JP6477832B1 - ポリプロピレン樹脂の親水化処理方法 - Google Patents

ポリプロピレン樹脂の親水化処理方法 Download PDFInfo

- Publication number

- JP6477832B1 JP6477832B1 JP2017210280A JP2017210280A JP6477832B1 JP 6477832 B1 JP6477832 B1 JP 6477832B1 JP 2017210280 A JP2017210280 A JP 2017210280A JP 2017210280 A JP2017210280 A JP 2017210280A JP 6477832 B1 JP6477832 B1 JP 6477832B1

- Authority

- JP

- Japan

- Prior art keywords

- polypropylene resin

- persulfuric acid

- plating

- treatment

- acid solution

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C18/00—Chemical coating by decomposition of either liquid compounds or solutions of the coating forming compounds, without leaving reaction products of surface material in the coating; Contact plating

- C23C18/16—Chemical coating by decomposition of either liquid compounds or solutions of the coating forming compounds, without leaving reaction products of surface material in the coating; Contact plating by reduction or substitution, e.g. electroless plating

- C23C18/18—Pretreatment of the material to be coated

- C23C18/20—Pretreatment of the material to be coated of organic surfaces, e.g. resins

- C23C18/2006—Pretreatment of the material to be coated of organic surfaces, e.g. resins by other methods than those of C23C18/22 - C23C18/30

- C23C18/2046—Pretreatment of the material to be coated of organic surfaces, e.g. resins by other methods than those of C23C18/22 - C23C18/30 by chemical pretreatment

- C23C18/2073—Multistep pretreatment

- C23C18/2086—Multistep pretreatment with use of organic or inorganic compounds other than metals, first

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J7/00—Chemical treatment or coating of shaped articles made of macromolecular substances

- C08J7/12—Chemical modification

- C08J7/14—Chemical modification with acids, their salts or anhydrides

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09K—MATERIALS FOR MISCELLANEOUS APPLICATIONS, NOT PROVIDED FOR ELSEWHERE

- C09K13/00—Etching, surface-brightening or pickling compositions

- C09K13/04—Etching, surface-brightening or pickling compositions containing an inorganic acid

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C18/00—Chemical coating by decomposition of either liquid compounds or solutions of the coating forming compounds, without leaving reaction products of surface material in the coating; Contact plating

- C23C18/16—Chemical coating by decomposition of either liquid compounds or solutions of the coating forming compounds, without leaving reaction products of surface material in the coating; Contact plating by reduction or substitution, e.g. electroless plating

- C23C18/18—Pretreatment of the material to be coated

- C23C18/20—Pretreatment of the material to be coated of organic surfaces, e.g. resins

- C23C18/22—Roughening, e.g. by etching

- C23C18/24—Roughening, e.g. by etching using acid aqueous solutions

-

- C—CHEMISTRY; METALLURGY

- C25—ELECTROLYTIC OR ELECTROPHORETIC PROCESSES; APPARATUS THEREFOR

- C25B—ELECTROLYTIC OR ELECTROPHORETIC PROCESSES FOR THE PRODUCTION OF COMPOUNDS OR NON-METALS; APPARATUS THEREFOR

- C25B1/00—Electrolytic production of inorganic compounds or non-metals

- C25B1/01—Products

- C25B1/28—Per-compounds

- C25B1/29—Persulfates

-

- C—CHEMISTRY; METALLURGY

- C25—ELECTROLYTIC OR ELECTROPHORETIC PROCESSES; APPARATUS THEREFOR

- C25B—ELECTROLYTIC OR ELECTROPHORETIC PROCESSES FOR THE PRODUCTION OF COMPOUNDS OR NON-METALS; APPARATUS THEREFOR

- C25B1/00—Electrolytic production of inorganic compounds or non-metals

- C25B1/01—Products

- C25B1/28—Per-compounds

- C25B1/30—Peroxides

-

- C—CHEMISTRY; METALLURGY

- C25—ELECTROLYTIC OR ELECTROPHORETIC PROCESSES; APPARATUS THEREFOR

- C25B—ELECTROLYTIC OR ELECTROPHORETIC PROCESSES FOR THE PRODUCTION OF COMPOUNDS OR NON-METALS; APPARATUS THEREFOR

- C25B11/00—Electrodes; Manufacture thereof not otherwise provided for

- C25B11/02—Electrodes; Manufacture thereof not otherwise provided for characterised by shape or form

- C25B11/036—Bipolar electrodes

-

- C—CHEMISTRY; METALLURGY

- C25—ELECTROLYTIC OR ELECTROPHORETIC PROCESSES; APPARATUS THEREFOR

- C25B—ELECTROLYTIC OR ELECTROPHORETIC PROCESSES FOR THE PRODUCTION OF COMPOUNDS OR NON-METALS; APPARATUS THEREFOR

- C25B11/00—Electrodes; Manufacture thereof not otherwise provided for

- C25B11/04—Electrodes; Manufacture thereof not otherwise provided for characterised by the material

- C25B11/042—Electrodes formed of a single material

- C25B11/043—Carbon, e.g. diamond or graphene

-

- C—CHEMISTRY; METALLURGY

- C25—ELECTROLYTIC OR ELECTROPHORETIC PROCESSES; APPARATUS THEREFOR

- C25B—ELECTROLYTIC OR ELECTROPHORETIC PROCESSES FOR THE PRODUCTION OF COMPOUNDS OR NON-METALS; APPARATUS THEREFOR

- C25B15/00—Operating or servicing cells

- C25B15/08—Supplying or removing reactants or electrolytes; Regeneration of electrolytes

- C25B15/087—Recycling of electrolyte to electrochemical cell

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J2323/00—Characterised by the use of homopolymers or copolymers of unsaturated aliphatic hydrocarbons having only one carbon-to-carbon double bond; Derivatives of such polymers

- C08J2323/02—Characterised by the use of homopolymers or copolymers of unsaturated aliphatic hydrocarbons having only one carbon-to-carbon double bond; Derivatives of such polymers not modified by chemical after treatment

- C08J2323/10—Homopolymers or copolymers of propene

- C08J2323/12—Polypropene

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C18/00—Chemical coating by decomposition of either liquid compounds or solutions of the coating forming compounds, without leaving reaction products of surface material in the coating; Contact plating

- C23C18/16—Chemical coating by decomposition of either liquid compounds or solutions of the coating forming compounds, without leaving reaction products of surface material in the coating; Contact plating by reduction or substitution, e.g. electroless plating

- C23C18/1601—Process or apparatus

- C23C18/1633—Process of electroless plating

- C23C18/1646—Characteristics of the product obtained

- C23C18/165—Multilayered product

- C23C18/1653—Two or more layers with at least one layer obtained by electroless plating and one layer obtained by electroplating

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C18/00—Chemical coating by decomposition of either liquid compounds or solutions of the coating forming compounds, without leaving reaction products of surface material in the coating; Contact plating

- C23C18/16—Chemical coating by decomposition of either liquid compounds or solutions of the coating forming compounds, without leaving reaction products of surface material in the coating; Contact plating by reduction or substitution, e.g. electroless plating

- C23C18/31—Coating with metals

- C23C18/32—Coating with nickel, cobalt or mixtures thereof with phosphorus or boron

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C18/00—Chemical coating by decomposition of either liquid compounds or solutions of the coating forming compounds, without leaving reaction products of surface material in the coating; Contact plating

- C23C18/16—Chemical coating by decomposition of either liquid compounds or solutions of the coating forming compounds, without leaving reaction products of surface material in the coating; Contact plating by reduction or substitution, e.g. electroless plating

- C23C18/31—Coating with metals

- C23C18/38—Coating with copper

Landscapes

- Chemical & Material Sciences (AREA)

- Organic Chemistry (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Materials Engineering (AREA)

- Engineering & Computer Science (AREA)

- Metallurgy (AREA)

- Electrochemistry (AREA)

- General Chemical & Material Sciences (AREA)

- Inorganic Chemistry (AREA)

- Medicinal Chemistry (AREA)

- Polymers & Plastics (AREA)

- Health & Medical Sciences (AREA)

- Mechanical Engineering (AREA)

- Life Sciences & Earth Sciences (AREA)

- Sustainable Development (AREA)

- Chemically Coating (AREA)

- Electrolytic Production Of Non-Metals, Compounds, Apparatuses Therefor (AREA)

- Treatments Of Macromolecular Shaped Articles (AREA)

Abstract

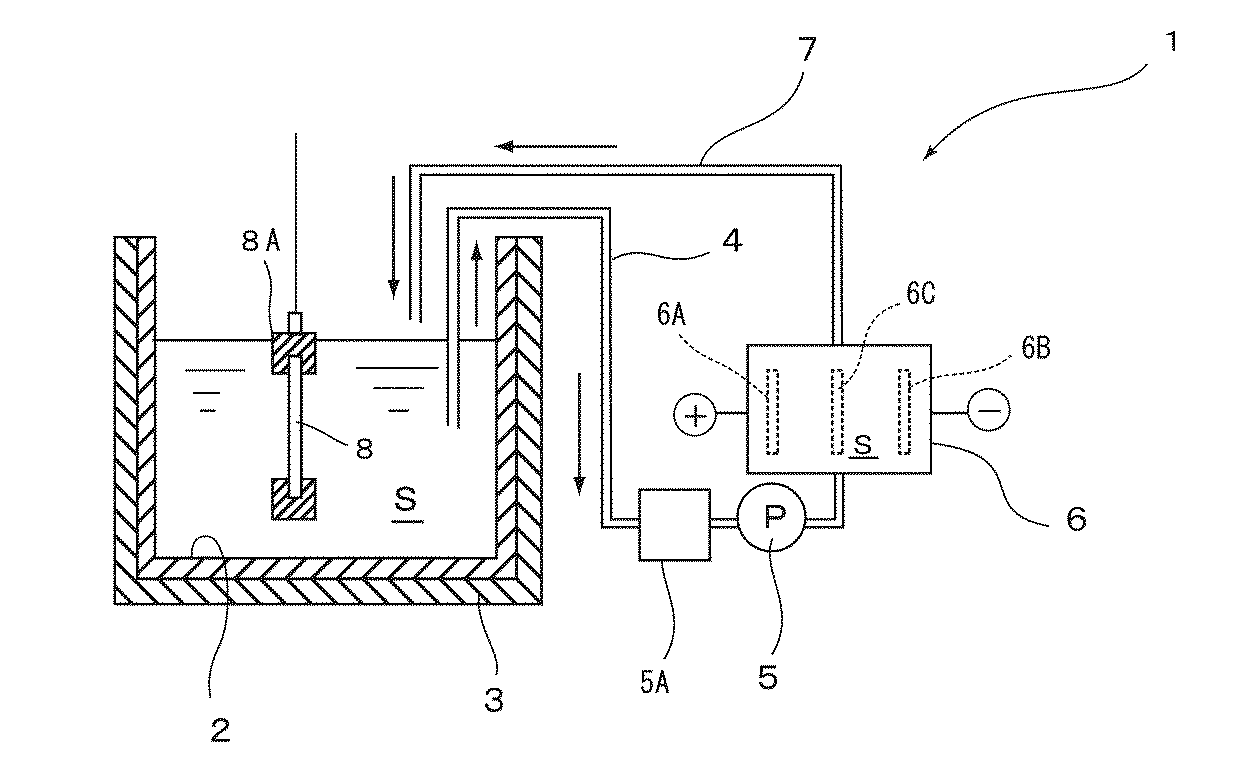

【解決手段】処理装置1が、処理槽2と、循環ポンプ5を備えた配管4から連続するダイヤモンド電極を備えた電解セル6と、この電解セル6から処理槽2に供給する配管7とを有し、処理槽2及び電解セル6には85〜98重量%の濃度の硫酸が充填されていて、電解セル6に電流を通電して、硫酸を電気分解することにより過硫酸溶液Sを生成して、この過硫酸溶液Sを配管7を経由して処理槽2に供給し、そして、処理槽2内には、被処理対象であるポリプロピレン樹脂板8が治具8Aに固定された状態で上下方向に吊設されていて、濃度が3g/L以上である過硫酸溶液Sによりポリプロピレン樹脂板8を100〜130℃で処理するポリプロピレン樹脂の親水化処理方法。

