WO2013175931A1 - 殺菌装置 - Google Patents

殺菌装置 Download PDFInfo

- Publication number

- WO2013175931A1 WO2013175931A1 PCT/JP2013/062247 JP2013062247W WO2013175931A1 WO 2013175931 A1 WO2013175931 A1 WO 2013175931A1 JP 2013062247 W JP2013062247 W JP 2013062247W WO 2013175931 A1 WO2013175931 A1 WO 2013175931A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- flow path

- light

- ultraviolet rays

- light source

- housing

- Prior art date

Links

- 230000001954 sterilising effect Effects 0.000 title claims abstract description 37

- 238000004659 sterilization and disinfection Methods 0.000 title abstract description 32

- 230000003287 optical effect Effects 0.000 claims abstract description 19

- 239000012530 fluid Substances 0.000 claims abstract description 18

- 230000001678 irradiating effect Effects 0.000 claims description 9

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 38

- 239000000758 substrate Substances 0.000 description 10

- 230000000844 anti-bacterial effect Effects 0.000 description 9

- 238000005192 partition Methods 0.000 description 7

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 4

- 238000000746 purification Methods 0.000 description 4

- 230000000694 effects Effects 0.000 description 3

- 239000008213 purified water Substances 0.000 description 3

- 230000006866 deterioration Effects 0.000 description 2

- 238000010586 diagram Methods 0.000 description 2

- 239000007788 liquid Substances 0.000 description 2

- 238000000034 method Methods 0.000 description 2

- 239000008399 tap water Substances 0.000 description 2

- 235000020679 tap water Nutrition 0.000 description 2

- 238000002834 transmittance Methods 0.000 description 2

- 241000894006 Bacteria Species 0.000 description 1

- ZAMOUSCENKQFHK-UHFFFAOYSA-N Chlorine atom Chemical compound [Cl] ZAMOUSCENKQFHK-UHFFFAOYSA-N 0.000 description 1

- 229910052801 chlorine Inorganic materials 0.000 description 1

- 239000000460 chlorine Substances 0.000 description 1

- 238000007599 discharging Methods 0.000 description 1

- 239000011521 glass Substances 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 230000035515 penetration Effects 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C02—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F1/00—Treatment of water, waste water, or sewage

- C02F1/28—Treatment of water, waste water, or sewage by sorption

-

- C—CHEMISTRY; METALLURGY

- C02—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F1/00—Treatment of water, waste water, or sewage

- C02F1/30—Treatment of water, waste water, or sewage by irradiation

- C02F1/32—Treatment of water, waste water, or sewage by irradiation with ultraviolet light

-

- C—CHEMISTRY; METALLURGY

- C02—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F1/00—Treatment of water, waste water, or sewage

- C02F1/30—Treatment of water, waste water, or sewage by irradiation

- C02F1/32—Treatment of water, waste water, or sewage by irradiation with ultraviolet light

- C02F1/325—Irradiation devices or lamp constructions

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61L—METHODS OR APPARATUS FOR STERILISING MATERIALS OR OBJECTS IN GENERAL; DISINFECTION, STERILISATION OR DEODORISATION OF AIR; CHEMICAL ASPECTS OF BANDAGES, DRESSINGS, ABSORBENT PADS OR SURGICAL ARTICLES; MATERIALS FOR BANDAGES, DRESSINGS, ABSORBENT PADS OR SURGICAL ARTICLES

- A61L2/00—Methods or apparatus for disinfecting or sterilising materials or objects other than foodstuffs or contact lenses; Accessories therefor

- A61L2/02—Methods or apparatus for disinfecting or sterilising materials or objects other than foodstuffs or contact lenses; Accessories therefor using physical phenomena

- A61L2/08—Radiation

- A61L2/10—Ultraviolet radiation

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61L—METHODS OR APPARATUS FOR STERILISING MATERIALS OR OBJECTS IN GENERAL; DISINFECTION, STERILISATION OR DEODORISATION OF AIR; CHEMICAL ASPECTS OF BANDAGES, DRESSINGS, ABSORBENT PADS OR SURGICAL ARTICLES; MATERIALS FOR BANDAGES, DRESSINGS, ABSORBENT PADS OR SURGICAL ARTICLES

- A61L9/00—Disinfection, sterilisation or deodorisation of air

- A61L9/16—Disinfection, sterilisation or deodorisation of air using physical phenomena

- A61L9/18—Radiation

- A61L9/20—Ultraviolet radiation

-

- C—CHEMISTRY; METALLURGY

- C02—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F2201/00—Apparatus for treatment of water, waste water or sewage

- C02F2201/009—Apparatus with independent power supply, e.g. solar cells, windpower or fuel cells

-

- C—CHEMISTRY; METALLURGY

- C02—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F2201/00—Apparatus for treatment of water, waste water or sewage

- C02F2201/32—Details relating to UV-irradiation devices

- C02F2201/322—Lamp arrangement

- C02F2201/3221—Lamps suspended above a water surface or pipe

-

- C—CHEMISTRY; METALLURGY

- C02—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F2201/00—Apparatus for treatment of water, waste water or sewage

- C02F2201/32—Details relating to UV-irradiation devices

- C02F2201/322—Lamp arrangement

- C02F2201/3222—Units using UV-light emitting diodes [LED]

-

- C—CHEMISTRY; METALLURGY

- C02—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F2201/00—Apparatus for treatment of water, waste water or sewage

- C02F2201/32—Details relating to UV-irradiation devices

- C02F2201/322—Lamp arrangement

- C02F2201/3228—Units having reflectors, e.g. coatings, baffles, plates, mirrors

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02A—TECHNOLOGIES FOR ADAPTATION TO CLIMATE CHANGE

- Y02A20/00—Water conservation; Efficient water supply; Efficient water use

- Y02A20/20—Controlling water pollution; Waste water treatment

- Y02A20/208—Off-grid powered water treatment

- Y02A20/212—Solar-powered wastewater sewage treatment, e.g. spray evaporation

Definitions

- the present invention relates to a sterilization apparatus for sterilizing a fluid such as liquid or gas.

- a water purifier or the like that includes a sterilizer that sterilizes water by irradiating ultraviolet rays (see Patent Document 1).

- a technique for repeatedly reflecting irradiated light when irradiating ultraviolet rays into a flow path is also known (see Patent Document 2).

- FIG. 9 is a schematic cross-sectional view of a sterilization apparatus according to virtual technology.

- the sterilization apparatus 600 includes a housing 610 having a fluid flow path R to be sterilized, and a light source unit 620 provided in the housing 610.

- the light source unit 620 includes an LED element 621 that is a light source for irradiating ultraviolet rays into the flow path R.

- the inner wall surface of the flow path R has a pair of reflecting surfaces 611 and 612 that reflect the ultraviolet rays irradiated from the LED elements 621 a plurality of times and direct the flow path R from one side to the other side.

- a line L in FIG. 9 indicates the center (optical axis) of the ultraviolet light emitted from the LED element 621.

- the relationship between the distance from one side to the other side on the center line of the flow path R and the light intensity is shown in a graph.

- the light intensity attenuates in inverse proportion to the square of the distance.

- the light intensity is reduced to such an extent that the human body or the like is not affected.

- the light intensity needs to be a certain value or more.

- the light intensity necessary for obtaining a bactericidal effect by the ultraviolet rays irradiated by the illustrated LED element 621 is Y0 [J / cm 2 ].

- the bactericidal effect can be obtained only in the region up to the distance X0 [mm].

- the light intensity of ultraviolet light attenuates in inverse proportion to the square of the distance. Therefore, in the case of the above virtual technique, there is a problem that the area where the sterilization effect can be obtained is narrow and the sterilization efficiency is low. On the other hand, in order to prevent the human body from being affected when ultraviolet rays leak to the outside, the problem is that the entire length of the housing 610 must be made longer than the region where the sterilizing effect can be obtained. There is also. In addition, ultraviolet rays cause a bad influence on the human body, and when the sterilizer 600 is attached to a water purifier or the like, it also causes deterioration of other members constituting the water purifier or the like.

- An object of the present invention is to provide a sterilization apparatus that is improved in sterilization efficiency while achieving downsizing.

- the present invention employs the following means in order to solve the above problems.

- the sterilization apparatus of the present invention A housing having a fluid flow path to be sterilized; A light source provided in the housing for irradiating ultraviolet rays into the flow path;

- a sterilizer comprising:

- the inner wall surface of the flow path has a pair of reflection surfaces (for example, mirrors) that are directed from the one side of the flow path to the other side while reflecting the ultraviolet rays emitted from the light source a plurality of times.

- One reflection surface side of the pair of reflection surfaces is configured by a surface perpendicular to the optical axis of the light after being reflected a plurality of times from the one side toward the other side. It is characterized in that a folding surface that is folded back in the direction of is provided.

- the ultraviolet light is reflected a plurality of times from one side of the flow path toward the other side by the pair of reflection surfaces, and then folded back by the folding surface and reflected on the other side of the flow path a plurality of times. From one side to the other. Therefore, the light intensity of the ultraviolet light passing through the flow path is the sum of the light intensity of the ultraviolet light directed from one side of the flow path to the other side and the light intensity of the ultraviolet light directed from the other side of the flow path to the one side. Accordingly, it is possible to increase the light intensity of ultraviolet rays passing through the flow path. Thereby, it becomes possible to expand the area

- the ultraviolet rays which go to the other side from the one side of the flow path can be folded back at the folding surface, it is possible to suppress the ultraviolet rays from leaking out of the housing. Accordingly, it is not necessary to lengthen the entire length of the housing in order to prevent the light intensity of the ultraviolet rays from affecting the human body and the like, and the housing can be downsized.

- the pair of reflecting surfaces can be configured so that the surfaces are both flat and the planes are parallel to each other and face each other.

- the following configuration is adopted as an arrangement configuration of a light source or the like for reflecting the ultraviolet ray irradiated from the light source a plurality of times and directing from one side of the flow path to the other side. obtain.

- positions a light source with respect to a housing is adopted so that the direction of the ultraviolet-ray irradiated from the light source may incline toward the other side from the one side of a flow path with respect to a normal line of a pair of reflective surfaces Can do.

- the light source is arranged in the housing so that the direction of the ultraviolet rays emitted from the light source coincides with the normal line of the pair of reflection surfaces, and further from the light source to one side of the flow path than the pair of reflection surfaces. It is possible to adopt a configuration in which a preliminary reflection surface that reflects the irradiated ultraviolet rays so as to be inclined toward the other side of the flow path is provided. Even in this case, after the ultraviolet light emitted from the light source is reflected by the preliminary reflecting surface, it can be reflected from the one side of the flow path to the other side while being reflected by the pair of reflecting surfaces a plurality of times.

- a window for preventing the penetration of the fluid while allowing the ultraviolet rays to pass through so that the fluid to be sterilized does not go to the light source side at the site where the ultraviolet rays irradiated from the light source enter the flow path.

- the reflected light from which the ultraviolet light emitted from the light source is first reflected does not enter the window. This is because the light that enters the window out of the reflected light does not return to the flow path and does not contribute to sterilization, resulting in a decrease in sterilization efficiency.

- the transmittance and reflectance of the half mirror are lower than that of a normal mirror and the amount of light is reduced. Therefore, it is desirable that the reflected light does not enter the window by the arrangement configuration of the light source and the preliminary reflecting surface. However, if the direction of the ultraviolet light emitted from the light source or the direction of the ultraviolet light reflected by the preliminary reflecting surface is too far toward the other side of the flow path, the distance from the reflection of the ultraviolet light to the next reflection becomes longer. End up.

- a region where ultraviolet rays do not pass is formed (increased) in the flow path.

- a reflection direction adjusting surface that adjusts the direction of reflected ultraviolet light can be provided on one of the pair of reflecting surfaces.

- the sterilization efficiency can be improved while downsizing.

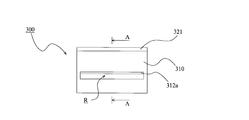

- FIG. 1 is a schematic configuration diagram of a water purifier provided with a sterilizer according to an embodiment of the present invention.

- FIG. 2 is a front view of the sterilizer according to Embodiment 1 of the present invention.

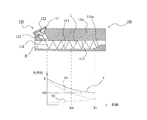

- FIG. 3 is a schematic cross-sectional view of the sterilizer according to Embodiment 1 of the present invention.

- FIG. 4 is a front view of a sterilizer according to Embodiment 2 of the present invention.

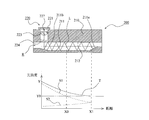

- FIG. 5 is a schematic cross-sectional view of a sterilizer according to Embodiment 2 of the present invention.

- FIG. 6 is a diagram for explaining disadvantages of the sterilizer according to the second embodiment of the present invention.

- FIG. 7 is a front view of a sterilizer according to Embodiment 3 of the present invention.

- FIG. 8 is a schematic cross-sectional view of a sterilizer according to Embodiment 3 of the present invention.

- FIG. 9 is a schematic cross-sectional view of a sterilization apparatus according to virtual technology.

- the sterilization apparatus can be applied to various uses such as sterilizing a liquid such as water (tap water) or a gas such as air.

- a liquid such as water (tap water) or a gas such as air.

- it can be used to sterilize water by being attached to a pot-type water purifier, attached to a faucet, or installed in a water purifier attached to water.

- it can be used to sterilize the exhaust gas by attaching it to an exhaust pipe, for example.

- a case of a cartridge type sterilizer to be attached to a pot type water purifier will be described with reference to FIG.

- a pot-type water purifier 500 shown in FIG. 1 includes a case 510, a partition portion 520 that partitions the space inside the case 510 into two regions, and a water purification cartridge 550 that is attached to the partition portion 520.

- a first lid 530 for putting raw water such as tap water into the case 510 and a second lid 540 for discharging the purified water to the outside are provided on the upper portion of the case 510.

- the water purification cartridge 550 is filled with activated carbon.

- the water purifier 500 configured as described above, when raw water is put into the case 510 with the first lid 530 opened, the water W purified by the water purification cartridge 550 is stored below the case 510. It is done. Then, the purified water W can be discharged to the outside by tilting the case 510 toward the second lid 540 with the second lid 540 opened.

- a cartridge type sterilizer 100 is mounted in the vicinity of the second lid 540 in order to sterilize the accumulated water W.

- the purified water W that has been collected is discharged to the outside of the case 510, the water W is sterilized by ultraviolet rays when passing through the flow path in the sterilizer 100.

- FIG. 2 is a front view of the sterilizer according to Embodiment 1 of the present invention.

- FIG. 3 is a schematic cross-sectional view (AA cross-sectional view in FIG. 2) of the sterilizer according to Embodiment 1 of the present invention.

- FIG. 3 the relationship between the light intensity and the distance from the one side to the other side on the center line of the flow path R is shown in a graph below the cross-sectional view.

- the sterilization apparatus 100 includes a housing 110 having a flow path R of a fluid to be sterilized (here, water), and a light source unit 120 provided in the housing 110.

- a fluid to be sterilized here, water

- a light source unit 120 provided in the housing 110.

- the light source unit 120 includes a substrate 121, an LED element 122 attached to the substrate 121, and a lens 123 that collects ultraviolet rays irradiated by the LED element 122.

- the LED element 122 is a light source for irradiating the flow path R with ultraviolet rays.

- the number of the LED elements 122 is not particularly limited, and a plurality of the LED elements 122 can be arranged in the longitudinal direction of the substrate 121 (the width direction of the housing 110).

- the power supply (battery) of the LED element 122 it may be provided in the sterilizer 100 (for example, the housing 110), or may be provided outside the sterilizer 100 (for example, the case 510 of the water purifier 500 described above). good.

- a window 124 is provided between the light source unit 120 and the flow path R.

- the window 124 is provided to partition the region where the light source unit 120 is disposed from the flow path R. That is, the window 124 plays a role of preventing the fluid from entering the light source unit 120 side while allowing the ultraviolet rays to pass therethrough so that the fluid (water) to be sterilized does not go to the light source unit 120 side.

- the flow path R provided in the housing 110 is configured such that the cross section thereof is rectangular.

- the inner wall surface of the flow path R has a pair of reflecting surfaces for reflecting the ultraviolet rays irradiated from the LED elements 122 a plurality of times and directing the flow path R from one side to the other side. ing.

- the pair of reflecting surfaces will be referred to as a first reflecting surface 111 and a second reflecting surface 112, respectively, as appropriate.

- the line L in FIG. 3 indicates the center (optical axis) of the ultraviolet light emitted from the LED element 122.

- the first reflecting surface 111 and the second reflecting surface 112 are both configured to have a flat surface, and the flat surfaces are parallel to each other and are opposed to each other. As shown in FIG. 3, the direction of the ultraviolet rays emitted from the LED element 122 with respect to the normal lines of the first reflecting surface 111 and the second reflecting surface 112 is changed from one side of the flow path R to the other side.

- the LED element 122 (light source unit 120) is disposed with respect to the housing 110 so as to be inclined toward the housing 110.

- the first reflecting surface 111 is provided with a folded surface 111 a on the other side of the flow path R further than the first reflecting surface 111.

- the folded surface 111a is configured by a surface perpendicular to the optical axis of light after being reflected a plurality of times from one side of the flow path R toward the other side. Thereby, the light after being reflected a plurality of times is folded back toward the original direction by the folding surface 111a.

- the light intensity attenuates in inverse proportion to the square of the distance.

