WO2020004257A1 - 容器殺菌用のキセノンフラッシュランプ - Google Patents

容器殺菌用のキセノンフラッシュランプ Download PDFInfo

- Publication number

- WO2020004257A1 WO2020004257A1 PCT/JP2019/024704 JP2019024704W WO2020004257A1 WO 2020004257 A1 WO2020004257 A1 WO 2020004257A1 JP 2019024704 W JP2019024704 W JP 2019024704W WO 2020004257 A1 WO2020004257 A1 WO 2020004257A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- container

- flash lamp

- xenon flash

- arc tube

- sterilizing

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61L—METHODS OR APPARATUS FOR STERILISING MATERIALS OR OBJECTS IN GENERAL; DISINFECTION, STERILISATION OR DEODORISATION OF AIR; CHEMICAL ASPECTS OF BANDAGES, DRESSINGS, ABSORBENT PADS OR SURGICAL ARTICLES; MATERIALS FOR BANDAGES, DRESSINGS, ABSORBENT PADS OR SURGICAL ARTICLES

- A61L2/00—Methods or apparatus for disinfecting or sterilising materials or objects other than foodstuffs or contact lenses; Accessories therefor

- A61L2/02—Methods or apparatus for disinfecting or sterilising materials or objects other than foodstuffs or contact lenses; Accessories therefor using physical phenomena

- A61L2/08—Radiation

- A61L2/10—Ultraviolet radiation

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01J—ELECTRIC DISCHARGE TUBES OR DISCHARGE LAMPS

- H01J61/00—Gas-discharge or vapour-discharge lamps

- H01J61/02—Details

- H01J61/30—Vessels; Containers

- H01J61/32—Special longitudinal shape, e.g. for advertising purposes

Definitions

- Xenon flash lamps are used for flash pulse sterilization.

- Xenon flash lamps contain abundant ultraviolet light with a wavelength of 200 to 300 nm, which is effective for sterilization.

- the flash sterilization process using a xenon flash lamp has a strong sterilizing effect, easy pulse control of light emission, no residue due to non-contact, and extremely short pulse irradiation for the object to be treated ( Containers and the like).

- the flash pulse sterilization treatment has a drawback that only the portion that can be irradiated with light can be sterilized. Therefore, even when irradiating the xenon flash lamp from the outside of the container, light does not sufficiently reach a part of the inner surface of the container (eg, the bottom of the container or a bottle-shaped shoulder having a small opening), and sufficient sterilization is not performed. There is a risk.

- Containers such as PET bottles generally have an extremely narrow shape with a smaller cross-sectional area at the opening at the upper end (a drinking part into which the lid is screwed) than the cross-sectional area of the body. Therefore, the thickness of the xenon flash lamp is regulated according to the inner diameter of the opening, and it is necessary to make the entire arc tube extremely thin.

- a xenon flash lamp for sterilizing containers which is suitable for sterilizing inner surfaces of containers having relatively narrow openings without reducing the sterilizing ability.

- a xenon flash lamp for sterilizing a container has, on one surface thereof, both ends of an arc tube composed of a cylindrical glass tube having a relatively large outer tube diameter, and both ends of the arc tube.

- a central portion of the arc tube may be bent in a T shape.

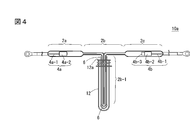

- the thickness of the bent portion of the arc tube inserted into the container may be greater than the thickness of both ends of the arc tube.

- the outer tube diameter of the bent portion of the arc tube inserted into the container may be 5 mm to 6 mm.

- a part of the central portion is formed in a U-shape, and the tube diameter of the U-shaped portion is formed relatively small, and can be inserted into the inside of the container from the opening. It may be.

- the U-shaped portion at the center may be insertable from the opening of the container to the vicinity of the bottom.

- the U-shaped portion at the center is made of a quartz jacket covered with a Teflon (registered trademark) film in order to prevent the fragments from scattering at the time of lamp rupture or glass breakage due to impact. It may be covered.

- a xenon flash lamp for container sterilization suitable for sterilizing an inner surface of a container having a relatively narrow opening without reducing the sterilizing ability.

