KR20120095411A - 반도체 식각 방법 - Google Patents

반도체 식각 방법 Download PDFInfo

- Publication number

- KR20120095411A KR20120095411A KR1020127014823A KR20127014823A KR20120095411A KR 20120095411 A KR20120095411 A KR 20120095411A KR 1020127014823 A KR1020127014823 A KR 1020127014823A KR 20127014823 A KR20127014823 A KR 20127014823A KR 20120095411 A KR20120095411 A KR 20120095411A

- Authority

- KR

- South Korea

- Prior art keywords

- semiconductor

- etching

- etched

- photoresist

- reactive

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/04—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer

- H01L21/18—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer the devices having semiconductor bodies comprising elements of Group IV of the Periodic Table or AIIIBV compounds with or without impurities, e.g. doping materials

- H01L21/30—Treatment of semiconductor bodies using processes or apparatus not provided for in groups H01L21/20 - H01L21/26

- H01L21/302—Treatment of semiconductor bodies using processes or apparatus not provided for in groups H01L21/20 - H01L21/26 to change their surface-physical characteristics or shape, e.g. etching, polishing, cutting

- H01L21/306—Chemical or electrical treatment, e.g. electrolytic etching

- H01L21/3065—Plasma etching; Reactive-ion etching

-

- H—ELECTRICITY

- H10—SEMICONDUCTOR DEVICES; ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10F—INORGANIC SEMICONDUCTOR DEVICES SENSITIVE TO INFRARED RADIATION, LIGHT, ELECTROMAGNETIC RADIATION OF SHORTER WAVELENGTH OR CORPUSCULAR RADIATION

- H10F77/00—Constructional details of devices covered by this subclass

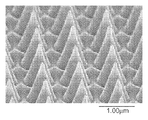

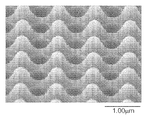

- H10F77/70—Surface textures, e.g. pyramid structures

- H10F77/703—Surface textures, e.g. pyramid structures of the semiconductor bodies, e.g. textured active layers

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/04—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer

- H01L21/34—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer the devices having semiconductor bodies not provided for in groups H01L21/18, H10D48/04 and H10D48/07, with or without impurities, e.g. doping materials

- H01L21/46—Treatment of semiconductor bodies using processes or apparatus not provided for in groups H01L21/428

- H01L21/461—Treatment of semiconductor bodies using processes or apparatus not provided for in groups H01L21/428 to change their surface-physical characteristics or shape, e.g. etching, polishing, cutting

- H01L21/465—Chemical or electrical treatment, e.g. electrolytic etching

-

- H—ELECTRICITY

- H10—SEMICONDUCTOR DEVICES; ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10H—INORGANIC LIGHT-EMITTING SEMICONDUCTOR DEVICES HAVING POTENTIAL BARRIERS

- H10H20/00—Individual inorganic light-emitting semiconductor devices having potential barriers, e.g. light-emitting diodes [LED]

- H10H20/01—Manufacture or treatment

-

- H—ELECTRICITY

- H10—SEMICONDUCTOR DEVICES; ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10H—INORGANIC LIGHT-EMITTING SEMICONDUCTOR DEVICES HAVING POTENTIAL BARRIERS

- H10H20/00—Individual inorganic light-emitting semiconductor devices having potential barriers, e.g. light-emitting diodes [LED]

- H10H20/80—Constructional details

- H10H20/81—Bodies

- H10H20/819—Bodies characterised by their shape, e.g. curved or truncated substrates

- H10H20/82—Roughened surfaces, e.g. at the interface between epitaxial layers

-

- H—ELECTRICITY

- H10—SEMICONDUCTOR DEVICES; ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10H—INORGANIC LIGHT-EMITTING SEMICONDUCTOR DEVICES HAVING POTENTIAL BARRIERS

- H10H20/00—Individual inorganic light-emitting semiconductor devices having potential barriers, e.g. light-emitting diodes [LED]

- H10H20/80—Constructional details

- H10H20/872—Periodic patterns for optical field-shaping, e.g. photonic bandgap structures

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02E—REDUCTION OF GREENHOUSE GAS [GHG] EMISSIONS, RELATED TO ENERGY GENERATION, TRANSMISSION OR DISTRIBUTION

- Y02E10/00—Energy generation through renewable energy sources

- Y02E10/50—Photovoltaic [PV] energy

Landscapes

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Plasma & Fusion (AREA)

- Condensed Matter Physics & Semiconductors (AREA)

- General Physics & Mathematics (AREA)

- Manufacturing & Machinery (AREA)

- Computer Hardware Design (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Power Engineering (AREA)

- Drying Of Semiconductors (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US25929909P | 2009-11-09 | 2009-11-09 | |

| US61/259,299 | 2009-11-09 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| KR20120095411A true KR20120095411A (ko) | 2012-08-28 |

Family

ID=43970710

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1020127014823A Withdrawn KR20120095411A (ko) | 2009-11-09 | 2010-11-02 | 반도체 식각 방법 |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US8765611B2 (enExample) |

| EP (1) | EP2499663A2 (enExample) |

| JP (1) | JP5723377B2 (enExample) |

| KR (1) | KR20120095411A (enExample) |

| CN (1) | CN102893378A (enExample) |

| TW (1) | TW201135832A (enExample) |

| WO (1) | WO2011056783A2 (enExample) |

Families Citing this family (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP5710433B2 (ja) * | 2011-09-13 | 2015-04-30 | 株式会社東芝 | 成膜装置のクリーニング方法および成膜装置 |

| FR2984769B1 (fr) * | 2011-12-22 | 2014-03-07 | Total Sa | Procede de texturation de la surface d'un substrat de silicium, substrat structure et dispositif photovoltaique comportant un tel substrat structure |

| US8883028B2 (en) * | 2011-12-28 | 2014-11-11 | Lam Research Corporation | Mixed mode pulsing etching in plasma processing systems |

| US9515223B2 (en) | 2012-08-21 | 2016-12-06 | Oji Holdings Corporation | Semiconductor light emitting device substrate including an uneven structure having convex portions, and a flat surface therebetween |

| WO2014051909A1 (en) * | 2012-09-25 | 2014-04-03 | Applied Materials, Inc. | Chamber clean with in gas heating source |

| CN103901516B (zh) * | 2012-12-26 | 2016-06-15 | 清华大学 | 光栅的制备方法 |

| US8941145B2 (en) * | 2013-06-17 | 2015-01-27 | The Boeing Company | Systems and methods for dry etching a photodetector array |

| US9012305B1 (en) * | 2014-01-29 | 2015-04-21 | Applied Materials, Inc. | Wafer dicing using hybrid laser scribing and plasma etch approach with intermediate non-reactive post mask-opening clean |

| JP6871706B2 (ja) | 2016-09-30 | 2021-05-12 | 日機装株式会社 | 半導体発光素子の製造方法 |

| KR102666776B1 (ko) * | 2019-05-10 | 2024-05-21 | 삼성디스플레이 주식회사 | 박막 트랜지스터의 제조 방법, 표시 장치의 제조 방법 및 박막 트랜지스터 기판 |

| EP4060076A4 (en) * | 2019-11-12 | 2023-01-25 | Showa Denko K.K. | Adhered substance removing method and film-forming method |

| CN113823992B (zh) * | 2021-09-14 | 2022-11-11 | 苏州长瑞光电有限公司 | 半导体器件制造方法及半导体器件 |

| CN115343788B (zh) * | 2022-08-18 | 2024-03-15 | 上海交通大学 | 基于循环刻蚀工艺的石英微透镜制备方法及石英微透镜 |

| WO2025153009A1 (en) * | 2024-01-17 | 2025-07-24 | The Hong Kong University Of Science And Technology | Apparatus and method for dry etching of aluminum gallium arsenide optical waveguides using argon gas plasma |

Family Cites Families (23)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH0294522A (ja) * | 1988-09-30 | 1990-04-05 | Toshiba Corp | ドライエッチング方法 |

| US5404027A (en) * | 1991-05-15 | 1995-04-04 | Minnesota Mining & Manufacturing Compay | Buried ridge II-VI laser diode |

| EP0647163B1 (en) * | 1992-06-22 | 1998-09-09 | Lam Research Corporation | A plasma cleaning method for removing residues in a plasma treatment chamber |

| DE4241045C1 (de) * | 1992-12-05 | 1994-05-26 | Bosch Gmbh Robert | Verfahren zum anisotropen Ätzen von Silicium |

| JPH07335620A (ja) * | 1994-06-09 | 1995-12-22 | Sony Corp | Ii−vi族化合物半導体の選択的ドライエッチング方法 |

| EP0774772A1 (en) | 1995-11-17 | 1997-05-21 | Applied Materials, Inc. | Methods for physically etching silicon electrically conducting surfaces |

| DE19736370C2 (de) * | 1997-08-21 | 2001-12-06 | Bosch Gmbh Robert | Verfahren zum anisotropen Ätzen von Silizium |

| KR100269323B1 (ko) * | 1998-01-16 | 2000-10-16 | 윤종용 | 반도체장치의백금막식각방법 |

| IT1301840B1 (it) * | 1998-06-30 | 2000-07-07 | Stmicroelettronica S R L | Metodo per incrementare la seletttvita' tra un film di materialefotosensibile ed uno strato da sottoporre ed incisione in processi |

| DE19919832A1 (de) * | 1999-04-30 | 2000-11-09 | Bosch Gmbh Robert | Verfahren zum anisotropen Plasmaätzen von Halbleitern |

| SE9903213D0 (sv) * | 1999-06-21 | 1999-09-10 | Carl Fredrik Carlstroem | Dry etching process of compound semiconductor materials |

| US6352081B1 (en) * | 1999-07-09 | 2002-03-05 | Applied Materials, Inc. | Method of cleaning a semiconductor device processing chamber after a copper etch process |

| US6347874B1 (en) * | 2000-02-16 | 2002-02-19 | 3M Innovative Properties Company | Wedge light extractor with risers |

| JP3776824B2 (ja) * | 2002-04-05 | 2006-05-17 | 株式会社東芝 | 半導体発光素子およびその製造方法 |

| DE10247913A1 (de) * | 2002-10-14 | 2004-04-22 | Robert Bosch Gmbh | Plasmaanlage und Verfahren zum anisotropen Einätzen von Strukturen in ein Substrat |

| US7238970B2 (en) * | 2003-10-30 | 2007-07-03 | Matsushita Electric Industrial Co., Ltd. | Semiconductor device and method for fabricating the same |

| JP2005353972A (ja) | 2004-06-14 | 2005-12-22 | Canon Inc | プラズマ処理方法 |

| US7402831B2 (en) * | 2004-12-09 | 2008-07-22 | 3M Innovative Properties Company | Adapting short-wavelength LED's for polychromatic, broadband, or “white” emission |

| US7575007B2 (en) * | 2006-08-23 | 2009-08-18 | Applied Materials, Inc. | Chamber recovery after opening barrier over copper |

| WO2008083188A2 (en) | 2006-12-29 | 2008-07-10 | 3M Innovative Properties Company | Led light source with converging extractor in an optical element |

| US8179034B2 (en) * | 2007-07-13 | 2012-05-15 | 3M Innovative Properties Company | Light extraction film for organic light emitting diode display and lighting devices |

| CN101472455A (zh) | 2007-12-29 | 2009-07-01 | 3M创新有限公司 | 电磁屏蔽衬垫和用于填充电磁屏蔽系统中的间隙的方法 |

| EP2449609A1 (en) * | 2009-06-30 | 2012-05-09 | 3M Innovative Properties Company | Cadmium-free re-emitting semiconductor construction |

-

2010

- 2010-11-02 WO PCT/US2010/055096 patent/WO2011056783A2/en not_active Ceased

- 2010-11-02 JP JP2012537938A patent/JP5723377B2/ja not_active Expired - Fee Related

- 2010-11-02 EP EP10828972A patent/EP2499663A2/en not_active Withdrawn

- 2010-11-02 CN CN2010800506808A patent/CN102893378A/zh active Pending

- 2010-11-02 US US12/917,826 patent/US8765611B2/en not_active Expired - Fee Related

- 2010-11-02 KR KR1020127014823A patent/KR20120095411A/ko not_active Withdrawn

- 2010-11-08 TW TW099138381A patent/TW201135832A/zh unknown

Also Published As

| Publication number | Publication date |

|---|---|

| US8765611B2 (en) | 2014-07-01 |

| TW201135832A (en) | 2011-10-16 |

| WO2011056783A2 (en) | 2011-05-12 |

| US20110108956A1 (en) | 2011-05-12 |

| JP5723377B2 (ja) | 2015-05-27 |

| WO2011056783A3 (en) | 2011-07-28 |

| EP2499663A2 (en) | 2012-09-19 |

| JP2013510442A (ja) | 2013-03-21 |

| CN102893378A (zh) | 2013-01-23 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US8765611B2 (en) | Etching process for semiconductors | |

| US8273663B2 (en) | Process for anisotropic etching of semiconductors | |

| EP3026716B1 (en) | Semiconductor light emitting element and method for manufacturing same | |

| US20150129544A1 (en) | Methods for forming structures by generation of isolated graphene layers having a reduced dimension | |

| Ng et al. | Patterning GaN microstructures by polarity-selective chemical etching | |

| CN103091747A (zh) | 一种光栅的制备方法 | |

| CN103258730A (zh) | Icp干法刻蚀工艺制备剖面为正梯形的台面的方法 | |

| Jaloustre et al. | Preferential crystal orientation etching of GaN nanopillars in Cl2 plasma | |

| Park et al. | Low angle forward reflected neutral beam source and its applications | |

| US20130140596A1 (en) | Light emitting diode | |

| Mondal et al. | Top-down micro and nano structuring of wide bandgap semiconductors for ultraviolet photodetection | |

| Pearton et al. | Science of dry etching of III-V materials | |

| Park et al. | Enhancement of photo-and electro-luminescence of GaN-based LED structure grown on a nanometer-scaled patterned sapphire substrate | |

| Byeon et al. | Enhancement of the photon extraction of green and blue LEDs by patterning the indium tin oxide top layer | |

| KR101586441B1 (ko) | 광전자소자용 팔라듐 금속층의 식각 방법 | |

| CN112921403A (zh) | 碳化硅晶片的刻蚀方法 | |

| Teo et al. | Deep reactive ion etching for pillar type nanophotonic crystal | |

| KR100780832B1 (ko) | 산화아연 물질에 대한 건식 식각 방법 | |

| Carlström | Ion beam etching of InP based materials | |

| Sunil | Nanofabrication of 2D Photonic Crystals for PCSELs emitting in UV region | |

| La Penna | Reactive ion etching of InP-based quantum cascade lasers | |

| Yoshida et al. | Formation of GaN self-organized nanotips by nanomasking effect | |

| Forchel et al. | InP/InGaAs nanofabrication and optical characterization | |

| Pearton et al. | Semiconductor (III-V) Thin Films: Plasma Etching | |

| Pearton | Dry Etching of Semiconductors at the Nano-and Micro-Scale |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PA0105 | International application |

Patent event date: 20120608 Patent event code: PA01051R01D Comment text: International Patent Application |

|

| PG1501 | Laying open of application | ||

| PC1203 | Withdrawal of no request for examination | ||

| WITN | Application deemed withdrawn, e.g. because no request for examination was filed or no examination fee was paid |