- the dotted line S1 is the light intensity of ultraviolet rays directed from one side of the flow path R to the other side

- the dotted line S2 is ultraviolet light directed from the other side of the flow path R to the one side by being folded by the folded surface 111a.

- the solid line T represents the light intensity of ultraviolet rays passing through the flow path R (that is, the sum of S1 and S2).

- the light intensity needs to be a certain value or more.

- the light intensity necessary for obtaining a bactericidal effect by ultraviolet rays irradiated by the LED element 122 is Y0 [J / cm 2 ].

- the light intensity is as indicated by the dotted line S1

- the bactericidal effect is obtained only in the region up to the distance X0 [mm].

- the folded surface 111a is provided in the vicinity where the light intensity is 1 ⁇ 2 of Y0.

- the bactericidal effect can be obtained in the region up to the distance X1 (> X0) [mm] where the folded surface 111a is provided.

- the light intensity of the ultraviolet light directed from the other side of the flow path R to the one side is sufficiently reduced in the vicinity of the light source unit 120. Further, the ultraviolet rays directed to one side of the flow path R enter the light source unit 120 side through the window 124. Therefore, ultraviolet rays hardly leak outside the housing 110.

- the ultraviolet light is reflected by the first reflecting surface 111 and the second reflecting surface 112 a plurality of times from one side of the flow path R to the other side, and then the folded surface 111a. And is reflected from the other side of the flow path R toward the one side while being reflected a plurality of times.

- the light intensity of the ultraviolet light passing through the flow path R is directed to the light intensity of the ultraviolet light (dotted line S1 in the graph of FIG. 3) from one side of the flow path R to the other side and from the other side of the flow path R to the one side.

- the ultraviolet light traveling from one side to the other side of the flow path R can be folded back by the folding surface 111a, it is possible to prevent the ultraviolet light from leaking out of the housing 110.

- the housing 110 it is not necessary to lengthen the entire length of the housing 110 so that the light intensity of the ultraviolet rays does not affect the human body and the like, and the housing 110 can be downsized. Moreover, since it can suppress that an ultraviolet-ray leaks out of the housing 110, when the sterilizer 100 is used for said water purifier 500, deterioration of case 510 grade

- direction of the fluid flowing in the flow path R is not particularly limited, and may flow from the left side to the right side in FIG. 3, or may flow from the right side to the left side, for example.

- FIG. 4 is a front view of a sterilizer according to Embodiment 2 of the present invention.

- FIG. 5 is a schematic cross-sectional view (AA cross-sectional view in FIG. 4) of the sterilizer according to Embodiment 2 of the present invention.

- FIG. 5 the relationship between the light intensity and the distance from the one side to the other side on the center line of the flow path R is shown in a graph below the cross-sectional view.

- An application example of the sterilization apparatus 200 according to the present embodiment is as described with reference to FIG.

- the sterilization apparatus 200 includes a housing 210 having a fluid flow path R to be sterilized and a light source unit 220 provided in the housing 210.

- the light source unit 220 includes a substrate 221, an LED element 222 attached to the substrate 221, and a lens 223 that collects ultraviolet rays irradiated by the LED element 222.

- the LED element 222 is a light source for irradiating the flow path R with ultraviolet rays.

- the number of the LED elements 222 is not particularly limited, and a plurality of the LED elements 222 can be arranged in the longitudinal direction of the substrate 221 (the width direction of the housing 210).

- the power supply (battery) of the LED element 222 it may be provided in the sterilizer 200 (for example, the housing 210) or may be provided outside the sterilizer 200 (for example, the case 510 of the water purifier 500 described above). good.

- a window 224 is provided between the light source unit 220 and the flow path R.

- the window 224 is provided to partition the region where the light source unit 220 is disposed from the flow path R. That is, the window 224 plays a role of preventing the fluid from entering the light source unit 220 side while allowing ultraviolet rays to pass therethrough so that the fluid (water) to be sterilized does not go to the light source unit 220 side.

- the flow path R provided in the housing 210 is configured such that the cross section thereof is rectangular.

- the inner wall surface of the flow path R has a pair of reflection surfaces for reflecting the ultraviolet rays irradiated from the LED elements 222 a plurality of times and directing the flow path R from one side to the other side. ing.

- the pair of reflection surfaces will be referred to as a first reflection surface 211 and a second reflection surface 212, respectively, as appropriate.

- a line L in FIG. 5 indicates the center (optical axis) of the ultraviolet light emitted from the LED element 222.

- the first reflecting surface 211 and the second reflecting surface 212 are both configured to have a flat surface, and the flat surfaces are parallel to each other and are opposed to each other. Then, as shown in FIG. 5, the LED element 222 (light source unit 220) so that the direction of the ultraviolet rays emitted from the LED element 222 matches the normal line of the first reflecting surface 211 and the second reflecting surface 212. Is disposed relative to the housing 210.

- a folding surface 211a is provided on the first reflection surface 211 side on the other side of the flow path R further than the first reflection surface 211.

- the folded surface 211a is configured by a surface perpendicular to the optical axis of light after being reflected a plurality of times from one side of the flow path R toward the other side. Thereby, the light after being reflected a plurality of times is folded back toward the original direction by the folding surface 211a.

- the spare that reflects the ultraviolet rays irradiated from the LED elements 222 toward the other side of the flow path R further toward the one side of the flow path R than the first reflection surface 211.

- a reflective surface 211b is provided.

- the same effect as the sterilizer 100 according to the first embodiment can be obtained.

- the light source unit 120 is arranged obliquely with respect to the housing 110, whereas in the case of the sterilization apparatus 200 according to the present embodiment, the light source Since the unit 220 does not need to be disposed obliquely with respect to the housing 210, there is an advantage that the entire apparatus can be further downsized.

- the window 224 is provided between the light source unit 220 and the flow path R.

- FIG. 6A shows the ultraviolet light emitted from the LED element 222, but the center (optical axis) is reflected by the second reflecting surface 212 without entering the window 224, but a part of the ultraviolet light enters the window 224. In this case, the case is shown (see line L1). In this example, almost half of the ultraviolet light emitted from the LED element 222 has entered the window 224.

- the window 224 may be provided with a half mirror that transmits ultraviolet light that is directed from the LED element 222 into the flow path R and that reflects ultraviolet light that is directed from the flow path R toward the LED element 222.

- a half mirror process in which a thin metal film is deposited on the surface of the window 224 made of glass can be performed.

- the transmittance and reflectance of the half mirror are lower than that of a normal mirror, and the amount of light is reduced. Therefore, it is desirable to prevent the reflected light from entering the window 224 depending on the arrangement configuration of various members.

- the reflected light can be prevented from entering the window 224.

- the distance between the first reflecting surface 211 and the second reflecting surface 212 becomes long, the housing 210 becomes large, and the downsizing of the sterilizer 200 is hindered.

- a line L1 indicates an optical path passing through the most one side of the flow path R.

- the distance from the time when the ultraviolet rays are reflected by the first reflecting surface 211 to the second reflecting surface 212 (the distance from one side of the flow path R to the other side) and the second reflecting surface 212.

- the distance from when the light is reflected to when it reaches the first reflecting surface 211 becomes longer. Therefore, in the flow path R, a region Z through which ultraviolet rays do not pass is created. Therefore, it becomes a cause that sterilization efficiency falls. Then, next, an embodiment capable of solving such a problem will be described.

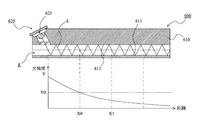

- FIG. 7 is a front view of a sterilizer according to Embodiment 3 of the present invention.

- FIG. 8 is a schematic cross-sectional view (AA cross-sectional view in FIG. 7) of the sterilizer according to Embodiment 3 of the present invention.

- FIG. 8 the relationship between the light intensity and the distance from the one side to the other side on the center line of the flow path R is shown in a graph below the cross-sectional view.

- An application example of the sterilizer 300 according to the present embodiment is as described with reference to FIG.

- the sterilization apparatus 300 includes a housing 310 having a fluid flow path R to be sterilized and a light source unit 320 provided in the housing 310.

- the light source unit 320 includes a substrate 321, an LED element 322 attached to the substrate 321, and a lens 323 that collects ultraviolet rays irradiated by the LED element 322.

- the LED element 322 is a light source for irradiating ultraviolet rays into the flow path R.

- the number of the LED elements 322 is not particularly limited, and a plurality of the LED elements 322 can be arranged in the longitudinal direction of the substrate 321 (the width direction of the housing 310).

- the power supply (battery) of the LED element 322 it may be provided in the sterilizer 300 (for example, the housing 310) or may be provided outside the sterilizer 300 (for example, the case 510 of the water purifier 500 described above). good.

- a window 324 is provided between the light source unit 320 and the flow path R.

- the window 324 is provided to partition the region where the light source unit 320 is disposed from the flow path R. That is, the window 324 plays a role of preventing the fluid from entering the light source unit 320 side while allowing ultraviolet light to pass therethrough so that the fluid (water) to be sterilized does not go to the light source unit 320 side.

- the flow path R provided in the housing 310 is configured such that its cross section is rectangular.

- the inner wall surface of the flow path R has a pair of reflection surfaces for reflecting the ultraviolet rays irradiated from the LED elements 322 a plurality of times and directing the flow path R from one side to the other side. ing.

- the pair of reflecting surfaces will be referred to as a first reflecting surface 311 and a second reflecting surface 312 as appropriate, respectively.

- a line L in FIG. 8 indicates the center (optical axis) of ultraviolet rays emitted from the LED element 322.

- the first reflecting surface 311 and the second reflecting surface 312 are both configured to have a flat surface, and the flat surfaces are parallel to each other and are opposed to each other. Then, as shown in FIG. 8, the LED element 322 (light source unit 320) so that the direction of the ultraviolet light emitted from the LED element 322 matches the normal line of the first reflecting surface 311 and the second reflecting surface 312. Is disposed relative to the housing 310.

- a folded surface 311a is provided on the first reflective surface 311 side, further on the other side of the flow path R than the first reflective surface 311.

- the folded surface 311a is a surface that is perpendicular to the optical axis of the light after being reflected a plurality of times from one side of the flow path R toward the other side. Thereby, the light after being reflected a plurality of times is folded back toward the original direction by the folding surface 311a.

- the ultraviolet ray irradiated from the LED element 322 is further emitted to one side of the flow path R from the first reflecting surface 311 on the other side of the flow path R.

- a preliminary reflecting surface 311b is provided to reflect the light so as to incline toward the surface.

- the preliminary reflection surface 311 b is provided so as to have a steep angle so that the reflected light of ultraviolet rays emitted from the LED element 322 does not enter the window 324.

- a line L1 indicates an optical path passing through the most one side of the flow path R.

- a reflection direction adjusting surface 312 a for adjusting the direction of reflected ultraviolet light is provided on one side of the flow path R further than the second reflecting surface 312.

- the reflection direction adjusting surface 312a the ultraviolet light emitted from the LED element 322 is reflected by the preliminary reflecting surface 311b, and after being reflected by the reflection direction adjusting surface 312a, the optical path of the ultraviolet light is Similar to Example 1. Therefore, as shown in the graph in FIG. 8, the relationship between the distance and the light intensity is the same as in the case of Example 1 (graph in FIG. 3).

- the light source unit 120 is arranged obliquely with respect to the housing 110, whereas in the case of the sterilization apparatus 300 according to the present embodiment, the light source unit 120 is implemented. As in the case of Example 2, it is not necessary to dispose the light source unit 320 at an angle with respect to the housing 310, so that the entire apparatus can be reduced in size.

- the case where a configuration in which a reflection direction adjustment surface is further added to the configuration shown in the second embodiment is shown. And by adopting the said structure, the reflected light reflected first among the ultraviolet rays irradiated from the LED element is prevented from entering the window, and the region where the ultraviolet rays do not pass in the optical path is eliminated (reduced). Made it possible. However, even in the configuration shown in the first embodiment, depending on the direction of the light source unit (LED element), there may be a region where the ultraviolet rays do not pass in the optical path (increased). Accordingly, in such a case, the optical path is adjusted by providing the reflection direction adjusting surface as shown in the present embodiment with respect to the configuration shown in the first embodiment, and the ultraviolet ray does not pass through the optical path. Can be eliminated (reduced).

- an ultraviolet ray should just be irradiated only when using it by providing an on-off switch, for example.

Landscapes

- Health & Medical Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Organic Chemistry (AREA)

- Water Supply & Treatment (AREA)

- Environmental & Geological Engineering (AREA)

- Hydrology & Water Resources (AREA)

- Toxicology (AREA)

- Veterinary Medicine (AREA)

- Animal Behavior & Ethology (AREA)

- Public Health (AREA)

- Epidemiology (AREA)

- General Health & Medical Sciences (AREA)

- Apparatus For Disinfection Or Sterilisation (AREA)

- Physical Water Treatments (AREA)

- Disinfection, Sterilisation Or Deodorisation Of Air (AREA)

Abstract

Description

殺菌対象となる流体の流路を有するハウジングと、

該ハウジングに設けられ、前記流路内に紫外線を照射する光源と、

を備える殺菌装置において、

前記流路の内壁面は、前記光源から照射された紫外線を複数回反射させつつ、前記流路の一方側から他方側に向かわせる一対の反射面(例えば、鏡)を有すると共に、

前記一対の反射面のうちの一方の反射面側には、前記一方側から他方側に向かって複数回反射された後の光の光軸に対して垂直な面で構成され、当該光を元の方向に向かって折り返す折り返し面が設けられていることを特徴とする。

本実施例に係る殺菌装置は、水(水道水)などの液体や空気などの気体を殺菌するためなど、各種用途に適用し得る。前者の場合には、例えば、ポット型の浄水器に装着したり、水道の蛇口に取り付けたり、水道に取付ける浄水器内に設置したりすることで水を殺菌するために用いることができる。また、後者の場合には、例えば排気管などに取付けることで、排気を殺菌するために用いることができる。ここでは、一例として、ポット型の浄水器に装着するカートリッジ型の殺菌装置の場合について、図1を参照して説明する。

図2及び図3を参照して、本発明の実施例1に係る殺菌装置について説明する。図2は本発明の実施例1に係る殺菌装置の正面図である。図3は本発明の実施例1に係る殺菌装置の模式的断面図(図2中のAA断面図)である。なお、図3においては、断面図の下方に、流路Rの中心線上における一方側から他方側に向かう距離と光強度との関係をグラフで示している。

本実施例に係る殺菌装置100によれば、紫外線は、第1反射面111と第2反射面112によって、流路Rの一方側から他方側に向かって複数回反射された後に、折り返し面111aによって折り返されて、複数回反射しながら流路Rの他方側から一方側に向かっていく。

図4及び図5には、本発明の実施例2が示されている。図4は本発明の実施例2に係る殺菌装置の正面図である。図5は本発明の実施例2に係る殺菌装置の模式的断面図(図4中のAA断面図)である。なお、図5においては、断面図の下方に、流路Rの中心線上における一方側から他方側に向かう距離と光強度との関係をグラフで示している。なお、本実施例に係る殺菌装置200の適用例については、図1を参照して説明した通りである。

図7及び図8には、本発明の実施例3が示されている。図7は本発明の実施例3に係る殺菌装置の正面図である。図8は本発明の実施例3に係る殺菌装置の模式的断面図(図7中のAA断面図)である。なお、図8においては、断面図の下方に、流路Rの中心線上における一方側から他方側に向かう距離と光強度との関係をグラフで示している。なお、本実施例に係る殺菌装置300の適用例については、図1を参照して説明した通りである。

110,210,310 ハウジング

111,211,311 第1反射面

111a,211a,311a 折り返し面

112,212,312 第2反射面

120,220,320 光源ユニット

121,221,321 基板

122,222,322 LED素子

123,223,323 レンズ

124,224,324 窓

211b,311b 予備反射面

312a 反射方向調整面

500 浄水器

510 ケース

520 仕切り部

530 第1蓋

540 第2蓋

550 浄水カートリッジ

Claims (1)

- 殺菌対象となる流体の流路を有するハウジングと、

該ハウジングに設けられ、前記流路内に紫外線を照射する光源と、

を備える殺菌装置において、

前記流路の内壁面は、前記光源から照射された紫外線を複数回反射させつつ、前記流路の一方側から他方側に向かわせる一対の反射面を有すると共に、

前記一対の反射面のうちの一方の反射面側には、前記一方側から他方側に向かって複数回反射された後の光の光軸に対して垂直な面で構成され、当該光を元の方向に向かって折り返す折り返し面が設けられていることを特徴とする殺菌装置。

Priority Applications (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201380026759.0A CN104334198B (zh) | 2012-05-21 | 2013-04-25 | 杀菌装置 |

| US14/402,130 US9233857B2 (en) | 2012-05-21 | 2013-04-25 | Sterilization device |

| GB1420925.8A GB2519243B (en) | 2012-05-21 | 2013-04-25 | A sterilization device |

| KR1020147032103A KR101617989B1 (ko) | 2012-05-21 | 2013-04-25 | 살균 장치 |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2012-115880 | 2012-05-21 | ||

| JP2012115880A JP5874532B2 (ja) | 2012-05-21 | 2012-05-21 | 殺菌装置 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2013175931A1 true WO2013175931A1 (ja) | 2013-11-28 |

Family

ID=49623630

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2013/062247 WO2013175931A1 (ja) | 2012-05-21 | 2013-04-25 | 殺菌装置 |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US9233857B2 (ja) |

| JP (1) | JP5874532B2 (ja) |

| KR (1) | KR101617989B1 (ja) |

| CN (1) | CN104334198B (ja) |

| GB (1) | GB2519243B (ja) |

| WO (1) | WO2013175931A1 (ja) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2016016603A1 (en) * | 2014-07-28 | 2016-02-04 | Typhon Treatment Systems Limited | A method, system and apparatus for treatment of fluids |

| WO2019064864A1 (ja) * | 2017-09-28 | 2019-04-04 | 株式会社エンプラス | 紫外線殺菌装置および紫外線照射装置 |

Families Citing this family (17)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP6236629B2 (ja) * | 2014-01-07 | 2017-11-29 | パナソニックIpマネジメント株式会社 | 流体用uv殺菌装置 |

| US9293670B2 (en) * | 2014-04-07 | 2016-03-22 | Crystal Is, Inc. | Ultraviolet light-emitting devices and methods |

| JP6355244B2 (ja) * | 2014-06-30 | 2018-07-11 | 国立大学法人埼玉大学 | 紫外線照射装置 |

| US9540252B1 (en) * | 2015-06-08 | 2017-01-10 | Rayvio Corporation | Ultraviolet disinfection system |

| US10246348B2 (en) | 2015-06-08 | 2019-04-02 | Rayvio Corporation | Ultraviolet disinfection system |

| JP6188969B1 (ja) | 2016-01-07 | 2017-08-30 | 三菱電機株式会社 | 紫外線殺菌装置およびそれを用いた空気調和機 |

| JP6682346B2 (ja) * | 2016-05-16 | 2020-04-15 | 国立大学法人埼玉大学 | 紫外線照射装置 |

| JP6807174B2 (ja) * | 2016-06-15 | 2021-01-06 | 国立大学法人埼玉大学 | 紫外線照射装置 |

| DK3516968T3 (da) * | 2016-09-20 | 2023-07-31 | Nippon Suisan Kaisha Ltd | Fremgangsmåde til fremstilling af fiskerognspasta med derfra fjernede fremmedstoffer, og apparat til fremstilling af fiskerognspasta med derfra fjernede fremmedstoffer |

| JP6530150B2 (ja) * | 2017-02-09 | 2019-06-12 | 株式会社アクアバンク | 飲料殺菌ユニットおよびこれを備えた飲料水供給装置 |

| JP7084574B2 (ja) * | 2017-09-22 | 2022-06-15 | 株式会社アクアバンク | Uv殺菌装置およびこれを備えた飲料水供給設備 |

| JPWO2019151364A1 (ja) * | 2018-02-02 | 2021-01-28 | 株式会社エンプラス | 紫外線殺菌管および紫外線殺菌装置 |

| JP2022542296A (ja) | 2019-07-31 | 2022-09-30 | アクセス ビジネス グループ インターナショナル リミテッド ライアビリティ カンパニー | 水処理システム |

| KR102343587B1 (ko) * | 2020-06-05 | 2021-12-27 | 주식회사 웰빙 | 살균 분무기 |

| CN111744047B (zh) * | 2020-07-03 | 2024-10-29 | 成都派斯光学有限公司 | 一种板式杀菌系统 |

| DE102020119962A1 (de) | 2020-07-29 | 2022-02-03 | LED3.0 GmbH | Vorrichtung und Verfahren zur Luftentkeimung |

| CN111939304A (zh) * | 2020-10-19 | 2020-11-17 | 武汉光谷航天三江激光产业技术研究院有限公司 | 一种基于光束整形及折反控制的激光杀毒装置 |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS63144835U (ja) * | 1987-03-13 | 1988-09-22 | ||

| JP2007502200A (ja) * | 2003-08-04 | 2007-02-08 | アトランティウム レイザーズ リミテッド | 光放射による液体及びガスの直列処理 |

| JP2007139230A (ja) * | 2005-11-15 | 2007-06-07 | Keiji Iimura | 光触媒を有する冷蔵庫 |

Family Cites Families (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS63144835A (ja) * | 1986-12-06 | 1988-06-17 | Soehara Kogyo Kk | 捻り柄洋食器の製造方法 |

| US6773608B1 (en) * | 1998-05-13 | 2004-08-10 | Uv Pure Technologies Inc. | Ultraviolet treatment for aqueous liquids |

| JP2000334448A (ja) | 1999-05-31 | 2000-12-05 | Kuniyasu Iwasaki | 流体殺菌浄化装置 |

| US6447721B1 (en) | 2000-07-31 | 2002-09-10 | Remotelight, Inc. | Drinking water UV disinfection system and method |

| JP2010214241A (ja) | 2009-03-13 | 2010-09-30 | Panasonic Electric Works Co Ltd | 浄水器 |

| JP5374697B2 (ja) * | 2009-07-09 | 2013-12-25 | ユーヴィックス株式会社 | 紫外線殺菌浄水装置とそれに使用する紫外線ledユニット |

| US20110291995A1 (en) * | 2010-05-25 | 2011-12-01 | Industrial Technology Research Institute | Sterilizing device and manufacturing method for sterilizing device |

| US20120168641A1 (en) * | 2010-09-08 | 2012-07-05 | Lizotte Todd E | Uv ptfe diffuser technology |

| DE102010047318A1 (de) * | 2010-10-01 | 2012-04-05 | Schott Ag | UV-Halbleiterlichtquellen-Bestrahlungseinrichtung und deren Verwendung |

| WO2012141709A1 (en) * | 2011-04-14 | 2012-10-18 | Empire Technology Development Llc | Ultraviolet water sterilization |

| JP2013158706A (ja) * | 2012-02-06 | 2013-08-19 | Panasonic Corp | 水浄化装置 |

-

2012

- 2012-05-21 JP JP2012115880A patent/JP5874532B2/ja not_active Expired - Fee Related

-

2013

- 2013-04-25 WO PCT/JP2013/062247 patent/WO2013175931A1/ja active Application Filing

- 2013-04-25 CN CN201380026759.0A patent/CN104334198B/zh not_active Expired - Fee Related

- 2013-04-25 KR KR1020147032103A patent/KR101617989B1/ko active IP Right Grant

- 2013-04-25 GB GB1420925.8A patent/GB2519243B/en not_active Expired - Fee Related

- 2013-04-25 US US14/402,130 patent/US9233857B2/en not_active Expired - Fee Related

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS63144835U (ja) * | 1987-03-13 | 1988-09-22 | ||

| JP2007502200A (ja) * | 2003-08-04 | 2007-02-08 | アトランティウム レイザーズ リミテッド | 光放射による液体及びガスの直列処理 |

| JP2007139230A (ja) * | 2005-11-15 | 2007-06-07 | Keiji Iimura | 光触媒を有する冷蔵庫 |

Cited By (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2016016603A1 (en) * | 2014-07-28 | 2016-02-04 | Typhon Treatment Systems Limited | A method, system and apparatus for treatment of fluids |

| JP2017530007A (ja) * | 2014-07-28 | 2017-10-12 | タイフォン・トリートメント・システムズ・リミテッド | 流体を処理するための方法、システムおよび装置 |

| GB2567342A (en) * | 2014-07-28 | 2019-04-10 | Typhon Treat Systems Limited | A method, system and apparatus for treatment of fluids |

| GB2567342B (en) * | 2014-07-28 | 2019-08-14 | Typhon Treat Systems Limited | A method, system and apparatus for treatment of fluids |

| GB2529008B (en) * | 2014-07-28 | 2019-08-14 | Typhon Treat Systems Limited | A method, system and apparatus for treatment of fluids |

| US10604423B2 (en) | 2014-07-28 | 2020-03-31 | Typhon Treatment Systems Limited | Method, system and apparatus for treatment of fluids |

| US11203534B2 (en) | 2014-07-28 | 2021-12-21 | Typhon Treatment Systems Limited | Method, system and apparatus for treatment of fluids |

| WO2019064864A1 (ja) * | 2017-09-28 | 2019-04-04 | 株式会社エンプラス | 紫外線殺菌装置および紫外線照射装置 |

| JP2019062960A (ja) * | 2017-09-28 | 2019-04-25 | 株式会社エンプラス | 紫外線殺菌装置および紫外線照射装置 |

| US11160889B2 (en) | 2017-09-28 | 2021-11-02 | Enplas Corporation | Ultraviolet irradiation device for sterilizing fluid flow |

Also Published As

| Publication number | Publication date |

|---|---|

| CN104334198A (zh) | 2015-02-04 |

| JP2013240487A (ja) | 2013-12-05 |

| US20150129777A1 (en) | 2015-05-14 |

| GB201420925D0 (en) | 2015-03-18 |

| KR101617989B1 (ko) | 2016-05-03 |

| CN104334198B (zh) | 2016-10-12 |

| US9233857B2 (en) | 2016-01-12 |

| GB2519243A (en) | 2015-04-15 |

| KR20150008413A (ko) | 2015-01-22 |

| GB2519243B (en) | 2017-08-02 |

| JP5874532B2 (ja) | 2016-03-02 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5874532B2 (ja) | 殺菌装置 | |

| KR20210116392A (ko) | 유수형 살균 장치 및 이를 이용하는 연결 장치 | |

| KR100891031B1 (ko) | 자외선 소독 장치 | |

| US20150250913A1 (en) | Air purifier | |

| WO2014058011A1 (ja) | 殺菌装置 | |

| US10329170B2 (en) | Liquid purification apparatus and method | |

| KR20150080489A (ko) | 자외선 살균 장치 및 살균 방법 | |

| JP7084574B2 (ja) | Uv殺菌装置およびこれを備えた飲料水供給設備 | |

| JP6963956B2 (ja) | 紫外線殺菌装置および紫外線照射装置 | |

| KR102070611B1 (ko) | 고출력 양방향 다중 집광형 수질 살균시스템 | |

| US11986579B2 (en) | Disinfection device and compressor system, connection device and treatment device with such a device | |

| JP2014076422A (ja) | 殺菌装置 | |

| JP2018064771A (ja) | 紫外光照射装置 | |

| KR102505921B1 (ko) | 유수형 살균 장치 및 이를 이용하는 연결 장치 | |

| CN111320230A (zh) | 用于为流体消毒的装置 | |

| JP2014076205A (ja) | 殺菌装置 | |

| KR20170051859A (ko) | 정수기 물 살균장치 및 이를 구비하는 정수기 | |

| KR20120037141A (ko) | Uv led를 갖는 정수기 | |

| US10639393B1 (en) | Fluid system with integrated disinfecting optics | |

| JP7071144B2 (ja) | 紫外線殺菌装置および紫外線照射装置 | |

| WO2022148746A1 (en) | A light emitting device | |

| JP2020014647A (ja) | 紫外線殺菌装置および紫外線照射装置 | |

| KR20090087204A (ko) | 정수기용 uv 필터 | |

| WO2021070350A1 (ja) | 紫外線殺菌装置および紫外線照射装置 | |

| US20240270608A1 (en) | Water filtration assembly with enhanced contaminant reduction performance |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 13793860 Country of ref document: EP Kind code of ref document: A1 |

|

| ENP | Entry into the national phase |

Ref document number: 20147032103 Country of ref document: KR Kind code of ref document: A |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 14402130 Country of ref document: US |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| ENP | Entry into the national phase |

Ref document number: 1420925 Country of ref document: GB Kind code of ref document: A Free format text: PCT FILING DATE = 20130425 |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 1420925.8 Country of ref document: GB |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 13793860 Country of ref document: EP Kind code of ref document: A1 |