JP6082255B2 - セラミックス部品及びその製造方法 - Google Patents

セラミックス部品及びその製造方法 Download PDFInfo

- Publication number

- JP6082255B2 JP6082255B2 JP2013007145A JP2013007145A JP6082255B2 JP 6082255 B2 JP6082255 B2 JP 6082255B2 JP 2013007145 A JP2013007145 A JP 2013007145A JP 2013007145 A JP2013007145 A JP 2013007145A JP 6082255 B2 JP6082255 B2 JP 6082255B2

- Authority

- JP

- Japan

- Prior art keywords

- ceramic substrate

- ceramic

- coating layer

- piezoelectric

- layer

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 239000000919 ceramic Substances 0.000 title claims description 128

- 238000004519 manufacturing process Methods 0.000 title claims description 18

- 239000000758 substrate Substances 0.000 claims description 226

- 239000011247 coating layer Substances 0.000 claims description 108

- 239000010410 layer Substances 0.000 claims description 80

- 239000011248 coating agent Substances 0.000 claims description 25

- 238000000576 coating method Methods 0.000 claims description 25

- 239000000463 material Substances 0.000 claims description 22

- 238000009751 slip forming Methods 0.000 claims description 11

- 238000005507 spraying Methods 0.000 claims description 11

- 238000004140 cleaning Methods 0.000 claims description 8

- 230000002093 peripheral effect Effects 0.000 claims description 6

- 239000007921 spray Substances 0.000 claims description 3

- 239000011347 resin Substances 0.000 description 118

- 229920005989 resin Polymers 0.000 description 118

- 238000000034 method Methods 0.000 description 36

- 239000002245 particle Substances 0.000 description 22

- 239000000853 adhesive Substances 0.000 description 15

- 230000001070 adhesive effect Effects 0.000 description 15

- 239000011521 glass Substances 0.000 description 15

- 239000002904 solvent Substances 0.000 description 10

- 238000003754 machining Methods 0.000 description 5

- 230000004048 modification Effects 0.000 description 5

- 238000012986 modification Methods 0.000 description 5

- 229920001721 polyimide Polymers 0.000 description 4

- WGTYBPLFGIVFAS-UHFFFAOYSA-M tetramethylammonium hydroxide Chemical compound [OH-].C[N+](C)(C)C WGTYBPLFGIVFAS-UHFFFAOYSA-M 0.000 description 4

- 239000004642 Polyimide Substances 0.000 description 3

- 230000003112 degranulating effect Effects 0.000 description 3

- 239000000428 dust Substances 0.000 description 3

- 238000005516 engineering process Methods 0.000 description 3

- 239000003822 epoxy resin Substances 0.000 description 3

- 238000010438 heat treatment Methods 0.000 description 3

- 229920000647 polyepoxide Polymers 0.000 description 3

- PXHVJJICTQNCMI-UHFFFAOYSA-N Nickel Chemical compound [Ni] PXHVJJICTQNCMI-UHFFFAOYSA-N 0.000 description 2

- 239000012670 alkaline solution Substances 0.000 description 2

- 238000010586 diagram Methods 0.000 description 2

- 239000007772 electrode material Substances 0.000 description 2

- 239000007788 liquid Substances 0.000 description 2

- 238000000059 patterning Methods 0.000 description 2

- BASFCYQUMIYNBI-UHFFFAOYSA-N platinum Chemical compound [Pt] BASFCYQUMIYNBI-UHFFFAOYSA-N 0.000 description 2

- 238000005406 washing Methods 0.000 description 2

- 229910052726 zirconium Inorganic materials 0.000 description 2

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 description 1

- JOYRKODLDBILNP-UHFFFAOYSA-N Ethyl urethane Chemical compound CCOC(N)=O JOYRKODLDBILNP-UHFFFAOYSA-N 0.000 description 1

- 229910001252 Pd alloy Inorganic materials 0.000 description 1

- JRPBQTZRNDNNOP-UHFFFAOYSA-N barium titanate Chemical compound [Ba+2].[Ba+2].[O-][Ti]([O-])([O-])[O-] JRPBQTZRNDNNOP-UHFFFAOYSA-N 0.000 description 1

- 229910002113 barium titanate Inorganic materials 0.000 description 1

- 238000009835 boiling Methods 0.000 description 1

- 238000007796 conventional method Methods 0.000 description 1

- 229910052802 copper Inorganic materials 0.000 description 1

- 239000010949 copper Substances 0.000 description 1

- NKZSPGSOXYXWQA-UHFFFAOYSA-N dioxido(oxo)titanium;lead(2+) Chemical compound [Pb+2].[O-][Ti]([O-])=O NKZSPGSOXYXWQA-UHFFFAOYSA-N 0.000 description 1

- 230000005684 electric field Effects 0.000 description 1

- -1 for example Substances 0.000 description 1

- PCHJSUWPFVWCPO-UHFFFAOYSA-N gold Chemical compound [Au] PCHJSUWPFVWCPO-UHFFFAOYSA-N 0.000 description 1

- 229910052737 gold Inorganic materials 0.000 description 1

- 239000010931 gold Substances 0.000 description 1

- 238000009434 installation Methods 0.000 description 1

- 238000010030 laminating Methods 0.000 description 1

- 239000000203 mixture Substances 0.000 description 1

- 229910052759 nickel Inorganic materials 0.000 description 1

- 229910052697 platinum Inorganic materials 0.000 description 1

- 239000009719 polyimide resin Substances 0.000 description 1

- 238000004080 punching Methods 0.000 description 1

- 238000007650 screen-printing Methods 0.000 description 1

- 229910052709 silver Inorganic materials 0.000 description 1

- 239000004332 silver Substances 0.000 description 1

- 239000000243 solution Substances 0.000 description 1

- 238000004528 spin coating Methods 0.000 description 1

- 238000004544 sputter deposition Methods 0.000 description 1

- 238000004506 ultrasonic cleaning Methods 0.000 description 1

- 238000001771 vacuum deposition Methods 0.000 description 1

Images

Classifications

-

- H—ELECTRICITY

- H10—SEMICONDUCTOR DEVICES; ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10N—ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10N30/00—Piezoelectric or electrostrictive devices

- H10N30/80—Constructional details

- H10N30/88—Mounts; Supports; Enclosures; Casings

- H10N30/883—Additional insulation means preventing electrical, physical or chemical damage, e.g. protective coatings

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B41/00—After-treatment of mortars, concrete, artificial stone or ceramics; Treatment of natural stone

- C04B41/80—After-treatment of mortars, concrete, artificial stone or ceramics; Treatment of natural stone of only ceramics

- C04B41/81—Coating or impregnation

-

- H—ELECTRICITY

- H10—SEMICONDUCTOR DEVICES; ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10N—ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10N30/00—Piezoelectric or electrostrictive devices

- H10N30/01—Manufacture or treatment

- H10N30/02—Forming enclosures or casings

-

- H—ELECTRICITY

- H10—SEMICONDUCTOR DEVICES; ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10N—ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10N30/00—Piezoelectric or electrostrictive devices

- H10N30/01—Manufacture or treatment

- H10N30/08—Shaping or machining of piezoelectric or electrostrictive bodies

- H10N30/081—Shaping or machining of piezoelectric or electrostrictive bodies by coating or depositing using masks, e.g. lift-off

-

- H—ELECTRICITY

- H10—SEMICONDUCTOR DEVICES; ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10N—ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10N30/00—Piezoelectric or electrostrictive devices

- H10N30/01—Manufacture or treatment

- H10N30/08—Shaping or machining of piezoelectric or electrostrictive bodies

- H10N30/085—Shaping or machining of piezoelectric or electrostrictive bodies by machining

- H10N30/088—Shaping or machining of piezoelectric or electrostrictive bodies by machining by cutting or dicing

-

- H—ELECTRICITY

- H10—SEMICONDUCTOR DEVICES; ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10N—ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10N30/00—Piezoelectric or electrostrictive devices

- H10N30/01—Manufacture or treatment

- H10N30/05—Manufacture of multilayered piezoelectric or electrostrictive devices, or parts thereof, e.g. by stacking piezoelectric bodies and electrodes

- H10N30/057—Manufacture of multilayered piezoelectric or electrostrictive devices, or parts thereof, e.g. by stacking piezoelectric bodies and electrodes by stacking bulk piezoelectric or electrostrictive bodies and electrodes

-

- H—ELECTRICITY

- H10—SEMICONDUCTOR DEVICES; ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10N—ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10N30/00—Piezoelectric or electrostrictive devices

- H10N30/50—Piezoelectric or electrostrictive devices having a stacked or multilayer structure

-

- H—ELECTRICITY

- H10—SEMICONDUCTOR DEVICES; ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10N—ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10N30/00—Piezoelectric or electrostrictive devices

- H10N30/80—Constructional details

- H10N30/85—Piezoelectric or electrostrictive active materials

- H10N30/853—Ceramic compositions

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T156/00—Adhesive bonding and miscellaneous chemical manufacture

- Y10T156/10—Methods of surface bonding and/or assembly therefor

- Y10T156/1052—Methods of surface bonding and/or assembly therefor with cutting, punching, tearing or severing

- Y10T156/1082—Partial cutting bonded sandwich [e.g., grooving or incising]

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/23—Sheet including cover or casing

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/23—Sheet including cover or casing

- Y10T428/232—Encased layer derived from inorganic settable ingredient

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/23—Sheet including cover or casing

- Y10T428/239—Complete cover or casing

Landscapes

- Engineering & Computer Science (AREA)

- Manufacturing & Machinery (AREA)

- Chemical & Material Sciences (AREA)

- Ceramic Engineering (AREA)

- Materials Engineering (AREA)

- Organic Chemistry (AREA)

- Structural Engineering (AREA)

- Compositions Of Oxide Ceramics (AREA)

- Particle Formation And Scattering Control In Inkjet Printers (AREA)

- Ceramic Capacitors (AREA)

- Fixed Capacitors And Capacitor Manufacturing Machines (AREA)

- General Electrical Machinery Utilizing Piezoelectricity, Electrostriction Or Magnetostriction (AREA)

- Piezo-Electric Or Mechanical Vibrators, Or Delay Or Filter Circuits (AREA)

Description

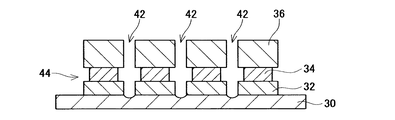

12:圧電体基板

14,16,52,54,62,72,74:樹脂コーティング層

18:圧電体層

20a,20b:表面電極

30:ガラス板

32:接着シート

34:犠牲層

36:圧電体基板シート

42:ダイシング溝

44:空間

46,64:ノズル

Claims (4)

- 1又は積層された複数のセラミックス層を含むセラミックス基板と、

前記セラミックス基板の表面の一部に形成された第1被覆層と、

前記セラミックス基板の裏面の一部に形成された第2被覆層と、を備えており、

前記第1被覆層は、前記セラミックス基板の側面となる機械加工面の表面側の第1領域まで連続して形成されており、

前記第2被覆層は、前記セラミックス基板の側面となる機械加工面の裏面側の第2領域まで連続して形成されており、

前記第1被覆層と前記第2被覆層の一方は、前記セラミックス基板の機械加工面において、前記第1被覆層と前記第2被覆層の他方の一部の上に形成されており、前記第1被覆層と前記第2被覆層の他方の一部の上に形成されていない部分は、前記セラミックス基板の側面となる機械加工面の上に形成されている、

セラミックス部品。 - 前記セラミックス基板は、平面視すると矩形状に形成されており、

前記第1被覆層は、前記セラミックス基板の表面の少なくとも4つの角に形成されている、請求項1に記載のセラミックス部品。 - 前記第1被覆層は、前記セラミックス基板の表面の周縁に沿って形成されている、請求項2に記載のセラミックス部品。

- セラミックス部品を製造する方法であって、

1又は積層された複数のセラミックス層を含むセラミックス基板シートの裏面を犠牲層を介して保持板に固定する固定工程と、

前記保持板に前記犠牲層を介して固定された状態を維持したまま前記セラミックス基板シートをダイシングするダイシング工程と、

前記保持板と前記セラミックス基板シートの間に位置する前記犠牲層の一部を、前記ダイシング工程によって前記セラミックス基板シートに形成された溝側から除去する除去工程と、

前記除去工程後、前記保持板に前記犠牲層を介して固定された状態の前記セラミックス基板シートの表面を洗浄する洗浄工程と、

前記洗浄工程後、前記セラミックス基板シートの前記溝に露出する側面にペースト状の被覆材料を吹付ける吹付け工程と、

前記セラミックス基板シートの前記側面に吹付けた前記被覆材料を硬化して、前記セラミックス基板シートの表面に前記被覆材料を固定する被覆材料固定工程と、

を有しており、

前記吹付け工程は、前記被覆材料固定工程後に、前記セラミックス基板シートの裏面の端部が前記被覆材料で覆われるように、前記セラミックス基板シートの前記側面に前記被覆材料を吹付ける、セラミックス部品の製造方法。

Priority Applications (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2013007145A JP6082255B2 (ja) | 2013-01-18 | 2013-01-18 | セラミックス部品及びその製造方法 |

| US14/153,472 US9950965B2 (en) | 2013-01-18 | 2014-01-13 | Ceramic element and method of manufacturing the same |

| EP14151044.6A EP2757606B1 (en) | 2013-01-18 | 2014-01-14 | Ceramic element and method of manufacturing the same |

| CN201410018974.2A CN103943773A (zh) | 2013-01-18 | 2014-01-15 | 陶瓷部件及其制造方法 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2013007145A JP6082255B2 (ja) | 2013-01-18 | 2013-01-18 | セラミックス部品及びその製造方法 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2014138144A JP2014138144A (ja) | 2014-07-28 |

| JP2014138144A5 JP2014138144A5 (ja) | 2015-11-05 |

| JP6082255B2 true JP6082255B2 (ja) | 2017-02-15 |

Family

ID=49917625

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2013007145A Active JP6082255B2 (ja) | 2013-01-18 | 2013-01-18 | セラミックス部品及びその製造方法 |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US9950965B2 (ja) |

| EP (1) | EP2757606B1 (ja) |

| JP (1) | JP6082255B2 (ja) |

| CN (1) | CN103943773A (ja) |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR101878019B1 (ko) | 2014-05-12 | 2018-07-13 | 파나소닉 아이피 매니지먼트 가부시키가이샤 | 압전 소자와 케이블 기판의 접속 방법, 케이블 기판 장착 압전 소자 및 이것을 사용한 잉크젯 헤드 |

| US11081639B2 (en) * | 2016-05-19 | 2021-08-03 | Konica Minolta, Inc. | Piezoelectric element manufacturing method |

| CN111095489B (zh) * | 2017-09-12 | 2023-11-28 | 日本碍子株式会社 | 芯片部件的制造方法 |

| CN111164775B (zh) | 2017-11-09 | 2023-12-12 | 株式会社村田制作所 | 压电部件、传感器以及促动器 |

Family Cites Families (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3946290A (en) * | 1973-10-09 | 1976-03-23 | Tdk Electronics Co. Ltd. | High tension ceramic condenser |

| US4916000A (en) * | 1987-07-13 | 1990-04-10 | Allied-Signal Inc. | Ballistic-resistant composite article |

| JP2599478B2 (ja) * | 1990-02-20 | 1997-04-09 | 松下電器産業株式会社 | チップ型電子部品 |

| US5750264A (en) * | 1994-10-19 | 1998-05-12 | Matsushita Electric Industrial Co., Inc. | Electronic component and method for fabricating the same |

| US6617762B2 (en) | 2000-08-03 | 2003-09-09 | Nec Tokin Ceramics Corporation | Microactuator device with a countermeasure for particles on a cut face thereof |

| CN101983438B (zh) | 2008-02-05 | 2014-10-29 | 摩根先进陶瓷有限公司 | 用于减少颗粒脱落的封装涂层 |

| US20120183716A1 (en) * | 2008-05-20 | 2012-07-19 | Jordan Robert F | Moldable ballistic armor panel |

| JP4948554B2 (ja) | 2009-02-16 | 2012-06-06 | 日本発條株式会社 | ヘッドサスペンション |

| WO2011016994A1 (en) | 2009-07-27 | 2011-02-10 | Cts Corporation | Encapsulated ceramic element and method of making the same |

| JP5522533B2 (ja) * | 2010-05-27 | 2014-06-18 | 三菱マテリアル株式会社 | 表面実装型電子部品およびその製造方法 |

| JP5951597B2 (ja) | 2011-03-31 | 2016-07-13 | 日本碍子株式会社 | セラミックス素子の製造方法 |

| JP5845668B2 (ja) * | 2011-07-08 | 2016-01-20 | Tdk株式会社 | 圧電素子及び圧電素子の製造方法 |

-

2013

- 2013-01-18 JP JP2013007145A patent/JP6082255B2/ja active Active

-

2014

- 2014-01-13 US US14/153,472 patent/US9950965B2/en not_active Expired - Fee Related

- 2014-01-14 EP EP14151044.6A patent/EP2757606B1/en not_active Not-in-force

- 2014-01-15 CN CN201410018974.2A patent/CN103943773A/zh active Pending

Also Published As

| Publication number | Publication date |

|---|---|

| US9950965B2 (en) | 2018-04-24 |

| EP2757606B1 (en) | 2016-11-30 |

| US20140202629A1 (en) | 2014-07-24 |

| JP2014138144A (ja) | 2014-07-28 |

| CN103943773A (zh) | 2014-07-23 |

| EP2757606A1 (en) | 2014-07-23 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6082255B2 (ja) | セラミックス部品及びその製造方法 | |

| KR101430596B1 (ko) | 터치 온 렌즈 소자 및 그 제조 방법 | |

| CN109461652B (zh) | 一种改善厚金属层lift off工艺图形异常的方法 | |

| JP2013165180A (ja) | 電子部品及び電子部品の製造方法 | |

| CN103928473B (zh) | 可挠式显示面板及可挠式显示面板的制作方法 | |

| CN111725124A (zh) | 一种微型发光二极管的转移方法 | |

| US20160186327A1 (en) | Method for forming a circuit pattern on a substrate | |

| JP2002330047A (ja) | 弾性表面波素子 | |

| TWI600354B (zh) | 具高彎折力之微電阻結構及其製造方法 | |

| JP2008205888A5 (ja) | ||

| CN111130482A (zh) | 一种石英晶体谐振器电极的加工方法 | |

| JP2014138144A5 (ja) | ||

| JP6388389B2 (ja) | 液体吐出ヘッドの製造方法 | |

| CN109859626B (zh) | 柔性显示屏及其制作方法 | |

| US9484519B2 (en) | Piezoelectric/electrostrictive element | |

| KR101066932B1 (ko) | 터치패널용 패드의 제조방법 및 이에 의해 제조되는 터치패널용 패드 | |

| CN105938302B (zh) | 提高液晶显示面板外围区域剥离效率的方法 | |

| JP2020004815A (ja) | チップ型電子部品の製造方法 | |

| JP6155420B2 (ja) | 薄膜キャパシタシートの製造方法 | |

| JP3951137B2 (ja) | 配線基板の製造方法及び電子デバイスの製造方法 | |

| JP4664700B2 (ja) | 振動体デバイスの製造方法 | |

| JP2020122208A5 (ja) | ||

| JPH01189102A (ja) | 回路部品の電極製造方法 | |

| JP3124624B2 (ja) | 積層コンデンサおよびその製造方法 | |

| JP2014049546A (ja) | 圧電アクチュエータの製造方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20150916 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20150916 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20160825 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20160906 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20161104 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20170117 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20170120 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 6082255 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |