WO2015025700A1 - 化粧用瞼整形用テープ及びその製造方法 - Google Patents

化粧用瞼整形用テープ及びその製造方法 Download PDFInfo

- Publication number

- WO2015025700A1 WO2015025700A1 PCT/JP2014/070449 JP2014070449W WO2015025700A1 WO 2015025700 A1 WO2015025700 A1 WO 2015025700A1 JP 2014070449 W JP2014070449 W JP 2014070449W WO 2015025700 A1 WO2015025700 A1 WO 2015025700A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- tape

- stretched

- cosmetic

- piece

- longitudinal direction

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A45—HAND OR TRAVELLING ARTICLES

- A45D—HAIRDRESSING OR SHAVING EQUIPMENT; EQUIPMENT FOR COSMETICS OR COSMETIC TREATMENTS, e.g. FOR MANICURING OR PEDICURING

- A45D44/00—Other cosmetic or toiletry articles, e.g. for hairdressers' rooms

- A45D44/22—Face shaping devices, e.g. chin straps; Wrinkle removers, e.g. stretching the skin

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J5/00—Adhesive processes in general; Adhesive processes not provided for elsewhere, e.g. relating to primers

Definitions

- the present invention is a state in which a tape-like member formed by applying a pressure-sensitive adhesive to a base material piece that can be stretched and has elastic shrinkage after the stretching is extended to a predetermined length by which the base material piece is stretched.

- a pseudo double fold or a bulge (a so-called tear bag) is formed on the lower fold.

- the present invention relates to a cosmetic wrinkle shaping tape that can be shaped and a method for producing the same.

- a solution type for applying a solution onto the skin of the wrinkle and an adhesive tape are conventionally used.

- the tape type Patent Documents 4 to 8 to be attached to the skin of the skin is known.

- these solution-type and tape-type are systems in which double folds are formed, mainly by double-faced adhesive tapes, adhesives, etc., in which the fold skins are bonded together in a folded state.

- Patent Document 9 a double fold forming tape (Patent Document 9) capable of forming a double fold by a completely different method from the conventional one.

- This double wrinkle-forming tape is composed of a tape-like member made of a synthetic resin that can be stretched and has elastic shrinkage even after being stretched.

- a tape-shaped member is inserted to form a constricted groove-shaped constriction along the tape-shaped member. As a result, when the upper collar is opened, the upper collar is folded back naturally at the constricted portion. A fold is formed.

- JP 2007-106711 A Registered Utility Model No. 3111511 Japanese Patent Laid-Open No. 02-188512 Registered Utility Model No. 3154139 Japanese Patent Laid-Open No. 10-304935 JP-A-2005-334108 JP 2007-111218 A JP 2009-195410 A Japanese Patent No. 3277180

- the tape-shaped member is made difficult to wrinkle, and various types of cosmetic wrinkles are formed along the tape-shaped member.

- it is necessary to stick the tape-shaped member to the skin of the heel in a state where the tape-shaped member is stretched and to shrink the heel together with the tape.

- the pressure-sensitive adhesive layer applied to the tape-shaped member is also extended at the same time, so that the thickness of the pressure-sensitive adhesive layer is reduced or the pressure-sensitive adhesive layer is cut in some cases. Part where there is no adhesive layer.

- the tape-like member when the tape-like member is stretched and attached to the eyelid skin, depending on the state of the eyelid skin, sufficient adhesive force can be obtained between the tape-like member and the eyelid skin.

- the tape-shaped member contracts, slipping occurs between the skin of the heel and as a result, the heel has a constriction with a depth corresponding to the actual contraction amount of the tape-shaped member, that is, a pseudo double fold. In some cases, it was not possible to form a constriction having a depth necessary for artificially shaping the heel, such as forming or forming a bulge on the lower heel.

- the technical problem of the present invention is that it is composed of a tape-like member in which an adhesive is applied to an elongated base material piece that can be stretched and has elastic shrinkage even after the stretching.

- An object of the present invention is to provide a cosmetic wrinkle shaping tape configured to form a constriction along the tape-like member on the heel, with improved adhesion of the heel to the skin, and a method for producing the same.

- a cosmetic wrinkle shaping tape according to the present invention is formed of a synthetic resin, can be stretched in the longitudinal direction, and has elastic contractility after the stretching. And a tape-like member formed by applying a pressure-sensitive adhesive for sticking the base material piece to the ridge, and the tape-like member is located at one end side and the other end side in the longitudinal direction.

- a sticking area for the tape-shaped member which has a pair of gripping areas provided for gripping with a fingertip, and a sticking area provided between the pair of gripping areas and used for sticking to a heel

- the tape-shaped member includes a core portion having first and second side ends that extend linearly from one end to the other end in the longitudinal direction and are parallel to each other on both sides in the width direction.

- the core portion is integrally formed with a protruding portion protruding in the width direction from each of the first and second side ends of the core portion.

- “stretching” means that a base material piece made of a synthetic resin is stretched and transferred to a plastic region, that is, plastically deformed, and “stretchable” means the user's own hand. It means that it can be used after being stretched.

- “elastic contractility” means only almost instantaneous contraction with elastic contraction force among contractions generated when the force is unloaded by stretching by pulling, ⁇ Having elastic shrinkage even after stretching '' means that after stretching, it has elastic shrinkability capable of forming a constriction along the tape-like member by being hard to wrinkle against the tension of the wrinkles. I mean.

- “ ⁇ ” means a generic name of upper and lower heels.

- the base material piece is stretched to the predetermined region.

- the adhesive layer in the sticking area is also stretched at the same time, but for the protrusion, the stretch rate of the base material piece becomes smaller toward the tip side.

- the agent layer can also ensure an appropriate thickness that is thicker than the core part. Therefore, when the adhesive region is pressed against the skin of the eyelid while the tape-like member is pulled, the adhesive layer is attached.

- the region can be more securely adhered to the skin of the eyelids, and the occurrence of slippage between the tape-like member and the skin of the eyelids can be suppressed when the base piece elastically contracts. it can. Therefore, the neck has a depth constricted according to the actual contraction amount of the tape-like member, that is, forms a pseudo double fold or a bulge (a so-called tear bag) on the lower heel, and so on. It is possible to more surely form a constriction having a depth necessary for performing general shaping.

- the protrusions are formed at each of the first and second side ends.

- the protrusions are formed at a uniform height and a uniform pitch at each of the first and second side ends, and more preferably, the height of the protrusions at the first side end.

- the height and pitch of the protrusions at the second side end and the pitch of the protrusions at the second side end are formed to be equal to each other.

- the protruding portion at the side end is formed in an opposite phase.

- the tape-like member has a uniform width from one end to the other end in the longitudinal direction, and in particular, the protruding portion is formed in a corrugated shape. It is desirable.

- the protruding portions may be formed at the first and second side ends over the entire length from one end to the other end of the tape-shaped member. .

- the cosmetic wrinkle shaping tape has the same shape as the tape-like member by a tape-like member in which an adhesive is applied to both surfaces of the base material piece and a synthetic resin that is easily peelable from the adhesive.

- the release sheet piece is attached to the adhesive surface to which the adhesive in the tape-like member is applied, and the release sheet piece is cut in the widthwise direction at the center in the longitudinal direction. It is desirable to have an easily breakable portion that is provided and breaks when pulled in the longitudinal direction. In this case, when the grip region of the tape-shaped member is gripped from above the release sheet piece and pulled in the longitudinal direction, the release sheet piece is broken at the easily breakable portion, and the base material piece is extended to the sticking region. It can be extended to a predetermined length.

- a part of the adhesive may be pushed out to the end face, so that the end faces on the side of the tape along the end face in the case It is easy to bond continuously in the longitudinal direction, and it may be difficult to peel off the bonded tapes during use.

- the tape-like member extends linearly from one end to the other end in the longitudinal direction and is parallel to both sides in the width direction.

- a core portion having an end, and at least in the sticking region, the core portion is formed by a protruding portion protruding in the width direction from each of the first and second side ends, and the release sheet piece is also It has the same shape as the tape-like member. Therefore, as long as the plurality of tapes housed in the case are slightly displaced in the longitudinal direction, even if the end surfaces of the tapes are bonded to each other, it becomes point-like or intermittent bonding, and is continuous along the end surfaces. Therefore, when the tape is taken out from the case and used, the adhered tapes can be easily peeled off.

- the cosmetic wrinkle shaping tape according to the present invention is particularly preferably used as a double wrinkle forming tape, in which case the sticking area of the tape-like member is extended to a predetermined length by which the base material piece is stretched. Affixed to the upper eyelid as it is, and by making use of the elastic shrinkage after stretching of the base piece, the tape-like member is made difficult to be placed on the upper eyelid along the tape-like member. A constriction is formed, and when the upper collar is opened, the upper collar is folded back by the constriction to form a double collar fold.

- the bulge is formed on the lower eyelid using the cosmetic wrinkle shaping tape according to the present invention

- the predetermined region in which the base material piece is stretched in the sticking region of the tape-like member similarly, the predetermined region in which the base material piece is stretched in the sticking region of the tape-like member.

- the tape-shaped member is made difficult to be inserted into the position using the elastic contractility after stretching of the base material piece while being stretched to the length and pasted to a lower position that forms a bulge in the lower heel.

- a constriction along the tape-like member is formed there.

- a bulge is formed above the constriction formed in the lower eyelid, and a three-dimensional effect can be given to the eyes.

- the cosmetic wrinkle shaping tape according to the present invention can be manufactured by a method having the following steps. (1) Step of preparing a pressure-sensitive adhesive sheet in which a pressure-sensitive adhesive is applied to both surfaces or one surface of a base material sheet made of a synthetic resin forming the base material piece (2) Cutting having a cutting edge having the same contour shape as the protruding portion A step of obtaining the cosmetic wrinkle shaping tape by cutting the pressure-sensitive adhesive sheet with the cutting blade while relatively moving the blade and the pressure-sensitive adhesive sheet

- a pair of gripping regions located at one end side and the other end side in the longitudinal direction of the tape-shaped member are gripped by a fingertip, and the tape-shaped member In the state where the adhesive region located between the gripping regions is stretched to a predetermined length in which the base piece is stretched (that is, the tape-shaped member is still pulled), Paste the area against the heel. And when the fingertip is released from the gripping area, the skin of the eyelids contracts with the contraction of the base piece, but the skin of the eyelids is formed in a convex curved surface to the outside substantially along the eyeball. Constriction of the depth required for artificial shaping of the heel, such as forming a pseudo double fold or forming a bulge in the lower heel, is difficult to fold along the tape-like member. It is formed.

- the holding region of the tape-shaped member is grasped with a fingertip and pulled in the longitudinal direction, whereby the sticking region has a predetermined length by which the base material piece is stretched.

- the adhesive layer in the sticking area is also stretched at the same time.

- the layer can also secure an appropriate thickness that is thicker than the core part. Therefore, when the adhesive area is pressed against the skin of the eyelid while the tape-like member is pulled, the adhesive area is It can be made to adhere more securely to the skin of the eyelids, and it is possible to suppress the occurrence of slipping between the tape-like member and the skin of the eyelids when the base material piece elastically contracts.

- the neck is deeply constricted according to the actual contraction amount of the tape-like member, that is, a pseudo double fold is formed or a bulge is formed in the lower heel, for example, a pseudo shaping is applied to the heel. Therefore, it is possible to more reliably form a constriction having a depth required for the above.

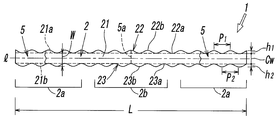

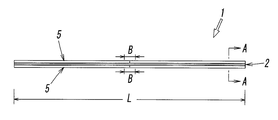

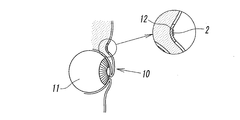

- FIG. 1 is a partially broken plan view showing a double wrinkle forming tape as one embodiment of a cosmetic wrinkle shaping tape according to the present invention. It is the figure which looked at the tape of FIG. 1 from the side.

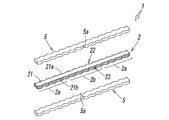

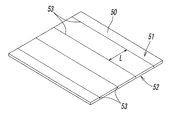

- FIG. 3 is a cross-sectional view of the tape of FIG. 2 along AA. It is a disassembled perspective view of the tape of FIG. FIG. 3 is an enlarged view of a portion B including an easily breakable portion of the tape of FIG. 2.

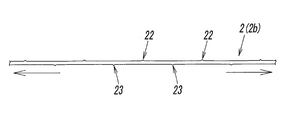

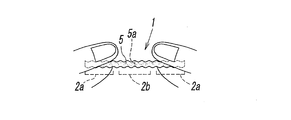

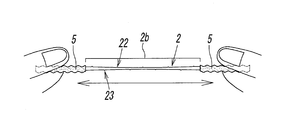

- the tape of FIG. 1 it is the schematic which shows the state of the sticking area

- FIG. 1 shows the formation method of the double wrinkles using the tape for cosmetic wrinkles which concerns on this invention.

- FIG. It is the same schematic 3.

- FIG. FIG. It is the same schematic diagram 6.

- FIG. FIG. 7 is a schematic view of the same.

- FIG. It is the same schematic 3.

- FIG. It is the same schematic FIG. (A) And (b) is a top view of the tape-shaped member which shows other embodiment of the tape for cosmetic wrinkle shaping

- A) And (b) is a top view of the sticking area

- (A)-(c) is a partial top view of the sticking area

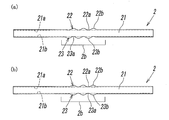

- a double wrinkle forming tape 1 as a cosmetic wrinkle shaping tape 1 according to the present invention is formed of a synthetic resin, can be stretched by stretching in the longitudinal direction, and is elastic after stretching.

- the tape-like member 2 is formed by applying adhesives 4 and 4 for adhering the base material piece 3 to the upper surface on both surfaces of the thin and long film-like base material piece 3 having a typical shrinkage. is doing.

- the sticking region 2b is stretched.

- the first side end 21a and the second side end 21b are respectively , It passes through the base ends 22a and 23a located inward of the protrusions 22 and 23 in the sticking region 2b.

- the entire length from one end to the other end of the tape-shaped member 2 is extended.

- a plurality of smoothly connected corrugated protrusions 22 and 23 are formed with uniform heights h1 and h2 and uniform pitches p1 and p2, and the height of the protrusions 22 at the first side end 21a.

