WO2017098796A1 - 冷凍サイクル装置 - Google Patents

冷凍サイクル装置 Download PDFInfo

- Publication number

- WO2017098796A1 WO2017098796A1 PCT/JP2016/079724 JP2016079724W WO2017098796A1 WO 2017098796 A1 WO2017098796 A1 WO 2017098796A1 JP 2016079724 W JP2016079724 W JP 2016079724W WO 2017098796 A1 WO2017098796 A1 WO 2017098796A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- heat exchanger

- heat medium

- cooling water

- heat

- air

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B25/00—Machines, plants or systems, using a combination of modes of operation covered by two or more of the groups F25B1/00 - F25B23/00

- F25B25/005—Machines, plants or systems, using a combination of modes of operation covered by two or more of the groups F25B1/00 - F25B23/00 using primary and secondary systems

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60H—ARRANGEMENTS OF HEATING, COOLING, VENTILATING OR OTHER AIR-TREATING DEVICES SPECIALLY ADAPTED FOR PASSENGER OR GOODS SPACES OF VEHICLES

- B60H1/00—Heating, cooling or ventilating [HVAC] devices

- B60H1/32—Cooling devices

- B60H1/3204—Cooling devices using compression

- B60H1/3205—Control means therefor

- B60H1/321—Control means therefor for preventing the freezing of a heat exchanger

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60H—ARRANGEMENTS OF HEATING, COOLING, VENTILATING OR OTHER AIR-TREATING DEVICES SPECIALLY ADAPTED FOR PASSENGER OR GOODS SPACES OF VEHICLES

- B60H1/00—Heating, cooling or ventilating [HVAC] devices

- B60H1/00642—Control systems or circuits; Control members or indication devices for heating, cooling or ventilating devices

- B60H1/00735—Control systems or circuits characterised by their input, i.e. by the detection, measurement or calculation of particular conditions, e.g. signal treatment, dynamic models

- B60H1/00764—Control systems or circuits characterised by their input, i.e. by the detection, measurement or calculation of particular conditions, e.g. signal treatment, dynamic models the input being a vehicle driving condition, e.g. speed

- B60H1/00778—Control systems or circuits characterised by their input, i.e. by the detection, measurement or calculation of particular conditions, e.g. signal treatment, dynamic models the input being a vehicle driving condition, e.g. speed the input being a stationary vehicle position, e.g. parking or stopping

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60H—ARRANGEMENTS OF HEATING, COOLING, VENTILATING OR OTHER AIR-TREATING DEVICES SPECIALLY ADAPTED FOR PASSENGER OR GOODS SPACES OF VEHICLES

- B60H1/00—Heating, cooling or ventilating [HVAC] devices

- B60H1/00642—Control systems or circuits; Control members or indication devices for heating, cooling or ventilating devices

- B60H1/00814—Control systems or circuits characterised by their output, for controlling particular components of the heating, cooling or ventilating installation

- B60H1/00878—Control systems or circuits characterised by their output, for controlling particular components of the heating, cooling or ventilating installation the components being temperature regulating devices

- B60H1/00899—Controlling the flow of liquid in a heat pump system

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60H—ARRANGEMENTS OF HEATING, COOLING, VENTILATING OR OTHER AIR-TREATING DEVICES SPECIALLY ADAPTED FOR PASSENGER OR GOODS SPACES OF VEHICLES

- B60H1/00—Heating, cooling or ventilating [HVAC] devices

- B60H1/02—Heating, cooling or ventilating [HVAC] devices the heat being derived from the propulsion plant

- B60H1/04—Heating, cooling or ventilating [HVAC] devices the heat being derived from the propulsion plant from cooling liquid of the plant

- B60H1/08—Heating, cooling or ventilating [HVAC] devices the heat being derived from the propulsion plant from cooling liquid of the plant from other radiator than main radiator

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60H—ARRANGEMENTS OF HEATING, COOLING, VENTILATING OR OTHER AIR-TREATING DEVICES SPECIALLY ADAPTED FOR PASSENGER OR GOODS SPACES OF VEHICLES

- B60H1/00—Heating, cooling or ventilating [HVAC] devices

- B60H1/32—Cooling devices

- B60H1/3204—Cooling devices using compression

- B60H1/3228—Cooling devices using compression characterised by refrigerant circuit configurations

- B60H1/32284—Cooling devices using compression characterised by refrigerant circuit configurations comprising two or more secondary circuits, e.g. at evaporator and condenser side

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B49/00—Arrangement or mounting of control or safety devices

- F25B49/02—Arrangement or mounting of control or safety devices for compression type machines, plants or systems

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25D—REFRIGERATORS; COLD ROOMS; ICE-BOXES; COOLING OR FREEZING APPARATUS NOT OTHERWISE PROVIDED FOR

- F25D21/00—Defrosting; Preventing frosting; Removing condensed or defrost water

- F25D21/002—Defroster control

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25D—REFRIGERATORS; COLD ROOMS; ICE-BOXES; COOLING OR FREEZING APPARATUS NOT OTHERWISE PROVIDED FOR

- F25D21/00—Defrosting; Preventing frosting; Removing condensed or defrost water

- F25D21/06—Removing frost

- F25D21/12—Removing frost by hot-fluid circulating system separate from the refrigerant system

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60H—ARRANGEMENTS OF HEATING, COOLING, VENTILATING OR OTHER AIR-TREATING DEVICES SPECIALLY ADAPTED FOR PASSENGER OR GOODS SPACES OF VEHICLES

- B60H1/00—Heating, cooling or ventilating [HVAC] devices

- B60H1/00642—Control systems or circuits; Control members or indication devices for heating, cooling or ventilating devices

- B60H1/00814—Control systems or circuits characterised by their output, for controlling particular components of the heating, cooling or ventilating installation

- B60H1/00878—Control systems or circuits characterised by their output, for controlling particular components of the heating, cooling or ventilating installation the components being temperature regulating devices

- B60H2001/00928—Control systems or circuits characterised by their output, for controlling particular components of the heating, cooling or ventilating installation the components being temperature regulating devices comprising a secondary circuit

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60H—ARRANGEMENTS OF HEATING, COOLING, VENTILATING OR OTHER AIR-TREATING DEVICES SPECIALLY ADAPTED FOR PASSENGER OR GOODS SPACES OF VEHICLES

- B60H1/00—Heating, cooling or ventilating [HVAC] devices

- B60H1/00642—Control systems or circuits; Control members or indication devices for heating, cooling or ventilating devices

- B60H1/00814—Control systems or circuits characterised by their output, for controlling particular components of the heating, cooling or ventilating installation

- B60H1/00878—Control systems or circuits characterised by their output, for controlling particular components of the heating, cooling or ventilating installation the components being temperature regulating devices

- B60H2001/00949—Control systems or circuits characterised by their output, for controlling particular components of the heating, cooling or ventilating installation the components being temperature regulating devices comprising additional heating/cooling sources, e.g. second evaporator

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60H—ARRANGEMENTS OF HEATING, COOLING, VENTILATING OR OTHER AIR-TREATING DEVICES SPECIALLY ADAPTED FOR PASSENGER OR GOODS SPACES OF VEHICLES

- B60H1/00—Heating, cooling or ventilating [HVAC] devices

- B60H1/00642—Control systems or circuits; Control members or indication devices for heating, cooling or ventilating devices

- B60H1/00814—Control systems or circuits characterised by their output, for controlling particular components of the heating, cooling or ventilating installation

- B60H1/00878—Control systems or circuits characterised by their output, for controlling particular components of the heating, cooling or ventilating installation the components being temperature regulating devices

- B60H2001/00961—Control systems or circuits characterised by their output, for controlling particular components of the heating, cooling or ventilating installation the components being temperature regulating devices comprising means for defrosting outside heat exchangers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60H—ARRANGEMENTS OF HEATING, COOLING, VENTILATING OR OTHER AIR-TREATING DEVICES SPECIALLY ADAPTED FOR PASSENGER OR GOODS SPACES OF VEHICLES

