WO2013146190A1 - 容器及び蓋のレーザ溶着による密封方法 - Google Patents

容器及び蓋のレーザ溶着による密封方法 Download PDFInfo

- Publication number

- WO2013146190A1 WO2013146190A1 PCT/JP2013/056473 JP2013056473W WO2013146190A1 WO 2013146190 A1 WO2013146190 A1 WO 2013146190A1 JP 2013056473 W JP2013056473 W JP 2013056473W WO 2013146190 A1 WO2013146190 A1 WO 2013146190A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- laser

- lid

- container

- thermoplastic resin

- msec

- Prior art date

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C65/00—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor

- B29C65/02—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor by heating, with or without pressure

- B29C65/14—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor by heating, with or without pressure using wave energy, i.e. electromagnetic radiation, or particle radiation

- B29C65/16—Laser beams

- B29C65/1629—Laser beams characterised by the way of heating the interface

- B29C65/1635—Laser beams characterised by the way of heating the interface at least passing through one of the parts to be joined, i.e. laser transmission welding

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65B—MACHINES, APPARATUS OR DEVICES FOR, OR METHODS OF, PACKAGING ARTICLES OR MATERIALS; UNPACKING

- B65B51/00—Devices for, or methods of, sealing or securing package folds or closures; Devices for gathering or twisting wrappers, or necks of bags

- B65B51/10—Applying or generating heat or pressure or combinations thereof

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C65/00—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor

- B29C65/02—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor by heating, with or without pressure

- B29C65/14—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor by heating, with or without pressure using wave energy, i.e. electromagnetic radiation, or particle radiation

- B29C65/16—Laser beams

- B29C65/1629—Laser beams characterised by the way of heating the interface

- B29C65/1654—Laser beams characterised by the way of heating the interface scanning at least one of the parts to be joined

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C65/00—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor

- B29C65/02—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor by heating, with or without pressure

- B29C65/14—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor by heating, with or without pressure using wave energy, i.e. electromagnetic radiation, or particle radiation

- B29C65/16—Laser beams

- B29C65/1677—Laser beams making use of an absorber or impact modifier

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C65/00—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor

- B29C65/78—Means for handling the parts to be joined, e.g. for making containers or hollow articles, e.g. means for handling sheets, plates, web-like materials, tubular articles, hollow articles or elements to be joined therewith; Means for discharging the joined articles from the joining apparatus

- B29C65/7841—Holding or clamping means for handling purposes

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/01—General aspects dealing with the joint area or with the area to be joined

- B29C66/05—Particular design of joint configurations

- B29C66/10—Particular design of joint configurations particular design of the joint cross-sections

- B29C66/13—Single flanged joints; Fin-type joints; Single hem joints; Edge joints; Interpenetrating fingered joints; Other specific particular designs of joint cross-sections not provided for in groups B29C66/11 - B29C66/12

- B29C66/131—Single flanged joints, i.e. one of the parts to be joined being rigid and flanged in the joint area

- B29C66/1312—Single flange to flange joints, the parts to be joined being rigid

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/01—General aspects dealing with the joint area or with the area to be joined

- B29C66/05—Particular design of joint configurations

- B29C66/20—Particular design of joint configurations particular design of the joint lines, e.g. of the weld lines

- B29C66/24—Particular design of joint configurations particular design of the joint lines, e.g. of the weld lines said joint lines being closed or non-straight

- B29C66/242—Particular design of joint configurations particular design of the joint lines, e.g. of the weld lines said joint lines being closed or non-straight said joint lines being closed, i.e. forming closed contours

- B29C66/2422—Particular design of joint configurations particular design of the joint lines, e.g. of the weld lines said joint lines being closed or non-straight said joint lines being closed, i.e. forming closed contours being circular, oval or elliptical

- B29C66/24221—Particular design of joint configurations particular design of the joint lines, e.g. of the weld lines said joint lines being closed or non-straight said joint lines being closed, i.e. forming closed contours being circular, oval or elliptical being circular

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/01—General aspects dealing with the joint area or with the area to be joined

- B29C66/05—Particular design of joint configurations

- B29C66/302—Particular design of joint configurations the area to be joined comprising melt initiators

- B29C66/3022—Particular design of joint configurations the area to be joined comprising melt initiators said melt initiators being integral with at least one of the parts to be joined

- B29C66/30223—Particular design of joint configurations the area to be joined comprising melt initiators said melt initiators being integral with at least one of the parts to be joined said melt initiators being rib-like

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/50—General aspects of joining tubular articles; General aspects of joining long products, i.e. bars or profiled elements; General aspects of joining single elements to tubular articles, hollow articles or bars; General aspects of joining several hollow-preforms to form hollow or tubular articles

- B29C66/51—Joining tubular articles, profiled elements or bars; Joining single elements to tubular articles, hollow articles or bars; Joining several hollow-preforms to form hollow or tubular articles

- B29C66/54—Joining several hollow-preforms, e.g. half-shells, to form hollow articles, e.g. for making balls, containers; Joining several hollow-preforms, e.g. half-cylinders, to form tubular articles

- B29C66/542—Joining several hollow-preforms, e.g. half-shells, to form hollow articles, e.g. for making balls, containers; Joining several hollow-preforms, e.g. half-cylinders, to form tubular articles joining hollow covers or hollow bottoms to open ends of container bodies

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/50—General aspects of joining tubular articles; General aspects of joining long products, i.e. bars or profiled elements; General aspects of joining single elements to tubular articles, hollow articles or bars; General aspects of joining several hollow-preforms to form hollow or tubular articles

- B29C66/51—Joining tubular articles, profiled elements or bars; Joining single elements to tubular articles, hollow articles or bars; Joining several hollow-preforms to form hollow or tubular articles

- B29C66/54—Joining several hollow-preforms, e.g. half-shells, to form hollow articles, e.g. for making balls, containers; Joining several hollow-preforms, e.g. half-cylinders, to form tubular articles

- B29C66/545—Joining several hollow-preforms, e.g. half-shells, to form hollow articles, e.g. for making balls, containers; Joining several hollow-preforms, e.g. half-cylinders, to form tubular articles one hollow-preform being placed inside the other

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/50—General aspects of joining tubular articles; General aspects of joining long products, i.e. bars or profiled elements; General aspects of joining single elements to tubular articles, hollow articles or bars; General aspects of joining several hollow-preforms to form hollow or tubular articles

- B29C66/65—General aspects of joining tubular articles; General aspects of joining long products, i.e. bars or profiled elements; General aspects of joining single elements to tubular articles, hollow articles or bars; General aspects of joining several hollow-preforms to form hollow or tubular articles with a relative motion between the article and the welding tool

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/70—General aspects of processes or apparatus for joining preformed parts characterised by the composition, physical properties or the structure of the material of the parts to be joined; Joining with non-plastics material

- B29C66/73—General aspects of processes or apparatus for joining preformed parts characterised by the composition, physical properties or the structure of the material of the parts to be joined; Joining with non-plastics material characterised by the intensive physical properties of the material of the parts to be joined, by the optical properties of the material of the parts to be joined, by the extensive physical properties of the parts to be joined, by the state of the material of the parts to be joined or by the material of the parts to be joined being a thermoplastic or a thermoset

- B29C66/733—General aspects of processes or apparatus for joining preformed parts characterised by the composition, physical properties or the structure of the material of the parts to be joined; Joining with non-plastics material characterised by the intensive physical properties of the material of the parts to be joined, by the optical properties of the material of the parts to be joined, by the extensive physical properties of the parts to be joined, by the state of the material of the parts to be joined or by the material of the parts to be joined being a thermoplastic or a thermoset characterised by the optical properties of the material of the parts to be joined, e.g. fluorescence, phosphorescence

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/70—General aspects of processes or apparatus for joining preformed parts characterised by the composition, physical properties or the structure of the material of the parts to be joined; Joining with non-plastics material

