JP7621617B2 - 成膜装置と半導体装置の製造方法 - Google Patents

成膜装置と半導体装置の製造方法 Download PDFInfo

- Publication number

- JP7621617B2 JP7621617B2 JP2021132611A JP2021132611A JP7621617B2 JP 7621617 B2 JP7621617 B2 JP 7621617B2 JP 2021132611 A JP2021132611 A JP 2021132611A JP 2021132611 A JP2021132611 A JP 2021132611A JP 7621617 B2 JP7621617 B2 JP 7621617B2

- Authority

- JP

- Japan

- Prior art keywords

- superheated steam

- mist

- substrate

- film

- solution

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C16/00—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes

- C23C16/22—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the deposition of inorganic material, other than metallic material

- C23C16/30—Deposition of compounds, mixtures or solid solutions, e.g. borides, carbides, nitrides

- C23C16/40—Oxides

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C16/00—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes

- C23C16/44—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating

- C23C16/448—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating characterised by the method used for generating reactive gas streams, e.g. by evaporation or sublimation of precursor materials

- C23C16/4486—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating characterised by the method used for generating reactive gas streams, e.g. by evaporation or sublimation of precursor materials by producing an aerosol and subsequent evaporation of the droplets or particles

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C16/00—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes

- C23C16/44—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating

- C23C16/455—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating characterised by the method used for introducing gases into reaction chamber or for modifying gas flows in reaction chamber

- C23C16/45561—Gas plumbing upstream of the reaction chamber

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C16/00—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes

- C23C16/44—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating

- C23C16/46—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating characterised by the method used for heating the substrate

-

- C—CHEMISTRY; METALLURGY

- C30—CRYSTAL GROWTH

- C30B—SINGLE-CRYSTAL GROWTH; UNIDIRECTIONAL SOLIDIFICATION OF EUTECTIC MATERIAL OR UNIDIRECTIONAL DEMIXING OF EUTECTOID MATERIAL; REFINING BY ZONE-MELTING OF MATERIAL; PRODUCTION OF A HOMOGENEOUS POLYCRYSTALLINE MATERIAL WITH DEFINED STRUCTURE; SINGLE CRYSTALS OR HOMOGENEOUS POLYCRYSTALLINE MATERIAL WITH DEFINED STRUCTURE; AFTER-TREATMENT OF SINGLE CRYSTALS OR A HOMOGENEOUS POLYCRYSTALLINE MATERIAL WITH DEFINED STRUCTURE; APPARATUS THEREFOR

- C30B25/00—Single-crystal growth by chemical reaction of reactive gases, e.g. chemical vapour-deposition growth

- C30B25/02—Epitaxial-layer growth

- C30B25/10—Heating of the reaction chamber or the substrate

-

- C—CHEMISTRY; METALLURGY

- C30—CRYSTAL GROWTH

- C30B—SINGLE-CRYSTAL GROWTH; UNIDIRECTIONAL SOLIDIFICATION OF EUTECTIC MATERIAL OR UNIDIRECTIONAL DEMIXING OF EUTECTOID MATERIAL; REFINING BY ZONE-MELTING OF MATERIAL; PRODUCTION OF A HOMOGENEOUS POLYCRYSTALLINE MATERIAL WITH DEFINED STRUCTURE; SINGLE CRYSTALS OR HOMOGENEOUS POLYCRYSTALLINE MATERIAL WITH DEFINED STRUCTURE; AFTER-TREATMENT OF SINGLE CRYSTALS OR A HOMOGENEOUS POLYCRYSTALLINE MATERIAL WITH DEFINED STRUCTURE; APPARATUS THEREFOR

- C30B25/00—Single-crystal growth by chemical reaction of reactive gases, e.g. chemical vapour-deposition growth

- C30B25/02—Epitaxial-layer growth

- C30B25/14—Feed and outlet means for the gases; Modifying the flow of the reactive gases

-

- C—CHEMISTRY; METALLURGY

- C30—CRYSTAL GROWTH

- C30B—SINGLE-CRYSTAL GROWTH; UNIDIRECTIONAL SOLIDIFICATION OF EUTECTIC MATERIAL OR UNIDIRECTIONAL DEMIXING OF EUTECTOID MATERIAL; REFINING BY ZONE-MELTING OF MATERIAL; PRODUCTION OF A HOMOGENEOUS POLYCRYSTALLINE MATERIAL WITH DEFINED STRUCTURE; SINGLE CRYSTALS OR HOMOGENEOUS POLYCRYSTALLINE MATERIAL WITH DEFINED STRUCTURE; AFTER-TREATMENT OF SINGLE CRYSTALS OR A HOMOGENEOUS POLYCRYSTALLINE MATERIAL WITH DEFINED STRUCTURE; APPARATUS THEREFOR

- C30B25/00—Single-crystal growth by chemical reaction of reactive gases, e.g. chemical vapour-deposition growth

- C30B25/02—Epitaxial-layer growth

- C30B25/18—Epitaxial-layer growth characterised by the substrate

- C30B25/20—Epitaxial-layer growth characterised by the substrate the substrate being of the same materials as the epitaxial layer

-

- C—CHEMISTRY; METALLURGY

- C30—CRYSTAL GROWTH

- C30B—SINGLE-CRYSTAL GROWTH; UNIDIRECTIONAL SOLIDIFICATION OF EUTECTIC MATERIAL OR UNIDIRECTIONAL DEMIXING OF EUTECTOID MATERIAL; REFINING BY ZONE-MELTING OF MATERIAL; PRODUCTION OF A HOMOGENEOUS POLYCRYSTALLINE MATERIAL WITH DEFINED STRUCTURE; SINGLE CRYSTALS OR HOMOGENEOUS POLYCRYSTALLINE MATERIAL WITH DEFINED STRUCTURE; AFTER-TREATMENT OF SINGLE CRYSTALS OR A HOMOGENEOUS POLYCRYSTALLINE MATERIAL WITH DEFINED STRUCTURE; APPARATUS THEREFOR

- C30B29/00—Single crystals or homogeneous polycrystalline material with defined structure characterised by the material or by their shape

- C30B29/10—Inorganic compounds or compositions

- C30B29/16—Oxides

-

- C—CHEMISTRY; METALLURGY

- C30—CRYSTAL GROWTH

- C30B—SINGLE-CRYSTAL GROWTH; UNIDIRECTIONAL SOLIDIFICATION OF EUTECTIC MATERIAL OR UNIDIRECTIONAL DEMIXING OF EUTECTOID MATERIAL; REFINING BY ZONE-MELTING OF MATERIAL; PRODUCTION OF A HOMOGENEOUS POLYCRYSTALLINE MATERIAL WITH DEFINED STRUCTURE; SINGLE CRYSTALS OR HOMOGENEOUS POLYCRYSTALLINE MATERIAL WITH DEFINED STRUCTURE; AFTER-TREATMENT OF SINGLE CRYSTALS OR A HOMOGENEOUS POLYCRYSTALLINE MATERIAL WITH DEFINED STRUCTURE; APPARATUS THEREFOR

- C30B35/00—Apparatus not otherwise provided for, specially adapted for the growth, production or after-treatment of single crystals or of a homogeneous polycrystalline material with defined structure

-

- H10P14/20—

-

- H10P14/24—

-

- H10P14/265—

-

- H10P14/2918—

-

- H10P14/3434—

-

- H10P14/3444—

-

- H10P14/3458—

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Materials Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- General Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Crystallography & Structural Chemistry (AREA)

- Mechanical Engineering (AREA)

- Inorganic Chemistry (AREA)

- Dispersion Chemistry (AREA)

- Manufacturing & Machinery (AREA)

- Condensed Matter Physics & Semiconductors (AREA)

- General Physics & Mathematics (AREA)

- Physics & Mathematics (AREA)

- Computer Hardware Design (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Power Engineering (AREA)

- Crystals, And After-Treatments Of Crystals (AREA)

- Chemical Vapour Deposition (AREA)

- Physical Deposition Of Substances That Are Components Of Semiconductor Devices (AREA)

Description

Claims (6)

- 成膜装置であって、

基板(12)を載置するステージ(16)と、

前記基板を加熱するヒータ(14)と、

H 2 Oに膜材料が溶解した溶液(21)のミスト(72)を供給するミスト供給源(20)と、

過熱水蒸気(43)を供給する過熱水蒸気供給源(80)と、

前記ミストと前記過熱水蒸気を前記基板の表面に向かって送出する送出装置、

を有し、

前記基板の前記表面に前記膜材料を含む膜を成長させ、

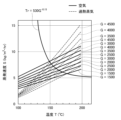

前記ミストと前記過熱水蒸気の合流位置における前記過熱水蒸気の質量速度G(kg/(m 2 ・hr))と、前記合流位置における前記過熱水蒸気の温度T(℃)が、

T<530G -0.15

の関係を満たす、成膜装置。 - 成膜装置であって、

基板(12)を載置するステージ(16)と、

前記基板を加熱するヒータ(14)と、

H 2 Oに膜材料が溶解した溶液(21)のミスト(72)を供給するミスト供給源(20)と、

過熱水蒸気(43)を供給する過熱水蒸気供給源(80)と、

前記ミストと前記過熱水蒸気を前記基板の表面に向かって送出する送出装置、

を有し、

前記基板の前記表面に前記膜材料を含む膜を成長させ、

前記過熱水蒸気が流れる流路内の気圧が大気圧未満であり、

前記過熱水蒸気の温度が100℃未満である、

成膜装置。 - 成膜装置であって、

基板(12)を載置するステージ(16)と、

前記基板を加熱するヒータ(14)と、

溶媒に膜材料が溶解した溶液(21)のミスト(72)を供給するミスト供給源(20)と、

前記溶媒と同じ材料の過熱蒸気(43)を供給する過熱蒸気供給源(80)と、

前記ミストと前記過熱蒸気を前記基板の表面に向かって送出する送出装置、

を有し、

前記基板の前記表面に前記膜材料を含む膜を成長させ、

前記過熱蒸気供給源が、前記溶媒と同じ材料によって構成された液体材料を前記液体材料の沸点よりも低い第1温度まで加熱し、その後、前記液体材料を減圧することによって前記液体材料の前記沸点を前記第1温度よりも低い温度まで低下させることによって前記過熱蒸気を発生させる、

成膜装置。 - 成膜装置を用いて半導体装置を製造する製造方法であって、

前記成膜装置が、

基板を載置するステージと、

前記基板を加熱するヒータと、

H 2 Oに膜材料が溶解した溶液のミストを供給するミスト供給源と、

過熱水蒸気を供給する過熱水蒸気供給源と、

前記ミストと前記過熱水蒸気を送出する送出装置、

を有し、

前記送出装置から前記基板の表面に向かって前記ミストと前記過熱水蒸気を送出することによって、前記基板の前記表面に前記膜材料を含む膜を成長させる工程、を有し、

前記ミストと前記過熱水蒸気の合流位置における前記過熱水蒸気の質量速度G(kg/(m 2 ・hr))と、前記合流位置における前記過熱水蒸気の温度T(℃)が、

T<530G -0.15

の関係を満たす、

製造方法。 - 成膜装置を用いて半導体装置を製造する製造方法であって、

前記成膜装置が、

基板を載置するステージと、

前記基板を加熱するヒータと、

H 2 Oに膜材料が溶解した溶液のミストを供給するミスト供給源と、

過熱水蒸気を供給する過熱水蒸気供給源と、

前記ミストと前記過熱水蒸気を送出する送出装置、

を有し、

前記送出装置から前記基板の表面に向かって前記ミストと前記過熱水蒸気を送出することによって、前記基板の前記表面に前記膜材料を含む膜を成長させる工程、を有し、

前記過熱水蒸気が流れる流路内の気圧が大気圧未満であり、

前記過熱水蒸気の温度が100℃未満である、

製造方法。 - 成膜装置を用いて半導体装置を製造する製造方法であって、

前記成膜装置が、

基板を載置するステージと、

前記基板を加熱するヒータと、

溶媒に膜材料が溶解した溶液のミストを供給するミスト供給源と、

前記溶媒と同じ材料の過熱蒸気を供給する過熱蒸気供給源と、

前記ミストと前記過熱蒸気を送出する送出装置、

を有し、

前記送出装置から前記基板の表面に向かって前記ミストと前記過熱蒸気を送出することによって、前記基板の前記表面に前記膜材料を含む膜を成長させる工程、を有し、

前記過熱蒸気供給源が、前記溶媒と同じ材料によって構成された液体材料を前記液体材料の沸点よりも低い第1温度まで加熱し、その後、前記液体材料を減圧することによって前記液体材料の前記沸点を前記第1温度よりも低い温度まで低下させることによって前記過熱蒸気を発生させる、

製造方法。

Priority Applications (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2021132611A JP7621617B2 (ja) | 2021-08-17 | 2021-08-17 | 成膜装置と半導体装置の製造方法 |

| US17/886,986 US20230059168A1 (en) | 2021-08-17 | 2022-08-12 | Film formation apparatus and method for manufacturing semiconductor device |

| CN202210973812.9A CN115704094A (zh) | 2021-08-17 | 2022-08-15 | 成膜设备和用于制造半导体器件的方法 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2021132611A JP7621617B2 (ja) | 2021-08-17 | 2021-08-17 | 成膜装置と半導体装置の製造方法 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2023027494A JP2023027494A (ja) | 2023-03-02 |

| JP7621617B2 true JP7621617B2 (ja) | 2025-01-27 |

Family

ID=85181549

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2021132611A Active JP7621617B2 (ja) | 2021-08-17 | 2021-08-17 | 成膜装置と半導体装置の製造方法 |

Country Status (3)

| Country | Link |

|---|---|

| US (1) | US20230059168A1 (ja) |

| JP (1) | JP7621617B2 (ja) |

| CN (1) | CN115704094A (ja) |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2011023596A (ja) | 2009-07-16 | 2011-02-03 | Doshisha | 原子層成長法を用いた成膜方法及びその成膜装置 |

| JP2017119907A (ja) | 2015-12-24 | 2017-07-06 | 株式会社Flosfia | ペロブスカイト膜の製造方法 |

| JP2020002426A (ja) | 2018-06-28 | 2020-01-09 | 信越化学工業株式会社 | 成膜装置及び成膜方法 |

| JP2020120034A (ja) | 2019-01-25 | 2020-08-06 | トヨタ自動車株式会社 | 成膜装置と半導体装置の製造方法 |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4061800A (en) * | 1975-02-06 | 1977-12-06 | Applied Materials, Inc. | Vapor desposition method |

| JP3527650B2 (ja) * | 1999-02-12 | 2004-05-17 | 池田食研株式会社 | 粉末調味料の製造方法および装置 |

| CN1719228A (zh) * | 2004-07-09 | 2006-01-11 | 北京林业大学 | 木材真空过热蒸汽干燥实验装置及检测方法 |

| KR20080023264A (ko) * | 2005-06-28 | 2008-03-12 | 아사히 테크 가부시끼가이샤 | 표면 개질된 부재, 표면 처리 방법 및 표면 처리 장치 |

| TWI831755B (zh) * | 2017-11-15 | 2024-02-11 | 日商Flosfia股份有限公司 | p型氧化物半導體膜及其形成方法 |

| JP7212890B2 (ja) * | 2019-06-05 | 2023-01-26 | 株式会社デンソー | 酸化物膜の成膜方法、半導体装置の製造方法、及び、酸化物膜の成膜装置 |

-

2021

- 2021-08-17 JP JP2021132611A patent/JP7621617B2/ja active Active

-

2022

- 2022-08-12 US US17/886,986 patent/US20230059168A1/en not_active Abandoned

- 2022-08-15 CN CN202210973812.9A patent/CN115704094A/zh active Pending

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2011023596A (ja) | 2009-07-16 | 2011-02-03 | Doshisha | 原子層成長法を用いた成膜方法及びその成膜装置 |

| JP2017119907A (ja) | 2015-12-24 | 2017-07-06 | 株式会社Flosfia | ペロブスカイト膜の製造方法 |

| JP2020002426A (ja) | 2018-06-28 | 2020-01-09 | 信越化学工業株式会社 | 成膜装置及び成膜方法 |

| JP2020120034A (ja) | 2019-01-25 | 2020-08-06 | トヨタ自動車株式会社 | 成膜装置と半導体装置の製造方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| JP2023027494A (ja) | 2023-03-02 |

| CN115704094A (zh) | 2023-02-17 |

| US20230059168A1 (en) | 2023-02-23 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| KR102730004B1 (ko) | 페로브스카이트 반도체의 증착을 위한 증기상 수송 시스템 및 방법 | |

| TWI535883B (zh) | Film forming apparatus and film forming method | |

| JP7212890B2 (ja) | 酸化物膜の成膜方法、半導体装置の製造方法、及び、酸化物膜の成膜装置 | |

| JP7216371B2 (ja) | 酸化物膜の成膜方法、半導体装置の製造方法、及び、酸化物膜の成膜装置 | |

| CN113196458B (zh) | 氧化镓膜的制造方法 | |

| JP6839694B2 (ja) | 酸化ガリウム膜の成膜方法 | |

| CN112053941A (zh) | Iii族氮化物半导体晶体的制造装置 | |

| JP7130962B2 (ja) | 成膜方法及び成膜装置 | |

| JP2019142756A (ja) | 成膜方法 | |

| JP7621617B2 (ja) | 成膜装置と半導体装置の製造方法 | |

| US11280023B2 (en) | Film formation apparatus and method of manufacturing semiconductor device | |

| CN111254489A (zh) | 成膜装置 | |

| JP7115688B2 (ja) | 成膜装置及び半導体装置の製造方法 | |

| JP2010003975A (ja) | 成膜装置および半導体素子の製造方法 | |

| JP7610231B2 (ja) | 原料溶液の製造方法、成膜方法及び製品ロット | |

| JP2021100077A (ja) | 成膜方法 | |

| JP4754087B2 (ja) | 成膜方法 | |

| JP2003252627A (ja) | 微粒子の製造方法および微粒子製造装置 | |

| JP2017178767A (ja) | 結晶製造方法及び気相成長装置 | |

| JP2023169572A (ja) | Iii族窒化物結晶の製造方法および製造装置 | |

| JP2022050497A (ja) | 半導体膜 | |

| JPS6353160B2 (ja) |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20231011 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20240619 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20240716 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20240910 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20241210 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20250106 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 7621617 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |