WO2016139835A1 - エンドピンホルダー - Google Patents

エンドピンホルダー Download PDFInfo

- Publication number

- WO2016139835A1 WO2016139835A1 PCT/JP2015/076540 JP2015076540W WO2016139835A1 WO 2016139835 A1 WO2016139835 A1 WO 2016139835A1 JP 2015076540 W JP2015076540 W JP 2015076540W WO 2016139835 A1 WO2016139835 A1 WO 2016139835A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- end pin

- support member

- receiving member

- pin holder

- cello

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- G—PHYSICS

- G10—MUSICAL INSTRUMENTS; ACOUSTICS

- G10D—STRINGED MUSICAL INSTRUMENTS; WIND MUSICAL INSTRUMENTS; ACCORDIONS OR CONCERTINAS; PERCUSSION MUSICAL INSTRUMENTS; AEOLIAN HARPS; SINGING-FLAME MUSICAL INSTRUMENTS; MUSICAL INSTRUMENTS NOT OTHERWISE PROVIDED FOR

- G10D3/00—Details of, or accessories for, stringed musical instruments, e.g. slide-bars

- G10D3/01—Endpins or accessories therefor

-

- G—PHYSICS

- G10—MUSICAL INSTRUMENTS; ACOUSTICS

- G10G—REPRESENTATION OF MUSIC; RECORDING MUSIC IN NOTATION FORM; ACCESSORIES FOR MUSIC OR MUSICAL INSTRUMENTS NOT OTHERWISE PROVIDED FOR, e.g. SUPPORTS

- G10G5/00—Supports for musical instruments

-

- G—PHYSICS

- G10—MUSICAL INSTRUMENTS; ACOUSTICS

- G10G—REPRESENTATION OF MUSIC; RECORDING MUSIC IN NOTATION FORM; ACCESSORIES FOR MUSIC OR MUSICAL INSTRUMENTS NOT OTHERWISE PROVIDED FOR, e.g. SUPPORTS

- G10G5/00—Supports for musical instruments

- G10G5/005—Supports for musical instruments while playing, e.g. cord, strap or harness

-

- G—PHYSICS

- G10—MUSICAL INSTRUMENTS; ACOUSTICS

- G10D—STRINGED MUSICAL INSTRUMENTS; WIND MUSICAL INSTRUMENTS; ACCORDIONS OR CONCERTINAS; PERCUSSION MUSICAL INSTRUMENTS; AEOLIAN HARPS; SINGING-FLAME MUSICAL INSTRUMENTS; MUSICAL INSTRUMENTS NOT OTHERWISE PROVIDED FOR

- G10D1/00—General design of stringed musical instruments

- G10D1/02—Bowed or rubbed string instruments, e.g. violins or hurdy-gurdies

Definitions

- the present invention relates to an end pin holder, and specifically to an end pin holder against which a tip of an end pin of a cello is abutted.

- the tip of the end pin is abutted and fixed to an end pin holder (also called an end pin stopper) placed on the floor so that the position of the end pin is fixed with respect to the floor.

- an end pin holder also called an end pin stopper

- Such a conventional end pin holder has a structure that presupposes that the tip of the end pin is firmly held at a fixed position and the vibration of the stringed instrument is propagated to the floor surface.

- Patent Document 1 Utility Model Registration No. 3153830.

- the original cello (called baroque cello), when the violin genus was developed, had no end pins and was played with the cello body sandwiched between both legs. In this case, since the cello body is played in a state where it floats in the air, it is easy to ensure natural resonance vibration of the cello.

- An object of the present invention is to solve the problems of these conventional end pin holders, and to provide an end pin holder capable of bringing the sound and sound quality close to those of natural instruments when playing a cello having end pins. There is.

- an end pin holder includes a receiving member provided with an abutment stage against which a tip of an end pin of a cello is abutted, and a support member that supports the receiving member, The receiving member is configured to be rotatably supported by the support member.

- the vibration of the cello having the end pin (mainly the vibration in the rotating direction of the receiving member) propagates to the floor. Can be suppressed. Further, the cello having the end pin can be held while allowing free vibration. As a result, when playing a cello having an end pin, the sound and sound quality can be brought close to the sound of a natural musical instrument.

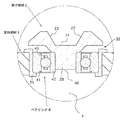

- FIG. 1 is a cross-sectional view of an end pin holder according to a first embodiment of the present invention

- FIG. 2 is a plan view of the end pin holder according to the first embodiment of the present invention

- 3 is a partially enlarged sectional view of FIG.

- FIG. 4 is a cross-sectional view showing a modification of the receiving member

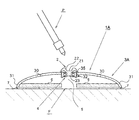

- FIG. 5 is a cross-sectional view of an end pin holder according to a second embodiment of the present invention

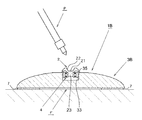

- FIG. 6 is a cross-sectional view of an end pin holder according to the third embodiment of the present invention.

- An end pin holder includes a receiving member provided with an abutment stage against which a tip portion of an end pin of a cello is abutted, and a supporting member that supports the receiving member, and the receiving member is the supporting member It is comprised so that it may be rotatably supported by.

- the receiving member is rotatably supported by the support member, it is possible to prevent the vibration of the cello having the end pin from propagating to the floor. Further, the cello having the end pin can be held while allowing free vibration. As a result, when playing a cello having an end pin, the sound and sound quality can be brought close to the sound of a natural musical instrument.

- the receiving member may be rotatably supported by the support member via a bearing, for example. According to this configuration, the contact stage of the receiving member can be smoothly rotated by the action of the bearing, and the vibration of the cello having the end pin can be prevented from propagating to the floor.

- the bearing may have an outer ring portion and an inner ring portion, for example, and the outer ring portion may be fixed to the support member and the inner ring portion fixed to the receiving member.

- the abutment stage may be configured to be positioned in, for example, a shaft hole surrounded by the inner ring portion of the bearing.

- the receiving member is configured to have a rising wall that rises upward at the outer peripheral portion of the abutting stage. According to this configuration, it is possible to prevent the end pin from being unintentionally detached from the abutting stage.

- the support member is configured so that the peripheral edge protrudes downward so that a space is formed below the receiving member.

- the receiving member when the end pin holder is installed on the floor surface, the receiving member is in a state of being floated from the floor surface, so that the vibration of the cello having the end pin can be further suppressed from propagating to the floor.

- the support member can be elastically deformed using the space, and the cello having the end pin can be elastically supported. As a result, it is possible to further suppress the vibration of the cello having the end pin from propagating to the floor.

- the support member is formed in a flat dome shape with a peripheral edge protruding downward so that a space is formed below the receiving member, and the support member has a plurality of spaces communicating with the outer surface side of the support member.

- a through hole may be formed.

- the support member can be more easily elastically deformed by forming a plurality of through holes in the support member. As a result, it is possible to further suppress the vibration of the cello having the end pin from propagating to the floor. Further, since the support member has a flat dome shape, it is easy to give the support member both elasticity and strength.

- the end pin holder according to the present invention may further include a reinforcing plate that is attached to the peripheral portion of the supporting member and reinforces the supporting member.

- end pin holder may further include an anti-slip member at a location in contact with the floor surface.

- An end pin holder according to each of the following embodiments includes a receiving member and a supporting member, and has a basic configuration in which the receiving member is rotatably supported by the supporting member.

- FIG.1, 5,6 in addition to an end pin holder, the end pin and the floor surface are also illustrated for convenience of explanation.

- the hatching of the cross section of the bearing is omitted.

- the end pin holder 1 is configured such that the receiving member 2 is rotatably supported by the support member 3 via the bearing 4.

- the support member 3 has a configuration in which the peripheral edge 31 protrudes downward. Thereby, a space 5 is formed below the receiving member 2.

- the receiving member 2 includes an abutment stage 21 against which the tip of the end pin P is abutted.

- the receiving member 2 is rotatably supported by the support member 3 by a bearing 4.

- the receiving member 2 is fixed to the inner ring portion 42 of the bearing 4 as shown in FIG. Specifically, an insertion portion 23 that fits into the shaft hole 40 surrounded by the inner ring portion 42 of the bearing 4 is formed in the lower portion of the receiving member 2.

- the receiving member 2 is fixed to the inner ring portion 42 of the bearing 4 by the insertion portion 23 being inserted and fitted into the shaft hole 40 of the bearing 4.

- the outer ring portion 41 of the bearing 4 is fixed to the support member 3 via the holder 35.

- the abutment stage 21 is formed above the insertion portion 23 of the receiving member 2.

- the abutment stage 21 is formed in a circular shape in plan view as shown in FIG.

- the abutment stage 21 is formed to have a flat surface parallel to the floor surface F or a substantially flat surface substantially parallel to the floor surface F in a state where the end pin holder 1 is placed on the floor surface F.

