WO2015053374A1 - プリプレグマイカテープ及びそれを用いたコイル - Google Patents

プリプレグマイカテープ及びそれを用いたコイル Download PDFInfo

- Publication number

- WO2015053374A1 WO2015053374A1 PCT/JP2014/077108 JP2014077108W WO2015053374A1 WO 2015053374 A1 WO2015053374 A1 WO 2015053374A1 JP 2014077108 W JP2014077108 W JP 2014077108W WO 2015053374 A1 WO2015053374 A1 WO 2015053374A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- mica

- mica tape

- boron nitride

- prepreg

- resin

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01B—CABLES; CONDUCTORS; INSULATORS; SELECTION OF MATERIALS FOR THEIR CONDUCTIVE, INSULATING OR DIELECTRIC PROPERTIES

- H01B3/00—Insulators or insulating bodies characterised by the insulating materials; Selection of materials for their insulating or dielectric properties

- H01B3/02—Insulators or insulating bodies characterised by the insulating materials; Selection of materials for their insulating or dielectric properties mainly consisting of inorganic substances

- H01B3/04—Insulators or insulating bodies characterised by the insulating materials; Selection of materials for their insulating or dielectric properties mainly consisting of inorganic substances mica

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J7/00—Adhesives in the form of films or foils

- C09J7/20—Adhesives in the form of films or foils characterised by their carriers

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01F—MAGNETS; INDUCTANCES; TRANSFORMERS; SELECTION OF MATERIALS FOR THEIR MAGNETIC PROPERTIES

- H01F5/00—Coils

- H01F5/06—Insulation of windings

Definitions

- the present invention relates to a prepreg mica tape and a coil using the same.

- a prepreg mica tape made of resin, mica, and a backing material is often used as an insulating layer of the coil.

- a technique of adding an inorganic filler having higher thermal conductivity than resin and mica to the tape is used.

- the prepreg mica tape may be required to have flexibility.

- Table 1 Example 3 and Example 4 of Japanese Patent Application Laid-Open No. 2005-199562 disclose mica tape in which mica is filled with alumina having high thermal conductivity as an inorganic filler. It is said that a mica tape having a thermal conductivity of 32 W / m ⁇ K to 0.36 W / m ⁇ K is obtained.

- Table 1 and Examples 1 to 7 of JP-A No. 2000-116047 disclose mica tapes in which alumina having a high thermal conductivity as an inorganic filler is filled in a resin. It is said that a mica tape having a thermal conductivity of 40 W / m ⁇ K to 0.60 W / m ⁇ K is obtained.

- the first problem is that the alumina particles are likely to fall off from the mesh when a method is used in which a slurry in which mica pieces and alumina particles are mixed is used to make the mica layer contain alumina. Therefore, it is difficult to make an alumina-containing mica paper, which increases the manufacturing cost.

- the second problem is that although the thermal conductivity of alumina is higher than that of mica and resin, the effect of improving the thermal conductivity of mica tape filled with alumina is actually not so remarkable.

- the thermal conductivity of mica tape filled with alumina cannot achieve 0.4 W / m ⁇ K.

- a conventional product to which a high thermal conductive inorganic filler is not added has a thermal conductivity of about 0.3 W / m ⁇ K. From the viewpoint of practicality, it is meaningless to fill the mica tape with alumina particles unless a thermal conductivity more than twice that of the conventional product is obtained.

- the third problem is that although the thermal conductivity of the mica tape is slightly increased by adding alumina, other characteristics required for the mica tape are easily impaired. For example, since a mica tape filled with alumina becomes hard, the taping work on the coil becomes difficult. In addition, when normally spherical alumina particles are added as compared with scaly mica pieces, the current path is shortened, so that the withstand voltage of the mica tape may be lowered. Furthermore, since the dielectric constant of alumina is large, it is not preferable for use as an electrical insulating material.

- mica tape that has a thermal conductivity of at least twice that of conventional products, that is, 0.6 W / m ⁇ K or more, but does not impair other mechanical and electrical properties even when BN is added. The situation was not reached.

- An object of the present invention is to provide a prepreg mica tape having high thermal conductivity, good flexibility and high dielectric strength, and a coil using the same.

- a backing material a boron nitride-containing layer containing boron nitride and a first resin provided on one surface of the backing material, and a surface of the backing material on which the boron nitride-containing layer is provided

- a prepreg mica tape having a mica-containing layer provided on top and containing mica and a second resin.

- ⁇ 2> The prepreg mica tape according to ⁇ 1>, wherein the boron nitride-containing layer and the mica-containing layer are provided in this order on one surface of the backing material.

- ⁇ 3> The prepreg mica according to ⁇ 1> or ⁇ 2>, wherein a ratio of mica pieces having a particle diameter of 2.8 mm or more when the mica is sieved using a JIS standard sieve is 50% by mass or more. tape.

- ⁇ 4> The prepreg mica tape according to any one of ⁇ 1> to ⁇ 3>, wherein the boron nitride has an average particle diameter of 1 ⁇ m to 40 ⁇ m.

- a coil provided with an insulating layer that is a laminate of the prepreg mica tape according to any one of ⁇ 1> to ⁇ 4>.

- the present invention it is possible to provide a prepreg mica tape having high thermal conductivity, good flexibility and high dielectric strength, and a coil using the prepreg mica tape.

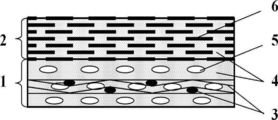

- FIG. 6 is a schematic cross-sectional view showing prepreg mica tapes of Examples 1 to 4.

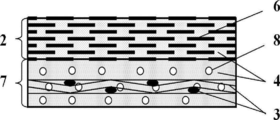

- FIG. 2 is a schematic cross-sectional view showing a prepreg mica tape of Comparative Example 1.

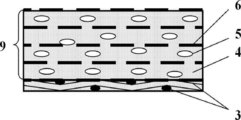

- FIG. 6 is a schematic cross-sectional view showing prepreg mica tapes of Comparative Examples 2 to 3.

- FIG. 6 is a schematic cross-sectional view showing a prepreg mica tape of Comparative Example 4.

- the term “process” is not limited to an independent process, and even if it cannot be clearly distinguished from other processes, the term “process” is used if the intended purpose of the process is achieved. included.

- a numerical range indicated by using “to” indicates a range including the numerical values described before and after “to” as the minimum value and the maximum value, respectively.

- the content of each component in the composition means the total amount of the plurality of substances present in the composition unless there is a specific notice when there are a plurality of substances corresponding to each component in the composition.

- the term “layer” includes a configuration of a shape formed in part in addition to a configuration of a shape formed on the entire surface when observed as a plan view.

- the prepreg mica tape of the present invention includes a backing material, a boron nitride-containing layer that is provided on one surface of the backing material and includes boron nitride and a first resin, and the boron nitride-containing layer of the backing material.

- the prepreg mica tape of the present invention has high thermal conductivity, and has both good flexibility and high withstand voltage.

- the reason why the prepreg mica tape of the present invention has high thermal conductivity and combines good flexibility and high dielectric strength is not clear, but is presumed as follows.

- the prepreg mica tape of the present invention has a boron nitride-containing layer containing boron nitride and a first resin. Since boron nitride is a filler exhibiting high thermal conductivity, it has a boron nitride-containing layer containing boron nitride.

- the prepreg mica tape of the present invention is presumed to have a high thermal conductivity.

- boron nitride has a hardness of about half or less compared to alumina, it is presumed that it exhibits better flexibility than a mica tape using alumina as a high thermal conductive filler. Furthermore, by providing the boron nitride-containing layer and the mica-containing layer separately, it is possible to prevent boron nitride particles from being mixed between the mica pieces. When boron nitride particles are mixed between mica pieces, the current path is shortened, and the insulation withstand voltage of the mica tape may be lowered. However, in the prepreg mica tape of the present invention, boron nitride particles are prevented from being mixed between mica pieces, so that the current path is unlikely to be shortened.