- B29C66/73—General aspects of processes or apparatus for joining preformed parts characterised by the composition, physical properties or the structure of the material of the parts to be joined; Joining with non-plastics material characterised by the intensive physical properties of the material of the parts to be joined, by the optical properties of the material of the parts to be joined, by the extensive physical properties of the parts to be joined, by the state of the material of the parts to be joined or by the material of the parts to be joined being a thermoplastic or a thermoset

- B29C66/739—General aspects of processes or apparatus for joining preformed parts characterised by the composition, physical properties or the structure of the material of the parts to be joined; Joining with non-plastics material characterised by the intensive physical properties of the material of the parts to be joined, by the optical properties of the material of the parts to be joined, by the extensive physical properties of the parts to be joined, by the state of the material of the parts to be joined or by the material of the parts to be joined being a thermoplastic or a thermoset characterised by the material of the parts to be joined being a thermoplastic or a thermoset

- B29C66/7392—General aspects of processes or apparatus for joining preformed parts characterised by the composition, physical properties or the structure of the material of the parts to be joined; Joining with non-plastics material characterised by the intensive physical properties of the material of the parts to be joined, by the optical properties of the material of the parts to be joined, by the extensive physical properties of the parts to be joined, by the state of the material of the parts to be joined or by the material of the parts to be joined being a thermoplastic or a thermoset characterised by the material of the parts to be joined being a thermoplastic or a thermoset characterised by the material of at least one of the parts being a thermoplastic

- B29C66/73921—General aspects of processes or apparatus for joining preformed parts characterised by the composition, physical properties or the structure of the material of the parts to be joined; Joining with non-plastics material characterised by the intensive physical properties of the material of the parts to be joined, by the optical properties of the material of the parts to be joined, by the extensive physical properties of the parts to be joined, by the state of the material of the parts to be joined or by the material of the parts to be joined being a thermoplastic or a thermoset characterised by the material of the parts to be joined being a thermoplastic or a thermoset characterised by the material of at least one of the parts being a thermoplastic characterised by the materials of both parts being thermoplastics

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/90—Measuring or controlling the joining process

- B29C66/91—Measuring or controlling the joining process by measuring or controlling the temperature, the heat or the thermal flux

- B29C66/914—Measuring or controlling the joining process by measuring or controlling the temperature, the heat or the thermal flux by controlling or regulating the temperature, the heat or the thermal flux

- B29C66/9141—Measuring or controlling the joining process by measuring or controlling the temperature, the heat or the thermal flux by controlling or regulating the temperature, the heat or the thermal flux by controlling or regulating the temperature

- B29C66/91411—Measuring or controlling the joining process by measuring or controlling the temperature, the heat or the thermal flux by controlling or regulating the temperature, the heat or the thermal flux by controlling or regulating the temperature of the parts to be joined, e.g. the joining process taking the temperature of the parts to be joined into account

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/90—Measuring or controlling the joining process

- B29C66/91—Measuring or controlling the joining process by measuring or controlling the temperature, the heat or the thermal flux

- B29C66/914—Measuring or controlling the joining process by measuring or controlling the temperature, the heat or the thermal flux by controlling or regulating the temperature, the heat or the thermal flux

- B29C66/9141—Measuring or controlling the joining process by measuring or controlling the temperature, the heat or the thermal flux by controlling or regulating the temperature, the heat or the thermal flux by controlling or regulating the temperature

- B29C66/91441—Measuring or controlling the joining process by measuring or controlling the temperature, the heat or the thermal flux by controlling or regulating the temperature, the heat or the thermal flux by controlling or regulating the temperature the temperature being non-constant over time

- B29C66/91443—Measuring or controlling the joining process by measuring or controlling the temperature, the heat or the thermal flux by controlling or regulating the temperature, the heat or the thermal flux by controlling or regulating the temperature the temperature being non-constant over time following a temperature-time profile

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/90—Measuring or controlling the joining process

- B29C66/91—Measuring or controlling the joining process by measuring or controlling the temperature, the heat or the thermal flux

- B29C66/919—Measuring or controlling the joining process by measuring or controlling the temperature, the heat or the thermal flux characterised by specific temperature, heat or thermal flux values or ranges

- B29C66/9192—Measuring or controlling the joining process by measuring or controlling the temperature, the heat or the thermal flux characterised by specific temperature, heat or thermal flux values or ranges in explicit relation to another variable, e.g. temperature diagrams

- B29C66/91951—Measuring or controlling the joining process by measuring or controlling the temperature, the heat or the thermal flux characterised by specific temperature, heat or thermal flux values or ranges in explicit relation to another variable, e.g. temperature diagrams in explicit relation to time, e.g. temperature-time diagrams

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/90—Measuring or controlling the joining process

- B29C66/93—Measuring or controlling the joining process by measuring or controlling the speed

- B29C66/934—Measuring or controlling the joining process by measuring or controlling the speed by controlling or regulating the speed

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/90—Measuring or controlling the joining process

- B29C66/93—Measuring or controlling the joining process by measuring or controlling the speed

- B29C66/939—Measuring or controlling the joining process by measuring or controlling the speed characterised by specific speed values or ranges

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B38/00—Ancillary operations in connection with laminating processes

- B32B38/0008—Electrical discharge treatment, e.g. corona, plasma treatment; wave energy or particle radiation

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65B—MACHINES, APPARATUS OR DEVICES FOR, OR METHODS OF, PACKAGING ARTICLES OR MATERIALS; UNPACKING

- B65B51/00—Devices for, or methods of, sealing or securing package folds or closures; Devices for gathering or twisting wrappers, or necks of bags

- B65B51/10—Applying or generating heat or pressure or combinations thereof

- B65B51/22—Applying or generating heat or pressure or combinations thereof by friction or ultrasonic or high-frequency electrical means, i.e. by friction or ultrasonic or induction welding

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65B—MACHINES, APPARATUS OR DEVICES FOR, OR METHODS OF, PACKAGING ARTICLES OR MATERIALS; UNPACKING

- B65B7/00—Closing containers or receptacles after filling

- B65B7/16—Closing semi-rigid or rigid containers or receptacles not deformed by, or not taking-up shape of, contents, e.g. boxes or cartons

- B65B7/28—Closing semi-rigid or rigid containers or receptacles not deformed by, or not taking-up shape of, contents, e.g. boxes or cartons by applying separate preformed closures, e.g. lids, covers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65B—MACHINES, APPARATUS OR DEVICES FOR, OR METHODS OF, PACKAGING ARTICLES OR MATERIALS; UNPACKING

- B65B7/00—Closing containers or receptacles after filling

- B65B7/16—Closing semi-rigid or rigid containers or receptacles not deformed by, or not taking-up shape of, contents, e.g. boxes or cartons

- B65B7/28—Closing semi-rigid or rigid containers or receptacles not deformed by, or not taking-up shape of, contents, e.g. boxes or cartons by applying separate preformed closures, e.g. lids, covers

- B65B7/2842—Securing closures on containers

- B65B7/2878—Securing closures on containers by heat-sealing

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C65/00—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor

- B29C65/02—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor by heating, with or without pressure

- B29C65/14—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor by heating, with or without pressure using wave energy, i.e. electromagnetic radiation, or particle radiation

- B29C65/16—Laser beams

- B29C65/1603—Laser beams characterised by the type of electromagnetic radiation

- B29C65/1612—Infrared [IR] radiation, e.g. by infrared lasers

- B29C65/1616—Near infrared radiation [NIR], e.g. by YAG lasers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/70—General aspects of processes or apparatus for joining preformed parts characterised by the composition, physical properties or the structure of the material of the parts to be joined; Joining with non-plastics material

- B29C66/71—General aspects of processes or apparatus for joining preformed parts characterised by the composition, physical properties or the structure of the material of the parts to be joined; Joining with non-plastics material characterised by the composition of the plastics material of the parts to be joined

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/70—General aspects of processes or apparatus for joining preformed parts characterised by the composition, physical properties or the structure of the material of the parts to be joined; Joining with non-plastics material

- B29C66/72—General aspects of processes or apparatus for joining preformed parts characterised by the composition, physical properties or the structure of the material of the parts to be joined; Joining with non-plastics material characterised by the structure of the material of the parts to be joined

- B29C66/723—General aspects of processes or apparatus for joining preformed parts characterised by the composition, physical properties or the structure of the material of the parts to be joined; Joining with non-plastics material characterised by the structure of the material of the parts to be joined being multi-layered

- B29C66/7234—General aspects of processes or apparatus for joining preformed parts characterised by the composition, physical properties or the structure of the material of the parts to be joined; Joining with non-plastics material characterised by the structure of the material of the parts to be joined being multi-layered comprising a barrier layer

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/80—General aspects of machine operations or constructions and parts thereof

- B29C66/83—General aspects of machine operations or constructions and parts thereof characterised by the movement of the joining or pressing tools

- B29C66/832—Reciprocating joining or pressing tools

- B29C66/8322—Joining or pressing tools reciprocating along one axis

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29K—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES B29B, B29C OR B29D, RELATING TO MOULDING MATERIALS OR TO MATERIALS FOR MOULDS, REINFORCEMENTS, FILLERS OR PREFORMED PARTS, e.g. INSERTS

- B29K2505/00—Use of metals, their alloys or their compounds, as filler

- B29K2505/08—Transition metals

- B29K2505/12—Iron

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29K—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES B29B, B29C OR B29D, RELATING TO MOULDING MATERIALS OR TO MATERIALS FOR MOULDS, REINFORCEMENTS, FILLERS OR PREFORMED PARTS, e.g. INSERTS

- B29K2507/00—Use of elements other than metals as filler

- B29K2507/04—Carbon

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29K—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES B29B, B29C OR B29D, RELATING TO MOULDING MATERIALS OR TO MATERIALS FOR MOULDS, REINFORCEMENTS, FILLERS OR PREFORMED PARTS, e.g. INSERTS

- B29K2995/00—Properties of moulding materials, reinforcements, fillers, preformed parts or moulds

- B29K2995/0018—Properties of moulding materials, reinforcements, fillers, preformed parts or moulds having particular optical properties, e.g. fluorescent or phosphorescent

- B29K2995/0026—Transparent

- B29K2995/0027—Transparent for light outside the visible spectrum

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29L—INDEXING SCHEME ASSOCIATED WITH SUBCLASS B29C, RELATING TO PARTICULAR ARTICLES

- B29L2031/00—Other particular articles

- B29L2031/712—Containers; Packaging elements or accessories, Packages

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29L—INDEXING SCHEME ASSOCIATED WITH SUBCLASS B29C, RELATING TO PARTICULAR ARTICLES

- B29L2031/00—Other particular articles

- B29L2031/712—Containers; Packaging elements or accessories, Packages

- B29L2031/7158—Bottles

- B29L2031/716—Bottles of the wide mouth type, i.e. the diameters of the bottle opening and its body are substantially identical

Definitions

- the present invention relates to a sealing method by laser welding of a container and a lid made of a thermoplastic resin, and more particularly to a laser welding method capable of reliably sealing the container and the lid in a short time.

- the heat seal portion is cooled and takes a predetermined time until it is completely sealed, the head that has been thermally expanded by the seal heat particularly when filling the contents having self-generated pressure or hot filling.

- the gas in the space may escape from the molten seal portion, which may cause seal peeling.

- Patent Document 2 laser welding is also known as a method for welding packaging members such as containers and lids.

- a bottom lid and an upper lid are welded to a container body by laser welding.

- the sealing interface is welded without much restrictions on the thickness of the member, etc., in the welding of the packaging member by laser welding.

- the time required for welding is shortened as compared with.

- the present inventors have a structure having a self-pressing mechanism that presses the members of the packaging body such as a container and a lid, and can perform laser welding without fixing the welded portion in advance by an external pressing mechanism.

- the sealing of the container and the lid by laser welding is performed in a short time with high productivity compared to the welding by the conventional heat seal, but even when the container and the lid are sealed by laser welding, Furthermore, in order to improve production efficiency, it is required to weld the container and the lid in a short time.

- laser welding is greatly affected by the physical properties of the resin to be heated, simply increasing the laser output generates excessive heat locally, causing the resin to thermally decompose, causing the resin to foam, etc. As a result, it was found that reliable sealing performance could not be secured in a short time.

- an object of the present invention is to provide a laser welding method capable of reliably sealing a container and a lid in a short time without causing foaming of resin or the like.

- one of the container and the lid contains a thermoplastic resin that can transmit the laser, and the other contains a heat generating material that generates heat by absorbing the laser in the thermoplastic resin.

- the laser is a laser capable of irradiating a rectangular beam having a uniform intensity distribution

- L is the length (mm) of the rectangular beam in the scanning direction

- S is the laser scanning speed (mm / msec) of 1.65 mm / msec or less.

- a sealing method is provided in which the upper limit temperature is reached in a heating time t (msec) represented by:

- the thermoplastic resin is any one of polystyrene resin, olefin resin, and polyester resin

- the container has a flange portion and is laser welded to the lid at the flange portion; 3.

- the container is made of a thermoplastic resin that can transmit laser, and the lid is made of a resin composition containing a heat generating material that absorbs the laser and generates heat. 4).

- the laser scanning speed is 1.40 to 1.65 mm / msec; Is preferred.

- the sealing method of the present invention by using a laser capable of irradiating a rectangular beam having a uniform intensity distribution (hereinafter, simply referred to as “rectangular laser”), compared with a general circular spot laser. Therefore, laser irradiation can be performed efficiently, and welding can be reliably performed in a short time without causing overheating of the resin. That is, when laser welding the container and the lid, it is necessary to scan the laser in a circular shape corresponding to the container opening, and therefore a rectangular laser having a length L in the scanning direction is used. Therefore, it is possible to increase the laser scanning speed without wasting energy as compared with increasing the diameter of a general spot laser, and the maximum scanning speed is 1.65 mm / sec.

- a resin composition containing a thermoplastic resin capable of transmitting laser hereinafter sometimes referred to as “laser transmitting thermoplastic resin” and a heat generating material that absorbs the laser and generates heat. Foaming of the laser-absorbing resin composition by setting the upper limit temperature of the welding interface of the product (hereinafter referred to as “laser-absorbing resin composition”) to a temperature not lower than the melting point of the thermoplastic resin and lower than the thermal decomposition start temperature. It is possible to reliably weld the container and the lid in a short time without causing any problems. Furthermore, in the present invention, it is possible to effectively weld these interfaces by using the same kind of thermoplastic resin as the thermoplastic resin used in the laser transmitting thermoplastic resin and the laser absorbing thermoplastic resin composition described above. it can.

- the predetermined length L is set in the scanning direction so as to perform reliable welding at the seal interface in a short time without causing overheating with the laser-absorbing thermoplastic resin composition.

- the temperature coefficient is measured experimentally by allocating irradiation time, for example, about three conditions according to the output of the laser to be used. It is possible to calculate the resin temperature according to the irradiation time, and as shown in FIG. 1, the laser transmitting thermoplastic resin and the laser absorbing thermoplastic resin composition are equal to or higher than the melting point of the thermoplastic resin. In addition, the heating time t1 (msec) required to reach a temperature equal to or higher than the thermal decomposition start temperature can be obtained.

- this heating time is the time that the laser is irradiated per unit length (mm) in the laser scanning direction

- a rectangular laser whose length in the laser scanning direction is L (mm) is used Is represented by the above formula (1). Therefore, in the present invention, the laser absorption resin composition is set by setting the length L or the scanning speed of the rectangular laser so that the heating time t represented by the above formula (1) becomes the heating time t1.

- the container and the lid can be surely welded in a short time without foaming.

- the laser transmitting thermoplastic resin is preferably a thermoplastic resin having a laser transmittance of 70% or more, particularly 80% or more.

- the laser transmittance can be obtained by measuring the transmittance of light corresponding to the wavelength of the laser light to be used using a spectrophotometer.

- the laser transmittance varies depending on the thickness even in the same thermoplastic resin.

- the laser transmittance means that the transmittance is 70% or more within the thickness range described later. is there.

- thermoplastic resins are preferably styrene resins such as impact-resistant polystyrene, low-, medium-, and high-density polyethylene, isotactic polypropylene, propylene / ethylene copolymers, polybutene-1 Olefin resins such as ethylene / propylene copolymer, ethylene / butene-1 copolymer, propylene / butene-1 copolymer, ethylene / propylene / butene-1 copolymer, or polyester resins such as polyethylene terephthalate, etc.

- styrene resins such as impact-resistant polystyrene, low-, medium-, and high-density polyethylene, isotactic polypropylene, propylene / ethylene copolymers, polybutene-1 Olefin resins such as ethylene / propylene copolymer, ethylene / butene-1 copolymer, propylene / buten

- the resin is conventionally used for packaging containers, and in particular, it is necessary that the resin be easily melted by the heat generated by the laser-absorbing resin composition. It can be easily welded and is suitable.

- polyethylene and polypropylene are preferably used. Can.

- the laser absorbing resin composition in the present invention, it is preferable from the viewpoint of laser weldability to use the same thermoplastic resin as the thermoplastic resin used in the above-described laser transmitting thermoplastic resin.

- the heat-generating substance in the laser-absorbing resin composition of the present invention, it is desirable that the heat-generating substance is uniformly contained in the resin composition from the viewpoint of easily melting the laser-transmitting thermoplastic resin at the seal interface.

- exothermic substances include oxygen absorbers such as iron powder and colored pigments such as carbon black.

- it depends on the type of the exothermic substance used it is generally desirable that the exothermic substance is blended in an amount of 0.01 to 0.30 parts by weight, particularly 0.05 to 0.15 parts by weight per 100 parts by weight of the thermoplastic resin. .

- the container and lid sealing method of the present invention is sealed by laser welding, it is possible to adopt various combinations of containers and lids without being restricted by the shape of the container and lid.

- either one of the container and the lid is made of a laser transmitting thermoplastic resin

- the other is made of a laser absorbing thermoplastic resin composition

- any of them may be a laser absorbing thermoplastic resin composition.

- the lid is made of a laser-absorbing thermoplastic resin composition.

- a container such as a cup or a tray formed by thermoforming such as vacuum forming, pressure forming, plug assist forming, or the like from a single or multi-layer sheet-like material, or formed by drawing.

- a bottomed cup or the like can be exemplified, and in particular, a cup having a flange portion is preferable.

- the container and the lid are brought into contact with the flange portion at a pressure of 550 kpa or more, and laser irradiation is performed. Then welded.

- the shape of the lid can take various shapes depending on the shape of the cup or tray of the container, for example, a flat shape, a drop lid shape in which the center is recessed inward, and hangs down from the outer peripheral end of the top plate portion.

- the shape can be appropriately changed according to the contact portion with the container, such as a molded lid such as an overcap-shaped lid having a skirt portion.

- Only the welded portion of the container or lid may be formed of the laser-absorbing thermoplastic resin composition, for example, only the flange portion of the container is made of the laser-absorbing thermoplastic resin composition, and the container body and the bottom are heated. It may be a laser transmitting thermoplastic resin containing no member, or a multilayer structure may be formed. Moreover, only the flange part of a lid

- cover may consist of a laser absorption thermoplastic resin composition, and the center part may consist of a laser permeation

- the thickness of the welded portion of the container and the lid is desirably 0.1 to 2.0 mm, particularly 0.5 to 1.2 mm, at the portion made of the laser transmitting thermoplastic resin. .

- the thickness of the portion made of the laser-transmitting thermoplastic resin is thinner than the above range, there is a possibility that it is difficult to perform reliable welding as compared with the case where it is in the above range. In this case, it is difficult to cause the laser beam to reach the portion made of the laser-absorbing thermoplastic resin composition under normal conditions, and it may be difficult to perform reliable welding as compared with the case where the laser beam is within the above range. There is.

- the portion made of the laser-absorbing thermoplastic resin composition is preferably in the range of 0.1 to 2.0 mm, particularly 0.5 to 1.2 mm.

- the thickness of the portion composed of the laser-absorbing thermoplastic resin composition is smaller than the above range, it may be difficult to perform reliable welding as compared with the above range, whereas it is thicker than the above range. However, it becomes inferior in economic efficiency.

- the laser-transmitting thermoplastic resin composition is heated by irradiating the abutting portion of the container and the lid with a laser beam from the side of the member made of laser-transmitting thermoplastic resin to generate heat.

- the resin is melted, and the contact surfaces of the container and the lid are melted and adhered.

- the sealing method of the present invention after the contents are filled in the container, the container or the laser oscillator is moved (rotated) in accordance with the shape of the seal part of the container and the lid, thereby moving the laser between the container and the lid. Let the seal part scan. When irradiating the laser beam, it is important to make the contact surfaces of the container and the lid closely adhere to each other efficiently.

- a jig or the like for pressing and fixing the two is used. It can also be brought into close contact with each other by molding the container and the lid into a size and shape such that the container and the lid are pressed against each other on the contact surface.

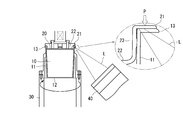

- FIG. 2 illustrates an example of a sealing method in which a container made of a laser-transmitting thermoplastic resin and a lid made of a laser-absorbing thermoplastic resin composition are welded at a flange portion.

- the container includes a trunk portion 11 and a bottom portion 12.

- a cup 10 comprising a flange portion 13 and a drop lid-shaped molding lid 20 in which a central portion 22 inside the peripheral edge portion 21 corresponding to the flange portion of the container is recessed inward as a lid.

- the cup 10 is installed and fixed on the turntable 30, and the molding lid 20 is installed such that the peripheral edge 21 of the molding lid 20 is positioned at the flange portion 13 of the cup 10.

- the contact surfaces of the flange portion 13 of the cup 10 and the peripheral portion 21 of the molding lid 20 are brought into close contact with each other.

- the laser beam L is irradiated from obliquely below the container and the lid, whereby the contact surfaces of the cup 10 and the molding lid 20 can be welded and sealed.

- the irradiation direction of the laser is not limited to the example of FIG. 2, and irradiation can be performed from various directions depending on the resin constituting the container and the lid, or the welding location.

- a protrusion 24 is formed on the side surface 23 of the drop-lid-shaped molding lid 20, and the inner surface of the cup 10 is pressed by the protrusion 24 to form a location where they are pressed against each other.

- laser irradiation can be performed from the side of the container and the lid.

- the container may be formed of a laser-absorbing thermoplastic resin composition

- the lid may be formed of a laser-transmitting thermoplastic resin

- the laser beam L may be irradiated from above.

- the member on the laser irradiation direction side is made of a laser transmitting thermoplastic resin.

- a laser used in the present invention a laser conventionally used for laser welding can be used, and a gas laser, a solid-state laser, a semiconductor laser, or the like can be used. It can be suitably used in terms of surface.

- the output of the laser oscillator is preferably in the range of 100 to 500 W, particularly 200 to 350 W. In order to enable welding at a high speed, it is conceivable to increase the laser output. However, as described above, there is a risk of foaming due to thermal decomposition of the laser-absorbing thermoplastic resin composition. This is significant in that high-speed welding is possible with an output in the range conventionally used for laser welding.

- the laser to be used is commercially determined by the permeability of the resin, the nature of the substance that generates heat by absorbing the laser beam, and the output, price, and safety of the laser oscillator.

- a rectangular beam as the laser beam that is, a laser having a rectangular cross section perpendicular to the axial direction of the laser beam, so that the container and the lid can be sealed by laser welding in a short time.

- the length of the rectangular beam in the scanning direction of the rectangular laser beam can be determined depending on the thermoplastic resin and the heat-generating material used, the content thereof, and the scanning speed, as described above, but in the range of 50 to 150 mm.

- the length in the scanning direction is 157 to 471 mm

- the width in the scanning direction and the horizontal direction is in the range of 0.5 to 3.0 mm, particularly 1.0 to 2.0 mm.

- the focal length of the laser beam is preferably 50 to 250 mm, particularly preferably 100 to 200 mm.

- the scanning speed of the laser beam is intended for laser welding at a high speed, so that it is 1.65 mm / msec or less, particularly 1 depending on the laser output and the thermal decomposition start temperature of the laser-absorbing thermoplastic resin composition. It is desirable to set it in the range of 40 to 1.65 mm / msec.

- the scanning speed (mm / msec) is calculated from the seal length (mm) calculated from the diameter of the container and the laser irradiation time (msec).

- Container Resin whose layer structure is (cup outer surface side) 450 ⁇ m polypropylene / 30 ⁇ m adhesive layer / 90 ⁇ m EVOH (ethylene / vinyl alcohol copolymer resin) / 30 ⁇ m adhesive layer / (cup inner surface side) 400 ⁇ m polypropylene (melting point: 160 ° C.)

- a flange portion having a reverse taper shape (taper angle: about 10 °) whose diameter decreases as the upper portion of the side wall portion goes upward by vacuum forming is used.

- the outer diameter of the opening is 80 mm and the inner volume is 120 ml.

- Molding lid 1000 ppm of carbon black was added to polypropylene resin (melting point: 160 ° C.), and a drop lid having a thickness of 0.7 mm was molded by injection molding.

- the cup-shaped container is filled with 100 g of water, and using a cradle that holds the container in the stack part of the cup-shaped container, the molding lid is pushed in to install and fix the cup-shaped container and the molding lid.

- the molding lid was placed so that the peripheral edge of the molding lid was located at the flange portion.

- a load is applied to the peripheral part of the molding lid from above so that the contact pressure of the contact surface of the peripheral part of the cup-shaped container flange and the molding lid is 800 kPa or more. The contact surface was brought into close contact.

- the turntable is rotated at 420 rpm, and the laser beam is irradiated for 0.15 seconds at an irradiation angle of 60 ° from below toward the position of ⁇ 75 mm with respect to the central axis of the cup-shaped container and the molding lid, and the strength of the welded portion is increased. evaluated.

- the welding conditions are as follows.

- Laser oscillator Nippon Steel Techno Research Co., Ltd. (maximum laser output 330 W), semiconductor (GaAs) laser, wavelength 806 ⁇ 10 nm, laser output 300 W, laser shape (beam cross section) 1.5 ⁇ 4 mm

- Laser irradiation diameter ⁇ 75mm

- Laser oscillation time 0.15 sec (base rotation speed 420 rpm, irradiation for 1.05 rotation, scan speed 1.65 mm / msec)

- Contact surface contact pressure about 800 kPa (contact surface area: about 4 cm 2 , load: 330 N)

- the heating time was such that the upper limit of the temperature rising by laser irradiation at the welding interface between the container and the lid was within the range above the melting point of polypropylene and below the thermal decomposition start temperature. I understand that.

- the container and the lid can be surely welded in a short time, and the welding is performed with an appropriate heating time that reaches a temperature above the melting point of the thermoplastic resin and above the thermal decomposition start temperature. Therefore, it can weld reliably, without producing foaming of resin. Therefore, it is excellent not only in sealing performance but also in productivity, and can be suitably used as a sealing method for mass-produced products.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Physics & Mathematics (AREA)

- Optics & Photonics (AREA)

- Thermal Sciences (AREA)

- Health & Medical Sciences (AREA)

- Electromagnetism (AREA)

- Toxicology (AREA)

- Plasma & Fusion (AREA)

- Lining Or Joining Of Plastics Or The Like (AREA)

- Closing Of Containers (AREA)

- Closures For Containers (AREA)

Abstract

Description

しかしながら、ヒートシールによる溶着は、熱溶着工程、及びその後に行われる冷却工程に時間がかかり、生産性の点で十分満足するものではない。また一般的なヒートシールバーを用いるヒートシール方式においては、溶着部分の外面からシール面に熱を伝導させる必要があることから、厚肉の容器等では熱の伝導に時間がかかり、生産性の低下を防止するためにはその肉厚に制約があるため、容器、蓋形状の自由度が低いという問題がある。更に、ヒートシール部が冷却され、完全に密閉されるまでに所定の時間がかかるため、特に自生圧力を有する内容物を充填する場合や熱間充填する場合などでは、シール熱で熱膨張したヘッドスペースの気体が溶融状態のシール部から逃げることで、シール剥離を発生するおそれもある。

また、本発明者等は、容器及び蓋等の包装体の部材を互いに押圧する自己押圧機構を有する構成とし、溶着部分を予め外部押圧機構により固定しなくてもレーザ溶着することができ、比較的肉厚の包装体の部材でも高速且つ安定的に密封することが可能な溶着方法を提案した(特許文献2)。

レーザ溶着においてより生産性を上げるためには、レーザのスキャン速度を上げると共に、短時間の照射で確実に溶着すべく、レーザの出力を上げることが考えられる。しかしながら、レーザ溶着は加熱対象の樹脂物性に大きく影響を受けることから、単にレーザの出力を上げただけでは、局所的に過剰な熱が発生して樹脂が熱分解し、樹脂が発泡する等の問題が生じ、結果として短時間で確実な密封性を確保できないことがわかった。

t(msec)=L/S …(1)

式中、Lは矩形ビームのスキャン方向の長さ(mm)、Sは1.65mm/msec以下のレーザのスキャン速度(mm/msec)である、

で表わされる加熱時間t(msec)で前記上限温度に達することを特徴とする密封方法が提供される。

1.熱可塑性樹脂が、ポリスチレン系樹脂、オレフィン系樹脂、ポリエステル樹脂の何れかであること、

2.容器がフランジ部を有し、該フランジ部で蓋とレーザ溶着されること、

3.容器がレーザを透過可能な熱可塑性樹脂から成り、蓋が熱可塑性樹脂にレーザを吸収して発熱する発熱物質を含有させた樹脂組成物から成ること、

4.レーザのスキャン速度が1.40乃至1.65mm/msecであること、

が好適である。

すなわち、容器及び蓋をレーザ溶着する場合には、容器開口部に対応した円形状にレーザを走査(スキャン)させることが必要であることから、スキャン方向に長さLを有する矩形レーザを用いることにより、一般的なスポットレーザにおいてその径を大きくするよりもエネルギーを無駄にすることなく、レーザのスキャン速度を上げることができ、最大スキャン速度が1.65mm/secという高速で容器及び蓋のレーザ溶着による密封を行うことが可能になる。

また、本発明においては、レーザを透過可能な熱可塑性樹脂(以下、「レーザ透過熱可塑性樹脂」ということがある)及び熱可塑性樹脂にレーザを吸収して発熱する発熱物質を含有させた樹脂組成物(以下、「レーザ吸収樹脂組成物」という)の溶着界面の上限温度を、熱可塑性樹脂の融点以上、且つ熱分解開始温度未満の範囲の温度とすることにより、レーザ吸収樹脂組成物の発泡を生じることなく、容器及び蓋を短時間で確実に溶着することが可能になる。

更に本発明においては、上述したレーザ透過熱可塑性樹脂及びレーザ吸収熱可塑性樹脂組成物に用いられる熱可塑性樹脂として、同種の熱可塑性樹脂を用いることで、これらの界面の溶着を有効に行うことができる。

本発明のレーザ溶着による密封方法においては、レーザ吸収熱可塑性樹脂組成物での過加熱を生じさせることなく、シール界面での確実な溶着を短時間で行うべく、スキャン方向に所定長さLを有する矩形レーザを用いること、及びレーザ溶着に際して容器及び蓋のシール界面の温度を、容器及び蓋を構成する熱可塑性樹脂の融点以上且つ熱分解開始温度未満の範囲内の温度に上昇させること、が重要な特徴である。

従って、本発明においては、上記式(1)で表される加熱時間tを、上記加熱時間t1となるように、矩形レーザの長さL或いはスキャン速度を設定することにより、レーザ吸収樹脂組成物の発泡を生じることなく、短時間で、容器及び蓋の確実な溶着を行うことが可能になる。

本発明においてレーザ透過熱可塑性樹脂としては、レーザ透過率が70%以上、特に80%以上の熱可塑性樹脂であることが好適である。レーザ透過率は、使用するレーザ光の波長に対応する光について分光光度計を用いて透過率を測定し求めることができる。

尚、レーザ透過率は、同一の熱可塑性樹脂であっても、厚みによって異なるものであり、本発明においては、後述する厚みの範囲内において70%以上の透過率を有することを意味するものである。

このような熱可塑性樹脂としては、好適には、耐衝撃性ポリスチレン等のスチレン系樹脂、低-、中-、高-密度のポリエチレン、アイソタクチックポリプロピレン、プロピレン・エチレン共重合体、ポリブテン-1、エチレン・プロピレン共重合体、エチレン・ブテン-1共重合体、プロピレン・ブテン-1共重合体、エチレン・プロピレン・ブテン-1共重合体等のオレフィン系樹脂、或いはポリエチレンテレフタレート等のポリエステル樹脂等、従来包装容器に用いられているものであることが望ましく、特にレーザ吸収樹脂組成物の発熱により容易に溶融するものであることが必要であることから、融点が250℃以下の熱可塑性樹脂を用いることが容易に溶着でき好適であり、特にポリエチレン、ポリプロピレンを好適に用いることができる。

本発明において、レーザ吸収樹脂組成物においては、上述したレーザ透過熱可塑性樹脂で用いた熱可塑性樹脂と同じ熱可塑性樹脂を用いることが、レーザ溶着性の点から好適である。

本発明のレーザ吸収樹脂組成物においては、樹脂組成物に均一に発熱物質が含有されていることがシール界面でのレーザ透過熱可塑性樹脂を容易に溶融させる観点から望ましい。このような発熱物質としては、鉄粉等の酸素吸収剤や、カーボンブラック等の着色顔料を挙げることができる。

発熱物質は、用いる発熱物質の種類にもよるが一般に、熱可塑性樹脂100重量部当り0.01乃至0.30重量部、特に0.05乃至0.15重量部の量で配合することが望ましい。

本発明の容器及び蓋の密封方法は、レーザ溶着により密封することから、容器及び蓋の形状の制約を受けず、種々の形態の容器及び蓋の組合せを採用することができる。

本発明においては、容器及び蓋の何れか一方がレーザ透過熱可塑性樹脂から成り、他方がレーザ吸収熱可塑性樹脂組成物から成るものであり、何れがレーザ吸収熱可塑性樹脂組成物であってもよいが、特に蓋がレーザ吸収性熱可塑性樹脂組成物から成ることが好適である。

容器としては、具体的には、単層又は多層のシート状の材料から真空成形、圧空成形、プラグアシスト成形等の熱成形によって成形されたカップ或いはトレイ等の容器や、絞り成形によって成形された有底カップ等を例示することができ、特にフランジ部を有するカップであることが好適であり、この場合には、フランジ部で容器及び蓋を550kpa以上の圧力で当接させて、レーザを照射し溶着される。

蓋の形状は、容器のカップ或いはトレイ等の形状によって、種々の形状をとることができ、例えば平面状のもの、中央が内方にへこんだ落とし蓋状、頂板部の外周端部から垂下するスカート部を有するオーバーキャップ状の蓋等の成形蓋等、容器との当接部分に合わせて適宜変更することができる。

尚、容器又は蓋の溶着箇所のみがレーザ吸収熱可塑性樹脂組成物で形成されていてもよく、例えば容器のフランジ部のみがレーザ吸収熱可塑性樹脂組成物から成り、容器胴部及び底部は、発熱部材を含有しないレーザ透過熱可塑性樹脂であってもよいし、或いは多層構造が形成されていてもよい。また蓋のフランジ部のみがレーザ吸収熱可塑性樹脂組成物から成り、中央部がレーザ透過熱可塑性樹脂から成っていてもよい。

また、レーザ吸収熱可塑性樹脂組成物から成る部分は、0.1乃至2.0mm、特に0.5乃至1.2mmの範囲にあることが望ましい。上記範囲よりもレーザ吸収熱可塑性樹脂組成物から成る部分の厚みが薄い場合には、上記範囲ある場合に比して確実な溶着を行うことが困難になるおそれがあり、一方上記範囲よりも厚くても経済性に劣るようになる。

本発明においては、前述した容器と蓋の当接部分を、レーザ透過熱可塑性樹脂から成る部材側からレーザビームを照射して、レーザ吸収熱可塑性樹脂組成物を発熱させることにより、レーザ透過熱可塑性樹脂を溶融して、容器及び蓋の当接面を溶融密着させる。

本発明の密封方法においては、容器内に内容物を充填した後、容器及び蓋のシール部分の形状に合わせて、容器或いはレーザ発振機を移動(回転)させることにより、レーザを容器及び蓋のシール部分にスキャンさせる。

レーザビームの照射に際し、容器及び蓋の当接面を密着させることが効率よく両者を溶着させる上で重要であり、図2及び3に示すように、両者を押圧固定する治具等を用いて密着させたり、或いは容器及び蓋が当接面において互いに押圧するような位置関係になるような寸法及び形状に、容器及び蓋を成形することによっても、密着させることができる。

ターンテーブル30にカップ10が設置・固定され、カップ10のフランジ部13の位置に成形蓋20の周縁部21が位置するように、成形蓋20を設置する。成形蓋20の上方から荷重Pを掛けることにより、カップ10のフランジ部13及び成形蓋20の周縁部21の当接面を密着させる。

次いで、ターンテーブル30の回転に合わせ、容器及び蓋の斜め下方からレーザビームLが照射されることにより、カップ10及び成形蓋20の当接面を溶着して密封することが可能となる。

例えば、図3に示すように、落とし蓋状の成形蓋20の側面23に突起24が形成されており、該突起24によってカップ10の内側面が押圧されて互いに圧着する箇所が形成されているような場合には、容器及び蓋の側方からレーザ照射することもできる。また図2に示した例において、容器をレーザ吸収熱可塑性樹脂組成物、蓋をレーザ透過熱可塑性樹脂から形成し、上方からレーザビームLを照射してもよい。この際、レーザ照射方向側の部材がレーザ透過熱可塑性樹脂から成ることはいうまでもない。

レーザ発振器の出力は100乃至500W、特に200乃至350Wの範囲にあることが好ましい。尚、高速での溶着を可能にするためには、レーザ出力を上げることが考えられるが、前述した通り、レーザ吸収熱可塑性樹脂組成物の熱分解による発泡を生じるおそれがあり、本発明においては、従来レーザ溶着に使用されていた範囲の出力で高速溶着を可能にした点に意義がある。

用いるレーザは、商業的には樹脂の透過性とレーザビームを吸収して発熱する物質の性質、及びレーザ発振器の出力、値段、安全性により決まる。

また、レーザビームの焦点距離は50乃至250mm、特に100乃至200mmの範囲にあることが好ましい。

本発明において、レーザビームのスキャン速度は、高速でのレーザ溶着を目的とすることから、レーザ出力及びレーザ吸収熱可塑性樹脂組成物の熱分解開始温度に応じて1.65mm/msec以下、特に1.40乃至1.65mm/msecの範囲となるように設定することが望ましい。尚、スキャン速度(mm/msec)は、容器の口径から算出されるシール長さ(mm)とレーザの照射時間(msec)から算出される。

容器:層構成が(カップ外面側)450μmポリプロピレン/30μm接着剤層/90μmEVOH(エチレン・ビニルアルコール共重合樹脂)/30μm接着剤層/(カップ内面側)400μmポリプロピレン(融点:160℃)となる樹脂シートから、真空成形法にて、側壁部の上部が上方に行くに従って径が減少する逆テーパ状(テーパ角:約10°)で、開口部外径が80mm、内容量が120mlのフランジ部を形成したカップ型容器を成形した。

成形蓋:ポリプロピレン樹脂(融点160℃)にカーボンブラックを1000ppm添加し、インジェクション成形で厚さが0.7mmの落とし蓋を成形した。

レーザ発振器:株式会社日鐵テクノリサーチ(最大レーザ出力330W)、半導体(GaAs)レーザ、波長806±10nm、レーザ出力300W、レーザ形状(ビーム断面)1.5×4mm

レーザ照射位置直径:Φ75mm

レーザ発振時間:0.15sec(受台回転数420rpm、1.05回転分照射、スキャン速度1.65mm/msec)

当接面接触圧:約800kPa(当接面面積 約4cm2、荷重330N)

十分な溶着強度と密封性を得るには、受台回転数330rpm(レーザ発振時間0.19sec、1.05回転分照射、スキャン速度1.30mm/msec)にする必要があったが、この条件では、成型蓋の周縁部の樹脂に発泡が見られた。

Claims (5)

- 容器及び蓋のレーザ溶着による密封方法において、前記容器又は蓋の一方がレーザを透過可能な熱可塑性樹脂、他方がレーザを吸収して発熱する発熱物質を熱可塑性樹脂に含有させた樹脂組成物から成り、前記レーザが、強度分布が一様な矩形ビームを照射可能なレーザであり、前記容器及び蓋の溶着界面における、レーザ照射により上昇する温度の上限温度が、前記熱可塑性樹脂の融点以上且つ熱分解開始温度未満の範囲にあり、下記式(1)

t(msec)=L/S …(1)

式中、Lは矩形ビームのスキャン方向の長さ(mm)、Sは1.65mm/msec以下のレーザのスキャン速度(mm/msec)である、

で表わされる加熱時間t(msec)で前記上限温度に達することを特徴とする密封方法。 - 前記熱可塑性樹脂が、スチレン系樹脂、オレフィン系樹脂、又はポリエステル樹脂の何れかである請求項1記載の密封方法。

- 前記容器がフランジ部を有し、該フランジ部で蓋とレーザ溶着される請求項1又は2記載の密封方法。

- 前記容器がレーザを透過可能な熱可塑性樹脂から成り、前記蓋が熱可塑性樹脂にレーザを吸収して発熱する発熱物質を含有させた樹脂組成物から成る請求項1乃至3の何れかに記載の密封方法。

- 前記レーザのスキャン速度が1.40乃至1.65mm/msecである請求項1乃至4の何れかに記載の密封方法。

Priority Applications (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| KR1020147029875A KR101775768B1 (ko) | 2012-03-29 | 2013-03-08 | 용기 및 덮개의 레이저 용착에 의한 밀봉 방법 |

| US14/387,063 US9550596B2 (en) | 2012-03-29 | 2013-03-08 | Method of sealing containers and lids by melt adhesion by laser |

| EP13767876.9A EP2832527B1 (en) | 2012-03-29 | 2013-03-08 | Method for sealing container and lid using laser welding |

| CN201380017519.4A CN104220238B (zh) | 2012-03-29 | 2013-03-08 | 通过使用激光进行熔接的密封容器和盖的方法 |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2012-077905 | 2012-03-29 | ||

| JP2012077905A JP6024152B2 (ja) | 2012-03-29 | 2012-03-29 | 容器及び蓋のレーザ溶着による密封方法 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2013146190A1 true WO2013146190A1 (ja) | 2013-10-03 |

Family

ID=49259458

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2013/056473 WO2013146190A1 (ja) | 2012-03-29 | 2013-03-08 | 容器及び蓋のレーザ溶着による密封方法 |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US9550596B2 (ja) |

| EP (1) | EP2832527B1 (ja) |

| JP (1) | JP6024152B2 (ja) |

| KR (1) | KR101775768B1 (ja) |

| CN (1) | CN104220238B (ja) |

| WO (1) | WO2013146190A1 (ja) |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20140217103A1 (en) * | 2013-02-07 | 2014-08-07 | Jenoptik Automatisierungstechnik Gmbh | Apparatus for Laser Transmission Welding, Method for Laser Transmission Welding, and a Receptacle Which is Produced Thereby and is Closed by Sheet |

| WO2015083555A1 (ja) | 2013-12-06 | 2015-06-11 | 東洋製罐株式会社 | 容器の密封装置及び密封システム |

| JP2015110428A (ja) * | 2013-12-06 | 2015-06-18 | 東洋製罐株式会社 | 容器のフランジ部洗浄装置及び洗浄システム |

| JP2015117065A (ja) * | 2013-12-20 | 2015-06-25 | 東洋製罐株式会社 | 容器の密封装置 |

Families Citing this family (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP6446770B2 (ja) * | 2013-09-20 | 2019-01-09 | 東洋製罐株式会社 | 無菌充填システム |

| JP5836544B2 (ja) * | 2013-12-06 | 2015-12-24 | 興亜硝子株式会社 | 化粧品用プラスチック容器およびその製造方法 |

| US9440424B2 (en) * | 2014-05-05 | 2016-09-13 | Picosys Inc | Methods to form and to dismantle hermetically sealed chambers |

| JP6025789B2 (ja) | 2014-08-19 | 2016-11-16 | 株式会社矢板製作所 | 透明プラスチック容器およびその製造方法 |

| JP6645097B2 (ja) * | 2015-09-29 | 2020-02-12 | 東洋製罐株式会社 | 密封包装体 |

| US20180099456A1 (en) * | 2016-10-12 | 2018-04-12 | Dukane Ias, Llc | Laser Welding System and Method for Producing Image-Containing Weld Seam |

| US11298861B2 (en) * | 2017-11-21 | 2022-04-12 | Silgan Specialty Packaging Llc | Multi-layer injection molded container |

| US11472579B2 (en) | 2018-12-04 | 2022-10-18 | Gpcp Ip Holdings Llc | Film securing apparatus and method |

| US11071411B2 (en) * | 2018-01-29 | 2021-07-27 | Thermos L.L.C. | Methods and systems for forming vacuum insulated containers |

| JP2019188726A (ja) * | 2018-04-26 | 2019-10-31 | アイシン精機株式会社 | 樹脂部品 |

| US11541609B2 (en) | 2018-07-03 | 2023-01-03 | Dukane Ias, Llc | System and method for simultaneous welding of plastic bags using a carrier film |

| US11548235B2 (en) | 2018-07-03 | 2023-01-10 | Dukane Ias, Llc | Laser welding system and method using machined clamping tool |

| US11819940B2 (en) | 2019-02-05 | 2023-11-21 | Dukane Ias, Llc | Systems and methods for laser-welding a workpiece with a laser beam that reaches inaccessible areas of the workpiece using multiple reflecting parts |

| US11931823B2 (en) | 2019-02-05 | 2024-03-19 | Dukane Ias, Llc | Systems and methods for laser-welding a workpiece with a laser beam that reaches inaccessible areas of the workpiece using multiple reflecting parts |

| US10926355B2 (en) | 2019-02-05 | 2021-02-23 | Dukane Ias, Llc | Systems and methods for laser-welding tubular components using a single, fixed optical reflector with multiple reflecting surfaces |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2000128166A (ja) | 1998-10-22 | 2000-05-09 | Fuji Seal Inc | 容器の製造方法及び容器 |

| JP2008207358A (ja) | 2007-02-23 | 2008-09-11 | Toyo Seikan Kaisha Ltd | 熱可塑性樹脂から成る層を有する部材の溶着方法及び蓋付熱可塑性樹脂容器 |

| JP2011020175A (ja) * | 2009-07-17 | 2011-02-03 | Hamamatsu Univ School Of Medicine | 筒状体のレーザ加工方法と筒状体のレーザ加工装置 |

| JP2011207056A (ja) * | 2010-03-30 | 2011-10-20 | Sumitomo Chemical Co Ltd | 複合体の製造方法 |