- ⁇ ⁇ A characteristic of the xenon flash lamp according to the present embodiment lies in the external shape of the lamp as compared with the conventional xenon flash lamp. Therefore, in order to facilitate understanding of the xenon flash lamp according to the present embodiment, a brief description will first be given of a conventional xenon flash lamp.

- FIG. 1 is a diagram illustrating a conventional xenon flash lamp.

- the conventional xenon flash lamp 110 has a structure in which an anode electrode 104a and a cathode electrode 104b are arranged at both ends of an arc tube 102 in which xenon of a rare gas is sealed.

- the arc tube 102 is made of quartz glass having a high ultraviolet transmittance, and is formed into a straight cylindrical shape having a fixed thickness with both ends sealed.

- the anode electrode 104a is formed of a tungsten rod having an anode large-diameter portion 104a-2 formed by processing the tip (the arc tube side) of the electrode lead rod 104a-1 into a cylindrical shape.

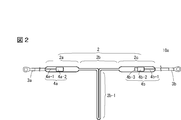

- the following description focuses on differences from the conventional xenon flash lamp 110 shown in FIG. Compared to the conventional xenon flash lamp 110, the anode electrode 4a and the cathode electrode 4b are arranged at both ends of the arc tube 2 in opposition.

- the central portion 2b of the arc tube 2 is formed in a T-shape, and is thinner than the tube diameters of both end portions 2a and 2c.

- a part of the central portion 2b is formed in a U-shape, and the tube diameter of the U-shaped portion 2b-1 is relatively small, so that the container can be inserted into the container from the opening.

- the thickness of the central portion 2b of the arc tube 2 is different in that it is formed thicker than the thickness of both end portions 2a and 2c.

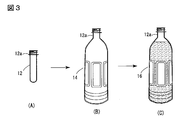

- the preform 12 is heated, placed in a plastic bottle-shaped female mold, and inserted into a stretching rod through an opening to inject air to be molded into a bottle shape. It becomes 14 and the product is filled with the beverage and becomes product 16.

- the shape of the opening (male screw forming portion) 12a serving as a drinking mouth does not change from the beginning.

- the xenon flash lamp according to the present embodiment has the following advantages and features.

- the central portion 2b of the arc tube has a small diameter, and a part thereof is formed in the U-shaped portion 2b-1, so that the arc tube can be inserted from the opening of the container to be sterilized.

- the entire inner surface of the container can be irradiated with pulsed light to perform a reliable sterilization treatment.

- the size of the arc tube can be determined according to the size in the container, and the lamp can be manufactured.

Landscapes

- Health & Medical Sciences (AREA)

- Epidemiology (AREA)

- Life Sciences & Earth Sciences (AREA)

- Animal Behavior & Ethology (AREA)

- General Health & Medical Sciences (AREA)

- Public Health (AREA)

- Veterinary Medicine (AREA)

- Apparatus For Disinfection Or Sterilisation (AREA)

- Vessels And Coating Films For Discharge Lamps (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201980042678.7A CN112368801B (zh) | 2018-06-26 | 2019-06-21 | 容器杀菌用的氙闪光灯 |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2018121322A JP6706435B2 (ja) | 2018-06-26 | 2018-06-26 | 容器殺菌用のキセノンフラッシュランプ |

| JP2018-121322 | 2018-06-26 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2020004257A1 true WO2020004257A1 (ja) | 2020-01-02 |

Family

ID=68986849

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2019/024704 Ceased WO2020004257A1 (ja) | 2018-06-26 | 2019-06-21 | 容器殺菌用のキセノンフラッシュランプ |

Country Status (3)

| Country | Link |

|---|---|

| JP (1) | JP6706435B2 (enExample) |

| CN (1) | CN112368801B (enExample) |

| WO (1) | WO2020004257A1 (enExample) |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN112867673B (zh) * | 2018-09-28 | 2023-06-30 | 岩崎电气株式会社 | 容器杀菌用的氙闪光灯照射装置 |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5737449A (en) * | 1980-08-14 | 1982-03-01 | Nippo Denki Kk | Ultraviolet ray sterilizing lamp |

| JPS60116359A (ja) * | 1983-11-30 | 1985-06-22 | 明治乳業株式会社 | 閃光発光殺菌法 |

| JPS61187295U (enExample) * | 1985-05-15 | 1986-11-21 | ||

| JPH0398248A (ja) * | 1989-09-12 | 1991-04-23 | Toshiba Lighting & Technol Corp | セラミック放電灯 |

| JP2001247108A (ja) * | 2000-03-08 | 2001-09-11 | Shokuhin Sangyo Denshi Riyo Gijutsu Kenkyu Kumiai | 容器殺菌方法及び装置 |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN2634649Y (zh) * | 2003-07-18 | 2004-08-18 | 启东计算机总厂有限公司 | 石英紫外线杀菌灯 |

| CN200990370Y (zh) * | 2006-12-27 | 2007-12-12 | 浙江江山三友电子有限公司 | 一种汞齐8字型细管径节能灯灯管 |

| CN104505329A (zh) * | 2014-11-28 | 2015-04-08 | 昆山博文照明科技有限公司 | 一种无电极紫外线灯 |

-

2018

- 2018-06-26 JP JP2018121322A patent/JP6706435B2/ja active Active

-

2019

- 2019-06-21 WO PCT/JP2019/024704 patent/WO2020004257A1/ja not_active Ceased

- 2019-06-21 CN CN201980042678.7A patent/CN112368801B/zh active Active

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5737449A (en) * | 1980-08-14 | 1982-03-01 | Nippo Denki Kk | Ultraviolet ray sterilizing lamp |

| JPS60116359A (ja) * | 1983-11-30 | 1985-06-22 | 明治乳業株式会社 | 閃光発光殺菌法 |

| JPS61187295U (enExample) * | 1985-05-15 | 1986-11-21 | ||

| JPH0398248A (ja) * | 1989-09-12 | 1991-04-23 | Toshiba Lighting & Technol Corp | セラミック放電灯 |

| JP2001247108A (ja) * | 2000-03-08 | 2001-09-11 | Shokuhin Sangyo Denshi Riyo Gijutsu Kenkyu Kumiai | 容器殺菌方法及び装置 |

Also Published As

| Publication number | Publication date |

|---|---|

| CN112368801B (zh) | 2022-03-01 |

| JP6706435B2 (ja) | 2020-06-10 |

| CN112368801A (zh) | 2021-02-12 |

| JP2020004549A (ja) | 2020-01-09 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP2017004702A (ja) | エキシマランプ | |

| WO2013081054A1 (ja) | エキシマランプ | |

| CN100472705C (zh) | 准分子灯泡 | |

| WO2020004257A1 (ja) | 容器殺菌用のキセノンフラッシュランプ | |

| JP7296057B2 (ja) | 容器殺菌用のキセノンフラッシュランプ照射装置 | |

| JP6813811B2 (ja) | 容器殺菌用のキセノンフラッシュランプ照射装置 | |

| JP2014146527A (ja) | エキシマランプ | |

| JP6800433B2 (ja) | 容器殺菌用のキセノンフラッシュランプ | |

| JP6557011B2 (ja) | エキシマランプ | |

| JP4258313B2 (ja) | フラッシュランプ | |

| JP7602726B2 (ja) | 飲食品容器の殺菌処理方法及び殺菌装置 | |

| JP2005216793A (ja) | フラッシュランプとその電極ユニット | |

| US10593536B2 (en) | UV mercury low-pressure lamp with amalgam deposit | |

| JP5640838B2 (ja) | 放電ランプ装置 | |

| JP6107789B2 (ja) | エキシマ放電ランプ | |

| KR0148310B1 (ko) | 오존 발생 장치 | |

| JP4093016B2 (ja) | フラッシュランプ用の電極ユニットとその製造方法 | |

| JP2020047558A (ja) | 放電ランプおよび紫外線照射装置 | |

| JP6869081B2 (ja) | 紫外線照射装置及びこれを用いた水殺菌装置 | |

| JP2005353386A (ja) | エキシマ放電ランプ装置 | |

| JP2021039851A (ja) | 放電ランプ | |

| TWM572063U (zh) | Ultraviolet irradiation device and water sterilization device using the same | |

| JP2001307681A (ja) | 無声放電灯 | |

| TWM571740U (zh) | Cold cathode ultraviolet lamp | |

| JP2008077909A (ja) | 誘電体バリア放電ランプ装置および紫外線照射装置 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 19826817 Country of ref document: EP Kind code of ref document: A1 |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 19826817 Country of ref document: EP Kind code of ref document: A1 |