- B60H1/00—Heating, cooling or ventilating [HVAC] devices

- B60H1/32—Cooling devices

- B60H2001/3236—Cooling devices information from a variable is obtained

- B60H2001/3255—Cooling devices information from a variable is obtained related to temperature

- B60H2001/3257—Cooling devices information from a variable is obtained related to temperature of the refrigerant at a compressing unit

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60H—ARRANGEMENTS OF HEATING, COOLING, VENTILATING OR OTHER AIR-TREATING DEVICES SPECIALLY ADAPTED FOR PASSENGER OR GOODS SPACES OF VEHICLES

- B60H1/00—Heating, cooling or ventilating [HVAC] devices

- B60H1/32—Cooling devices

- B60H2001/3236—Cooling devices information from a variable is obtained

- B60H2001/3255—Cooling devices information from a variable is obtained related to temperature

- B60H2001/326—Cooling devices information from a variable is obtained related to temperature of the refrigerant at a condensing unit

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B2309/00—Gas cycle refrigeration machines

- F25B2309/06—Compression machines, plants or systems characterised by the refrigerant being carbon dioxide

- F25B2309/061—Compression machines, plants or systems characterised by the refrigerant being carbon dioxide with cycle highest pressure above the supercritical pressure

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B2339/00—Details of evaporators; Details of condensers

- F25B2339/04—Details of condensers

- F25B2339/047—Water-cooled condensers

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B2700/00—Sensing or detecting of parameters; Sensors therefor

- F25B2700/19—Pressures

- F25B2700/193—Pressures of the compressor

- F25B2700/1931—Discharge pressures

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B2700/00—Sensing or detecting of parameters; Sensors therefor

- F25B2700/19—Pressures

- F25B2700/193—Pressures of the compressor

- F25B2700/1933—Suction pressures

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B2700/00—Sensing or detecting of parameters; Sensors therefor

- F25B2700/21—Temperatures

- F25B2700/2115—Temperatures of a compressor or the drive means therefor

- F25B2700/21151—Temperatures of a compressor or the drive means therefor at the suction side of the compressor

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B2700/00—Sensing or detecting of parameters; Sensors therefor

- F25B2700/21—Temperatures

- F25B2700/2115—Temperatures of a compressor or the drive means therefor

- F25B2700/21152—Temperatures of a compressor or the drive means therefor at the discharge side of the compressor

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B9/00—Compression machines, plants or systems, in which the refrigerant is air or other gas of low boiling point

- F25B9/002—Compression machines, plants or systems, in which the refrigerant is air or other gas of low boiling point characterised by the refrigerant

- F25B9/008—Compression machines, plants or systems, in which the refrigerant is air or other gas of low boiling point characterised by the refrigerant the refrigerant being carbon dioxide

Definitions

- the present disclosure relates to a refrigeration cycle apparatus.

- Patent Document 1 describes a refrigeration apparatus having a hot gas heating cycle.

- the hot gas heating cycle is a cycle in which the evaporator is heated using hot gas.

- Hot gas is a refrigerant compressed by a compressor.

- a defrost cycle is a defrost cycle which heats and melts the frost formed on the evaporator.

- This indication aims at providing the refrigerating cycle device which can perform defrosting, suppressing power consumption in view of the above-mentioned point.

- a refrigeration cycle apparatus includes a compressor that sucks and discharges a refrigerant, a high-pressure side heat exchanger that exchanges heat between a high-pressure refrigerant discharged from the compressor and a heat medium, and a high-pressure side.

- a decompression unit that decompresses the refrigerant heat-exchanged by the heat exchanger, a low-pressure side heat exchanger that exchanges heat between the low-pressure refrigerant decompressed by the decompression unit and the heat medium, and a heat medium that circulates through the low-pressure side heat exchanger

- a first pump that sucks and discharges

- a second pump that sucks and discharges the heat medium circulating in the high-pressure heat exchanger

- an in-vehicle device that circulates the heat medium and supplies heat to the heat medium

- a heat medium air heat exchanger that exchanges heat between the medium and air, and a state in which the heat medium circulates between the high-pressure side heat exchanger for each of the in-vehicle device and the heat medium air heat exchanger

- the low-pressure side A switching unit that switches between a state in which the heat medium circulates between the heat exchanger and the heat medium.

- the heat medium circulates between the low-pressure side heat exchanger and the vehicle-mounted device, and the high-pressure side heat exchanger and the heat medium air heat exchanger.

- a control unit that drives the compressor and controls the operation of the switching unit so as to be in a defrosting mode in which the heat medium circulates between.

- the heat of the in-vehicle device can be pumped from the low-pressure side heat exchanger side to the high-pressure side heat exchanger side through the heat medium and further dissipated to the heat medium air heat exchanger through the heat medium,

- the heat medium air heat exchanger can be defrosted using the heat of the in-vehicle device. Therefore, defrosting can be performed on the heat medium air heat exchanger while suppressing power consumed by the compressor.

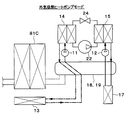

- the vehicle thermal management system 10 shown in FIG. 1 is used to adjust various devices and vehicle interiors provided in the vehicle to appropriate temperatures.

- the thermal management system 10 is applied to a hybrid vehicle that obtains driving force for vehicle traveling from an engine (for example, an internal combustion engine) and a traveling electric motor.

- the hybrid vehicle of this embodiment is configured as a plug-in hybrid vehicle that can charge power supplied from an external power source (for example, commercial power source) to a battery (for example, an in-vehicle battery) mounted on the vehicle when the vehicle is stopped. Yes.

- an external power source for example, commercial power source

- a battery for example, an in-vehicle battery mounted on the vehicle when the vehicle is stopped.

- the battery for example, a lithium ion battery can be used.

- the driving force output from the engine is used not only for driving the vehicle but also for operating the generator.

- the electric power generated by the generator and the electric power supplied from the external power source can be stored in the battery, and the electric power stored in the battery constitutes the thermal management system 10 as well as the electric motor for traveling. It is supplied to various in-vehicle devices such as electric components.

- the thermal management system 10 includes a first pump 11, a second pump 12, a radiator 13, a cooling water cooler 14, a cooling water heater 15, a cooler core 16, a heater core 17, a first switching valve 18, and A second switching valve 19 is provided.

- the first pump 11 and the second pump 12 are electric pumps that suck and discharge cooling water.

- the cooling water is a fluid as a heat medium.

- a liquid containing at least ethylene glycol, dimethylpolysiloxane or nanofluid, or an antifreeze liquid is used as the cooling water.

- the radiator 13 is a cooling water outside air heat exchanger that exchanges heat between cooling water and air outside the passenger compartment (hereinafter referred to as outside air).

- outside air cooling water outside air heat exchanger that exchanges heat between cooling water and air outside the passenger compartment

- sensible heat exchange is performed between the cooling water and the outside air.

- cooling water having a temperature equal to or higher than the outside air temperature to the radiator 13 heat can be radiated from the cooling water to the outside air.

- the radiator 13 can exhibit a function as a radiator that radiates heat from the cooling water to the outside air and a function as a heat absorber that absorbs heat from the outside air to the cooling water.

- the radiator 13 is a heat transfer device that has a flow path through which the cooling water flows and that transfers heat to and from the cooling water whose temperature has been adjusted by the cooling water cooler 14 or the cooling water heater 15.

- the outdoor blower 20 is an electric blower that blows outside air to the radiator 13.

- the radiator 13 and the outdoor blower 20 are disposed in the foremost part of the vehicle. For this reason, the traveling wind can be applied to the radiator 13 when the vehicle is traveling.

- the cooling water cooler 14 and the cooling water heater 15 are cooling water temperature adjusting heat exchangers that adjust the temperature of the cooling water by exchanging heat of the cooling water.

- the cooling water cooler 14 is a cooling water cooling heat exchanger that cools the cooling water.

- the cooling water heater 15 is a cooling water heating heat exchanger that heats the cooling water.

- the cooling water cooler 14 is a low pressure side heat exchanger that absorbs heat from the cooling water to the low pressure side refrigerant by exchanging heat between the low pressure side refrigerant of the refrigeration cycle 21 and the cooling water.

- the cooling water heater 15 is a high pressure side heat exchanger that radiates heat from the high pressure side refrigerant to the cooling water by exchanging heat between the high pressure side refrigerant of the refrigeration cycle 21 and the cooling water.

- the refrigeration cycle 21 is a vapor compression refrigerator that includes a compressor 22, a cooling water heater 15, a receiver (not shown), an expansion valve 24, and a cooling water cooler 14.

- a chlorofluorocarbon refrigerant is used as the refrigerant, and a subcritical refrigeration cycle in which the high-pressure side refrigerant pressure does not exceed the critical pressure of the refrigerant is configured.

- the compressor 22 is an electric compressor driven by electric power supplied from a battery, and sucks, compresses and discharges the refrigerant of the refrigeration cycle 21.

- the cooling water heater 15 is a condenser that condenses the high-pressure side refrigerant by exchanging heat between the high-pressure side refrigerant discharged from the compressor 22 and the cooling water. That is, in the cooling water heater 15, the high-pressure side refrigerant changes in latent heat.

- a receiver (not shown) separates the gas-liquid two-phase refrigerant flowing out from the cooling water heater 15 into a gas-phase refrigerant and a liquid-phase refrigerant, and causes the separated liquid-phase refrigerant to flow out to the expansion valve 24 side. It is.

- the expansion valve 24 is a decompression unit that decompresses and expands the liquid-phase refrigerant that has flowed out of the receiver 23.

- the expansion valve 24 has a temperature sensing part 24a.

- the temperature sensing unit 24a detects the degree of superheat of the cooling water cooler 14 outlet-side refrigerant based on the temperature and pressure of the cooling water cooler 14 outlet-side refrigerant.

- the expansion valve 24 is a temperature type expansion valve. The temperature type expansion valve adjusts the throttle passage area by a mechanical mechanism so that the degree of superheat of the coolant on the outlet side of the cooling water cooler 14 falls within a predetermined range.

- An electric expansion valve may be used in which the temperature sensing unit 24a is configured by a thermistor and the throttle passage area is adjusted by an electric mechanism so that the degree of superheat of the coolant on the outlet side of the cooling water cooler 14 falls within a predetermined range. .

- the cooling water cooler 14 is an evaporator that evaporates the low pressure refrigerant by exchanging heat between the low pressure refrigerant decompressed and expanded by the expansion valve 24 and the cooling water. That is, in the cooling water cooler 14, the low-pressure refrigerant changes in latent heat. The gas-phase refrigerant evaporated in the cooling water cooler 14 is sucked into the compressor 22 and compressed.

- the cooling water In the radiator 13, the cooling water is cooled by outside air, whereas in the cooling water cooler 14, the cooling water is cooled by the low-pressure refrigerant of the refrigeration cycle 21. For this reason, the temperature of the cooling water cooled by the cooling water cooler 14 can be made lower than the temperature of the cooling water cooled by the radiator 13. Specifically, the radiator 13 cannot cool the cooling water to a temperature lower than the temperature of the outside air, whereas the cooling water cooler 14 can cool the cooling water to a temperature lower than the temperature of the outside air.

- the cooler core 16 and the heater core 17 are heat medium air heat exchange that adjusts the temperature of the blown air by exchanging heat between the cooling water whose temperature is adjusted by the cooling water cooler 14 and the cooling water heater 15 and the blown air to the vehicle interior. It is a vessel.

- the cooler core 16 and the heater core 17 are heat medium distribution devices through which a heat medium flows.

- the cooler core 16 is an air cooling heat exchanger that cools the air blown into the vehicle interior by exchanging heat between the cooling water and the air blown into the vehicle interior. In the cooler core 16, sensible heat exchange is performed between the cooling water and the air blown into the passenger compartment.

- the heater core 17 is an air heating heat exchanger that heats the air blown into the vehicle interior by exchanging heat (sensible heat exchange) between the air blown into the vehicle cabin and the cooling water. In the heater core 17, sensible heat exchange is performed between the air blown into the passenger compartment and the cooling water.

- the first pump 11 is disposed in the first pump flow path 31.

- a cooling water cooler 14 is disposed on the discharge side of the first pump 11 in the first pump flow path 31.

- the second pump 12 is disposed in the second pump flow path 32.

- the cooling water heater 15 is disposed on the discharge side of the second pump 12 in the second pump flow path 32.

- the radiator 13 is disposed in the radiator flow path 33.

- the cooler core 16 is disposed in the cooler core flow path 36.

- the heater core 17 is disposed in the heater core flow path 37.

- the first pump flow path 31, the second pump flow path 32, and the radiator flow path 33 are connected to the first switching valve 18 and the second switching valve 19.

- the first switching valve 18 and the second switching valve 19 are switching units that switch the flow of cooling water.

- the first switching valve 18 has a first inlet 18a and a second inlet 18b as cooling water inlets.

- the first switching valve 18 has a first outlet 18c as an outlet for cooling water.

- the second switching valve 19 has a first outlet 19a and a second outlet 19b as cooling water outlets.

- the second switching valve 19 has a first inlet 19c as an inlet for cooling water.

- One end of the first pump flow path 31 is connected to the first inlet 18a of the first switching valve 18.

- the cooling water outlet side of the cooling water cooler 14 is connected to the first inlet 18 a of the first switching valve 18.

- One end of the second pump flow path 32 is connected to the second inlet 18b of the first switching valve 18.

- the cooling water outlet side of the cooling water heater 15 is connected to the second inlet 18 b of the first switching valve 18.

- One end of the radiator flow path 33 is connected to the first outlet 18 c of the first switching valve 18.

- the cooling water inlet side of the radiator 13 is connected to the first outlet 18 c of the first switching valve 18.

- the other end of the first pump flow path 31 is connected to the first outlet 19a of the second switching valve 19.

- the cooling water suction side of the first pump 11 is connected to the first outlet 19 a of the second switching valve 19.

- the other end of the second pump flow path 32 is connected to the second outlet 19b of the second switching valve 19.

- the cooling water suction side of the second pump 12 is connected to the second outlet 19 b of the second switching valve 19.

- the other end of the radiator flow path 33 is connected to the first inlet 19c of the second switching valve 19.

- the cooling water outlet side of the radiator 13 is connected to the first inlet 19 c of the second switching valve 19.

- the first switching valve 18 and the second switching valve 19 have a structure that can arbitrarily or selectively switch the communication state between each inlet and each outlet.

- the cooler core 16 and the heater core 17 are accommodated in a case 51 of the indoor air conditioning unit 50 of the vehicle air conditioner.

- the case 51 forms an air passage for the blown air that is blown into the vehicle interior, and is formed of a resin (for example, polypropylene) having a certain degree of elasticity and excellent strength.

- An inside / outside air switching box 52 is arranged on the most upstream side of the air flow in the case 51.

- the inside / outside air switching box 52 is an inside / outside air introduction unit that switches between air in the vehicle interior (hereinafter referred to as inside air) and outside air.

- the inside / outside air switching box 52 is formed with an inside air inlet 52a for introducing inside air into the case 51 and an outside air inlet 52b for introducing outside air.

- An inside / outside air switching door 53 is arranged inside the inside / outside air switching box 52.

- the inside / outside air switching door 53 is an air volume ratio changing unit that changes the air volume ratio between the air volume of the inside air introduced into the case 51 and the air volume of the outside air. Specifically, the inside / outside air switching door 53 continuously adjusts the opening areas of the inside air suction port 52a and the outside air suction port 52b to change the air volume ratio between the inside air volume and the outside air volume.

- the inside / outside air switching door 53 is driven by an electric actuator (not shown).

- An indoor blower 54 (for example, a blower) is disposed on the downstream side of the air flow in the inside / outside air switching box 52.

- the indoor blower 54 is a blower that blows air (that is, inside air and outside air) sucked through the inside / outside air switching box 52 toward the vehicle interior.

- the indoor blower 54 is an electric blower that drives a centrifugal multiblade fan (for example, a sirocco fan) with an electric motor.

- the cooler core 16 and the heater core 17 are disposed on the downstream side of the air flow of the indoor blower 54.

- a heater core bypass passage 51a is formed at the downstream side of the air flow of the cooler core 16.

- the heater core bypass passage 51 a is an air passage through which air that has passed through the cooler core 16 flows without passing through the heater core 17.

- An air mix door 55 is arranged between the cooler core 16 and the heater core 17 in the case 51.

- the air mix door 55 is an air volume ratio adjusting unit that continuously changes the air volume ratio between the air flowing into the heater core 17 and the air flowing into the heater core bypass passage 51a.

- the air mix door 55 is a rotatable plate-like door, a slidable door, or the like, and is driven by an electric actuator (not shown).

- the air mix door 55 is a temperature adjusting unit that adjusts the temperature of the blown air blown into the vehicle interior.

- the blower outlet 51b which blows off blowing air to the vehicle interior which is air-conditioning object space is arrange

- a defroster outlet, a face outlet, and a foot outlet are provided as the outlet 51b.

- the defroster outlet blows air conditioned air toward the inner surface of the front window glass of the vehicle.

- the face air outlet blows conditioned air toward the upper body of the passenger.

- the air outlet blows air-conditioned air toward the passenger's feet.

- An air outlet mode door (not shown) is disposed on the air flow upstream side of the air outlet 51b.

- a blower outlet mode door is a blower outlet mode switching part which switches blower outlet mode.

- the outlet mode door is driven by an electric actuator (not shown).

- the outlet mode switched by the outlet mode door for example, there are a face mode, a bi-level mode, a foot mode, and a foot defroster mode.

- the face mode is a blowout mode in which the face blowout is fully opened and air is blown out from the face blowout toward the upper body of the passenger in the passenger compartment.

- the bi-level mode is an air outlet mode in which both the face air outlet and the foot air outlet are opened and air is blown toward the upper body and the feet of the passengers in the passenger compartment.

- the foot mode is a blowout mode in which the foot blowout opening is fully opened and the defroster blowout opening is opened by a small opening so that air is mainly blown out from the foot blowout opening.

- the foot defroster mode is an air outlet mode in which the foot air outlet and the defroster air outlet are opened to the same extent and air is blown out from both the foot air outlet and the defroster air outlet.

- the thermal management system 10 further includes in-vehicle devices 81A, 81B, 81C.

- the in-vehicle devices 81A, 81B, 81C are a battery temperature adjusting heat exchanger 81A, an inverter 81B, and an engine cooling heat exchanger 81C.

- the battery temperature control heat exchanger 81A, the inverter 81B, and the engine cooling heat exchanger 81C are heat transfer devices that have a flow path through which the cooling water flows and that transfer heat to and from the cooling water.

- the battery temperature control heat exchanger 81A, the inverter 81B, and the engine cooling heat exchanger 81C are heat-generating devices that generate heat during operation.

- the battery temperature control heat exchanger 81A is a heat exchanger that is arranged in a blowing path to the battery and exchanges heat between the blown air and the cooling water.

- the battery temperature adjustment heat exchanger 81A is disposed in the battery heat exchange channel 80A.

- One end of the battery heat exchange channel 80A is connected to the battery heat exchange outlet 18f of the first switching valve 18.

- the other end of the battery heat exchange channel 80 ⁇ / b> A is connected to the battery heat exchange inlet 19 f of the second switching valve 19.

- the inverter 81B is a power conversion device that converts DC power supplied from the battery into AC voltage and outputs the AC voltage to the traveling electric motor.

- the inverter 81B is disposed in the inverter flow path 80B.

- One end of the inverter flow path 80B is connected to the inverter outlet 18g of the first switching valve 18.

- the other end of the inverter flow path 80 ⁇ / b> B is connected to the inverter inlet 19 g of the second switching valve 19.

- the engine cooling heat exchanger 81C includes a cooling water of the heat management system 10 (that is, a cooling water circulated by the first pump 11 or the second pump 12) and a cooling water of the engine cooling circuit 90 (for example, an engine heat medium). And a heat exchanger (for example, a heat medium heat medium heat exchanger).

- the engine cooling heat exchanger 81C is disposed in the heat exchanger flow path 80C.

- One end of the heat exchanger channel 80 ⁇ / b> C is connected to the heat exchanger outlet 18 h of the first switching valve 18.

- the other end of the heat exchanger channel 80 ⁇ / b> C is connected to the heat exchanger inlet 19 h of the second switching valve 19.

- one end of the cooler core flow path 36 is connected to the cooler core outlet 18i of the first switching valve 18.

- the other end of the cooler core flow path 36 is connected to the cooler core inlet 19 i of the second switching valve 19.

- One end of the heater core flow path 37 is connected to the heater core outlet 18j of the first switching valve 18.

- the other end of the heater core flow path 37 is connected to the heater core inlet 19 j of the second switching valve 19.

- the first switching valve 18 includes a state in which the cooling water discharged from the first pump 11 flows into each of the devices 13, 16, 17, 81 ⁇ / b> A, 81 ⁇ / b> B, 81 ⁇ / b> C connected to the outlet side thereof, and the second pump 12. Is switched between a state in which the cooling water discharged from the inflow flows and a state in which the cooling water discharged from the first pump 11 and the cooling water discharged from the second pump 12 do not flow in.

- the second switching valve 19 has a state in which the cooling water flows out to the first pump 11 and the cooling water to the second pump 12 for each of the devices 13, 16, 17, 81A, 81B, 81C connected to the inlet side thereof. Is switched between a state in which the coolant flows and a state in which the cooling water does not flow out to the first pump 11 and the second pump 12.

- the valve opening degree of the first switching valve 18 and the second switching valve 19 can be adjusted. Thereby, the flow volume of the cooling water which flows through each apparatus 13, 16, 17, 81A, 81B, 81C can be adjusted.

- the first switching valve 18 and the second switching valve 19 mix the cooling water discharged from the first pump 11 and the cooling water discharged from the second pump 12 at an arbitrary flow rate ratio to each device 13, 16. , 17, 81A, 81B, 81C.

- the engine cooling circuit 90 is a cooling water circulation circuit for cooling the engine 91.

- the engine cooling circuit 90 has a circulation passage 92 through which cooling water circulates.

- an engine 91, a third pump 93, an engine radiator 94, and an engine cooling heat exchanger 81C are arranged.

- the third pump 93 is an electric pump that sucks and discharges cooling water.

- the third pump 93 may be a mechanical pump driven by power output from the engine 91.

- the engine radiator 94 is a heat exchanger for radiating heat to dissipate the heat of the cooling water to the outside air by exchanging heat between the cooling water and the outside air.

- a radiator bypass channel 95 is connected to the circulation channel 92.

- the radiator bypass channel 95 is a channel through which cooling water flows bypassing the engine radiator 94.

- a thermostat 96 is disposed at a connection portion between the radiator bypass channel 95 and the circulation channel 92.

- the thermostat 96 is a cooling water temperature responsive valve configured by a mechanical mechanism that opens and closes a cooling water flow path by displacing a valve body by a thermo wax (for example, a temperature sensitive member) whose volume changes with temperature.

- the thermostat 96 closes the radiator bypass channel 95 when the temperature of the cooling water is higher than a predetermined temperature (for example, 80 ° C. or more), and when the temperature of the cooling water is lower than the predetermined temperature (for example, (Less than 80 ° C.), the radiator bypass channel 95 is opened.

- a predetermined temperature for example, 80 ° C. or more

- the predetermined temperature for example, (Less than 80 ° C.

- the circulation channel 92 is connected to an engine accessory flow channel 97.

- the engine auxiliary passage 97 is a passage through which cooling water flows in parallel with the engine cooling heat exchanger 81C.

- An engine accessory 98 is disposed in the engine accessory flow path 97.

- the engine accessory 98 is an oil heat exchanger, an EGR cooler, a throttle cooler, a turbo cooler, an engine auxiliary motor, or the like.

- the oil heat exchanger is a heat exchanger that adjusts the temperature of oil by exchanging heat between engine oil or transmission oil and cooling water.

- An EGR cooler is a heat exchanger that constitutes an EGR device (that is, an exhaust gas recirculation device) that recirculates a part of exhaust gas of an engine to an intake side to reduce a pumping loss generated by a throttle valve. And a heat exchanger that adjusts the temperature of the reflux gas by exchanging heat with cooling water.

- an EGR device that is, an exhaust gas recirculation device

- a heat exchanger that adjusts the temperature of the reflux gas by exchanging heat with cooling water.

- the throttle cooler is a water jacket provided inside the throttle to cool the throttle valve.

- the turbo cooler is a cooler for cooling the turbocharger by exchanging heat between the heat generated in the turbocharger and the cooling water.

- the engine auxiliary motor is a large motor that allows the engine belt to rotate even when the engine is stopped.

- the compressor or water pump driven by the engine belt can be operated even when there is no engine driving force, or the engine can be started. Sometimes used.

- a first reserve tank 99 is connected to the engine radiator 94.

- the first reserve tank 99 is an open-air container that stores cooling water. Therefore, the pressure at the coolant level stored in the first reserve tank 99 becomes atmospheric pressure.

- the 1st reserve tank 99 may be constituted so that the pressure in the level of the cooling water stored in the 1st reserve tank 99 may become a predetermined pressure different from atmospheric pressure.

- Storing excess cooling water in the first reserve tank 99 can suppress a decrease in the amount of cooling water circulating through each flow path.

- the first reserve tank 99 has a function of gas-liquid separation of bubbles mixed in the cooling water.

- the second reserve tank 100 is connected to the radiator flow path 33.

- the structure and function of the second reserve tank 100 are the same as those of the first reserve tank 99.

- Auxiliary heater 101 is disposed at the downstream side of the air flow of heater core 17 inside case 51 of indoor air conditioning unit 50 of the vehicle air conditioner.

- the auxiliary heater 101 has a PTC element (for example, a positive temperature coefficient thermistor), and is a PTC heater (for example, an electric heater) that generates heat and heats air when electric power is supplied to the PTC element.

- the operation of the auxiliary heater 101 (for example, the amount of generated heat) is controlled by the control device 60.

- the refrigeration cycle 21 has an internal heat exchanger 102.

- the internal heat exchanger 102 is a heat exchanger that exchanges heat between the refrigerant flowing out of the cooling water heater 15 and the refrigerant flowing out of the cooling water cooler 14.

- the control device 60 is composed of a well-known microcomputer including a CPU, ROM, RAM, etc. and its peripheral circuits, and performs various calculations and processing based on an air conditioning control program stored in the ROM, and is connected to the output side. It is a control part which controls operation of various control object equipment.

- Control target devices controlled by the control device 60 include the first pump 11, the second pump 12, the first switching valve 18, the second switching valve 19, the outdoor blower 20, the compressor 22, the indoor blower 54, and the inside of the case 51.

- the electric actuator etc. which drive the various doors (For example, the inside / outside air switching door 53, the air mix door 55, the blower outlet mode door, etc.) arrange

- the control device 60 is an integrated control unit that controls various control target devices connected to the output side.

- hardware and software for controlling the operation of each control target device constitute a control unit for controlling the operation of each control target device.

- the hardware and software for controlling the operation of the first pump 11 and the second pump 12 in the control device 60 are a pump control unit 60a.

- the pump control unit 60 a is a flow rate control unit that controls the flow rate of the cooling water flowing through the radiator 13.

- the pump control unit 60 a may be configured separately from the control device 60.

- the hardware and software for controlling the operation of the first switching valve 18 and the second switching valve 19 in the control device 60 are the switching valve control unit 60b.

- the switching valve control unit 60 b is a flow rate control unit that adjusts the flow rate of the cooling water flowing through the radiator 13.

- the switching valve control unit 60b may be configured separately from the control device 60.

- the hardware and software for controlling the operation of the compressor 22 in the control device 60 is a compressor control unit 60c.

- the compressor control unit 60 c is a refrigerant flow rate adjusting unit that controls the flow rate of the refrigerant discharged from the compressor 22.

- the compressor control unit 60 c may be configured separately from the control device 60.

- an inside air sensor 61 On the input side of the control device 60, an inside air sensor 61, an outside air sensor 62, a solar radiation sensor 63, a first water temperature sensor 64, a second water temperature sensor 65, a cooler core temperature sensor 66, a refrigerant temperature sensor 67, a radiator water temperature sensor 111, a battery temperature.

- Detection signals of sensor groups such as the sensor 112, the inverter temperature sensor 113, the engine water temperature sensor 114, and the refrigerant pressure sensor 115 are input.

- the inside air sensor 61 is an inside air temperature detection unit that detects the temperature of the inside air.

- the outside air sensor 62 is an outside air temperature detection unit that detects the temperature of the outside air.

- the solar radiation sensor 63 is a solar radiation amount detector that detects the amount of solar radiation in the passenger compartment.

- the first water temperature sensor 64 is a first water temperature detection unit that detects the temperature of the cooling water flowing through the first pump flow path 31 (for example, the temperature of the cooling water sucked into the first pump 11).

- the second water temperature sensor 65 is a second water temperature detection unit that detects the temperature of the cooling water flowing through the second pump flow path 32 (for example, the temperature of the cooling water sucked into the second pump 12).

- the second water temperature sensor 65 is a detection unit that detects a physical quantity related to the temperature Th of the cooling water circulating in the cooling water heater 15.

- the cooler core temperature sensor 66 is a cooler core temperature detection unit that detects the surface temperature of the cooler core 16.

- the cooler core temperature sensor 66 is, for example, a fin thermistor that detects the temperature of the heat exchange fins of the cooler core 16 or a water temperature sensor that detects the temperature of the cooling water flowing through the cooler core 16.

- the refrigerant temperature sensor 67 is a discharge side refrigerant temperature sensor 67A and a suction side refrigerant temperature sensor 67B.

- the discharge-side refrigerant temperature sensor 67A is a refrigerant temperature detection unit that detects the temperature of the refrigerant discharged from the compressor 22.

- the suction side refrigerant temperature sensor 67 ⁇ / b> B is a refrigerant temperature detection unit that detects the temperature of the refrigerant sucked into the compressor 22.

- the radiator water temperature sensor 111 is a water temperature detector that detects the temperature of the cooling water flowing through the radiator flow path 33 (for example, the temperature of the cooling water that has flowed out of the radiator 13).

- the battery temperature sensor 112 is a battery temperature detector that detects the temperature of the cooling water flowing through the battery heat exchange channel 80A (for example, the temperature of the cooling water flowing into the battery temperature adjustment heat exchanger 81A).

- the inverter temperature sensor 113 is an inverter temperature detection unit that detects the temperature of the cooling water flowing through the inverter flow path 80B (for example, the temperature of the cooling water flowing out of the inverter 81B).

- the engine water temperature sensor 114 is a water temperature detection unit that detects the temperature of cooling water circulating in the engine cooling circuit 90 (for example, the temperature of cooling water flowing inside the engine 91).

- the refrigerant pressure sensor 115B is a discharge side refrigerant pressure sensor 115A and a suction side refrigerant temperature sensor 115B.

- the discharge-side refrigerant pressure sensor 115 ⁇ / b> A is a refrigerant pressure detection unit that detects the pressure of the refrigerant discharged from the compressor 22.

- the suction side refrigerant temperature sensor 115 ⁇ / b> B is a refrigerant pressure detection unit that detects the pressure of the refrigerant sucked into the compressor 22.

- Operation signals from various air conditioning operation switches provided on the operation panel 69 disposed near the instrument panel in the front of the vehicle interior are input to the input side of the control device 60.

- various air conditioning operation switches provided on the operation panel 69 an air conditioner switch, an auto switch, an air volume setting switch of the indoor fan 54, a vehicle interior temperature setting switch, and the like are provided.

- the air conditioner switch is a switch for switching on / off (in other words, on / off) of air conditioning (that is, cooling or heating).

- the auto switch is a switch for setting or canceling automatic control of air conditioning.

- the vehicle interior temperature setting switch is a target temperature setting unit that sets the vehicle interior target temperature by the operation of the passenger.

- the control device 60 operates the first switching valve 18 and the second switching valve 19 to switch the cooling water flow mode to various modes shown in FIGS.

- FIGS. 3 to 7 show the thermal management system 10 in a simplified manner.

- the radiator 13 is connected to the cooling water cooler 14, the heater core 17 is connected to the cooling water heater 15, and the engine cooling heat exchanger 81C is connected to the cooling water cooler 14 and the cooling water. Do not connect to any of the heaters 15.

- the cooling water cooled by the cooling water cooler 14 and having a temperature lower than the outside air temperature flows through the radiator 13. Therefore, the cooling water absorbed by the cooling air from the outside air by the radiator 13 and heated by the cooling water heater 15. Since water flows through the heater core 17, the air blown into the passenger compartment is heated by the heater core 17.

- the refrigerant in the refrigeration cycle 21 absorbs heat from the outside air by the radiator 13 and dissipates heat to the cooling water by the cooling water heater 15. Therefore, it is possible to realize a heat pump operation that pumps up the heat of the outside air.

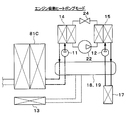

- the engine cooling heat exchanger 81C is connected to the cooling water cooler 14, the heater core 17 is connected to the cooling water heater 15, and the radiator 13 is connected to the cooling water cooler 14 and the cooling water. It is not connected to any of the heaters 15.

- the cooling water heated by the engine cooling heat exchanger 81C flows through the cooling water cooler 14, so that the cooling water is absorbed by the refrigerant in the cooling water cooler 14 and heated by the cooling water heater 15. Since water flows through the heater core 17, the air blown into the passenger compartment is heated by the heater core 17.

- the refrigerant in the refrigeration cycle 21 absorbs heat from the cooling water heated by the engine cooling heat exchanger 81C and dissipates heat to the cooling water by the cooling water heater 15. Therefore, a heat pump operation that pumps up the heat of the engine 91 can be realized.

- the engine endothermic heat pump mode if the other in-vehicle devices 81A and 81B are connected to the cooling water cooler 14, the heat of the other in-vehicle devices 81A and 81B can be pumped up. Therefore, the engine endothermic heat pump mode can be expressed as an equipment endothermic heat pump mode.

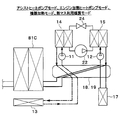

- the engine cooling heat exchanger 81C and the heater core 17 are connected to the cooling water heater 15, and the radiator 13 is cooled to the cooling water. Connect to cooler 14.

- the cooling water cooled by the cooling water cooler 14 flows through the radiator 13

- the cooling water absorbed by the cooling water from the outside air by the radiator 13 and heated by the cooling water heater 15 flows through the heater core 17.

- the air blown into the passenger compartment is heated.

- the refrigerant of the refrigeration cycle 21 absorbs heat from the outside air by the radiator 13 and becomes cooling water by the cooling water heater 15. Dissipate heat. Therefore, it is possible to realize a heat pump operation that pumps up the heat of the outside air.

- the heating heat source can be supplemented by the heat pump operation by executing the assist heat pump mode.

- the cooling water heated by the cooling water heater 15 flows through the engine cooling heat exchanger 81C, so that it is heated by the cooling water heater 15.

- the engine 91 can be heated with the cooling water.

- the engine heating heat pump mode if other in-vehicle devices 81A and 81B are connected to the cooling water heater 15, the other in-vehicle devices 81A and 81B can be heated with the cooling water heated by the cooling water heater 15. Therefore, the engine heating heat pump mode can be expressed as an equipment heating heat pump mode.

- the other on-vehicle devices 81A and 81B connected to the coolant heater 15 can be heated by the heat of the engine 91.

- the cooling water heated by the cooling water heater 15 flows through the engine cooling heat exchanger 81C by executing the heating mode using the heat mass, the heat mass (for example, heat capacity) of the engine 91 is used. Variations in cooling water temperature can be suppressed.

- the engine cooling heat exchanger 81C and the heater core 17 are connected to each other, and are not connected to either the cooling water cooler 14 or the cooling water heater 15.

- a cooling water pump that sucks and discharges cooling water is disposed in the cooling water flow path between the engine cooling heat exchanger 81C and the heater core 17. As a result, the cooling water heated by the engine cooling heat exchanger 81C flows through the heater core 17, so that the air blown into the vehicle compartment is heated by the heater core 17.

- the engine waste heat direct use mode In the engine waste heat direct use mode, if other heat generating devices (battery temperature control heat exchanger 81A, inverter 81B) are connected to the heater core 17, the cooling water heated by the other heat generating devices 81A, 81B Since it flows, the air blown into the passenger compartment can be heated by the heater core 17. Therefore, the engine waste heat direct use mode can be expressed as the equipment waste heat direct use mode.

- other heat generating devices battery temperature control heat exchanger 81A, inverter 81B

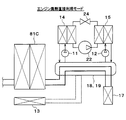

- the engine-cooling heat exchanger 81 ⁇ / b> C and the radiator 13 are connected to the cooling water heater 15, and the cooler core 16 is connected to the cooling water cooler 14.

- the cooling water cooled by the cooling water cooler 14 flows through the cooler core 16, so that the air blown into the vehicle interior is cooled by the cooler core 16, and the cooling water heated by the cooling water heater 15 flows through the radiator 13. Therefore, the radiator 13 radiates heat from the cooling water to the outside air.

- the cooling water heated by the cooling water heater 15 flows through the engine 91, it is possible to suppress the fluctuation of the cooling water temperature by using the thermal mass of the engine 91, and to suppress the increase in the water temperature, thereby increasing the refrigerant pressure. Since it can be suppressed, highly efficient cooling can be realized.

- control device 60 operates the first switching valve 18 and the second switching valve 19 to switch the cooling water flow mode to the engine independent mode.

- the engine cooling heat exchanger 81C is not connected to either the cooling water cooler 14 or the cooling water heater 15. Thereby, the waste heat of the engine 91 is not transferred to the cooling water cooler 14 and the cooling water heater 15.

- the engine independent mode is executed when the temperature detected by the engine water temperature sensor 114 during the cooling operation, that is, the temperature of the cooling water circulating in the engine cooling circuit 90 exceeds a preset reference temperature. Thereby, it can prevent that the air_conditioning

- FIG. 1 the temperature detected by the engine water temperature sensor 114 during the cooling operation, that is, the temperature of the cooling water circulating in the engine cooling circuit 90 exceeds a preset reference temperature.

- control device 60 executes the control process shown in the flowchart of FIG.

- the control process shown in the flowchart of FIG. 8 is executed as a subroutine for the main routine of the thermal management system 10.

- step S100 it is determined whether or not the radiator 13 needs to be defrosted. In other words, it is determined whether or not frost is attached to the radiator 13.

- frost has adhered to the radiator 13 is determined by determining the vehicle running speed, the temperature of the cooling water heat-exchanged by the cooling water cooler 14, the pressure of the low-pressure side refrigerant in the refrigeration cycle 21, the vehicle interior ventilation At least of the time of divergence between the target air blowing temperature TAO and the actual air blowing temperature TAV of the air blown into the passenger compartment, the temperature of the cooling water exchanged by the cooling water heater 15, the on / off state of the ignition switch of the vehicle, etc. This is done based on one.

- TAO Kset ⁇ Tset ⁇ Kr ⁇ Tr ⁇ Kam ⁇ Tam ⁇ Ks ⁇

- C Tset is the vehicle interior set temperature set by the vehicle interior temperature setting switch

- Tr is the vehicle interior temperature (internal air temperature) detected by the internal air sensor

- Tam is the external air temperature detected by the external air sensor

- As is the solar radiation sensor.

- Kset, Kr, Kam, Ks are control gains

- C is a correction constant.

- the actual blowout temperature TAV of the air blown into the passenger compartment is calculated from, for example, the temperature of the air that has flowed out of the heater core 17, the opening degree of the air mix door 55, and the like.

- a temperature sensor that detects the actual blowing temperature TAV of the air blown into the passenger compartment may be provided.

- step S100 If it is determined in step S100 that the radiator 13 needs to be defrosted, the process proceeds to step S110 to determine whether or not the vehicle is parked. Specifically, it is determined whether or not the vehicle is parked based on a vehicle speed sensor or an ignition switch.

- step S110 When it determines with the vehicle being parked in step S110, it progresses to step S120 and switches to the cooling water circuit of the defrost mode shown in FIG. Specifically, the cooling water circulates between the cooling water heater 15 and the radiator 13 as shown by a thick solid line in FIG. 9, and at least one of the cooling water cooler 14 and the cooling water cooler 14 as shown by a thick dotted line in FIG.

- the operation of the first switching valve 18 and the second switching valve 19 is controlled so that the cooling water circulates between the two in-vehicle devices 81A, 81B, 81C.

- the cooling water circuit in which the cooling water circulates between the cooling water heater 15 and the radiator 13 is referred to as a high water temperature circuit.

- the cooling water circuit in which the cooling water circulates between the cooling water cooler 14 and the at least one in-vehicle device 81A, 81B, 81C is referred to as a low water temperature circuit.

- the operation of the compressor 22 is controlled based on the coolant temperature Th of the high water temperature circuit.

- the control device 60 uses the temperature of the cooling water detected by the second water temperature sensor 65 as the cooling water temperature Th of the high water temperature circuit.

- step S130 of FIG. 8 the compressor 22 is driven in the high temperature range of the cooling water temperature Th, and the compressor 22 is stopped in the low temperature range of the cooling water temperature Th.

- a hysteresis width for preventing control hunting is set.

- the compressor 22 is driven when the cooling water temperature Th exceeds the first threshold Th1.

- the compressor 22 is stopped when the cooling water temperature Th falls below the second threshold Th2.

- the first threshold value Th1 and the second threshold value Th2 are stored in the control device 60 in advance.

- the second threshold Th2 is a value smaller than the first threshold Th1.

- the first threshold value Th1 is a value equal to or higher than the freezing point of pure water (that is, 0 ° C.).

- the compressor 22 can be driven to increase the cooling water temperature Th. That is, the heat of at least one in-vehicle device 81A, 81B, 81C is pumped from the cooling water cooler 14 side to the cooling water heater 15 side through the cooling water in the low water temperature circuit, and is supplied via the cooling water in the high water temperature circuit. 13 can dissipate heat, so that the coolant temperature Th of the high water temperature circuit can be increased.

- step S140 it is determined whether or not the coolant temperature Th of the high water temperature circuit exceeds the third threshold value Th3.

- the third threshold Th3 is stored in the control device 60 in advance.

- the third threshold value Th3 is a value equal to or higher than the freezing point of pure water (that is, 0 ° C.).

- step S140 When it is determined in step S140 that the cooling water temperature Th is higher than the third threshold Th3, the process proceeds to step S150, and the first switching valve 18 and the second switching valve 19 and the cooling water are supplied to the radiator 13. The operation of at least one of the second pumps 12 is controlled.

- the cooling water of the high water temperature circuit can be supplied to the radiator 13 to defrost the radiator 13.

- the radiator 13 can be defrosted without consuming power by the compressor 22.

- the radiator 13 can be defrosted using the heat of at least one in-vehicle device 81A, 81B, 81C, so that the power consumed by the compressor 22 can be suppressed.

- step S140 determines whether the cooling water temperature Th does not exceed the third threshold value Th3

- the process proceeds to step S160, and the first switching valve 18 and the second switching valve 19 are provided so that the cooling water is not supplied to the radiator 13. And the operation of at least one of the second pumps 12 is controlled.

- the flow rate of the cooling water supplied from the cooling water heater 15 to the radiator 13 is higher than when the cooling water temperature Th is higher than the third threshold Th3. Less.

- step S100 if it is determined in step S100 that the radiator 13 does not require defrosting, or if it is determined in step S110 that the vehicle is not parked, the process proceeds to step S170 to switch to the cooling water circuit in the defrosting mode. Ban. In other words, the mode is switched to a cooling water flow mode other than the defrosting mode. Therefore, the defrosting of the radiator 13 is not performed when the defrosting is not necessary for the radiator 13 or during traveling of the vehicle.

- steps S100, S120, and S130 when it is determined that the control device 60 needs to defrost the radiator 13, the cooling water cooler 14 and the in-vehicle device 81A, The operation of the first switching valve 18 and the second switching valve 19 so that the cooling water is circulated between 81B and 81C and the cooling water is circulated between the cooling water heater 15 and the radiator 13 And the compressor 22 is driven.

- the heat of the in-vehicle devices 81A, 81B, 81C can be pumped from the cooling water cooler 14 side to the cooling water heater 15 side through the cooling water, and further radiated to the radiator 13 through the cooling water.

- the radiator 13 can be defrosted using the heat of the in-vehicle devices 81A, 81B, 81C. Therefore, defrosting can be performed on the radiator 13 while suppressing the power consumed by the compressor 22.

- step S ⁇ b> 120 when it is determined that the control device 60 needs to defrost the radiator 13, the cooling water is cooled between the cooling water cooler 14 and the cooler core 16.

- the operation of the first switching valve 18 and the second switching valve 19 is controlled so as to circulate.

- the residual heat in the passenger compartment can be used as a heat source for defrosting the radiator 13. Further, in the defrost mode, the air blown into the passenger compartment can be cooled to dehumidify the passenger compartment.

- step S ⁇ b> 120 when it is determined that the control device 60 needs to defrost the radiator 13, the cooling water is cooled between the cooling water heater 15 and the heater core 17.

- the operation of the first switching valve 18 and the second switching valve 19 is controlled so as to circulate.

- the temperature of the heater core 17 can be adjusted by the cooling water heat-exchanged by the cooling water heater 15 while defrosting the radiator 13. That is, the vehicle interior can be heated while defrosting the radiator 13.

- step S ⁇ b> 130 when it is determined that the defrosting is required for the radiator 13, the control device 60 is based on the cooling water temperature detected by the second water temperature sensor 65. The operation of the compressor 22 is controlled.

- step S ⁇ b> 130 the control device 60 performs cooling based on the cooling water temperature detected by the second water temperature sensor 65 when it is determined that the radiator 13 needs to be defrosted.

- the compressor 22 is stopped.

- the radiator 13 is defrosted using the amount of heat of the cooling water circulating through the cooling water heater 15 without driving the compressor 22, the power consumed by the compressor 22 is further suppressed. Can do.

- the first threshold Th1 is a value equal to or higher than the freezing point of pure water. According to this, the radiator 13 can be reliably defrosted using the heat quantity of the cooling water circulating through the cooling water heater 15.

- the control device 60 increases the temperature of the cooling water circulating through the cooling water heater 15 based on the cooling water temperature detected by the second water temperature sensor 65. When it determines with having exceeded 1 threshold value Th1, the compressor 22 is stopped. When the control device 60 determines that the temperature of the cooling water circulating through the cooling water heater 15 has fallen below the second threshold Th ⁇ b> 2 based on the cooling water temperature detected by the second water temperature sensor 65, the compressor 22. Drive.

- the radiator 13 is removed by using the heat amount of the cooling water circulating through the cooling water heater 15 without driving the compressor 22. Can frost.

- the amount of heat of the cooling water circulating through the cooling water heater 15 decreases, the compressor 22 is driven, and the radiator 13 can be defrosted using the heat of the in-vehicle devices 81A, 81B, 81C.

- the control device 60 is based on the cooling water temperature detected by the second water temperature sensor 65 when it is determined that the defrosting of the radiator 13 is necessary.

- the cooling water heater 15 is circulated based on the cooling water temperature detected by the second water temperature sensor 65.

- the first switching valve 18 and the first switching valve 18 are configured so that the flow rate of the cooling water supplied from the cooling water heater 15 to the radiator 13 is reduced. The operation of at least one of the two switching valve 19 and the second pump 12 is controlled.

- the temperature Th of the cooling water circulating through the cooling water heater 15 is low, heat dissipation in the radiator 13 is suppressed when the defrosting capability is low, so the temperature of the cooling water circulating through the cooling water heater 15 Th can be increased as early as possible to increase the defrosting capacity.

- the third threshold Th3 is a value equal to or smaller than the first threshold.

- the third threshold Th3 is preferably equal to the first threshold Th1. Since the compressor 22 can be stopped immediately when the temperature Th of the cooling water circulating through the cooling water heater 15 becomes high and the defrosting capability becomes high, the power consumed by the compressor 22 is suppressed to the radiator 13 while suppressing the power as much as possible. This is because defrosting can be performed.

- the control device 60 is based on the cooling water temperature detected by the second water temperature sensor 65 when it is determined that the defrosting of the radiator 13 is necessary.

- the first switching is performed so that the supply of the cooling water from the cooling water heater 15 to the radiator 13 is stopped.

- the operation of at least one of the valve 18, the second switching valve 19 and the second pump is controlled.

- the control device 60 determines that the temperature of the cooling water circulating in the cooling water heater 15 is higher than the third threshold Th3 based on the cooling water temperature detected by the second water temperature sensor 65, the cooling water heater The operation of at least one of the first switching valve 18, the second switching valve 19, and the second pump is controlled so that the cooling water is supplied from 15 to the radiator 13.

- the temperature Th of the cooling water circulating through the cooling water heater 15 is low, the heat radiation in the radiator 13 is further suppressed when the defrosting capability is low, so that the cooling water circulating through the cooling water heater 15 is reduced. It is possible to increase the defrosting capability by increasing the temperature Th as early as possible.

- the third threshold Th3 is a value equal to or higher than the freezing point of pure water. Therefore, when defrosting is impossible, the heat dissipation in the radiator 13 can be suppressed.

- the in-vehicle devices 81A, 81B, and 81C are devices that generate heat with operation. According to this, since the radiator 13 can be defrosted by effectively using the waste heat of the in-vehicle devices 81A, 81B, 81C, the defrosting ability for the radiator 13 can be enhanced while suppressing the power consumed by the compressor 22.

- steps S110 and S170 even when the control device 60 determines that the radiator 13 needs to be defrosted, when the vehicle is running.

- the operation of the first switching valve 18 and the second switching valve 19 is controlled so that execution of the defrosting mode is prohibited.

- the control device 60 uses the temperature of the cooling water detected by the second water temperature sensor 65 as the cooling water temperature Th of the high water temperature circuit, but the control device 60 uses the cooling water heater 15.

- the coolant temperature Th of the high water temperature circuit may be estimated based on a physical quantity related to the temperature of the circulating coolant.

- the control device 60 supplies cooling water to the radiator 13 in step S150 and does not supply cooling water to the radiator 13 in step S160. However, the control device 60 does not supply the cooling water to step S150.

- the flow rate of the cooling water supplied to the radiator 13 may be set to a high flow rate, and the flow rate of the cooling water supplied to the radiator 13 may be set to a low flow rate in step S160.

- the cooler core 16 and the heater core 17 are provided as the heat medium circulation device, but other various in-vehicle devices may be provided as the heat medium circulation device.

- the temperature of other various in-vehicle devices can be managed while defrosting the radiator 13.

- cooling water is used as the heat medium, but various media such as oil may be used as the heat medium.

- Nanofluid may be used as the heat medium.

- a nanofluid is a fluid in which nanoparticles having a particle size of the order of nanometers are mixed.

- the effect of improving the thermal conductivity in a specific temperature range the effect of increasing the heat capacity of the heat medium, the effect of preventing the corrosion of metal pipes and the deterioration of rubber pipes, and the heat medium at an extremely low temperature

- liquidity of can be acquired.

- Such an effect varies depending on the particle configuration, particle shape, blending ratio, and additional substance of the nanoparticles.

- the thermal conductivity can be improved, it is possible to obtain the same cooling efficiency even with a small amount of heat medium as compared with the cooling water using ethylene glycol.

- the amount of cold storage heat due to the sensible heat of the heat medium itself can be increased.

- the aspect ratio of the nanoparticles is preferably 50 or more. This is because sufficient thermal conductivity can be obtained.

- the aspect ratio is a shape index that represents the ratio of the vertical and horizontal dimensions of the nanoparticles.

- Nanoparticles containing any of Au, Ag, Cu and C can be used. Specifically, Au nanoparticle, Ag nanowire, CNT, graphene, graphite core-shell nanoparticle, Au nanoparticle-containing CNT, and the like can be used as the constituent atoms of the nanoparticle.

- the CNT is a carbon nanotube.

- the graphite core-shell nanoparticle is a particle body having a structure such as a carbon nanotube surrounding the atom.

- a chlorofluorocarbon refrigerant is used as the refrigerant.

- the type of the refrigerant is not limited to this, and natural refrigerants such as carbon dioxide, hydrocarbon refrigerants, and the like are used. It may be used.

- the refrigeration cycle 21 of each of the above embodiments constitutes a subcritical refrigeration cycle in which the high-pressure side refrigerant pressure does not exceed the critical pressure of the refrigerant, but the supercritical refrigeration cycle in which the high-pressure side refrigerant pressure exceeds the critical pressure of the refrigerant. May be configured.

Landscapes

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Mechanical Engineering (AREA)

- Thermal Sciences (AREA)

- General Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Air-Conditioning For Vehicles (AREA)

Priority Applications (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US16/060,083 US10562376B2 (en) | 2015-12-11 | 2016-10-06 | Refrigeration cycle device |

| CN201680071823.0A CN108369047B (zh) | 2015-12-11 | 2016-10-06 | 制冷循环装置 |

| DE112016005665.6T DE112016005665T5 (de) | 2015-12-11 | 2016-10-06 | Kühlzyklusvorrichtung |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2015-242302 | 2015-12-11 | ||

| JP2015242302A JP6555112B2 (ja) | 2015-12-11 | 2015-12-11 | 冷凍サイクル装置 |

Publications (1)