrude from the side edge of the first lever in the process of rotating the first lever and the second lever in conjunction with each other.

- the connecting portion is located at the operation side end portion of the both ends in the length direction of the guide portion, which is closer to the operation portion. It is preferable to do so. According to this configuration, when both levers in the initial position are to be rotated to the side opposite to the fitting position, the connecting portion abuts on the operation side end portion of the guide portion. As a result, it is possible to prevent both levers in the initial position from rotating to the side opposite to the fitting position.

- the operating portion is located at the tip of both ends of the first lever in the length direction opposite to the first axis, and the first shaft of both ends of the guide portion in the length direction. It is preferable that the operation side end portion on the opposite side to the operation portion is located adjacent to the operation portion. According to this configuration, the dimension in which the tip of the first lever protrudes from the side edge of the second lever when both levers are in the initial positions can be shortened.

- the connecting portion is preferably located on a straight line connecting the first axis and the second axis. .. According to this configuration, the direction of the operating force applied to the operation unit for rotating the first lever around the first axis coincides with the direction of rotating the second lever around the second axis. Therefore, the operating force applied to the operating unit is exerted as a force for rotating the second lever without loss.

- the lever type connector F of this embodiment is fitted so as to approach the mating connector M from above.

- the mating side connector M has a mating side housing 40 and a plurality of male terminal fittings 43 (see FIG. 6) housed inside the mating side housing 40.

- a plurality of (three in this embodiment) cam followers 42 are formed on the left and right outer surfaces of the mating connector M at intervals in the front-rear direction.

- the upper surface of the mating housing 40 is a fitting surface facing the lever type connector F.

- the lever-type connector F has one housing 10, a plurality of female terminal fittings 16 (see FIG. 6), one first lever 18, one second lever 24, and a pair of left and right sliders 30. ..

- the housing 10 has a two-part structure in which a housing body 11 made of synthetic resin and an electric wire cover 12 made of synthetic resin are assembled.

- a plurality of female terminal fittings 16 are housed in the housing body 11.

- the lower surface of the housing body 11 is a fitting surface that faces the fitting surface of the mating connector M in the vertical direction.

- An electric wire (not shown) connected to each female terminal fitting 16 is led out upward from the upper surface of the housing main body 11, that is, the outer surface on the side opposite to the fitting direction to the mating housing 40.

- An electric wire cover 12 is attached to the upper surface of the housing body 11. Inside the electric wire cover 12, a plurality of electric wires led out from the housing main body 11 are turned so as to bend rearward. The converted electric wire is pulled out to the rear of the electric wire cover 12.

- a pair of left and right guide grooves 13 are formed inside the housing body 11.

- the guide grooves 13 are arranged along the left and right outer surfaces of the housing main body 11 and extend in the front-rear direction orthogonal to the fitting direction of both connectors F and M. Both front and rear ends of the guide groove 13 are open to the outside of the housing body 11.

- first shaft 14 On both the left and right outer surfaces of the housing body 11, a pair of first axes 14 whose axes are directed in the left-right direction, that is, in the direction orthogonal to the fitting direction of both connectors F and M, are formed coaxially.

- the first shaft 14 In the front-rear direction, the first shaft 14 is arranged at a position in front of the center of the housing 10. In the vertical direction, the first shaft 14 is arranged above the central height of the housing body 11.

- a pair of bearing portions 15 are formed on both the left and right outer surfaces of the housing body 11.

- the bearing portion 15 In the front-rear direction, the bearing portion 15 is arranged at the rear end portion of the housing 10, that is, at a position rearward from the first shaft 14.

- the bearing portion 15 In the vertical direction, the bearing portion 15 is arranged at the lower end portion of the housing body 11, that is, at a position below the first shaft 14.

- the bearing portion 15 is arranged at a position obliquely downward and rearward with respect to the

- the first lever 18 is a single component having a pair of symmetrical first arm portions 19 and an operation portion 20 in which the tip portions of both first arm portions 19 are connected to each other.

- a bearing hole 21 is formed at the base end portion of the first arm portion 19 so as to penetrate the first arm portion 19 in the left-right direction.