- the height h1 and the pitch p1, and the height h2 and the pitch p2 of the protrusion 23 at the second side end are formed to be equal to each other.

- the protruding portion 22 of the first side end 21a and the protruding portion 23 of the second side end 21b are formed in opposite phases (that is, the first side end 21a).

- the base end 23a of the projecting portion 23 exists on the second side end 21b side at the position where the tip 22b of the projecting portion 22 exists on the side, and conversely the projecting portion 22 on the first side end 21a side.

- the tip of the projecting portion 23 is present on the second side end 21b side), and as a result, the tape-like member 2 is uniform over the whole from one end to the other end. It has a width W.

- the pressure-sensitive adhesive 4 can also ensure an appropriate thickness that is thicker than that of the core portion 21, and can secure sufficient adhesion to the skin of the upper eyelid. Therefore, when the adhesive region 2b is pressed against the upper eyelid skin while the tape-like member 2 is pulled, the adhesive region 2b can be more reliably adhered to the upper eyelid skin. When the base material piece 3 is elastically contracted, the occurrence of slippage between the tape-like member 2 and the skin of the eyelid can be suppressed. Therefore, it is possible to more reliably form a constriction corresponding to the actual shrinkage amount of the tape-like member 2, that is, a constriction having a depth necessary for forming a pseudo double crease.

- the synthetic resin forming the base piece 3 is a polyolefin resin that can be easily stretched with a fingertip and transferred (stretched) to a plastic region, and has elastic shrinkage even after stretching.

- vinyl chloride resin, and the like but polyethylene is more preferable, and among these, low density polyethylene is most preferably used.

- the base piece 3 is not stretched or has a very low stretch ratio in the longitudinal direction (axis 1 direction), particularly in the axial direction during film production. It should be noted that additives such as pigments and lamé may be added to the synthetic resin forming the base piece 3 as necessary.

- the dimensions of the tape-shaped member 2, that is, various dimensions of the base material 3 should be determined in consideration of operability and portability in actual use when the base material 3 is formed of low density polyethylene.

- the length L is about 25 to 40 mm, and the length of the pasting region 2b after stretching is preferably about 5 to 10 cm.

- the width (namely, distance between the 1st side end 21a and the 2nd side end 21b) Cw and the thickness t1 of the base-material piece 3 are the width

- Cw is preferably about 1.0 to 5.0 mm

- t1 is preferably about 40 to 80 ⁇ m.

- the pitches p1 and p2 and the heights h1 and h2 of the protrusions 22 and 23 are, for example, suppression of slippage with the skin when attached to the upper eyelid after stretching, width when attached to the upper eyelid, etc.

- p1 and p2 are about 1.5 to 4.0 mm, and h1 and h2 are about 0.3 to 0.6 mm.

- the sum of the heights h1 and h2 of the projecting portions 22 and 23 is preferably smaller than the width Cw of the core portion 21.

- the various dimensions of the base material piece 3 are not limited to these ranges, and consider the material of the base material piece 3 and sensory evaluation such as operability, usability, and appearance of the double folds formed. Thus, it can be determined as appropriate.

- the adhesives 4 and 4 an acrylic adhesive for skin is preferably used, but is not limited thereto, and any adhesive that can be used for the skin may be used.

- the thickness t2 of the pressure-sensitive adhesives 4 and 4 is preferably about 40 to 60 ⁇ m considering the adhesiveness of the wrinkles to the skin, etc., but is not particularly limited to this range. It can be determined appropriately according to the properties.

- the pressure-sensitive adhesives 4 and 4 on both surfaces of the tape-like member 2 may use different pressure-sensitive adhesives, and may have different thicknesses t2.

- the double wrinkle forming tape 1 is formed of a synthetic resin that is easily peelable from the pressure-sensitive adhesive 4 and is attached to both surfaces of the tape-like member 2, that is, the pressure-sensitive adhesive surface on which the pressure-sensitive adhesives 4 and 4 are applied.

- the release sheet pieces 5 and 5 are provided.

- the release sheet piece 5 is formed in the same shape in plan view as the tape-like member 2 (that is, formed in the same outer shape and dimensions in plan view), and the adhesives 4 and 4 in the tape-like member 2 are applied. Covers the entire adhesive surface.

- ruptured by pulling to a longitudinal direction is cut and formed in the width direction at linear form.

- the easily breakable portion 5 a is formed by cutting from the inner surface side in contact with the adhesive 4 in the release sheet piece 5 to the middle in the thickness direction, Before use, the easily breakable portion 5a is prevented from being inadvertently broken. Further, here, the inner surface of the release sheet piece 5 is formed as a mirror surface and the outer surface is formed as a fine rough surface. In the manufacturing stage, the release sheet piece 5 is reversed and the surface in contact with the adhesive 4 is replaced. Thereby, the peelability of this peeling sheet piece 5 and the adhesive 4 can also be adjusted.

- the release sheet piece 5 is integrally formed of a silicone resin having both easy peelability to the pressure-sensitive adhesive 4 and breakability in the easily breakable portion 5a.

- the thickness t3 is preferably about 0.3 to 0.5 mm, but is particularly limited thereto. is not.

- the release sheet piece 5 may be, for example, a release paper provided with an easy release layer made of silicone resin on paper.

- the easily breakable portion 5a is not necessarily formed by the cut (half cut), and may be formed by, for example, a V-shaped notch.

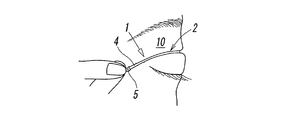

- FIGS. 7 a double wrinkle forming method using the double wrinkle forming tape 1 as the cosmetic wrinkle shaping tape 1 according to the present invention will be described with reference to FIGS.

- FIG. 7 the gripping areas 2 a and 2 a of the tape-like member 2 in the double fold-forming tape 1 are gripped from above the release sheet piece 5 with a fingertip. At that time, it is desirable to leave a sticking region 2b of at least about 1 cm between the gripping regions 2a and 2a.

- the release sheet piece 5 When the tape 1 is pulled in the longitudinal direction, the release sheet piece 5 is broken at the easily breakable portion 5a at the center, and the release sheet pieces 5 and 5 are peeled from the adhesives 4 and 4 in the sticking region 2b. Then, the sticking region 2b of the tape-like member 2 comes out while being extended. When further extended, as shown in FIG. 8, the base material piece 3 in the sticking region 2 b is stretched and is in a plastically deformed state that does not return to the original length even when the tensile force is unloaded. At this time, the base material piece 3 may be accompanied by so-called necking.

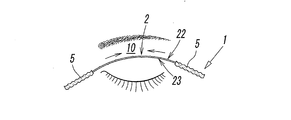

- the adhesive region 2b of the tape-like member 2 is extended to about 5 to 10 cm, the extension is stopped, and as shown in FIG. 9, the adhesive region 2b of the extended tape-like member 2 is kept tight.

- the adhesive region 2b is attached to the upper heel with the adhesive 4, and then both hands are separated from the tape 1 to the tape-like member 2. Unload the applied pulling force and pressing force on the upper arm 10.

- the adhesive region 2b is more reliably attached to the skin of the upper eyelid with the adhesive 4 of the protrusions 22 and 23.

- the skin of the upper eyelid 10 contracts together with the attaching region 2b of the tape-like member 2 attached to the eyelid.

- the skin of the upper eyelid 10 is generally formed as a convex curved surface toward the outside along the eyeball 11, so that the tape-like member 2 is not easily inserted into the tape-like member 2.

- a constricted constriction 12 is formed.

- the tape-like member 2 is attached to the bottom of the constriction 12.

- the upper collar 10 is opened as shown in FIGS. 12 and 13

- the upper collar 10 is naturally folded at the constriction 12 to form a double collar fold 13.

- the excess part of the both ends which is not sticking to the skin of the upper collar 10 of the tape-shaped member 2 is cut off at an appropriate position (position indicated by x in FIG. 12) with a cutter or the like. Thereafter, the shape of the double hook may be adjusted with a pusher or the like (not shown).

- the cosmetic wrinkle shaping tape 1 according to the present invention can also be used as a tape for forming a bulge (so-called tear bag) 17 on the lower eyelid 15 as shown in FIG.

- a bulge so-called tear bag

- the tape-like member 2 is attached to the lower position where the bulge 17 is formed, and the tape-like member 2 is inserted into the position of the tape-like member 2 by making use of the elastic contraction after stretching of the base piece 3.

- a constriction 16 is formed along.

- the cosmetic wrinkle shaping tape 1 according to the present invention is used as a tape for forming the bulge 17 in the lower eyelid 15 as described above, the length L of the tape 1 is made shorter than that for forming a double wrinkle. Also good.

- the other points are basically the same as in the case of the double fold forming tape 1 described above, and the description is omitted to avoid duplication.

- the above-described tape-shaped member 2 is sandwiched between the two release sheet pieces 5 and 5 and the release sheet pieces 5 and 5 and the tape-like member 2 are formed in the same shape as each other.

- the tapes 1 are independent of each other, when commercializing, it is common to store a plurality of the tapes together in the longitudinal direction in the case. .

- the applicant previously proposed in the above-mentioned Patent Document 9 is that both side surfaces of the tape are parallel to each other and extend in the longitudinal direction, and the edge of the adhesive layer is formed on the end surface.

- a part of the adhesive may be pushed out to the end face, so that the end faces on the side of the tape along the end face in the case It is easy to bond continuously in the longitudinal direction, and it may be difficult to peel off the bonded tapes during use.

- the tape-like member 2 extends linearly from one end to the other end in the longitudinal direction and is parallel to both sides in the width direction.

- a core portion 21 having two side ends 21a and 21b, and at least the sticking region 2b, and a protruding portion 22 protruding in the width direction from each of the first and second side ends 21a and 21b of the core portion 21, 23 and the release sheet pieces 5 and 5 have the same shape as the tape-like member 2.

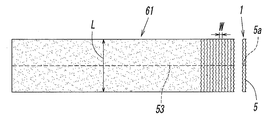

- a double-sided pressure-sensitive adhesive sheet 25 (FIG. 15) is prepared, in which pressure-sensitive adhesives 4 and 4 are coated on both surfaces of a base material sheet 30 made of a synthetic resin such as polyolefin resin or vinyl chloride resin. Further, as shown in FIG. 14, a silicone resin having a high hardness is thermoformed to produce a release sheet 50 in which the first surface 51 is a mirror surface and the opposite second surface 52 is a rough surface. A plurality of easily breakable lines 53 are formed on one surface 51 so as to be in the middle of the thickness direction and are parallel to each other at equal intervals L.

- the first surfaces 51 of the two release sheets 50 are respectively attached to the adhesives 4 and 4 on both sides of the double-sided adhesive sheet 25, thereby providing a double-sided adhesive sheet.

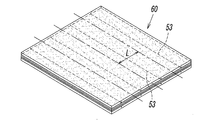

- a laminated sheet 60 in which 25 is sandwiched between two release sheets 50 and 50 is created.

- the easily breakable lines 53, 53 of the two release sheets 50, 50 extend in the same direction and face each other.

- the base sheet 30 of the double-sided pressure-sensitive adhesive sheet 25 is not stretched or has an extremely low stretch ratio in the film production, particularly with respect to the direction perpendicular to the easily breakable line 53.

- the said lamination sheet 60 is cut

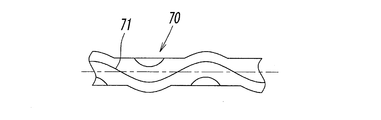

- a cutting blade 70 having a cutting edge 71 having the same contour shape as the protrusions 22 and 23 as shown in FIG. 17 is prepared.

- the cutting blade 70 and the strip-shaped laminated sheet 61 The sheet 61 is cut thinly in the direction perpendicular to the easily breakable line 53 with the cutting blade 70 while relatively moving the sheet 61 in the longitudinal direction of the sheet 61 with the feed width W.

- the double fold forming tape 1 in which the easily breakable portion 5a is provided at the center in the longitudinal direction.

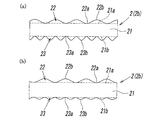

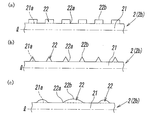

- the form of the protrusions 22 and 23 of the tape-shaped member 2 is not limited to that shown in FIG. 1, and for example, as shown in FIGS. 19A and 19B, 23 may be formed only in the sticking region 2b of the tape-like member 2, and the protrusions 22 and 23 on both sides may be in phase with each other as shown in FIG. 19 (b).

- the pitches p1 and p2 of the protrusions 22 and 23 may be different from each other.

- the heights h1 and h2 may also be different from each other. Then, as shown in FIGS.

- the protrusions 22 and 23 may be formed in a rectangular shape or a triangular shape, and may be provided at a predetermined interval, as shown in FIG. 21 (c). As shown, arc-shaped protrusions 22 and 23 having different heights h1 and h2 may be provided at predetermined intervals. Furthermore, you may combine the arrangement

- the adhesive 4 may be applied to only one side of the base material piece 3 to form the tape-like member 2.

- the release sheet piece 5 is also attached only to one side.

- a plurality of tape-like members 2 may be attached side by side to a sheet having easy releasability such as release paper provided with an easy peel layer made of silicone resin on paper.

Landscapes

- Chemical & Material Sciences (AREA)

- Organic Chemistry (AREA)

- Cosmetics (AREA)

- Absorbent Articles And Supports Therefor (AREA)

- Medicinal Preparation (AREA)

- Adhesive Tapes (AREA)

Priority Applications (6)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201480046616.0A CN105636478B (zh) | 2013-08-23 | 2014-08-04 | 化妆用眼睑整形用胶贴及其制造方法 |

| SG11201600562TA SG11201600562TA (en) | 2013-08-23 | 2014-08-04 | Cosmetic eyelid-reshaping tape and method for manufacturing same |

| KR1020167007556A KR102232970B1 (ko) | 2013-08-23 | 2014-08-04 | 화장용 눈꺼풀 정형용 테이프 및 그 제조 방법 |

| US14/913,434 US9980551B2 (en) | 2013-08-23 | 2014-08-04 | Cosmetic eyelid-reshaping tape and method for manufacturing same |

| HK16109327.7A HK1221127B (en) | 2013-08-23 | 2014-08-04 | Cosmetic eyelid-reshaping tape and method for manufacturing same |

| EP14837878.9A EP3037014B1 (en) | 2013-08-23 | 2014-08-04 | Cosmetic eyelid-reshaping tape and method for manufacturing same |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2013-173889 | 2013-08-23 | ||

| JP2013173889A JP6021760B2 (ja) | 2013-08-23 | 2013-08-23 | 化粧用瞼整形用テープ及びその製造方法 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2015025700A1 true WO2015025700A1 (ja) | 2015-02-26 |

Family

ID=52483481

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2014/070449 Ceased WO2015025700A1 (ja) | 2013-08-23 | 2014-08-04 | 化粧用瞼整形用テープ及びその製造方法 |

Country Status (9)

| Country | Link |

|---|---|

| US (1) | US9980551B2 (enExample) |

| EP (1) | EP3037014B1 (enExample) |

| JP (1) | JP6021760B2 (enExample) |

| KR (1) | KR102232970B1 (enExample) |

| CN (1) | CN105636478B (enExample) |

| MY (1) | MY177739A (enExample) |

| SG (1) | SG11201600562TA (enExample) |

| TW (1) | TWI623285B (enExample) |

| WO (1) | WO2015025700A1 (enExample) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN107809922A (zh) * | 2015-06-30 | 2018-03-16 | 耐克创新有限合伙公司 | 具有增强的拉伸特性的弹性带 |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP6712446B2 (ja) * | 2015-06-25 | 2020-06-24 | 株式会社アーツブレインズ | 化粧用瞼整形テープ、及びそれを用いた二重瞼の形成方法、並びに該テープの製造方法 |

| JP1572218S (enExample) * | 2016-08-17 | 2017-03-21 | ||

| JP6614703B2 (ja) * | 2016-08-17 | 2019-12-04 | 株式会社アーツブレインズ | 化粧用瞼整形テープ |

| JP1571956S (enExample) * | 2016-08-17 | 2017-03-21 | ||

| TWI605988B (zh) * | 2017-02-16 | 2017-11-21 | Wen-Ying Lu | Eyelid with adhesive adhesive patch packaging structure |

Citations (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH02188512A (ja) | 1989-01-12 | 1990-07-24 | Royal Biken:Kk | 二重瞼形成用処理剤 |

| JPH03111511A (ja) | 1989-09-23 | 1991-05-13 | Sumitomo Metal Ind Ltd | 低マンガン鋼の溶製方法 |

| JPH03154139A (ja) | 1989-11-10 | 1991-07-02 | Fuji Xerox Co Ltd | キャッシュメモリ |

| JPH10304935A (ja) | 1997-05-06 | 1998-11-17 | Shishida Seishindou:Kk | 二重まぶた形成用テープ |

| JP3277180B1 (ja) | 2000-10-03 | 2002-04-22 | 野尻 英行 | 二重瞼形成用テープまたは糸及びその製造方法 |

| JP2005334108A (ja) | 2004-05-25 | 2005-12-08 | Koji Honpo Co Ltd | 二重まぶた用テープ及びその保持体 |

| JP2007106711A (ja) | 2005-10-14 | 2007-04-26 | Koji Honpo Co Ltd | 二重瞼形成化粧料 |

| JP2007111218A (ja) | 2005-10-20 | 2007-05-10 | Nitto Denko Corp | 二重瞼形成用粘着シートまたはテープ片 |

| JP2009022592A (ja) * | 2007-07-20 | 2009-02-05 | Nichiban Co Ltd | 二重まぶた形成用粘着シート及び二重まぶたの形成方法 |

| JP2009195410A (ja) | 2008-02-20 | 2009-09-03 | Yamaichi Soshogu:Kk | まぶた装粧具とその製造方法 |

| JP2013000394A (ja) * | 2011-06-17 | 2013-01-07 | Cogit:Kk | 二重瞼形成用シート |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4653483A (en) * | 1982-11-12 | 1987-03-31 | Clavin Harold D | Cosmetic tape, applicator therefor and method |

| JP3111511U (ja) | 2005-03-22 | 2005-07-28 | ケン・プロダクツ株式会社 | 二重まぶた形成具 |

| DE102005051181A1 (de) * | 2005-10-24 | 2007-04-26 | Tesa Ag | Spaltfreudiges Klebeband, seine Verwendung und Werkzeug zu seiner Herstellung |

| JP3154139U (ja) | 2009-07-17 | 2009-10-08 | 株式会社 ディー・アップ | 二重まぶた形成用シートおよび二重まぶた形成キット |

-

2013

- 2013-08-23 JP JP2013173889A patent/JP6021760B2/ja active Active

-

2014

- 2014-08-04 CN CN201480046616.0A patent/CN105636478B/zh active Active

- 2014-08-04 WO PCT/JP2014/070449 patent/WO2015025700A1/ja not_active Ceased

- 2014-08-04 KR KR1020167007556A patent/KR102232970B1/ko active Active

- 2014-08-04 SG SG11201600562TA patent/SG11201600562TA/en unknown

- 2014-08-04 MY MYPI2016700565A patent/MY177739A/en unknown

- 2014-08-04 EP EP14837878.9A patent/EP3037014B1/en not_active Not-in-force

- 2014-08-04 US US14/913,434 patent/US9980551B2/en not_active Expired - Fee Related

- 2014-08-18 TW TW103128288A patent/TWI623285B/zh active

Patent Citations (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH02188512A (ja) | 1989-01-12 | 1990-07-24 | Royal Biken:Kk | 二重瞼形成用処理剤 |

| JPH03111511A (ja) | 1989-09-23 | 1991-05-13 | Sumitomo Metal Ind Ltd | 低マンガン鋼の溶製方法 |

| JPH03154139A (ja) | 1989-11-10 | 1991-07-02 | Fuji Xerox Co Ltd | キャッシュメモリ |

| JPH10304935A (ja) | 1997-05-06 | 1998-11-17 | Shishida Seishindou:Kk | 二重まぶた形成用テープ |

| JP3277180B1 (ja) | 2000-10-03 | 2002-04-22 | 野尻 英行 | 二重瞼形成用テープまたは糸及びその製造方法 |

| JP2005334108A (ja) | 2004-05-25 | 2005-12-08 | Koji Honpo Co Ltd | 二重まぶた用テープ及びその保持体 |

| JP2007106711A (ja) | 2005-10-14 | 2007-04-26 | Koji Honpo Co Ltd | 二重瞼形成化粧料 |

| JP2007111218A (ja) | 2005-10-20 | 2007-05-10 | Nitto Denko Corp | 二重瞼形成用粘着シートまたはテープ片 |

| JP2009022592A (ja) * | 2007-07-20 | 2009-02-05 | Nichiban Co Ltd | 二重まぶた形成用粘着シート及び二重まぶたの形成方法 |

| JP2009195410A (ja) | 2008-02-20 | 2009-09-03 | Yamaichi Soshogu:Kk | まぶた装粧具とその製造方法 |

| JP2013000394A (ja) * | 2011-06-17 | 2013-01-07 | Cogit:Kk | 二重瞼形成用シート |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN107809922A (zh) * | 2015-06-30 | 2018-03-16 | 耐克创新有限合伙公司 | 具有增强的拉伸特性的弹性带 |

Also Published As

| Publication number | Publication date |

|---|---|

| TW201521633A (zh) | 2015-06-16 |

| SG11201600562TA (en) | 2016-02-26 |

| CN105636478A (zh) | 2016-06-01 |

| US9980551B2 (en) | 2018-05-29 |

| KR20160051798A (ko) | 2016-05-11 |

| US20160198835A1 (en) | 2016-07-14 |

| KR102232970B1 (ko) | 2021-03-29 |

| HK1221127A1 (en) | 2017-05-26 |

| TWI623285B (zh) | 2018-05-11 |

| JP6021760B2 (ja) | 2016-11-09 |

| EP3037014B1 (en) | 2018-07-18 |

| JP2015039613A (ja) | 2015-03-02 |

| EP3037014A1 (en) | 2016-06-29 |

| MY177739A (en) | 2020-09-23 |

| CN105636478B (zh) | 2019-10-29 |

| EP3037014A4 (en) | 2017-03-29 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6021760B2 (ja) | 化粧用瞼整形用テープ及びその製造方法 | |

| TWI604836B (zh) | 形成雙眼皮用膠帶及其製造方法、及使用該膠帶形成雙眼皮之方法 | |

| JP2014212847A5 (enExample) | ||

| JP6614703B2 (ja) | 化粧用瞼整形テープ | |

| JP6712446B2 (ja) | 化粧用瞼整形テープ、及びそれを用いた二重瞼の形成方法、並びに該テープの製造方法 | |

| JP2013000394A (ja) | 二重瞼形成用シート | |

| JP2018027187A5 (enExample) | ||

| JP2017006558A5 (enExample) | ||

| JP2014076224A (ja) | 二重瞼形成テープ装着具及び二重瞼形成テープの装着方法 | |

| JP5690436B1 (ja) | 二重瞼形成テープ及び二重瞼形成テープの製造方法 | |

| JP7406342B2 (ja) | 二重瞼形成用シート | |

| JP5690437B1 (ja) | 二重瞼形成テープ及び二重瞼形成テープの製造方法 | |

| JP2023092791A (ja) | 二重瞼形成テープ及び二重瞼形成テープの製造方法 | |

| HK1221127B (en) | Cosmetic eyelid-reshaping tape and method for manufacturing same | |

| HK40007057A (en) | Cosmetic eyelid shaping tape |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 14837878 Country of ref document: EP Kind code of ref document: A1 |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 2014837878 Country of ref document: EP |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 14913434 Country of ref document: US |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| ENP | Entry into the national phase |

Ref document number: 20167007556 Country of ref document: KR Kind code of ref document: A |