【選択図】図1

Description

まず、ヨウ素滴定により処理液(過硫酸溶液S)中に含まれる全酸化剤濃度を測定する。このヨウ素滴定とは、過硫酸溶液Sにヨウ化カリウム(KI)を加えてヨウ素(I2)を遊離させ、そのI2をチオ硫酸ナトリウム標準溶液で滴定してI2の量を求め、そのI2の量から酸化剤濃度を求めるものである。次に、過硫酸溶液Sの過酸化水素濃度のみを過マンガン酸カリウム滴定により求め、ヨウ素滴定値から過マンガン酸カリウム滴定値を差し引くことにより過硫酸濃度を算出した。

過硫酸溶液Sにより親水化処理されたポリプロピレン樹脂板8に対し、下記表1に示す流れでめっき処理を施し、密着性試験用サンプルにとした。

図1に示す装置を用いて、ポリプロピレン樹脂板8の表面処理を行った。処理槽の仕様及び条件は次の通りである。

処理槽2の容積:40L

ポリプロピレン樹脂板8の大きさ:500mm×500mm×厚さ5mm

<過硫酸生成用電解セル6及び電解条件>

セル容積:0.5L

陽極及び陰極:ダイヤモンド電極(直径150mm)

バイポーラ電極材質:陽極、陰極と同じ

電流密度:50A/dm2

液循環量:52L/hr

<親水化処理条件>

硫酸濃度:92重量%

過硫酸濃度:10g/L

処理温度:120℃

処理時間:60分

電解硫酸処理条件を表2に示すように種々設定を変更した以外は実施例1と同様にしてクロムめっきを施し、めっきの密着性を評価した。結果を親水化処理条件とともに表2にあわせて示す。

過硫酸溶液の代わりに、硫酸濃度92重量%の硫酸溶液を用いた以外は実施例1と同様にしてクロムめっきを施し、めっきの密着性を評価した。結果を処理条件とともに表2にあわせて示す。

2 処理槽

3 恒温ヒータ

4 配管

5 循環ポンプ

5A 熱交換器

6 電解セル

6A 陽極

6B 陰極

6C バイポーラ電極

7 配管

8 ポリプロピレン樹脂板

S 過硫酸溶液

Claims (4)

- 硫酸を電気分解した溶液でポリプロピレン樹脂の表面を処理する、クロム及びマンガンフリーの、ポリプロピレン樹脂のめっき前処理としての親水化処理方法。

- 前記溶液の硫酸濃度が85〜98重量%である、請求項1に記載のポリプロピレン樹脂の親水化処理方法。

- 前記親水化処理における前記溶液の温度が100〜130℃である、請求項1又は2に記載のポリプロピレン樹脂の親水化処理方法。

- 前記溶液の過硫酸濃度が3g/L以上である、請求項1〜3のいずれかに記載のポリプロピレン樹脂の親水化処理方法。

Priority Applications (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2017210280A JP6477832B1 (ja) | 2017-10-31 | 2017-10-31 | ポリプロピレン樹脂の親水化処理方法 |

| PCT/JP2018/034105 WO2019087588A1 (ja) | 2017-10-31 | 2018-09-14 | ポリプロピレン樹脂の親水化処理方法 |

| US16/760,030 US20200347196A1 (en) | 2017-10-31 | 2018-09-14 | Hydrophilization treatment method of polypropylene resin |

| CN201880059526.3A CN111133129A (zh) | 2017-10-31 | 2018-09-14 | 聚丙烯树脂的亲水化处理方法 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2017210280A JP6477832B1 (ja) | 2017-10-31 | 2017-10-31 | ポリプロピレン樹脂の親水化処理方法 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP6477832B1 true JP6477832B1 (ja) | 2019-03-06 |

| JP2019081928A JP2019081928A (ja) | 2019-05-30 |

Family

ID=65655762

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2017210280A Active JP6477832B1 (ja) | 2017-10-31 | 2017-10-31 | ポリプロピレン樹脂の親水化処理方法 |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US20200347196A1 (ja) |

| JP (1) | JP6477832B1 (ja) |

| CN (1) | CN111133129A (ja) |

| WO (1) | WO2019087588A1 (ja) |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP7484389B2 (ja) * | 2020-04-28 | 2024-05-16 | 栗田工業株式会社 | 樹脂成形体のエッチング方法及び樹脂成形体用エッチング処理システム |

Family Cites Families (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3597336A (en) * | 1968-04-22 | 1971-08-03 | Phillips Petroleum Co | Electroplating plastics |

| JPS5755933A (en) * | 1980-09-18 | 1982-04-03 | Matsushita Electric Ind Co Ltd | Electroless plating method on polymer material |

| JP4808551B2 (ja) * | 2006-06-16 | 2011-11-02 | クロリンエンジニアズ株式会社 | 過硫酸の製造方法 |

| JP2010159457A (ja) * | 2009-01-08 | 2010-07-22 | Ebara-Udylite Co Ltd | プラスチック被めっき素材上への金属皮膜形成方法 |

| JP2010189748A (ja) * | 2009-02-20 | 2010-09-02 | Osaka Prefecture | 金属凸部を有するポリマー材料の製造方法 |

| JP5376152B2 (ja) * | 2009-09-05 | 2013-12-25 | 栗田工業株式会社 | 硫酸電解方法 |

| JP5710345B2 (ja) * | 2011-03-31 | 2015-04-30 | ペルメレック電極株式会社 | 酸化性物質の総濃度測定方法、酸化性物質の総濃度測定用濃度計およびそれを用いた硫酸電解装置 |

| US10260000B2 (en) * | 2012-01-23 | 2019-04-16 | Macdermid Acumen, Inc. | Etching of plastic using acidic solutions containing trivalent manganese |

| US9267077B2 (en) * | 2013-04-16 | 2016-02-23 | Rohm And Haas Electronic Materials Llc | Chrome-free methods of etching organic polymers with mixed acid solutions |

| JP6288213B1 (ja) * | 2016-11-01 | 2018-03-07 | 栗田工業株式会社 | プラスチック表面の処理方法 |

-

2017

- 2017-10-31 JP JP2017210280A patent/JP6477832B1/ja active Active

-

2018

- 2018-09-14 CN CN201880059526.3A patent/CN111133129A/zh active Pending

- 2018-09-14 US US16/760,030 patent/US20200347196A1/en not_active Abandoned

- 2018-09-14 WO PCT/JP2018/034105 patent/WO2019087588A1/ja not_active Ceased

Also Published As

| Publication number | Publication date |

|---|---|

| WO2019087588A1 (ja) | 2019-05-09 |

| US20200347196A1 (en) | 2020-11-05 |

| JP2019081928A (ja) | 2019-05-30 |

| CN111133129A (zh) | 2020-05-08 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6288213B1 (ja) | プラスチック表面の処理方法 | |

| JP6750293B2 (ja) | プラスチック表面の処理方法 | |

| CN106715763A (zh) | 夹具用电解剥离剂 | |

| WO2019045047A1 (ja) | Abs系樹脂表面のめっき前処理方法、abs系樹脂表面のめっき処理方法、及びabs系樹脂めっき製品 | |

| JP6477832B1 (ja) | ポリプロピレン樹脂の親水化処理方法 | |

| CN103014797A (zh) | 一种金属板材的表面处理工艺 | |

| JP6551563B1 (ja) | Abs系樹脂表面のめっき前処理方法、abs系樹脂表面のめっき処理方法、及びabs系樹脂めっき製品 | |

| JP6566064B1 (ja) | ポリフェニレンサルファイド樹脂表面の処理方法 | |

| JP6477831B1 (ja) | ポリフェニレンサルファイド樹脂の親水化処理方法 | |

| JP6540843B1 (ja) | ポリプロピレン樹脂の親水化処理方法 | |

| JP6947783B2 (ja) | Abs系樹脂表面のめっき前処理方法、及びabs系樹脂表面のめっき処理方法 | |

| JP6953484B2 (ja) | Abs系樹脂表面のめっき前処理方法、abs系樹脂表面のめっき処理方法、及びabs系樹脂めっき製品 | |

| JP2019203204A5 (ja) | ||

| GB2603003A (en) | Method of etching a plastic component | |

| HK1232571B (zh) | 夹具用电解剥离剂 | |

| HK1232571A1 (en) | Electrolytic stripping agent for jig |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20180914 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20181009 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20181203 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20190108 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20190121 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 6477832 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |