WO2012029935A1 - 保護機能付きスイッチング電源回路 - Google Patents

保護機能付きスイッチング電源回路 Download PDFInfo

- Publication number

- WO2012029935A1 WO2012029935A1 PCT/JP2011/069982 JP2011069982W WO2012029935A1 WO 2012029935 A1 WO2012029935 A1 WO 2012029935A1 JP 2011069982 W JP2011069982 W JP 2011069982W WO 2012029935 A1 WO2012029935 A1 WO 2012029935A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- circuit

- electrolytic capacitor

- primary

- switching

- power supply

- Prior art date

Links

Images

Classifications

-

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02H—EMERGENCY PROTECTIVE CIRCUIT ARRANGEMENTS

- H02H7/00—Emergency protective circuit arrangements specially adapted for specific types of electric machines or apparatus or for sectionalised protection of cable or line systems, and effecting automatic switching in the event of an undesired change from normal working conditions

- H02H7/10—Emergency protective circuit arrangements specially adapted for specific types of electric machines or apparatus or for sectionalised protection of cable or line systems, and effecting automatic switching in the event of an undesired change from normal working conditions for converters; for rectifiers

- H02H7/12—Emergency protective circuit arrangements specially adapted for specific types of electric machines or apparatus or for sectionalised protection of cable or line systems, and effecting automatic switching in the event of an undesired change from normal working conditions for converters; for rectifiers for static converters or rectifiers

- H02H7/1213—Emergency protective circuit arrangements specially adapted for specific types of electric machines or apparatus or for sectionalised protection of cable or line systems, and effecting automatic switching in the event of an undesired change from normal working conditions for converters; for rectifiers for static converters or rectifiers for DC-DC converters

-

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02M—APPARATUS FOR CONVERSION BETWEEN AC AND AC, BETWEEN AC AND DC, OR BETWEEN DC AND DC, AND FOR USE WITH MAINS OR SIMILAR POWER SUPPLY SYSTEMS; CONVERSION OF DC OR AC INPUT POWER INTO SURGE OUTPUT POWER; CONTROL OR REGULATION THEREOF

- H02M3/00—Conversion of dc power input into dc power output

- H02M3/22—Conversion of dc power input into dc power output with intermediate conversion into ac

- H02M3/24—Conversion of dc power input into dc power output with intermediate conversion into ac by static converters

- H02M3/28—Conversion of dc power input into dc power output with intermediate conversion into ac by static converters using discharge tubes with control electrode or semiconductor devices with control electrode to produce the intermediate ac

-

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02H—EMERGENCY PROTECTIVE CIRCUIT ARRANGEMENTS

- H02H7/00—Emergency protective circuit arrangements specially adapted for specific types of electric machines or apparatus or for sectionalised protection of cable or line systems, and effecting automatic switching in the event of an undesired change from normal working conditions

- H02H7/10—Emergency protective circuit arrangements specially adapted for specific types of electric machines or apparatus or for sectionalised protection of cable or line systems, and effecting automatic switching in the event of an undesired change from normal working conditions for converters; for rectifiers

- H02H7/12—Emergency protective circuit arrangements specially adapted for specific types of electric machines or apparatus or for sectionalised protection of cable or line systems, and effecting automatic switching in the event of an undesired change from normal working conditions for converters; for rectifiers for static converters or rectifiers

-

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02H—EMERGENCY PROTECTIVE CIRCUIT ARRANGEMENTS

- H02H7/00—Emergency protective circuit arrangements specially adapted for specific types of electric machines or apparatus or for sectionalised protection of cable or line systems, and effecting automatic switching in the event of an undesired change from normal working conditions

- H02H7/10—Emergency protective circuit arrangements specially adapted for specific types of electric machines or apparatus or for sectionalised protection of cable or line systems, and effecting automatic switching in the event of an undesired change from normal working conditions for converters; for rectifiers

- H02H7/12—Emergency protective circuit arrangements specially adapted for specific types of electric machines or apparatus or for sectionalised protection of cable or line systems, and effecting automatic switching in the event of an undesired change from normal working conditions for converters; for rectifiers for static converters or rectifiers

- H02H7/125—Emergency protective circuit arrangements specially adapted for specific types of electric machines or apparatus or for sectionalised protection of cable or line systems, and effecting automatic switching in the event of an undesired change from normal working conditions for converters; for rectifiers for static converters or rectifiers for rectifiers

- H02H7/1255—Emergency protective circuit arrangements specially adapted for specific types of electric machines or apparatus or for sectionalised protection of cable or line systems, and effecting automatic switching in the event of an undesired change from normal working conditions for converters; for rectifiers for static converters or rectifiers for rectifiers responsive to internal faults, e.g. by monitoring ripple in output voltage

-

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02M—APPARATUS FOR CONVERSION BETWEEN AC AND AC, BETWEEN AC AND DC, OR BETWEEN DC AND DC, AND FOR USE WITH MAINS OR SIMILAR POWER SUPPLY SYSTEMS; CONVERSION OF DC OR AC INPUT POWER INTO SURGE OUTPUT POWER; CONTROL OR REGULATION THEREOF

- H02M3/00—Conversion of dc power input into dc power output

- H02M3/22—Conversion of dc power input into dc power output with intermediate conversion into ac

- H02M3/24—Conversion of dc power input into dc power output with intermediate conversion into ac by static converters

- H02M3/28—Conversion of dc power input into dc power output with intermediate conversion into ac by static converters using discharge tubes with control electrode or semiconductor devices with control electrode to produce the intermediate ac

- H02M3/325—Conversion of dc power input into dc power output with intermediate conversion into ac by static converters using discharge tubes with control electrode or semiconductor devices with control electrode to produce the intermediate ac using devices of a triode or a transistor type requiring continuous application of a control signal

- H02M3/335—Conversion of dc power input into dc power output with intermediate conversion into ac by static converters using discharge tubes with control electrode or semiconductor devices with control electrode to produce the intermediate ac using devices of a triode or a transistor type requiring continuous application of a control signal using semiconductor devices only

-

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02M—APPARATUS FOR CONVERSION BETWEEN AC AND AC, BETWEEN AC AND DC, OR BETWEEN DC AND DC, AND FOR USE WITH MAINS OR SIMILAR POWER SUPPLY SYSTEMS; CONVERSION OF DC OR AC INPUT POWER INTO SURGE OUTPUT POWER; CONTROL OR REGULATION THEREOF

- H02M3/00—Conversion of dc power input into dc power output

- H02M3/22—Conversion of dc power input into dc power output with intermediate conversion into ac

- H02M3/24—Conversion of dc power input into dc power output with intermediate conversion into ac by static converters

- H02M3/28—Conversion of dc power input into dc power output with intermediate conversion into ac by static converters using discharge tubes with control electrode or semiconductor devices with control electrode to produce the intermediate ac

- H02M3/325—Conversion of dc power input into dc power output with intermediate conversion into ac by static converters using discharge tubes with control electrode or semiconductor devices with control electrode to produce the intermediate ac using devices of a triode or a transistor type requiring continuous application of a control signal

- H02M3/335—Conversion of dc power input into dc power output with intermediate conversion into ac by static converters using discharge tubes with control electrode or semiconductor devices with control electrode to produce the intermediate ac using devices of a triode or a transistor type requiring continuous application of a control signal using semiconductor devices only

- H02M3/33507—Conversion of dc power input into dc power output with intermediate conversion into ac by static converters using discharge tubes with control electrode or semiconductor devices with control electrode to produce the intermediate ac using devices of a triode or a transistor type requiring continuous application of a control signal using semiconductor devices only with automatic control of the output voltage or current, e.g. flyback converters

- H02M3/33523—Conversion of dc power input into dc power output with intermediate conversion into ac by static converters using discharge tubes with control electrode or semiconductor devices with control electrode to produce the intermediate ac using devices of a triode or a transistor type requiring continuous application of a control signal using semiconductor devices only with automatic control of the output voltage or current, e.g. flyback converters with galvanic isolation between input and output of both the power stage and the feedback loop

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05G—X-RAY TECHNIQUE

- H05G1/00—X-ray apparatus involving X-ray tubes; Circuits therefor

- H05G1/08—Electrical details

- H05G1/10—Power supply arrangements for feeding the X-ray tube

- H05G1/12—Power supply arrangements for feeding the X-ray tube with dc or rectified single-phase ac or double-phase

-

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02M—APPARATUS FOR CONVERSION BETWEEN AC AND AC, BETWEEN AC AND DC, OR BETWEEN DC AND DC, AND FOR USE WITH MAINS OR SIMILAR POWER SUPPLY SYSTEMS; CONVERSION OF DC OR AC INPUT POWER INTO SURGE OUTPUT POWER; CONTROL OR REGULATION THEREOF

- H02M1/00—Details of apparatus for conversion

- H02M1/32—Means for protecting converters other than automatic disconnection

Definitions

- the present invention relates to a technique for detecting deterioration of an electrolytic capacitor for a smoothing circuit provided in a switching power supply device and avoiding a damage accident in advance.

- an electrolytic capacitor used in a smoothing circuit deteriorates due to repeated charge / discharge of a large current and use over time. Therefore, if it continues to be used beyond its lifetime, the switching power supply device may be damaged as the electrolytic capacitor deteriorates, possibly resulting in smoke and fire accidents.

- Various techniques for detecting and coping with the deterioration of the electrolytic capacitor have also been studied by means of circuit on the switching power supply circuit.

- an increase in equivalent series resistance (ESR) due to deterioration of an electrolytic capacitor is detected based on a voltage difference between both ends of a secondary winding of a transformer, and a photocoupler (Photo Coupler) is detected.

- ESR equivalent series resistance

- a technique for feedback and detection to a primary side circuit using a signal is disclosed.

- Patent Document 1 requires a circuit change such as addition of a ripple voltage detection circuit using a transistor and a further photocoupler, which increases costs and requires a relatively large space for this countermeasure. There was a problem.

- an object of the present invention is to provide a low-cost switching power supply device having a function of detecting a deterioration of an electrolytic capacitor of a smoothing circuit by simply adding a simple circuit and avoiding a damage accident from the deterioration of the electrolytic capacitor. Is to provide.

- the first invention is a transformer having a primary winding, a secondary winding, and a tertiary winding, a primary side rectifier circuit that converts AC power into DC power, and a DC of the primary side rectifier circuit.

- a primary electrolytic capacitor that smoothes power, a secondary rectifier circuit that converts AC power output from the secondary winding of the transformer into DC power, and DC power output from the secondary rectifier circuit is smoothed

- the secondary side electrolytic capacitor to be converted, the tertiary side rectifying / smoothing circuit for smoothing by converting the AC power output from the tertiary winding of the transformer into DC power, and the voltage of the primary side electrolytic capacitor are input.

- a switching circuit that repeatedly opens and closes the primary winding of the transformer, a pulse width control circuit that controls a pulse width of a drive signal that controls opening and closing of the switching circuit, and 2 that detects deterioration of the secondary electrolytic capacitor Secondary electrolytic condenser A deterioration detection circuit; and a stop signal generation circuit for inputting a deterioration detection signal of the secondary electrolytic capacitor deterioration detection circuit, wherein the secondary electrolytic capacitor deterioration detection circuit outputs an output of the tertiary rectification smoothing circuit.

- the stop signal generation circuit When the voltage is input and the stop signal generation circuit generates a stop signal in response to the deterioration detection signal of the secondary electrolytic capacitor deterioration detection circuit, the supply of the drive signal from the pulse width control circuit to the switching circuit is stopped. Thus, the operation of the switching power supply circuit is stopped.

- a transformer having a primary winding, a secondary winding, and a tertiary winding, a primary side rectifier circuit that converts AC power to DC power, and the primary side rectifier circuit.

- a primary side electrolytic capacitor that smoothes DC power, a secondary side rectifier circuit that converts AC power output from the secondary winding of the transformer into DC power, and DC power output from the secondary rectifier circuit A secondary electrolytic capacitor to be smoothed, a switching circuit that repeatedly opens and closes the primary winding of the transformer that inputs the voltage of the primary electrolytic capacitor, and a pulse width of a drive signal that controls the opening and closing of the switching circuit

- a pulse width control circuit for controlling, a primary side electrolytic capacitor deterioration detecting circuit for detecting deterioration of the primary side electrolytic capacitor, and a stop signal generating circuit for inputting a deterioration detection signal of the primary side electrolytic capacitor deterioration detecting circuit

- the primary electrolytic capacitor deterioration detection circuit inputs the voltage of the primary electrolytic capacitor, and the stop signal generation circuit generates a stop signal in response to the deterioration detection signal of the primary electrolytic capacitor deterioration detection circuit

- the operation of the switching power supply circuit is stopped by stopping the supply

- a transformer having a primary winding, a secondary winding, and a tertiary winding, a primary side rectifier circuit that converts AC power into DC power, and the primary side rectifier circuit.

- a switching circuit that repeatedly opens and closes the primary winding of the transformer that is input, a pulse width control circuit that controls the pulse width of a drive signal that controls the opening and closing of the switching circuit, and the deterioration of the primary electrolytic capacitor are detected Primary electrolytic condenser Degradation detection circuit, secondary side electrolytic capacitor degradation detection circuit for detecting degradation of the secondary side electrolytic capacitor, degradation detection signals of the primary side electrolytic capacitor degradation detection circuit and the secondary side electrolytic capacitor degradation detection circuit

- a stop signal generation circuit for inputting, the primary electrolytic capacitor deterioration detection circuit inputs the voltage of the primary

- the secondary electrolytic capacitor deterioration detection circuit is connected to the second electrolytic capacitor through voltage increase from the secondary winding to the tertiary winding.

- the stop signal generation circuit generates a stop signal to the pulse width control circuit, and the pulse width control circuit stops supplying the drive signal to the switching circuit, thereby switching power supply. Stop and protect the circuit.

- the primary electrolytic capacitor deterioration detection circuit detects the deterioration of the primary electrolytic capacitor, and a stop signal generation circuit Generates a stop signal to the pulse width control circuit, and the pulse width control circuit stops supplying the drive signal to the switching circuit, thereby stopping and protecting the operation of the switching power supply circuit.

- the primary electrolytic capacitor deterioration detection circuit detects the deterioration of the primary electrolytic capacitor, and the secondary side

- the secondary electrolytic capacitor deterioration detection circuit detects the deterioration of the secondary electrolytic capacitor through a voltage increase from the secondary winding to the tertiary winding.

- the stop signal generation circuit generates a stop signal to the pulse width control circuit, and the pulse width control circuit stops the operation of the switching power supply circuit by stopping the supply of the drive signal to the switching circuit.

- the present invention low-cost and space-saving switching with a function of detecting deterioration of an electrolytic capacitor of a smoothing circuit by simply adding a simple circuit and avoiding a damage accident from the deterioration of the electrolytic capacitor in advance.

- a power supply device can be provided.

- the circuit of the present invention can be integrated with the pulse width control circuit to form an integrated circuit.

- FIG. 1 is a circuit diagram showing a schematic configuration of a first embodiment of a switching power supply circuit with a protection circuit of the present invention.

- a primary side rectifier circuit 101 has a bridge circuit configuration of diodes 121 to 124, and dc power including ripples is obtained by full-wave rectifying AC power (AC voltage A1) input from input terminals 141 and 142. Is output between the primary side DC terminal 147 and the primary side ground 145.

- the primary side electrolytic capacitor 102 is connected between the primary side DC terminal 147 and the primary side ground 145, and smoothes the DC power including the ripple output from the primary side rectifier circuit 101.

- the primary side rectification circuit 101 and the primary side electrolytic capacitor 102 constitute a primary side rectification smoothing circuit 103.

- the transformer 104 includes a primary winding N1, a secondary winding N2, and a tertiary winding N3.

- the ratio of the number of turns of the primary winding N1, the secondary winding N2, and the tertiary winding N3 is N1: N2: N3.

- the AC voltage applied to both ends of the primary winding N1 is output to both ends of the secondary winding N2 as an AC voltage approximately N2 / N1 times.

- an AC voltage approximately N3 / N2 times the voltage across the secondary winding N2 is output across the tertiary winding N3.

- a circuit related to the primary winding N1 is appropriately expressed as a primary side circuit

- a circuit related to the secondary winding N2 is referred to as a secondary side circuit

- a circuit related to the tertiary winding N3 is appropriately referred to as a tertiary side circuit.

- the first terminal of the primary winding N1 is connected to the primary side DC terminal 147, and the second terminal at the other end is the drain of an N-type MOSFET (Metal-Oxide-Semiconductor Field-Effect Transistor) constituting the switching circuit 108.

- the source of the N-type MOSFET is connected to the primary side ground 145 through the resistor 162.

- the first terminal of the secondary winding N2 is connected to the anode of the diode 125, and the cathode of the diode 125 is connected to the secondary side DC output terminal 143.

- the second terminal of the secondary winding N2 is connected to the secondary side DC output terminal 144 on the ground side.

- the secondary electrolytic capacitor 105 is connected between the secondary side DC output terminal 143 and the ground side secondary DC output terminal 144.

- the diode 125 constitutes a secondary side rectifier circuit (125), and rectifies the AC power induced in the secondary winding N2.

- the secondary electrolytic capacitor 105 smoothes the DC power including the rectified ripple output from the diode 125.

- the secondary-side rectifying / smoothing circuit 106 is configured by the secondary-side rectifier circuit (125) including the diode 125 and the secondary-side electrolytic capacitor 105.

- the secondary side rectifying / smoothing circuit 106 applies DC power (secondary side DC output voltage E2) between the secondary side DC output terminal 143 and the secondary side DC output terminal 144 connected to the secondary side ground 146. Output.

- the secondary side DC output terminal 144 is connected to the secondary side ground 146.

- the primary side ground 145 and the secondary side ground 146 are both grounded but are galvanically insulated.

- the first terminal of the tertiary winding N3 is connected to the anode of the diode 126, and the second terminal of the tertiary winding N3 is connected to the primary side ground 145.

- a smoothing capacitor 127 is connected between the cathode of the diode 126 and the primary side ground 145.

- the diode 126 constitutes a tertiary rectifier circuit 126, and rectifies the AC power induced in the tertiary winding N3.

- the smoothing capacitor 127 smoothes the DC power including the rectified ripple output from the diode 126.

- a tertiary-side rectifying / smoothing circuit 107 is configured by the tertiary-side rectifying circuit (126) including the diode 126 and the smoothing capacitor 127.

- the tertiary-side rectifying / smoothing circuit 107 obtains rectified and smoothed DC power from the AC power induced in the tertiary winding N3.

- the output error detection circuit 110 divides the DC voltage (secondary DC output voltage E2) output between the secondary DC output terminals 143 and 144 by the resistors 131 and 132, and the divided voltage and the shunt regulator. This is a circuit for detecting an error (difference) from a reference voltage incorporated in the circuit.

- the output error detection circuit 110 includes resistors 131, 132, 133, a shunt regulator 134, and a photocoupler 137 composed of a light emitting diode 138 (LED) and a phototransistor 139 (Photo Transistor).

- the voltage obtained by dividing the secondary side DC output voltage E2 by the resistor 131 and the resistor 132 is input to the REF terminal 135 of the shunt regulator 134.

- the anode of the shunt regulator 134 is connected to the secondary side ground 146, and the cathode of the shunt regulator 134 is connected to the cathode of the light emitting diode 138.

- the anode of the light emitting diode 138 is connected to the first terminal of the resistor 133, and the second terminal of the resistor 133 is connected to the secondary side DC output terminal 143.

- the light emitting diode 138 inputs the output of the emitted light to the base of the phototransistor 139.

- the emitter of the phototransistor 139 is connected to the primary side ground 145, and the collector is an output terminal of the output error detection circuit 110.

- the photocoupler 137 including the light emitting diode 138 and the phototransistor 139 is used because the primary side ground 145 and the secondary side ground 146 must be galvanically isolated, and the circuit used at each ground. This is because it cannot be directly transferred by an electrical signal, and is converted into an optical signal for transfer.

- the secondary side DC output voltage E2 it is determined whether the secondary side DC output voltage E2 is higher or lower than the voltage of (R1 + R2) / R2 times the reference voltage.

- the shunt regulator 134 is turned on (ON), current flows through the light emitting diode 138, the light emitting diode 138 emits light and outputs an optical signal, and the phototransistor 139 outputs it. Receive light (ON state).

- the shunt regulator 134 is turned off and no current flows through the light emitting diode 138. Therefore, since the light emitting diode 138 does not emit light, the phototransistor 139 is turned off (OFF state).

- the on / off (ON / OFF) detection signal of the phototransistor 139 is sent from the collector of the phototransistor 139, that is, the output terminal of the output error detection circuit 110 to the control input terminal 154 of the pulse width control circuit (PWM) 109. It is done.

- the output error detection circuit is used to stabilize the secondary side DC output voltage E2, and is not used to detect deterioration of the secondary electrolytic capacitor 105 described later.

- the power supply of the pulse width control circuit 109 is supplied from the 152 through the resistor 160 when the switching power supply circuit is started, but is supplied from the 152 through the output of the tertiary side rectifying and smoothing circuit 107 after the power supply is started up.

- the output terminal 151 of the pulse width control circuit 109 is connected to the gate (gate input terminal) of the N-type MOSFET which is the switching circuit 108, and controls the on / off of the N-type MOSFET. Note that the pulse width of the drive signal waveform output from the output terminal 151 of the pulse width control circuit 109 is controlled to be variable.

- the existing switching power supply circuit is basically configured.

- a primary-side electrolytic capacitor deterioration detection circuit 111, a secondary-side electrolytic capacitor deterioration detection circuit 112, and a stop signal generation circuit 113 are circuits relating to a protection function that is a feature of the present embodiment. Since it is not directly related to basic functions, it will be described later. First, the basic operation of the existing switching power supply circuit will be described first.

- the DC power rectified and smoothed from AC power by the primary side rectifying and smoothing circuit 103 is applied to both ends of the series circuit of the primary winding N1 of the transformer 104 and the N-type MOSFET which is the switching circuit 108. .

- the gate of the N-type MOSFET is connected to the output terminal 151 of the pulse width control circuit 109 via the resistor 161 and is controlled to be turned on / off.

- a current flows or does not flow in the primary winding N1 of the transformer 104.

- the generated AC component is induced and propagated from the primary winding N1 of the transformer 104 to the secondary winding N2.

- the AC power induced on the secondary side of the transformer 104 is converted again into DC power by the secondary side rectifying and smoothing circuit 106, and the secondary side DC output voltage E ⁇ b> 2 is connected between the secondary side DC output terminals 143 and 144. Generate DC power.

- the secondary side DC output voltage E2 is compared with a reference voltage built in the shunt regulator 134 of the output error detection circuit 110 and higher or lower than the voltage divided by the voltage dividing resistors R1 and R2.

- the output signal of the output error detection circuit 110 is sent to the pulse width control circuit 109.

- the pulse width control circuit 109 reflects the output signal of the output error detection circuit 110 to change the pulse width, and the switching circuit 108 By controlling the on / off time, the secondary side DC output voltage E2 is adjusted and maintained at the set voltage.

- FIG. 2 is a schematic diagram of the general characteristics showing how the secondary side DC output voltage E2 changes as a result of current flowing through the primary winding N1 of the transformer 104 due to on / off of the switching circuit 108 or no longer flowing. . It should be noted that the change is shown, and the value of the secondary side DC output voltage E2 and the waveform of the control signal do not necessarily correspond to the actual situation.

- FIG. 2 shows a case where the control waveform 212 to be turned on / off is the same in the high section 212H and the low section 212L.

- the average value of the secondary side DC output voltage E2 is the average value 210.

- (a) is a case where the control waveform 211 to be turned on / off is longer in the high section 211H than the low section 211L.

- the average value of the secondary side DC output voltage E2 becomes the average value 221. The value is higher than the average value 210 when the high section 212H and the low section 212L are equal.

- FIG. 2 shows a case where the control waveform 212 to be turned on / off is the same in the high section 212H and the low section 212L.

- the average value of the secondary side DC output voltage E2 is the average value 210.

- (c) shows a case where the ON / OFF control waveform 213 is shorter than the low section 213L of the high section 213H.

- the average value of the secondary side DC output voltage E2 becomes the average value 223.

- the value is lower than the average value 210 in the case where the high section 212H and the low section 212L are equal.

- the secondary side DC output voltage E2 is changed by controlling the time (pulse width) in which the current flows through the primary winding N1 of the transformer 104 when the switching circuit 108 is turned on and off.

- the existing switching power supply device maintains the secondary side DC output voltage E2 at the set voltage.

- the switching power supply circuit includes a primary side electrolytic capacitor 102 and a secondary side electrolytic capacitor 105 as smoothing capacitors in the primary side rectifying / smoothing circuit 103 and the secondary side rectifying / smoothing circuit 106, respectively. It is installed. As these electrolytic capacitors deteriorate, the equivalent series resistance (ESR) increases and the capacitance decreases.

- ESR equivalent series resistance

- an increase in equivalent series resistance (R) occurs, and if current (i) is passed, the electrolytic capacitor itself may become hot due to Joule heat (i 2 R) or may explode due to an increase in internal pressure. is there.

- a decrease in the capacitance of the electrolytic capacitor may cause a decrease in output characteristics of the switching power supply circuit (device) and abnormal heat generation of other components. Therefore, as described above, when the degradation of the electrolytic capacitor reaches the limit, it is necessary to detect the degradation and take a countermeasure.

- the primary side electrolytic capacitor deterioration detection circuit (Det1) 111 for detecting the deterioration of the primary side electrolytic capacitor 102 and the secondary side electrolytic capacitor deterioration detection circuit for detecting the deterioration of the secondary side electrolytic capacitor 105 are shown.

- (Det2) 112 is provided.

- the stop signal generation circuit 113 outputs the output of the stop signal generation circuit 113 as an N-type MOSFET of the switching circuit 108 according to the deterioration detection signal of the primary side electrolytic capacitor deterioration detection circuit 111 or the secondary side electrolytic capacitor deterioration detection circuit 112 , The drive signal output from the pulse width control circuit 109 is inhibited, and the operation of the switching power supply circuit is stopped.

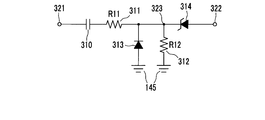

- FIG. 3 is a circuit diagram showing a configuration of the primary electrolytic capacitor deterioration detection circuit 111.

- the first terminal of the capacitor 310 is connected to an input terminal 321 serving as the primary electrolytic capacitor deterioration detection circuit 111.

- the second terminal of the capacitor 310 and the first terminal of the resistor (R11) 311 are connected.

- a resistor (R12) 312 is connected between the second terminal of the resistor 311 and the primary side ground 145.

- the anode of the diode 313 is connected to the primary side ground 145, and the cathode is connected to the second terminal of the resistor 311.

- a cathode of a Zener diode 314 is connected to the second terminal of the resistor 311.

- the anode of the Zener diode 314 is connected to an output terminal 322 as the primary electrolytic capacitor deterioration detection circuit 111.

- the DC component is cut by the capacitor 310, the voltage is divided to an appropriate value by the resistor 311 and the resistor 312, and a ripple (AC component) of the signal input from the input terminal 321 is detected at the dividing point 323. Further, the negative component of the signal is removed by the diode 313, and only the positive component is taken out. Further, the Zener diode 314 is turned on (ON, avalanche breakdown) when the ripple of the detected signal exceeds a certain voltage (Zener voltage, breakdown voltage) as described above, and serves as the primary side electrolytic capacitor deterioration detection circuit 111. The trigger signal is output from the output terminal 322 to the stop signal generation circuit 113 (FIG. 1).

- the input terminal 321 serving as the primary electrolytic capacitor deterioration detection circuit 111 is connected to the primary DC terminal 147, and the primary electrolytic capacitor 102 is deteriorated from the ripple voltage of the primary electrolytic capacitor 102. Is detected. This is because when the primary electrolytic capacitor 102 deteriorates and the equivalent series resistance increases or the capacitance decreases, the ripple voltage increases at the primary DC terminal 147.

- the voltage (potential) at the dividing point 323 can be changed to adjust the voltage applied to the Zener diode 314. Since the selection of the Zener voltage characteristic of the Zener diode 314 is limited, after the Zener diode 314 is selected, the resistance ratio (R11 / R12) is adjusted so that an appropriate voltage is applied to the characteristic of the Zener diode 314. Good.

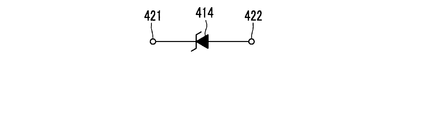

- FIG. 4 is a circuit diagram of the secondary electrolytic capacitor deterioration detection circuit 112, which is composed of a Zener diode 414.

- the cathode of the Zener diode 414 is connected to the input terminal 421 of the secondary side electrolytic capacitor deterioration detection circuit 112, and this input terminal 421 is connected to the output terminal 152 of the tertiary side rectifying and smoothing circuit 107.

- the anode of the Zener diode 414 is connected to the output terminal 422 of the secondary electrolytic capacitor deterioration detection circuit 112.

- the tertiary side rectifying / smoothing circuit 107 receives AC power induced by the tertiary winding N3 of the transformer 104, and the tertiary winding N3 is induced from AC power of the secondary winding N2. Therefore, when the secondary electrolytic capacitor 105 deteriorates and the equivalent series resistance increases, the voltage generated at both ends of the secondary electrolytic capacitor 105 also increases and is propagated from the secondary winding N2 to the tertiary winding N3. The voltage of the output of the tertiary side rectifying / smoothing circuit 107 also increases.

- the Zener diode 414 When this voltage increases with the deterioration of the secondary electrolytic capacitor 105 and exceeds a predetermined voltage, the Zener diode 414 is turned on, and a trigger signal is output from the output terminal 422 as the secondary electrolytic capacitor deterioration detection circuit 112. It outputs to the stop signal generation circuit 113 (FIG. 1).

- FIG. 5 is a circuit diagram showing a configuration of the stop signal generation circuit 113.

- a cathode of a thyristor 501 is connected to the primary side ground 145, and an anode and a gate are connected to an output terminal 532 and an input terminal 531 of the stop signal generation circuit 113, respectively.

- the resistor 511 is connected between the input terminal 531 of the stop signal generation circuit 113 and the primary side ground 145.

- the capacitor 512 may be connected between the input terminal 531 of the stop signal generation circuit 113 and the primary side ground 145 for stable circuit operation (preventing malfunction due to noise).

- the resistor 511 sets the bias voltage of the input terminal 531.

- An input terminal 531 of the stop signal generation circuit 113 is connected to an output terminal 322 of the primary electrolytic capacitor deterioration detection circuit 111 and an output terminal 422 of the secondary electrolytic capacitor deterioration detection circuit 112. Therefore, when there is a trigger signal that is a deterioration detection signal from the primary side electrolytic capacitor deterioration detection circuit 111 or the secondary side electrolytic capacitor deterioration detection circuit 112, the thyristor 501 is turned on. As a result, the output terminal 532 of the stop signal generation circuit 113 is substantially at the same potential as the primary side ground 145.

- the output terminal 532 of the stop signal generation circuit 113 is connected to the gate of the N-type MOSFET which is the switching circuit 108 in FIG.

- the gate of the N-type MOSFET is fixed to the potential of the primary side ground 145 and the N-type MOSFET is turned off.

- the N-type MOSFET is turned off, no current flows through the primary winding N1, and no current flows through the secondary winding N2. That is, the switching power supply circuit stops operating.

- a primary side electrolytic capacitor 102 and a secondary side electrolytic capacitor 105 which are smoothing capacitors, are mounted on the primary side circuit and the secondary side circuit, respectively.

- a primary side electrolytic capacitor deterioration detection circuit 111 As a means for detecting deterioration of the primary side electrolytic capacitor 102, there is a primary side electrolytic capacitor deterioration detection circuit 111, and as a means for detecting deterioration of the secondary side electrolytic capacitor 105, a secondary side electrolytic capacitor deterioration detection circuit 112 is provided. There is.

- the primary side electrolytic capacitor deterioration detection circuit 111 or the secondary side electrolytic capacitor deterioration detection circuit 112 detects that the ripple voltage or the terminal voltage has exceeded a certain set voltage, and the trigger signal is sent to the stop signal generation circuit 113. send.

- the stop signal generation circuit 113 prohibits the drive signal from the output terminal 151 of the pulse width control circuit 109, that is, the gate of the N-type MOSFET that is the switching circuit 108 is approximately at the same potential as the primary side ground 145.

- the switching power supply circuit is provided with the output error detection circuit 110 as described above, and the secondary side DC output voltage E2 is controlled to maintain a set voltage. Therefore, even if there is a slight deterioration of the primary side electrolytic capacitor 102 or the secondary side electrolytic capacitor 105, fluctuations in the input voltage A1 of the AC power supply, fluctuations in the DC load, or other factors, fluctuations may occur.

- the side DC output voltage E2 maintains a predetermined voltage. However, if the primary electrolytic capacitor 102 or the secondary electrolytic capacitor 105 exceeds the limit and deteriorates, the primary electrolytic capacitor deterioration detection circuit 111 or the secondary electrolytic capacitor deterioration detection circuit 112 detects an abnormality.

- FIG. 6 shows a schematic circuit configuration of the second embodiment of the present invention. Since the circuit configuration of FIG. 6 is based on FIG. 1 showing the circuit configuration of the first embodiment, it is almost the same circuit. The difference is that the output signal of the stop signal generation circuit 113 is connected to the gate of the N-type MOSFET of the switching circuit 108 in FIG. 1, whereas in FIG. This is connected to the output terminal 152 of the rectifying / smoothing circuit 107. Other circuit configurations are the same as those in FIG. 6 and FIG.

- the primary electrolytic capacitor deterioration detection circuit 111 or the secondary electrolytic capacitor deterioration detection circuit 112 detects the deterioration of the primary electrolytic capacitor 102 or the secondary electrolytic capacitor 105, and the stop signal generation circuit 113.

- Output signal 152 of the tertiary side rectifying / smoothing circuit 107, which is the power supply terminal of the pulse width control circuit 109, is substantially at the same potential as the primary side ground 145. .

- the pulse width control circuit 109 stops operating because the power is virtually not supplied, and stops supplying the drive signal from the output terminal 151 to the gate of the N-type MOSFET which is the switching circuit 108.

- the switching power supply circuit is stopped, no current flows through the primary side electrolytic capacitor 102 and the secondary side electrolytic capacitor 105, and the generation of Joule heat is stopped, so that the heat generation of the electrolytic capacitor and the internal pressure increase.

- the switching power supply circuit is protected by avoiding the abnormal heat generation and avoiding abnormal heat generation of other components.

- FIG. 7 shows a schematic circuit configuration of the third embodiment of the present invention. Since the circuit configuration of FIG. 7 is based on FIG. 1 showing the circuit configuration of the first embodiment, it is almost the same circuit. The difference is that the output signal of the stop signal generation circuit 113 is connected to the gate of the N-type MOSFET of the switching circuit 108 in FIG. 1, whereas the supply of the output signal of the pulse width control circuit 109 is controlled in FIG. It is connected to the control terminal 153. Other circuit configurations are the same as those in FIG. 7 and FIG.

- the primary electrolytic capacitor deterioration detection circuit 111 or the secondary electrolytic capacitor deterioration detection circuit 112 detects the deterioration of the primary electrolytic capacitor 102 or the secondary electrolytic capacitor 105, and the stop signal generation circuit 113. Is substantially the same potential as the primary side ground 145, the control terminal 153 of the pulse width control circuit 109 is substantially the same potential as the primary side ground 145. Then, the pulse width control circuit 109 stops supplying the drive signal from the output terminal 151.

- the supply of the drive signal to the gate of the N-type MOSFET which is the switching circuit 108 is stopped, and the potential of the primary side ground 145 is generally fixed. Then, the operation of the switching power supply circuit is stopped, so that no current flows through the primary side electrolytic capacitor 102 and the secondary side electrolytic capacitor 105, and the generation of Joule heat is stopped. Therefore, the heat generation of the electrolytic capacitor and the internal pressure increase.

- the switching power supply circuit is protected by avoiding the abnormal heat generation and avoiding abnormal heat generation of other components.

- the primary-side electrolytic capacitor deterioration detection circuit 111 includes a resistor 311 and a resistor 312. However, depending on the setting of the DC voltage of the primary-side circuit, either one resistor or both resistors It may be possible to delete.

- FIG. 4, and FIG. 5 show circuit examples of the primary electrolytic capacitor deterioration detection circuit 111, the secondary electrolytic capacitor deterioration detection circuit 112, and the stop signal generation circuit 113, respectively. It is only an example. Another circuit configuration having a similar function may be used. Further, these circuits (111, 112, 113) may be integrated with the pulse width control circuit 109 to form an integrated circuit, so that the occupied area (volume) and the number of circuit elements may be reduced as a whole.

- the switching circuit 108 uses an N-type MOSFET. However, if the polarity of the drive signal waveform output from the output terminal 151 of the pulse width control circuit 109 is changed, a P-type MOSFET is used. Also good. Moreover, it is not limited to MOSFET, For example, you may use IGBT (Insulated Gate Bipolar Transistor).

- IGBT Insulated Gate Bipolar Transistor

- a temperature fuse is brought into close contact with the primary side electrolytic capacitor 102 and the secondary side electrolytic capacitor 105, a temperature rise due to deterioration of the electrolytic capacitor is detected by the temperature fuse, and the temperature fuse is turned off, whereby the pulse width control circuit 109 is obtained.

- the driving signal may be stopped to protect the switching power supply circuit (device).

- an erroneous detection prevention circuit 801 (FIG. 8) that prevents erroneous detection of deterioration of the primary side electrolytic capacitor 102 by the primary side electrolytic capacitor deterioration detection circuit 111 at the time of turning on the power is replaced with the primary side rectifier circuit 101 and the primary side. It may be inserted between the electrolytic capacitor 102.

- the primary-side electrolytic capacitor deterioration detection circuit 111 indicates that the primary-side electrolytic capacitor 102 has deteriorated when the ripple voltage generated at both ends of the primary-side electrolytic capacitor 102 becomes equal to or higher than a predetermined reference voltage. After the determination, the operation of the switching circuit 108 by the pulse width control circuit 109 is stopped.

- the frequency of the ripple voltage to be detected and the value obtained by converting the rise time of the terminal voltage of the primary side electrolytic capacitor 102 at the time of power-on (the reciprocal thereof) into a frequency are approximate, and depending on the timing at the time of power-on

- the primary side electrolytic capacitor deterioration detection circuit 111 erroneously detects and stops the operation of the switching circuit 108. Therefore, the switching power supply circuit may not operate normally.

- the false detection prevention circuit 801 prevents this false detection when the power is turned on.

- the erroneous detection preventing circuit 801 will be described with reference to FIGS.

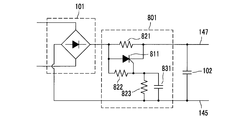

- FIG. 8 is a circuit diagram showing a configuration in which an erroneous detection preventing circuit 801 is inserted between the primary side rectifier circuit 101 and the primary side electrolytic capacitor 102 according to the first embodiment of the present invention.

- FIG. 9 is a circuit diagram showing a detailed configuration example of the false detection prevention circuit 801.

- a resistor (first resistor) 821 is a first DC output terminal (hereinafter referred to as a connection point between the cathodes of the diode 123 (FIG. 8) and the diode 124 (FIG. 8) of the primary rectifier circuit 101. (Referred to as the first DC output terminal) and the primary side DC terminal 147.

- One end of the resistor (second resistor) 822 is connected to the first DC output terminal of the primary side rectifier circuit 101, and the other end is connected to one end of the capacitor 831.

- the other end of the capacitor 831 is connected to the primary side ground 145.

- a resistor (third resistor) 823 is connected to the capacitor 831 in parallel.

- a second DC output terminal (hereinafter referred to as a second DC output terminal) which is a connection point between the anodes of the diode 121 (FIG. 8) and the diode 122 (FIG. 8) of the primary rectifier circuit 101 is 1 It is connected to the secondary ground 145.

- the anode of the thyristor 811 is connected to the first DC output terminal of the primary side rectifier circuit 101, and the cathode is connected to the primary side DC terminal 147.

- the gate of the thyristor 811 is connected to the connection point between the resistor 822 and the capacitor 831 connected in series.

- the primary side electrolytic capacitor 102 is connected between the primary side DC terminal 147 and the primary side ground 145.

- the primary side ground 145 is connected to the second DC output terminal of the primary side rectifier circuit 101.

- the primary side rectifier circuit 101 is a simplified representation of the diode bridge of the primary side rectifier circuit 101 in FIG. 8.

- the resistor 821 is inserted in series between the first DC output terminal of the primary side rectifier circuit 101 and the primary side electrolytic capacitor 102 in order to slow the rise time immediately after the power is turned on. Yes.

- the voltage across the primary electrolytic capacitor 102 rises due to the current path between the resistor 821 and the primary electrolytic capacitor 102 and rises with a time constant determined by the resistor 821 and the primary electrolytic capacitor 102.

- This time constant is set to a value sufficiently larger than the reciprocal of the frequency of the ripple voltage generated at both ends when the primary electrolytic capacitor 102 deteriorates.

- the gate voltage of the thyristor 811 also rises slowly by a time constant determined by the resistor 822, the resistor 823, and the capacitor 831.

- the equivalent impedance is sufficiently smaller than the resistor 823, and the capacitor 831 is dominant over the resistor 823 as the current path, so the gate voltage of the thyristor 811 is Rises slowly from 0 (potential of the primary ground 145) with a time constant determined by the resistor 822 and the capacitor 831. Therefore, immediately after the power is turned on, the thyristor 811 is off.

- the voltage across the primary electrolytic capacitor 102 becomes a voltage sufficient to operate the switching power supply circuit. Reach.

- the resistor 821 exists between the primary side rectifier circuit 101 and the primary side electrolytic capacitor 102, it becomes an obstacle or a large energy loss source to sufficiently flow the current for operating the switching power supply circuit. It becomes.

- the equivalent impedance of the capacitor 831 increases, and the gate voltage of the thyristor 811 rises with a time constant determined by the resistors 822, 823, and 831 and eventually triggers.

- the thyristor 811 When the voltage is reached, the thyristor 811 is turned on.

- the resistance value of the internal resistance of the turned-on thyristor 811 is very small compared to the resistance value of the resistor 821 and is connected in parallel to the resistor 821, so that the primary side electrolytic capacitor 102 is connected to the primary side rectifier circuit 101.

- the current flowing through the primary side DC terminal 147 passes through the thyristor 811.

- the internal resistance of the turned on thyristor 811 is sufficiently small, the energy loss due to the provision of the false detection prevention circuit 801 is very small. Further, if the charge is sufficiently accumulated in the capacitor 831, the equivalent impedance becomes too high and the gate voltage of the thyristor 811 may become unstable, and the charge accumulated in the capacitor 831 when the power supply is shut off is excluded. Therefore, the resistor 823 is connected in parallel with the capacitor 831. Note that in the case where a sufficient amount of charge is accumulated in the capacitor 831, the gate voltage of the thyristor 811 is divided by the resistors 822 and 823 between the first DC output terminal and the DC output terminal of the primary side rectifier circuit 101. It becomes a pressed voltage. By including the erroneous detection prevention circuit 801 having the above configuration, it is possible to prevent malfunction of the switching power supply circuit due to erroneous detection of the primary side electrolytic capacitor deterioration detection circuit 111 when the power is turned on.

- the erroneous detection prevention circuit 801 illustrated in FIG. 9 is merely an example of a circuit configuration.

- a MOSFET Metal Oxide Semiconductor Field Effect Transistor

- IGBT Insulated Gate Bipolar Transistor

- the circuit configuration shown in FIG. 8 is obtained by inserting a false detection prevention circuit 801 into the first embodiment of FIG. 1, but the second embodiment of FIG. 6 and the third embodiment of FIG. However, even if the false detection prevention circuit 801 is inserted in the same manner, the same effect can be obtained.

- the switching power supply circuit with a protection function of this embodiment detects the deterioration of the electrolytic capacitor of the smoothing circuit in the primary side circuit and the secondary side circuit, and automatically stops the operation of the switching power supply circuit. It has a function to avoid damage accidents due to capacitor deterioration.

- the method and circuit for detecting deterioration of the secondary side electrolytic capacitor 105 from the output voltage of the tertiary side rectifying and smoothing circuit 107 by the Zener diode 414, and the secondary side electrolytic capacitor deterioration detecting circuit and circuit configuration are disclosed in the prior art document.

- the above-described method and circuit of the present embodiment are characterized by being realized by adding simple circuit elements without changing the existing switching power supply circuit.

Landscapes

- Engineering & Computer Science (AREA)

- Power Engineering (AREA)

- Dc-Dc Converters (AREA)

- Protection Of Static Devices (AREA)

Abstract

Description

また、スイッチング電源回路における回路上の工夫によって、電解コンデンサの劣化を検知し、対処する技術も様々に検討されている。

特許文献1においては、トランスの2次側の巻線の両端の電圧の差分により、電解コンデンサの劣化にともなう等価直列抵抗(ESR:Equivalent Series Resistance)の増大を検出し、フォトカプラ(Photo Coupler)を使用して1次側回路へフィードバックし検知する技術が開示されている。

また、特許文献1に開示された方法では、トランジスタを用いたリプル電圧検出回路とさらなるフォトカプラの追加などの回路変更が必要であり、コスト上昇と、この対策のために比較的大きなスペースを必要とする問題があった。

すなわち第1の発明は、1次巻線と2次巻線と3次巻線とを有するトランスと、交流電力を直流電力に変換する1次側整流回路と、前記1次側整流回路の直流電力を平滑化する1次側電解コンデンサと、前記トランスの2次巻線が出力する交流電力を直流電力に変換する2次側整流回路と、前記2次側整流回路が出力する直流電力を平滑化する2次側電解コンデンサと、前記トランスの3次巻線の出力する交流電力を直流電力に変換して平滑化する3次側整流平滑化回路と、前記1次側電解コンデンサの電圧を入力する前記トランスの1次巻線の開閉を繰り返すスイッチング回路と、前記スイッチング回路の開閉を制御する駆動信号のパルス幅を制御するパルス幅制御回路と、前記2次側電解コンデンサの劣化を検知する2次側電解コンデンサ劣化検知回路と、前記2次側電解コンデンサ劣化検知回路の劣化検出信号を入力する停止信号発生回路と、を備え、前記2次側電解コンデンサ劣化検知回路は前記3次側整流平滑化回路の出力電圧を入力し、前記2次側電解コンデンサ劣化検知回路の劣化検出信号で前記停止信号発生回路が停止信号を発生することによって、前記パルス幅制御回路から前記スイッチング回路への駆動信号の供給が停止されることによりスイッチング電源回路の動作をとめることを特徴とする。

(第1実施形態)

まず、本発明の第1実施形態の回路構成について説明する。

図1は本発明の保護回路付きスイッチング電源回路の第1実施形態の概略の構成を示す回路図である。

図1において、1次側整流回路101はダイオード121~124のブリッジ回路構成によって、入力端子141、142から入力する交流電力(交流電圧A1)を全波整流してリプル(ripple)を含む直流電力を1次側直流端子147と1次側アース145の間に出力する。1次側電解コンデンサ102は1次側直流端子147と1次側アース145の間に接続されていて、1次側整流回路101の出力したリプルを含む直流電力を平滑化する。

なお、1次側整流回路101と1次側電解コンデンサ102によって1次側整流平滑化回路103が構成されている。

なお、1次巻線N1に関わる回路を1次側回路、2次巻線N2に関わる回路を2次側回路、3次巻線N3に関わる回路を3次側回路と、適宜、表記する。

なお、発光ダイオード138とフォトトランジスタ139からなるフォトカプラ137を用いるのは、1次側アース145と2次側アース146を直流的に絶縁する必要があって、それぞれのアースで使用している回路間は、直接電気信号で受け渡しできないので、光信号に変換して受け渡しするためである。

2次側直流出力電圧E2が高い場合には、シャントレギュレータ134はオン(ON)して発光ダイオード138に電流が流れ、発光ダイオード138が発光して光信号を出力し、フォトトランジスタ139はそれを受光(ON状態)する。

なお、出力誤差検出回路を用いたのは2次側直流出力電圧E2の安定化のためであって、後記する2次側電解コンデンサ105の劣化を検知するために用いている訳ではない。

なお、パルス幅制御回路109の出力端子151から出力される駆動信号波形のパルス幅は可変するように制御されている。

以上の構成により、既存のスイッチング電源回路は基本的に構成されている。

前記したように、1次側整流平滑化回路103により交流電力から整流平滑化された直流電力はトランス104の1次巻線N1とスイッチング回路108であるN型MOSFETの直列回路の両端に加えられる。N型MOSFETのゲートは抵抗161を経由して、パルス幅制御回路109の出力端子151に接続され、オンオフ制御されている。

図2において、(a)はオンオフする制御波形211がHighの区間211HがLowの区間211Lより長い場合であって、このとき2次側直流出力電圧E2の平均的な値は平均値221となり、前記したHighの区間212HとLowの区間212Lが等しい場合の平均値210よりも高くなる。

図2において、(c)はオンオフする制御波形213がHighの区間213HがLowの区間213Lより短い場合であって、このとき2次側直流出力電圧E2の平均的な値は平均値223となり、前記したHighの区間212HとLowの区間212Lが等しい場合の平均値210よりも低くなる。

以上のように制御することによって、既存のスイッチング電源装置は、設定された電圧に2次側直流出力電圧E2を保っている。

次に、スイッチング電源回路の保護回路について述べる。まず、保護回路が必要となる原因であるスイッチング電源回路に用いる電解コンデンサについて述べる。

スイッチング電源回路(装置)は、前記したように、1次側整流平滑化回路103と2次側整流平滑化回路106に平滑用コンデンサとしてそれぞれ1次側電解コンデンサ102と2次側電解コンデンサ105が搭載されている。これらの電解コンデンサは劣化が進むと等価直列抵抗(ESR:Equivalent Series Resistance)の増大と、静電容量の低下が起こる。

また、電解コンデンサにおける静電容量の低下はスイッチング電源回路(装置)の出力特性の低下や、他部品の異常発熱を引き起こすこともある。

したがって、前記したように、電解コンデンサの劣化が限度に達した場合は、その劣化を検知して対策をとる必要がある。

以上により、図1において、1次側電解コンデンサ102の劣化を検知する1次側電解コンデンサ劣化検知回路(Det1)111と2次側電解コンデンサ105の劣化を検知する2次側電解コンデンサ劣化検知回路(Det2)112が備えられている。

また、停止信号発生回路113は、1次側電解コンデンサ劣化検知回路111もしくは2次側電解コンデンサ劣化検知回路112の劣化検知信号により、前記停止信号発生回路113の出力がスイッチング回路108のN型MOSFETのゲートに入力されることによってパルス幅制御回路109から出力される駆動信号が禁止され、スイッチング電源回路の動作を停止する。

次に、1次側電解コンデンサ劣化検知回路111の具体的な回路構成について述べる。

図3は1次側電解コンデンサ劣化検知回路111の構成を示す回路図である。

図3において、コンデンサ310の第1端子は、1次側電解コンデンサ劣化検知回路111としての入力端子321に接続されている。コンデンサ310の第2端子と抵抗(R11)311の第1端子が接続されている。抵抗311の第2端子と1次側アース145の間に抵抗(R12)312が接続されている。ダイオード313のアノードは1次側アース145に接続され、カソードは抵抗311の第2端子に接続されている。ツェナーダイオード(Zener diode)314のカソードは抵抗311の第2端子に接続されている。ツェナーダイオード314のアノードは、1次側電解コンデンサ劣化検知回路111としての出力端子322に接続されている。

また、ダイオード313により信号のマイナス成分を除去し、プラス成分のみを取り出す。

また、ツェナーダイオード314は前述のように検出した信号のリプルが一定の電圧(ツェナー電圧、降伏電圧)を超した場合にオン(ON、アバランシェ降伏)して1次側電解コンデンサ劣化検知回路111としての出力端子322からトリガー信号を停止信号発生回路113(図1)に出力する。

次に、2次側電解コンデンサ劣化検知回路112の具体的な回路構成について述べる。

図4は2次側電解コンデンサ劣化検知回路112の回路図であり、ツェナーダイオード414から構成されている。ツェナーダイオード414のカソードは、2次側電解コンデンサ劣化検知回路112の入力端子421に接続されていて、また、この入力端子421は3次側整流平滑化回路107の出力端子152に接続されている。また、ツェナーダイオード414のアノードは、2次側電解コンデンサ劣化検知回路112の出力端子422に接続されている。

これは、3次側整流平滑化回路107の出力で2次側電解コンデンサ105の劣化を検知する場合の大きな長所であり、コストと設置スペースの低減につながる理由でもある。

次に、停止信号発生回路113の具体的な回路構成について述べる。図5は停止信号発生回路113の構成を示す回路図である。

図5において、サイリスタ(Thyristor)501のカソードは1次側アース145に接続され、アノードとゲートはそれぞれ停止信号発生回路113の出力端子532と入力端子531に接続されている。

抵抗511は停止信号発生回路113の入力端子531と1次側アース145の間に接続されている。

なお、回路の安定動作(ノイズによる誤動作防止)のために、コンデンサ512を停止信号発生回路113の入力端子531と1次側アース145の間に接続する場合もある。

停止信号発生回路113の入力端子531は、1次側電解コンデンサ劣化検知回路111の出力端子322と2次側電解コンデンサ劣化検知回路112の出力端子422とに接続されている。そのため1次側電解コンデンサ劣化検知回路111、または2次側電解コンデンサ劣化検知回路112から劣化検知信号であるトリガー信号があると、サイリスタ501がオンする。その結果、停止信号発生回路113の出力端子532は概ね1次側アース145と同電位となる。

以上において、個々の回路構成と、部分的な動作について述べたが全体としての動作の概略を、前記した内容と一部重複するが、以下に述べる。

スイッチング電源装置は、1次側回路、2次側回路にそれぞれ平滑用コンデンサである1次側電解コンデンサ102と2次側電解コンデンサ105が搭載されている。

1次側電解コンデンサ102の劣化を検知する手段として、1次側電解コンデンサ劣化検知回路111があり、また2次側電解コンデンサ105の劣化を検知する手段として、2次側電解コンデンサ劣化検知回路112がある。

なお、図1において、スイッチング電源回路には前記したように、出力誤差検出回路110が備えられていて、2次側直流出力電圧E2は設定された電圧を保つように制御されている。したがって、1次側電解コンデンサ102もしくは2次側電解コンデンサ105の若干の劣化や、交流電源の入力電圧A1の変動、直流負荷の変動、またはその他の要素の変化、変動があったとしても2次側直流出力電圧E2は所定の電圧を保っている。

ただし、1次側電解コンデンサ102もしくは2次側電解コンデンサ105が限度を超えて劣化を起こすと、1次側電解コンデンサ劣化検知回路111もしくは2次側電解コンデンサ劣化検知回路112が異常を検知する。

次に、本発明の第2実施形態について述べる。

<回路構成・第2実施形態>

図6に本発明の第2実施形態の概略の回路構成を示す。

図6の回路構成は、第1実施形態の回路構成を示した図1を基にしているので、ほぼ同一の回路である。異なる点は停止信号発生回路113の出力信号が、図1ではスイッチング回路108のN型MOSFETのゲートに接続されているのに対し、図6ではパルス幅制御回路109の電源端子である3次側整流平滑化回路107の出力端子152に接続されていることである。

他の回路構成は図6と図1は同一であるので説明は省略する。

図6において、1次側電解コンデンサ劣化検知回路111もしくは2次側電解コンデンサ劣化検知回路112が、1次側電解コンデンサ102もしくは2次側電解コンデンサ105の劣化を検知して、停止信号発生回路113の出力信号が概ね1次側アース145と同電位となると、パルス幅制御回路109の電源端子である3次側整流平滑化回路107の出力端子152も概ね1次側アース145と同電位となる。するとパルス幅制御回路109は電源が事実上、供給されなくなるので動作を停止し、出力端子151からスイッチング回路108であるN型MOSFETのゲートへの駆動信号の供給を止める。この結果、スイッチング電源回路の動作が停止するので1次側電解コンデンサ102と2次側電解コンデンサ105には電流が流れなくなり、ジュール熱の発生が止まり、したがって、電解コンデンサの発熱と内部圧力の上昇が回避されることと他の部品の異常発熱も回避されることでスイッチング電源回路は保護される。

次に、本発明の第3実施形態について述べる。

<回路構成・第3実施形態>

図7に本発明の第3実施形態の概略の回路構成を示す。

図7の回路構成は、第1実施形態の回路構成を示した図1を基にしているので、ほぼ同一の回路である。異なる点は停止信号発生回路113の出力信号が、図1ではスイッチング回路108のN型MOSFETのゲートに接続されているのに対し、図7ではパルス幅制御回路109の出力信号の供給を制御する制御端子153に接続されていることである。

他の回路構成は図7と図1は同一であるので説明は省略する。

図7において、1次側電解コンデンサ劣化検知回路111もしくは2次側電解コンデンサ劣化検知回路112が、1次側電解コンデンサ102もしくは2次側電解コンデンサ105の劣化を検知して、停止信号発生回路113の出力信号が概ね1次側アース145と同電位となると、パルス幅制御回路109の制御端子153は概ね1次側アース145と同電位となる。するとパルス幅制御回路109は、出力端子151からの駆動信号の供給を停止する。

図3において、1次側電解コンデンサ劣化検知回路111が抵抗311と抵抗312を備えた回路を示したが、1次側回路の直流電圧の設定によっては、どちらか一方の抵抗、もしくは両方の抵抗を削除することが可能となる場合もある。

また、これらの回路(111、112、113)をパルス幅制御回路109と一体化して集積回路化することで、全体として、占有面積(体積)、回路素子数をコンパクト化してもよい。

また、MOSFETに限定されず、例えばIGBT(Insulated Gate Bipolar Transistor、絶縁ゲートバイポーラトランジスタ)を用いてもよい。

前述したように1次側電解コンデンサ劣化検知回路111は、1次側電解コンデンサ102の両端に発生するリプル電圧が所定の基準電圧以上となったときに、1次側電解コンデンサ102が劣化したと判定して、パルス幅制御回路109によるスイッチング回路108の動作を停止する。しかしながら、検出したいリプル電圧の周波数と、電源投入時の1次側電解コンデンサ102の端子電圧の立ち上がり時間(の逆数)を周波数に換算した値とは近似しており、電源投入時のタイミングによっては、1次側電解コンデンサ劣化検知回路111が誤検知してスイッチング回路108の動作を止めてしまう可能性がある。したがって、スイッチング電源回路が正常に動作しない可能性がある。

誤検知防止回路801は、この電源投入時の誤検知を防止するものである。

次に、この誤検知防止回路801を図8と図9とを参照して説明する。

図8は、本発明の第1実施形態の1次側整流回路101と1次側電解コンデンサ102との間に誤検知防止回路801を挿入した構成を示す回路図である。

図9は、誤検知防止回路801の詳細な構成例を示す回路図である。

図9において、抵抗(第1抵抗)821は、1次側整流回路101のダイオード123(図8)とダイオード124(図8)のそれぞれのカソードの接続点である第1直流出力端子(以下、第1直流出力端子と称す)と、1次側直流端子147との間に接続されている。抵抗(第2抵抗)822の一端は1次側整流回路101の第1直流出力端子に接続され、他端はコンデンサ831の一端に接続されている。コンデンサ831の他端は1次側アース145に接続されている。抵抗(第3抵抗)823はコンデンサ831に並列に接続されている。

なお、1次側整流回路101のダイオード121(図8)とダイオード122(図8)のそれぞれのアノードの接続点である第2直流出力端子(以下、第2直流出力端子と称す)は、1次側アース145に接続されている。

また、1次側電解コンデンサ102は図8、図9にも示したように、1次側直流端子147と1次側アース145との間に接続されている。なお、1次側アース145は1次側整流回路101の第2直流出力端子に接続されている。

また、図9において1次側整流回路101は、図8における1次側整流回路101のダイオードブリッジを簡略化して表記している。

電源投入直後において、1次側電解コンデンサ102の両端の電圧は、抵抗821と1次側電解コンデンサ102との電流経路によって上昇し、抵抗821と1次側電解コンデンサ102によって定まる時定数により、立ち上がる。なお、この時定数は、1次側電解コンデンサ102が劣化したときに両端に発生するリプル電圧の周波数の逆数よりも充分に大きな値に設定する。

また、電源投入直後において、サイリスタ811のゲート電圧も、抵抗822と抵抗823とコンデンサ831とによって定まる時定数によってゆっくりと立ち上がる。電源投入直後は、コンデンサ831には電荷がほとんど蓄積されていないので等価インピーダンスは抵抗823より充分に小さく、電流経路としては、抵抗823よりもコンデンサ831が支配的であるため、サイリスタ811のゲート電圧は0(1次側アース145の電位)から抵抗822とコンデンサ831とによって定まる時定数でゆっくりと立ち上がる。したがって、電源投入直後、サイリスタ811はオフしている。

電源投入後から、コンデンサ831に電荷が蓄積されるにつれ、コンデンサ831の等価インピーダンスが増加し、サイリスタ811のゲート電圧は抵抗822と抵抗823とコンデンサ831とによって定まる時定数で上昇して、やがてトリガー電圧に達するとサイリスタ811はオンする。

オンしたサイリスタ811の内部抵抗の抵抗値は、抵抗821の抵抗値に比較して非常に小さく、かつ抵抗821に並列に接続されているので、1次側整流回路101から1次側電解コンデンサ102あるいは1次側直流端子147に流れる電流は、サイリスタ811を経由するようになる。

また、コンデンサ831に電荷が充分に蓄積されると、等価インピーダンスが高くなりすぎてサイリスタ811のゲート電圧が不安定となりかねないことと、電源を遮断したときにコンデンサ831に蓄積された電荷を除くために、抵抗823をコンデンサ831に並列に接続している。なお、コンデンサ831に電荷が充分に蓄積された場合においては、サイリスタ811のゲート電圧は、1次側整流回路101の第1直流出力端子と直流出力端子間の電圧が抵抗822と抵抗823によって分圧された電圧となる。

以上の構成の誤検知防止回路801を備えることにより、電源投入時の1次側電解コンデンサ劣化検知回路111の誤検知によるスイッチング電源回路の誤動作を防止できる

例えば、抵抗823を除いてもほぼ同様の回路動作をする。

また、サイリスタ811の代わりにMOSFET(Metal Oxide Semiconductor Field Effect Transistor)やIGBT(Insulated Gate Bipolar Transistor)を用いて構成してもよい。

また、図8に示した回路構成は、図1の第1実施形態に対して、誤検知防止回路801を挿入したものであるが、図6の第2実施形態や図7の第3実施形態に対しても、誤検知防止回路801を同様に挿入しても、同じような効果がある。

以上、本実施形態の保護機能付きスイッチング電源回路は、1次側回路と2次側回路における平滑回路の電解コンデンサの劣化を検知し、自動的にスイッチング電源回路の動作を停止することにより、電解コンデンサの劣化からの破損事故を未然に回避する機能を備えている。

とりわけ、2次側電解コンデンサ105の劣化を3次側整流平滑化回路107の出力電圧からツェナーダイオード414によって検知する方法と回路により、2次側電解コンデンサ劣化検知回路、および回路構成は先行技術文献に挙げた開示技術と比較して、大幅に削減でき、回路素子数と素子、配線の占有面積(体積)のコンパクト化ができて、コストも低減できるという大きな効果がある。

また、本実施形態の前記した方法と回路は、既存のスイッチング電源回路を変更すること無しに簡単な回路素子を付加するだけで実現するという特徴がある。

102 1次側電解コンデンサ

103 1次側整流平滑化回路

104 トランス

105 2次側電解コンデンサ

106 2次側整流平滑化回路

107 3次側整流平滑化回路

108 スイッチング回路

109 パルス幅制御回路(PWM)

110 出力誤差検出回路

111 1次側電解コンデンサ劣化検知回路(Det1)

112 2次側電解コンデンサ劣化検知回路(Det2)

113 停止信号発生回路

121、122、123、124 ダイオード

125 ダイオード、2次側整流回路

126 ダイオード、3次側整流回路

127 平滑コンデンサ

131 抵抗(R1)

132 抵抗(R2)

133、160、161、162、511 抵抗

134 シャントレギュレータ

135 シャントレギュレータREF端子

137 フォトカプラ

138 発光ダイオード

139 フォトトランジスタ

141、142 交流電源端子

143、144 2次側直流出力端子

145 1次側アース

146 2次側アース

147 1次側直流端子

151 出力端子

152 3次側整流平滑化回路の出力端子

153 制御端子

154 制御用の入力端子

310、512、831 コンデンサ

311 抵抗(R11)

312 抵抗(R12)

313 ダイオード

314、414 ツェナーダイオード

321、421、531 入力端子

322、422、532 出力端子

323 分割点

501、811 サイリスタ

801 誤検知防止回路

821 抵抗(第1抵抗)

822 抵抗(第2抵抗)

823 抵抗(第3抵抗)

A1 交流電圧、入力電圧

E2 2次側直流出力電圧

N1 1次巻線、1次巻線数

N2 2次巻線、2次巻線数

N3 3次巻線、3次巻線数

Claims (12)

- 1次巻線と2次巻線と3次巻線とを有するトランスと、

交流電力を直流電力に変換する1次側整流回路と、

前記1次側整流回路の直流電力を平滑化する1次側電解コンデンサと、

前記トランスの2次巻線が出力する交流電力を直流電力に変換する2次側整流回路と、

前記2次側整流回路が出力する直流電力を平滑化する2次側電解コンデンサと、

前記1次側電解コンデンサの電圧を入力する前記トランスの1次巻線の開閉を繰り返すスイッチング回路と、

前記スイッチング回路の開閉を制御する駆動信号のパルス幅を制御するパルス幅制御回路と、

前記1次側電解コンデンサの劣化を検知する1次側電解コンデンサ劣化検知回路と、

前記1次側電解コンデンサ劣化検知回路の劣化検出信号を入力する停止信号発生回路と、

を備え、

前記1次側電解コンデンサ劣化検知回路は前記1次側電解コンデンサの電圧を入力し、

前記1次側電解コンデンサ劣化検知回路の劣化検出信号で前記停止信号発生回路が停止信号を発生することによって、前記パルス幅制御回路から前記スイッチング回路への駆動信号の供給が停止されることによりスイッチング電源回路の動作を止めることを特徴とする保護機能付きスイッチング電源回路。 - 1次巻線と2次巻線と3次巻線とを有するトランスと、

交流電力を直流電力に変換する1次側整流回路と、

前記1次側整流回路の直流電力を平滑化する1次側電解コンデンサと、

前記トランスの2次巻線が出力する交流電力を直流電力に変換する2次側整流回路と、

前記2次側整流回路が出力する直流電力を平滑化する2次側電解コンデンサと、

前記トランスの3次巻線の出力する交流電力を直流電力に変換して平滑化する3次側整流平滑化回路と、

前記1次側電解コンデンサの電圧を入力する前記トランスの1次巻線の開閉を繰り返すスイッチング回路と、

前記スイッチング回路の開閉を制御する駆動信号のパルス幅を制御するパルス幅制御回路と、

前記2次側電解コンデンサの劣化を検知する2次側電解コンデンサ劣化検知回路と、

前記2次側電解コンデンサ劣化検知回路の劣化検出信号を入力する停止信号発生回路と、

を備え、

前記2次側電解コンデンサ劣化検知回路は前記3次側整流平滑化回路の出力電圧を入力し、前記2次側電解コンデンサ劣化検知回路の劣化検出信号で前記停止信号発生回路が停止信号を発生することによって、前記パルス幅制御回路から前記スイッチング回路への駆動信号の供給が停止されることによりスイッチング電源回路の動作をとめることを特徴とする保護機能付きスイッチング電源回路。 - 1次巻線と2次巻線と3次巻線とを有するトランスと、

交流電力を直流電力に変換する1次側整流回路と、

前記1次側整流回路の直流電力を平滑化する1次側電解コンデンサと、

前記トランスの2次巻線が出力する交流電力を直流電力に変換する2次側整流回路と、

前記2次側整流回路が出力する直流電力を平滑化する2次側電解コンデンサと、

前記トランスの3次巻線の出力する交流電力を直流電力に変換して平滑化する3次側整流平滑化回路と、

前記1次側電解コンデンサの電圧を入力する前記トランスの1次巻線の開閉を繰り返すスイッチング回路と、

前記スイッチング回路の開閉を制御する駆動信号のパルス幅を制御するパルス幅制御回路と、

前記1次側電解コンデンサの劣化を検知する1次側電解コンデンサ劣化検知回路と、

前記2次側電解コンデンサの劣化を検知する2次側電解コンデンサ劣化検知回路と、

前記1次側電解コンデンサ劣化検知回路と前記2次側電解コンデンサ劣化検知回路の劣化検出信号を入力する停止信号発生回路と、

を備え、

前記1次側電解コンデンサ劣化検知回路は前記1次側電解コンデンサの電圧を入力し、

前記2次側電解コンデンサ劣化検知回路は前記3次側整流平滑化回路の出力電圧を入力し、

前記1次側電解コンデンサ劣化検知回路、もしくは前記2次側電解コンデンサ劣化検知回路の劣化検出信号で前記停止信号発生回路が停止信号を発生することによって、前記パルス幅制御回路から前記スイッチング回路への駆動信号の供給が禁止されることにより、スイッチング電源回路の動作を止めることを特徴とする保護機能付きスイッチング電源回路。 - 前記停止信号発生回路の出力端子が前記スイッチング回路の制御入力端子に接続され、前記停止信号発生回路から停止信号が出力されることによって、前記パルス幅制御回路から前記スイッチング回路へ出力される駆動信号が禁止されてスイッチング電源回路の動作を停止することを特徴とする請求の範囲第1項乃至第3項のいずれか一項に記載の保護機能付きスイッチング電源回路。

- 前記停止信号発生回路の出力端子が前記パルス幅制御回路の電源端子に接続され、前記停止信号発生回路から停止信号が出力されることによって、前記パルス幅制御回路への電源供給が停止されてスイッチング電源回路の動作を停止することを特徴とする請求の範囲第1項乃至第3項のいずれか一項に記載の保護機能付きスイッチング電源回路。

- 前記停止信号発生回路の出力端子が前記パルス幅制御回路の発振停止端子に接続され、前記停止信号発生回路の出力信号が概ね1次側アースと同電位になることによって、前記パルス幅制御回路の発振が停止し、前記スイッチング回路への駆動信号の供給が停止され、スイッチング電源回路の動作を停止することを特徴とする請求の範囲第1項乃至第3項のいずれか一項に記載の保護機能付きスイッチング電源回路。

- 前記1次側電解コンデンサ劣化検知回路、または前記2次側電解コンデンサ劣化検知回路はツェナーダイオードを備えたことを特徴とする請求の範囲第3項に記載の保護機能付きスイッチング電源回路。

- 前記1次側電解コンデンサ劣化検知回路は、さらにコンデンサと抵抗とダイオードを備えたことを特徴とする請求の範囲第7項に記載の保護機能付きスイッチング電源回路。

- 前記停止信号発生回路はサイリスタを備えたことを特徴とする請求の範囲第3項または第7項または第8項に記載の保護機能付きスイッチング電源回路。

- さらに、

前記1次側整流回路と前記1次側電解コンデンサとの間に、電源投入時の前記1次側電解コンデンサ劣化検知回路による前記1次側電解コンデンサの劣化の誤検出を防止する誤検知防止回路

を備えたことを特徴とする請求の範囲第1項に記載の保護機能付きスイッチング電源回路。 - さらに、

前記1次側整流回路と前記1次側電解コンデンサとの間に、電源投入時の前記1次側電解コンデンサ劣化検知回路による前記1次側電解コンデンサの劣化の誤検出を防止する誤検知防止回路

を備えたことを特徴とする請求の範囲第3項に記載の保護機能付きスイッチング電源回路。 - 前記誤検知防止回路は、

前記1次側整流回路の第1直流出力端子と前記1次側電解コンデンサの1次側直流端子との間に接続された第1抵抗と、

前記第1直流出力端子に一端を接続された第2抵抗と、

当該第2抵抗の他端と、前記1次側電解コンデンサの1次側アースとの間に接続された第3抵抗と、

前記第2抵抗の他端と、前記1次側電解コンデンサの1次側アースとの間に接続されたコンデンサと、

アノードが前記第1直流出力端子に接続され、カソードが前記1次側直流端子に接続され、ゲートが前記第2抵抗と前記コンデンサの接続点に接続されたサイリスタと、

を備えて構成されることを特徴とする請求の範囲第10項または第11項に記載の保護機能付きスイッチング電源回路。

Priority Applications (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2012531972A JP5276750B2 (ja) | 2010-09-02 | 2011-09-02 | 保護機能付きスイッチング電源回路およびそれを用いた電子機器 |

| US13/820,502 US20130170621A1 (en) | 2010-09-01 | 2011-09-02 | Switching power supply circuit provided with protection function |

| KR1020137008361A KR101475399B1 (ko) | 2010-09-02 | 2011-09-02 | 보호 기능 부착된 스위칭 전원 회로 |

| EP11821949.2A EP2613431A1 (en) | 2010-09-02 | 2011-09-02 | Switching power supply circuit provided with protection function |

| CN201180039230.3A CN103038992B (zh) | 2010-09-02 | 2011-09-02 | 带保护功能的开关电源电路 |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2010197124 | 2010-09-02 | ||

| JP2010-197124 | 2010-09-02 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2012029935A1 true WO2012029935A1 (ja) | 2012-03-08 |

Family

ID=45773009

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2011/069982 WO2012029935A1 (ja) | 2010-09-01 | 2011-09-02 | 保護機能付きスイッチング電源回路 |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US20130170621A1 (ja) |

| EP (1) | EP2613431A1 (ja) |

| JP (2) | JP5276750B2 (ja) |

| KR (1) | KR101475399B1 (ja) |

| CN (1) | CN103038992B (ja) |

| WO (1) | WO2012029935A1 (ja) |

Families Citing this family (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102801320A (zh) * | 2011-05-24 | 2012-11-28 | 华硕电脑股份有限公司 | 电源供应器 |

| JP5887081B2 (ja) * | 2011-07-26 | 2016-03-16 | ローム株式会社 | Ac/dcコンバータおよびそれを用いたac電源アダプタおよび電子機器 |

| US9112419B2 (en) * | 2013-07-16 | 2015-08-18 | Rohm Co., Ltd. | AC/DC converter with control circuit that receives rectified voltage at input detection terminal |

| JP6381953B2 (ja) * | 2014-04-25 | 2018-08-29 | ローム株式会社 | スイッチング電源の制御回路およびそれを用いた電源回路、ならびに電子機器および基地局 |

| TWI563785B (en) * | 2014-06-19 | 2016-12-21 | Richtek Technology Corp | Flyback power supply circuit with programmable function and control method thereof |

| TWI568165B (zh) * | 2014-10-09 | 2017-01-21 | 立錡科技股份有限公司 | 具有可程式功能的返馳式電源供應電路及其控制電路與控制方法 |

| WO2016084159A1 (ja) * | 2014-11-26 | 2016-06-02 | 株式会社 東芝 | 電子機器 |

| WO2016097476A1 (en) * | 2014-12-17 | 2016-06-23 | Salcomp Oyj | Switched-mode power supply |

| JP6571442B2 (ja) | 2015-08-07 | 2019-09-04 | Necプラットフォームズ株式会社 | 交流入力直流出力型電源およびその制御方法 |

| JP6656956B2 (ja) * | 2016-03-07 | 2020-03-04 | エイブリック株式会社 | スイッチングレギュレータ |

| US9762131B1 (en) * | 2016-05-23 | 2017-09-12 | Inno-Tech Co., Ltd. | Flyback converter with no need for the auxiliary winding |

| JP6856859B2 (ja) * | 2017-03-23 | 2021-04-14 | 東日本旅客鉄道株式会社 | 電源装置の劣化検知装置および劣化検知方法 |

| US10320301B2 (en) | 2017-09-15 | 2019-06-11 | Semiconductor Components Industries, Llc | Power converter responsive to device connection status |

| JP7133436B2 (ja) * | 2018-10-26 | 2022-09-08 | 富士フイルムヘルスケア株式会社 | 高電圧装置およびx線画像診断装置 |

| JP2022087676A (ja) * | 2020-12-01 | 2022-06-13 | オムロン株式会社 | 残寿命予測装置及び残寿命予測方法 |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH08248086A (ja) * | 1995-03-10 | 1996-09-27 | Shindengen Electric Mfg Co Ltd | 電解コンデンサ劣化判定回路及びこれを搭載した直流電源 装置 |

| JP2000032747A (ja) | 1998-07-09 | 2000-01-28 | Canon Inc | スイッチング電源装置 |

| WO2005088819A1 (ja) * | 2004-03-17 | 2005-09-22 | Matsushita Electric Industrial Co., Ltd. | スイッチング電源装置 |

| JP2010130792A (ja) * | 2008-11-27 | 2010-06-10 | Toshiba Corp | 電源保護回路及び電源保護方法 |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP3351631B2 (ja) * | 1994-08-24 | 2002-12-03 | 株式会社東芝 | 電気車制御装置 |

| JP3370065B2 (ja) * | 2000-07-28 | 2003-01-27 | ニチコン株式会社 | リンギングチョークコンバータ |

| JP2008035901A (ja) * | 2006-08-01 | 2008-02-21 | Ge Medical Systems Global Technology Co Llc | 磁気共鳴撮像装置及びネットワークシステム |

| JP2009189202A (ja) * | 2008-02-08 | 2009-08-20 | Panasonic Corp | 電力変換装置、ブラシレスdcモータおよび換気送風装置 |

| CN201430705Y (zh) * | 2009-04-09 | 2010-03-24 | 翁延鸣 | 高转换效率的开关电源电路 |

-

2011

- 2011-09-02 EP EP11821949.2A patent/EP2613431A1/en not_active Withdrawn

- 2011-09-02 JP JP2012531972A patent/JP5276750B2/ja active Active

- 2011-09-02 WO PCT/JP2011/069982 patent/WO2012029935A1/ja active Application Filing

- 2011-09-02 CN CN201180039230.3A patent/CN103038992B/zh active Active

- 2011-09-02 KR KR1020137008361A patent/KR101475399B1/ko active IP Right Grant

- 2011-09-02 US US13/820,502 patent/US20130170621A1/en not_active Abandoned

-

2013

- 2013-04-05 JP JP2013079088A patent/JP5617000B2/ja active Active

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH08248086A (ja) * | 1995-03-10 | 1996-09-27 | Shindengen Electric Mfg Co Ltd | 電解コンデンサ劣化判定回路及びこれを搭載した直流電源 装置 |

| JP2000032747A (ja) | 1998-07-09 | 2000-01-28 | Canon Inc | スイッチング電源装置 |

| WO2005088819A1 (ja) * | 2004-03-17 | 2005-09-22 | Matsushita Electric Industrial Co., Ltd. | スイッチング電源装置 |

| JP2010130792A (ja) * | 2008-11-27 | 2010-06-10 | Toshiba Corp | 電源保護回路及び電源保護方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| KR101475399B1 (ko) | 2014-12-22 |

| EP2613431A1 (en) | 2013-07-10 |

| KR20130064800A (ko) | 2013-06-18 |

| US20130170621A1 (en) | 2013-07-04 |

| CN103038992B (zh) | 2015-09-30 |

| JP5276750B2 (ja) | 2013-08-28 |

| JPWO2012029935A1 (ja) | 2013-10-31 |

| JP5617000B2 (ja) | 2014-10-29 |

| JP2013138608A (ja) | 2013-07-11 |

| CN103038992A (zh) | 2013-04-10 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5276750B2 (ja) | 保護機能付きスイッチング電源回路およびそれを用いた電子機器 | |

| JP5210424B2 (ja) | 保護機能付きスイッチング電源回路およびそれを用いた電子機器 | |

| JP4752484B2 (ja) | Dc−dcコンバータ | |

| US7315461B2 (en) | Power supply device | |

| JP2009195033A (ja) | 電源装置及び照明器具 | |

| US11171480B2 (en) | Switching power supply device and semiconductor device | |

| US10651759B2 (en) | Switching power supply device and semiconductor device | |

| JP2015144542A (ja) | 過電圧保護回路、及びそれを備えた電力変換装置 | |

| JPWO2019239453A1 (ja) | 光源点灯装置、照明器具 | |

| JP5137121B2 (ja) | スイッチング電源装置 | |

| JP2009189103A (ja) | スイッチング電源装置 | |

| KR101220775B1 (ko) | 과전류 차단 기능을 갖는 스위칭 모드 전원 공급장치 | |

| JP2010263773A (ja) | 電源回路 | |

| JP2009081901A (ja) | 過電圧保護装置 | |

| US20180027619A1 (en) | Arcing protector | |

| US20190267902A1 (en) | Switched-mode power supply | |

| US20240243666A1 (en) | Switching power supply device | |

| JP2007267567A (ja) | 過電圧保護装置 | |

| KR20200103425A (ko) | 인버터 회로 | |

| JP2011035987A (ja) | スイッチング電源装置 | |

| CN117477913A (zh) | 开关电源装置以及控制方法,集成控制电路 | |

| JP2007174791A (ja) | スイッチング電源装置 | |

| JP2012138984A (ja) | リンギングチョークコンバータ | |

| JP2012161188A (ja) | スイッチング電源装置 | |

| JP2005198469A (ja) | スイッチング電源装置 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| WWE | Wipo information: entry into national phase |

Ref document number: 201180039230.3 Country of ref document: CN |

|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 11821949 Country of ref document: EP Kind code of ref document: A1 |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 2012531972 Country of ref document: JP |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 13820502 Country of ref document: US |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 2011821949 Country of ref document: EP |

|

| ENP | Entry into the national phase |

Ref document number: 20137008361 Country of ref document: KR Kind code of ref document: A |