KR20080098632A - 고 열 전도율을 가진 반도체 웨이퍼 - Google Patents

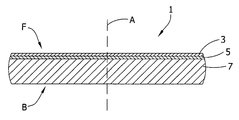

고 열 전도율을 가진 반도체 웨이퍼 Download PDFInfo

- Publication number

- KR20080098632A KR20080098632A KR1020087021333A KR20087021333A KR20080098632A KR 20080098632 A KR20080098632 A KR 20080098632A KR 1020087021333 A KR1020087021333 A KR 1020087021333A KR 20087021333 A KR20087021333 A KR 20087021333A KR 20080098632 A KR20080098632 A KR 20080098632A

- Authority

- KR

- South Korea

- Prior art keywords

- carriers

- substrate

- protective layer

- doped

- concentration

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

- 239000004065 semiconductor Substances 0.000 title claims abstract description 79

- 239000000758 substrate Substances 0.000 claims abstract description 124

- 239000010410 layer Substances 0.000 claims abstract description 92

- 239000011241 protective layer Substances 0.000 claims abstract description 88

- XUIMIQQOPSSXEZ-UHFFFAOYSA-N Silicon Chemical compound [Si] XUIMIQQOPSSXEZ-UHFFFAOYSA-N 0.000 claims abstract description 66

- 229910052710 silicon Inorganic materials 0.000 claims abstract description 59

- 239000010703 silicon Substances 0.000 claims abstract description 59

- 238000000034 method Methods 0.000 claims abstract description 53

- 230000008569 process Effects 0.000 claims abstract description 11

- 239000000969 carrier Substances 0.000 claims description 91

- 239000002019 doping agent Substances 0.000 claims description 67

- 239000000463 material Substances 0.000 claims description 21

- WGTYBPLFGIVFAS-UHFFFAOYSA-M tetramethylammonium hydroxide Chemical compound [OH-].C[N+](C)(C)C WGTYBPLFGIVFAS-UHFFFAOYSA-M 0.000 claims description 12

- 238000005530 etching Methods 0.000 claims description 11

- 238000004519 manufacturing process Methods 0.000 claims description 11

- HEMHJVSKTPXQMS-UHFFFAOYSA-M Sodium hydroxide Chemical compound [OH-].[Na+] HEMHJVSKTPXQMS-UHFFFAOYSA-M 0.000 claims description 9

- ZOXJGFHDIHLPTG-UHFFFAOYSA-N Boron Chemical compound [B] ZOXJGFHDIHLPTG-UHFFFAOYSA-N 0.000 claims description 8

- 229910052796 boron Inorganic materials 0.000 claims description 8

- QTBSBXVTEAMEQO-UHFFFAOYSA-N Acetic acid Chemical compound CC(O)=O QTBSBXVTEAMEQO-UHFFFAOYSA-N 0.000 claims description 6

- KRHYYFGTRYWZRS-UHFFFAOYSA-N Fluorane Chemical compound F KRHYYFGTRYWZRS-UHFFFAOYSA-N 0.000 claims description 4

- KWYUFKZDYYNOTN-UHFFFAOYSA-M Potassium hydroxide Chemical compound [OH-].[K+] KWYUFKZDYYNOTN-UHFFFAOYSA-M 0.000 claims description 4

- 230000002378 acidificating effect Effects 0.000 claims description 4

- GRYLNZFGIOXLOG-UHFFFAOYSA-N Nitric acid Chemical compound O[N+]([O-])=O GRYLNZFGIOXLOG-UHFFFAOYSA-N 0.000 claims description 2

- 150000001875 compounds Chemical class 0.000 claims description 2

- 229910017604 nitric acid Inorganic materials 0.000 claims description 2

- 239000002253 acid Substances 0.000 claims 1

- 150000002500 ions Chemical class 0.000 claims 1

- 230000007547 defect Effects 0.000 abstract description 6

- 230000007246 mechanism Effects 0.000 abstract description 5

- 238000012546 transfer Methods 0.000 abstract description 4

- 230000005855 radiation Effects 0.000 abstract description 3

- 235000012431 wafers Nutrition 0.000 description 82

- 238000010438 heat treatment Methods 0.000 description 9

- 125000004429 atom Chemical group 0.000 description 8

- 238000009792 diffusion process Methods 0.000 description 8

- 229910021421 monocrystalline silicon Inorganic materials 0.000 description 7

- 230000005684 electric field Effects 0.000 description 5

- 238000005516 engineering process Methods 0.000 description 5

- 229910052698 phosphorus Inorganic materials 0.000 description 5

- 239000002210 silicon-based material Substances 0.000 description 5

- 230000007704 transition Effects 0.000 description 5

- OAICVXFJPJFONN-UHFFFAOYSA-N Phosphorus Chemical compound [P] OAICVXFJPJFONN-UHFFFAOYSA-N 0.000 description 4

- 230000008901 benefit Effects 0.000 description 4

- 238000010586 diagram Methods 0.000 description 4

- 239000011574 phosphorus Substances 0.000 description 4

- 239000002800 charge carrier Substances 0.000 description 3

- 238000005229 chemical vapour deposition Methods 0.000 description 3

- 239000013078 crystal Substances 0.000 description 3

- 230000007423 decrease Effects 0.000 description 3

- 238000013461 design Methods 0.000 description 3

- 239000007789 gas Substances 0.000 description 3

- 230000017525 heat dissipation Effects 0.000 description 3

- 238000005468 ion implantation Methods 0.000 description 3

- 229910052751 metal Inorganic materials 0.000 description 3

- 239000002184 metal Substances 0.000 description 3

- 239000000126 substance Substances 0.000 description 3

- 239000010409 thin film Substances 0.000 description 3

- 239000012808 vapor phase Substances 0.000 description 3

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 2

- 238000007796 conventional method Methods 0.000 description 2

- 230000000694 effects Effects 0.000 description 2

- 239000010408 film Substances 0.000 description 2

- 230000006872 improvement Effects 0.000 description 2

- 238000005259 measurement Methods 0.000 description 2

- 238000004377 microelectronic Methods 0.000 description 2

- 229910052760 oxygen Inorganic materials 0.000 description 2

- 239000001301 oxygen Substances 0.000 description 2

- 230000000737 periodic effect Effects 0.000 description 2

- 238000005498 polishing Methods 0.000 description 2

- 230000001681 protective effect Effects 0.000 description 2

- 238000004088 simulation Methods 0.000 description 2

- 239000007858 starting material Substances 0.000 description 2

- 241000282461 Canis lupus Species 0.000 description 1

- 108091006149 Electron carriers Proteins 0.000 description 1

- GYHNNYVSQQEPJS-UHFFFAOYSA-N Gallium Chemical compound [Ga] GYHNNYVSQQEPJS-UHFFFAOYSA-N 0.000 description 1

- 229910052782 aluminium Inorganic materials 0.000 description 1

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 1

- 238000000137 annealing Methods 0.000 description 1

- 229910052787 antimony Inorganic materials 0.000 description 1

- WATWJIUSRGPENY-UHFFFAOYSA-N antimony atom Chemical compound [Sb] WATWJIUSRGPENY-UHFFFAOYSA-N 0.000 description 1

- 238000013459 approach Methods 0.000 description 1

- 238000000149 argon plasma sintering Methods 0.000 description 1

- 229910052785 arsenic Inorganic materials 0.000 description 1

- RQNWIZPPADIBDY-UHFFFAOYSA-N arsenic atom Chemical compound [As] RQNWIZPPADIBDY-UHFFFAOYSA-N 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 239000012159 carrier gas Substances 0.000 description 1

- 238000003486 chemical etching Methods 0.000 description 1

- 239000011248 coating agent Substances 0.000 description 1

- 238000000576 coating method Methods 0.000 description 1

- 230000007797 corrosion Effects 0.000 description 1

- 238000005260 corrosion Methods 0.000 description 1

- 238000002109 crystal growth method Methods 0.000 description 1

- 238000000354 decomposition reaction Methods 0.000 description 1

- 238000000151 deposition Methods 0.000 description 1

- 230000008021 deposition Effects 0.000 description 1

- 238000001978 electrochemical passivation Methods 0.000 description 1

- 238000007667 floating Methods 0.000 description 1

- 230000006870 function Effects 0.000 description 1

- 229910052733 gallium Inorganic materials 0.000 description 1

- 238000000227 grinding Methods 0.000 description 1

- 229910021478 group 5 element Inorganic materials 0.000 description 1

- 238000005286 illumination Methods 0.000 description 1

- 229910052738 indium Inorganic materials 0.000 description 1

- APFVFJFRJDLVQX-UHFFFAOYSA-N indium atom Chemical compound [In] APFVFJFRJDLVQX-UHFFFAOYSA-N 0.000 description 1

- 230000010354 integration Effects 0.000 description 1

- 150000002739 metals Chemical class 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 229910052757 nitrogen Inorganic materials 0.000 description 1

- 125000004430 oxygen atom Chemical group O* 0.000 description 1

- 239000005022 packaging material Substances 0.000 description 1

- 238000004806 packaging method and process Methods 0.000 description 1

- 230000003071 parasitic effect Effects 0.000 description 1

- 238000002161 passivation Methods 0.000 description 1

- 239000012071 phase Substances 0.000 description 1

- 230000000704 physical effect Effects 0.000 description 1

- 230000002265 prevention Effects 0.000 description 1

- 238000012545 processing Methods 0.000 description 1

- 230000009993 protective function Effects 0.000 description 1

- 238000000197 pyrolysis Methods 0.000 description 1

- 230000006798 recombination Effects 0.000 description 1

- 238000005215 recombination Methods 0.000 description 1

- 230000009467 reduction Effects 0.000 description 1

- 238000007493 shaping process Methods 0.000 description 1

- 150000003377 silicon compounds Chemical class 0.000 description 1

- 239000002356 single layer Substances 0.000 description 1

- 238000010561 standard procedure Methods 0.000 description 1

- 238000012876 topography Methods 0.000 description 1

- 230000001052 transient effect Effects 0.000 description 1

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/04—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer

- H01L21/18—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer the devices having semiconductor bodies comprising elements of Group IV of the Periodic Table or AIIIBV compounds with or without impurities, e.g. doping materials

- H01L21/30—Treatment of semiconductor bodies using processes or apparatus not provided for in groups H01L21/20 - H01L21/26

- H01L21/302—Treatment of semiconductor bodies using processes or apparatus not provided for in groups H01L21/20 - H01L21/26 to change their surface-physical characteristics or shape, e.g. etching, polishing, cutting

- H01L21/306—Chemical or electrical treatment, e.g. electrolytic etching

- H01L21/30604—Chemical etching

- H01L21/30608—Anisotropic liquid etching

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/04—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer

- H01L21/18—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer the devices having semiconductor bodies comprising elements of Group IV of the Periodic Table or AIIIBV compounds with or without impurities, e.g. doping materials

- H01L21/22—Diffusion of impurity materials, e.g. doping materials, electrode materials, into or out of a semiconductor body, or between semiconductor regions; Interactions between two or more impurities; Redistribution of impurities

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/02104—Forming layers

- H01L21/02365—Forming inorganic semiconducting materials on a substrate

- H01L21/02367—Substrates

- H01L21/0237—Materials

- H01L21/02373—Group 14 semiconducting materials

- H01L21/02381—Silicon, silicon germanium, germanium

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/02104—Forming layers

- H01L21/02365—Forming inorganic semiconducting materials on a substrate

- H01L21/02436—Intermediate layers between substrates and deposited layers

- H01L21/02439—Materials

- H01L21/02441—Group 14 semiconducting materials

- H01L21/0245—Silicon, silicon germanium, germanium

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/02104—Forming layers

- H01L21/02365—Forming inorganic semiconducting materials on a substrate

- H01L21/02518—Deposited layers

- H01L21/02521—Materials

- H01L21/02524—Group 14 semiconducting materials

- H01L21/02532—Silicon, silicon germanium, germanium

-

- H—ELECTRICITY

- H10—SEMICONDUCTOR DEVICES; ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10D—INORGANIC ELECTRIC SEMICONDUCTOR DEVICES

- H10D62/00—Semiconductor bodies, or regions thereof, of devices having potential barriers

-

- H—ELECTRICITY

- H10—SEMICONDUCTOR DEVICES; ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10D—INORGANIC ELECTRIC SEMICONDUCTOR DEVICES

- H10D62/00—Semiconductor bodies, or regions thereof, of devices having potential barriers

- H10D62/60—Impurity distributions or concentrations

-

- H—ELECTRICITY

- H10—SEMICONDUCTOR DEVICES; ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10F—INORGANIC SEMICONDUCTOR DEVICES SENSITIVE TO INFRARED RADIATION, LIGHT, ELECTROMAGNETIC RADIATION OF SHORTER WAVELENGTH OR CORPUSCULAR RADIATION

- H10F39/00—Integrated devices, or assemblies of multiple devices, comprising at least one element covered by group H10F30/00, e.g. radiation detectors comprising photodiode arrays

- H10F39/10—Integrated devices

- H10F39/12—Image sensors

- H10F39/199—Back-illuminated image sensors

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/04—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer

- H01L21/18—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer the devices having semiconductor bodies comprising elements of Group IV of the Periodic Table or AIIIBV compounds with or without impurities, e.g. doping materials

- H01L21/22—Diffusion of impurity materials, e.g. doping materials, electrode materials, into or out of a semiconductor body, or between semiconductor regions; Interactions between two or more impurities; Redistribution of impurities

- H01L21/225—Diffusion of impurity materials, e.g. doping materials, electrode materials, into or out of a semiconductor body, or between semiconductor regions; Interactions between two or more impurities; Redistribution of impurities using diffusion into or out of a solid from or into a solid phase, e.g. a doped oxide layer

- H01L21/2251—Diffusion into or out of group IV semiconductors

- H01L21/2252—Diffusion into or out of group IV semiconductors using predeposition of impurities into the semiconductor surface, e.g. from a gaseous phase

- H01L21/2253—Diffusion into or out of group IV semiconductors using predeposition of impurities into the semiconductor surface, e.g. from a gaseous phase by ion implantation

-

- H—ELECTRICITY

- H10—SEMICONDUCTOR DEVICES; ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10F—INORGANIC SEMICONDUCTOR DEVICES SENSITIVE TO INFRARED RADIATION, LIGHT, ELECTROMAGNETIC RADIATION OF SHORTER WAVELENGTH OR CORPUSCULAR RADIATION

- H10F39/00—Integrated devices, or assemblies of multiple devices, comprising at least one element covered by group H10F30/00, e.g. radiation detectors comprising photodiode arrays

- H10F39/80—Constructional details of image sensors

-

- H—ELECTRICITY

- H10—SEMICONDUCTOR DEVICES; ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10F—INORGANIC SEMICONDUCTOR DEVICES SENSITIVE TO INFRARED RADIATION, LIGHT, ELECTROMAGNETIC RADIATION OF SHORTER WAVELENGTH OR CORPUSCULAR RADIATION

- H10F77/00—Constructional details of devices covered by this subclass

- H10F77/10—Semiconductor bodies

- H10F77/14—Shape of semiconductor bodies; Shapes, relative sizes or dispositions of semiconductor regions within semiconductor bodies

- H10F77/148—Shapes of potential barriers

Landscapes

- Engineering & Computer Science (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Condensed Matter Physics & Semiconductors (AREA)

- General Physics & Mathematics (AREA)

- Manufacturing & Machinery (AREA)

- Computer Hardware Design (AREA)

- Physics & Mathematics (AREA)

- Power Engineering (AREA)

- Chemical & Material Sciences (AREA)

- Materials Engineering (AREA)

- Chemical Kinetics & Catalysis (AREA)

- General Chemical & Material Sciences (AREA)

- Recrystallisation Techniques (AREA)

- Crystals, And After-Treatments Of Crystals (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US76364306P | 2006-01-31 | 2006-01-31 | |

| US60/763,643 | 2006-01-31 |

Related Child Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1020127021211A Division KR20120106893A (ko) | 2006-01-31 | 2007-01-26 | 고 열 전도율을 가진 반도체 웨이퍼 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| KR20080098632A true KR20080098632A (ko) | 2008-11-11 |

Family

ID=38121741

Family Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1020087021333A Ceased KR20080098632A (ko) | 2006-01-31 | 2007-01-26 | 고 열 전도율을 가진 반도체 웨이퍼 |

| KR1020127021211A Ceased KR20120106893A (ko) | 2006-01-31 | 2007-01-26 | 고 열 전도율을 가진 반도체 웨이퍼 |

Family Applications After (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1020127021211A Ceased KR20120106893A (ko) | 2006-01-31 | 2007-01-26 | 고 열 전도율을 가진 반도체 웨이퍼 |

Country Status (8)

| Country | Link |

|---|---|

| US (3) | US20070176238A1 (enExample) |

| EP (3) | EP2637207A1 (enExample) |

| JP (1) | JP5261194B2 (enExample) |

| KR (2) | KR20080098632A (enExample) |

| CN (1) | CN101410977A (enExample) |

| MY (1) | MY153160A (enExample) |

| TW (1) | TWI429793B (enExample) |

| WO (1) | WO2007090055A1 (enExample) |

Families Citing this family (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20090050939A1 (en) * | 2007-07-17 | 2009-02-26 | Briere Michael A | Iii-nitride device |

| KR20100077363A (ko) * | 2008-12-29 | 2010-07-08 | 주식회사 동부하이텍 | 씨모스 이미지 센서의 제조 방법 |

| US7985658B2 (en) * | 2009-06-08 | 2011-07-26 | Aptina Imaging Corporation | Method of forming substrate for use in imager devices |

| EP2555244A1 (en) * | 2011-08-03 | 2013-02-06 | austriamicrosystems AG | A method of producing a photodiode device and a photodiode device comprising an etch stop layer |

| US8748315B2 (en) * | 2012-02-15 | 2014-06-10 | Taiwan Semiconductor Manufacturing Co., Ltd. | Condition before TMAH improved device performance |

| US8956938B2 (en) * | 2012-05-16 | 2015-02-17 | International Business Machines Corporation | Epitaxial semiconductor resistor with semiconductor structures on same substrate |

| US9111898B2 (en) * | 2013-02-19 | 2015-08-18 | Taiwan Semiconductor Manufacturing Company. Ltd. | Multiple layer substrate |

| CN104064688B (zh) * | 2014-07-11 | 2016-09-21 | 深圳市华星光电技术有限公司 | 具有存储电容的tft基板的制作方法及该tft基板 |

| CN112776003B (zh) * | 2019-11-07 | 2022-05-06 | 台达电子工业股份有限公司 | 散热装置及其适用的机器人 |

| CN112397570A (zh) * | 2020-11-17 | 2021-02-23 | 华虹半导体(无锡)有限公司 | 半导体基底结构及其制作方法 |

| EP4576168A1 (en) * | 2023-12-22 | 2025-06-25 | Nexperia B.V. | Suppression of auto-doping during epitaxial growth of epitaxy layer in a semiconductor device |

Family Cites Families (19)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4104090A (en) * | 1977-02-24 | 1978-08-01 | International Business Machines Corporation | Total dielectric isolation utilizing a combination of reactive ion etching, anodic etching, and thermal oxidation |

| US4247862B1 (en) * | 1977-08-26 | 1995-12-26 | Intel Corp | Ionzation resistant mos structure |

| US4506436A (en) * | 1981-12-21 | 1985-03-26 | International Business Machines Corporation | Method for increasing the radiation resistance of charge storage semiconductor devices |

| US4628591A (en) * | 1984-10-31 | 1986-12-16 | Texas Instruments Incorporated | Method for obtaining full oxide isolation of epitaxial islands in silicon utilizing selective oxidation of porous silicon |

| JPH0793282B2 (ja) * | 1985-04-15 | 1995-10-09 | 株式会社日立製作所 | 半導体装置の製造方法 |

| FR2638892B1 (fr) * | 1988-11-09 | 1992-12-24 | Sgs Thomson Microelectronics | Procede de modulation de la quantite d'or diffusee dans un substrat de silicium et diode rapide obtenue par ce procede |

| US5023200A (en) * | 1988-11-22 | 1991-06-11 | The United States Of America As Represented By The United States Department Of Energy | Formation of multiple levels of porous silicon for buried insulators and conductors in silicon device technologies |

| US5024723A (en) * | 1990-05-07 | 1991-06-18 | Goesele Ulrich M | Method of producing a thin silicon on insulator layer by wafer bonding and chemical thinning |

| JPH07187892A (ja) * | 1991-06-28 | 1995-07-25 | Internatl Business Mach Corp <Ibm> | シリコン及びその形成方法 |

| JPH06151303A (ja) * | 1992-11-11 | 1994-05-31 | Hitachi Ltd | 半導体ウエーハの形成方法 |

| US5880010A (en) * | 1994-07-12 | 1999-03-09 | Sun Microsystems, Inc. | Ultrathin electronics |

| US5668045A (en) * | 1994-11-30 | 1997-09-16 | Sibond, L.L.C. | Process for stripping outer edge of BESOI wafers |

| US5789309A (en) * | 1996-12-30 | 1998-08-04 | Memc Electronic Materials, Inc. | Method and system for monocrystalline epitaxial deposition |

| JPH10242153A (ja) * | 1997-02-26 | 1998-09-11 | Hitachi Ltd | 半導体ウエハ、半導体ウエハの製造方法、半導体装置および半導体装置の製造方法 |

| WO1998042010A1 (en) | 1997-03-17 | 1998-09-24 | Genus, Inc. | Bonded soi wafers using high energy implant |

| EP1148544A1 (de) | 2000-04-19 | 2001-10-24 | Infineon Technologies AG | Verfahren zum Dünnen eines Substrats |

| JP3785067B2 (ja) * | 2001-08-22 | 2006-06-14 | 株式会社東芝 | 半導体素子の製造方法 |

| JP4211696B2 (ja) | 2004-06-30 | 2009-01-21 | ソニー株式会社 | 固体撮像装置の製造方法 |

| DE102004039197B4 (de) * | 2004-08-12 | 2010-06-17 | Siltronic Ag | Verfahren zur Herstellung von dotierten Halbleiterscheiben aus Silizium |

-

2007

- 2007-01-26 JP JP2008553453A patent/JP5261194B2/ja active Active

- 2007-01-26 US US11/698,728 patent/US20070176238A1/en not_active Abandoned

- 2007-01-26 MY MYPI20082825A patent/MY153160A/en unknown

- 2007-01-26 EP EP13166824.6A patent/EP2637207A1/en not_active Withdrawn

- 2007-01-26 EP EP07762756A patent/EP1994562A1/en not_active Withdrawn

- 2007-01-26 KR KR1020087021333A patent/KR20080098632A/ko not_active Ceased

- 2007-01-26 KR KR1020127021211A patent/KR20120106893A/ko not_active Ceased

- 2007-01-26 CN CNA200780011360XA patent/CN101410977A/zh active Pending

- 2007-01-26 WO PCT/US2007/061128 patent/WO2007090055A1/en not_active Ceased

- 2007-01-26 EP EP13166827.9A patent/EP2637208A1/en not_active Withdrawn

- 2007-01-31 TW TW096103543A patent/TWI429793B/zh active

-

2009

- 2009-05-19 US US12/454,512 patent/US8080482B2/en active Active

-

2011

- 2011-09-02 US US13/199,587 patent/US8865601B2/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| WO2007090055A1 (en) | 2007-08-09 |

| JP2009525622A (ja) | 2009-07-09 |

| US20090233428A1 (en) | 2009-09-17 |

| US8080482B2 (en) | 2011-12-20 |

| TWI429793B (zh) | 2014-03-11 |

| EP2637208A1 (en) | 2013-09-11 |

| EP1994562A1 (en) | 2008-11-26 |

| US20070176238A1 (en) | 2007-08-02 |

| TW200801261A (en) | 2008-01-01 |

| US20110318912A1 (en) | 2011-12-29 |

| KR20120106893A (ko) | 2012-09-26 |

| JP5261194B2 (ja) | 2013-08-14 |

| US8865601B2 (en) | 2014-10-21 |

| EP2637207A1 (en) | 2013-09-11 |

| MY153160A (en) | 2015-01-29 |

| CN101410977A (zh) | 2009-04-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| TWI429793B (zh) | 具有高熱傳導性之半導體晶圓 | |

| US8815634B2 (en) | Dark currents and reducing defects in image sensors and photovoltaic junctions | |

| US8237126B2 (en) | X-ray imaging device and method for the manufacturing thereof | |

| Chilukuri et al. | Monolithic CMOS-compatible AlGaInP visible LED arrays on silicon on lattice-engineered substrates (SOLES) | |

| EP1102314A2 (en) | Method for manufacturing a SOI substrate | |

| US10141461B2 (en) | Textured multi-junction solar cell and fabrication method | |

| Zimin | Classification of electrical properties of porous silicon | |

| JPH11297976A (ja) | エピタキシャル半導体基板およびその製造方法ならびに半導体装置の製造方法ならびに固体撮像装置の製造方法 | |

| US20070290263A1 (en) | Semiconductor device and method for manufacturing the same | |

| KR101562696B1 (ko) | 배면측 조명되는 포토다이오드를 프로세싱하기 위한 시스템 및 방법 | |

| US8940580B2 (en) | Textured multi-junction solar cell and fabrication method | |

| US11967664B2 (en) | Photodiodes with serpentine shaped electrical junction | |

| Herrera et al. | Electrical and material characterization of sulfur-implanted GaSb | |

| US20250241075A1 (en) | Structure and formation method of semiconductor device with photosensing structure | |

| Zhou et al. | Comparison of silicon pin diode detector fabrication processes using ion implantation and thermal doping | |

| CN119815929A (zh) | 具有低电容的静电放电保护装置 | |

| US20230116053A1 (en) | Device integration using carrier wafer | |

| Chilukuri | Development of monolithic CMOS-compatible visible light emitting diode arrays on silicon | |

| Schippers | Dislocation engineered silicon Light Emitting Diode | |

| Kobayashi et al. | Assessment of radiation induced lattice defects in shallow trench isolation diodes irradiated by neutron | |

| KR20120074859A (ko) | 실리콘 기판의 제조방법 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PA0105 | International application |

Patent event date: 20080829 Patent event code: PA01051R01D Comment text: International Patent Application |

|

| PG1501 | Laying open of application | ||

| A201 | Request for examination | ||

| AMND | Amendment | ||

| PA0201 | Request for examination |

Patent event code: PA02012R01D Patent event date: 20100709 Comment text: Request for Examination of Application |

|

| E902 | Notification of reason for refusal | ||

| PE0902 | Notice of grounds for rejection |

Comment text: Notification of reason for refusal Patent event date: 20110929 Patent event code: PE09021S01D |

|

| AMND | Amendment | ||

| E601 | Decision to refuse application | ||

| PE0601 | Decision on rejection of patent |

Patent event date: 20120410 Comment text: Decision to Refuse Application Patent event code: PE06012S01D Patent event date: 20110929 Comment text: Notification of reason for refusal Patent event code: PE06011S01I |

|

| J201 | Request for trial against refusal decision | ||

| PJ0201 | Trial against decision of rejection |

Patent event date: 20120712 Comment text: Request for Trial against Decision on Refusal Patent event code: PJ02012R01D Patent event date: 20120410 Comment text: Decision to Refuse Application Patent event code: PJ02011S01I Appeal kind category: Appeal against decision to decline refusal Decision date: 20131129 Appeal identifier: 2012101006577 Request date: 20120712 |

|

| A107 | Divisional application of patent | ||

| AMND | Amendment | ||

| PA0104 | Divisional application for international application |

Comment text: Divisional Application for International Patent Patent event code: PA01041R01D Patent event date: 20120813 |

|

| PB0901 | Examination by re-examination before a trial |

Comment text: Amendment to Specification, etc. Patent event date: 20120813 Patent event code: PB09011R02I Comment text: Request for Trial against Decision on Refusal Patent event date: 20120712 Patent event code: PB09011R01I Comment text: Amendment to Specification, etc. Patent event date: 20111129 Patent event code: PB09011R02I Comment text: Amendment to Specification, etc. Patent event date: 20100709 Patent event code: PB09011R02I |

|

| B601 | Maintenance of original decision after re-examination before a trial | ||

| PB0601 | Maintenance of original decision after re-examination before a trial |

Comment text: Report of Result of Re-examination before a Trial Patent event code: PB06011S01D Patent event date: 20120903 |

|

| J301 | Trial decision |

Free format text: TRIAL DECISION FOR APPEAL AGAINST DECISION TO DECLINE REFUSAL REQUESTED 20120712 Effective date: 20131129 |

|

| PJ1301 | Trial decision |

Patent event code: PJ13011S01D Patent event date: 20131129 Comment text: Trial Decision on Objection to Decision on Refusal Appeal kind category: Appeal against decision to decline refusal Request date: 20120712 Decision date: 20131129 Appeal identifier: 2012101006577 |