- the prepreg mica tape of this invention comes to have a high withstand voltage. Furthermore, since both the boron nitride-containing layer and the mica-containing layer are provided on one side of the backing material, the backing material is provided on the other side of the prepreg mica tape of the invention. Workability when taping the mica tape into a coil or the like is improved.

- the prepreg mica tape of the present invention is also called a resin rich mica tape. That is, the resin-containing composition is preliminarily contained in a large amount in the entire prepreg mica tape, and the impregnating varnish is not required to be injected.

- the content of the resin-containing composition is generally in the range of about 15% by mass to 50% by mass with respect to the total mass of the prepreg mica tape, as described in JP 2010-193673 A. Set accordingly.

- the prepreg mica tape can be wound around the coil or the like while applying tension, so that the compressive force resulting from this tension is applied to the boron nitride-containing layer and mica-containing layer in the prepreg state. .

- the resin component existing in the boron nitride-containing layer and the mica-containing layer is more effectively transferred, and the mica density and nitriding of the mica-containing layer Since the boron-containing layer has a high boron nitride density, the electrical insulation as the insulating material of the prepreg mica tape of the present invention and the characteristics (for example, thermal conductivity) of boron nitride can be more effectively exhibited. .

- the thickness of the prepreg mica tape of the present invention is preferably 200 ⁇ m to 400 ⁇ m, more preferably 250 ⁇ m to 350 ⁇ m.

- the average thickness of the prepreg mica tape is determined by measuring the thickness at 10 points using a micrometer (MDC-SB, Mitutoyo Corporation) and calculating the arithmetic average value.

- the configuration of the prepreg mica tape of the present invention includes a backing material, a boron nitride-containing layer provided on one surface of the backing material, and a mica-containing layer provided on the surface of the backing material on which the boron nitride-containing layer is provided. And may have other layers as necessary. Further, the order of the boron nitride-containing layer and the mica-containing layer provided on one surface of the backing material is not particularly limited, and may be configured in the order of the backing material, the boron nitride-containing layer, and the mica-containing layer. , Backing material, mica-containing layer and boron nitride-containing layer.

- a boron nitride-containing layer and a mica-containing layer are provided in this order on one surface of the backing material from the viewpoint of ease of production.

- other layers provided as necessary include a protective layer (protective film) provided on the outermost surface of the backing material on which the boron nitride-containing layer or the like is provided, an adhesive layer, and the like.

- the boron nitride-containing layer according to the present invention includes boron nitride and a first resin.

- the boron nitride-containing layer according to the present invention may contain other components other than boron nitride and the first resin as necessary. Examples of other components include a curing agent, a curing catalyst, and various additives.

- the thickness of the boron nitride-containing layer is not particularly limited, but is preferably in the range of 80 ⁇ m to 200 ⁇ m.

- the thickness of the boron nitride-containing layer is determined by observing a secondary electron image at an acceleration voltage of 10 kV under high vacuum after platinum deposition on the cross section of the prepreg mica tape using a scanning electron microscope (SEM) (Philips, XL30). Can be obtained.

- SEM scanning electron microscope

- the boron nitride-containing layer may contain other inorganic fillers other than boron nitride.

- the content of boron nitride in the total amount of the inorganic filler contained in the boron nitride-containing layer is preferably 90% by mass to 100% by mass, more preferably 95% by mass to 100% by mass, and more preferably 98% by mass to 100% by mass. % Or less is more preferable.

- Examples of other inorganic fillers in the case where the boron nitride-containing layer contains other inorganic fillers other than boron nitride include alumina, magnesium oxide, aluminum nitride, silicon nitride, and silicon oxide.

- the mica-containing layer according to the present invention includes mica and a second resin.

- the mica-containing layer according to the present invention may contain other components other than mica and the second resin as necessary. Examples of other components include a curing agent, a curing catalyst, and various additives.

- the thickness of the mica-containing layer is not particularly limited, but is preferably in the range of 100 ⁇ m to 250 ⁇ m, and more preferably in the range of 110 ⁇ m to 230 ⁇ m.

- the thickness of the mica-containing layer is determined by observing a secondary electron image at an acceleration voltage of 10 kV under a high vacuum after platinum deposition on the cross section of the prepreg mica tape using a scanning electron microscope (SEM) (Philips, XL30). Can be obtained.

- SEM scanning electron microscope

- the mica-containing layer preferably contains no other inorganic filler (boron nitride or the like) other than mica.

- the content of other inorganic fillers other than mica in the total amount of the inorganic filler contained in the mica-containing layer is preferably 3% by mass or less, more preferably 2% by mass or less, still more preferably 1% by mass or less, 0 It is particularly preferable that the content is% by mass.

- a cloth obtained by using all or a part of fibers made of an organic material may be used.

- the organic material used for obtaining the cloth include aramid, polyamide, polyimide, and polyester.

- the fibers composed of the organic material may be used as warp, weft, or both.

- fibers other than fibers composed of organic materials inorganic fibers such as glass fibers may be used.

- a glass cloth using glass fiber and an organic polymer film may be used in combination.

- boron nitride-containing layer examples include hexagonal boron nitride (h-BN), cubic boron nitride (c-BN), and wurtzite boron nitride.

- h-BN hexagonal boron nitride

- c-BN cubic boron nitride

- wurtzite boron nitride hexagonal boron nitride

- the boron nitride may be primary particles of boron nitride formed in a scaly shape or secondary particles formed by agglomerating such primary particles.

- the average particle diameter of boron nitride is preferably 1 ⁇ m to 40 ⁇ m, more preferably 5 ⁇ m to 20 ⁇ m, still more preferably 5 ⁇ m to 10 ⁇ m.

- the average particle diameter of boron nitride is 1 ⁇ m or more, the thermal conductivity and the dielectric strength voltage tend to be further improved.

- the average particle diameter of boron nitride is 40 ⁇ m or less, it can be suppressed that the anisotropy of the thermal conductivity due to the anisotropy of the particle shape becomes too large.

- the average particle diameter of boron nitride can be measured by using a laser diffraction / scattering particle size distribution analyzer (Microtrack MT3000II, Nikkiso Co., Ltd.). After introducing boron nitride powder into pure water, it is dispersed by an ultrasonic disperser. By measuring the particle size distribution of this dispersion, the particle size distribution of boron nitride is measured. Based on the particle size distribution, the average particle size is obtained as a particle size corresponding to 50% of the cumulative volume from the small diameter side.

- a laser diffraction / scattering particle size distribution analyzer Microtrack MT3000II, Nikkiso Co., Ltd.

- one type of boron nitride may be used alone, or two or more types may be used in combination.

- two or more types of boron nitride are used in combination, for example, when two or more types of boron nitride having the same component and different average particle sizes are used, when two or more types of boron nitride having the same average particle size and different components are used, the average A case where two or more types of boron nitrides having different particle diameters and types are used.

- the content of boron nitride is preferably 10% by volume to 50% by volume, preferably 15% by volume to the total amount of the total solid content excluding the backing material and mica contained in the prepreg mica tape of the present invention. More preferably, it is 35% by volume. If the content rate of boron nitride is 10 volume% or more, it exists in the tendency for the heat conductivity of the prepreg mica tape of this invention to improve more. If the boron nitride content is 50% by volume or less, it tends to be difficult to fill the boron nitride resin.

- the first resin contained in the boron nitride-containing layer according to the present invention is not particularly limited.

- a curable resin as the first resin, and examples thereof include an epoxy resin, a phenol resin, an unsaturated polyester resin, and a silicone resin. From the viewpoints of adhesiveness and electrical insulation, an epoxy resin is preferable.

- the second resin contained in the mica-containing layer according to the present invention is not particularly limited. In order to make the mica tape into a prepreg state, it is desirable to use a curable resin as the second resin, and examples thereof include an epoxy resin, a phenol resin, an unsaturated polyester resin, and a silicone resin.

- an epoxy resin is preferable.