- the first lever 18 is attached so as to be able to rotate relative to the housing 10 by fitting the bearing hole 21 into the first shaft 14.

- the first arm portion 19 is positioned so as to overlap the outer surface of the housing 10 with a clearance in the left-right direction.

- the first arm portion 19 has an elongated plate shape extending in a straight line.

- Guide portions 22 are formed on both the left and right first arm portions 19 so as to penetrate the first arm portions 19 to the left and right, respectively.

- the guide portion 22 extends linearly from the operation portion 20 side toward the first shaft 14 side in parallel with the first arm portion 19 to form a groove shape.

- the guide portion 22 is closed at the operation side end portion 22A on the side closer to the operation portion 20 and the shaft side end portion 22B near the first shaft 14 side of both ends in the length direction of the guide portion 22.

- the second lever 24 is a single component having a pair of symmetrical second arm portions 25 and a connecting portion 26 in which the tip portions of both second arm portions 25 are connected to each other.

- a pair of second shafts 27 are formed at the base ends of both the left and right second arm portions 25.

- the pair of second axes 27 have a form in which the axes project from the inner surface of the base end portion in the left-right direction, and are arranged coaxially with each other.

- the second lever 24 is attached so as to be able to rotate relative to the housing 10 by fitting the second shaft 27 to the bearing portion 15.

- the second arm portion 25 When the second lever 24 is attached to the housing 10, the second arm portion 25 is positioned so as to overlap the outer surface of the housing 10 with a clearance in the left-right direction, and is located on the inner surface of the first arm portion 19. On the other hand, it is located so that it overlaps with a clearance in the left-right direction.

- the second arm portion 25 has an elongated curved shape when viewed in parallel with the axis of the second axis 27.

- a pair of connecting portions 28 are formed at the tip portions of the pair of second arm portions 25.

- the pair of connecting portions 28 have a cylindrical shape with the axes oriented in the left-right direction, that is, in the direction parallel to the first axis 14 and the second axis 27.

- the pair of connecting portions 28 project in the left-right direction from the outer surface of the tip end portion of the second arm portion 25.

- the outer diameter of the connecting portion 28 is the same as the width dimension of the guide portion 22, or slightly smaller than the width dimension of the guide portion 22.

- a pair of drive shafts 29 are formed on both the left and right second levers 24.

- the drive shaft 29 is arranged between the center of the second lever 24 and the second shaft 27. That is, the length dimension from the second shaft 27 to the drive shaft 29 is shorter than the length dimension from the second shaft 27 to the connecting portion 28.

- the drive shaft 29 has a form in which the axis line is directed in the left-right direction and protrudes from the inner surface of the second arm portion 25.

- the first lever 18 and the second lever 24 are connected so that they can rotate in conjunction with each other while being relatively displaced by fitting the connecting portion 28 into the guide portion 22.

- the connected first lever 18 and second lever 24 rotate between the initial position shown in FIGS. 1, 2 and 5 and the fitting position shown in FIGS. 4 and 6.

- the first lever 18 and the first shaft 14 rotate around the first lever 18, and the second lever 24 rotates about the second shaft 27.

- the first lever 18 takes a backward tilted posture so that the operation unit 20 is located behind the first axis 14 and the second axis 27.

- the second lever 24 is tilted backward so that the connecting portion 28 is located behind the second shaft 27.

- the connecting portion 28 is located at the operation side end portion 22A of the guide portion 22.

- Both levers 18 and 24 in the initial position are displaced to the fitting position by rotating in the counterclockwise direction in the side view shown in FIGS. 2 to 6.

- the first lever 18 takes a forward tilted posture so that the operating portion 20 is positioned in front of the first shaft 14.

- the second lever 24 takes a forward tilted posture so that the connecting portion 28 is located in front of the first shaft 14 and the second shaft 27.

- the line connecting the connecting portion 28 and the second axis 27 is defined as the virtual line V.

- the front area is defined as the area on the fitting position side among the two areas on the front side and the rear side partitioned by the virtual line V.

