WO2014038896A1 - 열가소성 리그닌축중합체 및 이의 제조방법 - Google Patents

열가소성 리그닌축중합체 및 이의 제조방법 Download PDFInfo

- Publication number

- WO2014038896A1 WO2014038896A1 PCT/KR2013/008095 KR2013008095W WO2014038896A1 WO 2014038896 A1 WO2014038896 A1 WO 2014038896A1 KR 2013008095 W KR2013008095 W KR 2013008095W WO 2014038896 A1 WO2014038896 A1 WO 2014038896A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- lignin

- condensation polymer

- reaction

- thermoplastic

- acid

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

- 0 CC*(C)C(NCC=CC)=O Chemical compound CC*(C)C(NCC=CC)=O 0.000 description 2

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08F—MACROMOLECULAR COMPOUNDS OBTAINED BY REACTIONS ONLY INVOLVING CARBON-TO-CARBON UNSATURATED BONDS

- C08F220/00—Copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and only one being terminated by only one carboxyl radical or a salt, anhydride ester, amide, imide or nitrile thereof

- C08F220/02—Monocarboxylic acids having less than ten carbon atoms; Derivatives thereof

- C08F220/10—Esters

-

- C—CHEMISTRY; METALLURGY

- C07—ORGANIC CHEMISTRY

- C07G—COMPOUNDS OF UNKNOWN CONSTITUTION

- C07G1/00—Lignin; Lignin derivatives

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08H—DERIVATIVES OF NATURAL MACROMOLECULAR COMPOUNDS

- C08H6/00—Macromolecular compounds derived from lignin, e.g. tannins, humic acids

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J5/00—Manufacture of articles or shaped materials containing macromolecular substances

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08L—COMPOSITIONS OF MACROMOLECULAR COMPOUNDS

- C08L97/00—Compositions of lignin-containing materials

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08L—COMPOSITIONS OF MACROMOLECULAR COMPOUNDS

- C08L97/00—Compositions of lignin-containing materials

- C08L97/005—Lignin

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08K—Use of inorganic or non-macromolecular organic substances as compounding ingredients

- C08K3/00—Use of inorganic substances as compounding ingredients

- C08K3/02—Elements

- C08K3/04—Carbon

- C08K3/041—Carbon nanotubes

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08K—Use of inorganic or non-macromolecular organic substances as compounding ingredients

- C08K3/00—Use of inorganic substances as compounding ingredients

- C08K3/02—Elements

- C08K3/04—Carbon

- C08K3/042—Graphene or derivatives, e.g. graphene oxides

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08K—Use of inorganic or non-macromolecular organic substances as compounding ingredients

- C08K3/00—Use of inorganic substances as compounding ingredients

- C08K3/34—Silicon-containing compounds

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10S—TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10S977/00—Nanotechnology

- Y10S977/70—Nanostructure

- Y10S977/734—Fullerenes, i.e. graphene-based structures, such as nanohorns, nanococoons, nanoscrolls or fullerene-like structures, e.g. WS2 or MoS2 chalcogenide nanotubes, planar C3N4, etc.

- Y10S977/742—Carbon nanotubes, CNTs

Definitions

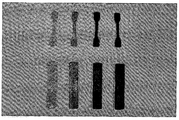

- Figure 4 is a photograph showing the appearance when the lignin condensation polymer obtained in a preferred embodiment of the present invention when heated to 200 °C.

- Table 1 shows the schematic structure of the lignin molecule and the structural change with temperature change. Also shown is a schematic structure of the thermoplastic lignin condensation polymer according to the present invention.

- the intermediate is prepared by reacting the lignin with a lactone-based compound, and the reactant having two or more acid reactors in dichloro acid, acid dianhydride and diacid.

- the thermoplastic lignin condensation polymer may be prepared through an ester condensation reaction or a urethane reaction reaction with one or more reactants selected from the group having two or more isocyanate reactors. It demonstrates in order below.

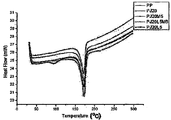

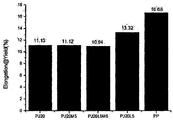

- thermoplastic lignin condensation polymer prepared in Example was prepared by the extrusion and injection process.

- thermoplastic lignin condensation polymer was prepared by the extrusion and injection process, the mechanical properties were measured using the ASTM D638 method.

Landscapes

- Chemical & Material Sciences (AREA)

- Organic Chemistry (AREA)

- Medicinal Chemistry (AREA)

- Polymers & Plastics (AREA)

- Health & Medical Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Materials Engineering (AREA)

- Engineering & Computer Science (AREA)

- Life Sciences & Earth Sciences (AREA)

- Biochemistry (AREA)

- Manufacturing & Machinery (AREA)

- Compositions Of Macromolecular Compounds (AREA)

- Other Resins Obtained By Reactions Not Involving Carbon-To-Carbon Unsaturated Bonds (AREA)

- Processes Of Treating Macromolecular Substances (AREA)

- Polyurethanes Or Polyureas (AREA)

Priority Applications (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US14/426,737 US9346904B2 (en) | 2012-09-07 | 2013-09-06 | Thermoplastic lignin condensation polymer, and preparation method therefor |

| CN201380058069.3A CN104781310B (zh) | 2012-09-07 | 2013-09-06 | 一种热塑性木质素缩聚物及其制备方法 |

| JP2015531012A JP6404818B2 (ja) | 2012-09-07 | 2013-09-06 | 熱可塑性リグニン縮重合体及びその製造方法 |

| EP13835036.8A EP2894187B1 (en) | 2012-09-07 | 2013-09-06 | Thermoplastic lignin condensation polymer, and preparation method therefor |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| KR1020120099291A KR101336465B1 (ko) | 2012-09-07 | 2012-09-07 | 열가소성 리그닌축중합체 및 이의 제조방법 |

| KR10-2012-0099291 | 2012-09-07 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2014038896A1 true WO2014038896A1 (ko) | 2014-03-13 |

Family

ID=49987169

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/KR2013/008095 Ceased WO2014038896A1 (ko) | 2012-09-07 | 2013-09-06 | 열가소성 리그닌축중합체 및 이의 제조방법 |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US9346904B2 (enExample) |

| EP (1) | EP2894187B1 (enExample) |

| JP (1) | JP6404818B2 (enExample) |

| KR (1) | KR101336465B1 (enExample) |

| CN (1) | CN104781310B (enExample) |

| WO (1) | WO2014038896A1 (enExample) |

Families Citing this family (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR101616946B1 (ko) * | 2013-11-28 | 2016-04-29 | 남재도 | 리그닌 고분자 나노복합재료 및 그 제조 방법 |

| KR101701568B1 (ko) * | 2014-11-13 | 2017-02-02 | 김동관 | 리그닌 함유 열가소성 수지 필름 및 이의 제조방법 |

| KR101809327B1 (ko) * | 2015-11-24 | 2017-12-14 | 주식회사 엔씨티 | 리그닌 기반 고분자 제조방법 |

| JP6945295B2 (ja) * | 2016-11-16 | 2021-10-06 | 旭有機材株式会社 | 摺動部材用成形材料、摺動部材及び製造方法 |

| CN106750365A (zh) * | 2017-01-20 | 2017-05-31 | 成都衔石科技有限公司 | 基于改善木质素口感的新型工艺 |

| KR101889744B1 (ko) * | 2017-07-04 | 2018-08-21 | (주)폴리피아 | 리그닌-셀룰로오스-올레핀계 복합소재 조성물 |

| CN109134883A (zh) * | 2018-07-04 | 2019-01-04 | 北京林业大学 | 一种提高碱木质素熔融性能的制备方法及所得产物 |

| KR102179075B1 (ko) | 2019-07-23 | 2020-11-16 | 단국대학교 산학협력단 | 에폭시화 대두유로 개질된 리그닌의 제조 방법 및 개질된 리그닌을 포함하는 생분해성 고분자 복합재 |

| KR102643510B1 (ko) | 2021-06-01 | 2024-03-04 | 단국대학교 산학협력단 | 바이오매스 리그닌을 포함하는 폴리올레핀 발포체 제조용 수지 조성물 및 이를 이용한 친환경 폴리올레핀 발포체의 제조 방법 |

| CN113771391A (zh) * | 2021-11-01 | 2021-12-10 | 宁波嘉信化工实业有限公司 | 一种增强型低温热塑材料及其制备工艺 |

| KR20230070095A (ko) | 2021-11-12 | 2023-05-22 | 단국대학교 산학협력단 | 바이오매스 리그닌을 포함하는 폴리에스테르 수지 조성물 및 이를 이용하여 제조된 생분해성 수지 발포체 |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR910018395A (ko) | 1990-04-12 | 1991-11-30 | 에이. 디롱 에드워드 | 리그닌의 제조방법 |

| JPH1129647A (ja) * | 1991-11-15 | 1999-02-02 | Nobuo Shiraishi | リグノセルロース系発泡体の製造方法 |

| JPH1171401A (ja) * | 1997-08-28 | 1999-03-16 | Agency Of Ind Science & Technol | 生分解性高分子材料及びその製造方法 |

| KR100242886B1 (ko) * | 1992-12-31 | 2000-02-01 | 유현식 | 생분해성 환상에스테르계 고분자 그라프트 리그노셀루로오즈 유도체 및 그 제조방법 |

| WO2012038259A1 (de) | 2010-09-23 | 2012-03-29 | Toho Tenax Europe Gmbh | Thermoplastisches lignin zur herstellung von kohlenstofffasern |

| JP2012515241A (ja) * | 2009-01-15 | 2012-07-05 | トウホウ テナックス ユーロップ ゲゼルシャフト ミット ベシュレンクテル ハフツング | リグニン誘導体、その誘導体を含む成形体、およびその成形体から製造される炭素繊維 |

Family Cites Families (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CA1278294C (en) | 1987-09-17 | 1990-12-27 | George S. Ritchie | Method for fractionation of lignins from steam exploded lignocellulosics to provide fractions with different, but reproducible properties,and some methods for their interconversions and the products so produced |

| CN1340555A (zh) * | 2000-09-01 | 2002-03-20 | 中国人民解放军国防科学技术大学 | 一种完全生物降解共聚物及其制备方法 |

| JP2003113326A (ja) * | 2001-10-04 | 2003-04-18 | Sekisui Chem Co Ltd | 生分解性樹脂組成物 |

| BRPI0815822A2 (pt) * | 2007-08-31 | 2017-05-16 | Biojoule Ltd | lignina e outros produtos a partir de material de planta, e métodos e composições para estes. |

| JP5184953B2 (ja) * | 2008-04-22 | 2013-04-17 | 学校法人金井学園 | 生分解性に優れた熱プレス成形材料及びその製造方法、並びに熱プレス成形体 |

| US8772406B2 (en) * | 2009-08-06 | 2014-07-08 | Robert J. Linhardt | Synthetic wood composite |

| US8383784B2 (en) | 2009-08-31 | 2013-02-26 | Weyerhaeuser Nr Company | Lignothermoplastic |

| JP5492746B2 (ja) * | 2010-03-26 | 2014-05-14 | キヤノン化成株式会社 | 電子写真装置用ブレード部材製造方法及び製造装置 |

| WO2012018422A1 (en) * | 2010-08-03 | 2012-02-09 | Ferro Corporation | Polymer composite foams |

-

2012

- 2012-09-07 KR KR1020120099291A patent/KR101336465B1/ko not_active Expired - Fee Related

-

2013

- 2013-09-06 CN CN201380058069.3A patent/CN104781310B/zh active Active

- 2013-09-06 US US14/426,737 patent/US9346904B2/en active Active

- 2013-09-06 WO PCT/KR2013/008095 patent/WO2014038896A1/ko not_active Ceased

- 2013-09-06 JP JP2015531012A patent/JP6404818B2/ja active Active

- 2013-09-06 EP EP13835036.8A patent/EP2894187B1/en active Active

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR910018395A (ko) | 1990-04-12 | 1991-11-30 | 에이. 디롱 에드워드 | 리그닌의 제조방법 |

| JPH1129647A (ja) * | 1991-11-15 | 1999-02-02 | Nobuo Shiraishi | リグノセルロース系発泡体の製造方法 |

| KR100242886B1 (ko) * | 1992-12-31 | 2000-02-01 | 유현식 | 생분해성 환상에스테르계 고분자 그라프트 리그노셀루로오즈 유도체 및 그 제조방법 |

| JPH1171401A (ja) * | 1997-08-28 | 1999-03-16 | Agency Of Ind Science & Technol | 生分解性高分子材料及びその製造方法 |

| JP2012515241A (ja) * | 2009-01-15 | 2012-07-05 | トウホウ テナックス ユーロップ ゲゼルシャフト ミット ベシュレンクテル ハフツング | リグニン誘導体、その誘導体を含む成形体、およびその成形体から製造される炭素繊維 |

| WO2012038259A1 (de) | 2010-09-23 | 2012-03-29 | Toho Tenax Europe Gmbh | Thermoplastisches lignin zur herstellung von kohlenstofffasern |

Also Published As

| Publication number | Publication date |

|---|---|

| EP2894187A1 (en) | 2015-07-15 |

| EP2894187A4 (en) | 2016-02-24 |

| EP2894187B1 (en) | 2020-05-06 |

| US20150225498A1 (en) | 2015-08-13 |

| CN104781310B (zh) | 2017-06-20 |

| KR101336465B1 (ko) | 2013-12-04 |

| CN104781310A (zh) | 2015-07-15 |

| US9346904B2 (en) | 2016-05-24 |

| JP6404818B2 (ja) | 2018-10-17 |

| JP2015529265A (ja) | 2015-10-05 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| WO2014038896A1 (ko) | 열가소성 리그닌축중합체 및 이의 제조방법 | |

| Wu et al. | Biobased poly (butylene 2, 5-furandicarboxylate) and poly (butylene adipate-co-butylene 2, 5-furandicarboxylate) s: From synthesis using highly purified 2, 5-furandicarboxylic acid to thermo-mechanical properties | |

| Zeng et al. | A novel biodegradable multiblock poly (ester urethane) containing poly (L-lactic acid) and poly (butylene succinate) blocks | |

| Fang et al. | Sustainable and tough polyurethane films with self-healability and flame retardance enabled by reversible chemistry and cyclotriphosphazene | |

| Mi et al. | Post-crosslinkable biodegradable thermoplastic polyurethanes: Synthesis, and thermal, mechanical, and degradation properties | |

| Yeganeh et al. | Investigation of thermal, mechanical, and electrical properties of novel polyurethanes/high molecular weight polybenzoxazine blends | |

| Didenko et al. | Co-poly (urethane-imide) s based on poly [di (ethylene glycol) adipate] and their compositions with thermoplastic polyimide: Synthesis and properties | |

| JP2012529544A (ja) | セグメント化ポリアリーレンエーテルブロックコポリマー | |

| CN113121787A (zh) | 一种生物基聚酰胺合成及其改性方法 | |

| WO2017150747A1 (ko) | 저융점 복합섬유 | |

| Li et al. | Branching and cross-linking of poly (ethylene terephthalate) and its foaming properties | |

| Sun et al. | Synthesis and characterization of biodegradable polyesteramides constructed mainly by alternating diesterdiamide units from N, N′-bis (2-hydroxyethyl)-adipamide and diacids | |

| CN119859394A (zh) | 一种可降解pla复合材料及其制备方法 | |

| CN116284714B (zh) | 一种可微波加热生物可降解材料的制造方法及应用 | |

| WO2015080483A1 (ko) | 리그닌 고분자 나노복합재료 및 그 제조 방법 | |

| CN110003533A (zh) | 一种醋酸纤维素复合材料及其应用 | |

| WO2016093395A1 (ko) | 생분해성 폴리에스테르 수지 및 그로부터 얻어진 발포체 | |

| Nie et al. | Self-healing, recyclable, thermally adaptive shape memory functional biopolymers based on multiple dynamic covalent bonds and hydrogen bonds derived from castor oil and vanillin | |

| CN116285164A (zh) | 一种环保型耐高温聚氯乙烯塑料及其制备方法 | |

| Zhao et al. | Biodegradable poly (butylene succinate-co-butylene dimerized fatty acid) s: Synthesis, crystallization, mechanical properties, and rheology | |

| KR101809327B1 (ko) | 리그닌 기반 고분자 제조방법 | |

| KR20100080085A (ko) | 점도 안정성이 향상된 전방향족 액정 폴리에스테르 수지, 및 이의 제조방법과 상기 수지를 포함하는 수지 컴파운드 | |

| CN117843678B (zh) | 一种二异氰酸酯单体及其制备方法和应用 | |

| CN114133518B (zh) | 一种耐热性能优异的热塑性聚氨酯弹性体及其制备方法 | |

| CN119060334B (zh) | 具有高残碳率的交联封端聚酰亚胺及其应用 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 13835036 Country of ref document: EP Kind code of ref document: A1 |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 14426737 Country of ref document: US |

|

| ENP | Entry into the national phase |

Ref document number: 2015531012 Country of ref document: JP Kind code of ref document: A |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 2013835036 Country of ref document: EP |