- the receiving member 2 has a rising wall 22 on the outer peripheral portion of the abutting stage 21.

- the rising wall 22 is formed on the outer peripheral portion of the abutment stage 21 so as to rise obliquely outward and upward.

- the receiving member 2 may be configured such that the abutment stage 21 is positioned in the shaft hole 40 of the bearing 4 as shown in FIG. Specifically, the receiving member 2 includes a substantially columnar insertion portion 24 that fits into the shaft hole 40 of the bearing 4, and the insertion portion 24 is inserted into the shaft hole 40 of the bearing 4 to fit.

- the inner ring portion 42 of the bearing 4 may be fixed.

- the receiving member 2 includes a flange portion 24a at the lower end portion of the insertion portion 24, and the insertion portion 24 has a shaft hole 40 so that the flange portion 24a contacts the lower end portion of the inner ring portion 42. It is fixed to the inner ring part 42 of the bearing 4 by being inserted from below.

- the upper surface of the receiving member 2 (the upper surface of the insertion portion 24) is the abutment stage 21.

- the insertion portion 24 has such a length (height) that the abutment stage 21 is positioned in the shaft hole 40 of the bearing 4.

- the abutment stage 21 is formed to have a flat surface parallel to the floor surface F or a substantially flat surface substantially parallel to the floor surface F in a state where the end pin holder 1 is placed on the floor surface F.

- the support member 3 is configured to rotatably support the receiving member 2 described above. More specifically, the support member 3 is configured to rotatably support the receiving member 2 via the bearing 4.

- the outer ring of the bearing 4 is fitted to the support member 3 by fitting the bearing 4 into the holding hole 32 provided in the central portion of the support member 3 via the holder 35.

- the part 41 is fixed.

- the bearing 4 is located in the center of the support member 3 in a horizontal state (a state where the shaft hole 40 is opened in the vertical direction).

- the receiving member 2 since the receiving member 2 is fixed in the shaft hole 40 of the bearing 4, the receiving member 2 can smoothly rotate with respect to the support member 3. As a result, the abutment stage 21 provided in the receiving member 2 is rotatable in a horizontal plane fixed to the inner ring portion 42 of the bearing 4. As a result, it is possible to suppress the horizontal vibration from propagating to the floor when the cello having the end pin P is played.

- the support member 3 has a configuration in which the peripheral edge portion 31 protrudes downward so that the space 5 is formed below the location where the receiving member 2 is located. Thereby, when the end pin holder 1 is installed on the floor surface F, the receiving member 2 is in a state of floating from the floor surface F, so that the vibration of the cello having the end pin P is further suppressed from propagating to the floor. Can do.

- the support member 3 preferably has a flat dome shape (vertical cross section is substantially arched) as shown in FIG.

- the material of the support member 3 it is preferable to use a material having relatively high elasticity such as wood, bamboo, or plastic. Thereby, moderate elasticity can be imparted to the support member 3.

- the support member 3 may be reinforced with carbon fiber or the like.

- a material of the support member 3 it is preferable to use a material having a small specific gravity so that the weight is reduced.

- the size of the support member 3 is, for example, 50 to 160 mm. Further, although the thickness of the support member 3 (thickness of the ceiling portion) depends on the material, it is preferably 2 to 7 mm in order to achieve both appropriate elasticity and strength.

- the support member 3 is formed with a plurality of through holes 30 that communicate the space 5 with the outer surface side of the support member 3.

- the shape of the through hole 30 is, for example, a circle or an ellipse.

- the size of each through hole 30 may be different from each other.

- the size (maximum diameter) of the through hole 30 is, for example, 2 mm or more.

- the number of the through holes 30 may be plural, and may be an appropriate number from the viewpoint of imparting appropriate elasticity according to the hardness and thickness of the material of the support member 3.

- the plurality of through holes 30 may be arranged on substantially the same circumference around the receiving member 2. Moreover, you may arrange

- the bearing 4 is used to rotatably support the receiving member 2 on the support member 3.

- the bearing 4 for example, as shown in FIG. 3, an outer ring portion 41 (outer race), an inner ring portion 42 (inner race), and a plurality of rolling elements disposed between the outer ring portion 41 and the inner ring portion 42. 43, so-called rolling bearings can be used.

- the inner diameter of the bearing 4 (the diameter of the shaft hole 40) is preferably 3 to 10 mm, and more preferably 5 to 8 mm.

