WO2018179725A1 - 穀物香が低減された麦芽飲料 - Google Patents

穀物香が低減された麦芽飲料 Download PDFInfo

- Publication number

- WO2018179725A1 WO2018179725A1 PCT/JP2018/001865 JP2018001865W WO2018179725A1 WO 2018179725 A1 WO2018179725 A1 WO 2018179725A1 JP 2018001865 W JP2018001865 W JP 2018001865W WO 2018179725 A1 WO2018179725 A1 WO 2018179725A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- malt

- malt beverage

- concentration

- ppb

- beer

- Prior art date

Links

- 235000021577 malt beverage Nutrition 0.000 title claims abstract description 81

- 239000000796 flavoring agent Substances 0.000 claims abstract description 18

- 235000019634 flavors Nutrition 0.000 claims abstract description 18

- QMAYBMKBYCGXDH-UHFFFAOYSA-N alpha-amorphene Natural products C1CC(C)=CC2C(C(C)C)CC=C(C)C21 QMAYBMKBYCGXDH-UHFFFAOYSA-N 0.000 claims abstract description 7

- 235000013339 cereals Nutrition 0.000 claims description 37

- GXCLVBGFBYZDAG-UHFFFAOYSA-N N-[2-(1H-indol-3-yl)ethyl]-N-methylprop-2-en-1-amine Chemical compound CN(CCC1=CNC2=C1C=CC=C2)CC=C GXCLVBGFBYZDAG-UHFFFAOYSA-N 0.000 claims description 36

- 235000008694 Humulus lupulus Nutrition 0.000 claims description 26

- 239000002994 raw material Substances 0.000 claims description 24

- 238000000034 method Methods 0.000 claims description 18

- 235000019658 bitter taste Nutrition 0.000 claims description 16

- XUEHVOLRMXNRKQ-KHMAMNHCSA-N alpha-cubebene Chemical compound CC(C)[C@@H]([C@H]12)CC[C@@H](C)[C@]32[C@@H]1C(C)=CC3 XUEHVOLRMXNRKQ-KHMAMNHCSA-N 0.000 claims description 12

- 229930004725 sesquiterpene Natural products 0.000 claims description 11

- 150000004354 sesquiterpene derivatives Chemical class 0.000 claims description 11

- -1 α-cubalben Chemical compound 0.000 claims description 6

- QMAYBMKBYCGXDH-KFWWJZLASA-N (1r,4as,8ar)-4,7-dimethyl-1-propan-2-yl-1,2,4a,5,6,8a-hexahydronaphthalene Chemical compound C1CC(C)=C[C@H]2[C@@H](C(C)C)CC=C(C)[C@H]21 QMAYBMKBYCGXDH-KFWWJZLASA-N 0.000 claims description 3

- 239000001490 (3R)-3,7-dimethylocta-1,6-dien-3-ol Substances 0.000 claims description 3

- 230000035807 sensation Effects 0.000 claims description 3

- 235000019615 sensations Nutrition 0.000 claims description 3

- 230000035597 cooling sensation Effects 0.000 claims 1

- FUCYIEXQVQJBKY-ZFWWWQNUSA-N (+)-δ-Cadinene Chemical compound C1CC(C)=C[C@H]2[C@H](C(C)C)CCC(C)=C21 FUCYIEXQVQJBKY-ZFWWWQNUSA-N 0.000 abstract description 4

- YOCDGWMCBBMMGJ-UHFFFAOYSA-N delta-cadinene Natural products C1C=C(C)CC2C(C(C)C)CCC(=C)C21 YOCDGWMCBBMMGJ-UHFFFAOYSA-N 0.000 abstract description 4

- USDOQCCMRDNVAH-UHFFFAOYSA-N sigma-cadinene Natural products C1C=C(C)CC2C(C(C)C)CC=C(C)C21 USDOQCCMRDNVAH-UHFFFAOYSA-N 0.000 abstract description 4

- 235000013405 beer Nutrition 0.000 description 26

- 238000009835 boiling Methods 0.000 description 14

- LFQSCWFLJHTTHZ-UHFFFAOYSA-N Ethanol Chemical compound CCO LFQSCWFLJHTTHZ-UHFFFAOYSA-N 0.000 description 13

- 238000000855 fermentation Methods 0.000 description 11

- 230000004151 fermentation Effects 0.000 description 11

- 108090000790 Enzymes Proteins 0.000 description 10

- 102000004190 Enzymes Human genes 0.000 description 10

- 235000013361 beverage Nutrition 0.000 description 10

- 229940088598 enzyme Drugs 0.000 description 10

- 239000007788 liquid Substances 0.000 description 10

- VLKZOEOYAKHREP-UHFFFAOYSA-N n-Hexane Chemical compound CCCCCC VLKZOEOYAKHREP-UHFFFAOYSA-N 0.000 description 9

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 9

- 238000004519 manufacturing process Methods 0.000 description 8

- 238000011156 evaluation Methods 0.000 description 7

- 239000000047 product Substances 0.000 description 7

- 240000004808 Saccharomyces cerevisiae Species 0.000 description 6

- 238000001914 filtration Methods 0.000 description 5

- 239000000463 material Substances 0.000 description 5

- 239000000203 mixture Substances 0.000 description 5

- 239000000126 substance Substances 0.000 description 5

- 229920002472 Starch Polymers 0.000 description 4

- 239000000284 extract Substances 0.000 description 4

- 238000002156 mixing Methods 0.000 description 4

- 235000019698 starch Nutrition 0.000 description 4

- 239000008107 starch Substances 0.000 description 4

- 235000019640 taste Nutrition 0.000 description 4

- ZEKCQHIPQALHSP-UHFFFAOYSA-N 1-(2,3-dihydro-1h-pyrrol-5-yl)ethanone Chemical compound CC(=O)C1=CCCN1 ZEKCQHIPQALHSP-UHFFFAOYSA-N 0.000 description 3

- CURLTUGMZLYLDI-UHFFFAOYSA-N Carbon dioxide Chemical compound O=C=O CURLTUGMZLYLDI-UHFFFAOYSA-N 0.000 description 3

- HEMHJVSKTPXQMS-UHFFFAOYSA-M Sodium hydroxide Chemical compound [OH-].[Na+] HEMHJVSKTPXQMS-UHFFFAOYSA-M 0.000 description 3

- 230000035622 drinking Effects 0.000 description 3

- 239000003205 fragrance Substances 0.000 description 3

- 229910017464 nitrogen compound Inorganic materials 0.000 description 3

- 150000002830 nitrogen compounds Chemical class 0.000 description 3

- 102000004169 proteins and genes Human genes 0.000 description 3

- 108090000623 proteins and genes Proteins 0.000 description 3

- 230000001953 sensory effect Effects 0.000 description 3

- 235000019583 umami taste Nutrition 0.000 description 3

- BSAIUMLZVGUGKX-BQYQJAHWSA-N (E)-non-2-enal Chemical compound CCCCCC\C=C\C=O BSAIUMLZVGUGKX-BQYQJAHWSA-N 0.000 description 2

- 240000005979 Hordeum vulgare Species 0.000 description 2

- 235000007340 Hordeum vulgare Nutrition 0.000 description 2

- 101000858051 Neurospora crassa (strain ATCC 24698 / 74-OR23-1A / CBS 708.71 / DSM 1257 / FGSC 987) Adenylate cyclase Proteins 0.000 description 2

- 240000008042 Zea mays Species 0.000 description 2

- 235000005824 Zea mays ssp. parviglumis Nutrition 0.000 description 2

- 235000002017 Zea mays subsp mays Nutrition 0.000 description 2

- 230000032683 aging Effects 0.000 description 2

- 235000013334 alcoholic beverage Nutrition 0.000 description 2

- 238000007796 conventional method Methods 0.000 description 2

- 238000001816 cooling Methods 0.000 description 2

- 235000005822 corn Nutrition 0.000 description 2

- 238000000605 extraction Methods 0.000 description 2

- 238000010438 heat treatment Methods 0.000 description 2

- 235000008216 herbs Nutrition 0.000 description 2

- 239000002244 precipitate Substances 0.000 description 2

- 235000013599 spices Nutrition 0.000 description 2

- OWEGMIWEEQEYGQ-UHFFFAOYSA-N 100676-05-9 Natural products OC1C(O)C(O)C(CO)OC1OCC1C(O)C(O)C(O)C(OC2C(OC(O)C(O)C2O)CO)O1 OWEGMIWEEQEYGQ-UHFFFAOYSA-N 0.000 description 1

- DBTMGCOVALSLOR-UHFFFAOYSA-N 32-alpha-galactosyl-3-alpha-galactosyl-galactose Natural products OC1C(O)C(O)C(CO)OC1OC1C(O)C(OC2C(C(CO)OC(O)C2O)O)OC(CO)C1O DBTMGCOVALSLOR-UHFFFAOYSA-N 0.000 description 1

- 229920002261 Corn starch Polymers 0.000 description 1

- RXVWSYJTUUKTEA-UHFFFAOYSA-N D-maltotriose Natural products OC1C(O)C(OC(C(O)CO)C(O)C(O)C=O)OC(CO)C1OC1C(O)C(O)C(O)C(CO)O1 RXVWSYJTUUKTEA-UHFFFAOYSA-N 0.000 description 1

- 108010073178 Glucan 1,4-alpha-Glucosidase Proteins 0.000 description 1

- 102100022624 Glucoamylase Human genes 0.000 description 1

- WQZGKKKJIJFFOK-GASJEMHNSA-N Glucose Natural products OC[C@H]1OC(O)[C@H](O)[C@@H](O)[C@@H]1O WQZGKKKJIJFFOK-GASJEMHNSA-N 0.000 description 1

- GUBGYTABKSRVRQ-PICCSMPSSA-N Maltose Natural products O[C@@H]1[C@@H](O)[C@H](O)[C@@H](CO)O[C@@H]1O[C@@H]1[C@@H](CO)OC(O)[C@H](O)[C@H]1O GUBGYTABKSRVRQ-PICCSMPSSA-N 0.000 description 1

- 240000007594 Oryza sativa Species 0.000 description 1

- 235000007164 Oryza sativa Nutrition 0.000 description 1

- 108091005804 Peptidases Proteins 0.000 description 1

- 239000004365 Protease Substances 0.000 description 1

- 102100037486 Reverse transcriptase/ribonuclease H Human genes 0.000 description 1

- 240000000111 Saccharum officinarum Species 0.000 description 1

- 235000007201 Saccharum officinarum Nutrition 0.000 description 1

- 241000209140 Triticum Species 0.000 description 1

- 235000021307 Triticum Nutrition 0.000 description 1

- 239000002253 acid Substances 0.000 description 1

- 230000002411 adverse Effects 0.000 description 1

- 230000001476 alcoholic effect Effects 0.000 description 1

- 102000004139 alpha-Amylases Human genes 0.000 description 1

- 108090000637 alpha-Amylases Proteins 0.000 description 1

- 229940024171 alpha-amylase Drugs 0.000 description 1

- 235000020054 awamori Nutrition 0.000 description 1

- WQZGKKKJIJFFOK-VFUOTHLCSA-N beta-D-glucose Chemical compound OC[C@H]1O[C@@H](O)[C@H](O)[C@@H](O)[C@@H]1O WQZGKKKJIJFFOK-VFUOTHLCSA-N 0.000 description 1

- GUBGYTABKSRVRQ-QUYVBRFLSA-N beta-maltose Chemical compound OC[C@H]1O[C@H](O[C@H]2[C@H](O)[C@@H](O)[C@H](O)O[C@@H]2CO)[C@H](O)[C@@H](O)[C@@H]1O GUBGYTABKSRVRQ-QUYVBRFLSA-N 0.000 description 1

- 235000013532 brandy Nutrition 0.000 description 1

- 150000001720 carbohydrates Chemical class 0.000 description 1

- 239000001569 carbon dioxide Substances 0.000 description 1

- 229910002092 carbon dioxide Inorganic materials 0.000 description 1

- 238000005119 centrifugation Methods 0.000 description 1

- 239000003795 chemical substances by application Substances 0.000 description 1

- WTEVQBCEXWBHNA-UHFFFAOYSA-N citral Chemical compound CC(C)=CCCC(C)=CC=O WTEVQBCEXWBHNA-UHFFFAOYSA-N 0.000 description 1

- 229940043350 citral Drugs 0.000 description 1

- WTEVQBCEXWBHNA-JXMROGBWSA-N citral A Natural products CC(C)=CCC\C(C)=C\C=O WTEVQBCEXWBHNA-JXMROGBWSA-N 0.000 description 1

- 150000001875 compounds Chemical class 0.000 description 1

- 235000009508 confectionery Nutrition 0.000 description 1

- 239000008120 corn starch Substances 0.000 description 1

- 238000000354 decomposition reaction Methods 0.000 description 1

- 230000002950 deficient Effects 0.000 description 1

- 230000006866 deterioration Effects 0.000 description 1

- 231100000676 disease causative agent Toxicity 0.000 description 1

- 239000003651 drinking water Substances 0.000 description 1

- 235000020188 drinking water Nutrition 0.000 description 1

- 235000013399 edible fruits Nutrition 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 235000019441 ethanol Nutrition 0.000 description 1