- the region on the rear side is defined as the region on the initial position side.

- the region on the fitting position side is a region in which the connecting portion 28 moves when the second lever 24 at the initial position rotates toward the fitting position.

- the first axis 14 is located in the region on the fitting position side with respect to the virtual line V.

- the first axis 14 is located inside the locus circle drawn by the connecting portion 28 as the second lever 24 rotates.

- the operation unit 20 is located outside the locus circle drawn by the connecting unit 28.

- the pair of sliders 30 are mounted in the guide groove 13 of the housing body 11 so as to be relatively displaced in the front-rear direction.

- a passive recess 31 is formed at the rear end of the slider 30.

- the slider 30 is formed with a plurality of (three in this embodiment) cam grooves 32 that function as boosting function units.

- the cam groove 32 has a groove portion in an oblique direction with respect to both the fitting direction of both connectors F and M and the moving direction of the slider 30.

- the entrance of the cam groove 32 is open to the lower end edge of the slider 30.

- the slider 30 is connected to the second lever 24 by fitting the passive recess 31 to the drive shaft 29.

- the second lever 24 can rotate relative to the slider 30 about the drive shaft 29.

- the operating force applied to the operating portion 20 of the first lever 18 acts as a rotational force with respect to the second lever 24 by passing through the guide portion 22 and the connecting portion 28. Be transmitted. Since the first axis 14 is arranged on the fitting position side with respect to the virtual line V, in the process in which both levers 18 and 24 rotate in the fitting direction, the connecting portion 28 moves along the guide portion 22 on the operating side. The relative displacement is performed from the end portion 22A toward the shaft side end portion 22B. As the connecting portion 28 moves toward the shaft side end portion 22B, the operating portion 20 moves away from the outer peripheral side with respect to the locus circle (not shown) drawn by the connecting portion 28 about the second axis 27. Displace relative to. As a result, the distance from the second shaft 27, which is interlocked with the boosting function, to the operating unit 20 to which the operating force is applied becomes long, so that the operating force required for the cam groove 32 to exert the boosting function is increased. It becomes smaller.

- the connecting portion 28 is a portion for transmitting rotational power from the first lever 18 to the second lever 24, when the first lever 18 is used as a lever and the first shaft 14 is used as a fulcrum for the lever,

- the connecting portion 28 is the point of action of the lever.

- the operation unit 20 is the point of effort of the lever, and the position of the operation unit 20 does not change even if the first lever 18 rotates.

- the connecting portion 28, which is the point of action approaches the first axis 14, which is the fulcrum of the lever, as both levers 18 and 24 rotate toward the fitting position side. Therefore, the boosting function when the operating force applied to the operating unit 20 is transmitted to the second lever 24 increases as the rotation of both levers 18 and 24 toward the fitting position progresses. ..

- the first lever 18 and the second lever 24 rotate relative to each other around the connecting portion 28.

- the angle ⁇ formed by the half straight line from the connecting portion 28 to the first axis 14 and the virtual line V from the connecting portion 28 to the second axis 27 fluctuates as it goes to the fitting position.

- the direction in which the second lever 24 rotates is a direction perpendicular to the virtual line V connecting the second shaft 27 and the connecting portion 28.

- the rotational power transmitted to the second lever 24 is transmitted to the slider 30 via the drive shaft 29 and the passive recess 31, and the slider 30 slides forward.

- the connecting portion 28 becomes the power point of the lever and the drive shaft 29 becomes the action point of the lever. Since the length from the second shaft 27 to the drive shaft 29 is shorter than the length from the second shaft 27 to the connecting portion 28, the driving force transmitted from the second lever 24 to the slider 30 is amplified by the action of the lever. Will be done.

- the first axis 14 is a region on the fitting position side with respect to the virtual line V connecting the second axis 27 and the connecting portion 28. It is kept in the state of being located in.

- the first shaft 14, the second shaft 27, and the connecting portion 28 are arranged so as to be substantially aligned with each other. This form means that the direction of the operating force acting on the operating unit 20 and the rotating direction of the second lever 24 are substantially parallel to each other. Therefore, the operating force applied to the operating unit 20 is transmitted as a driving force for rotating the second lever 24 as it is.

- the fitting resistance generated in the fitting process between the housing 10 and the mating housing 40 is maximized.

- the lever type connector F of this embodiment includes a housing 10, a first lever 18, a second lever 24, and a cam groove 32.

- the first lever 18 is attached to the housing 10 so as to be able to rotate about the first shaft 14.

- the second lever 24 is attached to the housing 10 so as to be able to rotate about the second shaft 27.

- the cam groove 32 is a boosting function unit that exerts a boosting function by interlocking with the rotation of the second lever 24.

- the first lever 18 has a guide portion 22 extending from the operation portion 20 of the first lever 18 toward the first shaft 14.

- the second lever 24 has a connecting portion 28 that is connected to the first lever 18 so as to be relatively displaced along the guide portion 22.

- the connecting portion 28 By fitting the connecting portion 28 into the guide portion 22, the first lever 18 and the second lever 24 are at the initial position where the housing 10 and the mating side housing 40 start to fit, and the housing 10 and the mating side housing 40. It rotates in conjunction with the fitting position that completes the fitting with.

- the first axis 14 is arranged in the area closer to the fitting position than the virtual line V. There is.

- the operating force applied to the operating portion 20 is applied to the connecting portion 28.

- the boosting function is exhibited by being transmitted to the second shaft 27 via the second lever 24.

- the connecting portion 28 is displaced relative to the first shaft 14 side from the operating portion 20 side along the guide portion 22, so that the operating portion 20 is displaced so as to move away from the second shaft 27. Therefore, the operating force required to rotate the second shaft 27 can be small. Since it is not necessary to lengthen the first lever 18 and the second lever 24, the operating force can be reduced without increasing the size.

- the connecting portion 28 is arranged at the tip end portion on the side opposite to the second axis 27 in the length direction of the second lever 24. According to this configuration, the tip of the second lever 24 does not protrude from the side edge of the first lever 18 in the process of rotating the first lever 18 and the second lever 24 in conjunction with each other.

- the connecting portion 28 In the state where the first lever 18 and the second lever 24 are in the initial positions, the connecting portion 28 is located at the operation side end portion 22A on the side closer to the operation portion 20 among both ends in the length direction of the guide portion 22. .. According to this configuration, when both levers 18 and 24 in the initial position are to be rotated to the side opposite to the fitting position, the connecting portion 28 abuts on the operating side end portion 22A of the guide portion 22. As a result, it is possible to prevent both levers 18 and 24 in the initial position from rotating to the side opposite to the fitting position.

- the operation unit 20 is located at the tip of the first lever 18 at both ends in the length direction opposite to the first axis 14. Of both ends of the guide portion 22 in the length direction, the operation side end portion 22A opposite to the first shaft 14 is located adjacent to the operation portion 20.

- the direction in which the operation side end 22A and the operation unit 20 are adjacent to each other is the length direction of the first lever 18, that is, the direction connecting the first shaft 14 and the operation unit 20. According to this configuration, when both levers 18 and 24 are in the initial positions, the dimension in which the tip of the first lever 18 protrudes from the side edge of the second lever 24 can be shortened.

- the connecting portion 28 is located on a straight line connecting the first shaft 14 and the second shaft 27. According to this configuration, the direction of the operating force applied to the operation unit 20 for rotating the first lever 18 around the first axis 14 rotates the second lever 24 around the second axis 27. Match the orientation. Therefore, the operating force applied to the operating unit 20 is exerted as a force for rotating the second lever 24 without loss.

- the connecting portion is arranged at the tip of the second lever, but the connecting portion may be arranged at a position closer to the second axis than the tip of the second lever.

- the connecting portion when both levers are in the initial position, the connecting portion is located at the operating side end of the guide portion, but when both levers are in the initial position, the connecting portion is located at the operating side end of the guide portion. It may be located on the first axis side.

- the operation unit is arranged at the tip of the first lever, but the operation unit may be arranged at a position closer to the first axis than the tip of the first lever.

- the operation side end portion of the guide portion is arranged so as to be adjacent to the operation portion, but the operation side end portion of the guide portion may be arranged at a position away from the operation portion.

- the rotational power of the second lever is transmitted to the slider, and the cam groove formed in the slider exerts a boosting function.

- a cam groove as a boosting function portion may be formed in the second lever. ..

- the first axis when both levers are located between the initial position and the fitting position, the first axis is located in the area on the fitting position side of the virtual line connecting the second axis and the connecting portion.

- the first axis may be located in the region on the initial position side of the virtual line while both levers are from the initial position to the fitting position.

Landscapes

- Details Of Connecting Devices For Male And Female Coupling (AREA)

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202080071748.4A CN114556714B (zh) | 2019-10-18 | 2020-08-21 | 杆式连接器 |

| US17/764,947 US12119588B2 (en) | 2019-10-18 | 2020-08-21 | Lever-type connector |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2019190861A JP7249506B2 (ja) | 2019-10-18 | 2019-10-18 | レバー式コネクタ |

| JP2019-190861 | 2019-10-18 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2021075149A1 true WO2021075149A1 (ja) | 2021-04-22 |

Family

ID=75537775

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2020/031610 Ceased WO2021075149A1 (ja) | 2019-10-18 | 2020-08-21 | レバー式コネクタ |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US12119588B2 (enExample) |

| JP (1) | JP7249506B2 (enExample) |

| CN (1) | CN114556714B (enExample) |

| WO (1) | WO2021075149A1 (enExample) |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN118899707B (zh) * | 2024-10-09 | 2024-12-24 | 江苏展鸣驱动科技有限公司 | 一种动力电池连接器 |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20050221647A1 (en) * | 2004-03-31 | 2005-10-06 | Jst Corporation | Dual action mechanical assisted connector |

| JP2007005088A (ja) * | 2005-06-22 | 2007-01-11 | Tokai Rika Co Ltd | コネクタの連結構造 |

| JP2010244799A (ja) * | 2009-04-03 | 2010-10-28 | Sumitomo Wiring Syst Ltd | コネクタ |

| JP2013004419A (ja) * | 2011-06-20 | 2013-01-07 | Sumitomo Wiring Syst Ltd | レバー式コネクタ |

Family Cites Families (17)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| IT1303186B1 (it) * | 1998-11-27 | 2000-10-30 | Framatome Connectors Italia | Connettore elettrico. |

| JP2001351729A (ja) * | 2000-06-07 | 2001-12-21 | Sumitomo Wiring Syst Ltd | レバー式コネクタ |

| JP2002219971A (ja) * | 2001-01-26 | 2002-08-06 | Auto Network Gijutsu Kenkyusho:Kk | パネル駆動装置 |

| US7070438B2 (en) * | 2004-03-31 | 2006-07-04 | Jst Corporation | Connector lever lock |

| ITTO20050089A1 (it) * | 2005-02-16 | 2006-08-17 | Fci Italia S P A | Connettore elettrico |

| CN101459297B (zh) * | 2007-12-14 | 2013-01-02 | 泰科电子(上海)有限公司 | 电气连接装置 |

| JP4468465B2 (ja) * | 2008-03-28 | 2010-05-26 | タイコエレクトロニクスジャパン合同会社 | レバー式コネクタ |

| US7789682B1 (en) * | 2009-04-21 | 2010-09-07 | Tyco Electronics Corporation | Electrical connector with lever and camming slide |

| US7862353B1 (en) * | 2010-06-22 | 2011-01-04 | J. S. T. Corporation | Electrical connector housing and electrical connector assembly incorporating the electrical connector housing |

| JP5748495B2 (ja) * | 2011-02-09 | 2015-07-15 | 矢崎総業株式会社 | レバー嵌合式コネクタ |

| EP2654134B1 (en) * | 2012-04-18 | 2018-09-19 | Tyco Electronics AMP Italia S.r.l. | Lever structures for electrical connectors |

| CN202906099U (zh) * | 2012-09-03 | 2013-04-24 | 泰科电子(上海)有限公司 | 带有杠杆机构的连接器及连接器组件 |

| WO2014046877A1 (en) * | 2012-09-18 | 2014-03-27 | Delphi Technologies, Inc. | Electrical distribution center |

| JP2014165031A (ja) * | 2013-02-26 | 2014-09-08 | Sumitomo Wiring Syst Ltd | 倍力機構付きコネクタ |

| JP6438360B2 (ja) * | 2015-07-10 | 2018-12-12 | モレックス エルエルシー | コネクタ及びコネクタ組立体 |

| DE102017125860A1 (de) * | 2017-11-06 | 2019-05-09 | Harting Electric Gmbh & Co. Kg | Verriegelungsbügel für ein Steckverbindergehäuse |

| JP6592475B2 (ja) * | 2017-04-27 | 2019-10-16 | 矢崎総業株式会社 | レバー嵌合式コネクタ |

-

2019

- 2019-10-18 JP JP2019190861A patent/JP7249506B2/ja active Active

-

2020

- 2020-08-21 CN CN202080071748.4A patent/CN114556714B/zh active Active

- 2020-08-21 WO PCT/JP2020/031610 patent/WO2021075149A1/ja not_active Ceased

- 2020-08-21 US US17/764,947 patent/US12119588B2/en active Active

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20050221647A1 (en) * | 2004-03-31 | 2005-10-06 | Jst Corporation | Dual action mechanical assisted connector |

| JP2007005088A (ja) * | 2005-06-22 | 2007-01-11 | Tokai Rika Co Ltd | コネクタの連結構造 |

| JP2010244799A (ja) * | 2009-04-03 | 2010-10-28 | Sumitomo Wiring Syst Ltd | コネクタ |

| JP2013004419A (ja) * | 2011-06-20 | 2013-01-07 | Sumitomo Wiring Syst Ltd | レバー式コネクタ |

Also Published As

| Publication number | Publication date |

|---|---|

| JP7249506B2 (ja) | 2023-03-31 |

| JP2021068516A (ja) | 2021-04-30 |

| CN114556714B (zh) | 2024-03-22 |

| US20220368073A1 (en) | 2022-11-17 |

| CN114556714A (zh) | 2022-05-27 |

| US12119588B2 (en) | 2024-10-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN110690622B (zh) | 连接器 | |

| US20110271507A1 (en) | Connector | |

| JP4622930B2 (ja) | レバー式コネクタ | |

| JP2009158151A (ja) | コネクタ | |

| CN108879218B (zh) | 杆式连接器 | |

| US10090620B2 (en) | Lever-type connector having a lever with two arms with one ends of the arms joined by an operating portion and other ends joined by a coupling | |

| JP2019021497A (ja) | レバー式コネクタ | |

| US9373913B2 (en) | Lever type connector | |

| WO2021075149A1 (ja) | レバー式コネクタ | |

| CN114914742B (zh) | 连接器 | |

| US11699876B2 (en) | Connector with lever and guide surfaces | |

| JPH0475272A (ja) | 低挿抜力電気コネクタ | |

| JP4904094B2 (ja) | コネクタ | |

| JP2009277588A (ja) | コネクタ | |

| CN109863279A (zh) | 车辆内侧把手装置 | |

| JP7377440B2 (ja) | コネクタ | |

| US20180083386A1 (en) | Lever-type connector | |

| JP6930502B2 (ja) | レバー式コネクタ | |

| US20250038457A1 (en) | Connector assembly and assembly method | |

| JP3566588B2 (ja) | コネクタの結合構造 | |

| JP5557024B2 (ja) | コネクタ | |

| JP2002216894A (ja) | レバー式コネクタ | |

| JP5163583B2 (ja) | コネクタ | |

| GB2442845A (en) | Connector with lever and fulcrum boss | |

| JP2025147855A (ja) | コネクタ |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 20875682 Country of ref document: EP Kind code of ref document: A1 |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 20875682 Country of ref document: EP Kind code of ref document: A1 |