KR20170093949A - 회전 척으로부터 손실 웨이퍼의 검출 - Google Patents

회전 척으로부터 손실 웨이퍼의 검출 Download PDFInfo

- Publication number

- KR20170093949A KR20170093949A KR1020177019065A KR20177019065A KR20170093949A KR 20170093949 A KR20170093949 A KR 20170093949A KR 1020177019065 A KR1020177019065 A KR 1020177019065A KR 20177019065 A KR20177019065 A KR 20177019065A KR 20170093949 A KR20170093949 A KR 20170093949A

- Authority

- KR

- South Korea

- Prior art keywords

- detection

- microelectronic substrate

- component

- position indicator

- rotating chuck

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

- 238000001514 detection method Methods 0.000 title claims description 83

- 238000009987 spinning Methods 0.000 title 1

- 239000000758 substrate Substances 0.000 claims abstract description 118

- 238000004377 microelectronic Methods 0.000 claims abstract description 108

- 238000000034 method Methods 0.000 claims abstract description 68

- 230000007246 mechanism Effects 0.000 claims abstract description 54

- 230000008569 process Effects 0.000 claims abstract description 43

- 238000012545 processing Methods 0.000 claims abstract description 23

- 239000000126 substance Substances 0.000 claims abstract description 10

- 230000005291 magnetic effect Effects 0.000 claims description 33

- 230000005355 Hall effect Effects 0.000 claims description 13

- 239000012530 fluid Substances 0.000 claims description 8

- 238000012993 chemical processing Methods 0.000 claims description 2

- 230000003247 decreasing effect Effects 0.000 claims 2

- 238000004590 computer program Methods 0.000 claims 1

- 230000008878 coupling Effects 0.000 claims 1

- 238000010168 coupling process Methods 0.000 claims 1

- 238000005859 coupling reaction Methods 0.000 claims 1

- 230000003287 optical effect Effects 0.000 claims 1

- 239000000463 material Substances 0.000 description 7

- 230000008859 change Effects 0.000 description 6

- 230000005684 electric field Effects 0.000 description 6

- 230000002596 correlated effect Effects 0.000 description 5

- 238000010586 diagram Methods 0.000 description 5

- 239000004065 semiconductor Substances 0.000 description 5

- 239000007789 gas Substances 0.000 description 4

- 239000007788 liquid Substances 0.000 description 3

- XEEYBQQBJWHFJM-UHFFFAOYSA-N Iron Chemical compound [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 description 2

- PXHVJJICTQNCMI-UHFFFAOYSA-N Nickel Chemical compound [Ni] PXHVJJICTQNCMI-UHFFFAOYSA-N 0.000 description 2

- 238000004891 communication Methods 0.000 description 2

- 230000003993 interaction Effects 0.000 description 2

- 238000012986 modification Methods 0.000 description 2

- 230000004048 modification Effects 0.000 description 2

- 230000009471 action Effects 0.000 description 1

- 230000008901 benefit Effects 0.000 description 1

- 239000006227 byproduct Substances 0.000 description 1

- 238000010924 continuous production Methods 0.000 description 1

- 230000001276 controlling effect Effects 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 230000009977 dual effect Effects 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 230000007613 environmental effect Effects 0.000 description 1

- 239000003302 ferromagnetic material Substances 0.000 description 1

- 230000006870 function Effects 0.000 description 1

- 229910052742 iron Inorganic materials 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 239000000203 mixture Substances 0.000 description 1

- 238000012544 monitoring process Methods 0.000 description 1

- 229910052759 nickel Inorganic materials 0.000 description 1

- 239000002245 particle Substances 0.000 description 1

- 238000000059 patterning Methods 0.000 description 1

- 230000004044 response Effects 0.000 description 1

- 238000012546 transfer Methods 0.000 description 1

- 230000007704 transition Effects 0.000 description 1

- 235000012431 wafers Nutrition 0.000 description 1

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/67—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere

- H01L21/67005—Apparatus not specifically provided for elsewhere

- H01L21/67242—Apparatus for monitoring, sorting or marking

- H01L21/67288—Monitoring of warpage, curvature, damage, defects or the like

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/67—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere

- H01L21/683—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for supporting or gripping

- H01L21/687—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for supporting or gripping using mechanical means, e.g. chucks, clamps or pinches

- H01L21/68714—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for supporting or gripping using mechanical means, e.g. chucks, clamps or pinches the wafers being placed on a susceptor, stage or support

- H01L21/68728—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for supporting or gripping using mechanical means, e.g. chucks, clamps or pinches the wafers being placed on a susceptor, stage or support characterised by a plurality of separate clamping members, e.g. clamping fingers

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/67—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere

- H01L21/683—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for supporting or gripping

- H01L21/687—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for supporting or gripping using mechanical means, e.g. chucks, clamps or pinches

- H01L21/68714—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for supporting or gripping using mechanical means, e.g. chucks, clamps or pinches the wafers being placed on a susceptor, stage or support

- H01L21/68764—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for supporting or gripping using mechanical means, e.g. chucks, clamps or pinches the wafers being placed on a susceptor, stage or support characterised by a movable susceptor, stage or support, others than those only rotating on their own vertical axis, e.g. susceptors on a rotating caroussel

Landscapes

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Condensed Matter Physics & Semiconductors (AREA)

- General Physics & Mathematics (AREA)

- Manufacturing & Machinery (AREA)

- Computer Hardware Design (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Power Engineering (AREA)

- Container, Conveyance, Adherence, Positioning, Of Wafer (AREA)

- Cleaning Or Drying Semiconductors (AREA)

- Exposure Of Semiconductors, Excluding Electron Or Ion Beam Exposure (AREA)

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| PCT/US2014/069557 WO2016093824A1 (en) | 2014-12-10 | 2014-12-10 | Detection of lost wafer from spinning chuck |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| KR20170093949A true KR20170093949A (ko) | 2017-08-16 |

Family

ID=56107842

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1020177019065A Withdrawn KR20170093949A (ko) | 2014-12-10 | 2014-12-10 | 회전 척으로부터 손실 웨이퍼의 검출 |

Country Status (4)

| Country | Link |

|---|---|

| JP (1) | JP2018501654A (cg-RX-API-DMAC7.html) |

| KR (1) | KR20170093949A (cg-RX-API-DMAC7.html) |

| CN (1) | CN107112257A (cg-RX-API-DMAC7.html) |

| WO (1) | WO2016093824A1 (cg-RX-API-DMAC7.html) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP7756571B2 (ja) * | 2022-01-19 | 2025-10-20 | 株式会社荏原製作所 | プッシャ、搬送装置、および基板処理装置 |

| CN115458471B (zh) * | 2022-08-31 | 2024-07-23 | 北京北方华创微电子装备有限公司 | 卡盘装置及监测晶圆状态的方法 |

Family Cites Families (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3538883A (en) * | 1967-12-12 | 1970-11-10 | Alco Standard Corp | Vacuum chuck with safety device |

| JP2529637Y2 (ja) * | 1991-08-30 | 1997-03-19 | 大日本スクリーン製造株式会社 | 基板の回転保持装置 |

| DE4237928C2 (de) * | 1992-07-09 | 1995-01-19 | Siemens Ag | Mikroschalter mit einem Magnetfeld-Sensor |

| US6459382B1 (en) * | 2001-04-26 | 2002-10-01 | Applied Materials, Inc. | Over clamp sensor |

| US6670807B2 (en) * | 2002-01-16 | 2003-12-30 | Applied Materials, Inc. | Proximity sensor detecting loss of magnetic field complete |

| KR100460807B1 (ko) * | 2002-07-08 | 2004-12-09 | 삼성전자주식회사 | 반도체소자 제조설비의 웨이퍼 외관 검사장치와 이를이용하는 세정설비 및 그 검사방법 |

| JP5379533B2 (ja) * | 2009-03-27 | 2013-12-25 | 大日本スクリーン製造株式会社 | 基板保持機構、およびこの基板保持機構を備える基板処理装置 |

| JP5646528B2 (ja) * | 2012-03-09 | 2014-12-24 | 東京エレクトロン株式会社 | 液処理装置 |

| CN102867771B (zh) * | 2012-09-18 | 2015-08-05 | 北京七星华创电子股份有限公司 | 具有监测半导体晶片状态功能的夹持装置和方法 |

| US9255894B2 (en) * | 2012-11-09 | 2016-02-09 | Kla-Tencor Corporation | System and method for detecting cracks in a wafer |

-

2014

- 2014-12-10 KR KR1020177019065A patent/KR20170093949A/ko not_active Withdrawn

- 2014-12-10 WO PCT/US2014/069557 patent/WO2016093824A1/en not_active Ceased

- 2014-12-10 CN CN201480084511.4A patent/CN107112257A/zh active Pending

- 2014-12-10 JP JP2017531335A patent/JP2018501654A/ja not_active Ceased

Also Published As

| Publication number | Publication date |

|---|---|

| CN107112257A (zh) | 2017-08-29 |

| WO2016093824A1 (en) | 2016-06-16 |

| JP2018501654A (ja) | 2018-01-18 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

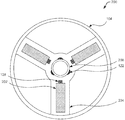

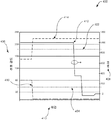

| US9564378B2 (en) | Detection of lost wafer from spinning chuck | |

| JP5387921B2 (ja) | 静電チャック装置及び基板の吸着状態判別方法 | |

| US11139180B2 (en) | Substrate processing apparatus and substrate processing method | |

| TWI259548B (en) | Proximity sensor | |

| JP7278838B2 (ja) | 基板支持装置及び基板洗浄装置 | |

| KR20170093949A (ko) | 회전 척으로부터 손실 웨이퍼의 검출 | |

| JP5379533B2 (ja) | 基板保持機構、およびこの基板保持機構を備える基板処理装置 | |

| JP2007220868A (ja) | 基板搬送・処理装置 | |

| WO2018059144A1 (zh) | Cmp设备抛光头掉片检测方法和系统 | |

| CN107504103A (zh) | 一种永磁失电制动器及其检测方法 | |

| JP4660576B2 (ja) | 可動対象物の亀裂検知システム | |

| JP6690995B2 (ja) | 回転テーブル用ウェーハ保持機構及び方法並びにウェーハ回転保持装置 | |

| JP2018501654A5 (cg-RX-API-DMAC7.html) | ||

| CN116454015A (zh) | 一种边缘夹持型晶圆卡盘装置 | |

| CN106783686A (zh) | 一种具有晶圆侦测功能的炉管设备 | |

| KR20060081851A (ko) | 웨이퍼의 파손을 방지할 수 있는 웨이퍼 감지 센서부가구비된 웨이퍼 이송 장치 | |

| JP6917864B2 (ja) | 液供給装置およびリーク検知方法 | |

| CN106702353A (zh) | 反应腔室 | |

| KR20070047174A (ko) | 이물질 감지 센서를 구비한 반도체 웨이퍼 정렬장치 | |

| KR20100060913A (ko) | 웨이퍼 이송 장치 | |

| JP6496474B2 (ja) | ウェハ搬送用装置 | |

| KR100807033B1 (ko) | 반도체 소자 제조 장비의 에러 처리 장치 | |

| JP2528703B2 (ja) | 液用ガラスヒ―タの破損検知方法 | |

| KR20060074307A (ko) | 반도체 웨이퍼의 미세 균열 제거 장치 및 그 방법 | |

| KR20080004738A (ko) | 기판 이송 장치 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PA0105 | International application |

Patent event date: 20170710 Patent event code: PA01051R01D Comment text: International Patent Application |

|

| PG1501 | Laying open of application | ||

| PC1203 | Withdrawal of no request for examination | ||

| WITN | Application deemed withdrawn, e.g. because no request for examination was filed or no examination fee was paid |