- the anti-slip member 7 makes the end pin holder 1 difficult to slip, and is provided at a location in contact with the floor surface F.

- the anti-slip member 7 is provided on the peripheral edge 31 of the support member 3.

- the material of the anti-slip member 7 may be any material as long as it has an anti-slip effect, and may be a rubber material such as natural rubber or synthetic rubber (for example, silicon rubber or urethane rubber).

- the end pin holder 1 since the receiving member 2 is rotatably supported by the support member 3, it is possible to suppress the vibration of the cello having the end pin P from propagating to the floor. . Further, the cello having the end pin P can be held while allowing free vibration. As a result, when playing the cello having the end pin P, the sound and sound quality can be brought close to the sound of a natural musical instrument.

- the end pin holder 1A according to the second embodiment is different from the end pin holder 1 according to the first embodiment in that it includes a support member 3A instead of the support member 3 and further includes a reinforcing plate 6. is there.

- the support member 3A is thinner than the support member 3 (the thickness of the ceiling), and is formed in a flat dome shape.

- a holding hole 32 that rotatably holds the receiving member 2 via a holder 35 and a bearing 4 is formed in the central portion of the support member 3A. Further, the number of through holes 30 provided in the support member 3 ⁇ / b> A is smaller than the number of through holes 30 provided in the support member 3.

- the reinforcing plate 6 reinforces the supporting member 3 ⁇ / b> A and is attached to the peripheral edge 31 of the supporting member 3.

- the reinforcing plate 6 is a plate-shaped member having a ring shape, and is attached so as to be fitted inside the peripheral edge portion 31 of the support member 3.

- the anti-slip member 7 is provided so as to straddle the lower surface of the reinforcing plate 6 and the peripheral edge 31 of the support member 3.

- the end pin holder 1A since the receiving member 2 is rotatably supported by the support member 3B, similarly to the end pin holder 1 according to the first embodiment, the end pin holder 1A is provided.

- the cello vibration can be prevented from propagating to the floor. Further, the cello having the end pin P can be held while allowing free vibration. As a result, when playing the cello having the end pin P, the sound and sound quality can be brought close to the sound of a natural musical instrument.

- the support member 3A since the support member 3A is formed in a flat dome shape with the peripheral edge protruding downward, the support member 3A has both elasticity and strength. It becomes easy. Thus, even if the number of through holes 30 provided in the support member 3A is smaller than the number of through holes 30 provided in the support member 3, the support member 3A can have elasticity equivalent to that of the support member 3. it can.

- the end pin holder 1B according to the third embodiment is different from the end pin holder 1 according to the first embodiment in that a support member 3B is provided instead of the support member 3.

- the support member 3B has a solid structure with a flat dome shape.

- a concave portion 33 is formed in the central portion of the upper surface of the support member 3B so as to accommodate the receiving member 2 via the holder 35 and the bearing 4 in a rotatable manner.

- the end pin holder 1B similarly to the end pin holder 1 according to the first embodiment, since the receiving member 2 is rotatably supported by the support member 3B, the end pin holder 1B has the end pin P.

- the cello vibration can be prevented from propagating to the floor. Further, the cello having the end pin P can be held while allowing free vibration. As a result, when playing the cello having the end pin P, the sound and sound quality can be brought close to the sound of a natural musical instrument.

- end pin holders 1, 1 ⁇ / b> A, 1 ⁇ / b> B are used, for example, by being placed so that the tip of the end pin P included in the cello abuts against the abutment stage 21 in a state of being placed on the floor surface F.

- the end pin holder according to the present invention can bring the sound and sound quality close to the sound of a natural musical instrument when playing a cello having an end pin, and thus is also useful for a stringed instrument having an end pin such as a contrabass.

Landscapes

- Physics & Mathematics (AREA)

- Engineering & Computer Science (AREA)

- Acoustics & Sound (AREA)

- Multimedia (AREA)

- Auxiliary Devices For Music (AREA)

- Stringed Musical Instruments (AREA)

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP15884001.7A EP3267436B1 (en) | 2015-03-02 | 2015-09-17 | Endpin holder |

| US15/554,862 US10013956B2 (en) | 2015-03-02 | 2015-09-17 | Endpin holder |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2015-040021 | 2015-03-02 | ||

| JP2015040021A JP6416017B2 (ja) | 2015-03-02 | 2015-03-02 | エンドピンホルダー |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2016139835A1 true WO2016139835A1 (ja) | 2016-09-09 |

Family

ID=56845146

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2015/076540 Ceased WO2016139835A1 (ja) | 2015-03-02 | 2015-09-17 | エンドピンホルダー |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US10013956B2 (enExample) |

| EP (1) | EP3267436B1 (enExample) |

| JP (1) | JP6416017B2 (enExample) |

| WO (1) | WO2016139835A1 (enExample) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| TWI680452B (zh) * | 2019-07-31 | 2019-12-21 | 王胤杰 | 弦樂器的支撐桿 |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP6416017B2 (ja) * | 2015-03-02 | 2018-10-31 | 政己 相見 | エンドピンホルダー |

| CN110136673B (zh) * | 2019-06-14 | 2025-01-07 | 吕云馨 | 乐器声响放大装置 |

| JP7052784B2 (ja) * | 2019-09-30 | 2022-04-12 | セイコーエプソン株式会社 | 光学デバイス、プロジェクター、及び光学デバイスの制御方法 |

| KR200499496Y1 (ko) * | 2022-12-05 | 2025-08-21 | 인하대학교 산학협력단 | 첼로 엔드핀용 스토퍼 |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB178336A (en) * | 1921-04-29 | 1922-04-20 | James Groves | An improved peg and support for violoncellos and the like |

| GB251989A (en) * | 1925-05-05 | 1926-09-30 | Pierre Lefevre | An improved rest or support |

| US2218142A (en) * | 1938-09-06 | 1940-10-15 | Walter R Becker | Accordion support |

| US2502229A (en) * | 1946-07-02 | 1950-03-28 | Miller James | Bass viol stand |

| JPH0625891U (ja) * | 1992-09-07 | 1994-04-08 | 郁雄 秋山 | エンドピン立具 |

| JP2007139876A (ja) * | 2005-11-15 | 2007-06-07 | Cosmo Japan:Kk | 弦楽器用支持具 |

Family Cites Families (21)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2814229A (en) * | 1956-01-18 | 1957-11-26 | Vaccaro Adelaide | Musical instrument support |

| US2974556A (en) * | 1958-01-30 | 1961-03-14 | Fawick Flexi Grip Co | End-rest foot-assembly for violoncellos, bass viols and the like |

| US3160050A (en) * | 1962-11-06 | 1964-12-08 | Klein Markus | End-rest assembly |

| US4018129A (en) * | 1974-11-26 | 1977-04-19 | Ralph Hollander | End-pin holder for string instruments |

| US4316402A (en) * | 1981-01-16 | 1982-02-23 | Richard Goldner | Adjustable end pin for the violoncello and the string bass |

| DE3935160A1 (de) * | 1989-02-01 | 1990-08-02 | Wilhelm Wolf | Parkettschoner fuer streichinstrumente |

| US5003858A (en) * | 1989-11-15 | 1991-04-02 | Rowell Frances E | Portable resonating platform and T-bar for securing the endpin and enhancing the tone of a cello |

| JPH0625891A (ja) | 1992-02-24 | 1994-02-01 | Olin Corp | 変色抵抗の改良方法 |

| US5297771A (en) * | 1992-12-10 | 1994-03-29 | Mark Gilbert | Support assembly for standing musical instruments |

| JP2593205Y2 (ja) * | 1993-08-26 | 1999-04-05 | 大三郎 澤居 | 楽器用音響振動遮断型エンドピン受け |

| DE19529482C1 (de) * | 1995-08-10 | 1997-02-13 | Reimund Korupp | Resonanzkasten |

| JP3194186B2 (ja) * | 1997-12-30 | 2001-07-30 | 泰永 上野 | 楽器またはスピーカの支持具 |

| US6696626B1 (en) * | 2002-06-19 | 2004-02-24 | Jon J. Pagenkopf | Cello endpin restraint |

| US7084337B1 (en) * | 2002-09-17 | 2006-08-01 | Thomas Hermann Schroeder | Ergonomic stringed instrument |

| US7342160B2 (en) * | 2004-04-23 | 2008-03-11 | Alberti John L | Adjustable support for a stringed musical instrument |

| JP3112322U (ja) * | 2005-05-06 | 2005-08-11 | 朝計 福原 | 絃楽器の絃安定調整器 |

| TWM290240U (en) * | 2005-11-21 | 2006-05-01 | Otto Musica Corp | Floor-type sounding apparatus of stringed instrument |

