JP6093363B2 - Hipimsを用いた基材のコーティング - Google Patents

Hipimsを用いた基材のコーティング Download PDFInfo

- Publication number

- JP6093363B2 JP6093363B2 JP2014532353A JP2014532353A JP6093363B2 JP 6093363 B2 JP6093363 B2 JP 6093363B2 JP 2014532353 A JP2014532353 A JP 2014532353A JP 2014532353 A JP2014532353 A JP 2014532353A JP 6093363 B2 JP6093363 B2 JP 6093363B2

- Authority

- JP

- Japan

- Prior art keywords

- pulse

- cathode

- metal

- power

- bias

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000000168 high power impulse magnetron sputter deposition Methods 0.000 title claims description 118

- 239000000758 substrate Substances 0.000 title claims description 70

- 238000000576 coating method Methods 0.000 title claims description 64

- 239000011248 coating agent Substances 0.000 title claims description 53

- 229910052751 metal Inorganic materials 0.000 claims description 74

- 239000002184 metal Substances 0.000 claims description 73

- 238000000034 method Methods 0.000 claims description 62

- 239000010936 titanium Substances 0.000 claims description 52

- 239000000203 mixture Substances 0.000 claims description 47

- 229910021645 metal ion Inorganic materials 0.000 claims description 36

- 229910052782 aluminium Inorganic materials 0.000 claims description 28

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 claims description 24

- 238000005477 sputtering target Methods 0.000 claims description 22

- 229910052719 titanium Inorganic materials 0.000 claims description 22

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 claims description 21

- 239000007789 gas Substances 0.000 claims description 21

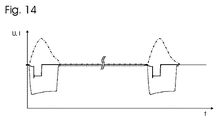

- 230000001360 synchronised effect Effects 0.000 claims description 19

- 238000004544 sputter deposition Methods 0.000 claims description 18

- 230000000694 effects Effects 0.000 claims description 16

- RTAQQCXQSZGOHL-UHFFFAOYSA-N Titanium Chemical compound [Ti] RTAQQCXQSZGOHL-UHFFFAOYSA-N 0.000 claims description 14

- 239000011651 chromium Substances 0.000 claims description 14

- 230000004907 flux Effects 0.000 claims description 12

- 229910052757 nitrogen Inorganic materials 0.000 claims description 12

- 238000000137 annealing Methods 0.000 claims description 10

- 238000003483 aging Methods 0.000 claims description 8

- 229910052710 silicon Inorganic materials 0.000 claims description 8

- 150000002739 metals Chemical class 0.000 claims description 7

- 238000011282 treatment Methods 0.000 claims description 7

- 230000000737 periodic effect Effects 0.000 claims description 6

- 239000012495 reaction gas Substances 0.000 claims description 6

- 229910052804 chromium Inorganic materials 0.000 claims description 5

- 229910052735 hafnium Inorganic materials 0.000 claims description 5

- 239000010703 silicon Substances 0.000 claims description 5

- 239000002245 particle Substances 0.000 claims description 4

- 229910052726 zirconium Inorganic materials 0.000 claims description 4

- VYZAMTAEIAYCRO-UHFFFAOYSA-N Chromium Chemical compound [Cr] VYZAMTAEIAYCRO-UHFFFAOYSA-N 0.000 claims description 3

- VBJZVLUMGGDVMO-UHFFFAOYSA-N hafnium atom Chemical compound [Hf] VBJZVLUMGGDVMO-UHFFFAOYSA-N 0.000 claims description 3

- 239000012535 impurity Substances 0.000 claims description 3

- QCWXUUIWCKQGHC-UHFFFAOYSA-N Zirconium Chemical compound [Zr] QCWXUUIWCKQGHC-UHFFFAOYSA-N 0.000 claims description 2

- 239000002923 metal particle Substances 0.000 claims description 2

- 239000010408 film Substances 0.000 description 45

- 150000002500 ions Chemical class 0.000 description 32

- 239000011247 coating layer Substances 0.000 description 29

- 239000010410 layer Substances 0.000 description 21

- 230000000052 comparative effect Effects 0.000 description 19

- 239000000463 material Substances 0.000 description 19

- 238000000151 deposition Methods 0.000 description 17

- 230000008021 deposition Effects 0.000 description 14

- 230000008569 process Effects 0.000 description 14

- 238000002441 X-ray diffraction Methods 0.000 description 9

- 230000015572 biosynthetic process Effects 0.000 description 9

- XKRFYHLGVUSROY-UHFFFAOYSA-N Argon Chemical compound [Ar] XKRFYHLGVUSROY-UHFFFAOYSA-N 0.000 description 8

- ATJFFYVFTNAWJD-UHFFFAOYSA-N Tin Chemical compound [Sn] ATJFFYVFTNAWJD-UHFFFAOYSA-N 0.000 description 7

- 229910045601 alloy Inorganic materials 0.000 description 7

- 239000000956 alloy Substances 0.000 description 7

- 238000010438 heat treatment Methods 0.000 description 6

- 238000003917 TEM image Methods 0.000 description 5

- 238000012360 testing method Methods 0.000 description 5

- XUIMIQQOPSSXEZ-UHFFFAOYSA-N Silicon Chemical compound [Si] XUIMIQQOPSSXEZ-UHFFFAOYSA-N 0.000 description 4

- 229910052786 argon Inorganic materials 0.000 description 4

- 230000008859 change Effects 0.000 description 4

- 238000011065 in-situ storage Methods 0.000 description 4

- 229910052760 oxygen Inorganic materials 0.000 description 4

- 238000005240 physical vapour deposition Methods 0.000 description 4

- 238000001330 spinodal decomposition reaction Methods 0.000 description 4

- 239000013077 target material Substances 0.000 description 4

- 229910052984 zinc sulfide Inorganic materials 0.000 description 4

- 229910004349 Ti-Al Inorganic materials 0.000 description 3

- 229910010037 TiAlN Inorganic materials 0.000 description 3

- 229910004692 Ti—Al Inorganic materials 0.000 description 3

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 3

- 230000008901 benefit Effects 0.000 description 3

- 229910052796 boron Inorganic materials 0.000 description 3

- 239000003990 capacitor Substances 0.000 description 3

- 238000000354 decomposition reaction Methods 0.000 description 3

- 230000007423 decrease Effects 0.000 description 3

- 230000001419 dependent effect Effects 0.000 description 3

- 238000010849 ion bombardment Methods 0.000 description 3

- 238000001755 magnetron sputter deposition Methods 0.000 description 3

- 238000002156 mixing Methods 0.000 description 3

- 239000001301 oxygen Substances 0.000 description 3

- 239000006104 solid solution Substances 0.000 description 3

- 229910018125 Al-Si Inorganic materials 0.000 description 2

- 229910018509 Al—N Inorganic materials 0.000 description 2

- 229910018520 Al—Si Inorganic materials 0.000 description 2

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 2

- 229910019590 Cr-N Inorganic materials 0.000 description 2

- 229910019588 Cr—N Inorganic materials 0.000 description 2

- 229910010038 TiAl Inorganic materials 0.000 description 2

- 238000004458 analytical method Methods 0.000 description 2

- 229910052799 carbon Inorganic materials 0.000 description 2

- 230000015556 catabolic process Effects 0.000 description 2

- 238000000541 cathodic arc deposition Methods 0.000 description 2

- 150000001875 compounds Chemical class 0.000 description 2

- 238000011109 contamination Methods 0.000 description 2

- 239000013078 crystal Substances 0.000 description 2

- 238000006731 degradation reaction Methods 0.000 description 2

- 238000011161 development Methods 0.000 description 2

- 238000010891 electric arc Methods 0.000 description 2

- 238000002003 electron diffraction Methods 0.000 description 2

- 238000010348 incorporation Methods 0.000 description 2

- 238000002347 injection Methods 0.000 description 2

- 239000007924 injection Substances 0.000 description 2

- 239000011159 matrix material Substances 0.000 description 2

- 239000012528 membrane Substances 0.000 description 2

- 230000003647 oxidation Effects 0.000 description 2

- 238000007254 oxidation reaction Methods 0.000 description 2

- 238000005546 reactive sputtering Methods 0.000 description 2

- 230000002441 reversible effect Effects 0.000 description 2

- 239000000126 substance Substances 0.000 description 2

- -1 titanium ions Chemical class 0.000 description 2

- 229910052720 vanadium Inorganic materials 0.000 description 2

- NQTSTBMCCAVWOS-UHFFFAOYSA-N 1-dimethoxyphosphoryl-3-phenoxypropan-2-one Chemical compound COP(=O)(OC)CC(=O)COC1=CC=CC=C1 NQTSTBMCCAVWOS-UHFFFAOYSA-N 0.000 description 1

- ZOXJGFHDIHLPTG-UHFFFAOYSA-N Boron Chemical compound [B] ZOXJGFHDIHLPTG-UHFFFAOYSA-N 0.000 description 1

- 229910000997 High-speed steel Inorganic materials 0.000 description 1

- 229910001199 N alloy Inorganic materials 0.000 description 1

- 229910007991 Si-N Inorganic materials 0.000 description 1

- 229910006294 Si—N Inorganic materials 0.000 description 1

- FAPWRFPIFSIZLT-UHFFFAOYSA-M Sodium chloride Chemical group [Na+].[Cl-] FAPWRFPIFSIZLT-UHFFFAOYSA-M 0.000 description 1

- 229910008484 TiSi Inorganic materials 0.000 description 1

- 229910007880 ZrAl Inorganic materials 0.000 description 1

- 238000005299 abrasion Methods 0.000 description 1

- 239000000654 additive Substances 0.000 description 1

- 238000013459 approach Methods 0.000 description 1

- 238000003491 array Methods 0.000 description 1

- 230000005540 biological transmission Effects 0.000 description 1

- 230000002051 biphasic effect Effects 0.000 description 1

- 238000006243 chemical reaction Methods 0.000 description 1

- 239000008199 coating composition Substances 0.000 description 1

- 239000002131 composite material Substances 0.000 description 1

- 230000006835 compression Effects 0.000 description 1

- 238000007906 compression Methods 0.000 description 1

- 238000002447 crystallographic data Methods 0.000 description 1

- 230000003111 delayed effect Effects 0.000 description 1

- 238000005137 deposition process Methods 0.000 description 1

- 238000001514 detection method Methods 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- 239000012895 dilution Substances 0.000 description 1

- 238000010790 dilution Methods 0.000 description 1

- 230000005674 electromagnetic induction Effects 0.000 description 1

- 238000005530 etching Methods 0.000 description 1

- 238000011156 evaluation Methods 0.000 description 1

- 230000002349 favourable effect Effects 0.000 description 1

- 229910002804 graphite Inorganic materials 0.000 description 1

- 239000010439 graphite Substances 0.000 description 1

- 238000007373 indentation Methods 0.000 description 1

- 238000007689 inspection Methods 0.000 description 1

- 229910052743 krypton Inorganic materials 0.000 description 1

- DNNSSWSSYDEUBZ-UHFFFAOYSA-N krypton atom Chemical compound [Kr] DNNSSWSSYDEUBZ-UHFFFAOYSA-N 0.000 description 1

- 238000013532 laser treatment Methods 0.000 description 1

- 238000004949 mass spectrometry Methods 0.000 description 1

- 238000005259 measurement Methods 0.000 description 1

- 238000001465 metallisation Methods 0.000 description 1

- 238000013508 migration Methods 0.000 description 1

- 230000005012 migration Effects 0.000 description 1

- 238000003801 milling Methods 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 150000004767 nitrides Chemical class 0.000 description 1

- 238000010587 phase diagram Methods 0.000 description 1

- 238000005191 phase separation Methods 0.000 description 1

- 239000000843 powder Substances 0.000 description 1

- 238000012545 processing Methods 0.000 description 1

- 239000012925 reference material Substances 0.000 description 1

- 238000009738 saturating Methods 0.000 description 1

- VSZWPYCFIRKVQL-UHFFFAOYSA-N selanylidenegallium;selenium Chemical compound [Se].[Se]=[Ga].[Se]=[Ga] VSZWPYCFIRKVQL-UHFFFAOYSA-N 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

- 238000001228 spectrum Methods 0.000 description 1

- 238000003786 synthesis reaction Methods 0.000 description 1

- 239000010409 thin film Substances 0.000 description 1

- 238000012546 transfer Methods 0.000 description 1

- 230000007704 transition Effects 0.000 description 1

- 238000004627 transmission electron microscopy Methods 0.000 description 1

- 238000000101 transmission high energy electron diffraction Methods 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C14/00—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material

- C23C14/22—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material characterised by the process of coating

- C23C14/34—Sputtering

- C23C14/3407—Cathode assembly for sputtering apparatus, e.g. Target

- C23C14/3414—Metallurgical or chemical aspects of target preparation, e.g. casting, powder metallurgy

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C14/00—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material

- C23C14/06—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material characterised by the coating material

- C23C14/0641—Nitrides

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C14/00—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material

- C23C14/22—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material characterised by the process of coating

- C23C14/34—Sputtering

- C23C14/35—Sputtering by application of a magnetic field, e.g. magnetron sputtering

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C14/00—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material

- C23C14/22—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material characterised by the process of coating

- C23C14/34—Sputtering

- C23C14/35—Sputtering by application of a magnetic field, e.g. magnetron sputtering

- C23C14/352—Sputtering by application of a magnetic field, e.g. magnetron sputtering using more than one target

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C30/00—Coating with metallic material characterised only by the composition of the metallic material, i.e. not characterised by the coating process

- C23C30/005—Coating with metallic material characterised only by the composition of the metallic material, i.e. not characterised by the coating process on hard metal substrates

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/26—Web or sheet containing structurally defined element or component, the element or component having a specified physical dimension

- Y10T428/263—Coating layer not in excess of 5 mils thick or equivalent

- Y10T428/264—Up to 3 mils

- Y10T428/265—1 mil or less

Landscapes

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Engineering & Computer Science (AREA)

- Materials Engineering (AREA)

- Mechanical Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Physical Vapour Deposition (AREA)

- Cutting Tools, Boring Holders, And Turrets (AREA)

- Laminated Bodies (AREA)

Applications Claiming Priority (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP11183582 | 2011-09-30 | ||

| EP11183582.3 | 2011-09-30 | ||

| EP12157769 | 2012-03-01 | ||

| EP12157769.6 | 2012-03-01 | ||

| PCT/EP2012/068887 WO2013045454A2 (en) | 2011-09-30 | 2012-09-25 | Coating of substrates using hipims |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2015501371A JP2015501371A (ja) | 2015-01-15 |

| JP2015501371A5 JP2015501371A5 (cg-RX-API-DMAC7.html) | 2015-11-05 |

| JP6093363B2 true JP6093363B2 (ja) | 2017-03-08 |

Family

ID=47010536

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2014532353A Active JP6093363B2 (ja) | 2011-09-30 | 2012-09-25 | Hipimsを用いた基材のコーティング |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US9416440B2 (cg-RX-API-DMAC7.html) |

| EP (1) | EP2761050B1 (cg-RX-API-DMAC7.html) |

| JP (1) | JP6093363B2 (cg-RX-API-DMAC7.html) |

| WO (1) | WO2013045454A2 (cg-RX-API-DMAC7.html) |

Families Citing this family (39)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP5892336B2 (ja) * | 2012-08-31 | 2016-03-23 | 三菱マテリアル株式会社 | 熱伝導性と潤滑特性にすぐれた表面被覆ドリル |

| JP6206133B2 (ja) * | 2012-11-30 | 2017-10-04 | 三菱マテリアル株式会社 | 表面被覆切削工具 |

| EP2784799B1 (en) * | 2013-03-28 | 2022-12-21 | CemeCon AG | Dense, hard coatings on substrates using HIPIMS |

| WO2015120893A1 (en) | 2014-02-13 | 2015-08-20 | Mimsi Materials Ab | Method of coating a substrate so as to provide a controlled in-plane compositional modulation |

| EP3149104A4 (en) * | 2014-05-30 | 2018-02-21 | Services Pétroliers Schlumberger | Degradable powder blend |

| US10008667B2 (en) * | 2014-08-29 | 2018-06-26 | Intel Corporation | Materials and components in phase change memory devices |

| FR3025929B1 (fr) * | 2014-09-17 | 2016-10-21 | Commissariat Energie Atomique | Gaines de combustible nucleaire, procedes de fabrication et utilisation contre l'oxydation. |

| US11049702B2 (en) | 2015-04-27 | 2021-06-29 | Advanced Energy Industries, Inc. | Rate enhanced pulsed DC sputtering system |

| US9812305B2 (en) | 2015-04-27 | 2017-11-07 | Advanced Energy Industries, Inc. | Rate enhanced pulsed DC sputtering system |

| US10689748B2 (en) * | 2015-07-15 | 2020-06-23 | Sumitomo Electric Industries, Ltd. | Coating |

| US10373811B2 (en) | 2015-07-24 | 2019-08-06 | Aes Global Holdings, Pte. Ltd | Systems and methods for single magnetron sputtering |

| JP6519795B2 (ja) * | 2015-09-30 | 2019-05-29 | 三菱マテリアル株式会社 | 耐チッピング性、耐摩耗性にすぐれた表面被覆切削工具 |

| GB201517879D0 (en) * | 2015-10-09 | 2015-11-25 | Spts Technologies Ltd | Method of deposition |

| US11440102B2 (en) * | 2015-12-22 | 2022-09-13 | Sandvik Intellectual Property Ab | Coated cutting tool and method |

| RU2730312C2 (ru) * | 2015-12-22 | 2020-08-21 | Сандвик Интеллекчуал Проперти Аб | Способ изготовления pvd-слоя и режущий инструмент с покрытием |

| US9994958B2 (en) * | 2016-01-20 | 2018-06-12 | Sumitomo Electric Hardmetal Corp. | Coating, cutting tool, and method of manufacturing coating |

| CN110023530B (zh) | 2016-12-28 | 2021-06-15 | 住友电气工业株式会社 | 被膜 |

| EP3676422B1 (en) * | 2017-08-31 | 2023-10-18 | Walter AG | Wear resistant pvd tool coating containing tialn nanolayer films |

| KR102064172B1 (ko) * | 2017-09-01 | 2020-01-09 | 한국야금 주식회사 | 내마모성과 인성이 우수한 경질피막 |

| EP3625377A1 (en) | 2017-09-05 | 2020-03-25 | Oerlikon Surface Solutions AG, Pfäffikon | Al-rich aitin-based films |

| JP6476261B1 (ja) * | 2017-10-17 | 2019-02-27 | 株式会社神戸製鋼所 | 成膜方法 |

| JP7072053B2 (ja) * | 2018-04-11 | 2022-05-19 | 住友電気工業株式会社 | 被膜 |

| US11821073B2 (en) | 2018-10-26 | 2023-11-21 | Oerlikon Surface Solutions Ag, Pfäffikon | Vanadium aluminium nitride (VAlN) micro alloyed with Ti and/or Si |

| JP7217866B2 (ja) * | 2019-03-19 | 2023-02-06 | 三菱マテリアル株式会社 | 表面被覆切削工具 |

| EP3736358A1 (en) * | 2019-05-08 | 2020-11-11 | Walter Ag | A coated cutting tool |

| KR20220038113A (ko) * | 2019-07-25 | 2022-03-25 | 어드밴스드 에너지 인더스트리즈 인코포레이티드 | 펄스형 dc 스퍼터링 시스템들 및 방법들 |

| DE102019124616A1 (de) * | 2019-09-12 | 2021-03-18 | Cemecon Ag | Mehrlagige Beschichtung |

| EP3839098A1 (en) * | 2019-12-20 | 2021-06-23 | Walter Ag | A coated cutting tool |

| WO2021187077A1 (ja) * | 2020-03-19 | 2021-09-23 | 日東電工株式会社 | 窒化物積層体、及び窒化物積層体の製造方法 |

| DE102020116157A1 (de) * | 2020-06-18 | 2021-12-23 | Cemecon Ag. | Verfahren und Vorrichtung zum Aufbringen einer Beschichtung sowie beschichteter Körper |

| CN111962034B (zh) * | 2020-08-14 | 2022-11-01 | 深圳后浪电子信息材料有限公司 | 一种覆铜板及其高速真空制备方法 |

| DE102020124032A1 (de) * | 2020-09-15 | 2022-03-17 | Cemecon Ag. | Beschichtungsvorrichtung und Beschichtungsverfahren mit unterteilten Pulsen |

| US12476090B2 (en) * | 2021-12-09 | 2025-11-18 | Ulvac, Inc. | Method of depositing silicon nitride film, apparatus for depositing film, and silicon nitride film |

| US11724317B1 (en) | 2022-03-10 | 2023-08-15 | Kennametal Inc. | Cubic phase refractory coatings and applications thereof |

| CN115029664A (zh) * | 2022-07-13 | 2022-09-09 | 海南大学 | 一种具有广谱抗菌性光热薄膜材料的制备方法 |

| CN116657104B (zh) * | 2023-05-31 | 2025-11-21 | 中国科学院宁波材料技术与工程研究所 | (110)面择优取向的max相涂层及制备方法与应用 |

| EP4471821A1 (de) * | 2023-06-02 | 2024-12-04 | Melec Gmbh | Verfahren zum magnetronsputtern |

| CN117448758A (zh) * | 2023-09-19 | 2024-01-26 | 中国科学院宁波材料技术与工程研究所 | 非晶碳涂层的磁控溅射方法 |

| CN118563265B (zh) * | 2024-05-23 | 2025-06-20 | 广东华升纳米科技股份有限公司 | 一种阴极一体化涂层制备方法、装置以及AlTiN涂层 |

Family Cites Families (22)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP3705381B2 (ja) * | 1996-09-03 | 2005-10-12 | 日立ツール株式会社 | 多層被覆硬質工具 |

| JP3439993B2 (ja) * | 1998-07-22 | 2003-08-25 | 株式会社不二越 | マグネトロンスパッタ装置 |

| JP4112834B2 (ja) * | 2000-12-28 | 2008-07-02 | 株式会社神戸製鋼所 | 切削工具用硬質皮膜を形成するためのターゲット |

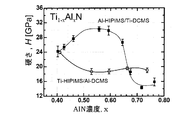

| SE526338C2 (sv) * | 2002-09-04 | 2005-08-23 | Seco Tools Ab | Skär med utskiljningshärdad slitstark refraktär beläggning |

| ATE355395T1 (de) * | 2002-11-19 | 2006-03-15 | Hitachi Tool Eng | Hartstoffschicht und damit beschichtetes werkzeug |

| JP2004230515A (ja) * | 2003-01-30 | 2004-08-19 | Nachi Fujikoshi Corp | 高機能加工用工具 |

| JP2006082210A (ja) * | 2004-09-17 | 2006-03-30 | Sumitomo Electric Hardmetal Corp | 表面被覆切削工具 |

| JP5060714B2 (ja) * | 2004-09-30 | 2012-10-31 | 株式会社神戸製鋼所 | 耐摩耗性および耐酸化性に優れた硬質皮膜、並びに該硬質皮膜形成用ターゲット |

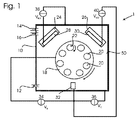

| DE102005033769B4 (de) | 2005-07-15 | 2009-10-22 | Systec System- Und Anlagentechnik Gmbh & Co.Kg | Verfahren und Vorrichtung zur Mehrkathoden-PVD-Beschichtung und Substrat mit PVD-Beschichtung |

| JP2007119810A (ja) * | 2005-10-26 | 2007-05-17 | Hitachi Tool Engineering Ltd | 被覆部材 |

| GB0608582D0 (en) * | 2006-05-02 | 2006-06-07 | Univ Sheffield Hallam | High power impulse magnetron sputtering vapour deposition |

| US8435389B2 (en) * | 2006-12-12 | 2013-05-07 | Oc Oerlikon Balzers Ag | RF substrate bias with high power impulse magnetron sputtering (HIPIMS) |

| SE0602814L (sv) * | 2006-12-27 | 2008-06-28 | Sandvik Intellectual Property | Skärverktyg med multiskiktbeläggning |

| JP4668214B2 (ja) * | 2007-01-17 | 2011-04-13 | 株式会社神戸製鋼所 | 成形用金型 |

| EP2208560B2 (en) * | 2007-10-12 | 2017-09-20 | Hitachi Tool Engineering, Ltd. | Process for the production of the member covered with hard coating |

| KR101647515B1 (ko) * | 2008-04-03 | 2016-08-10 | 에바텍 어드벤스드 테크놀로지스 아크티엔게젤샤프트 | 반도체 칩용 금속 배선 구조의 제조 방법, 그리고 반도체 칩용 금속 배선 구조 제조를 위한 금속 배선 구조 제조 장치의 제어 방법 |

| DE102008019202A1 (de) * | 2008-04-17 | 2009-10-22 | Kennametal Inc. | Beschichtungsverfahren , Werkstück oder Werkzeug und dessen Verwendung |

| DE202009018428U1 (de) * | 2008-04-28 | 2011-09-28 | Cemecon Ag | Vorrichtung zum Vorbehandeln und Beschichten von Körpern |

| JP5424103B2 (ja) * | 2008-09-24 | 2014-02-26 | 日立金属株式会社 | 塑性加工用被覆金型 |

| WO2010040494A1 (en) | 2008-10-10 | 2010-04-15 | Oerlikon Trading Ag, Trübbach | Non gamma - phase cubic alcro |

| JP5395454B2 (ja) * | 2009-02-17 | 2014-01-22 | 住友電気工業株式会社 | 表面被覆切削工具 |

| KR101614979B1 (ko) * | 2009-04-03 | 2016-04-22 | 산드빅 인터렉츄얼 프로퍼티 에이비 | 높은 온도를 발생시키는 금속 절삭 분야를 위한 코팅된 절삭 공구 |

-

2012

- 2012-09-25 EP EP12770444.3A patent/EP2761050B1/en active Active

- 2012-09-25 US US14/348,829 patent/US9416440B2/en active Active

- 2012-09-25 JP JP2014532353A patent/JP6093363B2/ja active Active

- 2012-09-25 WO PCT/EP2012/068887 patent/WO2013045454A2/en not_active Ceased

Also Published As

| Publication number | Publication date |

|---|---|

| JP2015501371A (ja) | 2015-01-15 |

| US20140234616A1 (en) | 2014-08-21 |

| WO2013045454A3 (en) | 2013-05-23 |

| EP2761050A2 (en) | 2014-08-06 |

| US9416440B2 (en) | 2016-08-16 |

| WO2013045454A2 (en) | 2013-04-04 |

| EP2761050B1 (en) | 2021-08-25 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6093363B2 (ja) | Hipimsを用いた基材のコーティング | |

| JP5336476B2 (ja) | Pvd被膜形成方法 | |

| RU2456371C2 (ru) | Слоистая система с по меньшей мере одним слоем смешанных кристаллов многокомпонентного оксида | |

| Wallin et al. | Synthesis of α-Al2 O3 thin films using reactive high-power impulse magnetron sputtering | |

| Alami et al. | High-power impulse magnetron sputtering of Ti–Si–C thin films from a Ti3SiC2 compound target | |

| EP2784799B1 (en) | Dense, hard coatings on substrates using HIPIMS | |

| US6824601B2 (en) | Hard film for cutting tools, cutting tool coated with hard film, process for forming hard film, and target used to form hard film | |

| JP5856148B2 (ja) | 混合結晶層を蒸着するためのpvdハイブリッド法 | |

| Schütze et al. | Pulsed plasma-assisted PVD sputter-deposited alumina thin films | |

| Li et al. | Toward energy-efficient physical vapor deposition: Routes for replacing substrate heating during magnetron sputter deposition by employing metal ion irradiation | |

| Diyatmika et al. | Superimposed high power impulse and middle frequency magnetron sputtering: Role of pulse duration and average power of middle frequency | |

| Zhou et al. | Effect of bias voltage on microstructure and optical properties of Al2O3 thin films prepared by twin targets reactive high power impulse magnetron sputtering | |

| Sønderby et al. | Industrial-scale high power impulse magnetron sputtering of yttria-stabilized zirconia on porous NiO/YSZ fuel cell anodes | |

| Shimizu et al. | Pressure dependence of (Ti, Al) N film growth on inner walls of small holes in high-power impulse magnetron sputtering | |

| Audronis et al. | Pulsed magnetron sputtering of chromium boride films from loose powder targets | |

| Ferreira et al. | Phase tailoring of tantalum thin films deposited in deep oscillation magnetron sputtering mode | |

| Lin et al. | Thick CrN/AlN superlattice coatings deposited by hot filament assisted HiPIMS for solid particle erosion and high temperature wear resistance | |

| JP2009293131A (ja) | 微細結晶硬質皮膜の形成方法 | |

| Selinder et al. | α-Alumina coatings on WC/Co substrates by physical vapor deposition | |

| Žemlička et al. | Enhancing mechanical properties and cutting performance of industrially sputtered AlCrN coatings by inducing cathodic arc glow discharge | |

| Sidelev et al. | Aluminum films deposition by magnetron sputtering systems: Influence of target state and pulsing unit | |

| JP4500061B2 (ja) | 硬質皮膜の成膜方法 | |

| de Abreu Vieira et al. | Approaches to influence the microstructure and the properties of Al–Cr–O layers synthesized by cathodic arc evaporation | |

| Bagcivan et al. | Comparison of (Cr0. 75Al0. 25) N coatings deposited by conventional and high power pulsed magnetron sputtering | |

| Haug et al. | Control of the nitrogen content in nanocomposite TiN/SiNx coatings deposited by an arc-sputter hybrid process |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20150914 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20150914 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20160714 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20160802 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20161021 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20170110 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20170210 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 6093363 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |