KR20160114627A - 구조화된 표면을 갖는 연마 재료 - Google Patents

구조화된 표면을 갖는 연마 재료 Download PDFInfo

- Publication number

- KR20160114627A KR20160114627A KR1020167022667A KR20167022667A KR20160114627A KR 20160114627 A KR20160114627 A KR 20160114627A KR 1020167022667 A KR1020167022667 A KR 1020167022667A KR 20167022667 A KR20167022667 A KR 20167022667A KR 20160114627 A KR20160114627 A KR 20160114627A

- Authority

- KR

- South Korea

- Prior art keywords

- less

- abrasive

- treatment

- structured surface

- layer

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B37/00—Lapping machines or devices; Accessories

- B24B37/11—Lapping tools

- B24B37/20—Lapping pads for working plane surfaces

- B24B37/26—Lapping pads for working plane surfaces characterised by the shape of the lapping pad surface, e.g. grooved

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B1/00—Processes of grinding or polishing; Use of auxiliary equipment in connection with such processes

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C14/00—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material

- C23C14/06—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material characterised by the coating material

- C23C14/0605—Carbon

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C14/00—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material

- C23C14/06—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material characterised by the coating material

- C23C14/0635—Carbides

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C16/00—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes

- C23C16/22—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the deposition of inorganic material, other than metallic material

- C23C16/26—Deposition of carbon only

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C16/00—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes

- C23C16/22—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the deposition of inorganic material, other than metallic material

- C23C16/30—Deposition of compounds, mixtures or solid solutions, e.g. borides, carbides, nitrides

- C23C16/32—Carbides

- C23C16/325—Silicon carbide

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C16/00—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes

- C23C16/44—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating

- C23C16/455—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating characterised by the method used for introducing gases into reaction chamber or for modifying gas flows in reaction chamber

- C23C16/45523—Pulsed gas flow or change of composition over time

- C23C16/45525—Atomic layer deposition [ALD]

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Materials Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- General Chemical & Material Sciences (AREA)

- Polishing Bodies And Polishing Tools (AREA)

- Inorganic Chemistry (AREA)

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US201461931136P | 2014-01-24 | 2014-01-24 | |

| US61/931,136 | 2014-01-24 | ||

| PCT/US2015/012158 WO2015112540A1 (en) | 2014-01-24 | 2015-01-21 | Abrasive material having a structured surface |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| KR20160114627A true KR20160114627A (ko) | 2016-10-05 |

Family

ID=53681879

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1020167022667A Withdrawn KR20160114627A (ko) | 2014-01-24 | 2015-01-21 | 구조화된 표면을 갖는 연마 재료 |

Country Status (6)

Families Citing this family (19)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP5921790B1 (ja) * | 2014-07-07 | 2016-05-24 | バンドー化学株式会社 | 研磨フィルム |

| US10967399B2 (en) * | 2016-06-30 | 2021-04-06 | 3M Innovative Properties Company | Fluorocarbon release coating |

| JP6925699B2 (ja) * | 2016-10-04 | 2021-08-25 | 株式会社ディスコ | 平面研削砥石 |

| SG11202000259RA (en) * | 2017-07-11 | 2020-02-27 | 3M Innovative Properties Co | Abrasive articles including conformable coatings and polishing system therefrom |

| JP7300441B2 (ja) * | 2017-07-11 | 2023-06-29 | スリーエム イノベイティブ プロパティズ カンパニー | 適合性コーティングを含む研磨物品及びそれらからのポリッシングシステム |

| JP7198801B2 (ja) * | 2017-07-11 | 2023-01-04 | スリーエム イノベイティブ プロパティズ カンパニー | 適合性コーティングを含む研磨物品及びそれによる研磨システム |

| US12048980B2 (en) * | 2017-08-25 | 2024-07-30 | 3M Innovative Properties Company | Surface projection polishing pad |

| TWI649775B (zh) * | 2018-01-02 | 2019-02-01 | 台灣積體電路製造股份有限公司 | 離子佈植機及離子佈植機腔室的製造方法 |

| CN110065011A (zh) * | 2018-01-23 | 2019-07-30 | 项刚 | 金刚石砂轮及其制备方法 |

| US11331767B2 (en) | 2019-02-01 | 2022-05-17 | Micron Technology, Inc. | Pads for chemical mechanical planarization tools, chemical mechanical planarization tools, and related methods |

| CN110530313B (zh) * | 2019-07-26 | 2021-05-28 | 西安交通大学 | 一种跨量级多尺度线宽标准器及其制备方法 |

| US20210040608A1 (en) * | 2019-08-05 | 2021-02-11 | GM Global Technology Operations LLC | Method for bonding a polymeric material to a substrate |

| KR102298114B1 (ko) * | 2019-11-05 | 2021-09-03 | 에스케이씨솔믹스 주식회사 | 연마패드, 이의 제조방법 및 이를 이용한 반도체 소자의 제조방법 |

| KR102287923B1 (ko) * | 2019-10-30 | 2021-08-09 | 에스케이씨솔믹스 주식회사 | 연마패드, 이의 제조방법, 및 이를 이용한 반도체 소자의 제조방법 |

| TWI761921B (zh) | 2019-10-30 | 2022-04-21 | 南韓商Skc索密思股份有限公司 | 研磨墊、製造該研磨墊之方法及使用該研磨墊以製造半導體裝置之方法 |

| US20210185793A1 (en) * | 2019-12-13 | 2021-06-17 | Applied Materials, Inc. | Adhesive material removal from photomask in ultraviolet lithography application |

| US20220178017A1 (en) * | 2020-12-03 | 2022-06-09 | Applied Materials, Inc. | Cfx layer to protect aluminum surface from over-oxidation |

| TWI779728B (zh) * | 2021-07-20 | 2022-10-01 | 大陸商廈門佳品金剛石工業有限公司 | 鑽石修整碟及其製造方法 |

| CN116652825B (zh) * | 2023-07-24 | 2023-11-10 | 北京寰宇晶科科技有限公司 | 一种金刚石cmp抛光垫修整器及其制备方法 |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

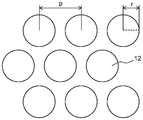

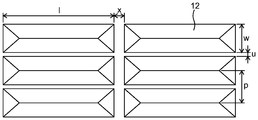

| JP2001179640A (ja) | 1999-12-21 | 2001-07-03 | Three M Innovative Properties Co | 研磨層が立体構造を有する研磨材料 |

| JP2002542057A (ja) | 1999-04-23 | 2002-12-10 | スリーエム イノベイティブ プロパティズ カンパニー | ガラスおよびガラスセラミックワークピースを研摩するのに好適な研摩物品 |

| WO2005012592A2 (en) | 2003-07-25 | 2005-02-10 | Morgan Advanced Ceramics, Inc. | Cvd diamond-coated composite substrate for making same |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6015597A (en) * | 1997-11-26 | 2000-01-18 | 3M Innovative Properties Company | Method for coating diamond-like networks onto particles |

| US6821189B1 (en) * | 2000-10-13 | 2004-11-23 | 3M Innovative Properties Company | Abrasive article comprising a structured diamond-like carbon coating and method of using same to mechanically treat a substrate |

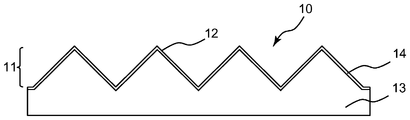

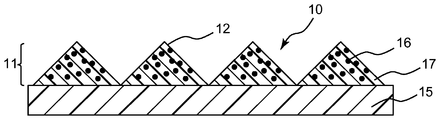

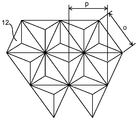

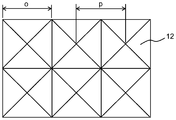

| US8080073B2 (en) * | 2007-12-20 | 2011-12-20 | 3M Innovative Properties Company | Abrasive article having a plurality of precisely-shaped abrasive composites |

| EP2240298A4 (en) * | 2007-12-31 | 2014-04-30 | 3M Innovative Properties Co | PLASMA TREATED ABRASIVE ARTICLE AND PROCESS FOR PRODUCING THE SAME |

-

2015

- 2015-01-21 JP JP2016548074A patent/JP2017503670A/ja not_active Withdrawn

- 2015-01-21 KR KR1020167022667A patent/KR20160114627A/ko not_active Withdrawn

- 2015-01-21 CN CN201580005532.7A patent/CN106413986A/zh active Pending

- 2015-01-21 WO PCT/US2015/012158 patent/WO2015112540A1/en active Application Filing

- 2015-01-21 US US15/113,244 patent/US20170008143A1/en not_active Abandoned

- 2015-01-23 TW TW104102413A patent/TW201538272A/zh unknown

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2002542057A (ja) | 1999-04-23 | 2002-12-10 | スリーエム イノベイティブ プロパティズ カンパニー | ガラスおよびガラスセラミックワークピースを研摩するのに好適な研摩物品 |

| JP2001179640A (ja) | 1999-12-21 | 2001-07-03 | Three M Innovative Properties Co | 研磨層が立体構造を有する研磨材料 |

| WO2005012592A2 (en) | 2003-07-25 | 2005-02-10 | Morgan Advanced Ceramics, Inc. | Cvd diamond-coated composite substrate for making same |

Also Published As

| Publication number | Publication date |

|---|---|

| CN106413986A (zh) | 2017-02-15 |

| US20170008143A1 (en) | 2017-01-12 |

| TW201538272A (zh) | 2015-10-16 |

| WO2015112540A1 (en) | 2015-07-30 |

| JP2017503670A (ja) | 2017-02-02 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| KR20160114627A (ko) | 구조화된 표면을 갖는 연마 재료 | |

| US5551959A (en) | Abrasive article having a diamond-like coating layer and method for making same | |

| US20090224370A1 (en) | Non-planar cvd diamond-coated cmp pad conditioner and method for manufacturing | |

| EP0878268B1 (en) | Polishing apparatus and method for hard material-coated wafer | |

| JP5453526B2 (ja) | 耐腐食性cmpコンディショニング工具並びにその作製および使用法 | |

| EP2978567B1 (en) | Nonwoven abrasive articles and methods of making the same | |

| US20050276979A1 (en) | CVD diamond-coated composite substrate containing a carbide-forming material and ceramic phases and method for making same | |

| KR101430580B1 (ko) | Cmp 패드 컨디셔너 | |

| TWI791028B (zh) | 包括可適形塗層之磨料物品及來自其之拋光系統 | |

| WO1999002309A1 (en) | Cvd diamond coated substrate for polishing pad conditioning head and method for making same | |

| WO2009088606A2 (en) | Plasma treated abrasive article and method of making same | |

| KR20090029842A (ko) | 기재를 갖지 않는 연마재 제품 | |

| JP2010510083A (ja) | ラッピングキャリア及びラッピング方法 | |

| CN110869166B (zh) | 包括适形涂层的磨料制品和由其形成的抛光系统 | |

| EP1574289B2 (en) | A method for manufacturing a carrier for holding an object to be polished | |

| US20050202762A1 (en) | Dresser for polishing cloth and method for producing the same | |

| WO2001034346A1 (en) | Chemical mechanical polishing apparatus components with enhanced corrosion resistance | |

| CN112223133B (zh) | 化学机械抛光垫调节器及其制造方法 | |

| US20140251952A1 (en) | Surface modified polishing pad | |

| Murashima et al. | New droplet removal polishing method for diamond-like carbon with carbon fiber brush | |

| KR20020003281A (ko) | 연마용 성형체 및 그것을 이용한 연마용 정반 | |

| KR20090025042A (ko) | 연마패드용 컨디셔닝 디스크 | |

| TW202510083A (zh) | 結構構件 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PA0105 | International application |

Patent event date: 20160819 Patent event code: PA01051R01D Comment text: International Patent Application |

|

| PG1501 | Laying open of application | ||

| PC1203 | Withdrawal of no request for examination | ||

| WITN | Application deemed withdrawn, e.g. because no request for examination was filed or no examination fee was paid |