KR20100087321A - 탄소 섬유 및 필름, 및 이들의 제조 방법 - Google Patents

탄소 섬유 및 필름, 및 이들의 제조 방법 Download PDFInfo

- Publication number

- KR20100087321A KR20100087321A KR1020107010388A KR20107010388A KR20100087321A KR 20100087321 A KR20100087321 A KR 20100087321A KR 1020107010388 A KR1020107010388 A KR 1020107010388A KR 20107010388 A KR20107010388 A KR 20107010388A KR 20100087321 A KR20100087321 A KR 20100087321A

- Authority

- KR

- South Korea

- Prior art keywords

- polymer

- film

- carbon

- graphite sheet

- component

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

- 238000000034 method Methods 0.000 title claims abstract description 217

- 239000004917 carbon fiber Substances 0.000 title claims abstract description 196

- 229920000049 Carbon (fiber) Polymers 0.000 title claims abstract description 195

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 claims abstract description 415

- 239000002041 carbon nanotube Substances 0.000 claims abstract description 200

- 229910021393 carbon nanotube Inorganic materials 0.000 claims abstract description 197

- 239000000835 fiber Substances 0.000 claims abstract description 196

- 239000010439 graphite Substances 0.000 claims abstract description 185

- 229910002804 graphite Inorganic materials 0.000 claims abstract description 185

- 229920000642 polymer Polymers 0.000 claims abstract description 92

- NLHHRLWOUZZQLW-UHFFFAOYSA-N Acrylonitrile Chemical compound C=CC#N NLHHRLWOUZZQLW-UHFFFAOYSA-N 0.000 claims abstract description 64

- VNWKTOKETHGBQD-UHFFFAOYSA-N methane Chemical compound C VNWKTOKETHGBQD-UHFFFAOYSA-N 0.000 claims description 89

- 229910052799 carbon Inorganic materials 0.000 claims description 83

- 238000001125 extrusion Methods 0.000 claims description 48

- 239000002243 precursor Substances 0.000 claims description 36

- 230000008569 process Effects 0.000 claims description 34

- 230000000087 stabilizing effect Effects 0.000 claims description 34

- 229920005594 polymer fiber Polymers 0.000 claims description 31

- 238000003763 carbonization Methods 0.000 claims description 30

- 238000005087 graphitization Methods 0.000 claims description 30

- 238000010438 heat treatment Methods 0.000 claims description 28

- 239000002071 nanotube Substances 0.000 claims description 28

- 230000006641 stabilisation Effects 0.000 claims description 27

- 238000011105 stabilization Methods 0.000 claims description 27

- 239000002238 carbon nanotube film Substances 0.000 claims description 25

- 238000010000 carbonizing Methods 0.000 claims description 24

- 238000000926 separation method Methods 0.000 claims description 20

- 238000004519 manufacturing process Methods 0.000 claims description 10

- 230000001590 oxidative effect Effects 0.000 claims description 8

- 239000002109 single walled nanotube Substances 0.000 claims description 7

- 230000003993 interaction Effects 0.000 claims description 6

- QJGQUHMNIGDVPM-UHFFFAOYSA-N nitrogen group Chemical group [N] QJGQUHMNIGDVPM-UHFFFAOYSA-N 0.000 claims description 6

- 239000002079 double walled nanotube Substances 0.000 claims description 5

- 239000002048 multi walled nanotube Substances 0.000 claims description 3

- 238000011284 combination treatment Methods 0.000 claims 5

- 239000002131 composite material Substances 0.000 abstract description 10

- 230000001976 improved effect Effects 0.000 abstract description 3

- 230000003287 optical effect Effects 0.000 abstract description 2

- 229920002239 polyacrylonitrile Polymers 0.000 description 74

- 239000000243 solution Substances 0.000 description 52

- ZMXDDKWLCZADIW-UHFFFAOYSA-N N,N-Dimethylformamide Chemical compound CN(C)C=O ZMXDDKWLCZADIW-UHFFFAOYSA-N 0.000 description 30

- 239000002904 solvent Substances 0.000 description 29

- 239000000203 mixture Substances 0.000 description 15

- OKKJLVBELUTLKV-UHFFFAOYSA-N Methanol Chemical compound OC OKKJLVBELUTLKV-UHFFFAOYSA-N 0.000 description 12

- 238000002156 mixing Methods 0.000 description 9

- 229920003229 poly(methyl methacrylate) Polymers 0.000 description 9

- 239000004926 polymethyl methacrylate Substances 0.000 description 9

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 8

- 238000002173 high-resolution transmission electron microscopy Methods 0.000 description 7

- 239000000463 material Substances 0.000 description 7

- 239000006185 dispersion Substances 0.000 description 6

- 238000002360 preparation method Methods 0.000 description 6

- 238000001237 Raman spectrum Methods 0.000 description 5

- 229920001577 copolymer Polymers 0.000 description 5

- 238000012545 processing Methods 0.000 description 5

- 239000000725 suspension Substances 0.000 description 5

- XKRFYHLGVUSROY-UHFFFAOYSA-N Argon Chemical compound [Ar] XKRFYHLGVUSROY-UHFFFAOYSA-N 0.000 description 4

- IAZDPXIOMUYVGZ-UHFFFAOYSA-N Dimethylsulphoxide Chemical compound CS(C)=O IAZDPXIOMUYVGZ-UHFFFAOYSA-N 0.000 description 4

- 238000009826 distribution Methods 0.000 description 4

- 230000006872 improvement Effects 0.000 description 4

- 239000012535 impurity Substances 0.000 description 4

- 239000000178 monomer Substances 0.000 description 4

- 229910052757 nitrogen Inorganic materials 0.000 description 4

- 201000006292 polyarteritis nodosa Diseases 0.000 description 4

- 239000000523 sample Substances 0.000 description 4

- WFDIJRYMOXRFFG-UHFFFAOYSA-N Acetic anhydride Chemical compound CC(=O)OC(C)=O WFDIJRYMOXRFFG-UHFFFAOYSA-N 0.000 description 3

- RENMDAKOXSCIGH-UHFFFAOYSA-N Chloroacetonitrile Chemical compound ClCC#N RENMDAKOXSCIGH-UHFFFAOYSA-N 0.000 description 3

- FXHOOIRPVKKKFG-UHFFFAOYSA-N N,N-Dimethylacetamide Chemical compound CN(C)C(C)=O FXHOOIRPVKKKFG-UHFFFAOYSA-N 0.000 description 3

- 125000002252 acyl group Chemical group 0.000 description 3

- 125000000217 alkyl group Chemical group 0.000 description 3

- 125000003710 aryl alkyl group Chemical group 0.000 description 3

- 125000003118 aryl group Chemical group 0.000 description 3

- 239000011203 carbon fibre reinforced carbon Substances 0.000 description 3

- 238000010586 diagram Methods 0.000 description 3

- 229940113088 dimethylacetamide Drugs 0.000 description 3

- 238000004299 exfoliation Methods 0.000 description 3

- 238000001891 gel spinning Methods 0.000 description 3

- 238000000265 homogenisation Methods 0.000 description 3

- 238000010348 incorporation Methods 0.000 description 3

- 229920006254 polymer film Polymers 0.000 description 3

- 238000000527 sonication Methods 0.000 description 3

- 238000009987 spinning Methods 0.000 description 3

- YEJRWHAVMIAJKC-UHFFFAOYSA-N 4-Butyrolactone Chemical compound O=C1CCCO1 YEJRWHAVMIAJKC-UHFFFAOYSA-N 0.000 description 2

- LFQSCWFLJHTTHZ-UHFFFAOYSA-N Ethanol Chemical compound CCO LFQSCWFLJHTTHZ-UHFFFAOYSA-N 0.000 description 2

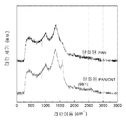

- 238000001069 Raman spectroscopy Methods 0.000 description 2

- 238000004458 analytical method Methods 0.000 description 2

- 229910052786 argon Inorganic materials 0.000 description 2

- 230000005540 biological transmission Effects 0.000 description 2

- 230000015572 biosynthetic process Effects 0.000 description 2

- 239000003054 catalyst Substances 0.000 description 2

- 230000003197 catalytic effect Effects 0.000 description 2

- 239000013078 crystal Substances 0.000 description 2

- MLIREBYILWEBDM-UHFFFAOYSA-N cyanoacetic acid Chemical compound OC(=O)CC#N MLIREBYILWEBDM-UHFFFAOYSA-N 0.000 description 2

- 229920006240 drawn fiber Polymers 0.000 description 2

- 230000000694 effects Effects 0.000 description 2

- 210000004177 elastic tissue Anatomy 0.000 description 2

- JBKVHLHDHHXQEQ-UHFFFAOYSA-N epsilon-caprolactam Chemical compound O=C1CCCCCN1 JBKVHLHDHHXQEQ-UHFFFAOYSA-N 0.000 description 2

- 238000009472 formulation Methods 0.000 description 2

- 125000000524 functional group Chemical group 0.000 description 2

- 229910052736 halogen Inorganic materials 0.000 description 2

- 150000002367 halogens Chemical class 0.000 description 2

- 229910052739 hydrogen Inorganic materials 0.000 description 2

- 125000002887 hydroxy group Chemical group [H]O* 0.000 description 2

- AMXOYNBUYSYVKV-UHFFFAOYSA-M lithium bromide Chemical compound [Li+].[Br-] AMXOYNBUYSYVKV-UHFFFAOYSA-M 0.000 description 2

- 238000010907 mechanical stirring Methods 0.000 description 2

- 238000002844 melting Methods 0.000 description 2

- 230000008018 melting Effects 0.000 description 2

- 229910052751 metal Inorganic materials 0.000 description 2

- 239000002184 metal Substances 0.000 description 2

- LYGJENNIWJXYER-UHFFFAOYSA-N nitromethane Chemical compound C[N+]([O-])=O LYGJENNIWJXYER-UHFFFAOYSA-N 0.000 description 2

- 238000006116 polymerization reaction Methods 0.000 description 2

- 125000002924 primary amino group Chemical group [H]N([H])* 0.000 description 2

- 238000000746 purification Methods 0.000 description 2

- 238000000197 pyrolysis Methods 0.000 description 2

- 238000011160 research Methods 0.000 description 2

- 239000007787 solid Substances 0.000 description 2

- 238000003756 stirring Methods 0.000 description 2

- IAHFWCOBPZCAEA-UHFFFAOYSA-N succinonitrile Chemical compound N#CCCC#N IAHFWCOBPZCAEA-UHFFFAOYSA-N 0.000 description 2

- HHVIBTZHLRERCL-UHFFFAOYSA-N sulfonyldimethane Chemical compound CS(C)(=O)=O HHVIBTZHLRERCL-UHFFFAOYSA-N 0.000 description 2

- 238000003786 synthesis reaction Methods 0.000 description 2

- 238000002411 thermogravimetry Methods 0.000 description 2

- 150000003573 thiols Chemical class 0.000 description 2

- 238000002525 ultrasonication Methods 0.000 description 2

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 2

- 238000002166 wet spinning Methods 0.000 description 2

- 238000004736 wide-angle X-ray diffraction Methods 0.000 description 2

- JIAARYAFYJHUJI-UHFFFAOYSA-L zinc dichloride Chemical compound [Cl-].[Cl-].[Zn+2] JIAARYAFYJHUJI-UHFFFAOYSA-L 0.000 description 2

- VPVXHAANQNHFSF-UHFFFAOYSA-N 1,4-dioxan-2-one Chemical compound O=C1COCCO1 VPVXHAANQNHFSF-UHFFFAOYSA-N 0.000 description 1

- DVVGIUUJYPYENY-UHFFFAOYSA-N 1-methylpyridin-2-one Chemical compound CN1C=CC=CC1=O DVVGIUUJYPYENY-UHFFFAOYSA-N 0.000 description 1

- DIZBQMTZXOUFTD-UHFFFAOYSA-N 2-(furan-2-yl)-3h-benzimidazole-5-carboxylic acid Chemical compound N1C2=CC(C(=O)O)=CC=C2N=C1C1=CC=CO1 DIZBQMTZXOUFTD-UHFFFAOYSA-N 0.000 description 1

- IZXIZTKNFFYFOF-UHFFFAOYSA-N 2-Oxazolidone Chemical compound O=C1NCCO1 IZXIZTKNFFYFOF-UHFFFAOYSA-N 0.000 description 1

- LCNFUJBFKYNDIL-UHFFFAOYSA-N 2-ethenylpyridine;prop-2-enenitrile Chemical compound C=CC#N.C=CC1=CC=CC=N1 LCNFUJBFKYNDIL-UHFFFAOYSA-N 0.000 description 1

- YHBMTHAEQRHTGJ-UHFFFAOYSA-N 2-methylidenebutanedioic acid;methyl prop-2-enoate;prop-2-enenitrile Chemical compound C=CC#N.COC(=O)C=C.OC(=O)CC(=C)C(O)=O YHBMTHAEQRHTGJ-UHFFFAOYSA-N 0.000 description 1

- SWUMLOXBPGDJOR-UHFFFAOYSA-N 2-methylidenebutanedioic acid;prop-2-enenitrile Chemical compound C=CC#N.OC(=O)CC(=C)C(O)=O SWUMLOXBPGDJOR-UHFFFAOYSA-N 0.000 description 1

- KFCDDRTYJQZGKK-UHFFFAOYSA-N 2-methylprop-2-enoic acid;prop-2-enenitrile Chemical compound C=CC#N.CC(=C)C(O)=O KFCDDRTYJQZGKK-UHFFFAOYSA-N 0.000 description 1

- KFTYFTKODBWKOU-UHFFFAOYSA-N 2-methylsulfonylethanol Chemical compound CS(=O)(=O)CCO KFTYFTKODBWKOU-UHFFFAOYSA-N 0.000 description 1

- BCGCCTGNWPKXJL-UHFFFAOYSA-N 3-(2-cyanoethoxy)propanenitrile Chemical compound N#CCCOCCC#N BCGCCTGNWPKXJL-UHFFFAOYSA-N 0.000 description 1

- BTJIUGUIPKRLHP-UHFFFAOYSA-N 4-nitrophenol Chemical compound OC1=CC=C([N+]([O-])=O)C=C1 BTJIUGUIPKRLHP-UHFFFAOYSA-N 0.000 description 1

- VOQWSNVAROVYCW-UHFFFAOYSA-N 5-(4-cyanobutylsulfonyl)pentanenitrile Chemical compound N#CCCCCS(=O)(=O)CCCCC#N VOQWSNVAROVYCW-UHFFFAOYSA-N 0.000 description 1

- 229920002972 Acrylic fiber Polymers 0.000 description 1

- ZOXJGFHDIHLPTG-UHFFFAOYSA-N Boron Chemical compound [B] ZOXJGFHDIHLPTG-UHFFFAOYSA-N 0.000 description 1

- CUTKVJUFVWFBQP-UHFFFAOYSA-N C(C(=C)C)(=O)O.C(C=C)#N.C(C=C)(=O)OC Chemical compound C(C(=C)C)(=O)O.C(C=C)#N.C(C=C)(=O)OC CUTKVJUFVWFBQP-UHFFFAOYSA-N 0.000 description 1

- UGFAIRIUMAVXCW-UHFFFAOYSA-N Carbon monoxide Chemical compound [O+]#[C-] UGFAIRIUMAVXCW-UHFFFAOYSA-N 0.000 description 1

- KKUKTXOBAWVSHC-UHFFFAOYSA-N Dimethylphosphate Chemical compound COP(O)(=O)OC KKUKTXOBAWVSHC-UHFFFAOYSA-N 0.000 description 1

- KMTRUDSVKNLOMY-UHFFFAOYSA-N Ethylene carbonate Chemical compound O=C1OCCO1 KMTRUDSVKNLOMY-UHFFFAOYSA-N 0.000 description 1

- UFHFLCQGNIYNRP-UHFFFAOYSA-N Hydrogen Chemical compound [H][H] UFHFLCQGNIYNRP-UHFFFAOYSA-N 0.000 description 1

- UWSDONTXWQOZFN-UHFFFAOYSA-N N-nitrosopiperidine Chemical compound O=NN1CCCCC1 UWSDONTXWQOZFN-UHFFFAOYSA-N 0.000 description 1

- GRYLNZFGIOXLOG-UHFFFAOYSA-N Nitric acid Chemical compound O[N+]([O-])=O GRYLNZFGIOXLOG-UHFFFAOYSA-N 0.000 description 1

- XOJVVFBFDXDTEG-UHFFFAOYSA-N Norphytane Natural products CC(C)CCCC(C)CCCC(C)CCCC(C)C XOJVVFBFDXDTEG-UHFFFAOYSA-N 0.000 description 1

- XUIMIQQOPSSXEZ-UHFFFAOYSA-N Silicon Chemical compound [Si] XUIMIQQOPSSXEZ-UHFFFAOYSA-N 0.000 description 1

- 229910000831 Steel Inorganic materials 0.000 description 1

- NINIDFKCEFEMDL-UHFFFAOYSA-N Sulfur Chemical compound [S] NINIDFKCEFEMDL-UHFFFAOYSA-N 0.000 description 1

- 239000002253 acid Substances 0.000 description 1

- 150000007513 acids Chemical class 0.000 description 1

- BTGRAWJCKBQKAO-UHFFFAOYSA-N adiponitrile Chemical compound N#CCCCCC#N BTGRAWJCKBQKAO-UHFFFAOYSA-N 0.000 description 1

- 230000002411 adverse Effects 0.000 description 1

- 238000004220 aggregation Methods 0.000 description 1

- 230000002776 aggregation Effects 0.000 description 1

- 238000013019 agitation Methods 0.000 description 1

- 150000001413 amino acids Chemical class 0.000 description 1

- 125000004103 aminoalkyl group Chemical group 0.000 description 1

- 229910003481 amorphous carbon Inorganic materials 0.000 description 1

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 1

- AIPVTTKYSPOWFO-UHFFFAOYSA-N azepane-1-carbaldehyde Chemical compound O=CN1CCCCCC1 AIPVTTKYSPOWFO-UHFFFAOYSA-N 0.000 description 1

- 230000008901 benefit Effects 0.000 description 1

- 238000009835 boiling Methods 0.000 description 1

- 229910052796 boron Inorganic materials 0.000 description 1

- 239000011449 brick Substances 0.000 description 1

- 239000003990 capacitor Substances 0.000 description 1

- 125000004432 carbon atom Chemical group C* 0.000 description 1

- 229910002091 carbon monoxide Inorganic materials 0.000 description 1

- 239000004568 cement Substances 0.000 description 1

- 230000002925 chemical effect Effects 0.000 description 1

- 238000007385 chemical modification Methods 0.000 description 1

- 238000006243 chemical reaction Methods 0.000 description 1

- GRFFKYTUNTWAGG-UHFFFAOYSA-N chloroethene;prop-2-enenitrile Chemical compound ClC=C.C=CC#N GRFFKYTUNTWAGG-UHFFFAOYSA-N 0.000 description 1

- 238000010924 continuous production Methods 0.000 description 1

- 238000005336 cracking Methods 0.000 description 1

- 238000002425 crystallisation Methods 0.000 description 1

- 230000008025 crystallization Effects 0.000 description 1

- 230000003247 decreasing effect Effects 0.000 description 1

- 238000001212 derivatisation Methods 0.000 description 1

- 238000001514 detection method Methods 0.000 description 1

- 238000004090 dissolution Methods 0.000 description 1

- 238000000578 dry spinning Methods 0.000 description 1

- 238000001035 drying Methods 0.000 description 1

- 238000001493 electron microscopy Methods 0.000 description 1

- 238000001523 electrospinning Methods 0.000 description 1

- DVWZQQXTOMQCCK-UHFFFAOYSA-N ethenyl acetate;prop-2-enenitrile Chemical compound C=CC#N.CC(=O)OC=C DVWZQQXTOMQCCK-UHFFFAOYSA-N 0.000 description 1

- 238000001704 evaporation Methods 0.000 description 1

- 230000008020 evaporation Effects 0.000 description 1

- 230000005284 excitation Effects 0.000 description 1

- 230000001747 exhibiting effect Effects 0.000 description 1

- 230000002349 favourable effect Effects 0.000 description 1

- 239000012634 fragment Substances 0.000 description 1

- 239000000446 fuel Substances 0.000 description 1

- 239000007789 gas Substances 0.000 description 1

- ZTOMUSMDRMJOTH-UHFFFAOYSA-N glutaronitrile Chemical compound N#CCCCC#N ZTOMUSMDRMJOTH-UHFFFAOYSA-N 0.000 description 1

- PCHJSUWPFVWCPO-UHFFFAOYSA-N gold Chemical compound [Au] PCHJSUWPFVWCPO-UHFFFAOYSA-N 0.000 description 1

- 239000010931 gold Substances 0.000 description 1

- 229910052737 gold Inorganic materials 0.000 description 1

- 238000000227 grinding Methods 0.000 description 1

- 230000009931 harmful effect Effects 0.000 description 1

- 230000036541 health Effects 0.000 description 1

- 239000001307 helium Substances 0.000 description 1

- 229910052734 helium Inorganic materials 0.000 description 1

- SWQJXJOGLNCZEY-UHFFFAOYSA-N helium atom Chemical compound [He] SWQJXJOGLNCZEY-UHFFFAOYSA-N 0.000 description 1

- 125000005842 heteroatom Chemical group 0.000 description 1

- 229920006253 high performance fiber Polymers 0.000 description 1

- 239000012456 homogeneous solution Substances 0.000 description 1

- 239000001257 hydrogen Substances 0.000 description 1

- 229910052738 indium Inorganic materials 0.000 description 1

- 230000001939 inductive effect Effects 0.000 description 1

- 229910001867 inorganic solvent Inorganic materials 0.000 description 1

- 239000003049 inorganic solvent Substances 0.000 description 1

- 239000010977 jade Substances 0.000 description 1

- CUONGYYJJVDODC-UHFFFAOYSA-N malononitrile Chemical compound N#CCC#N CUONGYYJJVDODC-UHFFFAOYSA-N 0.000 description 1

- 238000005259 measurement Methods 0.000 description 1

- 239000000155 melt Substances 0.000 description 1

- 238000002074 melt spinning Methods 0.000 description 1

- SMUVTFSHWISULV-UHFFFAOYSA-N methyl 2-methylprop-2-enoate;prop-2-enenitrile Chemical compound C=CC#N.COC(=O)C(C)=C SMUVTFSHWISULV-UHFFFAOYSA-N 0.000 description 1

- JFHJOMSTWVDDHW-UHFFFAOYSA-N methyl prop-2-enoate;prop-2-enenitrile Chemical compound C=CC#N.COC(=O)C=C JFHJOMSTWVDDHW-UHFFFAOYSA-N 0.000 description 1

- JWZXKXIUSSIAMR-UHFFFAOYSA-N methylene bis(thiocyanate) Chemical compound N#CSCSC#N JWZXKXIUSSIAMR-UHFFFAOYSA-N 0.000 description 1

- 238000000386 microscopy Methods 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 239000004570 mortar (masonry) Substances 0.000 description 1

- GNIARTJEBSBYFL-UHFFFAOYSA-N n-(2-cyanoethyl)-n-methylformamide Chemical compound O=CN(C)CCC#N GNIARTJEBSBYFL-UHFFFAOYSA-N 0.000 description 1

- 229910017604 nitric acid Inorganic materials 0.000 description 1

- 150000004767 nitrides Chemical class 0.000 description 1

- 239000003960 organic solvent Substances 0.000 description 1

- 239000001301 oxygen Substances 0.000 description 1

- 229910052760 oxygen Inorganic materials 0.000 description 1

- 239000002245 particle Substances 0.000 description 1

- 239000011049 pearl Substances 0.000 description 1

- SOUBRVXEOBMUKO-UHFFFAOYSA-N pentane-1,3,3,5-tetracarbonitrile Chemical compound N#CCCC(C#N)(C#N)CCC#N SOUBRVXEOBMUKO-UHFFFAOYSA-N 0.000 description 1

- 239000000843 powder Substances 0.000 description 1

- 102000004196 processed proteins & peptides Human genes 0.000 description 1

- 108090000765 processed proteins & peptides Proteins 0.000 description 1

- KUKFKAPJCRZILJ-UHFFFAOYSA-N prop-2-enenitrile;prop-2-enoic acid Chemical compound C=CC#N.OC(=O)C=C KUKFKAPJCRZILJ-UHFFFAOYSA-N 0.000 description 1

- RUOJZAUFBMNUDX-UHFFFAOYSA-N propylene carbonate Chemical compound CC1COC(=O)O1 RUOJZAUFBMNUDX-UHFFFAOYSA-N 0.000 description 1

- 239000010453 quartz Substances 0.000 description 1

- 230000009257 reactivity Effects 0.000 description 1

- 230000008707 rearrangement Effects 0.000 description 1

- 239000012779 reinforcing material Substances 0.000 description 1

- 230000029058 respiratory gaseous exchange Effects 0.000 description 1

- 239000012266 salt solution Substances 0.000 description 1

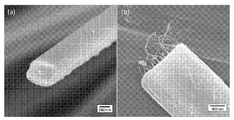

- 238000001878 scanning electron micrograph Methods 0.000 description 1

- 239000010703 silicon Substances 0.000 description 1

- 229910052710 silicon Inorganic materials 0.000 description 1

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N silicon dioxide Inorganic materials O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 description 1

- VGTPCRGMBIAPIM-UHFFFAOYSA-M sodium thiocyanate Chemical compound [Na+].[S-]C#N VGTPCRGMBIAPIM-UHFFFAOYSA-M 0.000 description 1

- 230000003381 solubilizing effect Effects 0.000 description 1

- 239000010959 steel Substances 0.000 description 1

- 238000003860 storage Methods 0.000 description 1

- 239000000126 substance Substances 0.000 description 1

- 238000006467 substitution reaction Methods 0.000 description 1

- 239000000758 substrate Substances 0.000 description 1

- 239000011593 sulfur Substances 0.000 description 1

- 229910052717 sulfur Inorganic materials 0.000 description 1

- QAOWNCQODCNURD-UHFFFAOYSA-N sulfuric acid Substances OS(O)(=O)=O QAOWNCQODCNURD-UHFFFAOYSA-N 0.000 description 1

- 230000002194 synthesizing effect Effects 0.000 description 1

- 238000009864 tensile test Methods 0.000 description 1

- 229920001897 terpolymer Polymers 0.000 description 1

- 238000012360 testing method Methods 0.000 description 1

- ISXOBTBCNRIIQO-UHFFFAOYSA-N tetrahydrothiophene 1-oxide Chemical compound O=S1CCCC1 ISXOBTBCNRIIQO-UHFFFAOYSA-N 0.000 description 1

- 239000004753 textile Substances 0.000 description 1

- 238000005292 vacuum distillation Methods 0.000 description 1

- 238000007740 vapor deposition Methods 0.000 description 1

- 235000005074 zinc chloride Nutrition 0.000 description 1

- 239000011592 zinc chloride Substances 0.000 description 1

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01B—CABLES; CONDUCTORS; INSULATORS; SELECTION OF MATERIALS FOR THEIR CONDUCTIVE, INSULATING OR DIELECTRIC PROPERTIES

- H01B1/00—Conductors or conductive bodies characterised by the conductive materials; Selection of materials as conductors

- H01B1/20—Conductive material dispersed in non-conductive organic material

- H01B1/24—Conductive material dispersed in non-conductive organic material the conductive material comprising carbon-silicon compounds, carbon or silicon

-

- D—TEXTILES; PAPER

- D01—NATURAL OR MAN-MADE THREADS OR FIBRES; SPINNING

- D01F—CHEMICAL FEATURES IN THE MANUFACTURE OF ARTIFICIAL FILAMENTS, THREADS, FIBRES, BRISTLES OR RIBBONS; APPARATUS SPECIALLY ADAPTED FOR THE MANUFACTURE OF CARBON FILAMENTS

- D01F1/00—General methods for the manufacture of artificial filaments or the like

- D01F1/02—Addition of substances to the spinning solution or to the melt

- D01F1/10—Other agents for modifying properties

-

- D—TEXTILES; PAPER

- D01—NATURAL OR MAN-MADE THREADS OR FIBRES; SPINNING

- D01F—CHEMICAL FEATURES IN THE MANUFACTURE OF ARTIFICIAL FILAMENTS, THREADS, FIBRES, BRISTLES OR RIBBONS; APPARATUS SPECIALLY ADAPTED FOR THE MANUFACTURE OF CARBON FILAMENTS

- D01F8/00—Conjugated, i.e. bi- or multicomponent, artificial filaments or the like; Manufacture thereof

- D01F8/04—Conjugated, i.e. bi- or multicomponent, artificial filaments or the like; Manufacture thereof from synthetic polymers

- D01F8/08—Conjugated, i.e. bi- or multicomponent, artificial filaments or the like; Manufacture thereof from synthetic polymers with at least one polyacrylonitrile as constituent

-

- D—TEXTILES; PAPER

- D01—NATURAL OR MAN-MADE THREADS OR FIBRES; SPINNING

- D01F—CHEMICAL FEATURES IN THE MANUFACTURE OF ARTIFICIAL FILAMENTS, THREADS, FIBRES, BRISTLES OR RIBBONS; APPARATUS SPECIALLY ADAPTED FOR THE MANUFACTURE OF CARBON FILAMENTS

- D01F9/00—Artificial filaments or the like of other substances; Manufacture thereof; Apparatus specially adapted for the manufacture of carbon filaments

- D01F9/08—Artificial filaments or the like of other substances; Manufacture thereof; Apparatus specially adapted for the manufacture of carbon filaments of inorganic material

- D01F9/12—Carbon filaments; Apparatus specially adapted for the manufacture thereof

- D01F9/14—Carbon filaments; Apparatus specially adapted for the manufacture thereof by decomposition of organic filaments

- D01F9/20—Carbon filaments; Apparatus specially adapted for the manufacture thereof by decomposition of organic filaments from polyaddition, polycondensation or polymerisation products

- D01F9/21—Carbon filaments; Apparatus specially adapted for the manufacture thereof by decomposition of organic filaments from polyaddition, polycondensation or polymerisation products from macromolecular compounds obtained by reactions only involving carbon-to-carbon unsaturated bonds

- D01F9/22—Carbon filaments; Apparatus specially adapted for the manufacture thereof by decomposition of organic filaments from polyaddition, polycondensation or polymerisation products from macromolecular compounds obtained by reactions only involving carbon-to-carbon unsaturated bonds from polyacrylonitriles

- D01F9/225—Carbon filaments; Apparatus specially adapted for the manufacture thereof by decomposition of organic filaments from polyaddition, polycondensation or polymerisation products from macromolecular compounds obtained by reactions only involving carbon-to-carbon unsaturated bonds from polyacrylonitriles from stabilised polyacrylonitriles

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/29—Coated or structually defined flake, particle, cell, strand, strand portion, rod, filament, macroscopic fiber or mass thereof

- Y10T428/2913—Rod, strand, filament or fiber

- Y10T428/2918—Rod, strand, filament or fiber including free carbon or carbide or therewith [not as steel]

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Chemical Kinetics & Catalysis (AREA)

- General Chemical & Material Sciences (AREA)

- Textile Engineering (AREA)

- Dispersion Chemistry (AREA)

- Physics & Mathematics (AREA)

- Spectroscopy & Molecular Physics (AREA)

- Manufacturing & Machinery (AREA)

- Inorganic Fibers (AREA)

- Carbon And Carbon Compounds (AREA)

- Artificial Filaments (AREA)

- Multicomponent Fibers (AREA)

- Spinning Methods And Devices For Manufacturing Artificial Fibers (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US97914607P | 2007-10-11 | 2007-10-11 | |

| US60/979,146 | 2007-10-11 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| KR20100087321A true KR20100087321A (ko) | 2010-08-04 |

Family

ID=40549598

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1020107010388A Withdrawn KR20100087321A (ko) | 2007-10-11 | 2008-10-10 | 탄소 섬유 및 필름, 및 이들의 제조 방법 |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US20100272978A1 (enExample) |

| EP (1) | EP2205364A4 (enExample) |

| JP (1) | JP2011500978A (enExample) |

| KR (1) | KR20100087321A (enExample) |

| CN (1) | CN101835542A (enExample) |

| WO (1) | WO2009049174A1 (enExample) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR101447078B1 (ko) * | 2013-10-22 | 2014-10-06 | 재단법인 한국탄소융합기술원 | 고 전기전도성 및 고강도 pan계 탄소섬유 및 그 pan 전구체를 제조하는 방법 |

| KR20170059995A (ko) * | 2014-09-18 | 2017-05-31 | 도레이 카부시키가이샤 | 입자상 다공질 탄소 재료, 입자상 탄소 재료 집합체 및 입자상 다공질 탄소 재료의 제조 방법 |

| US12173430B2 (en) | 2018-06-06 | 2024-12-24 | Cytec Industries Inc. | Process for producing carbon fibers and carbon fibers made therefrom |

Families Citing this family (33)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| ES2683744T3 (es) | 2005-07-28 | 2018-09-27 | Nanocomp Technologies, Inc. | Aparato y método para formación y recolección de hojas no tejidas nanofibrosas |

| WO2009137722A1 (en) | 2008-05-07 | 2009-11-12 | Nanocomp Technologies, Inc. | Carbon nanotube-based coaxial electrical cables and wiring harness |

| US8187700B2 (en) | 2008-11-12 | 2012-05-29 | The Boeing Company | Continuous, carbon-nanotube-reinforced polymer precursors and carbon fibers |

| FR2946176A1 (fr) * | 2009-05-27 | 2010-12-03 | Arkema France | Fibre conductrice multicouche et son procede d'obtention par co-extrusion. |

| CN101712452B (zh) * | 2009-11-20 | 2012-07-11 | 哈尔滨工程大学 | 纳米石墨片、碳纳米管和过渡金属氧化物复合材料及制法 |

| CN102087377B (zh) * | 2009-12-02 | 2013-12-11 | 鸿富锦精密工业(深圳)有限公司 | 偏振元件及其制作方法 |

| KR101272525B1 (ko) | 2011-11-30 | 2013-06-11 | 현대자동차주식회사 | 중공 탄소섬유의 제조방법 |

| KR101338200B1 (ko) | 2011-11-30 | 2013-12-06 | 현대자동차주식회사 | 초임계 유체를 이용한 중공 탄소섬유의 제조방법 |

| US9683310B2 (en) | 2011-12-10 | 2017-06-20 | The Boeing Company | Hollow fiber with gradient properties and method of making the same |

| US9683312B2 (en) * | 2011-12-10 | 2017-06-20 | The Boeing Company | Fiber with gradient properties and method of making the same |

| CN102586951B (zh) * | 2012-01-18 | 2013-08-07 | 浙江大学 | 一种基于石墨烯/聚丙烯腈复合碳纤维的制备方法 |

| US8735242B2 (en) * | 2012-07-31 | 2014-05-27 | International Business Machines Corporation | Graphene-based eFuse device |

| KR20140050540A (ko) * | 2012-10-19 | 2014-04-29 | 한국전자통신연구원 | 전계방출 에미터 전극 및 그 제조 방법 |

| US9718691B2 (en) | 2013-06-17 | 2017-08-01 | Nanocomp Technologies, Inc. | Exfoliating-dispersing agents for nanotubes, bundles and fibers |

| KR101625739B1 (ko) * | 2013-06-21 | 2016-06-13 | 코오롱인더스트리 주식회사 | 탄소섬유용 폴리아크릴로니트릴계 전구체 섬유 및 그 제조방법 |

| US9771669B2 (en) | 2013-11-08 | 2017-09-26 | Georgia Tech Research Corporation | Use, stabilization and carbonization of polyacrylonitrile/carbon composite fibers |

| JP6519485B2 (ja) * | 2013-12-27 | 2019-05-29 | 日本ゼオン株式会社 | カーボンナノチューブ、カーボンナノチューブ集合体およびカーボンナノチューブ集合体の製造方法 |

| KR101615338B1 (ko) * | 2014-04-17 | 2016-04-25 | 주식회사 포스코 | 탄소나노튜브 섬유 및 그 제조방법 |

| JP6497011B2 (ja) * | 2014-09-19 | 2019-04-10 | 東レ株式会社 | ポリアクリロニトリル系耐炎化繊維およびそれを用いたシート状物ならびにポリアクリロニトリル系耐炎化繊維の製造方法 |

| KR20170093792A (ko) | 2014-10-08 | 2017-08-16 | 조지아 테크 리서치 코오포레이션 | 고강도 및 고탄성 탄소 섬유 |

| WO2016086166A1 (en) * | 2014-11-26 | 2016-06-02 | Nanocomp Technologies, Inc. | Hierarchically structured carbon nanotube articles and methods for production thereof |

| KR20180063331A (ko) * | 2015-10-22 | 2018-06-11 | 코드사 테크닉 테크스틸 아노님 시르케티 | 바이어스 타이어용 카커스 보강재로서의 하이브리드 코드 |

| WO2017207036A1 (de) * | 2016-05-31 | 2017-12-07 | Taranis Gmbh | Verfahren zum herstellen eines nanokomposits, nanokomposit und dessen verwendung |

| CN106128608B (zh) * | 2016-08-24 | 2017-10-20 | 宁波华众和创工业设计有限公司 | 一种高强度柔性防火电缆及其制备方法 |

| CN106158121B (zh) * | 2016-08-24 | 2017-11-17 | 长乐智睿恒创节能科技有限责任公司 | 一种阻燃型柔性防火电缆及其制备方法 |

| CN106158147B (zh) * | 2016-08-24 | 2018-03-16 | 宁波华众和创工业设计有限公司 | 一种屏蔽型柔性防火电缆及其制备方法 |

| US10581082B2 (en) | 2016-11-15 | 2020-03-03 | Nanocomp Technologies, Inc. | Systems and methods for making structures defined by CNT pulp networks |

| DE102016015668A1 (de) * | 2016-12-23 | 2018-06-28 | Technische Universität Dresden | Vorrichtung und Verfahren zur Herstellung von Kohlenstofffasern oder von textilen Gebilden, die mit Kohlenstofffasern gebildet sind |

| US11279836B2 (en) | 2017-01-09 | 2022-03-22 | Nanocomp Technologies, Inc. | Intumescent nanostructured materials and methods of manufacturing same |

| US11180870B2 (en) * | 2018-08-17 | 2021-11-23 | Cence Inc. | Carbon nanofiber and method of manufacture |

| CN110013096B (zh) * | 2019-04-11 | 2020-06-05 | 碳翁(北京)科技有限公司 | 一种手持式热气流输出装置 |

| US20230304193A1 (en) * | 2021-12-02 | 2023-09-28 | Rahul Franklin | Dry-jet wet-spinning of multifunctional carbon fibers |

| CN116639682B (zh) * | 2023-05-11 | 2025-05-06 | 西安交通大学 | 一种多孔碳纤维-碳纳米管三维网络骨架薄膜及其制备方法 |

Family Cites Families (32)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5920004B2 (ja) * | 1977-03-23 | 1984-05-10 | 日本エクスラン工業株式会社 | 炭素繊維の製造方法 |

| US5269984A (en) * | 1987-02-20 | 1993-12-14 | Toray Industries, Inc. | Process of making graphite fiber |

| US5162074A (en) * | 1987-10-02 | 1992-11-10 | Basf Corporation | Method of making plural component fibers |

| EP0413688B1 (en) * | 1987-10-02 | 1994-06-22 | Basf Corporation | Method and apparatus for making profiled multi-component fibers |

| US5089135A (en) * | 1988-01-20 | 1992-02-18 | Mitsubishi Rayon Co., Ltd. | Carbon based porous hollow fiber membrane and method for producing same |

| JPH0345717A (ja) * | 1989-07-14 | 1991-02-27 | Mitsubishi Rayon Co Ltd | 耐炎化繊維及びその製法 |

| EP0463170B1 (en) * | 1990-01-17 | 1996-07-17 | Osaka Gas Co., Ltd. | Process for producing a carbon film |

| US5015522A (en) * | 1990-09-05 | 1991-05-14 | The Dow Chemical Company | Multicomponent fibers, films and foams |

| CA2107930C (en) * | 1992-10-29 | 2000-07-11 | John A. Hodan | Flow distribution plates |

| US5602644A (en) * | 1994-10-27 | 1997-02-11 | Nikon Corporation | Alignment apparatus utilizing a plurality of wavelengths |

| US6683783B1 (en) * | 1997-03-07 | 2004-01-27 | William Marsh Rice University | Carbon fibers formed from single-wall carbon nanotubes |

| AU3204399A (en) * | 1998-03-25 | 1999-10-18 | Hills, Inc. | Method and apparatus for extruding easily-splittable plural-component fibers forwoven and nonwoven fabrics |

| US6103181A (en) * | 1999-02-17 | 2000-08-15 | Filtrona International Limited | Method and apparatus for spinning a web of mixed fibers, and products produced therefrom |

| US6583075B1 (en) * | 1999-12-08 | 2003-06-24 | Fiber Innovation Technology, Inc. | Dissociable multicomponent fibers containing a polyacrylonitrile polymer component |

| US7223376B2 (en) * | 2000-02-10 | 2007-05-29 | Industrial Technology And Equipment Company | Apparatus and method for making carbon fibers |

| US6548429B2 (en) * | 2000-03-01 | 2003-04-15 | E. I. Du Pont De Nemours And Company | Bicomponent effect yarns and fabrics thereof |

| TW469312B (en) * | 2000-06-14 | 2001-12-21 | San Fang Chemical Industry Co | Microfiber substrate of improved carding ability and its manufacturing method |

| JP2002266170A (ja) * | 2000-12-20 | 2002-09-18 | Showa Denko Kk | 分岐状気相法炭素繊維、透明導電性組成物及びその用途 |

| US6852410B2 (en) * | 2002-07-01 | 2005-02-08 | Georgia Tech Research Corporation | Macroscopic fiber comprising single-wall carbon nanotubes and acrylonitrile-based polymer and process for making the same |

| JP2004043993A (ja) * | 2002-07-09 | 2004-02-12 | Mitsubishi Rayon Co Ltd | 炭素繊維前駆体繊維の製造方法、その炭素繊維前駆体繊維から得られる炭素繊維 |

| JP2004156194A (ja) * | 2002-10-15 | 2004-06-03 | Toray Ind Inc | カーボンナノファイバーの製造方法 |

| WO2005050757A2 (en) * | 2002-12-09 | 2005-06-02 | Rensselaer Polytechnic Institute | Nanotube-organic photoelectric conversion devices and methods of making same |

| US6911174B2 (en) * | 2002-12-30 | 2005-06-28 | Kimberly-Clark Worldwide, Inc. | Process of making multicomponent fiber incorporating thermoplastic and thermoset polymers |

| US7309522B2 (en) * | 2003-07-09 | 2007-12-18 | Advanced Design Concepts Gmbh | Fibers made from block copolymer |

| US7045211B2 (en) * | 2003-07-31 | 2006-05-16 | Kimberly-Clark Worldwide, Inc. | Crimped thermoplastic multicomponent fiber and fiber webs and method of making |

| US7150616B2 (en) * | 2003-12-22 | 2006-12-19 | Kimberly-Clark Worldwide, Inc | Die for producing meltblown multicomponent fibers and meltblown nonwoven fabrics |

| US20050228110A1 (en) * | 2003-12-24 | 2005-10-13 | Ko Frank K | Continuous organic and inorganic matrix composite fibrils and methods for their production from carbon nanotubes |

| EP1748091A4 (en) * | 2004-04-19 | 2012-11-28 | Nat Inst Of Advanced Ind Scien | CARBON FILM |

| US7238423B2 (en) * | 2004-12-20 | 2007-07-03 | Kimberly-Clark Worldwide, Inc. | Multicomponent fiber including elastic elements |

| JP4861693B2 (ja) * | 2004-12-21 | 2012-01-25 | 三菱レイヨン株式会社 | アクリル繊維、その製造方法および炭素繊維 |

| WO2006100783A1 (ja) * | 2005-03-24 | 2006-09-28 | Kuraray Co., Ltd. | 極細炭素繊維及びその製造方法 |

| WO2008112349A2 (en) * | 2007-01-30 | 2008-09-18 | Georgia Tech Research Corporation | Carbon fibers and films and methods of making same |

-

2008

- 2008-10-10 JP JP2010529090A patent/JP2011500978A/ja active Pending

- 2008-10-10 WO PCT/US2008/079536 patent/WO2009049174A1/en not_active Ceased

- 2008-10-10 US US12/682,588 patent/US20100272978A1/en not_active Abandoned

- 2008-10-10 CN CN200880111433A patent/CN101835542A/zh active Pending

- 2008-10-10 KR KR1020107010388A patent/KR20100087321A/ko not_active Withdrawn

- 2008-10-10 EP EP08837006A patent/EP2205364A4/en not_active Withdrawn

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR101447078B1 (ko) * | 2013-10-22 | 2014-10-06 | 재단법인 한국탄소융합기술원 | 고 전기전도성 및 고강도 pan계 탄소섬유 및 그 pan 전구체를 제조하는 방법 |

| KR20170059995A (ko) * | 2014-09-18 | 2017-05-31 | 도레이 카부시키가이샤 | 입자상 다공질 탄소 재료, 입자상 탄소 재료 집합체 및 입자상 다공질 탄소 재료의 제조 방법 |

| US12173430B2 (en) | 2018-06-06 | 2024-12-24 | Cytec Industries Inc. | Process for producing carbon fibers and carbon fibers made therefrom |

Also Published As

| Publication number | Publication date |

|---|---|

| EP2205364A1 (en) | 2010-07-14 |

| US20100272978A1 (en) | 2010-10-28 |

| CN101835542A (zh) | 2010-09-15 |

| JP2011500978A (ja) | 2011-01-06 |

| EP2205364A4 (en) | 2012-07-11 |

| WO2009049174A1 (en) | 2009-04-16 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| KR20100087321A (ko) | 탄소 섬유 및 필름, 및 이들의 제조 방법 | |

| US6852410B2 (en) | Macroscopic fiber comprising single-wall carbon nanotubes and acrylonitrile-based polymer and process for making the same | |

| US20100112322A1 (en) | Carbon fibers and films and methods of making same | |

| Zhou et al. | Development of carbon nanofibers from aligned electrospun polyacrylonitrile nanofiber bundles and characterization of their microstructural, electrical, and mechanical properties | |

| Datsyuk et al. | Thermal properties enhancement of epoxy resins by incorporating polybenzimidazole nanofibers filled with graphene and carbon nanotubes as reinforcing material | |

| Behabtu et al. | Carbon nanotube-based neat fibers | |

| JP5658567B2 (ja) | 超酸溶液から加工処理される整然と配列されたカーボンナノチューブ物品及びその製造方法 | |

| US11482348B2 (en) | Graphite oxide and polyacrylonitrile based composite | |

| US8927065B2 (en) | Process for producing continuous graphitic fibers from living graphene molecules | |

| Musiol et al. | Comparative study of the structure and microstructure of PAN-based nano-and micro-carbon fibers | |

| CN103827364A (zh) | 具有低电阻率、高模量和/或高热导率的碳纳米管纤维以及通过使用纤维纺丝原液纺丝而制备该纤维的方法 | |

| WO2004050764A1 (ja) | 全芳香族ポリアミドとカーボンナノチューブとからなるコンポジットファイバー | |

| Nain et al. | Zinc oxide nanorod assisted rapid single-step process for the conversion of electrospun poly (acrylonitrile) nanofibers to carbon nanofibers with a high graphitic content | |

| Jain et al. | Polyacrylonitrile/carbon nanofiber nanocomposite fibers | |

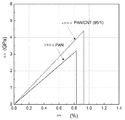

| Sui et al. | Desirable electrical and mechanical properties of continuous hybrid nano-scale carbon fibers containing highly aligned multi-walled carbon nanotubes | |

| US11959193B2 (en) | Method of manufacturing an aramid and carbon-nanotube composite fiber | |

| Le Lam | Electrospinning of single wall carbon nanotube reinforced aligned fibrils and yarns | |

| Sreekumar et al. | Oxidative stabilization of polyacrylonitrile in the presence of functionalized carbon nanotubes | |

| KR102576931B1 (ko) | 향상된 물성을 가지는 탄소나노튜브 섬유 및 그 제조방법 | |

| Lavin | Carbon fibres | |

| Kim et al. | Enhanced mechanical and electrical properties of single-walled carbon nanotube fibers via electric field-assisted wet spinning | |

| KR101398294B1 (ko) | 전기 방사를 이용한 탄소나노튜브 섬유의 제조방법 및 이를 이용한 유기 태양전지의 제조방법 | |

| HK1148243A (en) | Carbon fibers and films and methods of making same | |

| Newcomb | Gel spun PAN and PAN/CNT based carbon fibers: From viscoelastic solution to elastic fiber | |

| Chawla | Microstructure-Mechanical Property Relationships in Carbon Nanofibers |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PA0105 | International application |

Patent event date: 20100511 Patent event code: PA01051R01D Comment text: International Patent Application |

|

| PG1501 | Laying open of application | ||

| PC1203 | Withdrawal of no request for examination | ||

| WITN | Application deemed withdrawn, e.g. because no request for examination was filed or no examination fee was paid |