| JP3153830U (ja) * | 2009-03-29 | 2009-09-24 | 士郎 林 | 弦楽器演奏補助具 |

| US8735702B1 (en) * | 2012-03-21 | 2014-05-27 | Deborah R. Miles | Portable dissipating medium used for removal of vibrational interference in a bowed string of a violin family instrument |

| JP6416017B2 (ja) * | 2015-03-02 | 2018-10-31 | 政己 相見 | エンドピンホルダー |

| US9858903B2 (en) * | 2016-02-29 | 2018-01-02 | Thomas J DeVuono | Efficient acoustic enhancement of endpins and receptacles for stringed musical instruments and the like using customized filler materials |

-

2015

- 2015-03-02 JP JP2015040021A patent/JP6416017B2/ja active Active

- 2015-09-17 EP EP15884001.7A patent/EP3267436B1/en active Active

- 2015-09-17 WO PCT/JP2015/076540 patent/WO2016139835A1/ja not_active Ceased

- 2015-09-17 US US15/554,862 patent/US10013956B2/en active Active

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB178336A (en) * | 1921-04-29 | 1922-04-20 | James Groves | An improved peg and support for violoncellos and the like |

| GB251989A (en) * | 1925-05-05 | 1926-09-30 | Pierre Lefevre | An improved rest or support |

| US2218142A (en) * | 1938-09-06 | 1940-10-15 | Walter R Becker | Accordion support |

| US2502229A (en) * | 1946-07-02 | 1950-03-28 | Miller James | Bass viol stand |

| JPH0625891U (ja) * | 1992-09-07 | 1994-04-08 | 郁雄 秋山 | エンドピン立具 |

| JP2007139876A (ja) * | 2005-11-15 | 2007-06-07 | Cosmo Japan:Kk | 弦楽器用支持具 |

Non-Patent Citations (1)

| Title |

|---|

| See also references of EP3267436A4 * |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| TWI680452B (zh) * | 2019-07-31 | 2019-12-21 | 王胤杰 | 弦樂器的支撐桿 |

Also Published As

| Publication number | Publication date |

|---|---|

| US10013956B2 (en) | 2018-07-03 |

| EP3267436A1 (en) | 2018-01-10 |

| EP3267436B1 (en) | 2022-04-13 |

| JP6416017B2 (ja) | 2018-10-31 |

| JP2016161749A (ja) | 2016-09-05 |

| EP3267436A4 (en) | 2018-10-03 |

| US20180047371A1 (en) | 2018-02-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| WO2016139835A1 (ja) | エンドピンホルダー | |

| EP3010012B1 (en) | Device for vibrating a stringed instrument | |

| CN103065613B (zh) | 外架式电子爵士鼓 | |

| US7928303B2 (en) | Insert for cajon drum | |

| JP2007323075A (ja) | ギターのボディの補強 | |

| CN105321508B (zh) | 用于声学换能器的安装结构和乐器 | |

| US11232775B2 (en) | Handheld noisemaker | |

| CN106940994B (zh) | 用于优化音质的流线型古琴腹腔结构 | |

| JP5686923B1 (ja) | 擦弦楽器 | |

| JP3197284U (ja) | エンドピンホルダー | |

| CN103562991A (zh) | 一种改良版吉他 | |

| US1649376A (en) | Banjo bridge | |

| US20180240441A1 (en) | String instrument | |

| KR20220125009A (ko) | 현악기용 엔드핀 | |

| US7842866B1 (en) | Musical instrument | |

| JP3211420U (ja) | 弦楽器の駒 | |

| KR200459882Y1 (ko) | 개량 가야금 | |

| JP2020187264A (ja) | 回転式楽器 | |

| CN210073300U (zh) | 一种防滑落的旋转式小提琴肩托 | |

| KR200363432Y1 (ko) | 실로폰의 음판 고정구 | |

| US6872875B2 (en) | Mute for stringed instrument | |

| WO2018084026A1 (ja) | シンバル用支持具及びシンバル用支持具の使用方法 | |

| JP2025166447A (ja) | 方向付き楽器固定具 | |

| KR200379608Y1 (ko) | 징 받침대 | |

| KR200483276Y1 (ko) | 양손잡이용 기타 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 15884001 Country of ref document: EP Kind code of ref document: A1 |

|

| REEP | Request for entry into the european phase |

Ref document number: 2015884001 Country of ref document: EP |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 15554862 Country of ref document: US |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |