JP6297308B2 - 基板洗浄装置及び基板洗浄方法 - Google Patents

基板洗浄装置及び基板洗浄方法 Download PDFInfo

- Publication number

- JP6297308B2 JP6297308B2 JP2013238224A JP2013238224A JP6297308B2 JP 6297308 B2 JP6297308 B2 JP 6297308B2 JP 2013238224 A JP2013238224 A JP 2013238224A JP 2013238224 A JP2013238224 A JP 2013238224A JP 6297308 B2 JP6297308 B2 JP 6297308B2

- Authority

- JP

- Japan

- Prior art keywords

- substrate

- cleaning member

- cleaning

- end contact

- contact surface

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000004140 cleaning Methods 0.000 title claims description 395

- 239000000758 substrate Substances 0.000 title claims description 283

- 238000000034 method Methods 0.000 title claims description 10

- 239000007788 liquid Substances 0.000 claims description 44

- 230000002093 peripheral effect Effects 0.000 claims description 29

- 230000000052 comparative effect Effects 0.000 description 37

- 230000007547 defect Effects 0.000 description 19

- 238000005498 polishing Methods 0.000 description 13

- 230000002209 hydrophobic effect Effects 0.000 description 11

- 239000002245 particle Substances 0.000 description 11

- 238000001035 drying Methods 0.000 description 9

- 229910052751 metal Inorganic materials 0.000 description 9

- 239000002184 metal Substances 0.000 description 9

- 239000004065 semiconductor Substances 0.000 description 9

- 238000012546 transfer Methods 0.000 description 9

- 235000012431 wafers Nutrition 0.000 description 8

- 230000007246 mechanism Effects 0.000 description 7

- 238000012545 processing Methods 0.000 description 7

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 description 5

- 238000011109 contamination Methods 0.000 description 5

- 229910052802 copper Inorganic materials 0.000 description 5

- 239000010949 copper Substances 0.000 description 5

- 238000010586 diagram Methods 0.000 description 5

- 230000005661 hydrophobic surface Effects 0.000 description 5

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 5

- 238000009826 distribution Methods 0.000 description 4

- 230000005660 hydrophilic surface Effects 0.000 description 4

- 238000004519 manufacturing process Methods 0.000 description 4

- 230000032258 transport Effects 0.000 description 4

- 230000004888 barrier function Effects 0.000 description 3

- 230000000694 effects Effects 0.000 description 3

- 238000011086 high cleaning Methods 0.000 description 3

- 239000002002 slurry Substances 0.000 description 3

- XUIMIQQOPSSXEZ-UHFFFAOYSA-N Silicon Chemical compound [Si] XUIMIQQOPSSXEZ-UHFFFAOYSA-N 0.000 description 2

- 230000009471 action Effects 0.000 description 2

- 238000005452 bending Methods 0.000 description 2

- 238000003825 pressing Methods 0.000 description 2

- 230000009467 reduction Effects 0.000 description 2

- 229910052710 silicon Inorganic materials 0.000 description 2

- 239000010703 silicon Substances 0.000 description 2

- 239000000126 substance Substances 0.000 description 2

- WFKWXMTUELFFGS-UHFFFAOYSA-N tungsten Chemical compound [W] WFKWXMTUELFFGS-UHFFFAOYSA-N 0.000 description 2

- 229910052721 tungsten Inorganic materials 0.000 description 2

- 239000010937 tungsten Substances 0.000 description 2

- 244000043261 Hevea brasiliensis Species 0.000 description 1

- 230000001133 acceleration Effects 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 230000007423 decrease Effects 0.000 description 1

- 230000003247 decreasing effect Effects 0.000 description 1

- 238000011161 development Methods 0.000 description 1

- 239000010419 fine particle Substances 0.000 description 1

- 238000002347 injection Methods 0.000 description 1

- 239000007924 injection Substances 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 238000005259 measurement Methods 0.000 description 1

- 229920003052 natural elastomer Polymers 0.000 description 1

- 229920001194 natural rubber Polymers 0.000 description 1

- 238000005192 partition Methods 0.000 description 1

- 230000000704 physical effect Effects 0.000 description 1

- 230000008569 process Effects 0.000 description 1

- 239000000243 solution Substances 0.000 description 1

- 239000007921 spray Substances 0.000 description 1

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/04—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer

- H01L21/18—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer the devices having semiconductor bodies comprising elements of Group IV of the Periodic Table or AIIIBV compounds with or without impurities, e.g. doping materials

- H01L21/30—Treatment of semiconductor bodies using processes or apparatus not provided for in groups H01L21/20 - H01L21/26

- H01L21/302—Treatment of semiconductor bodies using processes or apparatus not provided for in groups H01L21/20 - H01L21/26 to change their surface-physical characteristics or shape, e.g. etching, polishing, cutting

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/02041—Cleaning

- H01L21/02057—Cleaning during device manufacture

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/67—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere

- H01L21/67005—Apparatus not specifically provided for elsewhere

- H01L21/67011—Apparatus for manufacture or treatment

- H01L21/67017—Apparatus for fluid treatment

- H01L21/67028—Apparatus for fluid treatment for cleaning followed by drying, rinsing, stripping, blasting or the like

- H01L21/6704—Apparatus for fluid treatment for cleaning followed by drying, rinsing, stripping, blasting or the like for wet cleaning or washing

- H01L21/67046—Apparatus for fluid treatment for cleaning followed by drying, rinsing, stripping, blasting or the like for wet cleaning or washing using mainly scrubbing means, e.g. brushes

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/67—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere

- H01L21/67005—Apparatus not specifically provided for elsewhere

- H01L21/67011—Apparatus for manufacture or treatment

- H01L21/67017—Apparatus for fluid treatment

- H01L21/67028—Apparatus for fluid treatment for cleaning followed by drying, rinsing, stripping, blasting or the like

- H01L21/6704—Apparatus for fluid treatment for cleaning followed by drying, rinsing, stripping, blasting or the like for wet cleaning or washing

- H01L21/67051—Apparatus for fluid treatment for cleaning followed by drying, rinsing, stripping, blasting or the like for wet cleaning or washing using mainly spraying means, e.g. nozzles

Landscapes

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Condensed Matter Physics & Semiconductors (AREA)

- General Physics & Mathematics (AREA)

- Manufacturing & Machinery (AREA)

- Computer Hardware Design (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Power Engineering (AREA)

- Cleaning Or Drying Semiconductors (AREA)

- Cleaning In General (AREA)

Description

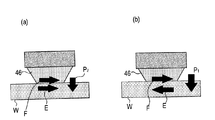

これにより、洗浄部材の基板の外周側により近い部分の洗浄部材の回転速度と基板の回転速度の相対回転速度を相対的に高めて、基板の外周側領域の洗浄効果を高めることができる。

これによって、基板の回転中心部を確実に洗浄することができる。

本発明の基板洗浄装置の他の態様は、洗浄液の存在下で、洗浄部材の下端接触面を基板の表面に擦り付けて該表面を洗浄する基板洗浄装置において、前記洗浄部材は、下端接触面と外周面上の直線とのなす角αが90°<α≦150°の逆円錐台形状を有し、前記洗浄部材を基板の表面に対して傾斜させながら、前記洗浄部材の下端接触面の全面を基板に接触させつつ前記洗浄部材を一方向に向けて移動させる。

図1は、本発明の実施形態に係る基板洗浄装置を備えた基板処理装置の全体構成を示す平面図である。図1に示すように、基板処理装置は、略矩形状のハウジング10と、多数の半導体ウエハ等の基板をストックする基板カセットが載置されるロードポート12を備えている。ロードポート12は、ハウジング10に隣接して配置されている。ロードポート12には、オープンカセット、SMIF(Standard Manufacturing Interface)ポッド、またはFOUP(Front Opening Unified Pod)を搭載することができる。SMIF、FOUPは、内部に基板カセットを収納し、隔壁で覆うことにより、外部空間とは独立した環境を保つことができる密閉容器である。

O5上を通過するようにしてもよい。

ここでは、薬液供給ノズルとして円錐ノズルを使用し、楕円状に洗浄液が分布するようにしているが、ノズル形状や洗浄液の分布形状がこれらに限定されることはない。

16 第1洗浄ユニット

18 第2洗浄ユニット(基板洗浄装置)

20 乾燥ユニット

24 搬送ユニット

30 制御部

40 基板保持機構

44 揺動アーム

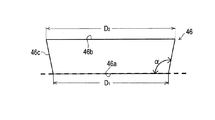

46 洗浄部材

46a 下端接触面

46b 上端面

46c 外周面

48 洗浄液供給ノズル

50 比較洗浄部材

Claims (7)

- 洗浄部材を、鉛直方向に延びる回転軸を中心に回転させながら一方向に向けて移動させ、洗浄液の存在下で、前記洗浄部材の下端接触面を水平に回転している基板の表面に擦り付けて該表面を洗浄する基板洗浄装置において、

前記洗浄部材は、下端接触面と外周面上の直線とのなす角αが90°<α≦150°の逆円錐台形状を有し、

前記洗浄部材の回転軸を該洗浄部材の移動方向と同じ方向に傾斜させながら、前記洗浄部材の下端接触面の全面を基板に接触させつつ前記洗浄部材を一方向に向けて移動させることを特徴とする基板洗浄装置。 - 前記洗浄部材を前記基板の回転方向に対して逆方向に回転させることを特徴とする請求項1に記載の基板洗浄装置。

- 前記洗浄部材の下端接触面が前記基板の回転中心を通り、かつ前記洗浄部材の回転軸が前記基板の回転中心を通らないように前記洗浄部材を一方向に向けて移動させることを特徴とする請求項1に記載の基板洗浄装置。

- 逆円錐台形状を有し、下端接触面と外周面上の直線とのなす角αが90°<α≦150°の洗浄部材を、鉛直方向に延びる回転軸を中心に回転させ、前記洗浄部材の回転軸を該洗浄部材の移動方向と同じ方向に傾斜させながら、前記洗浄部材の下端接触面の全面を基板に接触させつつ前記洗浄部材を一方向に向けて移動させ、洗浄液の存在下で、前記洗浄部材の下端接触面を水平に回転している基板の表面に擦り付けて該表面を洗浄することを特徴とする基板洗浄方法。

- 前記洗浄部材を前記基板の回転方向に対して逆方向に回転させることを特徴とする請求項4に記載の基板洗浄方法。

- 前記洗浄部材の下端接触面が前記基板の回転中心を通り、かつ前記洗浄部材の回転軸が前記基板の回転中心を通らないように前記洗浄部材を一方向に向けて移動させることを特徴とする請求項4に記載の基板洗浄方法。

- 洗浄液の存在下で、洗浄部材の下端接触面を基板の表面に擦り付けて該表面を洗浄する基板洗浄装置において、

前記洗浄部材は、下端接触面と外周面上の直線とのなす角αが90°<α≦150°の逆円錐台形状を有し、

前記洗浄部材を基板の表面に対して傾斜させながら、前記洗浄部材の下端接触面の全面を基板に接触させつつ前記洗浄部材を一方向に向けて移動させることを特徴とする基板洗浄装置。

Priority Applications (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2013238224A JP6297308B2 (ja) | 2012-12-06 | 2013-11-18 | 基板洗浄装置及び基板洗浄方法 |

| KR1020130148922A KR102103321B1 (ko) | 2012-12-06 | 2013-12-03 | 기판 세정 장치 및 기판 세정 방법 |

| TW102144346A TWI611848B (zh) | 2012-12-06 | 2013-12-04 | 基板洗淨裝置及基板洗淨方法 |

| US14/098,471 US9058977B2 (en) | 2012-12-06 | 2013-12-05 | Substrate cleaning apparatus and substrate cleaning method |

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2012267568 | 2012-12-06 | ||

| JP2012267568 | 2012-12-06 | ||

| JP2013238224A JP6297308B2 (ja) | 2012-12-06 | 2013-11-18 | 基板洗浄装置及び基板洗浄方法 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2014132639A JP2014132639A (ja) | 2014-07-17 |

| JP2014132639A5 JP2014132639A5 (ja) | 2016-11-17 |

| JP6297308B2 true JP6297308B2 (ja) | 2018-03-20 |

Family

ID=50879637

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2013238224A Active JP6297308B2 (ja) | 2012-12-06 | 2013-11-18 | 基板洗浄装置及び基板洗浄方法 |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US9058977B2 (ja) |

| JP (1) | JP6297308B2 (ja) |

| KR (1) | KR102103321B1 (ja) |

| TW (1) | TWI611848B (ja) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US10163664B2 (en) * | 2014-10-31 | 2018-12-25 | Ebara Corporation | Substrate cleaning apparatus and substrate cleaning method |

| JP6871499B2 (ja) * | 2016-06-16 | 2021-05-12 | サミー株式会社 | ぱちんこ遊技機 |

| JPWO2023145431A1 (ja) * | 2022-01-31 | 2023-08-03 |

Family Cites Families (18)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2628168B2 (ja) | 1987-07-14 | 1997-07-09 | 住友シチックス株式会社 | 半導体ウエーハの表面処理装置 |

| JP3447869B2 (ja) * | 1995-09-20 | 2003-09-16 | 株式会社荏原製作所 | 洗浄方法及び装置 |

| JP3302873B2 (ja) | 1995-12-05 | 2002-07-15 | 東京エレクトロン株式会社 | 洗浄方法と洗浄装置 |

| JPH09260322A (ja) * | 1996-03-26 | 1997-10-03 | Nippon Steel Corp | 洗浄装置 |

| JPH10199844A (ja) * | 1997-01-10 | 1998-07-31 | Dainippon Screen Mfg Co Ltd | 基板洗浄装置 |

| JPH10308374A (ja) | 1997-03-06 | 1998-11-17 | Ebara Corp | 洗浄方法及び洗浄装置 |

| JPH10312983A (ja) | 1997-05-12 | 1998-11-24 | Dainippon Screen Mfg Co Ltd | 基板洗浄装置 |

| JPH10312982A (ja) | 1997-05-12 | 1998-11-24 | Dainippon Screen Mfg Co Ltd | 基板洗浄装置 |

| JP4268239B2 (ja) * | 1998-06-29 | 2009-05-27 | 芝浦メカトロニクス株式会社 | ブラシ洗浄装置およびブラシ洗浄方法 |

| JP4091187B2 (ja) | 1998-12-08 | 2008-05-28 | 株式会社荏原製作所 | 洗浄具、基板洗浄装置及び基板洗浄方法 |

| JP2002018368A (ja) | 2000-07-05 | 2002-01-22 | Dainippon Screen Mfg Co Ltd | 基板処理装置 |

| US6648979B2 (en) * | 2001-01-24 | 2003-11-18 | International Business Machines Corporation | Apparatus and method for wafer cleaning |

| JP2003031536A (ja) | 2001-07-12 | 2003-01-31 | Nec Corp | ウエハの洗浄方法 |

| JP2004273961A (ja) * | 2003-03-12 | 2004-09-30 | Ebara Corp | 金属配線形成基板の洗浄処理装置 |

| JP2006073788A (ja) * | 2004-09-02 | 2006-03-16 | Sumco Corp | ウェーハの洗浄方法及び洗浄装置 |

| JP2005012238A (ja) * | 2004-09-02 | 2005-01-13 | Ebara Corp | 基板洗浄方法及び装置 |

| JP2007273608A (ja) * | 2006-03-30 | 2007-10-18 | Dainippon Screen Mfg Co Ltd | 基板処理装置および基板処理方法 |

| JP5336799B2 (ja) * | 2008-09-24 | 2013-11-06 | 東京エレクトロン株式会社 | 化学的機械研磨装置、化学的機械研磨方法及び制御プログラム |

-

2013

- 2013-11-18 JP JP2013238224A patent/JP6297308B2/ja active Active

- 2013-12-03 KR KR1020130148922A patent/KR102103321B1/ko active IP Right Grant

- 2013-12-04 TW TW102144346A patent/TWI611848B/zh active

- 2013-12-05 US US14/098,471 patent/US9058977B2/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| US20140158160A1 (en) | 2014-06-12 |

| TW201429567A (zh) | 2014-08-01 |

| KR20140073428A (ko) | 2014-06-16 |

| US9058977B2 (en) | 2015-06-16 |

| JP2014132639A (ja) | 2014-07-17 |

| TWI611848B (zh) | 2018-01-21 |

| KR102103321B1 (ko) | 2020-04-22 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5866227B2 (ja) | 基板洗浄方法 | |

| JP6265702B2 (ja) | 基板洗浄装置及び基板洗浄方法 | |

| US9466512B2 (en) | Substrate cleaning apparatus and substrate processing apparatus | |

| US20190088510A1 (en) | Substrate cleaning device, substrate cleaning method, substrate processing device, and substrate drying device | |

| US10737301B2 (en) | Substrate cleaning apparatus | |

| JP6312534B2 (ja) | 基板洗浄装置 | |

| CN107086190B (zh) | 基板清洗装置和基板处理装置 | |

| JP6297308B2 (ja) | 基板洗浄装置及び基板洗浄方法 | |

| JP6029975B2 (ja) | 基板洗浄装置及び基板洗浄方法 | |

| JP2014130883A (ja) | 基板洗浄装置及び基板洗浄方法 | |

| TWI810835B (zh) | 帶有整合基板對準台的乾燥系統 | |

| JP6934918B2 (ja) | 基板洗浄装置 | |

| JP6431159B2 (ja) | 基板洗浄装置 | |

| JP6612176B2 (ja) | 基板洗浄装置 | |

| JP2024092544A (ja) | 基板洗浄装置及び基板洗浄方法 | |

| JP2023156015A (ja) | 基板洗浄装置及び基板処理方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20160930 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20160930 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20170801 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20170927 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20180206 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20180221 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 6297308 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |