KR20110009097A - 전기화학 전지 및 이를 제조하는 방법 - Google Patents

전기화학 전지 및 이를 제조하는 방법 Download PDFInfo

- Publication number

- KR20110009097A KR20110009097A KR1020107022124A KR20107022124A KR20110009097A KR 20110009097 A KR20110009097 A KR 20110009097A KR 1020107022124 A KR1020107022124 A KR 1020107022124A KR 20107022124 A KR20107022124 A KR 20107022124A KR 20110009097 A KR20110009097 A KR 20110009097A

- Authority

- KR

- South Korea

- Prior art keywords

- cell

- housing

- polymer

- compartments

- polymer precursor

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

- 238000004519 manufacturing process Methods 0.000 title claims abstract description 14

- 238000000034 method Methods 0.000 title claims description 35

- 239000002243 precursor Substances 0.000 claims abstract description 55

- 229920006254 polymer film Polymers 0.000 claims abstract description 23

- 229920000052 poly(p-xylylene) Polymers 0.000 claims abstract description 15

- 229920013730 reactive polymer Polymers 0.000 claims abstract description 3

- 229920000642 polymer Polymers 0.000 claims description 50

- 238000000576 coating method Methods 0.000 claims description 19

- 239000011248 coating agent Substances 0.000 claims description 13

- 229910052751 metal Inorganic materials 0.000 claims description 10

- 239000002184 metal Substances 0.000 claims description 10

- 239000003792 electrolyte Substances 0.000 claims description 8

- 229910000831 Steel Inorganic materials 0.000 claims description 5

- 229920001577 copolymer Polymers 0.000 claims description 5

- 229920000620 organic polymer Polymers 0.000 claims description 5

- 239000010959 steel Substances 0.000 claims description 5

- 230000005855 radiation Effects 0.000 claims description 4

- 239000003566 sealing material Substances 0.000 claims description 4

- 239000005486 organic electrolyte Substances 0.000 claims description 3

- BVKZGUZCCUSVTD-UHFFFAOYSA-L Carbonate Chemical compound [O-]C([O-])=O BVKZGUZCCUSVTD-UHFFFAOYSA-L 0.000 claims description 2

- 238000010292 electrical insulation Methods 0.000 claims description 2

- 239000008151 electrolyte solution Substances 0.000 claims 1

- 239000000565 sealant Substances 0.000 abstract description 2

- 238000007789 sealing Methods 0.000 description 17

- 230000008569 process Effects 0.000 description 10

- PXHVJJICTQNCMI-UHFFFAOYSA-N Nickel Chemical compound [Ni] PXHVJJICTQNCMI-UHFFFAOYSA-N 0.000 description 8

- 238000005260 corrosion Methods 0.000 description 7

- 230000007797 corrosion Effects 0.000 description 7

- 238000001723 curing Methods 0.000 description 7

- 239000000758 substrate Substances 0.000 description 7

- 150000004703 alkoxides Chemical class 0.000 description 4

- 238000001746 injection moulding Methods 0.000 description 4

- 229910052759 nickel Inorganic materials 0.000 description 4

- 239000004971 Cross linker Substances 0.000 description 3

- 238000009833 condensation Methods 0.000 description 3

- 239000007789 gas Substances 0.000 description 3

- 150000002739 metals Chemical class 0.000 description 3

- 239000000178 monomer Substances 0.000 description 3

- 238000000465 moulding Methods 0.000 description 3

- 239000000126 substance Substances 0.000 description 3

- 101100327917 Caenorhabditis elegans chup-1 gene Proteins 0.000 description 2

- 239000000654 additive Substances 0.000 description 2

- 229910052793 cadmium Inorganic materials 0.000 description 2

- BDOSMKKIYDKNTQ-UHFFFAOYSA-N cadmium atom Chemical compound [Cd] BDOSMKKIYDKNTQ-UHFFFAOYSA-N 0.000 description 2

- 239000000919 ceramic Substances 0.000 description 2

- 150000001875 compounds Chemical class 0.000 description 2

- 230000005494 condensation Effects 0.000 description 2

- 238000005520 cutting process Methods 0.000 description 2

- 230000001419 dependent effect Effects 0.000 description 2

- 238000003980 solgel method Methods 0.000 description 2

- 239000007921 spray Substances 0.000 description 2

- 238000001029 thermal curing Methods 0.000 description 2

- VRBFTYUMFJWSJY-UHFFFAOYSA-N 28804-46-8 Chemical compound ClC1CC(C=C2)=CC=C2C(Cl)CC2=CC=C1C=C2 VRBFTYUMFJWSJY-UHFFFAOYSA-N 0.000 description 1

- WHXSMMKQMYFTQS-UHFFFAOYSA-N Lithium Chemical compound [Li] WHXSMMKQMYFTQS-UHFFFAOYSA-N 0.000 description 1

- 229910005813 NiMH Inorganic materials 0.000 description 1

- 239000004952 Polyamide Substances 0.000 description 1

- HCHKCACWOHOZIP-UHFFFAOYSA-N Zinc Chemical compound [Zn] HCHKCACWOHOZIP-UHFFFAOYSA-N 0.000 description 1

- 230000002378 acidificating effect Effects 0.000 description 1

- 230000009471 action Effects 0.000 description 1

- 239000011149 active material Substances 0.000 description 1

- 239000003513 alkali Substances 0.000 description 1

- 230000004888 barrier function Effects 0.000 description 1

- 230000001588 bifunctional effect Effects 0.000 description 1

- 239000011230 binding agent Substances 0.000 description 1

- 239000003990 capacitor Substances 0.000 description 1

- 239000003054 catalyst Substances 0.000 description 1

- 238000005229 chemical vapour deposition Methods 0.000 description 1

- 239000008199 coating composition Substances 0.000 description 1

- 239000002131 composite material Substances 0.000 description 1

- 238000002788 crimping Methods 0.000 description 1

- 238000000151 deposition Methods 0.000 description 1

- 230000008021 deposition Effects 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 150000002118 epoxides Chemical class 0.000 description 1

- 238000007306 functionalization reaction Methods 0.000 description 1

- 239000011521 glass Substances 0.000 description 1

- 230000007062 hydrolysis Effects 0.000 description 1

- 238000006460 hydrolysis reaction Methods 0.000 description 1

- 230000002209 hydrophobic effect Effects 0.000 description 1

- 239000003999 initiator Substances 0.000 description 1

- 230000000977 initiatory effect Effects 0.000 description 1

- 238000002347 injection Methods 0.000 description 1

- 239000007924 injection Substances 0.000 description 1

- 150000002500 ions Chemical class 0.000 description 1

- 239000007788 liquid Substances 0.000 description 1

- 229910052744 lithium Inorganic materials 0.000 description 1

- 239000007769 metal material Substances 0.000 description 1

- 238000005457 optimization Methods 0.000 description 1

- 239000000123 paper Substances 0.000 description 1

- 239000004033 plastic Substances 0.000 description 1

- 229920003023 plastic Polymers 0.000 description 1

- 229920000058 polyacrylate Polymers 0.000 description 1

- 229920002647 polyamide Polymers 0.000 description 1

- 229920000728 polyester Polymers 0.000 description 1

- 239000012704 polymeric precursor Substances 0.000 description 1

- 238000006116 polymerization reaction Methods 0.000 description 1

- 229920002635 polyurethane Polymers 0.000 description 1

- 239000004814 polyurethane Substances 0.000 description 1

- 239000011148 porous material Substances 0.000 description 1

- 229910052710 silicon Inorganic materials 0.000 description 1

- 239000010703 silicon Substances 0.000 description 1

- 239000002904 solvent Substances 0.000 description 1

- 230000000087 stabilizing effect Effects 0.000 description 1

- 229910001220 stainless steel Inorganic materials 0.000 description 1

- 239000010935 stainless steel Substances 0.000 description 1

- 239000007858 starting material Substances 0.000 description 1

- 239000002023 wood Substances 0.000 description 1

- 229910052725 zinc Inorganic materials 0.000 description 1

- 239000011701 zinc Substances 0.000 description 1

- 229910052726 zirconium Inorganic materials 0.000 description 1

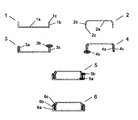

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M50/00—Constructional details or processes of manufacture of the non-active parts of electrochemical cells other than fuel cells, e.g. hybrid cells

- H01M50/10—Primary casings; Jackets or wrappings

- H01M50/147—Lids or covers

- H01M50/166—Lids or covers characterised by the methods of assembling casings with lids

- H01M50/171—Lids or covers characterised by the methods of assembling casings with lids using adhesives or sealing agents

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M50/00—Constructional details or processes of manufacture of the non-active parts of electrochemical cells other than fuel cells, e.g. hybrid cells

- H01M50/10—Primary casings; Jackets or wrappings

- H01M50/102—Primary casings; Jackets or wrappings characterised by their shape or physical structure

- H01M50/109—Primary casings; Jackets or wrappings characterised by their shape or physical structure of button or coin shape

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M50/00—Constructional details or processes of manufacture of the non-active parts of electrochemical cells other than fuel cells, e.g. hybrid cells

- H01M50/10—Primary casings; Jackets or wrappings

- H01M50/147—Lids or covers

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M50/00—Constructional details or processes of manufacture of the non-active parts of electrochemical cells other than fuel cells, e.g. hybrid cells

- H01M50/10—Primary casings; Jackets or wrappings

- H01M50/183—Sealing members

- H01M50/19—Sealing members characterised by the material

- H01M50/193—Organic material

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02E—REDUCTION OF GREENHOUSE GAS [GHG] EMISSIONS, RELATED TO ENERGY GENERATION, TRANSMISSION OR DISTRIBUTION

- Y02E60/00—Enabling technologies; Technologies with a potential or indirect contribution to GHG emissions mitigation

- Y02E60/10—Energy storage using batteries

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/49—Method of mechanical manufacture

- Y10T29/49002—Electrical device making

- Y10T29/49108—Electric battery cell making

- Y10T29/4911—Electric battery cell making including sealing

Landscapes

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Electrochemistry (AREA)

- General Chemical & Material Sciences (AREA)

- Sealing Battery Cases Or Jackets (AREA)

- Fuel Cell (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102008018172.2 | 2008-04-03 | ||

| DE102008018172A DE102008018172A1 (de) | 2008-04-03 | 2008-04-03 | Galvanische Zelle und Verfahren zu ihrer Herstellung |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| KR20110009097A true KR20110009097A (ko) | 2011-01-27 |

Family

ID=40652718

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1020107022124A Withdrawn KR20110009097A (ko) | 2008-04-03 | 2009-04-01 | 전기화학 전지 및 이를 제조하는 방법 |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US20110200871A1 (enExample) |

| EP (1) | EP2258010B1 (enExample) |

| JP (1) | JP5562936B2 (enExample) |

| KR (1) | KR20110009097A (enExample) |

| CN (1) | CN101983442A (enExample) |

| DE (1) | DE102008018172A1 (enExample) |

| WO (1) | WO2009121577A1 (enExample) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US10964924B2 (en) | 2018-03-30 | 2021-03-30 | Lg Chem, Ltd. | Packaging for flexible secondary battery and flexible secondary battery comprising the same |

| KR20220052511A (ko) | 2020-10-21 | 2022-04-28 | 울산과학대학교 산학협력단 | 반려묘 전용 장갑형 브러시 |

| US11664556B2 (en) | 2018-07-06 | 2023-05-30 | Lg Energy Solution, Ltd. | Secondary battery comprising a deformed gasket and method for manufacturing the same |

Families Citing this family (25)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US9153835B2 (en) | 2009-02-09 | 2015-10-06 | Varta Microbattery Gmbh | Button cells and method for producing same |

| DE102009017514A1 (de) | 2009-04-04 | 2010-10-07 | Varta Microbattery Gmbh | Knopfzelle ohne Bördelung |

| DE102009060800A1 (de) | 2009-06-18 | 2011-06-09 | Varta Microbattery Gmbh | Knopfzelle mit Wickelelektrode und Verfahren zu ihrer Herstellung |

| JP5550416B2 (ja) * | 2010-03-29 | 2014-07-16 | セイコーインスツル株式会社 | 端子付電気化学セルおよびその製造方法 |

| DE102010033577A1 (de) * | 2010-08-03 | 2012-02-09 | Varta Microbattery Gmbh | Knopfzelle mit Wickelelektrode mit thermischer Sicherung |

| EP2426750B1 (en) | 2010-09-07 | 2012-11-14 | swissbatt AG | Battery cell casing |

| US8747636B2 (en) * | 2011-03-11 | 2014-06-10 | Life Safety Distribution Ag | Low water vapour transfer coating of thermoplastic moulded oxygen gas sensors |

| AT512000B1 (de) * | 2011-09-15 | 2017-02-15 | Avl List Gmbh | Elektrischer energiespeicher |

| KR20140136831A (ko) * | 2013-05-21 | 2014-12-01 | 주식회사 엘지화학 | 파우치형 이차전지 및 이의 제조 방법 |

| WO2015108830A1 (en) * | 2014-01-14 | 2015-07-23 | Zpower, Llc | Polymer coatings for metal surfaces |

| DE102016222088A1 (de) * | 2016-11-10 | 2018-05-17 | Robert Bosch Gmbh | Fügeverfahren zur Herstellung einer Batterie sowie Batterie |

| US10553847B2 (en) * | 2017-07-24 | 2020-02-04 | Ford Global Technologies, Llc | Battery assembly having a shear cord and battery accessing method using the shear cord |

| CN207353301U (zh) * | 2017-10-25 | 2018-05-11 | 深圳市能锐创新科技有限公司 | 新型扣式锂离子电池 |

| CN107611312A (zh) * | 2017-10-25 | 2018-01-19 | 深圳市能锐创新科技有限公司 | 新型扣式锂离子电池 |

| EP3742515B1 (de) * | 2019-05-23 | 2024-12-18 | VARTA Microbattery GmbH | Herstellungsverfahren für knopfzellen und knopfzelle |

| CN110993838A (zh) * | 2019-12-31 | 2020-04-10 | 广东微电新能源有限公司 | 热封电池 |

| KR102322343B1 (ko) * | 2020-02-13 | 2021-11-09 | 한국과학기술연구원 | 전고상 박막 이차전지용 박막봉지 및 제조방법 |

| CN111162210A (zh) * | 2020-03-16 | 2020-05-15 | 惠州亿纬锂能股份有限公司 | 一种二次锂离子豆式电池及其制作方法 |

| CN111211259A (zh) * | 2020-03-16 | 2020-05-29 | 惠州亿纬锂能股份有限公司 | 一种豆式电池及其制作方法 |

| CN111180617A (zh) * | 2020-03-16 | 2020-05-19 | 惠州亿纬锂能股份有限公司 | 一种二次锂离子豆式电池及其制作方法 |

| CN111162211A (zh) * | 2020-03-16 | 2020-05-15 | 惠州亿纬锂能股份有限公司 | 一种豆式电池及其制作方法 |

| CN111211260A (zh) * | 2020-03-16 | 2020-05-29 | 惠州亿纬锂能股份有限公司 | 一种豆式电池及其制作方法 |

| CN111162209A (zh) * | 2020-03-16 | 2020-05-15 | 惠州亿纬锂能股份有限公司 | 一种二次锂离子豆式电池及其制作方法 |

| CN111834558B (zh) * | 2020-08-10 | 2024-05-07 | 惠州亿纬锂能股份有限公司 | 一种电子器件及其制作方法 |

| WO2024249476A2 (en) * | 2023-06-01 | 2024-12-05 | Wildcat Discovery Technologies, Inc. | Coin cell case |

Family Cites Families (31)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3713896A (en) * | 1970-08-19 | 1973-01-30 | Esb Inc | Seal for electrochemical cells |

| JPS5330742A (en) * | 1976-09-01 | 1978-03-23 | Suwa Seikosha Kk | Flat thin battery |

| JPS5341735A (en) * | 1976-09-28 | 1978-04-15 | Suwa Seikosha Kk | Panel battery |

| JPS5342335A (en) * | 1976-09-30 | 1978-04-17 | Suwa Seikosha Kk | Panel battery |

| JPS53121135A (en) * | 1977-03-30 | 1978-10-23 | Suwa Seikosha Kk | Thin flat type battery |

| US4225647B1 (en) * | 1977-12-02 | 1995-05-09 | Richard A Parent | Articles having thin, continuous, impervious coatings |

| JPS55111062A (en) * | 1979-02-20 | 1980-08-27 | Citizen Watch Co Ltd | Thin battery |

| US4248944A (en) * | 1979-12-21 | 1981-02-03 | Union Carbide Corporation | Seals for electrochemical cells |

| US4282293A (en) * | 1980-06-24 | 1981-08-04 | Union Carbide Corporation | Seals for electrochemical cells |

| DE3113309A1 (de) | 1981-04-02 | 1982-10-21 | Varta Batterie Ag, 3000 Hannover | Galvanisches element |

| JPS5878366A (ja) * | 1981-11-04 | 1983-05-11 | Fuji Elelctrochem Co Ltd | 密閉式アルカリ電池およびその製造方法 |

| JPS58164141A (ja) * | 1982-03-24 | 1983-09-29 | Citizen Watch Co Ltd | 小形薄形電池の製造方法 |

| US4503133A (en) | 1983-12-22 | 1985-03-05 | Union Carbide Corporation | Leak resistant galvanic cell and process for the production thereof |

| JPH03285257A (ja) * | 1990-03-30 | 1991-12-16 | Yuasa Corp | 薄型電池の製造法 |

| JPH04345749A (ja) * | 1991-05-22 | 1992-12-01 | Matsushita Electric Ind Co Ltd | モールド電池 |

| FR2693664B1 (fr) * | 1992-07-20 | 1994-09-02 | Ceramiques Tech Soc D | Dispositif à membrane pour filtration, séparation ou réaction catalytique. |

| JPH08153499A (ja) * | 1994-02-07 | 1996-06-11 | Seiko Instr Inc | アルカリ電池 |

| JP2651359B2 (ja) * | 1994-11-17 | 1997-09-10 | 工業技術院長 | 耐熱性ケイ素含有重合体の製造方法 |

| US5837398A (en) * | 1996-09-26 | 1998-11-17 | Three Bond Co., Ltd. | Radiation curable sealing material for batteries |

| DE19647593B4 (de) | 1996-11-18 | 2012-06-21 | Varta Microbattery Gmbh | Verfahren zur Herstellung einer Knopfzelle |

| JP3363910B2 (ja) * | 1997-03-19 | 2003-01-08 | 旭化成株式会社 | 非水系薄型電池 |

| DE10016324A1 (de) | 2000-03-31 | 2001-10-11 | Roehm Gmbh | Ormocere, Verfahren zu deren Herstellung sowie Verwendung |

| JP2003007270A (ja) * | 2001-06-21 | 2003-01-10 | Nok Corp | 電池用ガスケット |

| FR2831331B1 (fr) * | 2001-10-22 | 2004-11-19 | Commissariat Energie Atomique | Procede de fabrication d'une micro-batterie |

| JP2003346744A (ja) * | 2002-05-24 | 2003-12-05 | Matsushita Electric Ind Co Ltd | 扁平形電池の製造方法 |

| JP2006222018A (ja) * | 2005-02-14 | 2006-08-24 | Toyota Motor Corp | 2次電池 |

| US7553582B2 (en) * | 2005-09-06 | 2009-06-30 | Oak Ridge Micro-Energy, Inc. | Getters for thin film battery hermetic package |

| DE102005058132A1 (de) | 2005-11-30 | 2007-06-06 | Varta Microbattery Gmbh | Galvanisches Element mit neuartigem Gehäuse |

| EP1998847B1 (en) * | 2006-03-24 | 2013-02-13 | Medtronic, Inc. | Implantable medical device |

| JP2008059854A (ja) * | 2006-08-30 | 2008-03-13 | Tokai Rubber Ind Ltd | 色素増感型太陽電池の封止材用樹脂組成物およびそれを用いた色素増感型太陽電池用封止材 |

| DE102007018259A1 (de) | 2007-04-13 | 2008-10-16 | Varta Microbattery Gmbh | Knopfzelle mit beschichteter Außenseite |

-

2008

- 2008-04-03 DE DE102008018172A patent/DE102008018172A1/de not_active Withdrawn

-

2009

- 2009-04-01 JP JP2011502286A patent/JP5562936B2/ja active Active

- 2009-04-01 US US12/934,475 patent/US20110200871A1/en not_active Abandoned

- 2009-04-01 EP EP09728944A patent/EP2258010B1/de active Active

- 2009-04-01 CN CN200980112007XA patent/CN101983442A/zh active Pending

- 2009-04-01 WO PCT/EP2009/002364 patent/WO2009121577A1/de not_active Ceased

- 2009-04-01 KR KR1020107022124A patent/KR20110009097A/ko not_active Withdrawn

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US10964924B2 (en) | 2018-03-30 | 2021-03-30 | Lg Chem, Ltd. | Packaging for flexible secondary battery and flexible secondary battery comprising the same |

| US11664556B2 (en) | 2018-07-06 | 2023-05-30 | Lg Energy Solution, Ltd. | Secondary battery comprising a deformed gasket and method for manufacturing the same |

| KR20220052511A (ko) | 2020-10-21 | 2022-04-28 | 울산과학대학교 산학협력단 | 반려묘 전용 장갑형 브러시 |

Also Published As

| Publication number | Publication date |

|---|---|

| CN101983442A (zh) | 2011-03-02 |

| EP2258010A1 (de) | 2010-12-08 |

| JP2011517022A (ja) | 2011-05-26 |

| DE102008018172A1 (de) | 2009-10-08 |

| WO2009121577A1 (de) | 2009-10-08 |

| EP2258010B1 (de) | 2012-08-29 |

| US20110200871A1 (en) | 2011-08-18 |

| JP5562936B2 (ja) | 2014-07-30 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| KR20110009097A (ko) | 전기화학 전지 및 이를 제조하는 방법 | |

| CN100440583C (zh) | 电隔膜,其制备方法和用途 | |

| CN100454611C (zh) | 电隔片及其制备方法和在锂-高功率蓄电池中的应用 | |

| CN109792020B (zh) | 包括功能性粘合剂的电池隔板以及包括该电池隔板的电化学装置 | |

| CA2370490C (en) | Battery, tab of battery and method of manufacture thereof | |

| US20130143104A1 (en) | Button cell comprising a coated exterior | |

| JP5211460B2 (ja) | 電池用包装材料及びその製造方法 | |

| CN121076397A (zh) | 功能化的铅酸电池隔板、改进的铅酸电池及相关方法 | |

| KR20100097767A (ko) | 리튬 이온 배터리용 분리막-전극 유닛, 이의 제조방법 및 이를 포함하는 리튬 배터리 | |

| CN114128027B (zh) | 二次电池的电池壳体及制造袋型二次电池的方法 | |

| CN103081172A (zh) | 隔膜、其制造方法以及包含所述隔膜的电化学装置 | |

| JP2013084608A (ja) | 電池用包装材料 | |

| JP2007157412A (ja) | リチウムイオン電池タブ及びその製造方法並びにそれを用いたリチウムイオン電池 | |

| EP3528304B1 (en) | Secondary battery and method for manufacturing the same | |

| JP5168778B2 (ja) | 電池用外装体及びそれを用いた電池 | |

| WO2008038808A1 (fr) | Produit d'étanchéité pour des condensateurs électrolytiques et condensateur électrolytique utilisant ce produit d'étanchéité | |

| JP5088662B2 (ja) | 扁平型電気化学セル | |

| JP2009093799A (ja) | ガスケットとそれを用いた密閉構造体 | |

| US20230357578A1 (en) | Airtight film with ceramic sealing layer and polymer sealing layer | |

| KR101833913B1 (ko) | 알루미늄 파우치 필름 제조용 슬롯 다이 코터 | |

| KR102788555B1 (ko) | 기체발생제를 포함하는 분리막 및 이의 제조방법 | |

| EP4282907A1 (en) | Coating substrate by polymerization of amine compound, and apparatus having polymer coated substrate | |

| JP5333549B2 (ja) | ポリマー電池用包装材料及びその製造方法 | |

| US20240209231A1 (en) | Airtight film with ceramic sealing layer and polymer sealing layer | |

| US20250066570A1 (en) | Laminate device with metallic and polymer layers |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PA0105 | International application |

Patent event date: 20101004 Patent event code: PA01051R01D Comment text: International Patent Application |

|

| PG1501 | Laying open of application | ||

| PC1203 | Withdrawal of no request for examination | ||

| WITN | Application deemed withdrawn, e.g. because no request for examination was filed or no examination fee was paid |