- 238000001704 evaporation Methods 0.000 description 1

- 230000008020 evaporation Effects 0.000 description 1

- 239000006260 foam Substances 0.000 description 1

- 235000013531 gin Nutrition 0.000 description 1

- 239000008103 glucose Substances 0.000 description 1

- 230000001771 impaired effect Effects 0.000 description 1

- 239000004615 ingredient Substances 0.000 description 1

- 230000014759 maintenance of location Effects 0.000 description 1

- FYGDTMLNYKFZSV-UHFFFAOYSA-N mannotriose Natural products OC1C(O)C(O)C(CO)OC1OC1C(CO)OC(OC2C(OC(O)C(O)C2O)CO)C(O)C1O FYGDTMLNYKFZSV-UHFFFAOYSA-N 0.000 description 1

- 230000000813 microbial effect Effects 0.000 description 1

- 235000013379 molasses Nutrition 0.000 description 1

- 235000015097 nutrients Nutrition 0.000 description 1

- 230000003647 oxidation Effects 0.000 description 1

- 238000007254 oxidation reaction Methods 0.000 description 1

- 239000008188 pellet Substances 0.000 description 1

- 238000001556 precipitation Methods 0.000 description 1

- 235000009566 rice Nutrition 0.000 description 1

- 230000005070 ripening Effects 0.000 description 1

- 235000013533 rum Nutrition 0.000 description 1

- 235000020083 shōchū Nutrition 0.000 description 1

- 235000014214 soft drink Nutrition 0.000 description 1

- 235000015096 spirit Nutrition 0.000 description 1

- 238000004659 sterilization and disinfection Methods 0.000 description 1

- 235000013529 tequila Nutrition 0.000 description 1

- 235000019607 umami taste sensations Nutrition 0.000 description 1

- 235000013522 vodka Nutrition 0.000 description 1

- 235000015041 whisky Nutrition 0.000 description 1

- FYGDTMLNYKFZSV-BYLHFPJWSA-N β-1,4-galactotrioside Chemical compound O[C@@H]1[C@@H](O)[C@H](O)[C@@H](CO)O[C@H]1O[C@@H]1[C@H](CO)O[C@@H](O[C@@H]2[C@@H](O[C@@H](O)[C@H](O)[C@H]2O)CO)[C@H](O)[C@H]1O FYGDTMLNYKFZSV-BYLHFPJWSA-N 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C12—BIOCHEMISTRY; BEER; SPIRITS; WINE; VINEGAR; MICROBIOLOGY; ENZYMOLOGY; MUTATION OR GENETIC ENGINEERING

- C12C—BEER; PREPARATION OF BEER BY FERMENTATION; PREPARATION OF MALT FOR MAKING BEER; PREPARATION OF HOPS FOR MAKING BEER

- C12C5/00—Other raw materials for the preparation of beer

- C12C5/02—Additives for beer

-

- A—HUMAN NECESSITIES

- A23—FOODS OR FOODSTUFFS; TREATMENT THEREOF, NOT COVERED BY OTHER CLASSES

- A23L—FOODS, FOODSTUFFS, OR NON-ALCOHOLIC BEVERAGES, NOT COVERED BY SUBCLASSES A21D OR A23B-A23J; THEIR PREPARATION OR TREATMENT, e.g. COOKING, MODIFICATION OF NUTRITIVE QUALITIES, PHYSICAL TREATMENT; PRESERVATION OF FOODS OR FOODSTUFFS, IN GENERAL

- A23L2/00—Non-alcoholic beverages; Dry compositions or concentrates therefor; Their preparation

- A23L2/38—Other non-alcoholic beverages

- A23L2/382—Other non-alcoholic beverages fermented

-

- A—HUMAN NECESSITIES

- A23—FOODS OR FOODSTUFFS; TREATMENT THEREOF, NOT COVERED BY OTHER CLASSES

- A23L—FOODS, FOODSTUFFS, OR NON-ALCOHOLIC BEVERAGES, NOT COVERED BY SUBCLASSES A21D OR A23B-A23J; THEIR PREPARATION OR TREATMENT, e.g. COOKING, MODIFICATION OF NUTRITIVE QUALITIES, PHYSICAL TREATMENT; PRESERVATION OF FOODS OR FOODSTUFFS, IN GENERAL

- A23L2/00—Non-alcoholic beverages; Dry compositions or concentrates therefor; Their preparation

- A23L2/52—Adding ingredients

-

- A—HUMAN NECESSITIES

- A23—FOODS OR FOODSTUFFS; TREATMENT THEREOF, NOT COVERED BY OTHER CLASSES

- A23L—FOODS, FOODSTUFFS, OR NON-ALCOHOLIC BEVERAGES, NOT COVERED BY SUBCLASSES A21D OR A23B-A23J; THEIR PREPARATION OR TREATMENT, e.g. COOKING, MODIFICATION OF NUTRITIVE QUALITIES, PHYSICAL TREATMENT; PRESERVATION OF FOODS OR FOODSTUFFS, IN GENERAL

- A23L2/00—Non-alcoholic beverages; Dry compositions or concentrates therefor; Their preparation

- A23L2/52—Adding ingredients

- A23L2/56—Flavouring or bittering agents

-

- A—HUMAN NECESSITIES

- A23—FOODS OR FOODSTUFFS; TREATMENT THEREOF, NOT COVERED BY OTHER CLASSES

- A23L—FOODS, FOODSTUFFS, OR NON-ALCOHOLIC BEVERAGES, NOT COVERED BY SUBCLASSES A21D OR A23B-A23J; THEIR PREPARATION OR TREATMENT, e.g. COOKING, MODIFICATION OF NUTRITIVE QUALITIES, PHYSICAL TREATMENT; PRESERVATION OF FOODS OR FOODSTUFFS, IN GENERAL

- A23L27/00—Spices; Flavouring agents or condiments; Artificial sweetening agents; Table salts; Dietetic salt substitutes; Preparation or treatment thereof

- A23L27/84—Flavour masking or reducing agents

-

- C—CHEMISTRY; METALLURGY

- C12—BIOCHEMISTRY; BEER; SPIRITS; WINE; VINEGAR; MICROBIOLOGY; ENZYMOLOGY; MUTATION OR GENETIC ENGINEERING

- C12C—BEER; PREPARATION OF BEER BY FERMENTATION; PREPARATION OF MALT FOR MAKING BEER; PREPARATION OF HOPS FOR MAKING BEER

- C12C5/00—Other raw materials for the preparation of beer

- C12C5/02—Additives for beer

- C12C5/026—Beer flavouring preparations

-

- A—HUMAN NECESSITIES

- A23—FOODS OR FOODSTUFFS; TREATMENT THEREOF, NOT COVERED BY OTHER CLASSES

- A23V—INDEXING SCHEME RELATING TO FOODS, FOODSTUFFS OR NON-ALCOHOLIC BEVERAGES AND LACTIC OR PROPIONIC ACID BACTERIA USED IN FOODSTUFFS OR FOOD PREPARATION

- A23V2002/00—Food compositions, function of food ingredients or processes for food or foodstuffs

Definitions

- the present invention relates to malt beverages, and in particular to beer-like malt beverages.

- a malt beverage refers to a beverage produced using malt as a raw material.

- beverages obtained by fermenting malt-derived sugar liquid, beverages obtained by mixing malt-derived sugar liquid, and the like correspond to malt beverages.

- Specific examples of malt beverages include beer-like malt beverages.

- Beer refers to a beverage obtained by fermenting malt, hops and water as raw materials using yeast.

- a beer-like malt beverage refers to a malt beverage designed to have the same taste and aroma as beer.

- the beer-like malt beverage may be fermented or not fermented.

- Beverages containing beer and sparkling liquor and malt-derived sugar solution, hops, fragrances, carbon dioxide and the like are included in beer-like malt beverages. Beer-like malt beverages include so-called non-alcoholic beers that are substantially free of alcohol.

- Wort as a raw material for malt beverages is produced by crushing cereals containing malt, saccharifying starch by mixing and heating with auxiliary ingredients and water, adding hops to the resulting sugar solution and further boiling.

- the process of heating malt or the like with water is generally called saccharification, and the process of boiling the sugar solution is called wort boiling.

- the meaning of the word “wort” may include sugar liquid obtained after saccharification.

- Wort has a taste and grain flavor derived from malt and hops, and the higher the malt use ratio, the more the beer-like malt beverage is given a beer-like richness, a drinking response, and an aroma. On the other hand, if the scent of wort is excessive, the flavor of the beer-like malt beverage becomes heavier and the taste of the beer-like malt beverage is adversely affected.

- the cereal incense of malt beverages can be reduced by lowering the ratio of malt used as a source.

- the malt-derived nitrogen compound is deficient in wort, and the umami taste and richness of beer are also impaired.

- nitrogen compounds are also a nutrient source for yeast, the depletion thereof leads to unsatisfactory fermentation, and as a result, an unpleasant odor called unsatisfactory fermentation odor is imparted to beer.

- Patent Document 1 describes that a beer-like malt beverage having a reduced cereal aroma is produced by adjusting the pH at the time of boiling wort to a low value within a specific range.

- a process for adjusting the pH again to remove protein from the wort is required, which increases the work man-hours, the work amount, and the work time. The production cost of beverages is increased.

- Patent Document 2 describes that the flavor deterioration due to oxidation of a beer-taste beverage is suppressed by adding cuvé ball or ⁇ -casinene, which is a decomposition product thereof, to the beer-taste beverage.

- the oxidatively deteriorated flavor is different from the cereal flavor in that it is a flavor that does not exist at the beginning of the beverage.

- Patent Document 2 describes that trans-2-nonenal or citral can be cited as an example of the flavor-deteriorating substance of the beer-taste beverage, which is different from the causative agent of the malt beverage. To do.

- the present invention solves the above-mentioned conventional problems, and an object of the present invention is to provide a malt beverage that can be produced at a low cost while reducing the fragrance of grains while maintaining a rich feeling. .

- the present invention provides a malt beverage containing ⁇ -kadinene at a concentration of 3 to 10 ppb.

- the present invention provides a malt beverage containing cuvette balls at a concentration of 3 to 20 ppb.

- the present invention provides a malt beverage containing ⁇ -casinene at a concentration of 3 to 10 ppb and containing cube balls at a concentration of 3 to 20 ppb.

- the malt beverage is at least one selected from the group consisting of 4-epi-cubeball, ⁇ -cubeben, ⁇ -gambinal, ⁇ -cubeben, ⁇ -muololene, ⁇ -amorphene and ⁇ -muololene. And sesquiterpenes and derivatives thereof.

- any one of the sesquiterpenes and derivatives thereof has a peak area ratio of 0.2 to 3 measured using a GC / MS apparatus with D-linalool having a concentration of 6 ppb as an internal standard. Contained in an amount of 0.0.

- the malt beverage contains sesquiterpenes derived from Polaris hops and derivatives thereof.

- the malt beverage has a bitterness value of 10 ° EBC or more.

- the raw cereal in the malt beverage, contains 25% by weight or more of malt.

- the malt beverage is a beer-like fermented malt beverage.

- the present invention provides a method for reducing the cereal flavor of malt beverages, which comprises the step of containing ⁇ -casinene at a concentration of 3 to 10 ppb and containing cube balls at a concentration of 3 to 20 ppb.

- the method of reducing the grain aroma of the malt beverage further includes a step of adjusting the bitterness value to 10 ° EBC or more.

- the present invention provides a malt beverage for a cool sensation that contains ⁇ -casinene at a concentration of 3 to 10 ppb and contains cube balls at a concentration of 3 to 20 ppb.

- the said malt beverage for a cool sensation has a bitterness value of 10 degree EBC or more.

- a malt beverage that can be produced at a low cost while reducing the cereal aroma while maintaining a rich feeling.

- the malt beverage of the present invention has a flavor with an inconspicuous grain aroma and is particularly improved in ease of drinking and sharpness.

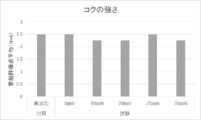

- 3 is a graph showing the relationship between the richness of beer and the concentration of ⁇ -kadinene.

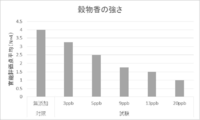

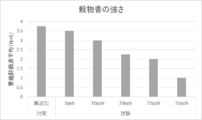

- 3 is a graph showing the relationship between the intensity of cereal flavor of beer and the concentration of ⁇ -kadinene.

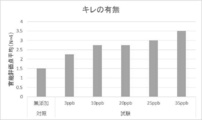

- 4 is a graph showing the relationship between the presence or absence of beer sharpness and the ⁇ -kadinene concentration. It is the graph which showed the relationship between the richness of beer, and a cue ball density

- the inventors of the present invention have found that the cereal aroma of the malt beverage can be reduced by adding a specific amount of ⁇ -casinene and cuvé ball to the malt beverage. Moreover, at that time, it has been found that the richness of the malt beverage is not substantially affected.

- Cube balls or ⁇ -casinene may be used alone or in admixture. Preferably, the cuvette ball and ⁇ -casinene are mixed and contained.

- the content of ⁇ -kadinene is adjusted in the range of 3 to 10 ppb.

- concentration of ⁇ -kadinene is less than 3 ppb, the grain aroma is conspicuous and the crispness is insufficient, and when it exceeds 10 ppb, the balance of flavor deteriorates.

- the content of ⁇ -casinene is preferably a concentration of 5 to 8 ppb.

- the content of the cuvé ball is adjusted within a range of 3 to 20 ppb.

- concentration of the cuvé ball is less than 3 ppb, the grain aroma is conspicuous and the crispness becomes insufficient, and when it exceeds 20 ppb, the balance of flavor deteriorates.

- the cuvé ball content is preferably 8 to 14 ppb.

- the concentration of ⁇ -kadinene or cuvé ball in the malt beverage can be measured using a GC / MS apparatus. Specifically, first, 10 mL of a test product is adjusted to pH 9 using sodium hydroxide, and then mixed with 40 mL of hexane to perform hexane extraction. Next, the hexane layer after extraction is concentrated to 1 mL by evaporation, and this concentrated solution is supplied to a GC / MS apparatus.

- ⁇ -casinene and cuvette ball there is no particular limitation on the method of adding ⁇ -casinene and cuvette ball to the malt beverage.

- ⁇ -Cadinene and cuve ball may be added by adding to the malt beverage, or may be included by adjusting the type and amount of the raw material.

- Examples of raw materials containing ⁇ -casinene and cuvé ball include Polaris hops.

- Hops are raw materials used in producing beer-like malt beverages for the purpose of imparting a bitter taste and refreshing fragrance, improving foam retention, and improving the microbial durability of beer.

- the form of adding hops as a raw material may be hop pellets or hop extracts.

- ⁇ -Cadinene and cue ball are contained in malt beverages when, for example, Polaris hops are used as raw materials.

- All or part of the normally used hops may be replaced with Polaris hops.

- Polaris hops are usually used in consideration of the content of ⁇ -casinene and cubebole and the flavor of the malt beverage. It is appropriately adjusted within the range of about 3% by weight or more of hops, preferably about 7 to 50% by weight, more preferably about 10 to 30% by weight.

- sesquiterpenes and derivatives thereof are contained in the malt beverage in addition to ⁇ -casinene and cubeball.

- Sesquiterpenes refer to a series of compounds having the chemical formula C 15 H 24 . Examples of such sesquiterpenes and derivatives thereof include 4-epi-cubeball, ⁇ -cubeben, ⁇ -gambinal, ⁇ -cubeben, ⁇ -muololene, ⁇ -amorphene and ⁇ -muololene.

- the malt beverage of the present invention preferably contains a component derived from Polaris hops, particularly at least one of the sesquiterpenes and derivatives thereof.

- the content of components derived from hops only needs to be a concentration generated in a malt beverage when Polaris hops are used when producing a malt beverage.

- the peak area ratio measured using a GC / MS apparatus with D-linalool at a concentration of 6 ppb as an internal standard is 0.2 to 3.0, preferably 0.5 to 2.5, more preferably 0.

- the amount is from 8 to 1.6.

- ⁇ -casinene and cuvé ball are included in the malt beverage to reduce the cereal flavor

- it can be included in an appropriate step in the production process of the malt beverage.

- it may be an arbitrary step such as a saccharification step of a raw material solution such as wort, during boiling of wort, a cooling step after boiling of wort, a fermentation step or an aging step.

- the production of the malt beverage of the present invention is carried out according to the methods and conditions usually used for producing beer or beer-like malt beverages, except that ⁇ -casinene and cuvette balls are included.

- a mash is prepared by adding malt crushed material, auxiliary materials such as barley, and warm water to a charging tank and mixing them. Miche can be prepared by a conventional method, for example, by holding at 35 to 60 ° C. for 20 to 90 minutes.

- enzyme components such as the saccharification enzyme and protease mentioned later, flavor components, such as spices and herbs, etc. other than the main raw material and an auxiliary

- Cereals used for saccharification include malt.

- the content of malt in the cereal subjected to saccharification is not particularly limited, but is 25% by weight or more, preferably 50% by weight or more, more preferably 67% by weight or more.

- the cereal subjected to saccharification may be 100% malt.

- the greater the content of malt in cereals the stronger the umami and richness of malt derived from the wort obtained.

- the higher the content of malt in cereals the higher the content of nitrogen compounds in the wort obtained, and it becomes difficult for fermentation irregularities to occur when wort is subjected to fermentation, resulting in an unpleasant odor. It becomes difficult.

- the malt contains 2-acetylpyrroline as an aroma component.

- the malt beverage of the present invention preferably has a high malt use ratio, and preferably contains 2-acetylpyrroline in a concentration of 0.2 ppb or more.

- the starch is gradually saccharified using an enzyme derived from malt or an enzyme added to the mash by gradually raising the temperature of the mash and holding it at a predetermined temperature for a certain period of time.

- the temperature and time during the saccharification treatment can be appropriately determined in consideration of the type of enzyme used, the amount of miche, the quality of the target malt alcoholic beverage, and the like, for example, 30 to 90 at 60 to 72 ° C. This can be done by holding for a minute.

- the mixture is kept at 76 to 78 ° C. for about 10 minutes, and then the mash is filtered in a wort filtration tank to obtain a transparent sugar solution.

- auxiliary materials mean raw materials other than malt and hops.

- auxiliary raw material examples include starch raw materials such as barley, wheat, corn starch, corn grits, rice and corn, and saccharide raw materials such as liquid sugar and sugar.

- the liquid sugar is produced by decomposing and saccharifying starchy substances with an acid or a saccharifying enzyme, and mainly contains glucose, maltose, maltotriose and the like.

- spices, herbs, fruits and the like used for the purpose of imparting or improving flavor are also included in the auxiliary materials.

- the above saccharifying enzyme means an enzyme that decomposes starch to produce sugar.

- Examples of the saccharifying enzyme include ⁇ -amylase, glucoamylase, and prunalase.

- Cereals used for saccharification include malt.

- the content of malt in cereals subjected to saccharification is not particularly limited, but is 5% by weight or more, preferably 50% by weight or more, more preferably 67% by weight or more.

- the cereal subjected to saccharification may be 100% malt. The greater the content of malt in cereals, the stronger the umami and richness of malt derived from the wort obtained.

- the operation of boiling the wort may be carried out according to the methods and conditions usually performed when producing beer.

- the sugar solution adjusted in pH is transferred to a boiling kettle and boiled. Hops are added during the whirlpool standing from the beginning of boiling of the sugar solution. You may use the hop extract or the component extracted from the hop as a hop.

- the sugar solution is then transferred to a precipitation tank called a whirlpool, where hop cakes and coagulated proteins produced by boiling are removed, and then cooled to an appropriate fermentation temperature with a plate cooler.

- a whirlpool a precipitation tank

- the obtained wort can be fermented and used as a raw material for producing an alcohol-containing beer-like fermented malt beverage, for example. What is necessary is just to perform fermentation of wort according to a conventional method. For example, yeast is inoculated into the cooled wort, transferred to a fermentation tank, and alcohol fermentation is performed. Furthermore, as a ripening step, the obtained fermentation broth is aged in a storage tank, stored under a low temperature condition of about 0 ° C., and stabilized. Then, as a filtration step, the yeast and protein are removed by filtering the fermented liquid after aging, and the target alcohol-containing beer-like fermented malt beverage is obtained.

- the method for producing a non-fermented beer-like malt beverage of the present invention includes the steps normally performed when producing a non-fermented beer-like malt beverage, except that ⁇ -casinene and cubeball are included in an appropriate step.

- a blend is first prepared by mixing a predetermined amount of a malt-derived material, a high molecular sugar, a sweet substance and other components.

- a predetermined amount of drinking water is added to the blend to prepare a primary raw material liquid. Hops are added and the primary raw material liquid is boiled, then cooled, alcohol is added, and carbonic acid is added by a carbonation process.

- Alcohol added is a source of alcohol, and for example, raw material alcohol, shochu, awamori, whiskey, brandy, vodka, rum, tequila, gin, spirits and the like can be used. From the viewpoint of cost, alcohol for raw materials is generally used.

- alcohol for raw material molasses obtained from sugarcane etc. is used as raw material, and alcohol fermented liquid is distilled to a ethanol concentration of about 95% with a continuous distiller. Adjusting and using is included.

- the precipitate can be separated and removed by filtration, centrifugation, etc. at each stage. Further, carbonated water may be added after the raw material liquid is prepared in a concentrated state. By using a normal soft drink manufacturing process, it is possible to easily prepare a non-fermented beer-like alcoholic beverage without having a fermentation facility.

- the malt beverage of the present invention has a certain bitter taste.

- the malt beverage of the present invention has a bitterness value of, for example, 10 ° EBC or more, preferably 18 ° EBC or more.

- the bitterness of malt beverages can be strengthened by means such as increasing the amount of hops used or adding a hop extract.

- Example 1 ⁇ -Cadinene addition test Commercial beer A was prepared. Divide this beer A into 6 parts, one not added for use as a control, and add ⁇ -kadinene to the remaining 5 to a concentration of 3, 5, 9, 13 and 20 ppb respectively. did.

- the blind beer was subjected to sensory evaluation by 4 well-trained panelists.

- As the evaluation performance the strength of the body, the strength of the grain aroma, and the presence or absence of sharpness were set.

- the evaluation criteria were set in five stages as follows. The scoring results by each panelist are shown in Table 1. In addition, the average values of the scoring results for each concentration are shown in FIGS.

- Example 3 Relationship between bitterness and cereal intensity (Manufacture of control products) 40 kg of pulverized malt was mixed with hot water, saccharified and filtered to obtain 160 L of wort. To this, 0.9 kg of Polaris seed hop was added and boiled for 60 minutes. After boiling, the mixture was cooled and a predetermined amount of yeast was added and fermented for 7 days. The fermented young beer was aged for 10 days, filtered after cooling.

- Evaluation performance set the intensity

- the evaluation criteria were set in five stages as follows. Table 3 shows the average score of each panelist.

- Example 3 From the results of Example 3, it is understood that in malt beverages using Polaris seed hops, malt beverages having a high bitterness value have a weaker grain aroma than low ones and increase the sharpness. In addition, it is understood that the higher the bitterness value, the stronger the cool feeling.

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Health & Medical Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- Food Science & Technology (AREA)

- Nutrition Science (AREA)

- Polymers & Plastics (AREA)

- Organic Chemistry (AREA)

- Bioinformatics & Cheminformatics (AREA)

- General Engineering & Computer Science (AREA)

- General Health & Medical Sciences (AREA)

- Genetics & Genomics (AREA)

- Biochemistry (AREA)

- Wood Science & Technology (AREA)

- Zoology (AREA)

- Distillation Of Fermentation Liquor, Processing Of Alcohols, Vinegar And Beer (AREA)

- Non-Alcoholic Beverages (AREA)

- Alcoholic Beverages (AREA)

Abstract

Description

δ-カジネンの添加試験

市販品のビールAを準備した。このビールAを6つに分割し、一つは対照として使用するために添加せず、残りの5つにδ-カジネンをその濃度がそれぞれ3、5、9、13及び20ppbとなるように添加した。

5:大変強い

4:強い

3:ある程度強い

2:やや弱い

1:弱い

5:大変強い

4:強い

3:ある程度強い

2:やや弱い

1:弱い

5:大変キレがある

4:キレがある

3:ある程度キレがある

2:ややキレがない

1:キレがない

キュベボールの添加試験

δ-カジネンの代わりにキュベボールをその濃度がそれぞれ3、10、20、25及び35ppbとなるように添加すること以外は実施例1と同様にしてビールを製造し、官能評価した。各パネリストによる採点結果を表2に示す。また、採点結果の濃度毎の平均値を図4~6に示す。

苦味価と穀物香強度との関係

(対照品の製造)

粉砕麦芽40kgを湯に混合し、糖化、濾過させて160Lの麦汁を得た。これに、ポラリス種ホップ0.9kgを添加し、60分煮沸した。煮沸後、冷却させて所定量の酵母を添加し、7日間発酵させた。発酵させた若ビールは10日間熟成させ、冷却後濾過した。

粉砕麦芽40kgを湯に混合し、糖化、濾過させて160Lの麦汁を得た。これに、ポラリス種ホップ0.9kgを添加し、60分煮沸した。煮沸後、冷却させて所定量の酵母を添加し、7日間発酵させた。発酵させた若ビールに対し、製品ビールの苦味価で10°EBC上昇するように、イソ化ホップエキスを添加した。その後、熟成・冷却し、濾過して製品ビールを得た。

5:大変強い

4:強い

3:ある程度強い

2:やや弱い

1:弱い

5:大変キレがある

4:キレがある

3:ある程度キレがある

2:ややキレがない

1:キレがない

5:大変冷涼感がある

4:冷涼感がある

3:ある程度冷涼感がある

2:やや冷涼感がない

1:冷涼感がない

Claims (13)

- δ-カジネンを3~10ppbの濃度で含有する麦芽飲料。

- キュベボールを3~20ppbの濃度で含有する麦芽飲料。

- δ-カジネンを3~10ppbの濃度で含有し、キュベボールを3~20ppbの濃度で含有する麦芽飲料。

- 4-エピ-キュベボール、α-キュベベン、α-カジノール、α-キュベベン、γ-ムウロレン、α-アモルフェン及びα-ムウロレンから成る群から選択される少なくとも一種のセスキテルペン類及びその誘導体をさらに含有する請求項1~3のいずれか一項に記載の麦芽飲料。

- 前記セスキテルペン類及びその誘導体のいずれか一種が、濃度6ppbのD-リナロールを内部標準とし、GC/MS装置を使用して測定されるピーク面積比が0.2~3.0になる量で含有される請求項4に記載の麦芽飲料。

- ポラリス種ホップ由来のセスキテルペン類及びその誘導体を含有する請求項1~5のいずれか一項に記載の麦芽飲料。

- 10°EBC以上の苦味価を有する請求項1~6のいずれか一項に記載の麦芽飲料。

- 原料である穀類が、25重量%以上の麦芽を含むものである請求項1~7のいずれか一項に記載の麦芽飲料。

- ビール様発酵麦芽飲料である請求項1~8のいずれか一項に記載の麦芽飲料。

- δ-カジネンを3~10ppbの濃度で含有させ、キュベボールを3~20ppbの濃度で含有させる工程を包含する麦芽飲料の穀物香を低減する方法。

- さらに、苦味価を10°EBC以上に調整する工程を包含する請求項10に記載の麦芽飲料の穀物香を低減する方法。

- δ-カジネンを3~10ppbの濃度で含有し、キュベボールを3~20ppbの濃度で含有する冷涼感体感用麦芽飲料。

- 10°EBC以上の苦味価を有する請求項12に記載の冷涼感体感用麦芽飲料。

Priority Applications (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US16/493,083 US11412763B2 (en) | 2017-03-31 | 2018-01-23 | Malt beverage having suppressed grain odor |

| KR1020197026179A KR102498654B1 (ko) | 2017-03-31 | 2018-01-23 | 곡물향이 저감된 맥아 음료 |

| AU2018245595A AU2018245595B2 (en) | 2017-03-31 | 2018-01-23 | Malt beverage having suppressed grain odor |

| EP18777892.3A EP3604491B1 (en) | 2017-03-31 | 2018-01-23 | Malt beverage having suppressed grain odor |

| CN201880021665.7A CN110475847B (zh) | 2017-03-31 | 2018-01-23 | 减少了谷物气味的麦芽饮料 |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2017071595A JP6910177B2 (ja) | 2017-03-31 | 2017-03-31 | 穀物香が低減された麦芽飲料 |

| JP2017-071595 | 2017-03-31 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2018179725A1 true WO2018179725A1 (ja) | 2018-10-04 |

Family

ID=63674618

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2018/001865 WO2018179725A1 (ja) | 2017-03-31 | 2018-01-23 | 穀物香が低減された麦芽飲料 |

Country Status (8)

| Country | Link |

|---|---|

| US (1) | US11412763B2 (ja) |

| EP (1) | EP3604491B1 (ja) |

| JP (2) | JP6910177B2 (ja) |

| KR (1) | KR102498654B1 (ja) |

| CN (1) | CN110475847B (ja) |

| AU (1) | AU2018245595B2 (ja) |

| TW (1) | TWI750331B (ja) |

| WO (1) | WO2018179725A1 (ja) |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP7522575B2 (ja) | 2020-03-27 | 2024-07-25 | サッポロビール株式会社 | 炭酸アルコール飲料、炭酸アルコール飲料の製造方法、及び、炭酸アルコール飲料の香味向上方法 |

Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2012029642A (ja) * | 2010-07-30 | 2012-02-16 | Kirin Brewery Co Ltd | みかん様の香りを伴ったフルーツ様の香気が付与されたビールテイスト飲料およびその製造方法 |

| JP2012029630A (ja) * | 2010-07-30 | 2012-02-16 | Kirin Brewery Co Ltd | パイナップル様のフルーツ香が付与されたビールテイスト飲料およびその製造方法 |

| JP2013511270A (ja) * | 2009-11-20 | 2013-04-04 | シムライズ アーゲー | 生理的冷感有効成分の使用およびそのような有効成分を含む薬剤 |

| JP2014033638A (ja) | 2012-08-08 | 2014-02-24 | Asahi Breweries Ltd | 穀物香が低減されたビール様麦芽飲料 |

| JP2014217347A (ja) | 2013-05-10 | 2014-11-20 | アサヒビール株式会社 | ビールテイスト飲料、ビールテイスト飲料の製造方法、及びビールテイスト飲料の香味劣化抑制方法 |

| JP2015536674A (ja) * | 2012-12-11 | 2015-12-24 | ディーエスエム アイピー アセッツ ビー.ブイ. | 安定な飲料の製造 |

| WO2016084976A1 (ja) * | 2014-11-28 | 2016-06-02 | 高砂香料工業株式会社 | 風味改善剤 |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH11276151A (ja) * | 1998-03-31 | 1999-10-12 | Suntory Ltd | ウイスキーの香味の改質方法 |

| WO2005042680A1 (en) | 2003-11-04 | 2005-05-12 | Firmenich Sa | Flavor ingredients for cooling preparations |

| SG172903A1 (en) | 2009-01-08 | 2011-08-29 | Kirin Brewery | Improvement in flavor of unfermented beer-flavored malt beverage |

| JP6490886B2 (ja) | 2013-09-03 | 2019-03-27 | アサヒビール株式会社 | 凍結乾燥ホップを原料に用いたビールテイスト飲料及びホップ香気の増強方法 |

| JP6280264B1 (ja) | 2016-08-12 | 2018-02-14 | アサヒビール株式会社 | 柑橘類果実様飲料及びその製造方法 |

| JP6491265B2 (ja) | 2017-06-06 | 2019-03-27 | アサヒビール株式会社 | ノンアルコールビールテイスト飲料、ノンアルコールビールテイスト飲料の製造方法、及びノンアルコールビールテイスト飲料の香味劣化抑制方法 |

-

2017

- 2017-03-31 JP JP2017071595A patent/JP6910177B2/ja active Active

-

2018

- 2018-01-23 AU AU2018245595A patent/AU2018245595B2/en active Active

- 2018-01-23 EP EP18777892.3A patent/EP3604491B1/en active Active

- 2018-01-23 CN CN201880021665.7A patent/CN110475847B/zh active Active

- 2018-01-23 KR KR1020197026179A patent/KR102498654B1/ko active IP Right Grant

- 2018-01-23 US US16/493,083 patent/US11412763B2/en active Active

- 2018-01-23 WO PCT/JP2018/001865 patent/WO2018179725A1/ja active Application Filing

- 2018-02-26 TW TW107106395A patent/TWI750331B/zh active

-

2021

- 2021-03-26 JP JP2021053591A patent/JP7181333B2/ja active Active

Patent Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2013511270A (ja) * | 2009-11-20 | 2013-04-04 | シムライズ アーゲー | 生理的冷感有効成分の使用およびそのような有効成分を含む薬剤 |

| JP2012029642A (ja) * | 2010-07-30 | 2012-02-16 | Kirin Brewery Co Ltd | みかん様の香りを伴ったフルーツ様の香気が付与されたビールテイスト飲料およびその製造方法 |

| JP2012029630A (ja) * | 2010-07-30 | 2012-02-16 | Kirin Brewery Co Ltd | パイナップル様のフルーツ香が付与されたビールテイスト飲料およびその製造方法 |

| JP2014033638A (ja) | 2012-08-08 | 2014-02-24 | Asahi Breweries Ltd | 穀物香が低減されたビール様麦芽飲料 |

| JP2015536674A (ja) * | 2012-12-11 | 2015-12-24 | ディーエスエム アイピー アセッツ ビー.ブイ. | 安定な飲料の製造 |

| JP2014217347A (ja) | 2013-05-10 | 2014-11-20 | アサヒビール株式会社 | ビールテイスト飲料、ビールテイスト飲料の製造方法、及びビールテイスト飲料の香味劣化抑制方法 |

| WO2016084976A1 (ja) * | 2014-11-28 | 2016-06-02 | 高砂香料工業株式会社 | 風味改善剤 |

Non-Patent Citations (3)

| Title |

|---|

| BISHOP, L. R.: "THE MEASUREMENT OF BITTERNESS IN BEERS", J. INST. BREW., vol. 70, no. 6, 1964, pages 489 - 497, XP055613154, ISSN: 2050-0416 * |

| BISHOP, L.R.: "EUROPEAN BREWERY CONVENTION THE E.B.C. SCALE OF BITTERNESS", J. INST. BREW., vol. 73, no. 6, November 1967 (1967-11-01) - December 1967 (1967-12-01), pages 525 - 527, XP055613155, ISSN: 2050-0416 * |

| POLARIS: "YACHIMA CHIEF HOPS", YACHIMACHIEF.COM, 21 December 2016 (2016-12-21), XP055613157, Retrieved from the Internet <URL:https://ychhops.com/varieties/polaris> [retrieved on 20180413] * |

Also Published As

| Publication number | Publication date |

|---|---|

| KR102498654B1 (ko) | 2023-02-09 |

| EP3604491B1 (en) | 2023-10-18 |

| TWI750331B (zh) | 2021-12-21 |

| EP3604491A4 (en) | 2021-01-27 |

| JP7181333B2 (ja) | 2022-11-30 |

| US11412763B2 (en) | 2022-08-16 |

| AU2018245595B2 (en) | 2022-06-16 |

| US20210186060A1 (en) | 2021-06-24 |

| CN110475847A (zh) | 2019-11-19 |

| KR20190129855A (ko) | 2019-11-20 |

| EP3604491A1 (en) | 2020-02-05 |

| EP3604491C0 (en) | 2023-10-18 |

| JP2018171004A (ja) | 2018-11-08 |

| TW201842179A (zh) | 2018-12-01 |

| JP6910177B2 (ja) | 2021-07-28 |

| AU2018245595A1 (en) | 2019-10-17 |

| JP2021100431A (ja) | 2021-07-08 |

| CN110475847B (zh) | 2023-07-18 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6802384B2 (ja) | 非甘味性飲料 | |

| TWI508668B (zh) | 非醱酵啤酒口味飲料及其製造方法 | |

| WO2011162118A1 (ja) | 麦芽飲料の製造方法 | |

| CN113811193A (zh) | 啤酒味饮料 | |

| JP2017046627A (ja) | 麦芽発酵飲料 | |

| CN113811595A (zh) | 啤酒味发酵麦芽饮料 | |

| JP2018086026A (ja) | ビール様アルコール飲料 | |

| JP2021136961A (ja) | ビール様飲料 | |

| JP5855579B2 (ja) | ピルビン酸含有量の高いビール様発泡性発酵飲料の製造方法 | |

| WO2021070930A1 (ja) | ビールテイスト発酵麦芽飲料 | |

| JP7181333B2 (ja) | 穀物香が低減された麦芽飲料 | |

| JP6997532B2 (ja) | ビール様発泡性飲料の製造方法、及びビール様発泡性飲料のキレを向上させる方法 | |

| WO2023276444A1 (ja) | 低アルコールビールテイスト飲料 | |

| JP6948835B2 (ja) | 麦芽飲料及びその製造方法 | |

| JP2007110910A (ja) | 発泡性飲料の製造方法と該方法により製造された発泡性飲料 | |

| JP7320918B2 (ja) | ビール様発酵麦芽飲料 | |

| RU2816894C2 (ru) | Напиток со вкусом пива | |

| JP7557178B1 (ja) | 低アルコールビール様飲料および低アルコールビール様飲料の製造方法 | |

| JP6867215B2 (ja) | 酸化劣化臭、老化臭及び老化味が減感された麦芽飲料 | |

| JP2024043250A (ja) | 低アルコールビールテイスト飲料及びその製造方法 | |

| JP2016093163A (ja) | コク感が増強された麦芽発酵飲料 | |

| JP2023042249A (ja) | ビール様発酵麦芽飲料 | |

| JP2024008051A (ja) | ビールテイスト飲料 | |

| JP2024114552A (ja) | ビール様飲料及びその製造方法 | |

| JP2019080579A (ja) | ノンアルコールビールテイスト飲料、ノンアルコールビールテイスト飲料の製造方法、及びノンアルコールビールテイスト飲料の香味劣化抑制方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 18777892 Country of ref document: EP Kind code of ref document: A1 |

|

| ENP | Entry into the national phase |

Ref document number: 20197026179 Country of ref document: KR Kind code of ref document: A |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| ENP | Entry into the national phase |

Ref document number: 2018245595 Country of ref document: AU Date of ref document: 20180123 Kind code of ref document: A |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 2018777892 Country of ref document: EP |

|

| ENP | Entry into the national phase |

Ref document number: 2018777892 Country of ref document: EP Effective date: 20191031 |