Family Cites Families (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| BE792903A (nl) * | 1971-12-30 | 1973-06-18 | American Can Co | Laserstraal-lassen van kunststoffen buizen |

| ES2230415T3 (es) * | 2002-05-16 | 2005-05-01 | Leister Process Technologies | Procedimiento y dispositivo para la union de materiales de plastico con alta velocidad de soldadura. |

| JP4081355B2 (ja) * | 2002-11-19 | 2008-04-23 | 株式会社豊田中央研究所 | 積層体の製造方法及び積層体 |

| DE102004004985B4 (de) * | 2004-01-30 | 2006-03-23 | Lpkf Laser & Electronics Ag | Verfahren und Vorrichtung zum Durchstrahlschweißen zweier thermoplastischer Bauteile |

| JP2006205216A (ja) * | 2005-01-28 | 2006-08-10 | Pioneer Electronic Corp | レーザ溶接装置、及びレーザ溶接方法 |

| FR2922149B1 (fr) * | 2007-10-10 | 2011-06-10 | Alstom Transport Sa | Procede de soudage de deux elements en materiau polymere opaques et resistant a haute temperature |

| JP4682179B2 (ja) | 2007-11-19 | 2011-05-11 | 三菱電機株式会社 | 樹脂材の溶着方法及び溶着装置 |

| JP5368814B2 (ja) * | 2009-01-29 | 2013-12-18 | 浜松ホトニクス株式会社 | 樹脂溶着方法 |

| JP2010184490A (ja) * | 2009-02-10 | 2010-08-26 | Ma Tech Kk | レーザ光線による樹脂溶着方法とレーザ光線による樹脂溶着装置 |

| US8506872B2 (en) * | 2009-05-29 | 2013-08-13 | Stanley Electric Co., Ltd. | Method for manufacturing resin mold assembly |

| JP5359703B2 (ja) * | 2009-09-02 | 2013-12-04 | 東洋製罐株式会社 | 密封容器及びその製造方法 |

| JP5554629B2 (ja) * | 2010-05-19 | 2014-07-23 | ポリプラスチックス株式会社 | 溶着条件の決定方法 |

| JP5588253B2 (ja) * | 2010-07-21 | 2014-09-10 | 浜松ホトニクス株式会社 | 樹脂溶着方法 |

-

2012

- 2012-03-29 JP JP2012077905A patent/JP6024152B2/ja active Active

-

2013

- 2013-03-08 CN CN201380017519.4A patent/CN104220238B/zh active Active

- 2013-03-08 KR KR1020147029875A patent/KR101775768B1/ko active IP Right Grant

- 2013-03-08 WO PCT/JP2013/056473 patent/WO2013146190A1/ja active Application Filing

- 2013-03-08 US US14/387,063 patent/US9550596B2/en active Active

- 2013-03-08 EP EP13767876.9A patent/EP2832527B1/en active Active

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2000128166A (ja) | 1998-10-22 | 2000-05-09 | Fuji Seal Inc | 容器の製造方法及び容器 |

| JP2008207358A (ja) | 2007-02-23 | 2008-09-11 | Toyo Seikan Kaisha Ltd | 熱可塑性樹脂から成る層を有する部材の溶着方法及び蓋付熱可塑性樹脂容器 |

| JP2011020175A (ja) * | 2009-07-17 | 2011-02-03 | Hamamatsu Univ School Of Medicine | 筒状体のレーザ加工方法と筒状体のレーザ加工装置 |

| JP2011207056A (ja) * | 2010-03-30 | 2011-10-20 | Sumitomo Chemical Co Ltd | 複合体の製造方法 |

Non-Patent Citations (1)

| Title |

|---|

| See also references of EP2832527A4 |

Cited By (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20140217103A1 (en) * | 2013-02-07 | 2014-08-07 | Jenoptik Automatisierungstechnik Gmbh | Apparatus for Laser Transmission Welding, Method for Laser Transmission Welding, and a Receptacle Which is Produced Thereby and is Closed by Sheet |

| WO2015083555A1 (ja) | 2013-12-06 | 2015-06-11 | 東洋製罐株式会社 | 容器の密封装置及び密封システム |

| JP2015110428A (ja) * | 2013-12-06 | 2015-06-18 | 東洋製罐株式会社 | 容器のフランジ部洗浄装置及び洗浄システム |

| CN105849001A (zh) * | 2013-12-06 | 2016-08-10 | 东洋制罐株式会社 | 容器密封设备及容器密封系统 |

| EP3078600A4 (en) * | 2013-12-06 | 2017-07-12 | Toyo Seikan Co., Ltd. | Vessel sealing device and sealing system |

| US10683117B2 (en) | 2013-12-06 | 2020-06-16 | Toyo Seikan Co., Ltd. | Container sealing apparatus and sealing system |

| JP2015117065A (ja) * | 2013-12-20 | 2015-06-25 | 東洋製罐株式会社 | 容器の密封装置 |

Also Published As

| Publication number | Publication date |

|---|---|

| US20150083302A1 (en) | 2015-03-26 |

| US9550596B2 (en) | 2017-01-24 |

| KR20140146624A (ko) | 2014-12-26 |

| EP2832527A1 (en) | 2015-02-04 |

| EP2832527B1 (en) | 2018-08-08 |

| CN104220238A (zh) | 2014-12-17 |

| JP2013203052A (ja) | 2013-10-07 |

| KR101775768B1 (ko) | 2017-09-06 |

| CN104220238B (zh) | 2016-10-26 |

| EP2832527A4 (en) | 2015-12-09 |

| JP6024152B2 (ja) | 2016-11-09 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6024152B2 (ja) | 容器及び蓋のレーザ溶着による密封方法 | |

| JP5516406B2 (ja) | レーザ溶着密封包装体及びその密封方法 | |

| JP4899923B2 (ja) | 熱可塑性樹脂から成る層を有する部材の溶着方法及び蓋付熱可塑性樹脂容器 | |

| JP5812225B1 (ja) | 成形蓋及びこの蓋の容器への嵌合方法並びに密封方法 | |

| JP5359703B2 (ja) | 密封容器及びその製造方法 | |

| WO2007018054A1 (ja) | 密封容器 | |

| CN102844173A (zh) | 由具有多内层的无铝平面复合材料通过冷折叠来生产食品容器的方法 | |

| JP5961927B2 (ja) | レーザ溶着密封容器及びその製造方法 | |

| JP5927762B2 (ja) | レーザ溶着密封包装体及びその製造方法 | |

| JP2009066820A (ja) | 水を介在させたプラスチック部材のレーザー溶接方法 | |

| CN102725137A (zh) | 由具有内层的无铝平面复合材料通过冷折叠来生产食品容器的方法 | |

| CN102844174A (zh) | 由具有多内层的无铝平面复合材料通过热折叠来生产食品容器的方法 | |

| JP5736704B2 (ja) | リシール性を有する密封容器 | |

| CN102725136A (zh) | 由具有内层的无铝平面复合材料通过热折叠来生产食品容器的方法 | |

| JP5463721B2 (ja) | 包装容器の製造方法 | |

| JP6645097B2 (ja) | 密封包装体 | |

| JP2008230163A (ja) | レーザー光吸収材の表面塗布による溶接方法 | |

| JP5750882B2 (ja) | 密封容器及びその製造方法 | |

| JP4628843B2 (ja) | 金属製密封容器及びその製造方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 13767876 Country of ref document: EP Kind code of ref document: A1 |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 2013767876 Country of ref document: EP |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 14387063 Country of ref document: US |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| ENP | Entry into the national phase |

Ref document number: 20147029875 Country of ref document: KR Kind code of ref document: A |