WO2019163650A1 - シリコン酸化物被覆軟磁性粉末およびその製造方法 - Google Patents

シリコン酸化物被覆軟磁性粉末およびその製造方法 Download PDFInfo

- Publication number

- WO2019163650A1 WO2019163650A1 PCT/JP2019/005474 JP2019005474W WO2019163650A1 WO 2019163650 A1 WO2019163650 A1 WO 2019163650A1 JP 2019005474 W JP2019005474 W JP 2019005474W WO 2019163650 A1 WO2019163650 A1 WO 2019163650A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- soft magnetic

- magnetic powder

- silicon oxide

- coated

- silicon

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C33/00—Making ferrous alloys

- C22C33/02—Making ferrous alloys by powder metallurgy

- C22C33/0207—Using a mixture of prealloyed powders or a master alloy

- C22C33/0228—Using a mixture of prealloyed powders or a master alloy comprising other non-metallic compounds or more than 5% of graphite

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F1/00—Metallic powder; Treatment of metallic powder, e.g. to facilitate working or to improve properties

- B22F1/05—Metallic powder characterised by the size or surface area of the particles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F1/00—Metallic powder; Treatment of metallic powder, e.g. to facilitate working or to improve properties

- B22F1/16—Metallic particles coated with a non-metal

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C19/00—Alloys based on nickel or cobalt

- C22C19/03—Alloys based on nickel or cobalt based on nickel

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C33/00—Making ferrous alloys

- C22C33/02—Making ferrous alloys by powder metallurgy

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C45/00—Amorphous alloys

- C22C45/02—Amorphous alloys with iron as the major constituent

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C18/00—Chemical coating by decomposition of either liquid compounds or solutions of the coating forming compounds, without leaving reaction products of surface material in the coating; Contact plating

- C23C18/02—Chemical coating by decomposition of either liquid compounds or solutions of the coating forming compounds, without leaving reaction products of surface material in the coating; Contact plating by thermal decomposition

- C23C18/12—Chemical coating by decomposition of either liquid compounds or solutions of the coating forming compounds, without leaving reaction products of surface material in the coating; Contact plating by thermal decomposition characterised by the deposition of inorganic material other than metallic material

- C23C18/1204—Chemical coating by decomposition of either liquid compounds or solutions of the coating forming compounds, without leaving reaction products of surface material in the coating; Contact plating by thermal decomposition characterised by the deposition of inorganic material other than metallic material inorganic material, e.g. non-oxide and non-metallic such as sulfides, nitrides based compounds

- C23C18/1208—Oxides, e.g. ceramics

- C23C18/1216—Metal oxides

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C18/00—Chemical coating by decomposition of either liquid compounds or solutions of the coating forming compounds, without leaving reaction products of surface material in the coating; Contact plating

- C23C18/02—Chemical coating by decomposition of either liquid compounds or solutions of the coating forming compounds, without leaving reaction products of surface material in the coating; Contact plating by thermal decomposition

- C23C18/12—Chemical coating by decomposition of either liquid compounds or solutions of the coating forming compounds, without leaving reaction products of surface material in the coating; Contact plating by thermal decomposition characterised by the deposition of inorganic material other than metallic material

- C23C18/125—Process of deposition of the inorganic material

- C23C18/1254—Sol or sol-gel processing

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01F—MAGNETS; INDUCTANCES; TRANSFORMERS; SELECTION OF MATERIALS FOR THEIR MAGNETIC PROPERTIES

- H01F1/00—Magnets or magnetic bodies characterised by the magnetic materials therefor; Selection of materials for their magnetic properties

- H01F1/01—Magnets or magnetic bodies characterised by the magnetic materials therefor; Selection of materials for their magnetic properties of inorganic materials

- H01F1/03—Magnets or magnetic bodies characterised by the magnetic materials therefor; Selection of materials for their magnetic properties of inorganic materials characterised by their coercivity

- H01F1/12—Magnets or magnetic bodies characterised by the magnetic materials therefor; Selection of materials for their magnetic properties of inorganic materials characterised by their coercivity of soft-magnetic materials

- H01F1/14—Magnets or magnetic bodies characterised by the magnetic materials therefor; Selection of materials for their magnetic properties of inorganic materials characterised by their coercivity of soft-magnetic materials metals or alloys

- H01F1/147—Alloys characterised by their composition

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01F—MAGNETS; INDUCTANCES; TRANSFORMERS; SELECTION OF MATERIALS FOR THEIR MAGNETIC PROPERTIES

- H01F1/00—Magnets or magnetic bodies characterised by the magnetic materials therefor; Selection of materials for their magnetic properties

- H01F1/01—Magnets or magnetic bodies characterised by the magnetic materials therefor; Selection of materials for their magnetic properties of inorganic materials

- H01F1/03—Magnets or magnetic bodies characterised by the magnetic materials therefor; Selection of materials for their magnetic properties of inorganic materials characterised by their coercivity

- H01F1/12—Magnets or magnetic bodies characterised by the magnetic materials therefor; Selection of materials for their magnetic properties of inorganic materials characterised by their coercivity of soft-magnetic materials

- H01F1/14—Magnets or magnetic bodies characterised by the magnetic materials therefor; Selection of materials for their magnetic properties of inorganic materials characterised by their coercivity of soft-magnetic materials metals or alloys

- H01F1/20—Magnets or magnetic bodies characterised by the magnetic materials therefor; Selection of materials for their magnetic properties of inorganic materials characterised by their coercivity of soft-magnetic materials metals or alloys in the form of particles, e.g. powder

- H01F1/22—Magnets or magnetic bodies characterised by the magnetic materials therefor; Selection of materials for their magnetic properties of inorganic materials characterised by their coercivity of soft-magnetic materials metals or alloys in the form of particles, e.g. powder pressed, sintered, or bound together

- H01F1/24—Magnets or magnetic bodies characterised by the magnetic materials therefor; Selection of materials for their magnetic properties of inorganic materials characterised by their coercivity of soft-magnetic materials metals or alloys in the form of particles, e.g. powder pressed, sintered, or bound together the particles being insulated

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01F—MAGNETS; INDUCTANCES; TRANSFORMERS; SELECTION OF MATERIALS FOR THEIR MAGNETIC PROPERTIES

- H01F1/00—Magnets or magnetic bodies characterised by the magnetic materials therefor; Selection of materials for their magnetic properties

- H01F1/01—Magnets or magnetic bodies characterised by the magnetic materials therefor; Selection of materials for their magnetic properties of inorganic materials

- H01F1/03—Magnets or magnetic bodies characterised by the magnetic materials therefor; Selection of materials for their magnetic properties of inorganic materials characterised by their coercivity

- H01F1/12—Magnets or magnetic bodies characterised by the magnetic materials therefor; Selection of materials for their magnetic properties of inorganic materials characterised by their coercivity of soft-magnetic materials

- H01F1/33—Magnets or magnetic bodies characterised by the magnetic materials therefor; Selection of materials for their magnetic properties of inorganic materials characterised by their coercivity of soft-magnetic materials mixtures of metallic and non-metallic particles; metallic particles having oxide skin

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F2301/00—Metallic composition of the powder or its coating

- B22F2301/15—Nickel or cobalt

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F2302/00—Metal Compound, non-Metallic compound or non-metal composition of the powder or its coating

- B22F2302/25—Oxide

- B22F2302/256—Silicium oxide (SiO2)

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F2304/00—Physical aspects of the powder

- B22F2304/10—Micron size particles, i.e. above 1 micrometer up to 500 micrometer

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C2202/00—Physical properties

- C22C2202/02—Magnetic

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/02—Ferrous alloys, e.g. steel alloys containing silicon

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/06—Ferrous alloys, e.g. steel alloys containing aluminium

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/08—Ferrous alloys, e.g. steel alloys containing nickel

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/18—Ferrous alloys, e.g. steel alloys containing chromium

Definitions

- the present invention relates to a silicon oxide-coated soft magnetic powder having good insulation and high magnetic permeability ( ⁇ ) suitable for manufacturing a dust core of an electric / electronic component such as an inductor, choke coil, transformer, reactor or motor, and It relates to the manufacturing method.

- powder magnetic cores using soft magnetic powders such as iron powders, iron-containing alloy powders, and intermetallic compound powders are known as magnetic cores for inductors, choke coils, transformers, reactors, motors, and the like.

- the powder magnetic core using the soft magnetic powder containing iron has a lower electrical resistivity than the powder magnetic core using ferrite, so the surface of the soft magnetic powder is coated with an insulating film. It is manufactured after compression molding and heat treatment.

- Various insulating coatings have been proposed in the past, and silicon oxide coatings are known as highly insulating coatings.

- Patent Document 1 discloses an Fe—Si—Cr—Ni alloy powder in which a SiO 2 film having a film thickness of 5 to 10 nm is formed by a vibration sputtering apparatus.

- Patent Document 2 discloses an Fe—Si—Cr based magnetic metal powder coated with an alkali borosilicate glass containing 79% by weight of SiO 2 using a mechano-fusion method.

- Patent Document 3 As a soft magnetic powder coated with silicon oxide by a wet method, for example, in Patent Document 3, an IPA (isopropanol) solution of tetraethoxysilane is coated with a hydrolyzed product of tetraethoxysilane and then dried at 120 ° C. Fe-6.5% Si powder is disclosed.

- Patent Document 4 discloses SiO 2 having a film thickness of 1 to 13 nm using tetraethylorthosilicate (tetraethoxysilane) as a magnetic powder obtained by coating a Fe—Pd core, which is a hard magnetic material, with Fe, which is a soft magnetic material. A technique for forming a coating is disclosed.

- the surface coating obtained in Patent Document 2 has a lot of voids, and the surface of the soft magnetic powder is partially exposed, so that there is a problem that good insulation cannot be secured. there were. Since the wet method is excellent in productivity, it is promising as an industrial manufacturing method of soft magnetic powder coated with an insulator. However, the insulating coated soft magnetic powder obtained in Patent Document 3 has an average film thickness of a coating layer.

- the present invention obtains a high powder density with excellent insulation properties by coating the surface of soft magnetic powder with silicon oxide having good film thickness uniformity and few defects.

- An object of the present invention is to provide a silicon oxide-coated soft magnetic powder that can be used and a method for producing the same.

- a silicon oxide-coated soft magnetic powder composed of particles in which a silicon oxide coating layer is formed on the surface of soft magnetic powder particles containing 20% by mass or more of iron.

- the average film thickness of the silicon oxide coating layer is not less than 1 nm and not more than 30 nm, the coverage ratio R defined by the following formula (1) is not less than 70%, and the dust density is 4.0 g. Silicon oxide-coated soft magnetic powder that is / cm 3 or more.

- Si Si ⁇ 100 / (Si + M) (1)

- Si is the molar fraction of Si obtained by X-ray photoelectron spectroscopy (XPS) measurement of the silicon oxide-coated soft magnetic powder

- M oxygen among the elements constituting the soft magnetic powder. It is the sum total of the molar fraction obtained by XPS measurement about the metal element and nonmetallic element except.

- the silicon oxide-coated soft magnetic powder preferably has a volume-based cumulative 50% particle size D 50 obtained by a laser diffraction particle size distribution measurement method of 1.0 ⁇ m or more and 5.0 ⁇ m or less.

- the present invention further relates to a method for producing a silicon oxide-coated soft magnetic powder in which the surface of a soft magnetic powder containing 20% by mass or more of iron is coated with silicon oxide, wherein water and an organic solvent are mixed, A step of preparing a mixed solvent containing not less than 40% by mass and not more than 40% by mass, a dispersing step of adding a soft magnetic powder containing 20% by mass or more of iron to the mixed solvent, and obtaining a slurry in which the soft magnetic powder is dispersed; An alkoxide addition step in which silicon alkoxide is added to the slurry in which the soft magnetic powder is dispersed, and a silicon alkoxide hydrolysis catalyst is added to the slurry in which the magnetic powder to which the silicon alkoxide is added are dispersed, and the silicon compound is coated.

- a step of obtaining a slurry in which the magnetic powder is dispersed, and a slurry in which the soft magnetic powder coated with the silicon compound is dispersed are subjected to solid-liquid separation.

- Hydrolysis catalyzed step of obtaining a soft magnetic powder coated with the emissions compound, drying the soft magnetic powder coated with the silicon compound comprises a method for producing a silicon oxide-coated soft magnetic powder is provided.

- the silicon oxide coating layer of the silicon oxide-coated soft magnetic powder has an average film thickness of 1 nm or more and 30 nm or less, represented by the following formula (1):

- the defined coverage ratio R is preferably 70% or more, and the green density is preferably 4.0 g / cm 3 or more.

- R Si ⁇ 100 / (Si + M) (1)

- Si is the molar fraction of Si obtained by X-ray photoelectron spectroscopy (XPS) measurement of the silicon oxide-coated soft magnetic powder

- M oxygen among the elements constituting the soft magnetic powder. It is the sum total of the molar fraction obtained by XPS measurement about the metal element and nonmetallic element except.

- the volume-based cumulative 50% particle diameter D 50 obtained by the laser diffraction particle size distribution measurement method of the silicon oxide-coated soft magnetic powder is 1. It is preferable that the thickness is from 0.0 ⁇ m to 5.0 ⁇ m.

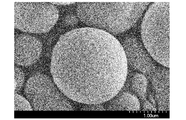

- Example 3 is a SEM photograph of the silicon oxide-coated soft magnetic powder obtained in Example 2.

- Soft magnetic powder In the present invention, a soft magnetic powder containing 20% by mass or more of iron is used as a starting material. Specific examples of soft magnetic powders containing 20 mass% or more of iron include Fe—Si alloys, Fe—Si—Cr alloys, Fe—Al—Si alloys (Sendust), and Fe—Ni alloys having a permalloy composition ( Ni mass 30 to 80 mass%). Moreover, a small amount (10 mass% or less) of Mo and Co may be added as needed. An alloy to which Mo is added is sometimes called amorphous powder because the crystal structure becomes amorphous.

- soft magnetic powder containing 20% by mass or more of iron is simply referred to as “soft magnetic powder”.

- the magnetic properties of the soft magnetic powder are not particularly specified, but a powder having a low coercive force (Hc) and a high saturation magnetization ( ⁇ s) is preferable.

- Hc coercive force

- ⁇ s saturation magnetization

- ⁇ s is preferably high, and is preferably 100 Am 2 / kg (100 emu / g) or more.

- the saturation magnetization is less than 100 Am 2 / kg, a large amount of magnetic powder is required, which inevitably increases the size of the magnetic core, which is not preferable.

- the average particle diameter of the primary particles of the soft magnetic powder is not particularly specified. Conventionally, the average particle diameter of the primary particles is from 0.80 ⁇ m to 5.0 ⁇ m. Soft magnetic powders having an average particle size of any primary particle in the range can be used.

- insulating silicon oxide is coated on the surfaces of the particles constituting the soft magnetic powder by a wet coating method using silicon alkoxide.

- the coating method using silicon alkoxide is a method generally called a sol-gel method, and is excellent in mass productivity as compared with the dry method described above.

- a part or all of the alkoxy group is substituted with a hydroxyl group (OH group) to form a silanol derivative.

- the surface of the soft magnetic powder is coated with the silanol derivative.

- the coated silanol derivative takes a polysiloxane structure by condensation or polymerization when heated, and further heats the polysiloxane structure to silica ( SiO 2 ).

- silica SiO 2

- from the silanol derivative coating in which a part of the organic alkoxy group remains to the silica coating is collectively referred to as silicon oxide coating.

- silicon alkoxide for example, trimethoxysilane, tetramethoxysilane, triethoxysilane, tetraethoxysilane, tripropoxysilane, tetrapropoxysilane, tributoxysilane, tributoxysilane, etc. can be used. It is preferable to use tetraethoxysilane because it has good wettability and can form a uniform coating layer.

- the average film thickness of the silicon oxide coating layer is preferably 1 nm or more and 30 nm or less, and more preferably 1 nm or more and 25 nm or less. If the film thickness is less than 1 nm, there are many defects in the coating layer, making it difficult to ensure insulation. On the other hand, if the film thickness exceeds 30 nm, the insulation is improved, but this is not preferable because the powder density of the soft magnetic powder is lowered and the magnetic properties are deteriorated.

- the average film thickness of the silicon oxide coating layer is measured by a dissolution method, and details of the measurement method will be described later.

- the average film thickness can be obtained by observing the cross section of the silicon oxide coating layer by transmission electron microscope (TEM) observation or scanning electron microscope (SEM) observation. In that case, a cross-sectional TEM photograph or SEM photograph can be taken, and the average film thickness can be obtained from the average value of 50 measurement points of arbitrary particles.

- the film thickness obtained by this method is also equivalent to the dissolution method. It is preferable that the coverage R (%) of the silicon oxide coating layer obtained by XPS measurement using the following formula (1) is 70% or more.

- Si Si ⁇ 100 / (Si + M) (1)

- Si is the molar fraction of Si obtained by X-ray photoelectron spectroscopy (XPS) measurement of the silicon oxide-coated soft magnetic powder

- M oxygen among the elements constituting the soft magnetic powder. It is the sum total of the molar fraction obtained by XPS measurement about the metal element and nonmetallic element except.

- M measured by XPS include Fe, Ni, Cr, Co, Mo, and Al.

- the physical meaning of the coverage ratio R is as follows.

- XPS is a surface analysis method that irradiates a solid surface with soft X-rays as an excitation source and separates photoelectrons emitted from the solid surface.

- the coverage ratio R is an index that comprehensively represents the average film thickness of the silicon oxide coating layer and the area ratio of the defect portion.

- R Si ⁇ 100 / (Si + Fe + Ni)

- the film thickness of the silicon oxide coating layer is thicker than the escape depth of the photoelectrons of Fe and Ni.

- the coverage ratio R is 100%.

- Si is contained as a constituent component of the soft magnetic powder, such as Fe—Si powder or Fe—Si—Cr powder

- the mole fraction of Si constituting the soft magnetic powder is expressed by the formula (1).

- the coverage can be obtained by subtracting from the molar fraction of Si in the denominator and the numerator.

- the molar fraction of Si constituting the soft magnetic powder can be determined by etching the silicon oxide coating layer of the silicon oxide-coated soft magnetic powder by an appropriate method and measuring XPS.

- the silicon oxide-coated soft magnetic powder is etched about 100 nm in terms of SiO 2 with an ion sputtering apparatus attached to XPS, or the silicon oxide-coated soft magnetic powder is dissolved in a 10% by weight aqueous solution of caustic soda, 80 ° C. ⁇

- the silicon oxide film can be completely etched by dipping under the condition of 20 min.

- the silicon oxide-coated soft magnetic powder preferably has a green density of 4.0 g / cm 3 or more. More preferably, it is 5.0 g / cm 3 or more.

- the dust density affects the permeability of the dust core. If the powder density is low, the magnetic permeability of the powder magnetic core will be low, and as a result, the size of the powder magnetic core will be large in order to obtain a predetermined permeability. Is not preferable. Although it is better that the green density is higher, the upper limit of the green density substantially obtained from the composition of the soft magnetic powder is about 7 g / cm 3 .

- the volume-based cumulative 50% particle diameter D 50 obtained by the laser diffraction particle size distribution measurement method of the silicon oxide-coated soft magnetic powder is preferably 1.0 ⁇ m or more and 5.0 ⁇ m or less.

- the particle size is smaller than 1.0 ⁇ m, secondary aggregation increases when silicon oxide is coated, the dust density does not exceed 4.0 g / cm 3 , and the magnetic permeability decreases.

- it is 5.0 ⁇ m or more, the magnetic loss at the high frequency when an inductor is used becomes large, which is not preferable.

- the silicon oxide-coated soft magnetic powder of the present invention has a silanol group on the surface and has water absorption, so that it is easy to adsorb moisture. When moisture is adsorbed on the surface of the silicon oxide-coated soft magnetic powder, it tends to cause a decrease in insulation, so it is preferable to keep the moisture content of the silicon oxide-coated soft magnetic powder low.

- the water content of the silicon oxide-coated soft magnetic powder is not particularly specified, but the water content with respect to the entire silicon oxide-coated soft magnetic powder is preferably 0.25% by mass or less.

- the water content can be reduced to 0.25% by mass or less. More preferably, the water content is 0.15% by mass or less.

- atmosphere arises, it is difficult to make water content 0, and a thing of 0.01 mass% or more is obtained normally.

- the hydrated Fe oxide surface is a kind of solid acid and shows behavior similar to that of weak acid as Brönsted acid, when silicon alkoxide is added to the slurry containing soft magnetic powder in the mixed solvent in the next step

- the reactivity between the silanol derivative, which is a hydrolysis product of silicon alkoxide, and the surface of the soft magnetic powder is improved.

- the water content in the mixed solvent is preferably 1% by mass or more and 40% by mass or less. More preferably, it is 5 mass% or more and 30 mass% or less, More preferably, it is 10 mass% or more and 20 mass% or less. When the water content is less than 1% by mass, the above-described action of hydrating the Fe oxide is insufficient.

- the organic solvent used for the mixed solvent it is preferable to use aliphatic alcohols such as methanol, ethanol, 1-propanol, 2-propanol, butanol, pentanol, and hexanol having an affinity for water.

- solubility parameter of the organic solvent is too close to that of water, the reactivity of water in the mixed solvent decreases, so 1-propanol, 2-propanol (isopropyl alcohol), butanol, pentanol, hexanol should be used. More preferred.

- the reaction temperature in the dispersion step is not particularly limited, but is preferably 20 ° C. or higher and 70 ° C. or lower. If the reaction temperature is less than 20 ° C., the rate of the hydration reaction of Fe oxide becomes slow, which is not preferable. On the other hand, when the reaction temperature exceeds 70 ° C., the hydrolysis reaction rate of the added silicon alkoxide is increased in the subsequent alkoxide addition step, and the uniformity of the silicon oxide coating layer is deteriorated.

- the holding time of the dispersion step is not particularly specified, but conditions are appropriately selected so that the holding time is 1 min or more and 30 min or less so that the hydration reaction of Fe oxide occurs uniformly.

- the silicon alkoxide is added to the slurry in which the soft magnetic powder is dispersed in the mixed solvent obtained by the dispersion step, while stirring by a known mechanical means, and then the slurry is held in that state for a certain time.

- the silicon alkoxide as described above, trimethoxysilane, tetramethoxysilane, triethoxysilane, tetraethoxysilane, tripropoxysilane, tetrapropoxysilane, tributoxysilane, tributoxysilane, and the like can be used.

- the silicon alkoxide added in this step is hydrolyzed into a silanol derivative by the action of water contained in the mixed solvent.

- the produced silanol derivative forms a reaction layer of the silanol derivative on the surface of the soft magnetic powder by condensation, chemical adsorption or the like.

- the hydrolysis of the silicon alkoxide occurs slowly, so that the reaction layer of the silanol derivative is considered to be formed uniformly. Since almost all of the silicon alkoxide added in this step is used to form the silicon oxide coating layer, the amount added is set to an amount that is 1 nm to 30 nm in terms of the average film thickness of the silicon oxide coating layer.

- the amount of silicon alkoxide added is determined by the following method.

- the mass of the soft magnetic powder contained in the slurry is Gp (g)

- the BET specific surface area before coating of the soft magnetic powder is S (m 2 / g)

- the target film thickness of the silicon oxide coating layer is t (nm).

- the number of moles of Si contained in the silicon oxide coating layer is determined as a value obtained by dividing Gc by the molecular weight of SiO 2 of 60.08.

- a silicon alkoxide having the number of moles corresponding to the target film thickness t (nm) is added to a slurry in which soft magnetic powder is dispersed in a mixed solvent.

- the silicon oxide coating soft magnetic powder was cut using a focused ion beam (FIB) processing apparatus, and the average film thickness of the silicon oxide coating layer measured by transmission electron microscope (TEM) observation was the silicon oxide coating layer.

- FIB focused ion beam

- the reaction temperature in the alkoxide addition step is not particularly specified, but is preferably 20 ° C. or higher and 70 ° C. or lower.

- the reaction temperature is less than 20 ° C., the reaction rate between the surface of the soft magnetic powder and the silanol derivative becomes slow, which is not preferable.

- the reaction temperature exceeds 70 ° C., the hydrolysis reaction rate of the added silicon alkoxide increases, and the uniformity of the silicon oxide coating layer is deteriorated.

- the reaction time of the alkoxide addition step is not particularly specified, but the conditions are appropriately set so that the reaction time is 10 min or less so that the reaction between the surface of the soft magnetic powder and the silanol derivative occurs uniformly. select.

- [Hydrolysis catalyst addition step] In the production method of the present invention, after a silanol derivative reaction layer is formed on the surface of the soft magnetic powder in the alkoxide addition step, the slurry in which the soft magnetic powder is dispersed in the mixed solvent is stirred by a known mechanical means. Then, a hydrolysis catalyst for silicon alkoxide is added. In this step, the hydrolysis reaction of silicon alkoxide is promoted by the addition of a hydrolysis catalyst, and the deposition rate of the silicon oxide coating layer is increased. From this step onward, the same method as the film formation method by the usual sol-gel method is used. An alkali catalyst is used as the hydrolysis catalyst.

- the reaction temperature in the hydrolysis catalyst addition step is not particularly specified, and may be the same as the reaction temperature in the alkoxide addition step, which is the previous step.

- the reaction time of the hydrolysis catalyst addition step is not particularly specified, but a long reaction time is economically disadvantageous, so that the reaction time is 5 min to 120 min. Is appropriately selected.

- the silicon oxide-coated soft magnetic powder is recovered from the slurry containing the silicon oxide-coated soft magnetic powder obtained by the series of steps described above using a known solid-liquid separation means.

- a known solid-liquid separation means such as filtration, centrifugation, and decantation can be used.

- a flocculant may be added for solid-liquid separation.

- the collected silicon-coated soft magnetic powder is dried in an air atmosphere at a temperature of 80 ° C. or higher. When the drying is performed at 80 ° C. or higher, the water content of the silicon oxide-coated soft magnetic powder can be reduced to 0.25% by mass or less.

- drying temperature 85 degreeC or more is preferable and 90 degreeC or more is more preferable. Further, the drying temperature is preferably 400 ° C. or lower, and more preferably 150 ° C. or lower so that the silicon oxide coating is not peeled off. When it is desired to suppress the oxidation of the soft magnetic powder, it is dried in an inert gas atmosphere or a vacuum atmosphere.

- the Si content was measured by a gravimetric method. Add hydrochloric acid and perchloric acid to the sample, decompose by heating, and heat until white smoke of perchloric acid is generated. Continue heating to dryness. After cooling, water and hydrochloric acid are added and heated to dissolve soluble salts. The insoluble residue is filtered using filter paper, the residue is transferred to the crucible together with the filter paper, dried and incinerated. Weigh together with crucible after standing to cool. Add a small amount of sulfuric acid and hydrofluoric acid, heat to dryness, and ignite. Weigh together with crucible after standing to cool. The Si concentration is obtained by subtracting the second weighing value from the first weighing value and calculating the weight difference as SiO 2 .

- BET specific surface area measurement The BET specific surface area was determined by the BET single point method using 4 Sorb US manufactured by Yuasa Ionics Co., Ltd. [SEM observation] SEM observation was performed using S-4700 manufactured by Hitachi High-Technologies Corporation at an acceleration voltage of 3 kV and a magnification of 30,000 times.

- the volume resistivity of the silicon oxide-coated soft magnetic powder is measured by Mitsubishi Chemical Analytech Co., Ltd. powder resistance measurement unit (MCP-PD51), Mitsubishi Chemical Analytech Co., Ltd. high resistivity meter Hiresta UP (MCP-HT450).

- MCP-PD51 powder resistance measurement unit

- MCP-HT450 high resistivity meter Hiresta UP

- 1.0 g of powder was vertically pressurized at 13 to 64 MPa (4 to 20 kN) by a double ring electrode method using a high resistance powder measurement system software manufactured by Mitsubishi Chemical Analytech Co., Ltd., and a voltage was applied. It was determined by measuring with.

- the green density was calculated from the thickness when pressed at 64 MPa (20 kN) and the weight of the sample.

- the volume resistivity at 64 MPa (20 kN) is preferably 1.0 ⁇ 10 6 ⁇ ⁇ cm or more. More preferably, it is 1.0 ⁇ 10 7 ⁇ ⁇ cm or more.

- the particle size distribution of the soft magnetic powder before the coating treatment and after the silicon oxide coating treatment was measured by a laser diffraction particle size distribution device (Hellos particle size distribution measuring device (HELOS & RODOS) manufactured by SYMPATEC).

- the volume-based cumulative 10% particle diameter (D 10 ), cumulative 50% particle diameter (D 50 ), cumulative 90% particle diameter (D 90 ) are obtained, and the cumulative 50% particle diameter (D 50 ) is the average particle.

- the diameter The diameter.

- a molded body having a real part ⁇ ′ of complex relative permeability at 100 MHz of 4.5 or more can be obtained.

- the molded body produced by using it exhibits excellent magnetic permeability characteristics, and can be suitably used for applications such as inductor magnetic cores that are required to be miniaturized.

- the water content in the silicon oxide-coated soft magnetic powder was measured by a coulometric titration method using a water vaporizer EV-2010 manufactured by Hiranuma Sangyo Co., Ltd. Specifically, a measurement sample is put into a measurement cell in a moisture vaporizer EV-2010 heated to 300 ° C., and the measured value is taken as the moisture content in the silicon oxide-coated soft magnetic powder.

- Example 1 In a 1000 mL reaction vessel, 70 g of pure water and 400 g of isopropyl alcohol (IPA) are charged at room temperature and mixed using a stirring blade to prepare a mixed solvent. Then, a FeNi alloy powder ( Fe 50% by mass, Ni 50% by mass, BET specific surface area: 0.77 m 2 / g, average particle size 1.9 ⁇ m, compaction density 5.47 g / cm 3 ) 250 g were added to prepare a slurry in which soft magnetic powder was dispersed. Obtained. Thereafter, the slurry was heated from room temperature to 40 ° C. while stirring the slurry at a stirring speed of 600 rpm.

- IPA isopropyl alcohol

- the holding time of the slurry in the dispersion step is 15 min.

- 3.74 g of tetraethoxysilane (TEOS: Wako Pure Chemical Industries special grade reagent) dispensed in a small amount of beaker was added to the stirred slurry in which the soft magnetic powder was dispersed in the mixed solvent.

- TEOS adhering to the vessel wall of a small amount of beaker was washed off using 5 g of IPA and added to the reaction vessel. After the addition of TEOS, stirring was continued for 5 minutes to cause a reaction between the hydrolysis product of TEOS and the surface of the soft magnetic powder.

- the film thickness t was 2 nm

- the coverage ratio R was 81% (Fe and Ni constituting the soft magnetic powder as M were detected by XPS measurement), and the water content was 0.10% by mass.

- Table 1 also shows the particle size distribution measurement results of the obtained silicon oxide-coated soft magnetic powder, and the measurement results of the powder density and the volume resistivity of the powder compact.

- Examples 2 to 5 Implementation was performed except that the amount of TEOS added to the slurry was changed to 9.36 g in Example 2, 21.0 g in Example 3, 31.4 g in Example 4, and 41.9 g in Example 5.

- a silicon oxide-coated soft magnetic powder was obtained in the same procedure as in Example 1.

- the film thickness, coverage, and water content of the silicon oxide coating layer calculated for the obtained silicon oxide-coated soft magnetic powder, as well as the particle size distribution, powder density, and volume of the powder compact of the silicon oxide-coated soft magnetic powder.

- the resistivity measurement results are also shown in Table 1.

- Fe and Ni constituting the soft magnetic powder as M were detected by XPS measurement, and in Example 5, metallic elements and nonmetallic elements other than oxygen were not measured.

- the SEM observation result of the silicon oxide covering soft magnetic powder obtained by Example 2 is shown in FIG.

- the length shown by the 11 white vertical lines shown in the lower right of FIG. 1 is 1.0 ⁇ m.

- the addition amount of TEOS is increased, the thickness of the silicon oxide coating layer is increased and the coverage is also increased.

- the volume resistivity of the green compacts obtained for the inventive examples is one digit or more higher than those for the comparative examples described below.

- the average particle size slightly increases with the increase in the thickness of the silicon oxide. This is because the silicon oxide serves as a binder and the soft magnetic particles adhere to each other. The increase in particle size due to secondary aggregation was small.

- Example 6 Iron powder (purity 99% by mass or more, average particle size 5.5 ⁇ m, specific surface area 0.40 m 2 / g) was used as soft magnetic powder, and the amount of TEOS added to the slurry was 4.80 g (equivalent to a SiO 2 film thickness of 5 nm).

- a silicon oxide-coated soft magnetic powder was obtained by the same procedure as in Example 1 except that. The film thickness, coverage, and water content of the silicon oxide coating layer calculated for the obtained silicon oxide-coated soft magnetic powder, as well as the particle size distribution, powder density, and volume of the powder compact of the silicon oxide-coated soft magnetic powder. The resistivity measurement results are also shown in Table 1.

- Example 7 A silicon oxide-coated soft magnetic powder was obtained in the same procedure as in Example 2 except that the drying temperature was 80 ° C. The film thickness, coverage, and water content of the silicon oxide coating layer calculated for the obtained silicon oxide-coated soft magnetic powder, as well as the particle size distribution, powder density, and volume of the powder compact of the silicon oxide-coated soft magnetic powder. The resistivity measurement results are also shown in Table 1. In addition, when the drying temperature in which Fe and Ni constituting the soft magnetic powder as M were detected by XPS measurement was 80 ° C., the water content was slightly high, and the volume resistivity of the green compact was slightly low. .

- Example 2 According to the method described in Example 1 of Patent Document 2, the soft magnetic FeNi alloy powder was coated with silicon oxide. In this production method, the dispersion step and the alkoxide addition step specified in the claims of the present invention are not performed, and the soft magnetic powder is immediately reacted with the coating liquid to which the hydrolysis catalyst is added. That is, 500 g of the FeNi alloy powder was immersed in a hydrolysis solution at room temperature of 25 ° C. consisting of 14 g of tetraethoxysilane (manufactured by Kanto Chemical Co., Inc.) and 100 mL of IPA, 2 mL of concentrated aqueous ammonia (28 mass%), and 30 g of water.

- a hydrolysis solution at room temperature of 25 ° C. consisting of 14 g of tetraethoxysilane (manufactured by Kanto Chemical Co., Inc.) and 100 mL of IPA, 2 mL of concentrated aqueous ammonia (28 mass%)

- the mixture was stirred for 3 hours using a propeller stirrer. Thereafter, the silicon oxide-coated soft magnetic powder and the hydrolysis solution were separated, and the silicon oxide-coated soft magnetic powder was heat treated at 120 ° C. for 1 hour to remove the IPA solution and water. Thereafter, the obtained silicon oxide-coated soft magnetic powder was evaluated in the same manner as in the examples of the present invention. The evaluation results are also shown in Table 1. Note that Fe and Ni constituting the soft magnetic powder as M were detected by XPS measurement.

- the film thickness of the silicon oxide-coated soft magnetic layer of the silicon oxide-coated soft magnetic powder obtained in this comparative example is 4 nm, which is included in the claims of the present invention, and the coverage is 52%,

- the volume resistivity of the green compact was inferior to those of the examples of the present invention.

- Example 3 A silicon oxide-coated soft magnetic powder was obtained under the same conditions as in Example 1 except that water was not added as a solvent for making the soft magnetic powder into a slurry, and only 400 g of IPA was used. Table 1 shows the characteristics of the obtained silicon oxide-coated soft magnetic powder. Note that Fe and Ni constituting the soft magnetic powder as M were detected by XPS measurement. The thickness of the silicon oxide-coated soft magnetic layer of the silicon oxide-coated soft magnetic powder obtained in this comparative example is 2 nm as in Example 1, but the coverage is 58%, and the volume of the green compact The resistivity was inferior compared to those of the examples of the present invention.

- a silicon oxide-coated soft magnetic powder was obtained by the same procedure as in Comparative Example 3 except that the amount of TEOS added to the slurry was changed to 55.4 g (equivalent to a SiO 2 film thickness of 30 nm).

- the film thickness, coverage, and water content of the silicon oxide coating layer calculated for the obtained silicon oxide-coated soft magnetic powder, as well as the particle size distribution, powder density, and volume of the powder compact of the silicon oxide-coated soft magnetic powder.

- the resistivity measurement results are also shown in Table 1. Note that Fe and Ni constituting the soft magnetic powder as M were detected by XPS measurement.

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Materials Engineering (AREA)

- Mechanical Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Dispersion Chemistry (AREA)

- Power Engineering (AREA)

- Physics & Mathematics (AREA)

- Inorganic Chemistry (AREA)

- Thermal Sciences (AREA)

- General Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Electromagnetism (AREA)

- Ceramic Engineering (AREA)

- Soft Magnetic Materials (AREA)

- Powder Metallurgy (AREA)

Priority Applications (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| KR1020207027093A KR102554525B1 (ko) | 2018-02-20 | 2019-02-15 | 실리콘 산화물 피복 연자성 분말 및 이의 제조방법 |

| DE112019000893.5T DE112019000893T5 (de) | 2018-02-20 | 2019-02-15 | Mit siliciumoxid beschichtetes weichmagnetisches pulver und herstellungsverfahren dafür |

| CN201980011187.6A CN111683768B (zh) | 2018-02-20 | 2019-02-15 | 硅氧化物被覆软磁性粉末及其制造方法 |

| US16/963,602 US20210060642A1 (en) | 2018-02-20 | 2019-02-15 | Silicon oxide-coated soft magnetic powder and method for producing same |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2018027545 | 2018-02-20 | ||

| JP2018-027545 | 2018-02-20 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2019163650A1 true WO2019163650A1 (ja) | 2019-08-29 |

Family

ID=67688435

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2019/005474 Ceased WO2019163650A1 (ja) | 2018-02-20 | 2019-02-15 | シリコン酸化物被覆軟磁性粉末およびその製造方法 |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US20210060642A1 (enExample) |

| JP (1) | JP6719607B2 (enExample) |

| KR (1) | KR102554525B1 (enExample) |

| CN (1) | CN111683768B (enExample) |

| DE (1) | DE112019000893T5 (enExample) |

| TW (1) | TWI781291B (enExample) |

| WO (1) | WO2019163650A1 (enExample) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN111060545A (zh) * | 2019-10-24 | 2020-04-24 | 兰溪致德新能源材料有限公司 | 锂离子电池活性物质包覆完整度的检测方法 |

| CN114365242A (zh) * | 2019-08-30 | 2022-04-15 | 同和电子科技有限公司 | 硅氧化物被覆Fe系软磁性粉末及其制造方法 |

| CN114728334A (zh) * | 2019-11-27 | 2022-07-08 | 同和电子科技有限公司 | 硅氧化物被覆软磁性粉末及制造方法 |

Families Citing this family (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2021060479A1 (ja) * | 2019-09-26 | 2021-04-01 | Tdk株式会社 | 軟磁性金属粉末、軟磁性金属焼成体、およびコイル型電子部品 |

| JP7447563B2 (ja) | 2020-03-09 | 2024-03-12 | 味の素株式会社 | 樹脂組成物 |

| JP7781405B2 (ja) * | 2020-03-27 | 2025-12-08 | 株式会社フロアエージェント | コンクリート床面の施工方法 |

| JP7599833B2 (ja) * | 2020-03-30 | 2024-12-16 | 味の素株式会社 | 磁性組成物 |

| JP7742238B2 (ja) * | 2020-04-24 | 2025-09-19 | 三井金属鉱業株式会社 | 金属粒子の製造方法 |

| CN113096906B (zh) * | 2021-03-24 | 2022-11-18 | 华南理工大学 | 具有双包覆层的FeSiCr合金磁粉及其制备方法、磁粉芯及其制备方法 |

| CN113066629B (zh) * | 2021-03-26 | 2024-08-30 | 福建尚辉润德新材料科技有限公司 | 一种金属软磁复合材料的绝缘包覆方法、金属软磁复合材料 |

| CN113223843B (zh) * | 2021-04-25 | 2022-12-20 | 宁波中科毕普拉斯新材料科技有限公司 | 一种复合软磁粉末的绝缘包覆方法 |

| JP2023118231A (ja) * | 2022-02-15 | 2023-08-25 | セイコーエプソン株式会社 | 磁性ビーズ、磁性ビーズ分散液、磁性ビーズの製造方法、及び磁性ビーズ分散液の製造方法 |

| WO2024251579A1 (en) | 2023-06-05 | 2024-12-12 | Basf Se | Improved temperature-stable soft-magnetic powder |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2005286315A (ja) * | 2004-03-01 | 2005-10-13 | Showa Denko Kk | シリカ被覆した希土類系磁性粉末およびその製造方法並びにその用途 |

| JP2009041101A (ja) * | 2007-03-28 | 2009-02-26 | Hitachi Chem Co Ltd | 絶縁膜被覆粉体及びその製造方法 |

| JP2009164401A (ja) * | 2008-01-08 | 2009-07-23 | Fuji Electric Device Technology Co Ltd | 圧粉磁心の製造方法 |

| WO2015067608A1 (en) * | 2013-11-06 | 2015-05-14 | Basf Se | Temperature-stable soft-magnetic powder |

| JP2015126047A (ja) * | 2013-12-26 | 2015-07-06 | 日立金属株式会社 | 圧粉磁心、それを用いたコイル部品および圧粉磁心の製造方法 |

| WO2016132696A1 (ja) * | 2015-02-16 | 2016-08-25 | 株式会社 東芝 | 圧粉磁心とその製造方法、およびそれを用いた磁性部品 |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2007013436A1 (ja) | 2005-07-26 | 2007-02-01 | Sony Chemical & Information Device Corporation | 軟磁性材料 |

| JP5263654B2 (ja) | 2008-03-21 | 2013-08-14 | 日立金属株式会社 | 圧粉磁心用軟磁性粉末のシリカ被覆形成方法および圧粉磁心の製造方法 |

| WO2014013896A1 (ja) | 2012-07-20 | 2014-01-23 | 株式会社村田製作所 | 積層コイル部品の製造方法 |

| JP6651082B2 (ja) * | 2015-07-31 | 2020-02-19 | Jfeスチール株式会社 | 軟磁性圧粉磁芯の製造方法 |

| JP2017152609A (ja) | 2016-02-26 | 2017-08-31 | トヨタ自動車株式会社 | 磁性体 |

-

2019

- 2019-02-15 KR KR1020207027093A patent/KR102554525B1/ko active Active

- 2019-02-15 DE DE112019000893.5T patent/DE112019000893T5/de active Pending

- 2019-02-15 US US16/963,602 patent/US20210060642A1/en not_active Abandoned

- 2019-02-15 WO PCT/JP2019/005474 patent/WO2019163650A1/ja not_active Ceased

- 2019-02-15 CN CN201980011187.6A patent/CN111683768B/zh active Active

- 2019-02-15 JP JP2019025026A patent/JP6719607B2/ja active Active

- 2019-02-19 TW TW108105452A patent/TWI781291B/zh active

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2005286315A (ja) * | 2004-03-01 | 2005-10-13 | Showa Denko Kk | シリカ被覆した希土類系磁性粉末およびその製造方法並びにその用途 |

| JP2009041101A (ja) * | 2007-03-28 | 2009-02-26 | Hitachi Chem Co Ltd | 絶縁膜被覆粉体及びその製造方法 |

| JP2009164401A (ja) * | 2008-01-08 | 2009-07-23 | Fuji Electric Device Technology Co Ltd | 圧粉磁心の製造方法 |

| WO2015067608A1 (en) * | 2013-11-06 | 2015-05-14 | Basf Se | Temperature-stable soft-magnetic powder |

| JP2015126047A (ja) * | 2013-12-26 | 2015-07-06 | 日立金属株式会社 | 圧粉磁心、それを用いたコイル部品および圧粉磁心の製造方法 |

| WO2016132696A1 (ja) * | 2015-02-16 | 2016-08-25 | 株式会社 東芝 | 圧粉磁心とその製造方法、およびそれを用いた磁性部品 |

Cited By (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN114365242A (zh) * | 2019-08-30 | 2022-04-15 | 同和电子科技有限公司 | 硅氧化物被覆Fe系软磁性粉末及其制造方法 |

| CN111060545A (zh) * | 2019-10-24 | 2020-04-24 | 兰溪致德新能源材料有限公司 | 锂离子电池活性物质包覆完整度的检测方法 |

| CN111060545B (zh) * | 2019-10-24 | 2022-09-06 | 兰溪致德新能源材料有限公司 | 锂离子电池活性物质包覆完整度的检测方法 |

| CN114728334A (zh) * | 2019-11-27 | 2022-07-08 | 同和电子科技有限公司 | 硅氧化物被覆软磁性粉末及制造方法 |

| CN114728334B (zh) * | 2019-11-27 | 2024-06-11 | 同和电子科技有限公司 | 硅氧化物被覆软磁性粉末及制造方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| JP2019143241A (ja) | 2019-08-29 |

| DE112019000893T5 (de) | 2020-11-05 |

| TW201937516A (zh) | 2019-09-16 |

| JP6719607B2 (ja) | 2020-07-08 |

| KR102554525B1 (ko) | 2023-07-13 |

| CN111683768A (zh) | 2020-09-18 |

| US20210060642A1 (en) | 2021-03-04 |

| TWI781291B (zh) | 2022-10-21 |

| KR20200121867A (ko) | 2020-10-26 |

| CN111683768B (zh) | 2023-04-18 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6719607B2 (ja) | シリコン酸化物被覆軟磁性粉末およびその製造方法 | |

| CN114728334B (zh) | 硅氧化物被覆软磁性粉末及制造方法 | |

| JP6436172B2 (ja) | 軟磁性材料粉末及びその製造方法、並びに、磁心及びその製造方法 | |

| KR102832990B1 (ko) | 실리콘 산화물 피복 Fe계 연자성 분말 및 이의 제조 방법 | |

| JP7542714B2 (ja) | シリコン酸化物被覆軟磁性粉末 | |

| JP6443269B2 (ja) | 磁心及びその製造方法 | |

| JP7201417B2 (ja) | シリコン酸化物被覆鉄粉およびその製造方法並びにそれを用いたインダクタ用成形体およびインダクタ | |

| JP7441113B2 (ja) | 圧粉磁心 | |

| KR102376001B1 (ko) | 실리콘 산화물 피복 철분 및 이의 제조 방법 및 이를 사용한 인덕터용 성형체 및 인덕터 | |

| WO2025142346A1 (ja) | シリコン酸化物被覆軟磁性粉末およびシリコン酸化物被覆軟磁性粉末の製造方法 | |

| JP4803353B2 (ja) | 軟磁性材料及びその製造法、該軟磁性材料を含む圧粉磁心 | |

| JP4969556B2 (ja) | 高磁束密度圧粉磁心 | |

| JP2015115482A (ja) | 軟磁性金属微粒子および磁性体複合材料 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 19757954 Country of ref document: EP Kind code of ref document: A1 |

|

| ENP | Entry into the national phase |

Ref document number: 20207027093 Country of ref document: KR Kind code of ref document: A |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 19757954 Country of ref document: EP Kind code of ref document: A1 |