- the types of the first resin and the second resin may be the same or different. From the viewpoint of ease of production of the prepreg mica tape of the present invention, the types of the first resin and the second resin are preferably the same.

- examples of the epoxy resin include bisphenol A type epoxy resin, bisphenol F type epoxy resin, phenol novolac type epoxy resin, cresol novolac type epoxy resin, and naphthalene type epoxy.

- Resins, biphenyl type epoxy resins, and cycloaliphatic epoxy resins are preferable to use.

- the mesogenic group referred to in the present invention refers to a group that can form a higher order structure in a cured resin product when the epoxy resin is cured to form a cured resin product.

- the higher order structure as used in the field of this invention means the state in which the molecule

- an epoxy resin may be used individually by 1 type, and may use 2 or more types together.

- mica contained in the mica-containing layer according to the present invention unfired hard laminated mica, fired hard laminated mica, unfired soft laminated mica, fired soft laminated mica, synthetic mica, flake mica, and the like can be used.

- unfired hard laminated mica as mica from the viewpoints of price and availability.

- mica preferably has a ratio of mica pieces having a particle diameter of 2.8 mm or more when sieved using a JIS standard sieve, of 50% by mass or more, and 55% by mass. More preferably, it is more preferably 60% by mass or more. If the ratio of mica pieces having a particle diameter of 2.8 mm or more is 50% by mass or more, the mica paper can be self-supported without fibrosis. It is advantageous for thermal conductivity not to include fibrites.

- the measurement of the particle diameter of the mica pieces is performed according to the following method. 1% by mass of mica to be measured is added to 20 g of pure water, and mica is dispersed with an ultrasonic disperser to prepare a dispersion. After the dispersion is applied onto the film, the film is placed on a hot plate and dried at 110 ° C. for 30 minutes. After drying, the particle size of the mica is measured by visually observing the size of the mica pieces on the film. Moreover, the ratio (mass basis) of the mica pieces having a particle diameter of 2.8 mm or more is measured by the following method.

- one kind of mica may be used alone, or two or more kinds may be used in combination.

- two or more types of mica are used in combination, for example, when two or more types of mica having the same component and different average particle sizes are used, when two or more types of mica having the same average particle size and different components are used, and the average particle size and The case where two or more types of different mica are used is mentioned.

- boron nitride-containing layer and the mica-containing layer according to the present invention examples include a curing agent, a curing catalyst, and various additives.

- the boron nitride-containing layer and the mica-containing layer according to the present invention include at least one curing agent in addition to the curable resin as a curable component. Furthermore, it is preferable to include.

- curing agent According to the kind of curable resin, it can select suitably.

- the curing agent can be appropriately selected from curing agents usually used as a curing agent for epoxy resins. Specific examples include amine curing agents such as dicyandiamide and aromatic diamine; phenolic resin curing agents such as phenol novolak and cresol novolak.

- the curable resin is an epoxy resin, the ratio of the curing agent to the epoxy resin is 0.8 to 1.2 in terms of equivalent ratio (curing agent / epoxy resin). It is preferable from the viewpoint.

- the boron nitride-containing layer and the mica-containing layer according to the present invention have a curable resin curing reaction or a curable resin-curing agent curing reaction.

- a curing catalyst may be added for the purpose of accelerating the process.

- the curing catalyst include triphenylphosphine, trimethylamine, 2-methyl-4-ethylimidazole, and BF 3 monoethylamine.

- the curable resin is an epoxy resin

- the content of the curing catalyst is usually 0.01% by mass to 5% by mass with respect to the total amount of the epoxy resin and the curing agent used as necessary. Is.

- the boron nitride-containing layer and the mica-containing layer according to the present invention can further contain various additives as necessary.

- additives include various additives generally used for resin compositions such as coupling agents, elastomers, antioxidants, antioxidants, stabilizers, flame retardants, and thickeners.

- the content of these additives is not particularly limited as long as the effects of the present invention are not impaired.

- the prepreg mica tape of the present invention may be produced through any process, and conventionally known production methods can be applied.

- boron nitride is prepared by preparing a boron nitride mixed solution (BN-containing resin varnish) in which a resin, boron nitride, and other materials used as necessary are mixed in a solvent.

- a mixed solution preparing step, a coating step of applying the boron nitride mixed solution on one side of the backing material, and an attaching step of attaching mica paper to the side of the backing material to which the boron nitride mixed solution is applied are performed.

- a method is mentioned.

- the resin may be diluted with a solvent.

- the solvent used is appropriately selected from commonly used organic solvents. Specific examples include solvents such as methyl ethyl ketone, methanol, and cyclohexanone.

- the boron nitride-containing liquid is applied on one surface of the backing material, and dried to form the boron nitride-containing layer according to the present invention.

- the mica paper By impregnating the mica paper bonded to the surface of the backing material to which the boron nitride mixed solution is applied with the resin contained in the boron nitride mixed solution and other materials used as necessary, the mica paper The place where there was a mica-containing layer according to the present invention.

- Both the first resin and the second resin according to the prepreg mica tape of the present invention manufactured through the above steps are the same type of resin originating from the resin contained in the boron nitride mixed solution.

- the boron nitride mixed liquid when applied on one side of the backing material in the coating step, when a cloth such as a glass cloth is used as the backing material, a part of the boron nitride mixed liquid is on the other side of the backing material. May ooze to the side.

- a boron nitride-containing layer may be formed also on the other surface side of the backing material, but the prepreg mica tape in which the boron nitride-containing layer is also formed on the other surface side of the backing material, It is included in the scope of the prepreg mica tape of the present invention.

- the prepreg mica tape of the present invention can be used for forming an insulating layer of a coil.

- the prepreg mica tape of the present invention can also be used as a heat-resistant electrical insulating and heat radiating spacer, for example, as a material having improved heat dissipation in a power transistor heat radiating insulating plate.

- the coil of this invention is provided with the insulating layer which is a laminated body formed by laminating

- a method of forming an insulating layer using the prepreg mica tape of the present invention for example, after the tape is wound around a portion where a coil insulating layer is to be formed using the prepreg mica tape of the present invention, heating and heating are performed.

- the first resin and the second resin contained in the boron nitride-containing layer and the mica-containing layer are cured or fused to form a prepreg mica tape by heating or pressurizing after pressurization or vacuum treatment. And a method of forming an insulating layer.

- the prepreg mica tape of the present invention Since the prepreg mica tape of the present invention has good flexibility, it is excellent in workability when winding the tape. Moreover, since the prepreg mica tape of the present invention has a high dielectric strength voltage, the coil of the present invention is excellent in terms of insulation reliability. Furthermore, since the prepreg mica tape of the present invention has a high thermal conductivity, when cooling the coil of the present invention, a hydrogen cooling system or an air cooling is also applied to a coil of a scale that conventionally employs a direct water cooling system. It becomes possible to adopt a method, and the structure of the coil can be simplified.

- Example 1 Production of mica paper Mica (the content of mica pieces having a particle diameter of 2.8 mm or more is 63% by mass) is dispersed in water to form mica particles, which are made by a paper machine and have an average thickness of 0.13 mm. Paper was prepared. The average thickness of the mica paper was determined by measuring the thickness at 10 points using a micrometer (Mitutoyo Corporation, MDC-SB) and calculating the arithmetic average value. Hereinafter, the average thickness of the mica paper was measured by the same method.

- MDC-SB micrometer

- BN-containing resin varnish 30.8 parts by mass of epoxy resin (Dow Chemical Japan Co., Ltd., trade name “DEN438”) and BF 3 monoethylamine (Wako Pure Chemical Industries, Ltd.) 1.0 as a curing catalyst Part by mass and 37.2 parts by mass of methyl ethyl ketone (Wako Pure Chemical Industries, Ltd.) as a solvent were mixed. Thereafter, 31.0 parts by mass of boron nitride (average particle size 5 ⁇ m, Denki Kagaku Kogyo Co., Ltd., trade name “SP-3”) was added and further mixed to obtain a BN-containing resin varnish. In addition, the content rate of the boron nitride in the total solid content volume of BN containing resin varnish was 35 volume%.

- Preparation of Prepreg Mica Tape The obtained BN-containing resin varnish was applied to a glass cloth (Soyo Corporation, WEA 03G 103) with a roll coater, and further bonded to mica paper. After drying, it was cut to a width of 30 mm to form a prepreg mica tape.

- the average thickness of the obtained prepreg mica tape was 280 ⁇ m.

- the average thickness of the prepreg mica tape was determined by measuring the thickness at 10 points using a micrometer (Mitutoyo Corporation, MDC-SB) and calculating the arithmetic average value.

- the average thickness of the prepreg mica tape was measured by the same method.

- Thermal conductivity About the obtained mica tape cured product, the thermal resistance value of the mica tape cured product was measured using a thermal resistance device (Yamayo Tester Co., Ltd., YST-901S). The thermal conductivity (W / m ⁇ K) was calculated by back-calculating the obtained thermal resistance value. The thermal conductivity of the cured mica tape was 0.75 W / m ⁇ K.

- a dielectric breakdown electric field was measured using a dielectric breakdown test apparatus (SOKEN insulating material test system, DAC-6032C). The measurement was performed with a cylindrical electrode having a diameter of 10 mm, a pressure increase rate of 500 V / s, an AC of 50 Hz, a cutoff current of 10 mA, room temperature (25 ⁇ 1 ° C.), and in oil.

- the dielectric breakdown electric field of the cured mica tape was 39 kV / mm.

- Example 2 Production of mica paper Mica paper was produced in the same manner as in Example 1.

- BN-containing resin varnish 41.5 parts by mass of epoxy resin (Dow Chemical Japan Co., Ltd., trade name “DEN438”) and BF 3 monoethylamine (Wako Pure Chemical Industries, Ltd.) 1.3 as a curing catalyst Part by mass and 31.2 parts by mass of methyl ethyl ketone (Wako Pure Chemical Industries, Ltd.) as a solvent were mixed. Thereafter, 26.0 parts by mass of boron nitride (average particle size 5 ⁇ m, Denki Kagaku Kogyo Co., Ltd., trade name “SP-3”) was added and further mixed to obtain a BN-containing resin varnish. In addition, the content rate of the boron nitride in the total solid content volume of BN containing resin varnish was 25 volume%.

- Preparation of Prepreg Mica Tape The obtained BN-containing resin varnish was applied to a glass cloth (Soyo Corporation, WEA 03G 103) with a roll coater, and further bonded to mica paper. After drying, it was cut to a width of 30 mm to form a prepreg mica tape. The average thickness of the obtained prepreg mica tape was 280 ⁇ m.

- the obtained prepreg mica tape and cured mica tape were evaluated in the same manner as in Example 1.

- the flexibility of the prepreg mica tape obtained above was 76 N / m, the handling was good, and no trouble occurred during the taping operation.

- the heat conductivity of the obtained mica tape cured product was 0.63 W / m ⁇ K.

- the dielectric breakdown electric field of the obtained mica tape cured product was 38 kV / mm.

- Example 3 Production of mica paper Mica paper was produced in the same manner as in Example 1.

- BN-containing resin varnish 24.5 parts by mass of epoxy resin (Dow Chemical Japan Co., Ltd., trade name “DEN438”) and BF 3 monoethylamine (Wako Pure Chemical Industries, Ltd.) 0.8 as a curing catalyst Part by mass and 49.8 parts by mass of methyl ethyl ketone (Wako Pure Chemical Industries, Ltd.) as a solvent were mixed. Thereafter, 24.9 parts by mass of boron nitride (average particle size 2 ⁇ m, Denki Kagaku Kogyo Co., Ltd., trade name “SP3-7”) was added and further mixed to obtain a BN-containing resin varnish. In addition, the content rate of the boron nitride in the total solid content volume of BN containing resin varnish was 35 volume%.

- Preparation of Prepreg Mica Tape The obtained BN-containing resin varnish was applied to a glass cloth (Soyo Corporation, WEA 03G 103) with a roll coater, and further bonded to mica paper. After drying, it was cut to a width of 30 mm to form a prepreg mica tape. The average thickness of the obtained prepreg mica tape was 280 ⁇ m.

- the obtained prepreg mica tape and cured mica tape were evaluated in the same manner as in Example 1.

- the flexibility of the prepreg mica tape obtained above was 59 N / m, the handling was good, and no trouble occurred during the taping operation.

- the heat conductivity of the obtained mica tape cured product was 0.67 W / m ⁇ K.

- the dielectric breakdown electric field of the obtained mica tape cured product was 37 kV / mm.

- Example 4 Production of mica paper Mica paper was produced in the same manner as in Example 1.

- BN-containing resin varnish 34.1 parts by mass of epoxy resin (Dow Chemical Japan Co., Ltd., trade name “DEN438”) and BF 3 monoethylamine (Wako Pure Chemical Industries, Ltd.) 1.1 as a curing catalyst Part by mass and 43.2 parts by mass of methyl ethyl ketone (Wako Pure Chemical Industries, Ltd.) as a solvent were mixed. Thereafter, 21.6 parts by mass of boron nitride (average particle size 2 ⁇ m, Denki Kagaku Kogyo Co., Ltd., trade name “SP3-7”) was added and further mixed to obtain a BN-containing resin varnish. In addition, the content rate of the boron nitride in the total solid content volume of BN containing resin varnish was 25 volume%.

- Preparation of Prepreg Mica Tape The obtained BN-containing resin varnish was applied to a glass cloth (Soyo Corporation, WEA 03G 103) with a roll coater, and further bonded to mica paper. After drying, it was cut to a width of 30 mm to form a prepreg mica tape. The average thickness of the obtained prepreg mica tape was 280 ⁇ m.

- the obtained prepreg mica tape and cured mica tape were evaluated in the same manner as in Example 1.

- the flexibility of the prepreg mica tape obtained above was 62 N / m, handling was good, and no trouble occurred during taping work.

- the heat conductivity of the obtained mica tape cured product was 0.61 W / m ⁇ K.

- the dielectric breakdown electric field of the obtained mica tape cured product was 36 kV / mm.

- the obtained prepreg mica tape and cured mica tape were evaluated in the same manner as in Example 1.

- the flexibility of the prepreg mica tape obtained above was 95 N / m, it was easy to handle, and no trouble occurred during taping work.

- the thermal conductivity of the obtained mica tape cured product was 0.30 W / m ⁇ K.

- the dielectric breakdown electric field of the obtained mica tape cured product was 35 kV / mm.

- alumina-containing resin varnish 25.2 parts by mass of epoxy resin (Dow Chemical Japan Co., Ltd., trade name “DEN438”) and BF 3 monoethylamine (Wako Pure Chemical Industries, Ltd.) 0.8 as a curing catalyst Part by mass and 27.8 parts by mass of methyl ethyl ketone (Wako Pure Chemical Industries, Ltd.) as a solvent were mixed. Thereafter, 46.2 parts by mass of alumina (average particle size 3 ⁇ m, Denki Kagaku Kogyo Co., Ltd., trade name “AA3”) was added and further mixed to obtain an alumina-containing resin varnish. In addition, the content rate of the alumina in the total solid content volume of an alumina containing resin varnish was 35 volume%.

- Preparation of Prepreg Mica Tape The obtained alumina-containing resin varnish was applied to a glass cloth (Soyo Corporation, WEA 03G 103) with a roll coater, and further bonded to mica paper. After drying, it was cut to a width of 30 mm to form a prepreg mica tape. The average thickness of the obtained mica tape was 280 ⁇ m.

- the obtained prepreg mica tape and cured mica tape were evaluated in the same manner as in Example 1.

- the prepreg mica tape obtained above had a flexibility of 300 N / m and was hard and could not be taped into a coil.

- the heat conductivity of the obtained mica tape cured product was 0.41 W / m ⁇ K.

- the dielectric breakdown electric field of the obtained mica tape cured product was 30 kV / mm.

- alumina-containing resin varnish 35.1 parts by mass of epoxy resin (Dow Chemical Japan Co., Ltd., trade name “DEN438”) and BF 3 monoethylamine (Wako Pure Chemical Industries, Ltd.) 1.1 as a curing catalyst Part by mass and 24.0 parts by mass of methyl ethyl ketone (Wako Pure Chemical Industries, Ltd.) as a solvent were mixed. Thereafter, 39.8 parts by mass of alumina (average particle size 3 ⁇ m, Denki Kagaku Kogyo Co., Ltd., trade name “AA3”) was added and further mixed to obtain an alumina-containing resin varnish. In addition, the content rate of the alumina in the total solid content volume of an alumina containing resin varnish was 25 volume%.

- Preparation of Prepreg Mica Tape The obtained alumina-containing resin varnish was applied to a glass cloth (Soyo Corporation, WEA 03G 103) with a roll coater, and further bonded to mica paper. After drying, it was cut to a width of 30 mm to form a prepreg mica tape. The average thickness of the obtained prepreg mica tape was 280 ⁇ m.

- the obtained prepreg mica tape and cured mica tape were evaluated in the same manner as in Example 1.

- the prepreg mica tape obtained above had a softness of 250 N / m and was too hard to tap into the coil.

- the thermal conductivity of the obtained mica tape cured product was 0.35 W / m ⁇ K.

- the dielectric breakdown electric field of the obtained mica tape cured product was 31 kV / mm.

- BN-containing mica paper Mica the content of mica pieces having a particle diameter of 2.8 mm or more is 63% by mass

- boron nitride average particle diameter of 5 ⁇ m, Denki Kagaku Kogyo Co., Ltd., trade name “SP-3”

- the filling rate of boron nitride was 35 volume% with respect to the volume sum of boron nitride and mica.

- Preparation of Prepreg Mica Tape The obtained filler-free resin varnish was applied to a glass cloth (Soyo Corporation, WEA 03G 103) with a roll coater, and further bonded to the BN-containing mica paper.

- the boron nitride content was 35% by volume with respect to the total amount of the total solid content excluding the backing material and mica contained in the prepreg mica tape. Then, it cut

- the obtained prepreg mica tape and cured mica tape were evaluated in the same manner as in Example 1.

- the flexibility of the prepreg mica tape obtained above was 80 N / m, the handling was good, and no trouble occurred during taping work.

- the heat conductivity of the obtained mica tape cured product was 0.40 W / m ⁇ K.

- the dielectric breakdown electric field of the obtained mica tape cured product was 34 kV / mm.

- FIG. 1 is a schematic sectional view showing prepreg mica tapes of Examples 1 to 4.

- FIG. 2 the schematic sectional drawing showing the prepreg mica tape of the comparative example 1 is shown.

- FIG. 3 is a schematic sectional view showing the prepreg mica tapes of Comparative Examples 2 to 3.

- FIG. 4 the schematic sectional drawing showing the prepreg mica tape of the comparative example 4 is shown.

- reference numeral 1 denotes a boron nitride-containing layer

- reference numeral 2 denotes a mica-containing layer

- reference numeral 3 denotes a backing material

- reference numeral 4 denotes a resin (first resin and second resin)

- reference numeral 5 Represents a boron nitride particle

- 6 represents a mica

- 7 represents an alumina-containing layer

- 8 represents an alumina particle

- 9 represents a boron nitride-containing mica-containing layer.

- the inorganic filler refers to BN or alumina and excludes mica.

- the inorganic filler-containing layer of the prepreg mica tape is filled with boron nitride as an inorganic filler, and the inorganic filler-containing layer and the mica-containing layer are provided independently. It can be seen that a high thermal conductivity prepreg mica tape can be obtained which has a high thermal conductivity of 6 W / m ⁇ K or more, is excellent in taping work on the coil, and can achieve both high breakdown voltage.

- the entire disclosure of Japanese application 2013-212223 is incorporated herein by reference.

- all the documents, patent applications, and technical standards described in this specification are the same as when individual documents, patent applications, and technical standards are specifically and individually described to be incorporated by reference. Which is incorporated herein by reference.

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Power Engineering (AREA)

- Inorganic Chemistry (AREA)

- Organic Chemistry (AREA)

- Insulating Bodies (AREA)

- Insulated Conductors (AREA)

- Laminated Bodies (AREA)

- Reinforced Plastic Materials (AREA)

- Insulation, Fastening Of Motor, Generator Windings (AREA)

- Insulating Of Coils (AREA)

- Inorganic Insulating Materials (AREA)

- Compositions Of Macromolecular Compounds (AREA)

Priority Applications (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201480055766.8A CN105637599B (zh) | 2013-10-09 | 2014-10-09 | 预浸云母带及使用其的线圈 |

| JP2015541640A JP6094683B2 (ja) | 2013-10-09 | 2014-10-09 | プリプレグマイカテープ及びそれを用いたコイル |

| US15/027,802 US10373727B2 (en) | 2013-10-09 | 2014-10-09 | Prepreg mica tape and coil using same |

| EP14851852.5A EP3046117A4 (en) | 2013-10-09 | 2014-10-09 | Prepreg mica tape and coil using same |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2013-212223 | 2013-10-09 | ||

| JP2013212223 | 2013-10-09 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2015053374A1 true WO2015053374A1 (ja) | 2015-04-16 |

Family

ID=52813189

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2014/077108 Ceased WO2015053374A1 (ja) | 2013-10-09 | 2014-10-09 | プリプレグマイカテープ及びそれを用いたコイル |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US10373727B2 (enExample) |

| EP (1) | EP3046117A4 (enExample) |

| JP (2) | JP6094683B2 (enExample) |

| CN (3) | CN105637599B (enExample) |

| WO (1) | WO2015053374A1 (enExample) |

Cited By (18)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN105835482A (zh) * | 2016-03-30 | 2016-08-10 | 江苏华荣绝缘材料有限公司 | 一种用于大型发电机组的高导热少胶云母带 |

| WO2017014202A1 (ja) * | 2015-07-17 | 2017-01-26 | 日立化成株式会社 | 回転電機用コイル、回転電機用コイルの製造方法及びマイカテープ |

| JP2017059335A (ja) * | 2015-09-15 | 2017-03-23 | 三菱マテリアル株式会社 | 絶縁皮膜 |

| WO2017175875A1 (ja) | 2016-04-08 | 2017-10-12 | 日立化成株式会社 | 回転電機用コイル、回転電機用コイルの製造方法、マイカテープ、マイカテープの硬化物及び絶縁物 |

| WO2018002972A1 (ja) * | 2016-07-01 | 2018-01-04 | 東芝三菱電機産業システム株式会社 | 絶縁構造製造方法、絶縁構造および回転電機 |

| WO2018002971A1 (ja) * | 2016-07-01 | 2018-01-04 | 東芝三菱電機産業システム株式会社 | 絶縁構造製造方法、絶縁構造および回転電機 |

| WO2018003044A1 (ja) * | 2016-06-29 | 2018-01-04 | 日立化成株式会社 | 回転電機用コイル、回転電機用コイルの製造方法、マイカテープ、マイカテープの硬化物及び絶縁物 |

| WO2018003043A1 (ja) * | 2016-06-29 | 2018-01-04 | 日立化成株式会社 | 回転電機用コイル、回転電機用コイルの製造方法、マイカテープ、マイカテープの製造方法、マイカテープの硬化物及び絶縁物 |

| WO2018096603A1 (ja) * | 2016-11-22 | 2018-05-31 | 日立化成株式会社 | 回転電機用コイル、回転電機用コイルの製造方法、マイカテープ、マイカテープの硬化物及び絶縁層付き物品 |

| WO2018096602A1 (ja) * | 2016-11-22 | 2018-05-31 | 日立化成株式会社 | 回転電機用コイル、回転電機用コイルの製造方法、マイカテープ、マイカテープの硬化物及び絶縁層付き物品 |

| WO2018096601A1 (ja) * | 2016-11-22 | 2018-05-31 | 日立化成株式会社 | 回転電機用コイル、回転電機用コイルの製造方法、マイカテープ、マイカテープの硬化物及び絶縁層付き物品 |

| WO2018179437A1 (ja) * | 2017-03-31 | 2018-10-04 | 日立化成株式会社 | 回転電機用コイル、回転電機用コイルの製造方法、ドライマイカテープ及び絶縁物 |

| WO2018179439A1 (ja) * | 2017-03-31 | 2018-10-04 | 日立化成株式会社 | 回転電機用コイル、回転電機用コイルの製造方法、マイカテープ、マイカテープの硬化物及び絶縁物 |

| WO2018179440A1 (ja) * | 2017-03-31 | 2018-10-04 | 日立化成株式会社 | 回転電機用コイル、回転電機用コイルの製造方法、マイカテープ、マイカテープの硬化物及び絶縁物 |

| WO2019130588A1 (ja) * | 2017-12-28 | 2019-07-04 | 日立化成株式会社 | プリプレグマイカテープ、回転電機用コイル及びその製造方法 |

| WO2019130586A1 (ja) * | 2017-12-28 | 2019-07-04 | 日立化成株式会社 | プリプレグマイカテープ、回転電機用コイル及びその製造方法 |

| JP2023101093A (ja) * | 2022-01-07 | 2023-07-20 | 日立Astemo株式会社 | 回転電機の固定子 |

| JP7788283B2 (ja) | 2022-01-07 | 2025-12-18 | Astemo株式会社 | 回転電機の固定子 |

Families Citing this family (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2015053374A1 (ja) * | 2013-10-09 | 2015-04-16 | 日立化成株式会社 | プリプレグマイカテープ及びそれを用いたコイル |

| JP6028267B2 (ja) * | 2015-03-05 | 2016-11-16 | 株式会社明電舎 | 回転電機のコイル |

| US10584228B2 (en) * | 2015-05-22 | 2020-03-10 | Hitachi Chemical Company, Ltd. | Epoxy resin composition, thermally-conductive material precursor, B-stage sheet, prepreg, heat dissipation material, laminate, metal substrate, and printed circuit board |

| KR101798123B1 (ko) * | 2015-09-14 | 2017-11-15 | 윤성구 | 하수 폐열회수 및 여과장치 |

| JP6712774B2 (ja) * | 2016-03-23 | 2020-06-24 | パナソニックIpマネジメント株式会社 | プリプレグ、金属張積層板、プリント配線板、プリプレグの製造方法 |

| WO2018002974A1 (ja) * | 2016-07-01 | 2018-01-04 | 東芝三菱電機産業システム株式会社 | コロナ放電防止構造製造方法、コロナ放電防止構造および回転電機 |

| JP2019533286A (ja) * | 2016-09-28 | 2019-11-14 | ハンツマン・アドヴァンスト・マテリアルズ・ライセンシング・(スイッツランド)・ゲーエムベーハー | 発電機およびモーターのためのエポキシ樹脂基剤の電気絶縁系 |

| CN110915107A (zh) * | 2017-06-09 | 2020-03-24 | Abb瑞士股份有限公司 | 具有导体布置和用于所述导体布置的绝缘部的电机 |

| KR102772339B1 (ko) | 2019-07-18 | 2025-02-25 | 삼성전자 주식회사 | 플렉서블 케이블 |

| CN111470084B (zh) * | 2019-12-13 | 2021-08-24 | 海安鑫福缘农业科技有限公司 | 一种错位叠层的棉花打包方法 |

| CN111549567A (zh) * | 2020-05-13 | 2020-08-18 | 湖南睿达云母新材料有限公司 | 一种高导热云母纸的改性制备方法 |

| CN111777963B (zh) * | 2020-08-12 | 2023-03-21 | 苏州宝优际科技股份有限公司 | 隔热贴片 |

| US20250119018A1 (en) * | 2021-09-21 | 2025-04-10 | Mitsubishi Electric Corporation | Rotary machine coil, method for manufacturing same, and rotary machine |

| CN113808778B (zh) * | 2021-11-01 | 2024-09-13 | 哈尔滨理工大学 | 一种高导热氮化硼云母带及其制备方法 |

Citations (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS56159011A (en) * | 1980-05-09 | 1981-12-08 | Mitsubishi Electric Corp | Electrically insulating tape |

| JPS57172607A (en) * | 1981-04-15 | 1982-10-23 | Mitsubishi Electric Corp | Method of producing interlayer insulating paper |

| JPH04162312A (ja) * | 1990-10-25 | 1992-06-05 | Okabe Maika Kogyosho:Kk | 高温電気絶縁用マイカ板状部材 |

| JPH0945133A (ja) * | 1995-08-01 | 1997-02-14 | Japan Mica Ind Co Ltd | マイカ基材シート状体及び絶縁コイル |

| JP2000116047A (ja) | 1998-09-29 | 2000-04-21 | Hitachi Ltd | 高熱伝導絶縁コイル及びこのコイルを用いた回転電機装置 |

| JP2002093257A (ja) * | 2000-09-13 | 2002-03-29 | Japan Mica Ind Co Ltd | マイカ基材シート状体及び絶縁コイル |

| JP2005199562A (ja) | 2004-01-15 | 2005-07-28 | Toshiba Corp | テープ部材或いはシート部材並びにテープ部材或いはシート部材の製造方法 |

| JP2008027819A (ja) * | 2006-07-24 | 2008-02-07 | Toshiba Corp | プリプレグ材、電気絶縁用プリプレグテープ及びこれを用いた回転電機 |

| JP2008220095A (ja) * | 2007-03-06 | 2008-09-18 | Toshiba Corp | 回転電機のコイル絶縁物 |

| JP2010158113A (ja) * | 2008-12-26 | 2010-07-15 | Toshiba Corp | 電気絶縁部材、回転電機用固定子コイルおよび回転電機 |

| JP2010166809A (ja) * | 2010-03-03 | 2010-07-29 | Toshiba Corp | 回転電機 |

| JP2010193673A (ja) | 2009-02-20 | 2010-09-02 | Hitachi Ltd | ドライマイカテープ、それを用いた電気絶縁線輪,固定子コイル及び回転電機 |

| JP2012175799A (ja) * | 2011-02-21 | 2012-09-10 | Toshiba Corp | 回転電機固定子、回転電機固定子の製造方法、及び回転電機固定子用絶縁テープ |

| JP2012244861A (ja) * | 2011-05-24 | 2012-12-10 | Mitsubishi Electric Corp | 絶縁コイル |

| JP2013212223A (ja) | 2012-03-31 | 2013-10-17 | Sanyo Product Co Ltd | 遊技機 |

| JP5611485B1 (ja) * | 2013-01-10 | 2014-10-22 | 三菱電機株式会社 | 絶縁テープ及びその製造方法、並びに固定子コイル |

Family Cites Families (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS535799A (en) | 1976-07-07 | 1978-01-19 | Hitachi Ltd | Insulator materials of electric conductor |

| JPS5861605A (ja) * | 1981-10-08 | 1983-04-12 | Hitachi Chem Co Ltd | 絶縁線輪 |

| US4491618A (en) | 1980-11-08 | 1985-01-01 | Hitachi Chemical Company, Ltd. | Reconstituted mica materials, reconstituted mica prepreg materials, reconstituted mica products and insulated coils |

| JPS57141474A (en) * | 1981-02-25 | 1982-09-01 | Toshiba Corp | Epoxy mica tape and sheet |

| JP2000058314A (ja) * | 1998-08-03 | 2000-02-25 | Hitachi Ltd | 高熱伝導コイル、絶縁シート及びその製造方法 |

| US7776392B2 (en) * | 2005-04-15 | 2010-08-17 | Siemens Energy, Inc. | Composite insulation tape with loaded HTC materials |

| US20080027819A1 (en) * | 2006-07-29 | 2008-01-31 | John Ruckart | Methods, systems, and products for purchasing products |

| CN101262452A (zh) * | 2008-05-04 | 2008-09-10 | 杭州华三通信技术有限公司 | 网络连接的控制方法和控制装置及路由设备 |

| SG10201600443SA (en) * | 2011-03-07 | 2016-02-26 | Mitsubishi Gas Chemical Co | Resin composition, and prepreg as well as laminate using the same |

| US20140079913A1 (en) * | 2011-03-28 | 2014-03-20 | Tomoo Nishiyama | Multilayer resin sheet, resin sheet laminate, cured multilayer resin sheet and method for producing same, multilayer resin sheet with metal foil, and semiconductor device |

| US8568855B2 (en) * | 2011-06-08 | 2013-10-29 | Siemens Energy, Inc. | Insulation materials having apertures formed therein |

| WO2015053374A1 (ja) * | 2013-10-09 | 2015-04-16 | 日立化成株式会社 | プリプレグマイカテープ及びそれを用いたコイル |

-

2014

- 2014-10-09 WO PCT/JP2014/077108 patent/WO2015053374A1/ja not_active Ceased

- 2014-10-09 CN CN201480055766.8A patent/CN105637599B/zh active Active

- 2014-10-09 CN CN201710409030.1A patent/CN107240439B/zh not_active Expired - Fee Related

- 2014-10-09 EP EP14851852.5A patent/EP3046117A4/en not_active Withdrawn

- 2014-10-09 JP JP2015541640A patent/JP6094683B2/ja not_active Expired - Fee Related

- 2014-10-09 US US15/027,802 patent/US10373727B2/en active Active

- 2014-10-09 CN CN201710408080.8A patent/CN107123461A/zh active Pending

-

2017

- 2017-02-15 JP JP2017026288A patent/JP6520966B2/ja active Active

Patent Citations (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS56159011A (en) * | 1980-05-09 | 1981-12-08 | Mitsubishi Electric Corp | Electrically insulating tape |

| JPS57172607A (en) * | 1981-04-15 | 1982-10-23 | Mitsubishi Electric Corp | Method of producing interlayer insulating paper |

| JPH04162312A (ja) * | 1990-10-25 | 1992-06-05 | Okabe Maika Kogyosho:Kk | 高温電気絶縁用マイカ板状部材 |

| JPH0945133A (ja) * | 1995-08-01 | 1997-02-14 | Japan Mica Ind Co Ltd | マイカ基材シート状体及び絶縁コイル |

| JP2000116047A (ja) | 1998-09-29 | 2000-04-21 | Hitachi Ltd | 高熱伝導絶縁コイル及びこのコイルを用いた回転電機装置 |

| JP2002093257A (ja) * | 2000-09-13 | 2002-03-29 | Japan Mica Ind Co Ltd | マイカ基材シート状体及び絶縁コイル |

| JP2005199562A (ja) | 2004-01-15 | 2005-07-28 | Toshiba Corp | テープ部材或いはシート部材並びにテープ部材或いはシート部材の製造方法 |

| JP2008027819A (ja) * | 2006-07-24 | 2008-02-07 | Toshiba Corp | プリプレグ材、電気絶縁用プリプレグテープ及びこれを用いた回転電機 |

| JP2008220095A (ja) * | 2007-03-06 | 2008-09-18 | Toshiba Corp | 回転電機のコイル絶縁物 |

| JP2010158113A (ja) * | 2008-12-26 | 2010-07-15 | Toshiba Corp | 電気絶縁部材、回転電機用固定子コイルおよび回転電機 |

| JP2010193673A (ja) | 2009-02-20 | 2010-09-02 | Hitachi Ltd | ドライマイカテープ、それを用いた電気絶縁線輪,固定子コイル及び回転電機 |

| JP2010166809A (ja) * | 2010-03-03 | 2010-07-29 | Toshiba Corp | 回転電機 |

| JP2012175799A (ja) * | 2011-02-21 | 2012-09-10 | Toshiba Corp | 回転電機固定子、回転電機固定子の製造方法、及び回転電機固定子用絶縁テープ |

| JP2012244861A (ja) * | 2011-05-24 | 2012-12-10 | Mitsubishi Electric Corp | 絶縁コイル |

| JP2013212223A (ja) | 2012-03-31 | 2013-10-17 | Sanyo Product Co Ltd | 遊技機 |

| JP5611485B1 (ja) * | 2013-01-10 | 2014-10-22 | 三菱電機株式会社 | 絶縁テープ及びその製造方法、並びに固定子コイル |

Non-Patent Citations (1)

| Title |

|---|

| See also references of EP3046117A4 |

Cited By (35)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN107534341A (zh) * | 2015-07-17 | 2018-01-02 | 日立化成株式会社 | 旋转电机用线圈、旋转电机用线圈的制造方法以及云母带 |

| WO2017014202A1 (ja) * | 2015-07-17 | 2017-01-26 | 日立化成株式会社 | 回転電機用コイル、回転電機用コイルの製造方法及びマイカテープ |

| JPWO2017014202A1 (ja) * | 2015-07-17 | 2018-04-26 | 日立化成株式会社 | 回転電機用コイル、回転電機用コイルの製造方法及びマイカテープ |

| JP2017059335A (ja) * | 2015-09-15 | 2017-03-23 | 三菱マテリアル株式会社 | 絶縁皮膜 |

| CN105835482A (zh) * | 2016-03-30 | 2016-08-10 | 江苏华荣绝缘材料有限公司 | 一种用于大型发电机组的高导热少胶云母带 |

| WO2017175397A1 (ja) * | 2016-04-08 | 2017-10-12 | 日立化成株式会社 | マイカテープ、マイカテープの硬化物及び絶縁物 |

| JP2020092597A (ja) * | 2016-04-08 | 2020-06-11 | 日立化成株式会社 | 回転電機用コイル、回転電機用コイルの製造方法、マイカテープ、マイカテープの硬化物及び絶縁物 |

| EP3442098A4 (en) * | 2016-04-08 | 2019-10-30 | Hitachi Chemical Co., Ltd. | COIL FOR ROTATING ELECTRIC MACHINE, METHOD FOR MANUFACTURING COIL FOR ROTATING ELECTRIC MACHINE, MICA BAND, CURED MICA BAND PRODUCT, AND INSULATING MATERIAL |

| CN108886286A (zh) * | 2016-04-08 | 2018-11-23 | 日立化成株式会社 | 旋转电机用线圈、旋转电机用线圈的制造方法、云母带、云母带的固化物和绝缘物 |

| WO2017175875A1 (ja) | 2016-04-08 | 2017-10-12 | 日立化成株式会社 | 回転電機用コイル、回転電機用コイルの製造方法、マイカテープ、マイカテープの硬化物及び絶縁物 |

| JPWO2017175875A1 (ja) * | 2016-04-08 | 2018-11-29 | 日立化成株式会社 | 回転電機用コイル、回転電機用コイルの製造方法、マイカテープ、マイカテープの硬化物及び絶縁物 |

| WO2018003044A1 (ja) * | 2016-06-29 | 2018-01-04 | 日立化成株式会社 | 回転電機用コイル、回転電機用コイルの製造方法、マイカテープ、マイカテープの硬化物及び絶縁物 |

| WO2018003951A1 (ja) * | 2016-06-29 | 2018-01-04 | 日立化成株式会社 | 回転電機用コイル、回転電機用コイルの製造方法、マイカテープ、マイカテープの硬化物及び絶縁物 |

| WO2018003043A1 (ja) * | 2016-06-29 | 2018-01-04 | 日立化成株式会社 | 回転電機用コイル、回転電機用コイルの製造方法、マイカテープ、マイカテープの製造方法、マイカテープの硬化物及び絶縁物 |

| WO2018003950A1 (ja) * | 2016-06-29 | 2018-01-04 | 日立化成株式会社 | 回転電機用コイル、回転電機用コイルの製造方法、マイカテープ、マイカテープの製造方法、マイカテープの硬化物及び絶縁物 |

| JPWO2018003951A1 (ja) * | 2016-06-29 | 2019-05-16 | 日立化成株式会社 | 回転電機用コイル、回転電機用コイルの製造方法、マイカテープ、マイカテープの硬化物及び絶縁物 |

| JPWO2018003950A1 (ja) * | 2016-06-29 | 2019-03-28 | 日立化成株式会社 | 回転電機用コイル、回転電機用コイルの製造方法、マイカテープ、マイカテープの製造方法、マイカテープの硬化物及び絶縁物 |

| JPWO2018002972A1 (ja) * | 2016-07-01 | 2019-06-13 | 東芝三菱電機産業システム株式会社 | 絶縁構造製造方法、絶縁構造および回転電機 |

| WO2018002971A1 (ja) * | 2016-07-01 | 2018-01-04 | 東芝三菱電機産業システム株式会社 | 絶縁構造製造方法、絶縁構造および回転電機 |

| US10938260B2 (en) | 2016-07-01 | 2021-03-02 | Toshiba Mitsubishi-Electric Industrial Systems Corporation | Electrical insulating structure producing method, electrical insulating structure and rotating electrical machine |

| US10931159B2 (en) | 2016-07-01 | 2021-02-23 | Toshiba Mitsubishi-Electric Industrial Systems Corporation | Electrical insulating structure producing method, electrical insulating structure and rotating electrical machine |

| WO2018002972A1 (ja) * | 2016-07-01 | 2018-01-04 | 東芝三菱電機産業システム株式会社 | 絶縁構造製造方法、絶縁構造および回転電機 |

| EP3480920A4 (en) * | 2016-07-01 | 2020-03-04 | Toshiba Mitsubishi-Electric Industrial Systems Corporation | METHOD FOR PRODUCING AN INSULATING STRUCTURE, INSULATING STRUCTURE, AND ELECTRIC LATHE |

| JPWO2018002971A1 (ja) * | 2016-07-01 | 2019-06-13 | 東芝三菱電機産業システム株式会社 | 絶縁構造製造方法、絶縁構造および回転電機 |

| EP3480921A4 (en) * | 2016-07-01 | 2020-03-04 | Toshiba Mitsubishi-Electric Industrial Systems Corporation | METHOD FOR PRODUCING AN INSULATING STRUCTURE, INSULATING STRUCTURE, AND ELECTRIC LATHE |

| WO2018096602A1 (ja) * | 2016-11-22 | 2018-05-31 | 日立化成株式会社 | 回転電機用コイル、回転電機用コイルの製造方法、マイカテープ、マイカテープの硬化物及び絶縁層付き物品 |

| WO2018096603A1 (ja) * | 2016-11-22 | 2018-05-31 | 日立化成株式会社 | 回転電機用コイル、回転電機用コイルの製造方法、マイカテープ、マイカテープの硬化物及び絶縁層付き物品 |

| WO2018096601A1 (ja) * | 2016-11-22 | 2018-05-31 | 日立化成株式会社 | 回転電機用コイル、回転電機用コイルの製造方法、マイカテープ、マイカテープの硬化物及び絶縁層付き物品 |

| WO2018179440A1 (ja) * | 2017-03-31 | 2018-10-04 | 日立化成株式会社 | 回転電機用コイル、回転電機用コイルの製造方法、マイカテープ、マイカテープの硬化物及び絶縁物 |

| WO2018179437A1 (ja) * | 2017-03-31 | 2018-10-04 | 日立化成株式会社 | 回転電機用コイル、回転電機用コイルの製造方法、ドライマイカテープ及び絶縁物 |

| WO2018179439A1 (ja) * | 2017-03-31 | 2018-10-04 | 日立化成株式会社 | 回転電機用コイル、回転電機用コイルの製造方法、マイカテープ、マイカテープの硬化物及び絶縁物 |

| WO2019130586A1 (ja) * | 2017-12-28 | 2019-07-04 | 日立化成株式会社 | プリプレグマイカテープ、回転電機用コイル及びその製造方法 |

| WO2019130588A1 (ja) * | 2017-12-28 | 2019-07-04 | 日立化成株式会社 | プリプレグマイカテープ、回転電機用コイル及びその製造方法 |

| JP2023101093A (ja) * | 2022-01-07 | 2023-07-20 | 日立Astemo株式会社 | 回転電機の固定子 |

| JP7788283B2 (ja) | 2022-01-07 | 2025-12-18 | Astemo株式会社 | 回転電機の固定子 |

Also Published As

| Publication number | Publication date |

|---|---|

| CN107240439A (zh) | 2017-10-10 |

| JPWO2015053374A1 (ja) | 2017-03-09 |

| CN105637599B (zh) | 2017-06-27 |

| US10373727B2 (en) | 2019-08-06 |

| CN107123461A (zh) | 2017-09-01 |

| US20160247595A1 (en) | 2016-08-25 |

| JP2017095733A (ja) | 2017-06-01 |

| CN107240439B (zh) | 2020-04-03 |

| JP6520966B2 (ja) | 2019-05-29 |

| CN105637599A (zh) | 2016-06-01 |

| EP3046117A1 (en) | 2016-07-20 |

| EP3046117A4 (en) | 2017-05-17 |

| JP6094683B2 (ja) | 2017-03-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6094683B2 (ja) | プリプレグマイカテープ及びそれを用いたコイル | |

| EP3761355B1 (en) | Insulating heat dissipation sheet | |

| JP6677249B2 (ja) | 樹脂組成物、樹脂シート、プリプレグ、絶縁物、樹脂シート硬化物及び放熱部材 | |

| JP6889153B2 (ja) | 回転電機用コイル、回転電機用コイルの製造方法、マイカテープ、マイカテープの硬化物及び絶縁物 | |

| US9925744B2 (en) | Insulating tape, method for producing same, and stator coil | |

| US20180137956A1 (en) | Coil for rotary electrical machine, method of producing rotary electrical machine and mica tape | |

| JP2014122346A (ja) | 電気絶縁用高熱伝導性コンポジットおよびその物品 | |

| WO2018003950A1 (ja) | 回転電機用コイル、回転電機用コイルの製造方法、マイカテープ、マイカテープの製造方法、マイカテープの硬化物及び絶縁物 | |

| JP2019122099A (ja) | 回転電機用コイル、回転電機用コイルの製造方法、マイカテープ、マイカテープの硬化物及び絶縁物 | |

| JP6891887B2 (ja) | 回転電機用コイル、回転電機用コイルの製造方法、マイカテープ、マイカテープの硬化物及び絶縁物 | |

| WO2018179439A1 (ja) | 回転電機用コイル、回転電機用コイルの製造方法、マイカテープ、マイカテープの硬化物及び絶縁物 | |

| JP2019217668A (ja) | ドライマイカテープ、絶縁物、回転電機用コイル及び回転電機用コイルの製造方法 | |

| JP2018170252A (ja) | 回転電機用コイル、プリプレグマイカテープ、プリプレグマイカテープの製造方法、プリプレグマイカテープの硬化物、絶縁層付き物品、及び回転電機用コイルの製造方法 | |

| WO2018179440A1 (ja) | 回転電機用コイル、回転電機用コイルの製造方法、マイカテープ、マイカテープの硬化物及び絶縁物 | |

| WO2018179437A1 (ja) | 回転電機用コイル、回転電機用コイルの製造方法、ドライマイカテープ及び絶縁物 | |

| WO2024090364A1 (ja) | 積層体及びその製造方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 14851852 Country of ref document: EP Kind code of ref document: A1 |

|

| ENP | Entry into the national phase |

Ref document number: 2015541640 Country of ref document: JP Kind code of ref document: A |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 15027802 Country of ref document: US |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| REEP | Request for entry into the european phase |

Ref document number: 2014851852 Country of ref document: EP |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 2014851852 Country of ref document: EP |