WO2020105720A1 - 単結晶x線構造解析装置および試料ホルダ取り付け装置 - Google Patents

単結晶x線構造解析装置および試料ホルダ取り付け装置Info

- Publication number

- WO2020105720A1 WO2020105720A1 PCT/JP2019/045689 JP2019045689W WO2020105720A1 WO 2020105720 A1 WO2020105720 A1 WO 2020105720A1 JP 2019045689 W JP2019045689 W JP 2019045689W WO 2020105720 A1 WO2020105720 A1 WO 2020105720A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- sample holder

- sample

- ray

- crystal

- applicator

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N23/00—Investigating or analysing materials by the use of wave or particle radiation, e.g. X-rays or neutrons, not covered by groups G01N3/00 – G01N17/00, G01N21/00 or G01N22/00

- G01N23/20—Investigating or analysing materials by the use of wave or particle radiation, e.g. X-rays or neutrons, not covered by groups G01N3/00 – G01N17/00, G01N21/00 or G01N22/00 by using diffraction of the radiation by the materials, e.g. for investigating crystal structure; by using scattering of the radiation by the materials, e.g. for investigating non-crystalline materials; by using reflection of the radiation by the materials

- G01N23/20008—Constructional details of analysers, e.g. characterised by X-ray source, detector or optical system; Accessories therefor; Preparing specimens therefor

- G01N23/20025—Sample holders or supports therefor

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N23/00—Investigating or analysing materials by the use of wave or particle radiation, e.g. X-rays or neutrons, not covered by groups G01N3/00 – G01N17/00, G01N21/00 or G01N22/00

- G01N23/20—Investigating or analysing materials by the use of wave or particle radiation, e.g. X-rays or neutrons, not covered by groups G01N3/00 – G01N17/00, G01N21/00 or G01N22/00 by using diffraction of the radiation by the materials, e.g. for investigating crystal structure; by using scattering of the radiation by the materials, e.g. for investigating non-crystalline materials; by using reflection of the radiation by the materials

- G01N23/20008—Constructional details of analysers, e.g. characterised by X-ray source, detector or optical system; Accessories therefor; Preparing specimens therefor

- G01N23/20016—Goniometers

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N23/00—Investigating or analysing materials by the use of wave or particle radiation, e.g. X-rays or neutrons, not covered by groups G01N3/00 – G01N17/00, G01N21/00 or G01N22/00

- G01N23/20—Investigating or analysing materials by the use of wave or particle radiation, e.g. X-rays or neutrons, not covered by groups G01N3/00 – G01N17/00, G01N21/00 or G01N22/00 by using diffraction of the radiation by the materials, e.g. for investigating crystal structure; by using scattering of the radiation by the materials, e.g. for investigating non-crystalline materials; by using reflection of the radiation by the materials

- G01N23/207—Diffractometry using detectors, e.g. using a probe in a central position and one or more displaceable detectors in circumferential positions

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N2223/00—Investigating materials by wave or particle radiation

- G01N2223/30—Accessories, mechanical or electrical features

- G01N2223/309—Accessories, mechanical or electrical features support of sample holder

Definitions

- the present invention relates to a next-generation single crystal X-ray structure analysis apparatus that enables a structure of a material to be analyzed by a microscopic aggregate structure such as an arrangement of atoms or molecules, and particularly to a single crystal sample to be analyzed.

- the present invention relates to the configurations of a single crystal X-ray structure analysis device and a sample holder attachment device, including the mounting of the same on the device.

- this single crystal X-ray structure analysis had a major limitation that a single crystal had to be prepared by crystallizing a sample.

- a material called “crystal sponge” for example, pores having an infinite number of pores having a diameter of 0.5 nm to 1 nm.

- the present invention has been achieved in view of the above-mentioned problems in the conventional technique, and the object thereof is to provide a sample proposed by the present invention, in particular, even without specialized knowledge of X-ray structural analysis.

- a sample proposed by the present invention in particular, even without specialized knowledge of X-ray structural analysis.

- the work of taking out an ultrafine and fragile crystal sponge containing a sample in a single crystal X-ray structure analysis using a crystal sponge and mounting it at the X-ray irradiation position in the device In addition, a user-friendly single crystal X-ray structure analysis apparatus that enables reliable and easy operation, in other words, has good yield and efficiency, is highly versatile, and includes automation of mounting a sample holder. To provide.

- a sample holder attaching device for attaching a sample holder that holds a sample to a single crystal X-ray structure analyzing device for performing a structural analysis of a substance, wherein the sample holder provided by being attached to a removable applicator,

- the goniometer of the single crystal X-ray structure analyzer is equipped with a sample holder attachment mechanism for attaching the sample holder in a state where the sample holder is detached from the applicator, and the sample holder mounts the sample in a plurality of fine holes formed inside.

- the sample holder attaching mechanism includes a sample holder grasping portion that grasps the sample holder and an applicator grasping portion that grasps the applicator, and the sample holder At least one of the holder gripping part and the applicator gripping part is in a direction of removing the sample holder from the applicator gripped by the applicator gripping part in a state where the sample holder gripping part grips the sample holder. It is characterized by being movable.

- the sample holder gripping portion is movable in the extension direction of the pin-shaped holding portion of the sample holder to which the porous complex crystal is attached. I am trying.

- the sample holder holding portion is rotatable while holding the sample holder.

- the sample holder holding portion is movable in a direction of attaching the sample holder to a sample holder attaching position of the goniometer while holding the sample holder. Is characterized by.

- the single crystal X-ray structure analyzing apparatus of the present invention is a single crystal X-ray structure analyzing apparatus for analyzing the structure of a substance, the X-ray source generating X-rays, the sample holder, and A goniometer with a sample holder attached and rotating, an X-ray irradiator for irradiating the sample held by the sample holder attached to the goniometer with X-rays from the X-ray source, and diffraction by the sample.

- an X-ray detection measurement unit that detects and measures scattered X-rays

- a structural analysis unit that performs structural analysis of the sample based on diffraction or scattered X-rays detected by the X-ray detection measurement unit

- a minute amount can be achieved without the conventional minute and minute work that requires swiftness.

- a series of operations including occlusion of the sample in the ultrafine and fragile crystal sponge after occlusion of the sample and mounting on the device thereafter can be performed quickly, reliably and easily.

- a user-friendly single crystal X-ray structure analysis apparatus which has a high yield and efficiency, is excellent in versatility, and includes automation of mounting of a sample holder. From this, single crystal X-ray structural analysis using a crystal sponge can be easily used and widely spread.

- FIG. 1 It is a figure which shows an example of a structure of the pretreatment apparatus used in the said single crystal X-ray-structure-analysis method. It is a conceptual diagram which shows an example of a structure of the sample holder removal / mounting mechanism which removes a sample holder from an applicator and mounts it on a goniometer in the said single crystal X-ray analysis apparatus. It is an operation explanatory view showing an example of the removal / mounting operation by the sample holder removal / mounting mechanism. It is an operation explanatory view showing another removal / mounting operation by the sample holder removal / mounting mechanism.

- a or B means “at least one of A and B”, and includes “A and B” unless there is a special circumstance that A and B cannot exist.

- FIG. 1 attached herewith shows an overall appearance configuration of a single crystal X-ray structure analysis apparatus including a single crystal X-ray diffraction apparatus according to an embodiment of the present invention.

- the single crystal X-ray structure analysis apparatus 1 has a base 4 that stores a cooling device and an X-ray generation power supply unit, and an X-ray protection cover 6 that is placed on the base 4.

- the anti-X-ray cover 6 has a casing 7 surrounding the single crystal X-ray diffraction device 9, a door 8 provided on the front surface of the casing 7, and the like.

- the door 8 provided on the front surface of the casing 7 can be opened, and various operations can be performed on the internal single crystal X-ray diffraction device 9 in this opened state.

- the present embodiment shown in the figure is a single crystal X-ray structure analyzing apparatus 1 including a single crystal X-ray diffracting apparatus 9 for performing structural analysis of a substance by using a crystal sponge which will be described later.

- the single crystal X-ray diffractometer 9 has an X-ray tube 11 and a goniometer 12 as shown in FIG.

- the X-ray tube 11 has a filament, a target (also referred to as “anticathode”) that is arranged to face the filament, and a casing that hermetically stores them, and the filament is It is energized by the X-ray generation power supply unit stored in the base 4 of FIG. 1 to generate heat and emit thermoelectrons. Further, a high voltage is applied between the filament and the target by the X-ray generation power supply unit, and the thermoelectrons emitted from the filament are accelerated by the high voltage and collide with the target.

- the X-ray tube 11 is configured to include an optical element such as a microfocus tube and a multilayer film condensing mirror, and can emit a beam of higher brightness. It is also possible to select from radiation sources such as Cu, Mo and Ag.

- the filament, the target arranged facing the filament, and the casing that hermetically stores them function as an X-ray source, and an optical element such as a microfocus tube and a multilayer film condensing mirror.

- the configuration for X-ray irradiation including the above functions as an X-ray irradiation unit.

- the goniometer 12 supports the sample S to be analyzed and is arranged around the ⁇ rotary table 16 and the ⁇ rotary table 16 which is rotatable around the sample axis ⁇ passing through the X-ray incident point of the sample S. And a 2 ⁇ rotary table 17 rotatable about the sample axis ⁇ .

- the sample S is occluded in the inside of a crystal sponge previously attached to a part of the sample holder 250 which will be described in detail later.

- a drive device (not shown) for driving the ⁇ rotary table 16 and the 2 ⁇ rotary table 17 described above is stored inside the base 18 of the goniometer 12, and is driven by these drive devices to drive ⁇

- the rotary table 16 rotates intermittently or continuously at a predetermined angular velocity, so-called ⁇ rotation.

- the 2 ⁇ rotation base 17 rotates intermittently or continuously, so-called 2 ⁇ rotation.

- the above drive device can be configured by any structure, for example, a power transmission structure including a worm and a worm wheel.

- An X-ray detector 22 is mounted on a part of the outer circumference of the goniometer 12, and the X-ray detector 22 is, for example, a CCD type or CMOS type two-dimensional pixel detector or a hybrid type pixel detector. Composed.

- the X-ray detection and measurement unit refers to a configuration that detects and measures X-rays diffracted or scattered by the sample, and includes the X-ray detector 22 and a control unit that controls the X-ray detector 22.

- the sample S rotates ⁇ around the sample axis ⁇ by the ⁇ rotation of the ⁇ rotary table 16 of the goniometer 12.

- X-rays generated from the X-ray focal point in the X-ray tube 11 and directed toward the sample S are incident on the sample S at a predetermined angle and are diffracted / diverged. That is, the incident angle of the X-ray incident on the sample S changes according to the ⁇ rotation of the sample S.

- the sample S When the Bragg diffraction condition is satisfied between the incident angle of the X-ray incident on the sample S and the crystal lattice plane, the sample S generates diffracted X-rays. This diffracted X-ray is received by the X-ray detector 22 and its X-ray intensity is measured. As described above, the angle of the X-ray detector 22 with respect to the incident X-ray, that is, the intensity of the diffracted X-ray corresponding to the diffraction angle is measured, and the crystal structure or the like of the sample S is analyzed from the measurement result.

- FIG. 3 (A) shows an example of details of an electrical internal configuration of the control unit 110 in the single crystal X-ray structure analysis apparatus.

- the present invention is not limited to the embodiments described below.

- This single crystal X-ray structure analyzing apparatus 1 includes the above-mentioned internal structure, and further, a measuring apparatus 102 for measuring an appropriate substance as a sample, an input apparatus 103 composed of a keyboard, a mouse, etc., and a display.

- An image display device 104 as a means, a printer 106 as a means for printing and outputting an analysis result, a CPU (Central Processing Unit) 107, a RAM (Random Access Memory) 108, and a ROM (Read Only Memory) 109 and a hard disk 111 as an external storage medium.

- CPU Central Processing Unit

- RAM Random Access Memory

- ROM Read Only Memory

- the image display device 104 is composed of an image display device such as a CRT display or a liquid crystal display, and displays an image on the screen according to an image signal generated by the image control circuit 113.

- the image control circuit 113 generates an image signal based on the image data input thereto.

- the image data input to the image control circuit 113 is formed by the operation of various calculation means implemented by a computer including a CPU 107, a RAM 108, a ROM 109 and a hard disk 111.

- the printer 106 may be an ink plotter, a dot printer, an inkjet printer, an electrostatic transfer printer, or any other type of printing device.

- the hard disk 111 may be composed of a magneto-optical disk, a semiconductor memory, or a storage medium having any structure.

- analysis application software 116 that controls the overall operation of the single crystal X-ray structure analysis apparatus 1

- measurement application software 117 that controls the operation of measurement processing using the measurement apparatus 102

- image display The display application software 118 that controls the operation of the display process using the device 104 is stored.

- These application software realizes a predetermined function after being read from the hard disk 111 and transferred to the RAM 108 as needed.

- the single crystal X-ray structure analyzing apparatus 1 further includes, for example, a database placed in a cloud area for storing various measurement results including the measurement data obtained by the measuring apparatus 102.

- a database placed in a cloud area for storing various measurement results including the measurement data obtained by the measuring apparatus 102.

- an XRDS information database 120 that stores the XRDS image data obtained by the measuring device 102

- a microscope image database 130 that stores an actually measured image obtained by a microscope, and further, for example, , An XRF, a Raman ray, and the like, and a measurement result obtained by analysis other than X-rays

- another analysis database 140 that stores physical property information.

- these databases do not necessarily have to be installed inside the single crystal X-ray structure analysis apparatus 1, and may be provided outside and connected to each other via a network 150 or the like so that they can communicate with each other. ..

- the single crystal X-ray structure analyzing apparatus 1 controls the operation of the measurement process using the measuring apparatus 102 by the X-ray detecting and measuring unit, and detects the X-rays diffracted or scattered by the sample. Receive and manage various measurement results including the measurement data obtained in. Further, the structural analysis unit performs structural analysis of the sample based on various measurement results including measurement data obtained by detecting X-rays diffracted or scattered by the sample.

- a method of storing each measurement data in an individual file can be considered, but in the present embodiment, as shown in FIG.

- a plurality of measurement data are continuously stored in one data file.

- the storage area described as “condition” in FIG. 3B is an area for storing various pieces of information including device information when the measurement data is obtained and measurement conditions.

- Such measurement conditions include (1) measurement target substance name, (2) measurement device type, (3) measurement temperature range, (4) measurement start time, (5) measurement end time, and (6) measurement angle. Range, (7) moving speed of the scanning movement system, (8) scanning conditions, (9) type of X-rays incident on the sample, (10) whether or not an attachment such as a sample high temperature device is used, and various other conditions Can be considered.

- An XRDS (X-ray Diffraction and Scattering) pattern or image (see FIG. 4) is used to detect an X-ray received on a plane that is a two-dimensional space of the X-ray detector 22 that constitutes the measurement apparatus 102. It is obtained by receiving / accumulating light for each pixel arranged in a plane which constitutes the container and measuring the intensity thereof. For example, by detecting the intensity of the received X-ray by integration for each pixel of the X-ray detector 22, a pattern or image in a two-dimensional space of r and ⁇ can be obtained.

- the XRDS pattern or image in the observation space obtained by diffraction or scattering of X-rays by the target material with respect to the irradiated X-rays reflects the information of the electron density distribution in the real space of the target material.

- the XRDS pattern is a two-dimensional space of r and ⁇ , and does not directly express the symmetry in the real space of the target material, which is a three-dimensional space. Therefore, it is generally difficult to specify the (spatial) arrangement of the atoms and molecules that make up the material using only the existing XRDS image, and requires specialized knowledge of X-ray structural analysis. Therefore, in the present embodiment, the measurement application software described above is adopted for automation.

- X-ray diffraction data measurement / processing software called “CrysAlis Pro ”, which is a platform for single crystal structure analysis, is installed, Performs preliminary measurement, setting of measurement conditions, main measurement, data processing, etc. Further, by mounting an automatic structural analysis plug-in called “AutoChem”, structural analysis and structural refinement are executed in parallel with X-ray diffraction data acquisition. Then, the structure analysis program called “Olex 2 ” also shown in FIG. 6 performs space group determination, phase determination, molecular model construction and modification, structure refinement, final report, and CIF file creation.

- a “crystal sponge” which is an extremely minute and fragile porous complex crystal with a number of pores with a diameter of 0.5 nm to 1 nm opened innumerably and having a size of about several tens ⁇ m to several hundreds ⁇ m, Due to the development of the so-called material, single crystal X-ray structural analysis is widely applied to liquid compounds that do not crystallize, or very small samples such as several ng to several ⁇ g that cannot be secured in sufficient amounts for crystallization. It is possible to do.

- the present invention has been achieved based on the findings of the inventor as described above, and a single crystal X-ray structural analysis using a crystal sponge that is extremely minute and fragile is performed by the following sample holder for crystal sponge ( It is possible to perform quickly, reliably and easily by using the sample holder mounting mechanism described below together with the applicator which is also a sample holder) and its handling (operation) instrument.

- the present invention realizes a single crystal X-ray structure analysis apparatus which has a high yield, is efficient, is excellent in versatility, and is user-friendly.

- next-generation single-crystal X-ray structure analysis apparatus an extremely minute and fragile crystal sponge that occludes an extremely small amount of sample S is prepared, and further, the sample S (crystal sponge ) Has to be taken out from the occlusion container and attached to the predetermined position of the tip of the goniometer 12 accurately and promptly in a short time so that the crystal sponge is not destroyed by drying, but there is a major limitation.

- sample S crystal sponge

- the present invention solves such a problem, that is, while using an extremely minute and fragile (fragile) difficult-to-handle crystal sponge, including mounting work of the sample occluded in the crystal sponge to the device, anyone, Device and method for performing single crystal X-ray structural analysis that is quick, reliable, easy, efficient with high yield, can be performed in a user-friendly manner, and has excellent versatility, and further an instrument therefor Are provided and are described in detail below.

- FIG. 7 (A) shows the tip of the goniometer 12 in an enlarged manner.

- a crystal sponge 200 for occluding the sample to be analyzed proposed by the present invention is attached to the tip in advance.

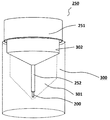

- FIG. 7B shows an enlarged view of a so-called sample holder 250 mounted (mounted) on the goniometer head 121 at the tip of the goniometer 12.

- the sample holder 250 is attachable / detachable to / from the goniometer head 121 at the tip of the goniometer 12 by, for example, a mounting / positioning mechanism using magnetic force, and anyone can easily and accurately mount the sample holder 250 at an accurate position. It is possible.

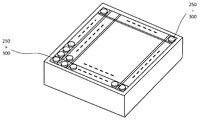

- FIG. 8 shows an overall perspective view of the sample holder 250 described above, and FIG. 9 shows its cross section.

- the sample holder 250 includes a pin (cylindrical) sample on the base portion 251 of a disc-shaped or conical holder made of metal or the like that is attached to the goniometer head 121 (see FIG. 7A) at the tip of the goniometer 12.

- a holding portion (hereinafter, also simply referred to as a holding portion) 252 (corresponding to a so-called gonio head pin) is planted in the center of one surface (lower surface in the figure) of the pin-shaped holding portion.

- the crystal sponge 200 for storing the above-described sample to be analyzed is previously fixed integrally with the sample holder 250. Further, a positioning mechanism such as a magnet (not shown) is provided on the other surface (upper surface in the drawing) of the disk-shaped base portion 251. The sample holder 250 is detachably attached to the tip of the goniometer 12 by this positioning mechanism.

- a so-called applicator 300 which is a handling (manipulation) instrument for being used together with the sample holder 250 to store the sample in the crystal sponge 200 previously attached to the sample holder, is shown. It is shown.

- the applicator 300 is formed of, for example, a transparent or opaque member such as glass, resin, or metal, and a storage space 301 for storing the sample holder 250 is formed therein. Further, an opening portion 302 for inserting and removing the sample holder 250 is formed on the upper portion thereof.

- a seal portion (a hatched portion in FIG. 9) is provided so as to be kept airtight from the outside in a state where the sample holder 250 is stored in the storage space 301 therein. Are shown).

- a pair of penetrating pores 253, 253 for introducing the sample to be analyzed into the crystal sponge 200 located inside the applicator 300 (storage space 301). are formed.

- the pores 253 and 253 are a preferable example of the sample introduction structure, and other structures can be adopted.

- these pores 253, 253 are also provided with a seal portion, which allows a sample introduction tube (hereinafter, simply referred to as a sample introduction tube for introducing the sample into the crystal sponge 200, as shown in the figure.

- a sample introduction tube hereinafter, simply referred to as a sample introduction tube for introducing the sample into the crystal sponge 200, as shown in the figure.

- the storage space 301 inside the applicator 300 is kept airtight even when the introduction pipes 254 and 254 are inserted into the pores 253 and 253.

- a part of the sample holder 250 is configured.

- the crystal sponge 200 attached to the tip of the pin-shaped holding portion 252 (corresponding to a goniometer head pin) can be safely and easily handled without being damaged or departing from the sample holder 250. That is, the crystal sponge 200 that has occluded a very small amount of sample is taken out from the occluding container as a single unit as in the conventional case and is not damaged, and is safe, simple and easy, and in a short time not to be destroyed by drying. , Can be quickly prepared on the gonio head 121.

- the sample holder 250 whose occlusion of the sample has been completed is removed from the applicator 300 and attached to the goniometer head 121 (see FIG. 7A) at the tip of the goniometer 12.

- the sample S occluded in the crystal sponge 200 can be easily, accurately and quickly arranged at a predetermined position in the single crystal X-ray diffractometer 9 without requiring highly specialized knowledge or precise work. Will be done.

- sample holders 250 are integrated (unitized) with the applicator 300 which is a handling (operating) instrument, and as shown in FIG. It could be housed in a case and provided as a so-called set.

- sample holder 250 and the applicator 300 may be provided as a unit (unit) or as a set, as described above.

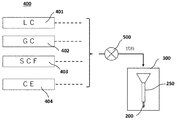

- FIG. 11 conceptually shows a single crystal X-ray structure analysis method using a sample holder 250, which is an embodiment of the present invention.

- a very small amount of sample is introduced into the sample holder 250 provided integrally (unit) with the applicator 300, and necessary occlusion is performed.

- a pair of sample introductions are made to the pair of penetrating pores 253 and 253 (see FIG. 9) formed in the sample holder 250.

- the tubes 254 and 254 the sample can be occluded in the crystal sponge 200 attached to the tip of the sample holder 250.

- LC liquid chromatography

- GC gas chromatography

- SCF supercritical fluid chromatography

- the sample is sent from the supply-side pipe to the supply-side sample introduction pipe 254, and is supplied from the tip portion of the supply-side sample introduction pipe 254 to the sample holder 250 inside the applicator 300.

- a sample alone or a solution in which a sample and a storage solvent (carrier) are mixed is supplied through the sample introduction tube 254 on the supply side.

- the introduced minute amount of the sample S comes into contact with the crystal sponge 200 attached to the tip of the pin-shaped holding portion 252 of the sample holder 250 in the storage space 301 of the applicator 300 to occlude the sample. Is done.

- the electrophoresis device here includes various electrophoresis devices such as capillary electrophoresis and isoelectric focusing.

- an excess sample or a solution in which a sample and a storage solvent (carrier) are mixed is discharged from the sample introduction pipe 254 on the discharge side after a predetermined time has elapsed while the sample is injected. To be done.

- unnecessary storage solvent (carrier) or solution flows in the sample introduction pipe 254 on the discharge side and is discharged. Therefore, the sample may not flow into the sample introduction pipe 254 on the discharge side.

- gas or supercritical fluid is used as the carrier, the carrier containing the sample is discharged.

- the sample holder 250 that has completed this occlusion process is removed from the applicator 300, and is placed at a predetermined position in the single crystal X-ray diffraction apparatus 9, that is, at the tip of the goniometer head pin of the goniometer 121 at the tip of the goniometer 12.

- the X-ray beam from the corresponding X-ray tube 11 is accurately attached to a position where the X-ray beam is condensed and irradiated, for example, by using the sample holder attaching mechanism described below and the above-described positioning mechanism such as magnetic force.

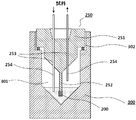

- FIG. 13 is a configuration of a sample holder attachment mechanism 600 for removing the sample holder 250 to which the crystal sponge 200 whose occlusion has been completed is attached from the applicator 300 and attaching (mounting) it to the goniometer head 121 at the tip of the goniometer 12. Shows an example. As shown in the figure, the sample holder attachment mechanism 600 is arranged in parallel with each other, and moves close to or away from each other (see the arrow in the figure) while the base portion 251 of the sample holder 250 is moved between them.

- a sample holder grip 610 including a pair of rod-shaped grips 611, 611 for holding / releasing, and also arranged parallel to each other and movable toward and away from each other (see arrow in the figure), in between.

- An applicator grip 620 including a pair of rod-shaped members 621 and 621 that holds / releases the applicator 300.

- the former sample holder gripping portion 610 is configured to further rotate itself and move its position toward the goniometer 121 of the goniometer 12 as shown by an arrow in the figure. From the function of the sample holder mounting mechanism 600, it is preferable that the sample holder mounting mechanism 600 is arranged at a position close to the goniometer 12 in the single crystal X-ray diffraction apparatus 9.

- the sample holder attachment mechanism 600 may be arranged outside the single crystal X-ray diffraction device 9, such as the storage device 500 or between the storage device 500 and the single crystal X-ray diffraction device 9.

- the base holder 251 of the sample holder 250 is grasped by the sample holder grasping portion 610, and at the same time, the applicator 300 is grasped by the applicator grasping portion 620, and then the sample holder grasping portion is indicated by an arrow in FIG. 610 moves in a direction in which the gripped sample holder 250 is detached from the applicator 300, for example, in the vertical direction here, more specifically, in the extension direction of the pin-shaped holding portion 252.

- the sample holder 250 can be safely applied to the sample holder 250 without the crystal sponge 200 attached to the tip of the pin-shaped holding portion 252 coming into contact with a part of the applicator 300 and being damaged or deviated. Can be removed from the computer 300.

- the sample holder gripping part 610 is attached to the tip of the goniometer head 121 of the goniometer 12 in a state in which the sample holder gripping part 610 is rotated up and down (see the arrow in the figure) and turned upside down.

- the sample holder gripping portion 610 moves to the position of the goniometer head 121 while holding the outer periphery of the base 251 (or applicator 300), and rotates. Then, the sample holder 250 integrated with the applicator 300 may be mounted on the gonio head 121. In this case, thereafter, the applicator gripping portion 620 grips the outer periphery of the applicator 300, and at the same time, the sample holder gripping portion 610 grips the base portion 251 and stands still.

- the crystal sponge 200 can be safely removed from the applicator 300 and attached to the tip of the goniometer head 121 without abutting against a part of the applicator 300 and damaging or deviating, similarly to the above. Can be installed.

- the sample holder gripping portion 610 and the applicator gripping portion 620 are each described as being composed of a pair of parallel-movable rod-shaped members. However, these gripping portions are the sample holder or the applicator.

- a grasping means such as a so-called robot arm. That would be obvious.

- the crystal sponge 200 attached to a part (tip) of the pin-shaped holding portion 252 of the sample holder 250 attached to the tip of the goniometer 121 of the goniometer 12 is stored in the sample holder 250 after the occlusion is completed. Even when removing from the applicator 300, the position where the X-ray beam from the X-ray tube 11 is focused and radiated accurately and safely can be contacted with other parts without being damaged or deviated. Will be placed in. In other words, the sample occluded in the crystal sponge 200 is accurately, quickly and safely arranged at a predetermined position in the X-ray diffractometer 9, and then the sample S is sampled by the single crystal X-ray diffractometer. The intensity of the diffracted X-ray from is measured, and its crystal structure and the like are analyzed.

- the sample holder 250, the applicator 300, and the sample holder mounting mechanism 600 of the present invention anyone can easily and safely integrate a very small amount of sample in advance into the sample holder 250.

- the crystal sponge 200 having a very small size attached thereto is occluded, and then the sample S is accurately and accurately placed on the goniometer 12 in a short time, quickly and safely so that the crystal sponge is not destroyed by drying. It becomes possible to mount it.

- a single crystal X-ray structure analysis device that is highly versatile and that can perform a single crystal X-ray structure analysis using a crystal sponge efficiently with good yield, and that also includes automation of mounting a sample holder. Will be provided.

- the present invention is not limited to the above-described embodiments and includes various modifications.

- the above-described embodiment is a detailed description of the entire system in order to explain the present invention in an easy-to-understand manner, and is not necessarily limited to one having all the configurations described.

- part of the configuration of one embodiment can be replaced with the configuration of another embodiment, and the configuration of another embodiment can be added to the configuration of one embodiment. It would be possible to add, delete, or replace some of the example configurations with other configurations.

- the present invention can be widely used in a method for searching a material structure, an X-ray structure analysis apparatus used for the method, and the like.

Landscapes

- Chemical & Material Sciences (AREA)

- Crystallography & Structural Chemistry (AREA)

- Physics & Mathematics (AREA)

- Health & Medical Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- Analytical Chemistry (AREA)

- Biochemistry (AREA)

- General Health & Medical Sciences (AREA)

- General Physics & Mathematics (AREA)

- Immunology (AREA)

- Pathology (AREA)

- Analysing Materials By The Use Of Radiation (AREA)

Priority Applications (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2020557644A JP7237373B2 (ja) | 2018-11-22 | 2019-11-21 | 単結晶x線構造解析装置および試料ホルダ取り付け装置 |

| EP19886782.2A EP3885749B1 (en) | 2018-11-22 | 2019-11-21 | Single-crystal x-ray structure analysis apparatus and sample holder attaching device |

| US17/295,857 US11835476B2 (en) | 2018-11-22 | 2019-11-21 | Single-crystal X-ray structure analysis apparatus and sample holder attaching device |

| CN201980088771.1A CN113287006A (zh) | 2018-11-22 | 2019-11-21 | 单晶x射线结构解析装置以及试样保持架安装装置 |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2018-218756 | 2018-11-22 | ||

| JP2018218756 | 2018-11-22 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2020105720A1 true WO2020105720A1 (ja) | 2020-05-28 |

Family

ID=70774426

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2019/045689 Ceased WO2020105720A1 (ja) | 2018-11-22 | 2019-11-21 | 単結晶x線構造解析装置および試料ホルダ取り付け装置 |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US11835476B2 (enExample) |

| EP (1) | EP3885749B1 (enExample) |

| JP (1) | JP7237373B2 (enExample) |

| CN (1) | CN113287006A (enExample) |

| WO (1) | WO2020105720A1 (enExample) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2022073621A1 (en) * | 2020-10-09 | 2022-04-14 | Merck Patent Gmbh | Flexible sample holder for crystalline sponge |

Citations (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH11304999A (ja) * | 1998-04-22 | 1999-11-05 | Rigaku Denki Kk | X線結晶構造解析装置のための試料保持用ゴニオメータ |

| JP2003139726A (ja) * | 2001-11-02 | 2003-05-14 | Toyota Motor Corp | 水素吸蔵合金の結晶構造解析方法 |

| US20050163280A1 (en) * | 2001-12-12 | 2005-07-28 | The Regents Of The University Of California | Integrated crystal mounting and alignment system for high-throughput biological crystallography |

| JP2007003394A (ja) | 2005-06-24 | 2007-01-11 | Rigaku Corp | 双晶解析装置 |

| US7660389B1 (en) * | 2007-08-17 | 2010-02-09 | Bruker Axs, Inc. | Sample alignment mechanism for X-ray diffraction instrumentation |

| JP2010203843A (ja) * | 2009-03-02 | 2010-09-16 | Rigaku Corp | X線及び熱分析装置 |

| JP2010286431A (ja) * | 2009-06-15 | 2010-12-24 | Rigaku Corp | 凍結結晶の処理装置及び処理方法 |

| US20110211674A1 (en) * | 2010-03-01 | 2011-09-01 | Cornell University | Goniometer base apparatus and method |

| WO2014038220A1 (ja) * | 2012-09-07 | 2014-03-13 | 独立行政法人 科学技術振興機構 | ゲスト化合物内包高分子金属錯体結晶、その製造方法、結晶構造解析用試料の作製方法、及び有機化合物の分子構造決定方法 |

| WO2016017770A1 (ja) | 2014-07-31 | 2016-02-04 | 国立研究開発法人 科学技術振興機構 | 回折データの解析方法、コンピュータプログラム及び記録媒体 |

| JP2018155680A (ja) * | 2017-03-21 | 2018-10-04 | 大学共同利用機関法人 高エネルギー加速器研究機構 | カセット装填装置 |

Family Cites Families (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP3053502B2 (ja) | 1992-12-25 | 2000-06-19 | 日機装株式会社 | 粉末品分析用試料の精秤分取装置 |

| US20030068829A1 (en) | 2001-06-25 | 2003-04-10 | Symyx Technologies, Inc. | High throughput crystallographic screening of materials |

| JP3640383B2 (ja) | 2001-09-10 | 2005-04-20 | 独立行政法人理化学研究所 | サンプルの支持機構 |

| JP3697246B2 (ja) * | 2003-03-26 | 2005-09-21 | 株式会社リガク | X線回折装置 |

| WO2011115223A1 (ja) | 2010-03-18 | 2011-09-22 | 独立行政法人理化学研究所 | 生体高分子の結晶化条件探査方法及びそれに用いる装置 |

| JP2013156218A (ja) | 2012-01-31 | 2013-08-15 | Japan Synchrotron Radiation Research Institute | 微小試料用キャピラリー |

| JP6131595B2 (ja) | 2012-12-28 | 2017-05-24 | 株式会社ニコン | 測定方法 |

| WO2015132909A1 (ja) | 2014-03-05 | 2015-09-11 | 株式会社島津製作所 | 試料分析システム |

| EP3173774A1 (en) * | 2015-11-24 | 2017-05-31 | Paul Scherrer Institut | A system and a method for resolving a crystal structure of a crystal at atomic resolution by collecting x-ray diffraction images |

| DE102015224143B3 (de) * | 2015-12-03 | 2017-02-23 | Incoatec Gmbh | Verfahren zur Justage der Primärseite eines Röntgendiffraktometers und zugehöriges Röntgendiffraktometer |

| US10794844B2 (en) * | 2016-08-10 | 2020-10-06 | Proto Manufacturing, Ltd. | Mounting system and sample holder for X-ray diffraction apparatus |

| JP6606658B2 (ja) * | 2016-08-18 | 2019-11-20 | 株式会社リガク | X線回折装置 |

| JP6931214B2 (ja) * | 2017-01-19 | 2021-09-01 | 株式会社日立ハイテクサイエンス | 荷電粒子ビーム装置 |

| US11815475B2 (en) | 2017-03-01 | 2023-11-14 | The University Of Tokyo | Method for identifying molecular structure |

| JP2018169276A (ja) * | 2017-03-29 | 2018-11-01 | 株式会社島津製作所 | X線分析装置 |

| CN106932419A (zh) * | 2017-04-19 | 2017-07-07 | 南京大学 | X射线衍射仪毛细样品管支架及其使用方法 |

-

2019

- 2019-11-21 US US17/295,857 patent/US11835476B2/en active Active

- 2019-11-21 CN CN201980088771.1A patent/CN113287006A/zh active Pending

- 2019-11-21 WO PCT/JP2019/045689 patent/WO2020105720A1/ja not_active Ceased

- 2019-11-21 JP JP2020557644A patent/JP7237373B2/ja active Active

- 2019-11-21 EP EP19886782.2A patent/EP3885749B1/en active Active

Patent Citations (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH11304999A (ja) * | 1998-04-22 | 1999-11-05 | Rigaku Denki Kk | X線結晶構造解析装置のための試料保持用ゴニオメータ |

| JP2003139726A (ja) * | 2001-11-02 | 2003-05-14 | Toyota Motor Corp | 水素吸蔵合金の結晶構造解析方法 |

| US20050163280A1 (en) * | 2001-12-12 | 2005-07-28 | The Regents Of The University Of California | Integrated crystal mounting and alignment system for high-throughput biological crystallography |

| JP2007003394A (ja) | 2005-06-24 | 2007-01-11 | Rigaku Corp | 双晶解析装置 |

| US7660389B1 (en) * | 2007-08-17 | 2010-02-09 | Bruker Axs, Inc. | Sample alignment mechanism for X-ray diffraction instrumentation |

| JP2010203843A (ja) * | 2009-03-02 | 2010-09-16 | Rigaku Corp | X線及び熱分析装置 |

| JP2010286431A (ja) * | 2009-06-15 | 2010-12-24 | Rigaku Corp | 凍結結晶の処理装置及び処理方法 |

| US20110211674A1 (en) * | 2010-03-01 | 2011-09-01 | Cornell University | Goniometer base apparatus and method |

| WO2014038220A1 (ja) * | 2012-09-07 | 2014-03-13 | 独立行政法人 科学技術振興機構 | ゲスト化合物内包高分子金属錯体結晶、その製造方法、結晶構造解析用試料の作製方法、及び有機化合物の分子構造決定方法 |

| WO2016017770A1 (ja) | 2014-07-31 | 2016-02-04 | 国立研究開発法人 科学技術振興機構 | 回折データの解析方法、コンピュータプログラム及び記録媒体 |

| JP2018155680A (ja) * | 2017-03-21 | 2018-10-04 | 大学共同利用機関法人 高エネルギー加速器研究機構 | カセット装填装置 |

Non-Patent Citations (9)

| Title |

|---|

| "Direct observation of hydrogen molecules adsorbed in a microporous coordination polymer", SPRING-8 INFORMATION, vol. 10, no. 1, January 2005 (2005-01-01), pages 24 - 29, XP001236796 * |

| "X-ray analysis on the nanogram to microgram scale using porous complexes", NATURE, vol. 495, 28 March 2013 (2013-03-28), pages 461 - 466, XP055400439 * |

| HOSHINO ET AL., THE UPDATED CRYSTALLINE SPONGE METHOD IUCRJ, vol. 3, 2016, pages 139 - 151 |

| KUROIWA, YOSHIHIRO: "Study on precise structural properties by powder crystal", SPRING-8 RIYOSHA JOHO - SPRING-8 INFORMATION, SPRING-8 RIYOSHA JOHO HENSHU IINKAI, KAMIGORI-CHO, JP, vol. 11, no. 4, 30 June 2006 (2006-06-30), JP, pages 202 - 219, XP009528339, ISSN: 1341-9668 * |

| MAKOTO FUJITA: "X-ray analysis on the nanogram to microgram scale using porous complexes", NATURE, vol. 495, 28 March 2013 (2013-03-28), pages 461 - 466, XP055400439, DOI: 10.1038/nature11990 |

| MASAHIKO HIRAKI: "RSJ2014AC1Q3-01: Development of sample exchange system for synchrotron radiation beamline", ANNUAL CONFERENCE OF THE ROBOTICS SOCIETY OF JAPAN , vol. 32, no. 1, 4 September 2014 (2014-09-04), JP, pages 1 - 2, XP009521330 * |

| See also references of EP3885749A4 |

| TAKATA MASAKI: "New Nano Science for one-dimensional arrays of dioxygen", SPRING-8 INFORMATION, vol. 8, no. 6, November 2003 (2003-11-01), pages 406 - 412, XP009521329, ISSN: 2187-4794 * |

| TAKATA, MASAKI; KATO, KEN-ICHI: "Precise structural studies for novel materials science by synchrotron radiation powder diffraction", JSAP INTERNATIONAL, vol. 74, no. 9, 31 August 2005 (2005-08-31), JP, pages 1201 - 1204, XP009528328, ISSN: 0369-8009, DOI: 10.11470/oubutsu.74.9_1201 * |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2022073621A1 (en) * | 2020-10-09 | 2022-04-14 | Merck Patent Gmbh | Flexible sample holder for crystalline sponge |

| JP2023544856A (ja) * | 2020-10-09 | 2023-10-25 | メルク パテント ゲゼルシャフト ミット ベシュレンクテル ハフツング | 結晶スポンジのための可撓性試料ホルダ |

Also Published As

| Publication number | Publication date |

|---|---|

| CN113287006A (zh) | 2021-08-20 |

| US20220128491A1 (en) | 2022-04-28 |

| EP3885749A1 (en) | 2021-09-29 |

| JP7237373B2 (ja) | 2023-03-13 |

| US11835476B2 (en) | 2023-12-05 |

| JPWO2020105720A1 (ja) | 2021-10-07 |

| EP3885749A4 (en) | 2022-10-12 |

| EP3885749B1 (en) | 2025-02-19 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP7520419B2 (ja) | 試料ホルダユニット | |

| JP7278526B2 (ja) | 単結晶x線構造解析システム | |

| JP7252654B2 (ja) | 単結晶x線構造解析試料の吸蔵装置及び吸蔵方法 | |

| JP7278528B2 (ja) | 単結晶x線構造解析装置用試料ホルダユニット | |

| WO2020105716A1 (ja) | 単結晶x線構造解析装置と方法、及び、そのための試料ホルダ | |

| JP7462164B2 (ja) | 単結晶x線構造解析装置用試料ホルダ、試料ホルダユニットおよび吸蔵方法 | |

| JP7237373B2 (ja) | 単結晶x線構造解析装置および試料ホルダ取り付け装置 | |

| JP7493847B6 (ja) | 単結晶x線構造解析装置とそのための方法 | |

| JP7278527B2 (ja) | 単結晶x線構造解析装置用試料ホルダユニット | |

| JP7237374B2 (ja) | 単結晶x線構造解析装置と方法、そのための試料ホルダ及びアプリケータ | |

| WO2020105725A1 (ja) | 単結晶x線構造解析用試料の吸蔵装置と吸蔵方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 19886782 Country of ref document: EP Kind code of ref document: A1 |

|

| ENP | Entry into the national phase |

Ref document number: 2020557644 Country of ref document: JP Kind code of ref document: A |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| ENP | Entry into the national phase |

Ref document number: 2019886782 Country of ref document: EP Effective date: 20210622 |